Abstract

Polypyrrole (PPy) hybrid composites are prepared with nitrogen-functionalized graphene (NFG) via in situ polymerization of pyrrole in the presence of NFG suspension (PPy/NFG). PPy nanorods with 60 nm in diameter are uniformly dispersed on the surface of NFG sheets. The PPy/NFG composites are used as supercapacitor electrodes, and the electrochemical performances are evaluated by cyclic voltammetry, galvanostatic charge/discharge measurement, and electrochemical impedance spectroscopy, respectively. The PPy/NFG composite exhibits good capacitive behavior with specific capacitances of 962 and 815 F g−1 at a current density of 0.5 and 8 A g−1, respectively. The PPy/NFG symmetric supercapacitor device also presents high specific capacitance, good cycle stability, and large energy density of 57.8 Wh kg−1 at power density of 14.9 kW kg−1. The results demonstrate the PPy/NFG composites can be used as promising supercapacitor electrode materials for high performance energy storage devices.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Supercapacitors with high power densities and long cycle life have become promising energy storage systems for portable electronic devices and electric vehicles [1]. There are two types of charge storage mechanisms in supercapacitors [2], namely, electric charges accumulation at the carbon electrode/electrolyte interface (electrical double layer capacitors (EDLCs)) and reversible Faradic reactions (pseudocapacitors) at the conductive polymers or metal oxides electrode surfaces. EDLCs are highly stable because they do not involve any phase changes during charge storage process.

Up to now, many studies have been reported on the synthesis of graphene as EDLCs, owing to its good electrical conductivity, excellent mechanical property, open porous nanostructure, and high theoretical surface area (2630 m2 g−1) [3–5]. However, the effective surface area and charge storage capacity deteriorated significantly because of the aggregation of graphene sheets in the reduction process. To fully utilize and promote the energy storage of graphene, tremendous research has been achieved in functionalized graphene. To date, various functionalized graphene have been proved to enhance charge storage ability in comparison with unmodified graphene counterparts [6–9]. The introduced functional groups onto graphene flake can significantly enhance the specific capacitance of graphene due to their pseudocapacitive reactions and improve electrolyte affinity [10].

Polypyrrole (PPy) is treated as one of potential electrode materials for supercapacitors among conductive polymers, owing to its intrinsic electrical conductivity, facile synthesis, and good environmental stability [11]. Nevertheless, the volume expansion induced by doping and dedoping in the electrochemical progress lowers the stability of supercapacitors. In order to enhance the long-term stability and capacity of electrode materials, various graphene-based composites were proposed to incorporate pseudocapacitance with EDLC of graphene [12–15]. Hybrid composite materials based on the combination of graphene and PPy are expected not only can improve the PPy conductivity and stability but also relieve graphene aggregation via a synergistic effect of two components [16–18]. The graphene-PPy hybrid solid-state flexible supercapacitor presented a specific capacitance of 514 F g−1 at a current density of 0.2 A g−1 [16]. PPy nanotubes/graphene aerogel showed a specific capacitance up to 253 F g−1 at a current density of 0.5 A g−1 [19].

Herein, the present work demonstrated a facile and green synthetic hydrothermal route to prepare polypyrrole/nitrogen-functionalized graphene (PPy/NFG) composite via in situ polymerization of pyrrole in the presence of NFG suspension. Due to the synergistic effect of the enlarged ion accessible surface area and electrolyte wettability property, the PPy/NFG supercapacitor electrode exhibited a high specific capacitance of 962 F g−1 at a discharge current density of 0.5 A g−1 with excellent rate performance and cycling stability. The PPy/NFG symmetric supercapacitor device also presented a high specific capacitance (588 F g−1 at a current density of 0.5 A g−1), good cycle stability, and large energy density of 57.8 Wh kg−1 at power density of 14.9 kW kg−1.

Experimental

Preparation of materials

Pyrrole was distilled under the protection of high purity N2 and then kept in a refrigerator before use. All the other chemicals were analytical reagent and used without further purification. Ni foam was treated with dilute HCl under ultrasonication for 30 min and then washed with deionized water for several times. Finally, the Ni foam was dried in an oven at 60 °C.

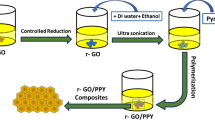

Graphite oxide was synthesized from graphite powder by the modified Hummers method [20]. NFG was synthesized by following a reported procedure [8]. Briefly, 150 mg of graphite oxide was dispersed in 60 mL of deionized water and ultrasonication for 2 h to obtain graphene oxide (GO) dispersion. Then, the above dispersion was centrifuged at 6000 rpm for 10 min to remove visible particles. In this process, graphite oxide was completely exfoliated down to individual sheets to form a stably dispersed GO/H2O suspension. After that, 250 μL of ethylenediamine was added into the GO suspension and vigorously stirred for 30 min. The mixed dispersion was transferred into a 100mL Teflon-lined autoclave for the hydrothermal reaction at 180 °C for 10 h. After hydrothermal treatment, the resultant precipitate was collected and washed with deionized water and ethanol repeatedly to remove residual unreacted compounds. Finally, the sample was dried in an oven at 60 °C. The hydrothermally treated GO (HTGO) was processed by following the abovementioned procedure of NFG without the use of ethylenediamine.

Homogenous composites of the PPy/NFG with different mass ratios were synthesized through in situ polymerization of pyrrole monomer in the presence of NFG suspension. The mass ratio of pyrrole to NFG was varied as 95:5, 90:10, and 80:20. The resulting composites were signed as PGratio, like PG90:10, indicating the mass ratio of pyrrole and NFG was 90:10. The typical route is as follows, for example, when the mass ratio is 90:10. Fifty-four milligrams of NFG was dispersed in 300 mL of water containing 0.5 mL of pyrrole under ultrasonication for 2 h. Afterwards, ammonium persulfate (APS, 0.008 mol) was dissolved in 50 mL of 0.8 M glutaric acid and added dropwise to the above reaction system. The polymerization reaction was allowed to stir at 0~4 °C for 5 h. Finally, the resulting precipitate was filtered and washed with water until the filtrate was neutral and dried at 60 °C for 10 h under vacuum. For comparison, the pure PPy was also prepared by using the similar procedure without the presence of NFG.

Characterization and measurements

The morphologies of samples were analyzed by scanning electron microscopy (SEM, HITACHI S-4800). Transmission electron microscopy (TEM) was recorded with JEOL JEM-2100F electron microscope. XRD measurements were recorded on X-ray diffraction system (D8-Advance, Germany). X-ray photoelectron spectroscopy (XPS) measurements were performed on ESCALAB MK2 spectrometer (VG Co., UK) equipped with Mg Kα X-ray radiation as the source for excitation. The Brunauer-Emmett-Teller (BET) surface area of the samples was measured using nitrogen adsorption data over a relative pressure ranging from 0.05 to 0.3.

Electrochemical performances were characterized by cyclic voltammetry (CV) and electrochemical impedance spectroscopy (EIS) using CHI 660E electrochemical workstation (ChenHua Instruments Co., Shanghai, China). In the electrochemical test, the active electrode was assembled into a three-electrode cell system, consisting of the working electrode, platinum as the counter electrode, and a saturated calomel electrode (SCE) as the reference electrode. Galvanostatic charge/discharge (GCD) curves were measured using computer controlled cycling equipment (LAND, Wuhan, China).

Fabrication of supercapacitor electrodes and devices

The supercapacitor electrodes were prepared by mixing 85 wt% electroactive materials with 10 wt% acetylene black as a conductive agent and 5 wt% polytetrafluoroethylene (PTFE) dissolved in ethanol as a binder to form slurry. The resulting mixture was coated onto the nickel foam substrate (1 × 2 cm2) and then pressing and drying under vacuum at 120 °C for 12 h.

The symmetric supercapacitor device was assembled by two pieces of the PPy/NFG composite electrodes. The loading mass of PPy/NFG in each electrode was about 6 mg. PVA/H2SO4 gel was used as the electrolyte and separator. The PVA/H2SO4 gel was prepared by adding 6 g of PVA and 6 g of H2SO4 in 60 mL of deionized water and heated at 85 °C under stirring until the solution became clear. Two pieces of the PPy/NFG electrodes were separated by a filter paper dipped into the PVA/H2SO4 gel electrolyte and then dried at room temperature for 4 h. Finally, they were wrapped with parafilm and evaporated excess water.

Results and discussion

Microstructure characterizations

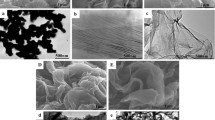

The surface morphologies of pure PPy and the PPy/NFG composite are characterized by FE-SEM, as shown in Fig. 1. The pure PPy (Fig. 1a) shows obvious nanorod morphology with a diameter of 55 nm and length up to 500 nm. As shown in Fig. 1b and Fig. 1c, the PG90:10 composite exhibits a large scale of dense PPy nanorods on the order of 60 nm attached on the surface of NFG sheets. Because of the nanorod morphology and high overall coverage of PPy, the layered structure of NFG cannot be seen clearly. The surface morphologies of PPy and PPy/NFG composite can be investigated and observed from the TEM images, as shown in Fig. 2. Figure 2a shows pure PPy nanorods have been synthesized with hundreds of nanometers in length and 55 nm in width. Figure 2b presents the image of PG90:10 composite, in which PPy nanorods with diameter of 60 nm coated on the surface of NFG nanosheets. NFG can be used as support materials for the polymerization of PPy and thus would be beneficent to improve the conductivity of the composites.

The powder XRD was used to characterize the structure of samples. Figure 3a represents the XRD patterns of GO, NFG, PPy, and PG90:10 composite, respectively. The GO shows a sharp diffraction peak at 2θ = 10.7o, corresponding to the (001) reflection. After the hydrothermal treatment, a new sharp peak at 2θ = 24.0o can be seen from NFG, attributing to the (002) reflection. Amorphous PPy exhibits a broad peak centered at 2θ = 24.5o, which was associated with the scattering from PPy chains at the interplaner spacing. The XRD pattern of PG90:10 is almost the same as pure PPy. From the XRD patterns, we can see that the amorphous nature of PPy was preserved, and no additional crystalline phase changes occurred in the PPy/NFG composites. XPS was further used to investigate the structure of HTGO and NFG. As shown in Fig. 3b, it can be observed that the HTGO presents C 1 s and O 1 s peaks at 285 and 532 eV with atomic percentages of 80 and 20%, respectively. As for NFG, three peaks located at 285, 400, and 532 eV, corresponding to C 1 s, N 1 s, and O 1 s peaks, respectively. The N 1 s appears in the NFG spectrum, indicating the successful introduction of nitrogen to graphene surface. The presence of O 1 s peak for HTGO and NFG investigates that the oxygen is not completely removed during the hydrothermal process. The atomic percentages in NFG were 80%, 7%, and 13% for C, N, and O. The specific surface area of NFG is calculated by BET method, and the value is 306.8 m2 g−1. The BET surface area of PG95:5 (54.1 m2 g−1), PG90:10 (72.3 m2 g−1), and PG80:20 (81.7 m2 g−1) is much larger than that of pure PPy (35.2 m2 g−1). The BET surface area of the samples has an obvious enhancement with increasing the NFG content, indicating the introduction of NFG into PPy can effectively increase the surface area.

Electrochemical behavior

The electrochemical performances of the as-synthesized electrode materials were evaluated by CV, GCD, and EIS in 1.0 M KCl aqueous solution with a three-electrode configuration. The specific capacitance can be calculated according to the following equation from CV curves:

where C is the specific capacitance (F g−1), I is the response current (A), V is the potential window (V), v is the potential scan rate (V s−1), and m is the mass of the active electrode material (g).

The CV tests were performed within potential windows from −0.2 to 0.5 V vs. SCE. The representative CV curves of PG95:5, PG90:10, and PG80:20 are shown in Fig. 4a. The capacitive performances of the PPy/NFG composites are enhanced to different degrees as the mass ratio changes. It can be found that the surrounded by CV curves of PG90:10 are much larger than that of PG95:5 and PG80:20. More interestingly, the CV shapes of different PPy/NFG composites have a little change. The CV behavior actually exhibits the synergetic performance of PPy and NFG. The PPy provide enhanced electrode/electrolyte interface areas, which can enable the electrochemical accessibility of electrolyte through the loosely PPy nanorod structure. Furthermore, the NFG not only offer highly conductive path but also serve as large surface area for the polymerization of PPy, facilitating rapid transport of the electrolyte ions in the electrode in rapid charge/discharge processes. Figure 4b illustrates the CV curves of HTGO, NFG, PPy, and PG90:10 electrodes. The HTGO electrode shows a rectangular shape in CV, which is a typical behavior for EDLC. The NFG has larger enclosed CV area in comparison with the HTGO electrode, indicating higher specific capacitance. This may be attributed to the incorporation of electrochemically active nitrogen functional groups on the graphene sheets, which can effectively enhance the surface activity and electrochemical performance [21]. It can be apparently found that the surrounded by CV curve of PG90:10 composite is apparently larger than that of pure PPy and NFG electrodes, presenting the behavior of combination of both pseudocapacitance of PPy and EDLC arising from graphene. Figure 4c exhibits the CV curves of the PG90:10 electrode at different scan rates from 5 to 300 mV s−1. All CV curves maintain symmetric and nearly rectangular shape even at a high scan rate of 300 mV s−1, indicating fast ion diffusions in the electrodes. Figure 4d displays the relationship of the specific capacitance of the synthesized materials and scan rates. The specific capacitances decrease as the scan rates increase. The specific capacitances of the PPy/NFG composites are much higher than that of pure NFG, HTGO, and PPy electrodes at the same scan rates. The maximum specific capacitance of 970 F g−1 is obtained at a scan rate of 5 mV s−1 for PG90:10, in comparison with 795, 906, 295, 250, and 198 F g−1 for the PG95:5, PG80:20, PPy, NFG, and HTGO electrodes, respectively. By further increasing the scan rate to 600 mV s−1, the specific capacitances are kept as high as 675, 877, 786, 182, 185, and 135 F g−1 for the PG95:5, PG90:10, PG80:20, PPy, NFG, and HTGO electrodes, respectively. The samples present enhanced rate capability than the previous reported results of graphene/PPy composites [16, 17, 19, 22].

a CV curves of various PPy/NFG composites at scan rate of 5 mV s−1 in 1 M KCl solution. b CV curves of the PPy, HTGO, NFG, and PG90:10 electrodes at scan rate of 5 mV s−1. c CV curves of the PG90:10 at different scan rates. d Rate-dependence specific capacitances of the PPy, NFG, and PPy/NFG composite electrodes

The GCD is a reliable method to evaluate the electrochemical properties of supercapacitor electrodes under controlled current conditions. Figure 5a displays the GCD curves of the PPy/NFG composites, PPy, NFG, and HTGO electrodes for the initial 2 cycles at a current density of 1 A g−1. The charge/discharge curves of PG95:5, PG90:10, and PG80:20 almost maintain the similar shape in the potential range from −0.2 to 0.5 V, revealing the hybrid electrode material can experience a broad electric current range. The PG90:10 composite has much longer charge/discharge durations, presenting higher charge storage capacities. The GCD curves of HTGO and NFG electrodes are almost linear, indicating mainly double-layer capacitive behavior. The small deviation from an ideal triangle shape for NFG may due to the electroactive nitrogen functional groups on graphene sheets. The GCD curve of PPy also has a similar symmetrical triangle shape in neutral solution.

a GCD curves of the PPy, HTGO, NFG, and PPy/NFG electrodes at a current density of 1 A g−1. b GCD curves of the PG90:10 at various discharge current densities. c Variation of specific capacitances of the PPy/NFG composites, PPy, NFG, and HTGO at different discharge current densities. d Impedance spectra of the PPy, NFG, and PG90:10 measured at open circuit potential

Figure 5b gives the GCD curves of PG90:10 composite at different discharge current densities. All the curves present symmetric and linear line, demonstrating the PG90:10 composite contains a capacitive feature of EDLC as well as pseudocapacitance. The specific capacitances of the PPy/NFG composites compared to PPy, NFG, and HTGO electrodes are calculated from the GCD curves according to the following equation:

where I is the discharge current (A), Δt is the discharge time (s), ΔV is the voltage change during the discharge process, and m is the mass of active electrode material (g). The PPy/NFG composites have higher specific capacitances than those of pure PPy, NFG, and HTGO electrodes at the same discharge current densities, which can be clearly found from Fig. 5c. The specific capacitance can be evaluated as 308, 188, 241, 772, 962, and 882 F g−1 for pure PPy, HTGO, NFG, PG95:5, PG90:10, and PG80:20 electrodes at a current density of 0.5 A g−1, respectively. Even at a current density of 8 A g−1, the specific capacitance of the PG90:10 electrode remains 815 F g−1. PG95:5 and PG80:20 exhibit specific capacitance of about 594 and 711 F g−1 at a discharge current density of 8 A g−1, while that of pure PPy, NFG, and HTGO sharply decrease to 155, 183, and 118 F g−1, respectively. It is noted that the PG90:10 shows not only high capacitance but also better rate capability, indicating this ratio is optimal among all the composite samples. The improved specific capacitance and better rate capability of PG90:10 might be mainly ascribed to the synergetic effect between the two components, which can greatly reduce the diffusion length, resulting in the improvement of electrochemical properties.

The EIS analysis is also conducted to examine the fundamental behavior of electrodes, as shown in Fig. 5d. It is notable that PPy presents well-defined semicircle over the high-frequency range, followed by a straight sloped line in the low-frequency region. The dimension of semicircle at high-frequency region reflects the faradic charge transfer impedance. The PG90:10 electrode shows the smallest semicircle, indicating the lowest faradic charge transfer resistance. The PG90:10 electrode also exhibits a more vertical line than PPy and NFG electrodes at low-frequency, indicating a better capacitor behavior and lower ion diffusion resistance. Altogether, the capacitive behaviors of three electrodes extracted from the EIS measurements are well consistent with the CV results.

The stability of supercapacitors during long-term charge/discharge processes is an important property. The electrochemical stabilities of the PPy, NFG, and PG90:10 electrodes were evaluated by repeating the CV test between −0.2 and 0.5 V at a scan rate of 50 mV s−1. The specific capacitance as a function of cycle number is presented in Fig. 6a. The specific capacitance of the PG90:10 increases during the first 500 cycles and then decreases. The capacitance is retained about 102% after 500 cycles. The increase of specific capacitance of the PG90:10 may be attributed to activate the electrode material nanostructure during cycling, which can provide better contact between electrolyte and electrode material. The capacitance retention of the PG90:10 is 99 and 92% after 1000 and 2000 cycles, while just only 90 and 52% for NFG and PPy after 2000 cycles, demonstrating that the PG90:10 electrodes have long-term electrochemical stability. Figure 6b illustrates the CV changes at the 1st, 1000th, and 2000th cycles of the PG90:10 composites. The CV curves have a little change after 2000 cycles. The conducting polymers may cause swelling and shrinkage during the charge/discharge processes, which may lead to degradation of the polymeric conductivity and charge storage capability [23]. The NFG nanosheets can undertake some mechanical deformation in the redox process of PPy, which can prevent PPy chains from severely swelling and shrinking during charge/discharge process. The NFG-layered structure would also avoid the destruction of the electrode material and is beneficial for a better stability during the charge/discharge processes.

The reproducibility of the electrochemical capacitances of the NFG, PPy, PG95:5, PG90:10, and PG80:20 was also tested by repetitive recording of GCD at a discharge current density of 1 A g−1 in 1.0 M KCl aqueous solution. It is found that the relative standard deviation (R.S.D.) of the specific capacitance for 15 replicate determinations is 3.3, 3.9, 3.6, 3.1, and 3.4%, respectively. Ten pieces of the proposed supercapacitor electrodes are fabricated and the R.S.D. for the individual determinations were 3.6, 3.9, 3.5, 3.1, and 3.3%, respectively. These results demonstrate that the prepared supercapacitor electrodes have excellent reproducibility.

Symmetric PG90:10 supercapacitor device was also fabricated in order to investigate the electrochemical performances of the hybrid electrodes. The GCD curves of the supercapacitor device at various discharge current densities are shown in Fig. 7a. The GCD curves are linear and symmetric, indicating the supercapacitor has good electrochemical behavior. Specific capacitance was calculated from GCD curves according to Eq. (2). Figure 7b gives the detailed specific capacitance of the PG90:10 supercapacitor at different current densities. The specific capacitance reached to 588 F g−1 at a current density of 0.5 A g−1. Even as the current density increases to 30 A g−1, the specific capacitance also retains a high value of 416 F g−1, about 71% retention of the capacitance at 0.5 A g−1, which probably result from the combination of PPy nanorods and NFG-layered structures. The Ragone plot, consisting of energy density and power density, is an important parameter for the energy storage device. The Ragone plot for the PPy/NFG symmetric supercapacitor device is presented in Fig. 7c. The supercapacitor shows a high energy density of 81.7 Wh kg−1 at a power density of 0.25 kW kg−1 with a discharge current density of 0.5 A g−1. Moreover, upon increasing the power density up to 14.9 kW kg−1, the energy density remains at 57.8 Wh kg−1. Such a high and stable energy density indicates that the PPy/NFG can act as a promising material for practical application in supercapacitors. The cycling life of the PPy/NFG supercapacitor device was also studied by GCD technique for 3000 cycles at a current density of 1 A g−1. As shown in Fig. 7d, the supercapacitor device shows a slight increase during the first 500 cycles and remains about 107% of the initial capacitance after 500 cycles. Then, the specific capacitance decreases and remains about 104, 98, and 93% retention of the initial capacitance after 1000, 2000, and 3000 cycles, respectively.

Electrochemical performances of the PG90:10 supercapacitor measured in a two-electrode system. a GCD curves of the supercapacitor at different current densities ranging from 1 to 20 A g−1. b The specific capacitance of the supercapacitor at different current densities. c Ragone plot of the supercapacitor. d Cycling stability of the supercapacitor by GCD curves at 1 A g−1

Conclusions

In summary, we have fabricated the PPy/NFG composites through in situ polymerization of pyrrole in NFG suspension. The introduction of NFG into the composites provides a relatively large surface area for dispersing PPy nanorods, which can effectively enhance the capacitive behavior. The obtained PPy/NFG composites exhibited good electrochemical properties and cycling stability. Large specific capacitances of 962 and 815 F g−1 have been achieved at a current density of 0.5 and 8 A g−1 for PG90:10. After 2000 charge/discharge cycles, the capacitance of the PG90:10 composite decreased only 8% of the initial capacitance, indicating excellent electrochemical stability. The PPy/NFG symmetric supercapacitor device also exhibited a good electrochemical capacitance (588 F g−1 at a current density of 0.5 A g−1), good retention capability (70% capacitance retention at current density up to 30 A g−1), good cycling stability (93% capacitance retention after 3000 cycles), and large energy density of 57.8 Wh kg−1 at power density of 14.9 kW kg−1. The greatly enhanced electrochemical performances are due to the synergic effect of the two components of NFG and PPy nanorods. The PPy/NFG composites are quite suitable and promising electrode materials for supercapacitors.

References

Simon P, Gogotsi Y (2008) Materials for electrochemical capacitors. Nat Mater 7:845–854

Conway BE (1999) Electrochemical supercapacitors: scientific fundamentals and technological applications. Kluwer Academic/Plenum Press, New York

Zhang L, DeArmond D, Alvarez NT, Zhao DL, Wang TT, Hou GF, Malik R, Heineman WR, Shanov V (2016) Beyond graphene foam, a new form of three-dimensional graphene for supercapacitor electrodes. J Mater Chem A 4:1876–1886

Liao YQ, Huang YL, Shu D, Zhong YY, Hao JN, He C, Zhong J, Song XN (2016) Three-dimensional nitrogen-doped graphene hydrogels prepared via hydrothermal synthesis as high-performance supercapacitor materials. Electrochim Acta 194:136–142

Zhu Y, Murali S, Stoller MD, Ganesh KJ, Cai W, Ferreira PJ, Pirkle A, Wallace RM, Cychosz KA, Thommes M, Su D, Stach EA, Ruoff RS (2011) Carbon-based supercapacitors produced by activation of graphene. Science 332:1537–1541

Xia H, Hong CY, Li B, Zhao B, Lin ZX, Zheng MB, Savilov SV, Aldoshin SM (2015) Facile synthesis of hematite quantum-dot/functionalized graphene-sheet composites as advanced anode materials for asymmetric supercapacitors. Adv Funct Mater 25:627–635

Yan J, Wang Q, Wei T, Jiang LL, Zhang ML, Jing XY, Fan ZJ (2014) Template-assisted low temperature synthesis of functionalized graphene for ultrahigh volumetric performance supercapacitors. ACS Nano 8:4720–4729

Umashankar M, Palaniappan S (2015) Hybrid composite of nitrogen functionalized graphene-polyaniline electrode for high performance supercapacitor. RSC Adv 5:70675–70681

Lee WSV, Leng M, Li M, Huang XL, Xue JM (2015) Sulphur-functionalized graphene towards high performance supercapacitor. Nano Energy 12:250–257

Chen Y, Zhang XO, Zhang DC, Yu P, Ma YW (2011) High performance supercapacitors based on reduced graphene oxide in aqueous and ionic liquid electrolytes. Carbon 49:573–580

Sun W, Chen XY (2009) Preparation and characterization of polypyrrole films for three-dimensional micro supercapacitor. J Power Sources 193:924–929

Yang C, Zhang LL, Hu NT, Yang Z, Wei H, Zhang YF (2016) Reduced graphene oxide/polypyrrole nanotube papers for flexible all-solid-state supercapacitors with excellent rate capability and high energy density. J Power Sources 302:39–45

Liu Y, Zhou J, Tang J, Tang WH (2015) Three-dimensional, chemically bonded polypyrrole/bacterial cellulose/graphene composites for high-performance supercapacitors. Chem Mater 27:7034–7041

Kalambate PK, Dar RA, Karna SP, Srivastava AK (2015) High performance supercapacitor based on graphene-silver nanoparticles-polypyrrole nanocomposite coated on glassy carbon electrode. J Power Sources 276:262–270

Yu CF, Ma PP, Zhou X, Wang AQ, Qian T, Wu SS, Chen Q (2014) All-solid-state flexible supercapacitors based on highly dispersed polypyrrole nanowire and reduced graphene oxide composites. Acs Appl Mater Inter 6:17937–17943

Kashani H, Chen LY, Ito Y, Han JH, Hirata A, Chen MW (2016) Bicontinuous nanotubular graphene-polypyrrole hybrid for high performance flexible supercapacitors. Nano Energy 19:391–400

Li J, Xie HQ, Li Y (2013) Fabrication of graphene oxide/polypyrrole nanowire composite for high performance supercapacitor electrodes. J Power Sources 241:388–395

Cao JY, Wang YM, Chen JC, Li XH, Walsh FC, Ouyang JH, Jia DC, Zhou Y (2015) Three-dimensional graphene oxide/polypyrrole composite electrodes fabricated by one-step electrodeposition for high performance supercapacitors. J Mater Chem A 3:14445–14457

Ye SB, Feng JC (2014) Self-assembled three-dimensional hierarchical graphene/polypyrrole nanotube hybrid aerogel and its application for supercapacitors. Acs Appl Mater Inter 6:9671–9679

Hummers WS, Offeman RE (1958) Preparation of graphitic oxide. J Am Chem Soc 80:1339–1339

Chen CN, Fan W, Ma T, Fu XW (2014) Fabrication of functionalized nitrogen-doped graphene for supercapacitor electrodes. Ionics 20:1489–1494

Li J, Xie HQ (2012) Synthesis of graphene oxide/polypyrrole nanowire composites for supercapacitors. Mater Lett 78:106–109

Khomenko V, Frackowiak E, Beguin F (2005) Determination of the specific capacitance of conducting polymer/nanotubes composite electrodes using different cell configurations. Electrochim Acta 50:2499–2506

Acknowledgments

This work was supported by the National Natural Science Foundation of China (51402185), the Natural Science Foundation of Shanghai (13ZR1454700), the Major Program of the National Natural Science Foundation of China (51590902), and the key subject of Shanghai Polytechnic University (Material Science and Engineering, XXKZD1601).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, J., Zhang, Y., Xie, H. et al. Electrochemical performance of polypyrrole nanorods/functionalized graphene composites for supercapacitors. J Solid State Electrochem 21, 2201–2208 (2017). https://doi.org/10.1007/s10008-017-3546-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10008-017-3546-y