Abstract

2D transition metal dichalcogenides such as MoS2 with the unique layered structure have received great attention in the field of lithium-ion batteries (LIBs). However, the low conductivity and poor structural stability adversely affect the rate performance of LIBs. Herein, a flexible and free-standing high-performance lithium-ion battery electrode (MoS2/C@Ti3C2Tx) composed of rice-candy-like MoS2/C intercalated Ti3C2Tx and PVP-derived carbon with a large interlayer distance of MoS2 is designed and demonstrated. Lithium-ion batteries have attracted great attention due to their high energy density. Consequently, as an anode material for lithium-ion batteries, MoS2/C@Ti3C2Tx provides a high discharge capacity of 538.5 mAh g−1 at 0.05 A g−1 and rapid charge/discharge capability of 256.7 mAh g−1 at 2 A g−1, as well as outstanding cycling property (96.7% capacity retention after 150 cycles at 2 A g−1). Density-functional theory (DFT) calculation reveals that the rice-candy-like MoS2/C structure favors adsorption and diffusion of lithium ions and facilitates the redox reactions. The MoS2/C@Ti3C2Tx structure is expected to boost the development of novel 2D materials for high-performance lithium-ion batteries.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Lithium-ion batteries (LIBs) boasting many advantages such as large energy density, long-term cycle life, and environmental friendliness are widely used in portable electronics and electric vehicles [1,2,3]. As a class of 2D materials, molybdenum disulfide (MoS2) with a graphene-like layered structure has attracted attention in physics and chemistry [4, 5]. The layered structure composed of S–Mo–S units stacked by van der Waals attraction [6,7,8] has a large theoretical specific capacity of 670 mAh g−1 for Li-ion batteries [9,10,11]. However, commercial adoption of MoS2 is hampered by the low electrical properties, which limit ion and electron transport [12], large volume variation during adsorption and diffusion of lithium ions [13], and polysulfide dissolution during charging and discharging [14]. To overcome these hurdles, efforts have been made to design nanoscale structures of MoS2 and MoS2/carbon composites such as MoS2 nanosheets [15, 16], MoS2/graphene [17, 18], and MoS2/CNT composites [19, 20]. In fact, MoS2 with large interlayer spacing and abundant active sites increases the diffusion coefficient of Li+ and enhances the battery performance [21,22,23]. For example, Jing et al. fabricated 1–3 layers MoS2 with wide spacing by lithiation-exfoliation process; the LIB shows a rate capacity of 350 mAh g−1 at 0.5 A g−1 and the coulombic efficiency only 52% at the first cycle [24]. Hence, expansion of the interlayer distance can be realized by introducing carbon materials during the synthesis of MoS2 to improve storage of lithium ions.

Recently, MXene (e.g., Ti3C2Tx, V2CTx, and Ti2CTx) as a new candidate of two-dimensional materials has attracted extensive attention in energy storage devices. MXenes are also described as Mn+1XnTx, where M stands for early transition metal. X represents a carbon or nitrogen element. Tx is the surface chemical groups. MXene, a promising material for LIBs with more unique properties than graphene or other 2D materials, has been regarded as a potential material for electrochemical energy storage because of its layered structure and excellent conductivity. For example, Qiu et al. fabricated few-layered MoS2 nanoplates on Ti3C2Tx nanosheets stabilized by a carbon layer, which exhibited outstanding electrochemical performance for lithium storage [25]. Fabrication of MXene hybrid nanostructures with other materials is a well-known method, which can be utilized for important applications including supercapacitors [26] and sensors [27, 28]. Yola et al. prepared MWCNTs with Ti3C2Tx (mass ratio 3:1) colloidal solution, which exhibited high sensitivity of electrochemistry [29]. Therefore, these characteristics make Ti3C2Tx a suitable candidate for the base material to construct excellent performance MoS2 nanohybrid anode materials for lithium-ion storage.

In the present work, rice-candy-like MoS2 is mixed with Ti3C2Tx to form the self-supporting composite film of MoS2/C@Ti3C2Tx by vacuum filtration. The sandwiched structure of free-standing MoS2/C@Ti3C2Tx offers many advantages. It solves the stacking problem of Ti3C2Tx and MoS2 and dynamically enhances Li+ transport. Moreover, the free-standing MoS2/C@Ti3C2Tx electrode buffers the volume change and avoids fast capacity decay at high charging/discharging rates. The key for MoS2/C@Ti3C2Tx is that PVP-derived carbon is encapsulated on the MoS2 layer, so that diffusion of lithium ions is facilitated and the volume variation of MoS2 in charging and discharging is buffered. Consequently, the flexible MoS2/C@Ti3C2Tx exhibits higher reversible capacity and better cycling stability than MoS2@Ti3C2Tx. Density-functional theory (DFT) calculation proves that the large interlayer distance enhances the lithium storage capacity.

Experimental

Sample preparation

Synthesis of Ti3AlC2

Ti, Al, and TiC powders with a molar ratio of 1:1.1:2 were mixed for 12 h by the ball mill method, and Ti3AlC2 was prepared by spark plasma sintering (SPS, 211HF) at 1400 °C for 20 min at a pressure of 20 MPa under vacuum. The Ti3AlC2 monolith was milled and sieved to obtain 400 mesh Ti3AlC2 powder.

Preparation of Ti3C2Tx

The Ti3C2Tx solution was prepared by selective etching of the Ti3AlC2 powder. Typically, 1 g of LiF was immersed in 20 mL of 9 M HCl and stirred magnetically until LiF dissolved completely at 35 °C. One gram of Ti3AlC2 was introduced and stirred vigorously at 35 °C for 12 h. Afterwards, the precipitate was rinsed with deionized water several times until the pH was approximately 6. The sediment was dispersed in 150 mL of DI water and sonicated for 60 min under flowing Ar. After centrifugation at 3500 rpm for 60 min, the dark green supernatant of Ti3C2Tx was collected.

Synthesis of MoS2/C

A total of 0.1 g of ammonium molybdate, 0.09 g of thiourea, and 0.41 g of polyvinyl pyrrolidone were dissolved in 30 mL of DI water under magnetic stirring and transferred to a Teflon-lined stainless steel autoclave (50 mL) which was heated to 190 °C for 18 h in an electric oven. After natural cooling to room temperature, the MoS2/C composite material was gathered by centrifugation, washed with DI water and anhydrous ethanol several times, and then freeze-dried for 12 h. The MoS2/C composite was then heat-treated at 500 °C for 3 h under Ar. The MoS2 composite was prepared by the same method but without adding PVP.

Fabrication of the flexible MoS2/C@Ti3C2Tx film

The diluted aqueous dispersion (1 mg mL−1) of MoS2/C was prepared by sonication for 30 min. It was introduced to the Ti3C2Tx solution (0.04 g, 2 mg mL−1) and stirred magnetically. The total volume of the solution was 40 mL with the Ti3C2Tx:MoS2/C ratio of 2:3. After vacuum filtration, the membrane was freeze-dried for 9 h. The flexible MoS2/C@Ti3C2Tx film was gathered by peeling from the filter membrane and used directly as an anode for the LIBs. As a reference, the MoS2@Ti3C2Tx film was also produced by the same procedure.

Materials characterization

X-Ray diffraction was performed on the D2-Advance (Bruker) automated X-ray diffractometer with Cu Kα radiation (λ = 1.5418 Å), and the STA449F5 (NETZSCH) was employed in the thermogravimetric (TG) analysis from 20 to 800 °C at 10 °C min−1 at an oxygen flow rate of 100 mL min−1. Field-emission scanning electron microscopy (FESEM, JEOL S-4800, 10 kV) and transmission electron microscopy (TEM, Tecnai G2 F20) were carried out to examine the structure of the MoS2/C@Ti3C2Tx film. X-Ray photoelectron spectroscopy was characterized on the K-ALPHA 0.5 eV with monochromatic Al Kα radiation, and Raman scattering was investigated by the INVIA Raman microprobe (Renishaw Instruments) with a 532-nm laser source.

Electrochemical measurements

A lithium foil was utilized for the counter electrode in the 2032-type coin cell, and the electrolyte was 1 M LiPF6 in a mixture of ethylene carbonate (EC):diethylene carbonate (DEC) (1:1 by volume). Assembly was carried out in an argon-filled glovebox. Electrochemical impedance spectroscopy (EIS) was performed in the frequency range from 0.01 Hz to 100 kHz with a potentiostatic signal amplitude of 5 mV. Cyclic voltammetry (CV) was tested on a VMP3 electrochemical workstation at different scanning rates, and galvanostatic charge-discharge experiments were measured using the Neware battery testing system with the voltage range of 0.01–3 V (vs Li/Li+).

Theoretical calculation

First-principles calculation was performed by the Perdew-Burke-Ernzerhof (PBE) exchange-correlation functional within the general gradient approximation (GGA) using the VASP code and considering all the spin-polarized calculation. The geometric structure was relaxed until the Feynman force on each atom was less than 0.01 eV/Å. The energy was optimized until the convergence condition was less than 10−5 eV. Considering the van der Waals interactions, the DFT-D2 approach was adopted in the dispersion correction. The 3 × 3 and 4 × 4 supercells of MoS2/C were chosen as the substrate for the bilayer MoS2, and the G sandwiched structure was adopted. The c axis vacuum was set as 15 Å to avoid interactions between slabs. The plane wave cutoff energy was 450 eV. A k-points mesh of 3 × 3 × 1 in the gamma-center sampling scheme was used for geometry optimization and electronic self-consistency.

Results and discussion

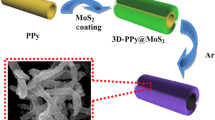

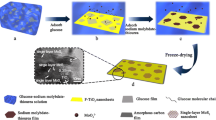

The fabrication procedures of the flexible MoS2/C@Ti3C2Tx film are illustrated in Fig. 1. Ti3C2Tx nanosheets are synthesized by selectively etching the Al layer from Ti3AlC2. Using ammonium molybdate as the molybdenum source, thiourea as the sulfur source, and PVP as the carbon source, carbon-encapsulated nanosphere-assembled MoS2 nanosheets are prepared by a hydrothermal reaction and annealing at 500 °C under flowing Ar. The sandwiched structure of MoS2/C@Ti3C2Tx flexible film was synthesized by vacuum filtration and freeze-drying.

The homogeneous MoS2/C@Ti3C2Tx solution is the key to the preparation of the flexible film. Figure S1a displays the Tyndall effect of the Ti3C2Tx solution, and after mixing the rice-candy-like MoS2/C solution with the Ti3C2Tx solution under vigorous stirring, a well-dispersed MoS2/C@Ti3C2Tx solution is obtained as verified by the Tyndall effect as shown in Fig. S1b [30]. The X-ray diffraction (XRD) patterns of Ti3AlC2, Ti3C2Tx, MoS2/C, and MoS2 in Fig. 2a and b reveal the presence of Ti3AlC2. After etching and delamination, the sharp diffraction peak at 9.5° disappears but a new peak arising from the (002) plane of Ti3C2Tx is observed at 7° further confirming successful delaminate of the Ti3C2Tx nanosheets [31]. The XRD pattern of MoS2 in Fig. 2b can be indexed to the JCPDS card (37-1492) with a d (002) spacing of 0.615 nm. The sharp diffraction peak at 14.378° indicates that MoS2 is made of a single or a few layers assembled by van der Waals attraction [32]. Although the 14.375° diffraction peaks of MoS2 cannot be observed from MoS2/C@Ti3C2Tx, there are two diffraction peaks at 6.584° and 12.93° corresponding to interlayer distances of 13.41 Å and 6.84 Å, respectively, indicating that the large interlayer distance of 0.67 nm for the PVP-derived carbon layer is combined into the two MoS2 interlayers. The calculation shows it is the middle spacing of the MoS2 interlayer distance [33]. The XRD result of MoS2/C@Ti3C2Tx is presented in Fig. S2. As displayed in Fig. S3, The E12g (381.68 cm-1) and A1g (404.78 cm-1) peaks correspond to the in-plane vibration of Mo and S atoms and the out-of-plane vibration of S atoms, respectively. The separation (Δk) of MoS2/C is 23.1 cm-1, which smaller than 27.4 cm-1 of MoS2 [33, 34]. The Δk is positively correlated with the layer number, which increases with the layer number. From the Raman Spectroscopy, it can be concluded the MoS2/C not only has a less number of layers, but also has a large interlayer distance than MoS2. The content of PVP-derived carbon is calculated by Eq. (1) based on the thermogravimetric analysis (TGA) in an oxygen atmosphere:

where a is the molecular weight of MoS2, b is the molecular weight of MoO3, and c is the total residual weight. According to the TG analysis (Fig. 2c), the PVP-derived carbon concentration is 25.69%.

Figure 2d exhibits the presence of Ti, C, Mo, S, and O, and the elemental composition is listed in Table S1. Figure 2e can be deconvoluted into three peaks: 455.1 and 461.1 eV for Ti-C, 455.6 and 462 eV for Ti2+, 456.4 eV for Ti3+, 457.5 eV for Ti-O, 458.9 eV for Ti-F [35,36,37,38]. Figure 2f shows that the peaks at 281.9 eV, 284.6 eV, and 286.2 eV are related to C-Ti, C-C, and C-O, respectively [39], and Fig. 2g shows that the peaks at 529.6 eV, 531.8 eV, 532.2 eV, and 533.1 eV are related to O-Ti, O-Ti/OH, O-C/OH, and H2O, respectively [40]. As shown in Fig. 2h and i, the Mo 3d spectra of MoS2/C@Ti3C2Tx exhibiting three main peaks at 229.4 eV, 232.6 eV, and 225.8 eV are assigned to Mo 3d5/2, Mo 3d3/2, and Mo4+. The S 2p1/2 and S 2p3/2 peaks in the S 2p spectrum are at 162.4 and 161.3 eV, respectively [41].

The morphology of the Ti3AlC2, Ti3C2Tx, MoS2/C@Ti3C2Tx, and MoS2@Ti3C2Tx is observed by SEM and TEM. The SEM image shows that the pristine Ti3AlC2 powder has a slightly layered texture but it appears to be seamless (Fig. S4a). The flake-shape folded structure in Fig. S4b corroborates successful synthesis of Ti3C2Tx nanosheets. After vacuum filtration of the Ti3C2Tx suspension, a flexible film is produced as shown in Fig. S4c. The TEM image of Ti3C2Tx in Fig. S4d reveals the flexible characteristic, and Fig. 3a shows that the MoS2/C nanosheets and Ti3C2Tx are well-dispersed together with the sandwiched structure of Ti3C2Tx and MoS2/C. The inset in Fig. 3a is the digital photograph of the MoS2/C@Ti3C2Tx film and the magnified image is in Fig. 3b. The MoS2 nanosphere/carbon hybrid has a nanosheet morphology resembling rice candies (Fig. 3c).

The high-resolution TEM (HR-TEM) image in Fig. 3d shows that the MoS2/C nanospheres consist of layered nanoflakes. The interlayer spacing of the MoS2/C (002) plane is 13.41 Å, which is much larger than that of the MoS2 (002) plane of 6.2 Å as shown in Fig. 3e and f. This result is in accordance with the above XRD calculations. Figure S5a and 5b show that MoS2 are single nanospheres. Figure 3g shows dense and sparse contrast difference suggesting some overlapping of Ti, C, Mo, and S. Furthermore, in the MoS2/C@Ti3C2Tx structure, Mo, S, and C are concentrated in the MoS2/C nanoflakes and Ti overlaps along the folded Ti3C2Tx, providing evidence that the MoS2/C nanoflakes are mixed uniformly with the flake-shaped folded Ti3C2Tx nanosheets. It can be concluded that PVP-derived carbon is intercalated into MoS2 to expand the interlayer distance. The abundant active sites and rapid Li+ diffusion arise from the larger interlayer distance and PVP-derived carbon.

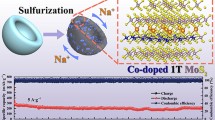

The lithium storage property of the flexible MoS2/C@Ti3C2Tx is determined from lithium-ion half-cells. Figure 4a presents the first three cycles of the cyclic voltammetry (CV) curves of the MoS2/C@Ti3C2Tx flexible electrode at 0.1 mV s−1. In the first cathodic scan, three reduction peaks at 0.8 V, 0.5 V, and 0.2 V can be seen. The first one (0.8 V) represents intercalation of Li+ insertion into MoS2 to form LixMoS2 [42], and the other two peaks (0.5 and 0.2 V) are attributed to reduction of LixMoS2 to metallic Mo and Li2S by the conversion reaction and creation of a solid electrolyte interphase (SEI) layer on the electrode [43]. In addition, anodic peaks appear at 1.3 V and 2.3 V corresponding to partial oxidation of Mo to MoS2 and Li2S to S, respectively. In the subsequent cathodic scan, the peak at 1.2 V is related to the conversion of MoS2 into Mo and that at 1.9 V is related to the formation of Li2S [44]. As shown in Fig. 4b, the galvanostatic discharge/charge curves of the flexible MoS2/C@Ti3C2Tx electrode at 0.05 A g-1 over the range between 0.01 V and 3.0 V deliver initial discharge and charge capacities of 733 and 597 mAh g−1, respectively, in conjunction with an initial coulombic efficiency of 81.4%. The irreversible capacity loss in the first cycle can be attributed to the formation of the irreversible SEI film. In subsequent cycles, the discharge/charge capacity is quite similar, illustrating the high reversibility in the electrochemical reactions.

a CV curves of MoS2/C@Ti3C2Tx at 0.1 mV s−1. b Galvanostatic discharge/charge curves of the MoS2/C@Ti3C2Tx electrode at 50 mA g−1. c Rate capability of the MoS2/C@Ti3C2Tx, MoS2/Ti3C2Tx, MoS2/C, MoS2, and Ti3C2Tx electrode at various current densities. d Long-term cycling performance of the MoS2/C@Ti3C2Tx and MoS2@Ti3C2Tx at 0.1 A g−1 and 2 A g−1. e Nyquist plots of the MoS2/C@Ti3C2Tx electrode. f b values determined by the plot of log (i) versus log (υ). g Normalized ratio of pseudocapacitive and diffusion-controlled contribution of the MoS2/C@Ti3C2Tx at different sweep rates. h Capacitive contribution at 1.0 mV s−1

A comparison of the rate and cycling performance of the MoS2/C@Ti3C2Tx, MoS2@Ti3C2Tx, MoS2/C, MoS2, and Ti3C2Tx samples at different various current densities is shown in Fig. 4c. As expected, the flexible MoS2/C@Ti3C2Tx electrode exhibits excellent rate capabilities of 538.5, 510.5, 461.8, 405.6, 337.7, and 256.7 mAh g−1 at 0.05, 0.1, 0.2, 0.5, 1, and 2 A g−1, respectively. When the current density rises again to 0.05 A g−1, the discharge capacity of 538 mAh g−1 can be restored rapidly implying remarkable reversibility. In addition, the long cycling stability of the flexible MoS2/C@Ti3C2Tx electrode is assessed. Figure 4d shows the cycling performances at current densities of 0.1 A g−1 and 2 A g−1; the retain capacities of 489.3 and 248.4 mA h g−1 are observed after 150 cycles, respectively. The excellent rate performance of MoS2/C@Ti3C2Tx mainly ascribed to PVP-derived carbon is intercalated into MoS2 to expand the interlayer distance, and dynamically facilitates electron/ion transport. Apparently, the result indicates that the ultra-wide interlayer spacing MoS2 and Ti3C2Tx flexible film could dramatically enhance lithium storage capacity as expected. Compared with other 2D materials for LIBs, the as-prepared MoS2/C@Ti3C2Tx shows a high rate performance (Table S2). Figure S6 depicts the cross-sectional SEM image of MoS2/C@Ti3C2Tx after 150 cycles at 0.1 A g−1, and MoS2/C@Ti3C2Tx retains the sandwiched morphology confirming the good structural stability. Therefore, the superior rate performance of MoS2/C@Ti3C2Tx is mainly attributed to the larger interlayer distance of MoS2 and the high electrical conductivity of Ti3C2Tx.

To further confirm the impact of PVP-derived carbon, the Nyquist plots of the flexible electrodes are shown in Fig. 4e. It has been shown that the diameter of the semicircle is related to the charge transfer resistance (Rct) and the slope in the low-frequency region is related to the Warburg impedance (Zw). In the equivalent circuit, Rs corresponds to the contact resistance, Rct is the charge transfer resistance, CPE corresponds to the constant phase element, and Zw is the Warburg impedance (insets in Fig. 4e and Fig. S7). The flexible MoS2/C@Ti3C2Tx electrode has a smaller Rct (38.9 Ω) than MoS2@Ti3C2Tx (74.65 Ω), suggesting that addition of PVP-derived carbon enhances the charge transfer ability [45]. In addition, the large slope indicates large lithium-ion diffusion rates as a result of the larger interlayer distance.

To detect the electrochemical kinetics of the flexible MoS2/C@Ti3C2Tx electrode, CV is performed at scanning rates from 0.1 to 1 mV s−1 to determine the redox pseudocapacitance contributions (Fig. S8). The relationship between the peak current (i) and scanning rate (v) follows the following power law [46]:

where b = 0.5 or 1 corresponds to the diffusion-controlled or behavior pseudocapacitive effect, respectively. Figure 4f shows that the b values of the anodic and cathodic peaks are 0.80 and 0.87, respectively, suggesting the surface faradaic redox reaction is predominant in the electrochemical reaction. The ratio of the capacitive contribution is further quantified by Eq. (3) [47]:

where k1v is the non-diffusion contribution and k2v1/2 is the diffusion-controlled contribution [48]. As observed in Fig. 4g, with increasing scanning rates, the charge storage rate increases in the surface-controlled process. The pseudocapacitive contribution exhibits an increasing tendency with scanning rates and is 81% for a scanning rate of 1 mV s−1 (Fig. 4h). The high pseudocapacitive contribution of the MoS2/C@Ti3C2Tx composite mainly originates from the PVP-derived carbon, which can provide more active redox sites for the pseudocapacitive behavior [49]. The results indicate that a large high pseudocapacitive contribution is crucial to the electron transport kinetics.

Since the PVP-derived carbon increases the interlayer distance of MoS2, the Li+ storage mechanism is determined by DFT calculation of MoS2/C [50, 51] in which the carbon layer is graphene. As shown in Fig. 5a and b, MoS2/C exhibits stronger chemical adsorption with lower binding energies (Ea = − 0.245 eV) than MoS2 which shows weaker physical adsorption with a larger binding energy (Ea = 1.727 eV) (Table S3). Therefore, the PVP-derived carbon enhances adsorption of Li+ due to the larger negative adsorption energy and better charge transfer [34, 52]. To further study the electronic structure of MoS2/C, the charge density is analyzed as shown in Fig. 5c. Charge exchange occurs between the PVP-derived carbon and MoS2, and charges are mainly lost from Li to accumulate in the Li-S and Li-C bonds. In this way, the intercalated PVP-derived carbon (graphene in this model) creates a stable channel for Li+ transport consequently improving charge transport.

Conclusions

The flexible sandwiched structure consisting of rice-candy-like MoS2/C nanosheets intercalated in Ti3C2Tx is designed and demonstrated as high-performance electrode materials in Li-ion batteries. The large interlayer spacing provides abundant and rapid diffusion channels for the electrolyte and there are more adsorption sites to enhance the electrochemical characteristics. The PVP-derived carbon layer enhances the electrical conductivity and structural robustness. As a demonstration of the commercial viability in Li-ion batteries, the flexible MoS2/C@Ti3C2Tx anode exhibits remarkable reversible capacities and coulombic efficiency, improved rate performance, and outstanding cycling stability. DFT calculation reveals that lithium storage on the MoS2/C nanosheets leads to more intercalation to enhance adsorption/diffusion of lithium ions. The flexible MoS2/C@Ti3C2Tx electrode has large commercial potential, and the design and fabrication strategy provide insights into the development of superior electrochemical properties for flexible energy storage equipment.

References

Wang YJ, Zhen MM, Liu HL, Wang C (2018) Interlayer-expanded MoS2/graphene composites as anode materials for high-performance lithium-ion batteries. J Solid State Electrochem 22(10):3069–3076

Hu ZL, Kuai XX, Chen JT, Sun PT, Zhang QB, Wu HH, Zhang L (2020) Strongly coupled MoS2 nanocrystal/Ti3C2 nanosheet hybrids enable high-capacity lithium-ion storage. ChemSusChem 13(6):1485–1490

Sen UK, Mitra S (2014) Improved electrode fabrication method to enhance performance and stability of MoS2-based lithium-ion battery anode. J Solid State Electrochem 18(10):2701–2708

Chen X, Berner NC, Backes C, Duesberg GS, McDonald AR (2016) Functionalization of two-dimensional MoS2 on the reaction between MoS2 and organic thiols. Angew Chem Int Ed 55(19):5803–5808

Ma XX, Li N, Liu SK, Zhang K, Chi CX, Zhao JP, Liu XX, Li Y (2018) Pyrrolic nitrogen-doped carbon sandwiched monolayer MoS2 vertically anchored on graphene oxide for high-performance sodium-ion battery anodes. J Solid State Electrochem 22(9):2801–2809

Xu GB, Yang LW, Wei XL, Ding JW, Zhong JX, Chu PK (2016) MoS2-Quantum-dot-interspersed Li4Ti5O12 nanosheets with enhanced performance for Li- and Na-ion batteries. Adv Funct Mater 26(19):3349–3358

Ali GAM, Thalji MR, Soh WC, Algarni H, Chong KF (2020) One-step electrochemical synthesis of MoS2/graphene composite for supercapacitor application. J Solid State Electrochem 24(1):25–34

Song XH, Chen QB, Shen EH, Liu HL (2019) Supercapacitive performances of few-layer MoS2 on reduced graphene oxides. J Solid State Electrochem 23(3):911–923

Jiang Y, Guo YB, Lu WJ, Feng ZY, Xi BJ, Kai SS, Zhang JZ, Feng JK, Xiong SL (2017) Rationally incorporated MoS2/SnS2 nanoparticles on graphene sheets for lithium-ion and sodium-ion batteries. ACS Appl Mater Interfaces 9(33):27697–27706

Li ZY, Fan RY, Hu Z, Li WC, Zhou HJ, Kang SH, Zhang YX, Zhang HM, Wang GZ (2020) Ethanol introduced synthesis of ultrastable 1T-MoS2 for removal of Cr (VI). J Hazard Mater 394:122525

Zhu ZQ, Tang YX, Lv ZS, Wei JQ, Zhang YY, Wang RH, Zhang W, Xia HR, Ge MZ, Chen XD (2018) Fluoroethylene carbonate enabling a robust LiF-rich solid electrolyte interphase to enhance the stability of the MoS2 anode for lithium-ion storage. Angew Chem Int Ed 57(14):3656–3660

Yao ZR, Zhu KJ, Li X, Wang J, Yan K, Liu JS (2020) Interlayer-expanded MoS2 nanosheets/nitrogen-doped carbon as a high-performance anode for sodium-ion batteries. J Alloys Compd 838:155541

Sun HH, Wang J-G, Zhang Y, Hua W, Li YY, Liu HY (2018) Ultrafast lithium energy storage enabled by interfacial constructing interlayer-expanded MoS2 /N-doped carbon nanowires. J Mater Chem A 6(27):13419–13427

Zhang YL, Mu ZJ, Yang C, Xu ZK, Zhang S, Zhang XY, Li YJ, Lai JP, Sun ZH, Yang Y, Chao YG, Li CJ, Ge XX, Yang WX, Guo SJ (2018) Rational design of MXene/1T-2H MoS2-C nanohybrids for high-performance lithium–sulfur batteries. Adv Funct Mater 28(38):1707578

Ji YJ, Wei QL, Sun YG (2018) Superior capacitive performance enabled by edge-oriented and interlayer-expanded MoS2 nanosheets anchored on reduced graphene oxide sheets. Ind Eng Chem Res 57(13):4571–4576

Ning MQ, Man QK, Tan GG, Lei ZK, Li JB, Li R-W (2020) Ultrathin MoS2 nanosheets encapsulated in hollow carbon spheres: a case of a dielectric absorber with optimized impedance for efficient microwave absorption. ACS Appl Mater Interfaces 12(18):20785–20796

Xu X, Zhao RS, Ai W, Chen B, Du HF, Wu LS, Zhang H, Huang W, Yu T (2018) Controllable design of MoS2 nanosheets anchored on nitrogen-doped graphene: toward fast sodium storage by tunable pseudocapacitance. Adv Mater 30(27):1800658

Dong XY, Xing Z, Zheng GJ, Gao XR, Hong HP, Ju ZC, Zhuang QC (2020) MoS2/N-Doped graphene aerogels composite anode for high performance sodium/potassium ion batteries. Electrochim Acta 339:135932

Guan XB, Zhao LP, Zhang PL, Liu J, Song XF, Gao L (2020) Electrode material of core-shell hybrid MoS2@C/CNTs with carbon intercalated few-layer MoS2 nanosheets. Mater Today Energy 16:100379

Yang XD, Yang YB, Fu LN, Zou MC, Li ZH, Cao AY, Yuan Q (2018) An ultrathin flexible 2D membrane based on single-walled nanotube–MoS2 hybrid film for high-performance solar steam generation. Adv Funct Mater 28(3):1704505

Wu P-R, Zhang W, Liu Z, Cheng Z-L (2019) A novel preparation method for MoS2 nanosheets with good tribology performance by the combination of expansion and freeze exfoliation. Ceram Int 45(2):1730–1736

Sun HH, Liu HY, Hou ZD, Zhou R, Liu XR, Wang J-G (2020) Edge-terminated MoS2 nanosheets with an expanded interlayer spacing on graphene to boost supercapacitive performance. Chem Eng J 387:124204

Wang G, Zhang J, Yang S, Wang FX, Zhuang XD, Müllen K, Feng XL (2017) Vertically aligned MoS2 nanosheets patterned on electrochemically exfoliated graphene for high-performance lithium and sodium storage. Adv Energy Mater 8:1702254

Jing Y, Ortiz-Quiles EO, Cabrera CR, Chen ZF, Zhou Z (2014) Layer-by-layer hybrids of MoS2 and reduced graphene oxide for lithium-ion batteries. Electrochim Acta 147:392–400

Wu X, Wang Z, Yu M, Xiu L, Qiu J (2017) Stabilizing the MXenes by carbon nanoplating for developing hierarchical nanohybrids with efficient lithium storage and hydrogen evolution capability. Adv Mater 29(24):1607017

Wang WX, Lu Y, Zhao ML, Luo RJ, Yang Y, Peng T, Yan HL, Liu XM, Luo YS (2019) Controllable tuning of cobalt nickel-layered double hydroxide arrays as multifunctional electrodes for flexible supercapattery device and oxygen evolution reaction. ACS Nano 13(10):12206–12218

Medetalibeyoglu H, Beytur M, Akyıldırım O, Atar N, Yola ML (2020) Validated electrochemical immunosensor for ultra-sensitive procalcitonin detection: carbon electrode modified with gold nanoparticles functionalized sulfur doped MXene as sensor platform and carboxylated graphitic carbon nitride as signal amplification. Sensors Actuators B Chem 319:128195

Kadirsoy S, Atar N, Yola ML (2020) Molecularly imprinted QCM sensor based on delaminated MXene for chlorpyrifos detection and QCM sensor validation. New J Chem 44(16):6524–6532

Özcan N, Medetalibeyoglu H, Akyıldırım O, Atar N, Yola ML (2020) Electrochemical detection of amyloid-β protein by delaminated titanium carbide MXene/multi-walled carbon nanotubes composite with molecularly imprinted polymer. Mater Today Commun 23:101097

Chen X, Wang SL, Shi JJ, Du XY, Cheng QH, Xue R, Wang Q, Wang M, Ruan LM, Zeng W (2019) Direct laser etching free-standing MXene-MoS2 film for highly flexible micro-supercapacitor. Adv Mater Interfaces 6(22):1901160

Yu P, Cao GJ, Yi S, Zhang X, Li C, Sun XZ, Wang K, Ma YW (2018) Binder-free 2D titanium carbide (MXene)/carbon nanotube composites for high-performance lithium-ion capacitors. Nanoscale 10(13):5906–5913

Wu CL, Zhao GY, Gong S, Zhang NQ, Sun KN (2019) A PVP incorporated MoS2 as Mg ion host with enhanced capacity and durability. J Mater Chem A 7(9):4426–4430

Wang YH, Yang Y, Zhang DY, Wang YB, Luo XK, Liu XM, Kim J-K, Luo YS (2020) Inter-overlapped MoS2/C composites with large-interlayer -spacing for high-performance sodium-ion batteries. Nanoscale Horiz 5(7):1127–1135

Deng ZN, Jiang H, Hu YJ, Liu Y, Zhang L, Liu HL, Li C (2017) 3D ordered macroporous MoS2@C nanostructure for flexible Li-ion batteries. Adv Mater 29(10):1603020

Ding L, Wei YY, Wang YJ, Chen HB, Caro JG, Wang HH (2017) A Two-dimensional lamellar membrane: MXene nanosheet stacks. Angew Chem Int Ed 56(7):1825–1829

Fu JJ, Yun JM, Wu SX, Li LL, Yu LT, Kim K (2018) Architecturally robust graphene-encapsulated MXene Ti2CTx@Polyaniline composite for high-performance pouch-type asymmetric supercapacitor. ACS Appl Mater Interfaces 10(40):34212–34221

Su TM, Hood ZD, Naguib M, Bai L, Luo S, Rouleau CM, Ivanov IN, Ji HB, Qin ZZ, Wu ZL (2019) Monolayer Ti3C2Tx as an effective co-catalyst for enhanced photocatalytic hydrogen production over TiO2. ACS Appl Energy Mater 2(7):4640–4651

Pan ZH, Cao F, Hu X, Ji XH (2019) Facile CuS decorated Ti3C2 MXene with enhanced performance for asymmetric supercapacitor. J Mater Chem A 7(15):8984–8992

Liu J, Zhang H-B, Sun RH, Liu YF, Liu ZS, Zhou A, Yu Z-Z (2017) Hydrophobic, flexible, and lightweight MXene foams for high-performance electromagnetic-interference shielding. Adv Mater 29(38):1702367

Yan J, Ren CE, Maleski K, Hatter CB, Anasori BA, Urbankowski P, Sarycheva A, Gogotsi Y (2017) Flexible MXene/graphene films for ultrafast supercapacitors with outstanding volumetric capacitance. Adv Funct Mater 27(30):1701264

Zhao Z-H, Hu X-D, Wang HQ, Ye M-Y, Sang Z-Y, Ji H-M, Li X-L, Dai Y (2018) Superelastic 3D few-layer MoS2/carbon framework heterogeneous electrodes for highly reversible sodium-ion batteries. Nano Energy 48:526–535

Ma K, Jiang H, Hu YJ, Li CZ (2018) 2D Nanospace confined synthesis of pseudocapacitance-dominated MoS2-in-Ti3C2 superstructure for ultrafast and stable Li/Na-ion batteries. Adv Funct Mater 28(40):1804306

Xie XQ, Makaryan T, Zhao MQ, Van Aken KL, Gogotsi Y, Wang GX (2016) MoS2 nanosheets vertically aligned on carbon paper: a freestanding electrode for highly reversible sodium-ion batteries. Adv Energy Mater 6(5):1502161

Wang J-G, Liu HY, Zhou R, Liu XG, Wei BW (2019) Onion-like nanospheres organized by carbon encapsulated few-layer MoS2 nanosheets with enhanced lithium storage performance. J Power Sources 413:327–333

Lei ZD, Xu LQ, Jiao YL, Du AJ, Zhang Y, Zhang HJ (2018) Strong coupling of MoS2 nanosheets and nitrogen-doped graphene for high-performance pseudocapacitance lithium storage. Small 14(25):1704410

Chao YF, Jalili RH, Ge Y, Wang CY, Zheng T, Shu KW, Wallace GG (2017) self-assembly of flexible free-standing 3D porous MoS2-reduced graphene oxide structure for high-performance lithium-ion batteries. Adv Funct Mater 27:1700234

Bai J, Zhao BC, Lin S, Li KZ, Zhou JF, Dai JM, Zhu XB, Sun YP (2020) Construction of hierarchical V4C3-MXene/MoS2/C nanohybrids for high-rate lithium-ion batteries. Nanoscale 12(2):1144–1154

Huang HW, Cui J, Liu GX, Bi R, Zhang L (2019) Carbon coated MoSe2/MXene hybrid nanosheets for superior potassium storage. ACS Nano 13(3):3448–3456

Wu YT, Nie P, Jiang JM, Ding B, Dou H, Zhang XG (2017) MoS2 Nanosheets decorated 2D titanium carbide (MXene) as high-performance anodes for sodium-ion batteries. ChemElectroChem 4(6):1560–1565

Veerasubramani GK, Park M-S, Nagaraju G, Kim D-W (2019) Unraveling the Na-ion storage performance of a vertically aligned interlayer-expanded two-dimensional MoS2@C@MoS2 heterostructure. J Mater Chem A 7(42):24557–24568

Chen C, Xie X, Anasori B, Sarycheva A, Makaryan T, Zhao MQ, Urbankowski P, Miao L, Jiang JJ, Gogotsi Y (2018) MoS2-on-MXene heterostructures as highly reversible anode materials for lithium-ion batteries. Angew Chem Int Ed 57(7):1846–1850

Xie XQ, Ao ZM, Su DW, Zhang JQ, Wang GX (2015) MoS2/graphene composite anodes with enhanced performance for sodium-ion batteries: the role of the two-dimensional heterointerface. Adv Funct Mater 4:1393–1403

Funding

This work was financially supported by the National Natural Science Foundation of China (Nos. 61574122 and 61874093), Zhongyuan Thousand Talents Plan - Science & Technology Innovation Leading Talents Project (No. 194200510009), Key Scientific Research Projects of Higher Education Institutions in Henan Province (19A430023), and the Nanhu Scholars Program for Young Scholars of XYNU, Xinyang Normal University Analysis & Testing Center, and City University of Hong Kong Strategic Research Grant (SRG) (No. 7005505).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

ESM 1

(DOCX 17701 kb).

Rights and permissions

About this article

Cite this article

Bai, Z., Yang, Y., Zhang, D. et al. Carbon-encapsulated nanosphere-assembled MoS2 nanosheets with large interlayer distance for flexible lithium-ion batteries. J Solid State Electrochem 25, 1657–1665 (2021). https://doi.org/10.1007/s10008-021-04936-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10008-021-04936-8