Abstract

In blasting works, the aim is to provide proper rock fragmentation and to avoid undesirable environmental impacts such as back-break. Therefore, predicting fragmentation and back-break is a significant step in achieving a technically and economically successful outcome. In this paper, considering the robustness of artificial intelligence methods utilized in engineering problems, an artificial neural network (ANN) was applied to predict rock fragmentation and back-break; an artificial bee colony (ABC) algorithm was also utilized to optimize the blasting pattern parameters. In this regard, blasting parameters, including burden, spacing, stemming length, hole length and powder factor, as well as back-break and fragmentation were collected at the Anguran mine in Iran. Root mean square error (RMSE) values equal to 2.76 and 0.53 for rock fragmentation and back-break, respectively, reveal the high reliability of the ANN model. In addition, ABC algorithm results suggest values of 29 cm and 3.25 m for fragmentation and back-break, respectively. For comparison purposes, an empirical model (Kuz-Ram) was performed to predict the mean fragment size in the Anguran mine. A mean fragment size of 33.5 cm shows the ABC algorithm can optimize rock fragmentation with a high degree of accuracy.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Blasting is a common rock fragmentation technique utilized in mining operations, as well as some civil engineering applications such as tunneling and road construction. In blasting operations, only 20–30 % of the produced energy is utilized to fragment and displace the rock mass (Jahed Armaghani et al. 2013; Khandelwal and Monjezi 2013). The rest of this energy is wasted to produce undesirable environmental impacts such as ground vibration, air-overpressure, flyrock and back-break (Monjezi et al. 2012; Görgülü et al. 2013; Hajihassani et al. 2014a, b; Raina et al. 2014). Among these environmental impacts, back-break is the unwanted consequence of an unsuitable blast design (Khandelwal and Monjezi 2013). This phenomenon is defined as fragmentation of rocks beyond the limits of the rear row of holes in a blast pattern (Jimeno et al. 1995). Back-break may cause rock mine wall instability, fallings, improper fragmentation, and an increased total blasting cost (Esmaeili et al. 2012; Mohammadnejad et al. 2013).

In addition, the main objective of blasting is to control the amount and quality of the rock fragmentation. The size distribution of fragmented rock plays an important role in the overall mining and processing plant economics (Michaux and Djordjevic 2005; Monjezi et al. 2009). Blast design is a significant factor in the process of securing desired fragmentation. However, it should be mentioned that rock fragmentation faces several problems due to the fact that there are many issues not within the control of a blast engineer; hence, solving these problems seems to be difficult. Three different categories are introduced by Thornton et al. (2002) as factors most pertinent to rock fragmentation: properties of rock masses, blast geometry and explosive properties. Normally, rock fragmentation around a blast-hole depends on several parameters such as detonation and the dynamic response of the rock (Zheming et al. 2007).

Utilizing soft computing approaches such as an artificial neural network (ANN) in solving complex and non-linear problems of geotechnical engineering (Atici 2011; Tonnizam Mohamad et al. 2012, 2014; Jahed Armaghani et al. 2014a) and also for prediction of back-break and rock fragmentation are highlighted in the literature (Bahrami et al. 2011; Sayadi et al. 2013). In the present study, an attempt has been made to minimize rock fragmentation and back-break resulting from blasting using the blasting data measured at the Anguran mine in Iran. In addition, a new algorithm based on the artificial bee colony (ABC) algorithm was utilized to optimize the blasting pattern in this mine.

Previous investigation

Numerous researchers have focused on the prediction of back-break and fragmentation through artificial intelligent approaches. Fuzzy inference system (FIS) and multivariable regression (MR) models were developed to predict back-break using data collected from the Gol-E-Gohar iron mine in Iran by Monjezi et al. (2010a). Burden, spacing, hole depth, specific drilling, stemming, charge per delay, rock density, and powder factor were set as system inputs. They found that the performance capacity of the FIS model is higher than that of the MR model for prediction of back-break. Esmaeili et al. (2012) applied an ANN, the adaptive neuro-fuzzy inference system (ANFIS) and MR models to predict back-break using the data collected from the Sangan iron mine in Iran. Their results show the capability of the ANFIS model in predicting back-break compared to other techniques. In an other study of back-break estimation, Mohammadnejad et al. (2013) predicted the back-break phenomenon in blasting work using a support vector machine (SVM). They selected system inputs based on simple and multiple regression analyses. Finally, they introduced the SVM technique as a reliable and accurate tool for prediction of back-break. Monjezi et al. (2009) used the FIS model and regression analysis to predict rock fragmentation using 415 datasets collected from the Gol-E-Gohar iron mine in Iran. In their study, burden, spacing, hole depth, specific drilling, stemming, charge per delay, rock density and powder factor were chosen as input parameters. Results indicated the superiority of the FIS approach for prediction of fragmentation. An ANN model was proposed to predict rock fragmentation utilizing 250 blasting datasets from the Sangan iron mine in Iran by Monjezi et al. (2010b). A model topology with an 8-3-3-2 neuron architecture with a coefficient of determination (R 2) equal to 0.98 was suggested for fragmentation prediction. The sensitivity analysis results show that charge per delay, burden to spacing ratio, rock density, and number of blasting rows are the most influential parameters on fragmentation. Table 1 shows some recent studies with their performances in predicting back-break and rock fragmentation induced by blasting.

Case study and data collection

In this study, a site investigation was conducted at the Anguran lead and zinc mine. The Anguran mine is situated 135 km southwest of Zanjan province, Iran, at 47º20′E longitude and 36º40′N latitude, at an altitude of 2,950 m above sea level (see Fig. 1). The Anguran mine, which is the largest and oldest lead and zinc mine in Iran, has been excavated since 1940 and is one of the examples of improper management that has encountered several instabilities in its northern and western flanks. The site is a part of the Oroumieh-Poldokhtar zone, where it extends between the Zagros belt and the central Iranian district. The mine is a central core of a turned anticline and dominant rock at the mine area, composed of graphite-bearing metamorphic limestones. The effect of folding is reduced beyond the carbonaceous part of the district toward the west and metabasic rocks. The studied area is composed of a series of volcanic, sedimentary and metamorphic rocks. The evidence of plutonic and volcanic activity is predominant in the area. These are the primary instances of metamorphism and hydrothermal intrusion that formed the different ore veins at the mines in the region. The total geological resource of the deposit is about 25 Mt, whereas the proven reserve is about 12 Mt, with average grades of 27.87 and 4.26 % for zinc and lead, respectively.

Blasting operations at the Anguran mine utilize blast holes of 114 mm, explosive material of ammonium nitrate/fuel oil (ANFO; specific gravity of 0.85–0.95 gr/cm3), vertical blast holes and a delay timing of 5 s. In this mine, the blast holes are stemmed with drill cutting. One of the most important problems of blasting operations in the Anguran mine is back-break causing damage to the pit walls (see Fig. 2). Moreover, large fragmented rocks are another problem in this mine (see Fig. 3). Based on this figure, these large size rocks should be excavated by using secondary blasting in the Anguran mine. It is well known that back-break (damage) and fragmentation are influenced by several rock parameters as well as blast design. Therefore, after going through these parameters, the most influential parameters in back-break and fragmentation, including burden, spacing, stemming length, hole length, and powder factor, were measured in the Anguran mine.

Hole depths in the blasted area were in the range of 11.5–13.5 m. Overall, the design of holes was rhomb-like with distances (B×S) of 3.5 m × 4.5 m in the rock deposit. Overall, powder factors in these operations ranged between 0.55 and 0.75 kg/m3 , whereas, the exact ranges were between 0.45 and 0.95 kg/m3. The maximum measured stemming length (fine gravel) was 4.3 m.

In order to determine size distribution, an image analysis technique was performed in this study. Due to accuracy, rapidity and economy of this model, it can be employed rather than the traditional sieve method. As such, a sufficient number of digital images were processed on a computer; thereafter, a size distribution curve could be made. Fragmentation quality has been determined on the basis of 80 % passing size (D80). The D80 quantity determines loading machines and primary crusher efficiency; the lesser the D80, the higher the performance of the equipment. In this study, Split-Desktop software was used to analyze size distributions of the fragmented rocks using digital images. In this regard, a number of photographs were taken after each blasting operation. The results of the Split-Desktop software, as well as blasting pattern parameters, were prepared to refine the proposed models. Figure 4 shows a sample size distribution curve obtained via the Split-Desktop software.

A minimum and maximum of 15 and 40 cm were calculated for fragmentation. Also, a maximum amount of 7 m of backbreak (measured by measuring tape) is being observed beyond the last row of blast holes. Table 2 shows variations of the input and output parameters and their range. In total, the aforementioned parameters of 34 blasting events were obtained to construct the predictive models.

In order to minimize back-break and provide desirable rock fragmentation using ANN and ABC algorithms, the following steps were performed (see Fig. 5):

-

1.

Blasting pattern parameters, as well as back-break and rock fragmentation (D80), were measured in the Anguran mine;

-

2.

Back-break and rock fragmentation values were predicted using an ANN;

-

3.

In order to minimize back-break and provide desirable rock fragmentation, an ABC model was proposed.

Artificial neural network (ANN)

An ANN is a soft computation technique inspired by the human-brain information process. A typical ANN consists of three main constituents, namely the learning rule, the network architecture, and the transfer function (Simpson 1990). There are two major types of ANNs: recurrent and feed-forward. Shahin et al. (2002) recommended that if there is no time-dependent parameter in the ANN, the feed-forward (FF) ANN can be employed. A multi-layer perceptron (MLP) neural network is one of the most well-known FF-ANNs (Monjezi et al. 2013). An MLP consists of a number of nodes or neurons in three layers (input, hidden and output) linked to each other by weights. Du et al. (2002) and Kalinli et al. (2011) stated the high efficiency of MLP-ANNs in approximating various functions in high-dimensional spaces. Among the many kinds of learning algorithms to train MLP-FF models, the back-propagation (BP) algorithm is the most extensively utilized (Dreyfus 2005; Jahed Armaghani et al. 2014b; Momeni et al. 2015). In a BP-ANN, the imported data in the input layer starts to propagate to hidden neurons through connection weights (Kuo et al. 2010). Within a FF-BP algorithm, the signals flow from the input layer to output layer (the forward pass). The output is then compared to the actual values and the value of the difference or error is computed. The calculated error is propagated back through the network (the backward pass) and the individual weights are updated. Weights in the BP algorithm can be calculated based on delta rule as follows:

where out j is the output of the jth neuron, μ is the training rate, and Ep is the ANN error that can be obtained using Eq. 3:

where \( d_{\text{pk}} \,{\text{and}}\,O_{\text{pk}} \) are actual and predicted values of the kth neuron, k is the total number of neurons, and P is the number of datasets.

In this study, burden, spacing, stemming length, hole length and powder factor were considered as inputs, whereas, fragmentation and back-break were set as output parameters. The performance of ANN models is strongly dependent on the suggested architecture of the network. Therefore, determination of the optimal architecture is required to design an ANN model. The network architecture is defined as the number of hidden layers and the number of nodes in each hidden layer. Zhu et al. (2008) suggest that utilizing one or two hidden layers can achieve better results in non-linear prediction applications. Several ANN models with different architectures were modelled for prediction of fragmentation and back-break. It should be noted that, in a conventional ANN model, the dataset was divided into two subsets: 70 % of the dataset was set for training purposes and the remaining 30 % was utilized for checking the network performance. Finally, an ANN architecture with two hidden layers consisting of five and four neurons in the hidden layers was selected as the best ANN model (see Fig. 6). It is worth mentioning that, in the recommended ANN model, the learning rate and momentum coefficient were set to be 0.1 and 0.9, respectively. Figures 7 and 8 show the actual and predicted values of the rock fragmentation and back-break for all datasets, respectively, using the ANN model. Based on these figures, the predicted rock fragmentation and back-break values are in close agreement with their measured values, indicating the capability of an ANN in predicting these parameters. Furthermore, in order to control model performance, the values of R 2, root mean square error (RMSE) and amount of "value account for" (VAF) were computed for two ANN models (see Table 3):

where y, y′ and \( \tilde{y} \) are the measured, predicted and mean of the y values, respectively, and N is the total number of data points. The model will be excellent if the VAF is 100 and RMSE is zero. Based on Table 3, the ANN can predict fragmentation and back-break values with a high degree of accuracy.

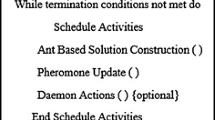

Artificial bee colony (ABC) algorithm

ABC theory

An artificial bee colony (ABC) algorithm was proposed by Karaboga (2005) to optimize complex engineering problems. Intelligent searching behaviour of honey bee swarms can be simulated by the ABC algorithm. Colony bees are divided to three categories: employed, onlookers and scouts (Kisi et al. 2012). Initially, searching for a food source is started by scout bees. In the searching period, several colony bees are considered continuous onlooker bees. Communication among scout bees about the food sources quality occurs in the dancing area. The dance is referred to as the "waggle dance," which is performed by employed bees when a high quality food source is found. Then, by using this information, the colony bees select the desirable food sources (see Fig. 9). In the ABC algorithm, a possible solution of the problem can be optimized by a food source. The quantity of nectar in a food source corresponds to the quality of the solution represented by that food source.

Adjustable parameters in the ABC algorithm include the number of scout bees (N), the number of food sources (M), the number of selected food sources (E), the number of bees dispatched to selected food sources (N re), the number of bees dispatched to other food sources (N sp), the radius of the neighborhood search (N gh) and the number of repetitions (I max). In the ABC algorithm, initial solutions (food source positions) are created within the problem parameter ranges:

where i = 1, …, N, j = 1, …, D, N is the number of food sources, D is the number of optimized variables. In the next step of the ABC algorithm, a new solution of V jk in the neighborhood of X k is produced for each solution as follows:

where φ jk is uniform distribution of random numbers in the range [−1,1] and \( X_{jk} \) shows the jth solution from kth population solution in which k is selected randomly from the range of [1, …, N]. If the new solution is more compatible, it will replace the previous solution. In the scout bee phase, by using Eq. 10 and based on calculated possibilities, each bee selects a solution. Subsequently, an onlooker bee finds a new solution against the selected solution; if the new solution is well-matched it will be chosen.

ABC algorithm evaluation

In order to evaluate the ABC algorithm, Rastrigin’s function is utilized (see Eq. 11). Due to the non-linear and non-convex nature of Rastrigin’s function (see Fig. 10), it is one of the most popular functions used to examine the performance of optimization algorithms (Bozorg Haddad 2005). Implementation of the ABC algorithm written by MATLAB in Rastrigin’s function can be seen in Fig. 11. As shown in this figure, by using the ABC algorithm, the optimum point of Rastrigin’s function can be found. Based on this figure, the error result equals 0.0003 and shows the applicability of the ABC algorithm. This indicates that the ABC algorithm written by MATLAB is acceptable for use in this study.

Optimization of blasting pattern using ABC algorithm

In order to optimize the blasting pattern in the Anguran mine, an ABC algorithm is utilized. Several ABC models were constructed using different adjustable parameters. After performing a series of analyses, the most appropriate ABC parameters were obtained, as tabulated in Table 4. Based on the presented ABC parameters, blasting pattern parameters using the ABC technique were suggested (see Table 5). According to this table, the best achievable values obtained via the optimization process are 3.25 m and 29 cm for back-break and fragmentation, respectively. Also, values of 3.9, 4.0, 3.3, 12.9 m, and 0.45 kg/m3 were suggested for burden, spacing, stemming length, hole length and powder factor, respectively by the ABC model. However, convergence of ABC models in 10 repetitions is displayed in Fig. 12. It is worth mentioning that, in these models, each bee represents the information of one blasting pattern.

Comparison of optimization results with empirical model

The Kuz-Ram model was proposed to empirically predict the size of fragmented rock and has been utilized extensively in industrial application (Cunningham 1983, 1987). This model can be presented as follows:

where \( \bar{X} \) is the mean fragment size (cm), F r is rock factor (considered 8 for the Anguran mine; see Table 6), q is the powder factor (kg/m3), \( Q_{b} \) is the explosive weight in each hole (kg), and E is the strength of explosive material (assigned a value of 100 for ANFO). In order to evaluate the results of the optimization part, the mean fragment size in the Anguran mine was predicted by the Kuz-Ram model. Input parameter values used in the Kuz-Ram model can be seen in Table 7. By using Eq. 12, the result of the Kuz-Ram model (\( \bar{X} \) = 33.5 cm) is in good agreement with the optimized result of the ABC algorithmm (29 cm). The result obtained from the Kuz-Ram model showed the accuracy level of the ABC algorithm.

Discussion and conclusion

In this study an attempt has been made to minimize rock fragmentation and back-break resulting from blasting by optimization of blasting pattern parameters. In this regard, blasting parameters of 34 blasting operations as well as back-break and rock fragmentation were collected at the Anguran mine in Iran. In this study, burden, spacing, stemming length, hole length and powder factor were considered as network inputs to predict fragmentation and back-break. Fragmentation and back-break values were predicted by an ANN using the blasting parameters measured in the mine. R 2 values of 0.78 and 0.77 for fragmentation and back-break, respectively, suggest superior prediction capabilities of the ANN technique. In addition, the computed values of the models’ performance indices indicate that the ANN approach can predict fragmentation and back-break values with a high degree of accuracy. Furthermore, in order to optimize the blasting pattern, an ABC algorithm is utilized. According to the ABC algorithm results, values of 29 cm and 3.25 m for fragmentation and back-break, respectively, were recommended. For the sake of evaluation, an empirical model (Kuz-Ram) was applied to predict the mean fragment size in the Anguran mine. A mean fragment size of 33.5 cm reveals the ABC algorithm can optimize rock fragmentation with acceptable accuracy.

References

Atici U (2011) Prediction of the strength of mineral admixture concrete using multivariable regression analysis and an artificial neural network. Expert Syst Appl 38:9609–9618

Bagheri M, Khoshru H (2012) A new model for design of blasting pattern based on modified Kuz-Ram model in Gole- Gohar mine, Iran. In 1st technology conference of mining, Iran

Bahrami A, Monjezi M, Goshtasbi K, Ghazvinian A (2011) Prediction of rock fragmentation due to blasting using artificial neural network. Eng Comput 27(2):177–181

Bozorg Haddad O (2005) Hydro system optimization using bee colony algorithm, Ph.D thesis, university of science and technology, Iran

Cunningham CVB (1983) The Kuz-Ram model for prediction of fragmentation from blasting. In: Proceedings of the first international symposium on rock fragmentation by blasting, Lulea, Sweden, pp 439–453

Cunningham CVB (1987) Fragmentation estimations and the Kuz-Ram model-Four years on. In: Proc. 2nd Int. Symp. on Rock Fragmentation by Blasting, pp 475–487

Dreyfus G (2005) Neural networks: methodology and application. Springer, Berlin

Du KL, Lai AKY, Cheng KKM, Swamy MNS (2002) Neural methods for antenna array signal processing: a review. Signal Process 82:547–561

Esmaeili M, Osanloo M, Rashidinejad F, Bazzazi AA, Taji M (2012) Multiple regression, ANN and ANFIS models for prediction of backbreak in the open pit blasting. Eng Comput. doi:10.1007/s00366-012-0298-2

Görgülü K, Arpaz E, Demirci A, Koçaslan A, Dilmaç MK, Yüksek AG (2013) Investigation of blast-induced ground vibrations in the Tülü boron open pit mine. Bull Eng Geol Environ 72(3–4):555–564

Hajihassani M, Jahed Armaghani D, Marto A, Tonnizam Mohamad E (2014a) Ground vibration prediction in quarry blasting through an artificial neural network optimized by imperialist competitive algorithm. Bull Eng Geol Environ. doi:10.1007/s10064-014-0657-x

Hajihassani M, Jahed Armaghani D, Sohaei H, Tonnizam Mohamad E, Marto A (2014b) Prediction of airblast-overpressure induced by blasting using a hybrid artificial neural network and particle swarm optimization. Appl Acoust 80:57–67

Jahed Armaghani D, Hajihassani M, Mohamad ET, Marto A, Noorani SA (2013) Blasting-induced flyrock and ground vibration prediction through an expert artificial neural network based on particle swarm optimization. Arab J Geosci. doi:10.1007/s12517-013-1174-0

Jahed Armaghani D, Hajihassani M, Yazdani Bejarbaneh B, Marto A, Tonnizam Mohamad E (2014a) Indirect measure of shale shear strength parameters by means of rock index tests through an optimized artificial neural network. Measurement 55:487–498

Jahed Armaghani D, Tonnizam Mohamad E, Momeni E, Narayanasamy MS, Mohd Amin MF (2014b) An adaptive neuro-fuzzy inference system for predicting unconfined compressive strength and Young’s modulus: a study on main range granite. Bull Eng Geol Environ. doi:10.1007/s10064-014-0687-4

Jimeno CL, Jimeno EL, Carcedo FJA (1995) Drilling and blasting of rocks. Balkema, Rotterdam

Kalinli A, Acar MC, Gunduz Z (2011) New approaches to determine the ultimate bearing capacity of shallow foundations based on artificial neural networks and ant colony optimization. Eng Geol 117:29–38

Karaboga D (2005) An idea based on honey bee swarm for numerical optimization, Technical Report-TR06, Erciyes University, Engineering Faculty, Computer Engineering Department

Khandelwal M, Monjezi M (2013) Prediction of backbreak in open-pit blasting operations using the machine learning method. Rock Mech Rock Eng 46(2):389–396

Kisi O, Ozkan C, Akay B (2012) Modeling discharge—sediment relationship using neural networks with artificial bee colony algorithm. J Hydrol 428:94–103

Kuo RJ, Wang YC, Tien FC (2010) Integration of artificial neural network and MADA methods for green supplier selection. J Clean Prod 18(12):1161–1170

Michaux S, Djordjevic N (2005) Influence of explosive energy on the strength of the rock fragments and SAG mill throughput. Min Eng 18(4):439–448

Mohammadnejad M, Gholami R, Sereshki F, Jamshidi A (2013) A new methodology to predict backbreak in blasting operation. Int J Rock Mech Min Sci 60:75–81

Momeni E, Jahed Armaghani D, Hajihassani M, Mohd Amin MF (2015) Prediction of uniaxial compressive strength of rock samples using hybrid particle swarm optimization-based artificial neural networks. Measurement 60:50–63

Monjezi M, Rezaei M, Yazdian Varjani A (2009) Prediction of rock fragmentation due to blasting in Gol-E-Gohar iron mine using fuzzy logic. Int J Rock Mech Min Sci 46(8):1273–1280

Monjezi M, Bahrami A, Yazdian Varjani A (2010a) Simultaneous prediction of fragmentation and flyrock in blasting operation using artificial neural networks. Int J Rock Mech Min Sci 47(3):476–480

Monjezi M, Rezaei M, Yazdian A (2010b) Prediction of backbreak in open-pit blasting using fuzzy set theory. Expert Syst Appl 37(3):2637–2643

Monjezi M, Khoshalan HA, Varjani AY (2012) Prediction of flyrock and backbreak in open pit blasting operation: a neuro-genetic approach. Arab J Geosci 5(3):441–448

Monjezi M, Hasanipanah M, Khandelwal M (2013) Evaluation and prediction of blast-induced ground vibration at Shur River Dam, Iran, by artificial neural network. Neural Comput Appl 22:1637–1643

Monjezi M, Rizi SH, Majd VJ, Khandelwal M (2014) Artificial neural network as a tool for backbreak prediction. Geotech Geol Eng 32(1):21–30

Raina AK, Murthy VMSR, Soni AK (2014) Flyrock in bench blasting: a comprehensive review. Bull Eng Geol Environ. doi:10.1007/s10064-014-0588-6

Sayadi A, Monjezi M, Talebi N, Khandelwal M (2013) A comparative study on the application of various artificial neural networks to simultaneous prediction of rock fragmentation and backbreak. J Rock Mech Geotech Eng 5(4):318–324

Shahin MA, Maier HR, Jaksa MB (2002) Predicting settlement of shallow foundations using neural networks. J Geotech Geoenviron Eng 128(9):785–793

Simpson PK (1990) Artificial neural system: foundation, paradigms, applications and implementations. Pergamon, New York

Thornton D, Kanchibotla SS, Brunton I (2002) Modelling the impact of rock mass and blast design variation on blast fragmentation. Int J Blast Fragm 6(2):169–1168

Tonnizam Mohamad E, Hajihassani M, Jahed Armaghani D, Marto A (2012) Simulation of blasting-induced air overpressure by means of artificial neural networks. Int Rev Model Simul 5(6):2501–2506

Tonnizam Mohamad E, Jahed Armaghani D, Momeni E, Alavi Nezhad Khalil, Abad SV (2014) Prediction of the unconfined compressive strength of soft rocks: a PSO-based ANN approach. Bull Eng Geol Environ. doi:10.1007/s10064-014-0638-0

Zheming X, Mohanty B, Heping Z (2007) Numerical investigation of blasting- induced crack initiation and propagation in rocks. Int J Rock Mech Min Sci 44:412–424

Zhu HT, Huang CZ, Wang J, Lu XY (2008) Machinability of glass by abrasive waterjet. Int J Mater Product Technol 31(1):106–112

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ebrahimi, E., Monjezi, M., Khalesi, M.R. et al. Prediction and optimization of back-break and rock fragmentation using an artificial neural network and a bee colony algorithm. Bull Eng Geol Environ 75, 27–36 (2016). https://doi.org/10.1007/s10064-015-0720-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10064-015-0720-2