Abstract

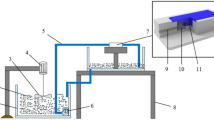

Soft abrasive flow(SAF) finishing can process the irregular geometric surfaces, but with the matter of low processing efficiency. To address the issue, an improved SAF finishing method based on turbulent kinetic energy enhancing is proposed. A constrained flow passage with serration cross-section is constructed to increase the turbulence intensity. Taking the constrained flow passage as the objective, a two-phase fluid dynamic model is set up by using particle trajectory model and standard k-ε turbulence model, and the flow field characteristics of the flow passage are acquired. The numerical results show that the serration flow passage can enhance the turbulence intensity, uniform the particles distribution, and increase the particle concentration near the bottom wall. The observation results by particle image velocimetry(PIV) show that the internal vortex structures are formed in flow passage, and the abrasive flow takes on turbulence concentrating phenomenon in near-wall region. The finishing experiments prove that the proposed method can obtain better surface uniformity, and the processing efficiency can be improved more 35%. This research provides an abrasive flow modeling method to reveal the particle motion regulars, and can offer references to the technical optimization of fluid-based precision processing.

Similar content being viewed by others

References

HUANG Y H, GU L Z. Digitalized accurate modeling of SPCB with multi-spiral surface based on CPC algorithm[J]. Chinese Journal of Mechanical Engineering, 2015, 28(5): 1039–1047.

LI Y B, TAN D P, WEN D H, et al. Parameters optimization of a novel 5-DOF gasbag polishing machine tool[J]. Chinese Journal of Mechanical Engineering, 2013, 26(4): 680–688.

SANKAR M R, JAIN V K, RAMKUMAR J. Rheological characterization of styrene-butadiene based medium and its finishing performance using rotational abrasive flow finishing process[J]. International Journal of Machine Tools and Manufacture, 2011, 51(12): 947–957.

ZENG X, JI S M, JIN M S, et al. Investigation on machining characteristic of pneumatic wheel based on softness consolidation abrasives[J]. International Journal of Precision Engineering and Manufacturing, 2014, 15(10): 2031–2039.

JI S M, XIAO F Q, TAN D P. Analytical method for softness abrasive flow field based on discrete phase model[J]. Science China - Technological Sciences, 2010, 53(10): 2867–2877.

JI S M, WENG X X, TAN D P. Analytical method of softness abrasive two-phase flow field based on 2D model of LSM[J]. Acta Physica Sinica, 2012, 61(1): 10205.

TAN D P, LI P Y, PAN X H. Application of improved HMM algorithm in slag detection system[J]. Journal of Iron and Steel Research, International, 2009, 16(1): 1–6.

TAN D P, LI P Y, JI Y X, et al. SA-ANN-based slag carry-over detection method and the embedded WME platform[J]. IEEE Transactions on Industrial Electronics, 2013, 60(10): 4702–4713.

TAN D P, JI S M, LI P Y, et al. Development of vibration style ladle slag detection method and the key technologies[J]. Science China - Technological Sciences, 2010, 53(9): 2378–2387.

JI S M, XIAO F Q, TAN D P. A new ultraprecision machining method with softness abrasive flow based on discrete phase model[J]. Advanced Materials Research, 2010, 97–101: 3055–3059.

YUAN Q L, JI S M, TAN D P, et al. Analytical method for softness abrasive flow field based on low Reynolds k-epsilon model[J]. Advanced Materials Research, 2011, 188: 230–235.

JI S M, ZHONG J Q, TAN D P, et al. Research of distribution and dynamic characteristic of particle group in the structural flow passage[J]. Key Engineering Materials, 2012, 499: 271–276.

LI C, JI S M, TAN D P. Softness abrasive flow method oriented to tiny scale mold structural surface[J]. International Journal of Advanced Manufacturing Technology, 2012, 61: 975–987.

ZENG X, JI S M, TAN D P, et al. Zhang. Softness consolidation abrasives material removal characteristic oriented to laser hardening surface[J]. International Journal of Advanced Manufacturing Technology, 2013, 69(9–12): 2323–2332.

JI S M, QIU Y, CAI Y J, et al. Research on mechanism of ultrasound enhancing and the experiment based on softness abrasive flow[J]. Chinese Journal of Mechanical Engineering, 2014, 50(4): 84–93.

TAN D P, JI S M, FU Y Z. An improved soft abrasive flow finishing method based on fluid collision theory[J]. International Journal of Advanced Manufacturing Technology, 2016, 85(5–8): 1261–1274.

ZENG X, JI S M, JIN M S, et al. Research on dynamic characteristic of softness consolidation abrasives in machining process[J]. International Journal of Advanced Manufacturing Technology, 2016, 82(5–8): 1115–1125.

KAVITHAA T S, BALASHANMUGAM N. Nanometric surface finishing of typical industrial components by abrasive flow finishing[J]. International Journal of Advanced Manufacturing Technology, 2016, 85(9–12): 2189–2196.

CHEN J L, XU F, TAN D P, et al. A control method for agricultural greenhouse heating based on computational fluid dynamics and energy prediction model[J]. Applied Energy, 2015, 141: 106–118.

TAN D P, JI S M, JIN M S. Intelligent computer-aided instruction modeling and a method to optimize study strategies for parallel robot instruction[J]. IEEE Transactions on Education, 2013, 56(3): 268–273.

TAN D P, ZHANG L B. A WP-based nonlinear vibration sensing method for invisible liquid steel slag detection[J]. Sensors and Actuators B - Chemical, 2014, 202: 1257–1269.

TAN D P, YANG T, ZHAO J, et al. Free sink vortex Ekman suction-extraction evolution mechanism [J]. Acta Physica Sinica, 2016, 65(5): 054701.

TAN D P, LI P Y, PAN X H. Intelligent industry monitoring network architecture UPnP based[J]. Chinese Journal of Electronics, 2008, 17(4): 607–610.

LI C, JI S M, TAN D P. Multiple-loop digital control method for 400 Hz inverter system based on phase feedback[J]. IEEE Transactions on Power Electronics, 2013, 28(1): 408–417.

HU C L, WANG G Y, HUANG B A. Experimental investigation on cavitating flow shedding over an axisymmetric blunt body[J]. Chinese Journal of Mechanical Engineering, 2015, 28(2): 387–393.

Author information

Authors and Affiliations

Corresponding author

Additional information

Supported by National Natural Science Foundation of China (Grant Nos. 51375446, 51575494), and Zhejiang Provincial Natural Science Foundation of China (Grant Nos. LR16E050001, LZ14E050001).

Rights and permissions

About this article

Cite this article

LI, J., JI, S. & TAN, D. Improved Soft Abrasive Flow Finishing Method Based on Turbulent Kinetic Energy Enhancing. Chin. J. Mech. Eng. 30, 301–309 (2017). https://doi.org/10.1007/s10033-017-0071-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10033-017-0071-y