Abstract

The discrete element method (DEM) has been extensively used to capture the macroscopic and particulate response of granular materials. Although particle rolling (i.e. controlled by rolling resistance) has been acknowledged as a major contributing factor towards micro-mechanical behaviour of idealized spherical granular material, its influence on characteristic behaviour has not been thoroughly investigated within critical state soil mechanics (CSSM) framework. For instance, the influence of particle rolling on characteristic features of undrained and drained behaviour (e.g. phase transformation, characteristic state, instability, dilatancy, critical state) and the state parameter, (ψ) has not been captured. In this study, a series of constant volume (CV) and drained triaxial compression simulations were undertaken using a rolling resistance linear contact model, deployed within a DEM software. The CSSM framework was centrally used to assess the influence of particle rolling tendencies/resistance on CV and drained behaviours from both a macro- and micro-mechanical standpoint. The study advanced the current understanding of the influence of rolling resistance on CS-related behaviour.

Graphic abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The critical state line (CSL) in e-log p′ space has been used as a reference line to predict granular material behaviour; where e is the void ratio and p′ is the mean effective stress. A granular material with a state (i.e. e and p′) above the CSL exhibits contractive behaviour, whilst a state below the CSL exhibits dilative behaviour. Been and Jefferies [4] defined such a state with the state parameter (ψ), as the difference between current e and the e on the CSL (measured at same p′) as presented in Fig. 1. In general, a positive ψ (above CSL) indicates contractive behaviour, whilst negative ψ (below CSL) indicates dilative behaviour. ψ has also been correlated with many characteristic behaviour of soil such as instability [26, 28, 59, 67, 70, 73, 74, 87], generation of excess pore water pressure (Δu) [69, 92], phase transformation (PT) and characteristic states (ChS) [55, 60, 92] and cyclic shear behaviour [69, 73, 74]. The CSL in q − p′ space defines intrinsic material properties such as the constant volume friction angle (ϕcv) and critical state stress ratio M = (q/p′)cs. The concept of state dependency and intrinsic material properties at CS have been used in many state-dependent constitutive models [16, 34, 42–44, 48]. Popular state-dependent constitutive models such as an earlier version of the SANISAND models described in Li and Dafalias [43] assume particle arrangement in specimens are the same i.e. formed via the same deposition/reconstitution method. However, specimens prepared by different deposition methods may have different stress–strain behaviour with same or different CSL [85] and has to be considered as different/partially different soil for constitutive modelling. The initial particle arrangement and the evolution of their interlocking, which is often indirectly captured by the mobilised inter-particle friction angle [20, 79], affects the observed stress–strain behaviour of granular materials. Therefore, understanding the evolution of particle arrangement, along with CS, is needed to develop further understanding of soil behaviour. However, capturing the micro-mechanical response of sand is challenging in an experimental setting. Experimental techniques such as Scanning Electron Microscopy (SEM) and Computed Tomography (CT) scanning have been used to capture different aspects of the micromechanical behaviour of granular materials with limited success [18, 25, 30, 89]. Although some micro-CT scanning techniques exist, which allow for the soil fabric behaviour to be captured in triaxial compression [18, 19], capturing the continuous fabric evolution behaviour using such techniques may be deemed expensive and time-consuming.

The discrete element method (DEM), proposed by Cundall and Strack [14], has become popular as an alternative approach to develop a qualitative understanding of soil behaviour due to its capability of generating a numerical assembly of particles with a desired grain size distribution, friction coefficient and shape, and allowing an in-depth understanding of micromechanics [23, 26, 28, 59, 63]. Thus, DEM has proven to be a useful tool in capturing the micromechanical interactions of granular materials and is capable of providing a physical explanation of the overall behaviour of such materials. The role of fabric and contact density on the characteristic behaviour of granular materials have been explored using DEM. However, in many of these recent studies, rolling characteristics of particles have been neglected within the DEM contact model [22, 23, 93]. This is a crude assumption as many DEM studies employ spherical particles, which characteristically exhibit large particle rolling tendencies. Through X-ray and photo-elastic techniques, Oda et al. [66] and Oda and Kazama [65] suggested particle rolling is a dominant micro-deformation mechanism which controls the dilatancy and peak strength behaviours of granular materials. Their experimental study reported that rolling resistance can somewhat indirectly capture particle shape and surface texture features of granular material. Zhao et al. [95] studied the shear behaviour of variable particle shapes within a rolling resistance model in DEM and observed that particle shape could somewhat be captured by rolling resistance. However, the model was only effective in doing so for particle shapes which have slight distortion from the spherical particle. Assemblies mobilised with rolling resistance usually show higher shear strength and volumetric dilation [32, 54, 65, 94]. Liu et al. [46] reported similar observations but only until a threshold rolling resistance value of 0.3. However, Plassiard et al. [68] showed there was no clear link between rolling resistance with peak dilatancy or drained CS strength. Although, other DEM studies have observed that the addition of rolling resistance enhances the peak and residual friction angle [1]. Iwashita and Oda [32] observed shear band formation and strain localization behaviour to intensify with the inclusion of rolling resistance, which led to higher dilative tendencies. Zhao and Guo [94] and Liu et al. [46] observed fabric anisotropy to increase with the inclusion of rolling resistance. Some studies have observed the CS to strengthen with rolling resistance, although the application of CSSM to evaluate the influence of rolling resistance on constitutional (characteristic) behaviour has not been performed [17, 100]. For example, Zhao and Guo [94] & Chang et al. [10] investigated the influence of rolling resistance within CSSM framework and observed an upwards shift of the CSL in e-log p′ space with the inclusion of rolling resistance. Although, CSSM (i.e. evaluating the performance of ψ) was not used to capture the influence of particle rolling on characteristic features and constitutional shearing behaviour (e.g. phase transformation, characteristic state, undrained instability state, maximum dilatancy).

In this study, a rolling resistance linear contact model (RRLCM) is deployed in DEM to advance the understanding of the influence of particle rolling on shearing behaviour. The influence of particle rolling (or rolling resistance) on macro-mechanical features (e.g. instability, phase transformation (PT), characteristic states (ChS), peak dilatancy, CS etc.) was evaluated, advancing the understanding of the influence of particle rolling on the characteristic response of granular material. The influence of particle rolling on characteristic features was also captured via ψ (i.e. CSSM framework was utilised) and their behaviours could be bridged with the observed micro-mechanical response in the RRLCM (i.e. contact density, fabric, contact network). Currently, the ability for the CSSM (i.e. ψ) to capture the influence of particle rolling on soil behaviour is not understood. Consequently, existing state-dependent framework (e.g. the flow-rule equation in [43]) and state-dependent constitutive models and their ability to capture the influence of particle rolling on soil behaviour is not known. Through assessing the response between particle rolling resistance and the aforementioned characteristic features of triaxial compression behaviour, the ability for a state-dependent constitutive framework to capture the particle rolling effect may be analysed.

Additionally, through a focus on the DEM-observed characteristic behaviour of granular material, the understanding of the CSSM in DEM may be built upon. For instance, the recently debated [60, 92] CSSM-related phenomenon—the equivalency of the PT and ChS in undrained and drained triaxial shearing, could be analysed. Although the happening of the PT and ChS corresponds to the transition between contractive and dilative behaviours in undrained and drained triaxial shearing, the micro-mechanical influence on the happening of this transition has not been investigated. The micro-mechanical behaviour is captured at characteristic states, in order to assess the micro-mechanical influence on the happening of the PT and ChS states.

2 DEM model details

DEM software, PFC3D (Itasca [31] was used to simulate constant volume (CV or undrained) and drained triaxial compression tests. Inter-particle forces and displacements were resolved using the rolling resistance linear contact model (RRLCM). The RRLCM is identical in nature to the conventional linear contact model (see Supplemental Data), however with a rolling spring and dashpot installed at the contact (Fig. 2). The rolling spring simulates the linear elastic (non-tension) frictional behaviour caused by particle rolling, whilst the dashpot accounts for any viscous behaviour due to particle rolling. It should be noted, whilst twisting may occur at the contact, the behaviour resulting from particle twisting is not incorporated in the model. Many DEM studies which attempted to analyse the influence of particle rolling behaviour have assumed constant values for either normal stiffness (kn), tangential stiffness (ks) and/or rolling stiffness (kr) over an entire particle size distribution [32, 46, 54, 84]. In reality, particle stiffness has been observed to be particle size-dependent [86]. In this study, kn, ks and kr of individual particles are computed based on their radius and potential deformation of particles at the contact. The deformability of granular material which share contact can be described by the elastic constants of the material, i.e. Young’s modulus (E) and Poisson’s ratio (ν). In this study, kn, ks and kr are a direct function of an effective modulus (E*) and k* = kn/ks, which are emergent properties of E and ν. The method of deformability installed in the contact model and the mathematical formulations of kn, ks and kr are further described in Appendix A. An average contact overlap ratio representative of sand particles was maintained. That is, an average overlap ratio less than 6% was achieved [51]. An E* = 50 MPa was selected and critical state stress ranges (i.e. p′cs) observed in this study aligned with those observed in experimental studies of identical graded granular material [75]. Unlike other studies, this study therefore evaluates the rolling behaviour of particles where contact stiffness varied with radius and potential deformation. The full mathematical description of the inherited RRLCM is presented in “Appendix B”.

Various approaches have been used to mimic the rolling resistance (or potential) created at a contact. Two of the more common methods of modelling rolling resistance in DEM is through either- 1) an eccentricity parameter [98, 99] with a unit length which is related to a rolling moment arm between two contacting particles or 2) a dimensionless shape parameter, δ [35] which apparently reflected the contact width between contacting entities and their relative particle shapes. A more commonly used approach is adopting a dimensionless rolling resistance parameter (μr) due to its established physical basis:

where β corresponds to the maximum angle of a plane at which a particle sitting on it possesses a resisting moment equal to its natural rolling torque. The mathematical definition of μr is conveniently in close association with the definition of angle of repose and therefore sliding friction (μ). Further, Ai et al. [2] indicated that the μr definition is preferable in measuring rolling resistance due to its clear physical basis. μ and μr were used simultaneously in all simulations. In this study, various μr values were used to investigate the effect of particle rolling on overall behaviour.

3 Triaxial simulations

In this study, 90 triaxial tests with different consolidation stresses, p′0 (48–500 kPa), different initial void ratio, e0 (0.594–0.889) and different μr (0–1) were simulated. A summary of DEM input parameters and test conditions are presented in Tables 1 and 2 respectively. The range of 0 ≤ μr ≤ 1 was selected as at μr ≈ 1 a threshold rolling value is approached, and minimal change in soil and CS behaviour were observed.

Spherical particles were used to represent clean sand with median particle size, D50 of 0.279 mm. The particle size distribution of the assembly is presented in Fig. 3. Particles were initially generated with no initial contact within a cubic domain bounded by six rigid and frictionless walls. A staged isotropic compression technique was used to achieve the desired void ratio before consolidation, ei. During this process, a smaller μ (≈ 0–0.4) was used to form dense assemblies, whilst a large μ (≈ 0.6–1) was used to form loose assemblies. After the desired ei was achieved, μ was set to a representative value for granular material (μ = 0.5) before the commencement of consolidation in all triaxial simulations. All specimens were isotropically compressed to different p′0.

In undrained (constant volume) shearing constant volume was ensured through a servo-control mechanism applied to the vertical walls while shearing strains were applied at the top and bottom walls. Drained shearing was achieved through strain control of the top and bottom walls, whilst the stresses on the vertical walls were controlled simulating constant cell pressure.

4 Numerical stability of DEM simulations

The deterministic nature of elastoplastic theories suggests that the mechanical behaviour of granular material in DEM assemblies should be independent of size i.e. number of particles [36]. Figure 4 presents the shearing responses for three specimens with different particle number (N) and strain deformation rates. TRR26 and TRR31 were conducted with the same strain rate of strain of 0.001 s−1 but with N = 10,506 and N = 17,921 respectively. TRR33 was conducted with N = 10,506 and a strain rate five times smaller than TRR26 (0.0002 s−1). Negligible discrepancies in their q–εq and q–p′ paths in Fig. 4a, b suggest that a strain rate of 0.001 s−1 with N = 10,506 achieves numerical stability. This specimen size and strain rate was used in all further simulations in this study.

The coordination number, CN = 2Nc/N [78], is a micromechanical entity which quantifies the contact density of a granular assembly; where Nc is the number of particle contacts. Figure 4c shows that specimen size and strain rate had a negligible influence in their CN-εq paths. The inertial number (I) proposed by da Cruz et al. [15] has been used as a performance parameter in DEM which assesses whether a quasi-static deformation of particles in the assembly throughout shearing is upheld. I is defined as,

where \(\dot{\varepsilon }\) is the shear strain rate, \(d\) is the mean particle diameter, and \(\rho_{g}\) is the particle density. All simulations satisfied the condition of I < 10−3 i.e. the influence of particle kinematics on the observed shear behaviour corresponded to a quasi-static condition [47, 50].

5 Results

The major and minor principal stresses (σ′11 and σ′33) were computed from the stress tensor as suggested by Christoffersen et al. [11]:

where \(V\) is the total assembly volume, \(N_{c}\) is the total number of contacts, \(f_{i}^{c}\) is the ith component of contact force at contact c and \(l_{j}^{c}\) represents the jth branch vector connecting the centres of two contacting particles, at contact c. Only particle to particle contacts are considered in Eq. 3 so that the effect of the rigid boundary end-restraint is reduced [21, 49]. p′ and q (in triaxial space) were derived from the stress tensor as below:

5.1 Constant volume tests

Figure 5 shows the response during CV shearing for six samples with different μr (0 ≤ μr ≤ 1). All tests were conducted with p′0 of 100 kPa and similar e0 values (between 0.594 and 0.601). Each simulation was continued up to εq of 50%. Due to the very dense nature of the presented tests, a strict condition of CS was sometimes not reached, as the condition dΔu = 0 was not satisfied. Note, Δu was indirectly derived from the difference between p′ in CV and drained paths (Δu = p′D − p′CV) as described by Sitharam et al. [81]. In cases where the CS condition of dΔu = 0 was not reached, an extrapolation approach [8, 55, 75] was used. All specimens underwent strain hardening until a near CS was reached, and therefore exhibited non-flow (NF) behaviour. Specimens with large μr values manifested the strongest behaviour characterised by prolonged strain hardening legs, resulting in the manifestation of larger CS strengths. An identical trend reoccurred in effective stress path space (Fig. 5b), suggesting the increase in strength with μr is largely due to the enhancement of frictional properties. In Fig. 5a, b, M = q/p′ or CS strength increased with μr, but became less sensitive to changes as μr → 1 indicating a theoretical state of maximum rolling resistance is approached. The DEM study of Huang et al. [26, 28] detected similar behaviour in the case of μ.

The influence of μr on Δu is evaluated in Fig. 5c. When εq < 25%, assemblies mobilised with low μr were observed to exhibit the largest negative pore water pressure changes. Although, assemblies with larger μr, generate negative Δu at larger rates past intermediate (≈ 25%,) strains. A clear trend between Δu and μr at CS is hard to observe as most tests are yet to reach CS and are changing at different rates.

Earlier studies suggested that a large CN is often associated with a large CS strength or dense assembly [22, 59]. To evaluate the effect of μr on CN, the isotropic compression paths are presented first in Fig. 6a. A negligible influence of μr on CN was observed, i.e. these paths were almost identical. The evolution of CN during shearing was then presented in Fig. 6b. Although CN at the start of shearing is identical for all simulations, during shearing, a specimen with larger μr value achieved a lower CN at the critical state and vice versa. For instance, assemblies with large rolling tendencies (lower μr) achieved a critical state strength via a larger number of weaker contacts. On the other hand, the efficiency of strong contact formation was superior for assemblies mobilised with a larger μr. The strong formation efficiency or interlocking behaviour may therefore be tuned via μr. Although, these findings are important in understanding the qualitative influence of particle rolling on contact density, the RRLCM may have the tendency to generate magnitudes of CN which may not be realistic [95].

The contact force networks at CS for four undrained specimens with similar initial states but varying μr illustrate this effect (Fig. 7). A profound influence of particle rolling on the contact force network and the contact anisotropy throughout shearing can be observed. In a free-rolling environment (i.e. μr = 0, Fig. 7a) a dense contact network was formed (i.e. large CN). The network was rife with contacts largely disorientated to the direction of loading, i.e. weak contact forces were predominate [52]. Following Radjai et al. [72], an assembly which possesses a contact network of this type may behave as an interstitial fluid. In agreement, Zhou et al. [97] indicated the reduction in μr conforms to a lubrication or softening effect of particles in contact. When μr was large, strong contacts with larger magnitude (i.e. a hardening effect) dominated the force chain network, ultimately with a reduction of CN at CS. The amount of sliding or rolling contacts are therefore limited [72] and ultimately interlocking capabilities are enhanced. Guo and Su [24] in their laboratory experiments and Huang et al. [26, 28] in their DEM simulations also observed interlocking behaviour to be closely related with particle angularity—a parallel that could be drawn between particle rolling resistance and angularity. Although an interlocking effect can be simulated via rolling resistance, through capturing the twisting resistance at the contact, the interlocking could be better approximated.

The change in force chain networks could also be explained by a transitional behaviour from rolling-dominanting contact networks to sliding-dominating contacts networks, as μr is varied. Reportedlty, for the granular mixtures mobilised with small μr values, the displacement of contacts are dominated by particle rolling. As μr increased, the participation of sliding at the contacts was increased, in lieu of rolling behaviour [27]. Nevertheless, a clear strengthening effect is observed with the addition of μr.

Many studies have reported the internal structure or spatial arrangement (i.e. soil fabric) of granular material to be highly anisotropic which influences the soil behaviour [56, 64, 91]. Similar to CN, observing the anisotropic fabric and its evolution throughout shearing may assist in explaining the macro-response of a granular material. To quantify anisotropic fabric, Satake [80] and Rothenburg and Bathurst [78] proposed similar second-order fabric tensors. Via the former, the fabric tensor, F may be expressed as:

where nk is the directional unit vector for the kth contact, Fij is scalar counterpart of F. Rahman et al. [76] showed that the deviatoric fabric and its evolution throughout shearing could be represented by the von Mises fabric, FvM= 3(FJ2D)0.5[77], where FJ2D represents the second invariant of F:

Figure 8 illustrates the evolution of deviatoric fabric for each of the CV simulations. The deviatoric fabric intensified to a peak FvM and then reduced until CS was reached where the changes of von Mises fabric dFvM approached zero. In agreement with Li and Dafalias [41], dFvM= 0 may be considered as a supplementary condition of CS. Specimens mobilised with large μr values displayed a large peak and CS FvM. Assemblies with large strong contact networks typically exhibit large anisotropy [26, 28], which potentially explains why assemblies with large μr exhibit large peak FvM or deviatoric anisotropies. The observations also highlight that the deviatoric fabric is largest for assemblies mobilised with large μr [96].

The phase transformation (PT) state corresponds to the transition from contractive to dilative behaviour, which may be observed in the undrained shearing of dense and medium-dense specimens. Mathematically the PT can be defined as when dp′ = 0 [38] and corresponds to the ‘knee’ in the effective stress path as shown in Fig. 9a. Alternatively, dΔu = 0 has been used to define the PT state as shown in Fig. 9b [83]. The later description (dΔu/dεq = 0) was used to define PT in this study. The rolling tendencies manifested within an assembly was observed to influence the PT. Specifically, the PT was observed at slightly larger εq, Δu and q values for assemblies with larger μr. In Fig. 9c the PT point observed at dΔu = 0 was projected on the CN evolution path for each simulation. Interestingly, the PT point does not correspond to a change in contact behaviour, i.e. a change from decreasing contact density to increasing contact density. Literature has linked the local minimum of the CN path to the quasi-steady state [88], although it seems there is no relation with the classical PT point. The PT point was also projected on the fabric evolution path (Fig. 9d). It seems, the occurrence of PT cannot be explained by a sudden change (local maximum) in the granular material deviatoric fabric or spatial arrangement. The CN and FvM behaviour has been useful in explaining CS behaviour from a micromechanical standpoint [3, 26, 28, 57], although explaining the occurrence of PT from these two micromechanical entities is challenging.

At the happening of PT a sharp change from contractive to dilative behaviour is observed. Although, such behaviour is not believed to arise as a result of DEM imposed testing conditions. For instance in Ishihara [29] study of Toyoura sand, a sharp change from contractive to dilative behaviour was also observed. In the experimental study of Murthy et al. [55] a clear ‘knee’ in the effective stress path could also be observed—both studies yielded similar ‘knee’ or PT behaviour as this manuscript.

5.2 Drained shearing tests

Figure 10 shows the drained shearing responses for samples with p′0 of 100 kPa, e0 within a narrow range of 0.594–0.601 and varying of μr values. In Fig. 10a, all specimens exhibited dilative behaviour to a peak deviatoric stress (qpeak) followed by strain-softening to CS. Similar to the observations made for constant volume shearing, an increase in CS strength is associated with a rise in μr (see Fig. 10a). For large μr, hardening occurred over a larger range of εq, thus a higher qpeak was reached at larger deviatoric strains. Specimens with large μr manifested steep strain softening (i.e. brittle) behaviour.

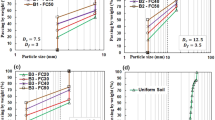

The highly dilative nature of assemblies mobilised with large μr is illustrated in εv − εq space; where εv represents the volumetric strain (Fig. 10b). Volume dilation shows to increase with μr. Although, when μr > 0.3, insignificant increase in volume dilation occurs. Each of the drained tests peak dilatancy, i.e. \(d_{peak} = \left( {\frac{{{\text{d}}\varepsilon_{q}^{p} }}{{{\text{d}}\varepsilon_{v}^{p} }}} \right)_{peak} ,\) was captured (Fig. 10c); where superscript “p” refers to plastic. Note, following many researchers \({\text{d}}\varepsilon_{q}^{p} \approx {\text{d}}\varepsilon_{q}\) and \({\text{d}}\varepsilon_{v}^{p} \approx {\text{d}}\varepsilon_{v}\) were assumed for large strain behaviour of granular materials [43, 73, 74]. Figure 10c supports the supposition that there is insignificant change in dilatancy behaviour at ranges of μr > 0.3 is further supported. Although in q − εq space at μr > 0.3, the change in peak strength is more significant. Thus, at this range of μr it seems an enhancement of frictional properties (i.e. M or ϕcv) rather than dilatancy properties is responsible for strengthening the materials response via strong contacts. When μr < 0.3, the response is governed more equally by both dilatancy as well as frictional behaviour. In Fig. 10c, the peak dilatancy, was observed to increase initially with μr although Plassiard et al. [68] observed peak dilatancy to be independent of rolling resistance. In Fig. 10d, e the evolution of CN and FvM during drained shearing is presented. The behaviour is identical to what is observed throughout CV simulations.

Similar to the PT state in undrained shearing, a characteristic state (ChS) exists in drained shearing which signifies the transition between contractive and dilative behaviour [38]. The ChS in εv − εq space is presented in Fig. 11a. The ChS can be pinpointed as the state of dεv = 0, i.e. dilatancy, d = dεv/|dεq| = 0. Similar to the PT, the ChS is influenced by μr. The ChS occurred at larger εv and εq for specimens mobilised with large μr for specimens sheared with similar initial states. Thus, in both CV and drained shearing of medium dense/dense specimens, initial contractive tendencies were prolonged for assemblies mobilised with larger rolling resistance. It is likely, this is due to the unease of displacing strong interlocking contacts, and thus dense assemblies stay in a contractive state for longer, until contacts may be displaced at larger shear stresses. The ChS point was projected on the CN and FvM evolution paths (Fig. 11b, c). Similar to observations in CV shearing (Fig. 9), no change in soil micromechanics was observed at the ChS states in drained shearing. This supports the notion of continuum mechanics that the happening of PT and ChS states are related to the responses of dilative tendencies, not due to a change of particle contact density or particle spatial arrangement.

6 Critical state behaviour

6.1 Influence of rolling resistance on CSL

The CS data points from both CV and drained simulations with five different μr of 0, 0.1, 0.3, 0.5 and 0.7 are plotted in the e-log p′ space as shown in Fig. 12a. The CSLs can be represented by the following power function as proposed by Li et al. [45]:

where pa is the atmospheric reference stress i.e. pa = 100 kPa and elim, λ and ξ are dimensionless curve fitting parameters. The CSLs were independent of drainage condition aligning with early experimental studies [5, 9, 82, 90, 6, 71] and DEM studies [60]. These CSLs are curved and shifted upwards with increasing μr. Previous literature had suggested the curvature of the CSL to only be attributed to particle breakage (Konrad 1998). However, the DEM particles were unbreakable and therefore suggest otherwise—which is consistent with other DEM studies inheriting different contact models and particle shapes [59, 61, 62]. The pronunciation of the CSL curvature became more prominent at large μr values which led to merging CSLs at higher p′ (> 1000 kPa) irrespective of μr. A conversing trend for CS data points at higher p′ was also found with particle angularity in DEM [61]. However, Huang et al. [26, 28] using a simplified Hertz–Mindlin contact model where particle rotations were allowed (following Calvetti and Emeriault [7]) in DEM software LAMMPS found almost parallel CSLs with very mild curvature up to p′ of 10,000 kPa for two frictional constraints. They also observed an unusual increase of critical state void ratio with increasing p′ for μ ≥ 0.5. μ = 0.5 was used in this study and the unusual behaviour was not observed. Such difference with this study may be attributed to the difference in contact models, implementation platform i.e. PFC & LAMMPS and limited CS data in Huang et al. [26, 28]. The CS data points for other μr values are also projected with these CSLs in Fig. 12b. The data suggests there is negligible influence of μr on CSL in the e-log p′ space when μr ≥ 0.4 and one CSL may be assumed in this range of μr.

The CSLs in the q − p′ space were also μr-dependant (Fig. 12c). Within the range of 0 ≤ μr ≤ 1, M increased from 0.73 to 1.38 with a noticeable change from 0.73 to 1.15 for μr only increased from 0.0 to 0.3. The increasing trend of M with μr is very similar to increasing M with increasing particle angularity in DEM [61]. Therefore, rolling resistance between particles contribute to the CSLs and its curvature in the e-log p′ space in a similar manner to particle shape and thus, μr may be inferred as contributor to frictional properties of particle shape.

6.2 Change in CS behaviour with μr

A series of CV and drained simulations, where shearing commenced from similar initial states (p′0 = 100 kPa, e0 = 0.5975 ± 0.0035) for both drained and CV simulations were performed and the influence of rolling resistance on q, CN and FvM at CS was captured (Fig. 13). The change in μr with the three quantities are similar between drainage conditions. In Fig. 13a, q at CS (qcs) increases gradually with μr before plateauing at approximately μr = 0.4. Thus, at larger μr ranges the influence of particle rolling resistance on qcs is negligible. Similar tendencies were also observed for CN and FvM in Fig. 13b, c respectively. Although strictly not a threshold μr value, the change in CS behaviour becomes relatively unnoticeable as μr → 1. Liu et al. [46] reported a threshold μr value of 0.3 where at μr ≥ 0.3 the strength of granular material shows negligible change. Similar is observed here, although micromechanical entities CN and FvM are observed to change differently at μr ≥ 0.3. Therefore, a threshold rolling value may only be applicable for selected entities/performance parameters rather than applying for the entire material response. Further, it should be acknowledged that the change in contact model (e.g. contact stiffness algorithms) and model parameters (e.g. μ) which may influence particle rolling behaviour may lead to different observations relating to a threshold μr value.

6.3 Rolling resistance and associated micro-mechanics for CSL

Both linear [22] and power [58] functions have been used to express the relationship between CN and p′ at CS. Providing a better fit for the data in this study, a power function was used:

where CNcs is the CN at CS and A, B and C are fitting constants. A strong relation between p′ and CNcs for each μr value, irrespective of drainage condition was observed (see Fig. 14a). For any given p′cs value the CNcs decreased with increasing μr. In Fig. 14b, the contact networks of two assemblies, TRR10 and T14, which possess μr values of 0 and 0.3, but similar p′cs values reflect this change in contact density. The contact network for TRR10 relies on a larger number of weak contacts to achieve a similar CS strength when compared to T14. For specimen TRR10, p′cs = 363 kPa is achieved via widespread weak contact forces which may be easily displaced or rearranged, whilst T14 achieves p′cs = 354 kPa through the efficient formation of strong contact forces which possess larger shear resistance. Ultimately, a change in rolling tendencies substantially impacts fabric related entities such as contact orientation and contact intensity at CS.

For all CV and drained simulations, the FvM(cs) behaviour was captured by CSLs in FvM − log p′ space (Fig. 15). No influence of drainage condition on observed CS fabric behaviour. Firstly, it is encouraging that CS fabric behaviour is analogous with overall observed CS behaviour, e.g. CSL in e − log p′ space—further showing fabric is highly influential on soil behaviour and advancing the theory that fabric should be encapsulated under CSSM framework [41]. The CSL in FvM − log p′ space shifted upwards with μr. Huang et al. [26, 28] observed identical behaviour, with the case of μ. The increasing anisotropy with μr may be explained by the intensification of strong contact formation (observed in Fig. 7), which primarily contributes to the deviatoric stress (and therefore likely deviatoric fabric) component of the assembly [52, 72].

7 Particle rotation and angular velocity

In PFC3D, the angular velocity, which represents rotational tendency of individual particles, can be captured throughout shearing. At prescribed εq values, the angular velocity for each particle was recorded and the average angular velocity, ωavg of the entire assembly was calculated. In Fig. 16, the variation of ωavg and average angular velocity at critical state, ωcs for a series of drained shearing tests (with similar initial states, i.e. p′0 = 100 kPa and e0 = 0.5975 ± 0.0035) are plotted against rolling resistance. A very strong relationship between μr and ωavg was observed. Low rolling resistance corresponded to high particle rotations and vice versa. The observations indicate ωavg can be used within DEM to quantify rolling behaviour. From herein, ωavg is used as an indirect measure to capture particle rolling tendencies.

In Fig. 17a, the influence of e0 and p′0 on the rotational tendencies of granular material is assessed. All specimens had μr = 0.1 and exhibited NF behaviour (Fig. 17b). Although unpronounced, a trend in Fig. 17 is that during strain hardening, ωavg increases. Further, particle rolling was observed to increase with e0 (on comparison between TRR34 and TRR35), i.e. rolling is more prone to occur in loose specimens. The influence of p′0 on rolling tendencies (on comparison of TRR35 and TRR38) is negligible.

In Fig. 18, the variation of ωavg is plotted against the post-compression state parameter, ψ0 for μr = 0.1 and μr = 0.3. Notably, contractive specimens with higher ψ0 corresponded to large rotational/rolling behaviour. In dilative specimens rolling/rotational behaviour still existed although tendencies were minimised. The trend line shifts downwards in the ωavg − ψ0 space as μr increased. Thus, depending on μr, each ωavg − ψ0 possesses its own characteristic rolling tendency.

8 Influence of rolling resistance on instability state

Instability triggering is a state which corresponds to the peak q in undrained shearing before strain softening occurs and is also known to be the onset of static liquefaction. The instability state is a characteristic feature of undrained behaviour of loose sand. It has been characterised using approaches, such as the collapse line (CL) [82] or the instability line (IL) [13, 37]. Perhaps the instability stress ratio, ηIS = (q/p′)peak is better suited to quantify instability behaviour as it can be linked with mechanical performance parameters such as ψ0 [53, 87, 39]. Yang [87] developed an exponential relationship and Rahman and Lo [53] modified the relationship between ηIS and ψ in the form of:

where A and B are curve fitting parameters. Equation (10) captures the instability behaviour as a function of soil state. In Fig. 19a the relationship between ηIS and ψ0 for varying μr values is captured. The instability data points in the ηIS − ψ0 space showed a clear upward shift with increasing μr. However. in the free-rolling case, a steeper reduction in ηIS occurs than those assemblies mobilised with a finite μr. Through a reanalysis of DEM data, Nguyen et al. [59] asserted a steep slope in ηIS − ψ0 space to be attributed to low particle angularity and interlocking capabilities. Aligning with the force chain networks in Fig. 7 it can be suspected that the steep behaviour shown for μr = 0 is also due to poor interlocking and highly lubricative behaviour. Therefore, a link between particle angularity and rolling resistance share a relation may be made between the two studies. That is, it is possible that μr can be used as a tuneable parameter in DEM to indirectly control particle angularity.

When the FvM at ηIS, FvM(IS) is plotted against ψ0 (Fig. 19b), two separate relationships are yielded. Following on from Fig. 19a, when μr = 0, a steeper decrease of FvM(IS) occurs with increasing ψ0, in comparison to those assemblies mobilised with a finite μr value. Thus, for μr = 0 the behaviour observed in ηIS − ψ0 is reflected in FvM(IS) − ψ0 space. Again, this behaviour could be attributed to the associated low interlocking capabilities. Secondly, when μr > 0 the influence of μr on FvM(IS) appears to be nullified. In fact, a single trend line can be approximated to represent the trend in FvM(IS) − ψ0.

9 Influence of rolling resistance on PT and ChS

Both PT and ChS states correspond to the change over from contractive to dilative tendency and, therefore, they can be assumed as a state of zero dilatancy and equivalent. Thus, the dilatancy equation of SANISAND model [43] can be manipulated to derive the following relation between stress ratio at PT (ηPT) and ChS (ηChS) with ψ –

However, some experimental studies suggested the equivalence between ηPT and ηChS [12, 40], whilst others observed different behaviour [92]. Therefore, the equivalence of these states and the functional relation has significant importance in granular material modelling.

It is found in Fig. 20a that assemblies with large rolling resistance possesses larger ηPT or ηChS at the same ψ0, however both ηPT and ηChS possess single relation with ψ0 for each μr i.e. ηPT and ηChS are equivalent. When ηPT and ηChS were normalised by M (Fig. 20b), a single trend line is developed, further indicating the equivalence of ηPT and ηChS, and support normalisation in constitutive relation. However, the best fit function is slightly different than Eq. (11) and presented as below:

While this observation confirms the relationship between characteristic features with ψ0 in the state-dependent constitutive modelling [43], it also indicates possible adjustment. The deviatoric fabric at PT and ChS states, FvM(PT/ChS) (normalised with M) also shared a unique relation with ψ0, irrespective of μr (Fig. 20c).

10 Conclusions

A series of CV and drained triaxial simulations were undertaken using the RRLCM within PFC3D. The influence of particle rolling on clean sand behaviour was captured through the CSSM framework. The key conclusions drawn from the study are summarised below:

-

i.

Rolling resistance has significant influence on the observed behaviour of granular material. Assemblies mobilised with high rolling resistance possessed highly frictional behaviour with dilative tendencies. Assemblies with low rolling resistance manifested less dilative tendencies. Thus, the dilative tendency shared a dependency with μr. Although, at approximately μr > 0.3, the influence of μr on volume dilation and peak dilatancy was almost unnoticeable.

-

ii.

Strong contact formation thrived for assemblies mobilised with large rolling resistance inferring that interlocking behaviour is influenced by rolling tendencies/resistance. A potential by-product of the strong contact formation is strain softening or brittle failure after peak deviatoric stress, q. Assemblies mobilised with low rolling resistance were incapable of forming strong interlocking contacts and instead yielded contact networks that were rife with weak contact forces. μr could therefore be used as a parameter to indirectly control the interlocking capabilities of a granular assembly.

-

iii.

The influence of μr on characteristic features of undrained shearing (i.e. PT and ηIS) and drained shearing (i.e. ChS) were captured. For dense/medium-dense specimens, initial contractive tendencies were prolonged in terms of deviatoric strain (εq) for assemblies mobilised with large rolling resistance. The stress ratio (q/p′) at PT, ChS and instability states, i.e. ηPT, ηCh and ηIS respectively, were all shown to increase with μr. ηPT, ηChS and ηIS also showed correlations with ψ0 for different values of μr. The study observed an equivalence between ηPT and ηChS.

-

iv.

CS parameters were significantly influenced by particle rolling. The CSL in e-log p′ space shifted upwards when rolling resistance increased. When μr was large, the curvature of the CSL became increasingly pronounced. Thus, the geometry of the CSL was influenced by rolling behaviour rather than particle breakage, which was suggested in the literature. An increase of M was observed with μr. Although at large ranges of μr, even though M continued to increase, changes in other mechanical entities such as FvM, CN, q and the CSL in e-log p′ space were mostly unnoticeable.

-

v.

A larger deviatoric fabric was observed with increasing μr. FvM(IS) and FvM(PT) showed relationships with initial state parameter (ψ0) with respect to μr.

Although the study presents valuable DEM findings relating to the influence of particle rolling on the characteristic (undrained and drained) behaviour of granular material, it should be noted that several rolling resistance models/frameworks exist, as noted in Ai et al. [2]. Utilising a rolling resistance model/algorithm which differs from that used in this study may lead to observed behaviour which diverges from the observations in this study. The influence of particle rolling on soil behaviour has been isolated in the manuscript, although sliding and twisting behaviour which occurs at the contact may also influence granular material behaviour.

Abbreviations

- Δu :

-

Excess pore water pressure

- ε q :

-

Deviatoric strain

- ε v :

-

Volumetric strain

- η IS :

-

Stress ratio at instability state

- η ChS :

-

Stress ratio at instability state

- η PT :

-

Stress ratio at phase transformation

- μ :

-

Inter-particle friction coefficient

- μ r :

-

Rolling resistance coefficient

- σ 11 :

-

Maximum principal stress

- σ 33 :

-

Minor principal stress

- ϕ cv :

-

Constant volume friction angle

- ϕ p :

-

Peak friction angle

- ψ :

-

State parameter

- ψ 0 :

-

State parameter at the beginning of shearing

- ω avg :

-

Average angular velocity

- ω cs :

-

Average angular velocity at critical state

- CN :

-

Coordination number

- D 50 :

-

Median particle size

- e :

-

Void ratio

- e 0 :

-

POST-consolidation void ratio

- F :

-

Fabric tensor

- F vM :

-

Von Mises fabric

- I :

-

Inertial number

- k n :

-

Normal contact stiffness

- k s :

-

Tangential contact stiffness

- k r :

-

Rolling contact stiffness

- M :

-

Slope of CSL in q − p′ space

- N :

-

Total number of particles

- N c :

-

Total number of contacts

- p′:

-

Mean effective confining stress

- p′cs :

-

Mean effective confining stress at critical state

- p′0 :

-

Post-consolidation mean effective confining stress

- q :

-

Deviatoric stress

References

Aboul Hosn, R., Sibille, L., Benahmed, N., Chareyre, B.: Discrete numerical modeling of loose soil with spherical particles and interparticle rolling friction. Granular Matter 19(1), 1–12 (2017)

Ai, J., Chen, J., Rotter, M., Ooi, J.Y.: Assessment of rolling resistance models in discrete element simulations. Powder Technol. 206, 269–282 (2011)

Barnett, N., Rahman, M.M., Karim, M.R., Nguyen, H.B.K., Carraro, J.A.H.: Equivalent state theory for sand with non-plastic fine mixtures: a DEM investigation. In press, Geotechnique (2020)

Been, K., Jefferies, M.G.: A state parameter for sands. Geotechnique 35(2), 99–112 (1985)

Been, K., Jefferies, M.G., Hachey, J.: The critical state of sands. Geotechnique 41(3), 365–381 (1991)

Bobei, D.C., Wanatowski, D., Rahman, M.M., Lo, S.R., Gnanendran, C.T.: The effect of drained pre-shearing on the undrained behaviour of loose sand with a small amount of fines. Acta Geotech. 8(3), 311–322 (2013)

Calvetti, F., Emeriault, F.: Interparticle forces distribution in granular materials: link with the macroscopic behaviour. Mech. Cohes-Frict. Mat. 4(3), 247–279 (1999)

Carrera, A., Coop, M., Lancellotta, R.: Influence of grading on the mechanical behaviour of stava tailings. Geotechnique 61(11), 935–946 (2011)

Casagrande, A.: Liquefaction and cyclic deformation of sands. In: 5th Pan American conference on soil mechanics Buenos Aires, pp. 80–133 (1975)

Chang, X., Wang, Y., Zhou, W., Ma, G., Liu, J.: The influence of rotational resistance on critical state of granular materials. In: Proceedings of the 7th International Conference on Discrete Element Methods (2016)

Christoffersen, J., Mehrabadi, M.M., Nemat-Nasser, S.: A micromechanical description of granular material behavior. J. Appl. Mech. 48(2), 339–344 (1981)

Chu, J.: An experimental examination of the critical state and other similar concepts for granular soils. Can. Geotech. J. 32(6), 1065–1075 (1995)

Chu, J., Leong, W.K.: Effect of fines on instability behaviour of loose sand. Geotechnique 52(10), 751–755 (2002)

Cundall, P.A., Strack, O.D.L.: A discrete numerical model for granular assemblies. Geotechnique 29(1), 47–65 (1979)

da Cruz, F., Emam, S., Prochnow, M., Roux, J.-N., Chevoir, F.: Rheophysics of dense granular materials: discrete simulation of plane shear flows. Phys. Rev. E 72(2), 021309 (2005)

Dafalias, Y.F., Taiebat, M.: SANISAND-Z: zero elastic range sand plasticity model. Geotechnique, 1–15 (2016)

Estrada, N., Taboada, A., Radjaï, F.: Shear strength and force transmission in granular media with rolling resistance. Phys. Rev. E Stat. Nonlinear Soft Matter Phys. 78(2), 021301–021301 (2008)

Fonseca, J., O’Sullivan, C., Coop, M., Lee, P.D.: Quantifying the evolution of soil fabric during shearing using directional parameters. Geotechnique 63(6), 487–499 (2013)

Fonseca, J., O’sullivan, C., Coop, M.R., Lee, P.D.: Non-invasive characterization of particle morphology of natural sands. Soils Found. 52(4), 712–722 (2012)

Frossard, E.: Effect of sand grain shape on interparticle friction; indirect measurements by Rowe’s stress dilatancy theory. Geotechnique 29(3), 341–350 (1979)

Fu, P., Dafalias, Y.F.: Fabric evolution within shear bands of granular materials and its relation to critical state theory. Int. J. Numer. Anal. Meth. Geomech. 35(18), 1918–1948 (2011)

Gu, X., Huang, M., Qian, J.: DEM investigation on the evolution of microstructure in granular soils under shearing. Granular Matter 16(1), 91–106 (2014)

Guo, N., Zhao, J.: The signature of shear-induced anisotropy in granular media. Comput. Geotech. 47, 1–15 (2013)

Guo, P., Su, X.: Shear strength, interparticle locking, and dilatancy of granular materials. Can. Geotech. J. 44(5), 579–591 (2007)

Hasan, A., Alshibli, K.A.: Experimental assessment of 3D particle-to-particle interaction within sheared sand using synchrotron microtomography. Geotechnique 60(5), 369–379 (2012)

Huang, X., Hanley, K.J., O’Sullivan, C., Kwok, C.Y.: Exploring the influence of interparticle friction on critical state behaviour using DEM. Int. J. Numer. Anal. Meth. Geomech. 38(12), 1276–1297 (2014)

Huang, X., Hanley, K.J., O’sullivan, C., Kwok, C.-Y.: Implementation of rotational resistance models: a critical appraisal. Particuology 34, 14–23 (2017)

Huang, X., O’sullivan, C., Hanley, K.J., Kwok, C.Y.: Discrete-element method analysis of the state parameter. Geotechnique, 954–965 (2014)

Ishihara, K.: Liquefaction and flow failure during earthquakes. Geotechnique 43(3), 351–415 (1993)

Isomokos, A., Georgiannou, V.: Effect of grain shape and angularity on the undrained response of fine sands. Can. Geotech. J. 47(5), 539 (2010)

Itasca: Particle Flow Code in 3 Dimensions (PFC3D) Version 4. Minnesota, USA (2008)

Iwashita, K., Oda, M.: Rolling resistance at contacts in simulation of shear band development by DEM. J. Eng. Mech. 124, 285–292 (1998)

Iwashita, K., Oda, M.: Micro-deformation mechanism of shear banding process based on modified distinct element method. Powder Technol. 109(1), 192–205 (2000)

Jefferies, M.G.: Nor-Sand: a simple critical state model for sand. Geotechnique 43(1), 91–103 (1993)

Jiang, M.J., Yu, H.-S., Harris, D.: A novel discrete model for granular material incorporating rolling resistance. Comput. Geotech. 32(5), 340–357 (2005)

Kuhn, M.R., Bagi, K.: Specimen size effect in discrete element simulations of granular assemblies. J. Eng. Mech. 109(1), 485–492 (2018)

Lade, P.V.: Static instability and liquefaction of loose fine sandy slopes. J Geotech. Eng.-Asce. 118(1), 51–71 (1992)

Lade, P.V., Ibsen, L.B.: A study of the phase transformation and characteristic lines of sand. In: Deformation and Progressive Failure in Geomechanics IS-NAGOYA, pp. 353–358 (1997)

Lashkari, A., Khodadadi, M., Binesh, S.M., Rahman, Md.M.: Instability of particulate assemblies under constant shear drained stress path: DEM approach. Int. J. Geomech. 19(6), 04019049 (2019)

Lee, K.L., Seed, H.B.: Dynamic strength of anisotropically consolidated sand. Proc. ASCE 93(SM5), 169–190 (1967)

Li, X., Dafalias, Y.: Anisotropic critical state theory: role of fabric. J. Eng. Mech. 138(3), 263–275 (2012)

Li, X.S.: A sand model with state-dependent dilatancy. Geotechnique 52(3), 173–186 (2002)

Li, X.S., Dafalias, Y.F.: Dilatancy for cohesionless soils. Geotechnique 50(4), 449–460 (2000)

Li, X.S., Dafalias, Y.F.: A constitutive framework for anisotropic sand including nonproportional loading. Geotechnique 54(1), 41–55 (2004)

Li, X.S., Dafalias, Y.F., Wang, Z.-L.: State-dependant dilatancy in critical-state constitutive modelling of sand. Can. Geotech. J. 36(4), 599–611 (1999)

Liu, Y., Liu, H., Mao, H.: The influence of rolling resistance on the stress-dilatancy and fabric anisotropy of granular materials. Granular Matter 20(1), 1–16 (2018)

Lopera Perez, J.C., Kwok, C.Y., O’Sullivan, C., Huang, X., Hanley, K.J.: Assessing the quasi-static conditions for shearing in granular media within the critical state soil mechanics framework. Soils Found. 56(1), 152–159 (2016)

Manzari, M.T., Dafalias, Y.F.: A critical state two-surface plasticity model for sands. Geotechnique 47(2), 255–272 (1997)

Marketos, G., Bolton, M.D.: Flat boundaries and their effect on sand testing. Int. J. Numer. Anal. Meth. Geomech. 34(8), 821–837 (2010)

MiDi, G.D.R.: On dense granular flows. Eur. Phys. J. E 14(4), 341–365 (2004)

Minh, N., Cheng, Y.: A DEM investigation of the effect of particle-size distribution on one-dimensional compression. Geotechnique 63(1), 44–53 (2013)

Minh, N., Cheng, Y., Thornton, C.: Strong force networks in granular mixtures. Granular Matter 16(1), 69–78 (2014)

Mizanur, R.M., Lo, S.R.: Predicting the onset of static liquefaction of loose sand with fines. J. Geotech. Geoenviron. Eng. 138(8), 1037–1041 (2012)

Mohamed, A., Gutierrez, M.: Comprehensive study of the effects of rolling resistance on the stress-strain and strain localization behavior of granular materials. Granular Matter 12(5), 527–541 (2010)

Murthy, T.G., Loukidis, D., Carraro, J.A.H., Prezzi, M., Salgado, R.: Undrained monotonic response of clean and silty sands. Geotechnique 57(3), 273–288 (2007)

Nakata, Y., Hyodo, M., Murata, H., Yasufuku, N.: Flow deformation of sands subjected to principal stress rotation. Soils Found. 38(2), 115–128 (1998)

Nguyen, H.B.K.: Critical State Behaviour of Granular Materials and Associated Micro-Mechanics: A DEM Study. University of South Australia, Adelaide (2017)

Nguyen, H.B.K., Rahman, M.M., Cameron, D.A., Fourie, A.B.: The effect of consolidation path on undrained behaviour of sand - A DEM approach. In: A. M. Fusao Oka, Ryosuke Uzuoka, Sayuri Kimoto (eds.) Computer Methods and Recent Advances in Geomechanics. CRC Press: Taylor & Francis Group, pp. 175–180 (2015)

Nguyen, H.B.K., Rahman, M.M., Fourie, A.B.: Undrained behaviour of granular material and the role of fabric in isotropic and K0 consolidations: DEM approach. Geotechnique 67(2), 153–167 (2017)

Nguyen, H.B.K., Rahman, M.M., Fourie, A.B.: Characteristic behavior of drained and undrained triaxial compression tests: DEM study. J. Geotech. Geoenviron. Eng. 144(9), 1–13 (2018)

Nguyen, H.B.K., Rahman, M.M., Fourie, A.B.: How particle shape affects the critical state, triggering of instability and dilatancy of granular materials – results from a DEM study. Géotechnique (2020). https://doi.org/10.1680/jgeot.18.P.211

Nguyen, H.B.K., Rahman, M.M., Fourie, A.B.: Effect of Particle Shape on Constitutive Relation: DEM Study. J. Geotech. Geoenviron. Eng. 146(7), 04020058 (2020)

O’sullivan, C., Wadee, M.A., Hanley, K.J., Barreto, D.: Use of DEM and elastic stability analysis to explain the influence of the intermediate principal stress on shear strength. Geotechnique, 1298–1309 (2013)

Oda, M.: Fabric tensor for discontinuous geological materials. Soils Found. 22(4), 96–108 (1982)

Oda, M., Kazama, M.: Microstructure of shear bands and its relation to the mechanisms of dilatancy and failure of dense granular soils. Geotechnique 48(4), 465–481 (1998)

Oda, M., Konishi, J., Nemat-Nasser, S.: Experimental micromechanical evaluation of strength of granular materials: effect of particle rolling. Mech. Mater. 1, 269–283 (1982)

Perez, J.C.L., Kwok, C.Y., O’Sullivan, C., Huang, X., Hanley, K.J.: Exploring the micro-mechanics of triaxial instability in granular materials. Geotechnique, 1–16 (2016)

Plassiard, J., Belheine, N., Donzé, F.: A spherical discrete element model: calibration procedure and incremental response. Granular Matter 11(5), 293–306 (2009)

Qadimi, A., Coop, M.R.: The undrained cyclic behaviour of a carbonate sand. Geotechnique 57(9), 739–750 (2007)

Rabbi, A.T.M.Z., Rahman, M.M., Cameron, D.A.: Undrained behavior of silty sand and the role of isotropic and K0 consolidation. J. Geotech. Geoenviron. Eng. 144(4), 1–11 (2018)

Rabbi, A.T.M.Z., Rahman, M.M., Cameron, D.A.: Critical state study of natural silty sand instability under undrained and constant shear drained path. Int. J. Geomech. 19(8), 04019083 (2019)

Radjai, F., Wolf, D.E., Jean, M., Moreau, J.: Bimodal character of stress transmission in granular packings. Phys. Rev. Lett. 80(1), 61–64 (1998)

Rahman, M., Baki, M., Lo, S.: Prediction of undrained monotonic and cyclic liquefaction behavior of sand with fines based on the equivalent granular state parameter. Int. J. Geomech. 14(2), 254–266 (2014)

Rahman, M.M., Lo, S.-C.R., Dafalias, Y.F.: Modelling the static liquefaction of sand with low-plasticity fines. Geotechnique 64(11), 881–894 (2014)

Rahman, M.M., Lo, S.R.: Undrained behaviour of sand-fines mixtures and their state parameters. J. Geotech. Geoenviron. Eng. 140(7) (2014)

Rahman, M.M., Nguyen, H.B.K., Rabbi, A.T.M.Z.: The effect of consolidation on undrained behaviour of granular materials: experiment and DEM simulation. Geotech. Res. 5(4), 199–217 (2018). https://doi.org/10.1680/jgere.17.00019

Rahman, M.M., Nguyen, H.B.K., Fourie, A.B., Kuhn, M.: Critical state soil mechanics for cyclic liquefaction and post-liquefaction behaviour: a DEM study. J. Geotech. Geoenviron. Eng. (2020). https://doi.org/10.1061/(ASCE)GT.1943-5606.0002453

Rothenburg, L., Bathurst, R.J.: Analytical study of induced anisotropy in idealized granular materials. Geotechnique 39(4), 601–614 (1989)

Rowe, P.W.: The stress-dilatancy relation for static equilibrium of an assembly of particles in contact. Proc. R. Soc. Lond. Ser. A Math. Phys. Sci., 269(1339), 500–527 (1962)

Satake, M.: Fabric tensor in granular materials. In: Proceedings of the IUTAM Symposium on Deformations and Failure of Granular Materials, pp. 93–96 (1982)

Sitharam, T.G., Vinod, J.S., Ravishankar, B.V.: Evaluation of undrained response from drained triaxial shear tests: DEM simulations and experiments. Geotechnique 58(7), 605–608 (2008)

Sladen, J.A., D’Hollander, R.D., Krahn, J.: The liquefaction of sands, a collapse surface approach. Can. Geotech. J. 22(4), 564–578 (1985)

Sukumaran, B., Leonards, G.A., Fox, J.P.: Discussion: liquefaction and postliquefaction behaviour of sand. J. Geotech. Geoenviron. Eng. 122(6), 502–503 (1996)

Tang, H., Dong, Y., Chu, X., Zhang, X.: The influence of particle rolling and imperfections on the formation of shear bands in granular material. Granular Matter 18(1), 1–12 (2016)

Vaid, Y.P., Sivathayalan, S., Stedman, D.: Influence of specimen-reconstituting method on the undrained response of sand. Geotech. Test. J. 22(3), 187–195 (1999)

Yan, W., Dong, J.: Effect of particle grading on the response of an idealized granular assemblage. Int. J. Geomech. 11(4), 276–285 (2011)

Yang, J.: Non-uniqueness of flow liquefaction line for loose sand. Geotechnique 52(10), 757–760 (2002)

Yang, J., Dai, B.B.: Is the quasi-steady state a real behaviour? A micromechanical perspective. Geotechnique 61(2), 175–183 (2011)

Yang, Z.X., Li, X.S., Yang, J.: Quantifying and modelling fabric anisotropy of granular soils. Geotechnique 58(4), 237–248 (2008)

Yoshimine, M., Ishihara, K.: Flow potential of sand during liquefaction. Soils Found. 38(3), 189–198 (1998)

Yoshimine, M., Ishihara, K., Vargas, W.: Effects of principal stress direction and intermediate principal stress on undrained shear behaviour of sand. Soils Found. 38(3), 179–188 (1998)

Zhang, J., Lo, S.C.R., Rahman, M.M., Yan, J.: “Characterizing monotonic behaviour of pond ash within critical state approach. J. Geotech. Geoenviron. Eng., 144(1) (2018)

Zhao, J., Guo, N.: Unique critical state characteristics in granular media considering fabric anisotropy. Geotechnique, 695–704 (2013)

Zhao, J., Guo, N.: Rotational resistance and shear-induced anisotropy in granular media. Acta Mech. Solida Sin. 27(1), 1–14 (2014)

Zhao, S., Evans, T.M., Zhou, X.: Shear-induced anisotropy of granular materials with rolling resistance and particle shape effects. Int. J. Solids Struct. 150, 268–281 (2018)

Zhou, W., Liu, J., Ma, G., Chang, X.: Three-dimensional DEM investigation of critical state and dilatancy behaviors of granular materials. Acta Geotech. 12(3), 527–540 (2017)

Zhou, W., Xu, K., Ma, G., Yang, L., Chang, X.: Effects of particle size ratio on the macro- and microscopic behaviors of binary mixtures at the maximum packing efficiency state. Granular Matter 18(4), 1–13 (2016)

Zhou, Y.C., Wright, B.D., Yang, R.Y., Xu, B.H., Yu, A.B.: Rolling friction in the dynamic simulation of sandpile formation. Physica Stat. Mech. Appl. 269(2), 536–553 (1999)

Zhou, Y.C., Xu, B.H., Yu, A.B., Zulli, P.: Numerical investigation of the angle of repose of monosized spheres. Phys. Rev. E 64, 213011 (2001)

Zhu, Y., Nie, Z., Gong, J.: Influence of the rolling-resistance-based shape of coarse particles on the shear responses of granular mixtures. Particuology (2020)

Acknowledgements

The first author acknowledges the support provided by the Research Training Program domestic (RTPd) scholarship, awarded by The School of Natural and Built Environments, University of South Australia.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Appendices

Appendix A: Method of deformability

1.1 Computation of stiffness parameters

Through the method of deformability:

here A = πr2 represents the contact area. Depending on the type of entities in contact r is computed:

where \(R^{\left( 1 \right)}\) denotes the radius of contact entity 1. In similar nature the contact length (L) is computed based on contact type:

E* and k* = kn/ks are input parameters in the study and are discussed and presented in Table 1 in the manuscript. The rolling radius, Rr and its formulation is also presented in the manuscript.

Appendix B: Rolling resistance linear contact model

The rolling resistance linear contact model (RRLCM) utilised in this study adds to the conventional linear contact model commonly used in DEM through the installation of a rolling spring and dashpot at the contact (Fig. 21).

Rolling resistance linear contact model. After Iwashita and Oda [32]

In a rheological sense, the rolling spring signifies the presence of an elastic resisting moment between contacting pieces (\(M_{r}^{k} )\), whilst the dashpot signifies the presence of a viscous moment at the contact \((M_{r}^{d} )\). The overall rolling resistance moment (Mr) may be mathematically defined as:

to effectively utilize the RRLCM in a numerical modelling environment, Mr must be updated incrementally with respect to the time step. At time t + Δt, \(M_{r}^{k}\) may be computed via:

here M* represents the maximum (limiting) resisting torque (\(M^{ *} = \mu_{r} \bar{R}F_{n}\)) and \(\bar{R} = \left( {r_{i} r_{j} } \right)/\left( {r_{i} + r_{j} } \right)\); where Fn is the normal contact force, \(\bar{R}\) represents the effective radius of the contact, \(r_{i}\) and \(r_{j}\) are the radii of contacting entities. When a boundary or wall element is the contacting entity, r → ∞. Notice, when \(\mu_{r} = 0\), \(M^{ *} = 0\) and therefore a free-rolling environment is created. \(M_{r}^{k}\) is the incremental rolling resistance torque observed at time, t + Δt and is computed through consideration of the rolling stiffness, kr and the relative rotation between two contacting particles, θr,

where kr = ksRr. A limitation of the model is defining a kr which has strong physical basis. kr is related to ks based on an idealized consideration that the moment generated at a contact due to shear displacement is equivalent to the moment generated due to rolling displacement. \(M_{r}^{d}\) in Equation 17 is also updated with respect to the time step, t + Δt:

where \(C_{r} = 2_{r} \sqrt {I_{r} k_{r} }\) is the viscous damping rolling coefficient, ηr is the critical viscous damping ratio and Ir is the equivalent moment of inertia about the contact point between two contacting entities. Instead of an oscillating resisting moment applied at the contact, as applied in some rolling resistance contact models [2], the applied resisting moment at the contact within a quasi-static system is stable and therefore the packing behaviour of the assembly is stabilized. For such reasons, this model is often used in DEM simulation of quasi-static systems. Using various modified versions of this model in DEM along with the tuning of μr, some have captured the influence of particle rolling on the behaviour of granular material in triaxial compression. In particular some observed that with the addition of rolling resistance, shear strength and dilatancy increases [32, 46, 54, 94], shear banding and strain localization intensifies [32, 33, 54, 84] and fabric anisotropy intensifies [46].

Rights and permissions

About this article

Cite this article

Barnett, N., Rahman, M.M., Karim, M.R. et al. Evaluating the particle rolling effect on the characteristic features of granular material under the critical state soil mechanics framework. Granular Matter 22, 89 (2020). https://doi.org/10.1007/s10035-020-01055-5

Received:

Published:

DOI: https://doi.org/10.1007/s10035-020-01055-5