Abstract

Objectives

The purpose of this study was to investigate the microhardness, polymerization shrinkage, and translucency of bulk-fill composites (BFCs) which have different light attenuation properties and filler contents.

Materials and methods

Five BFCs [Filtek Bulk Fill (FB), SureFil SDR (SS), Venus Bulk Fill (VB), SonicFill (SF), and Tetric N-Ceram Bulk Fill (TB)] and two resin-based composites (RBCs) [Tetric N-Ceram (TN) and Filtek Z350XT Flowable (ZF)] were chosen. Numbers of transmitted photons, refractive index, microhardness at different thicknesses, polymerization shrinkage, and translucency parameter (TP) were evaluated.

Results

Attenuation coefficients (ACs) based on measured photons ranged from −0.88 to −1.90. BFCs, except SF, had lower AC values than TN or ZF, and BFCs, except TN, had smaller refractive index decreases between top and bottom surfaces. Regardless of an exponential decrease in photon counts, microhardness decreased linearly as specimen thickens. Moreover, microhardness of BFCs showed smaller top-to-bottom decreases (11.5–48.8 %) than TN or ZF (57.3 and 71.5 %, respectively). BFCs with low filler contents showed lower microhardness and higher polymerization shrinkage than those of high filler contents. Also, BFCs had significantly higher (p < 0.001) TP values than TN or ZF.

Conclusion

BFCs attenuated light less than RBCs. However, some BFCs had much lower top surface microhardness and higher polymerization shrinkage than tested RBCs.

Clinical relevance

Despite the convenience of bulk filling, careful selection of BFC is advised because some BFCs have worse microhardness and polymerization shrinkage than RBCs due to their lower filler contents.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Resin-based composites (RBCs) are the primary option for the restoration of tooth cavity because they have acceptable mechanical and esthetic properties. Easy handling, long working time, but short curing times are other advantages over other restoration materials. However, as a commixture of fillers and monomers, polymerization shrinkage induced by the methacrylate-based monomers produces unwanted problems such as postoperative sensitivity, recurrence of secondary caries, and marginal leakage [1–3]. A turbid nature of RBCs due to pigments and refractive index mismatching between fillers and monomers causes insufficient light transmission and results in insufficient curing of the subsurface. To eliminate these problems, less than 2-mm-thick layering became a routine option even though it is a time-consuming process [4, 5].

Recently, resin-based bulk-fill composites (BFCs) have been introduced with claims that they can fill cavity up to 4–6 mm at one time [6–9]. Easy and quick filling of BFCs is possible because they have flowable nature by itself or with an aid of ultrasonic device. Regardless of their type, such as bulk fill, nanohybrid, and flowable, flowability can reduce processing time during restoration. To cure specimens of such deeply filled, BFCs must have high translucency to allow the incident light to be reached at the bottom surface. To achieve high translucency, choice of fillers and monomers those have a similar refractive index (refractive index matching) is important [10–12]. Generally, low viscous BFCs [for example, Filtek Bulk Fill (FB), SureFil SDR (SS), and Venus Bulk Fill (VB)] have low filler content to increase flowability, and their filler contents are much lower than those of many flowable resins. However, despite high filler content, SonicFill (SF) achieves flowability through sonic activation, and Tetric N-Ceram Bulk Fill (TB) contains a new initiator to enhance polymerization. Also, BFCs are claimed to have a low shrinkage stress through the inclusion of stress reliever (TB), polymerization modulator (SS), or their own closed ways to lessen high possible stress induced by the massive filling [13, 14].

In a clinical aspect, bulk filling of cavity would be beneficial if compared with 2-mm-thick layering of RBCs in reducing treatment time for cavity restoration, polymerization stress, and improving esthetic quality. Also, due to the reduced contraction stress, reduction of cuspal deflection can be expected [15, 16]. However, the reduced filler content of BFCs for achieving high light transmission can weaken their mechanical properties and decrease load resistance during mastication compared with RBCs which are not allowed to fill the tooth cavity over 2 mm at one time [17, 18]. Since bulk filling itself increases light path length into the deep subsurface and resin volume by the increased cavity depth and each BFCs adopt different strategies for achieving high light transmission and flowability, their complex effects on hardness, polymerization shrinkage, and color may have different trend compared to those of general RBCs. The purpose of the present study was to evaluate microhardness and polymerization shrinkage of BFCs. Also, light attenuation, refractive index, and translucency parameter were evaluated. The null hypotheses to be tested were that (1) BFCs have low microhardness change on the bottom surface compared with that of the top surface and (2) have low polymerization shrinkage compared with the tested RBCs which are usually recommended to fill less than 2-mm thick.

Materials and methods

Bulk-fill composites

In the present study, five different bulk-fill composites (BFCs) [los viscous: Filtek Bulk Fill (FB), SureFil SDR (SS), and Venus Bulk Fill (VB); high viscous: SonicFill (SF) and Tetric N-Ceram Bulk Fill (TB)] and two RBCs [Tetric N-Ceram (TN) and Filtek Z350XT Flowable (ZF)] were used. Compositional details of these resins are listed in Table 1. For light curing, a LED light-curing unit (LCU) [L.E.Demetron (DE), Kerr, Danbury, CT, USA] was used as a light source with 900 mW/cm2 condition.

Filler weight

The filler weight (wt%) of each resin product was determined using standard ash method in addition to the nominal weight which was provided by the manufacturers [19]. Approximately 50 mg of each resin specimen (n = 5) was measured using an analytical balance, light cured, and heated in an electric furnace at 650 °C for 30 min to burn out the organic matrix. The wt% was determined by dividing the weight of original specimen to that of the remaining specimen after heating in furnace.

Photon counts and attenuation coefficient

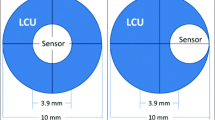

To measure the number of photons, those arriving at the bottom of the tested specimens, specimens (n = 3) of different thicknesses (diameter, 7 mm; thickness, 1, 2, 3, and 4 mm) were prepared, placed over a stage (thickness, 1 mm) which has a hole (diameter, 6 mm) on it. Light was irradiated from above the hole. The detector was placed under the hole at a fixed position to measure the photons with consistency. The photodiode detector (M1420, EG&G, PURC, Princeton, NJ, USA) was connected to a spectrometer (SpectroPro-500, Acton Research, Acton, MA, USA).

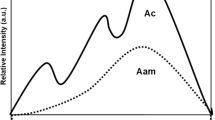

To evaluate how the light intensity decreases its intensity within the specimen, the attenuation coefficient (AC, mm−1) was estimated using the measured photons at different thicknesses based on Beer-Lambert law (I = I 0·e − α·z, where I 0 is the initial light intensity, it is the measure of photons in the absence of specimen, α is the attenuation coefficient, and z is the specimen thickness at the time of measurement.)

Refractive index

The refractive index of the specimens (n = 5) was measured using an Abbe-type refractometer (NAR-1T; ATAGO, Tokyo, Japan). For the measurement, a tiny amount of resin was sandwiched between two thin glass slides to be approximately 50 μm thick, placed below the mold of 1, 2, 3, and 4 mm thick, and light was irradiated from the top of the mold to the bottom direction for 40 s. The light-cured specimens were stored for 24 h in a 37 °C dry and dark chamber. One drop of high refractive index interfacial contact agent, monobromonaphthalen (nD = 1.64 where nD is the refractive index at the D line wavelength, the center of the yellow sodium double emission at 589 nm), was added on the specimen, and then the milky white refractor (nD = 1.6199) was placed over it to enhance diffuse scattering of the cured slabs. Diffuse scattering at the front surface is necessary to improve the accuracy of the measurement. Refractive index readings were performed at room temperature (23 ± 1.0 °C) unless otherwise mentioned. The system used in this study gives sodium D-line (589 nm) light.

Microhardness test

To measure the surface microhardness (n = 12 for each condition) of specimens, each resin was filled into ring-type molds (internal diameter, 7 mm; thickness, 1, 2, 3, 4 mm). The top surface of the resin-filled mold was covered with a thin glass slide, pressed firmly, and light cured for 40 s by contacting the light guide to the top surface of the glass slide at an environmental temperature of 23 ± 1 °C. Cured specimen was removed from mold and stored for 24 h in a 37 °C dry and dark chamber. The microhardness of top (z = 0) and each surfaces (z = 1, 2, 3, and 4 mm) of each specimen was measured using a Vickers hardness tester (MVK-H1, Akashi, Tokyo, Japan). Measurements were performed by determining the sizes of the microindentations generated on the specimen surface using a 200-g load and 10-s dwell time.

Polymerization shrinkage

The polymerization shrinkage (percent) of the specimens during and after the light-curing process was measured (n = 5 for each product) using a linometer (RB 404, R& B Inc., Daejon, Korea). A resin of cylinder shape (diameter, 4 mm; thickness, 2 and 4 mm) was placed over the aluminum disk (the specimen stage of the linometer), and its top surface was secured using a glass slide. Since resin can flow downward, placing resin over the aluminum disk was performed as quickly as possible through the repeated practice. The end of the light guide was placed in contact with the glass slide. Before light curing, the initial position (the distance between the aluminum disk and inductive shrinkage sensor) of the aluminum disk was set to zero and then the light from the LCU was irradiated for 40 s. The amount of disk displacement from the sensor that occurred due to polymerization shrinkage was measured automatically for 130 s using the sensor. The resolution and measurement range of the sensor were 0.1 and 100 μm, respectively.

Color evaluation

To make disk-type specimens, ring-type molds (inner diameter, 8 mm; thickness, 1, 2, 3, and 4 mm) were placed over a glass slide, filled the mold with resin, covered the top surface with a glass slide, pressed firmly to flatten the surfaces, then light cured for 40 s. The cured specimen was then removed from the mold and stored for 24 h in a 37 °C dry and dark chamber. Colors of specimens (n = 7) were measured in a reflectance (%R) mode, and CIEL * a * b * color coordinates were evaluated from the obtained %R values. Here, L * represents the degree of gray, and it corresponds to a lightness. Parameter a * represents the red–green axis, whereas b * is a parameter for the blue–yellow axis. The translucency parameter (TP) was obtained using the formula.

Where subscript B refers to color coordinates obtained using a black background (L * = 2.93, a * = 0.38, and b * = −0.34) and W refers to those obtained using a white background (L * = 93.26, a * = −0.61, and b * = 2.09).

Statistical analysis

The results of polymerization shrinkage and TP were analyzed using one-way ANOVA where the factor was resin product. A post hoc Tukey test was used to determine significant differences between individual groups. All tests were analyzed at p < 0.05.

Results

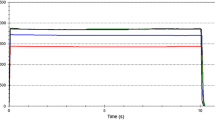

The detected photons from the specimens of different thicknesses were shown in Fig. 1. The number of the detected photons decreased exponentially as specimen thickens. Table 2 shows the estimated attenuation coefficients (AC, mm−1) of different specimens using the curve fit of photon counts by assuming exponential decrease. Among the specimens, VB and SF showed the lowest and highest AC values (−0.88 and −1.90), respectively.

Figure 2 shows the refractive index of specimens at different thicknesses. Specimens showed a linearly decreasing (R > 0.87) refractive index values as specimen thickens. Among the specimens, ZF showed the highest refractive index change (0.55 %) if compared values of the top and bottom surfaces.

Figure 3 and Table 3 show the microhardness (Hv) of specimens at different thicknesses. Among the specimens, ZF and VB showed the highest (71.5 %) and lowest (11.5 %) microhardness decrease if compared values of the top and bottom surfaces. BFCs showed less microhardness decrease (11.5–48.8 %) compared with TN and ZF (57.3 and 71.5 %).

Table 4 shows the polymerization shrinkage (percent) of specimens for two different thicknesses. For 2-mm-thick case, FB and TN showed the highest (1.46 %) and lowest (0.78 %) shrinkage, respectively. For 4-mm-thick case, VB and TN showed the highest (1.16 %) and lowest (0.42 %) shrinkage, respectively. Among BFCs, FB, SS, and VB showed greater shrinkage than ZF.

Table 5 showed the CIEL * a * b * values of the specimens for different backgrounds. Among the specimens, despite their A3 shade, FB and VB showed much lower lightness (L *) values (39.1 and 43.9) than the others (>53.9) regardless of background. The estimated TP values are showed in Fig. 4. Among the specimens, VB showed the highest TP (8.89) and SF and TN showed similarly the lowest TP (0.37 and 0.36), respectively.

Discussion

From the obtained data, the first hypothesis that BFCs have low microhardness change on the bottom surface compared with that of the top surface is acceptable. However, the second hypothesis that BFCs have low polymerization shrinkage values compared with that of the tested RBCs is partially acceptable because some BFCs have much higher shrinkage values than that of RBCs.

The tested BFCs are claimed by the manufacturers that they can bulk-fill the cavity to the depth of 4–6 mm at one time without extended light-curing time, but with normal light intensity condition, such high bulk-fill nature would be attributable to high transmission of incident light compared with that of RBCs. Low light attenuation can be related with high light transmission. According to the obtained data (Table 2), BFCs showed less light attenuation (0.88–1.52) than RBCs (1.61 and 1.76), so high transmission in BFCs seems natural. Light attenuation within the specimen is the result of complicated scattering and absorption process by constituents, such as monomer, pigments, and fillers [20–22]. According to the formula, light intensity by Raleigh scattering within the medium relies on the volume fraction of fillers, filler size, and refractive index of resin matrix and fillers. It also inversely relies on the wavelength of the incident light [23, 24]. So, as filler volume and size increase, the resultant light transmission will be changed (increased or decreased) as well. In the present study, attenuation coefficient (AC) was linearly correlated (R = 0.73) with filler volume of the tested resin products. So as specimen volume decreases, less light attenuation (low attenuation coefficient) can be probable due to the decreased blocking of incident light by less bulky fillers [20, 25]. The tested BFCs have two different viscosities based on the manufacturers’ claim: low and high. Except the inclusion of TEGDMA, diluent, filler content can be involved in controlling viscosity as well. FB, SS, and VB are claimed to be of low viscosity. Actually, their filler volumes are less than those of other BFCs (SF and TB) and RBCs (TN and ZF).

Refractive index differently changed depending on resin product as specimen thickens. Basically, fraction of refractive index will inconsistently change depending on the combination of monomer and filler because the refractive index of typical monomers and fillers are different (Bis-GMA, 1.551; TEGMA, 1.460; UDMA, 1.484; Silica, 1.463; Barium, 1.530; Strontium, 1.510) [10, 26]. Furthermore, resin matrix of each resin products are complex mixture of these monomers and fillers; the resultant refractive index cannot be simply quantified. Also, as specimen thickens, refractive index in subsurface decreases due to incomplete polymerization and subsequently by less shrinkage [27]. Since the refractive index is a measure of the speed of light in the medium, refractive index on the top surface is high due to much condensation by high light intensity, but low on the bottom surface due to less condensation by reduced light intensity. Among the BFCs, VB and TB showed less than 0.13 % and FB, SS, and SF showed 0.22–0.33 % refractive index change between values of their top and bottom surfaces. These values are much lower than that by ZF (flowable resin, 0.55 %), but not lower than that by TN (nanocomposite, 0.17 %).

According to the results, some BFCs (FB, SS, and VB) have lower top-surface microhardness values compared with ZF (26.0–27.8 Hv vs. 45.6 Hv) despite their higher filler weight (59.7–66.1 % vs. 58.7 %). A report by Zorzin et al. was similar in trend to those of the present study even though experimental conditions in two studies are a little different [28]. Generally, microhardness has high correlation with filler content, and such correlation was found in the present study for vol% and wt% (R > 0.72), but these BFCs have contradictory result despite high correlation. On the bottom surface (z = 4 mm), these BFCs have slightly higher microhardness values than ZF (14.7–24.6 Hv vs. 13.0 Hv). Slightly higher microhardness values on the bottom surface would be due to higher filler weight but less light attenuation due to lower filler volume.

Polymerization shrinkage occurs as a result of the shortening of molecular distance by the changed governing molecular bond from van der Waals to covalent and causes many clinically unwanted problems [1–3]. Since shrinkage occurs in the course of monomer conversion to polymer, the lesser the filler content, the higher the resultant shrinkage will be probable [29, 30]. In the present study, filler content has correlation with polymerization shrinkage (R > −0.78 for 2- and 4-mm-thick specimens). High shrinkage of FB, SS, and VB and low shrinkage of SF and TB in BFCs regardless of specimen thickness would be related with low and high filler content, respectively. These results are also similar in trend to the study by Zorzin et al. [28]. Also, their values are comparable or slightly higher than the values of ZF and TN, respectively. After all, some products can increase light transmission by lowering filler content, but it adversely can increase polymerization shrinkage much further than that of flowable resin.

The tested BFCs have higher TP values (0.37–8.89) compared with that of TN and ZF. However, except VB, TP difference among BFCs was not high (0.37–1.89). For the tested specimens, filler volume has a negative linear correlation with TP (R = 0.77), so specimens of lower filler volume (FB, SS, and VB) have a significantly (p < 0.001) higher TP than SF and TB whose filler volumes are greater than those of FB, SS, and VB [31]. A linear correlation of TP with attenuation coefficient (R = −0.83) and polymerization shrinkage (R = 0.79 for 4-mm-thick specimens) seems probable.

Conclusions

The tested BFCs have a significantly higher light transmission compared with that of the tested RBCs. However, since these products have apparently different filler contents, some of them have much lower top-surface microhardness or higher polymerization shrinkage compared with those of RBCs even though refractive index and microhardness change of BFCs on the bottom surface was not high due to low light attenuation. Filling over 4 mm can be convenient and time-saving, but due to inconsistent outcomes by the different ways for increasing transmission of light in BFCs, a careful selection of BFC would be asked for the reliable and durable restoration.

References

Kemp-Scholte CM, Davidson CL (1988) Marginal sealing of curing contraction gaps in class V composite resin restorations. J Dent Res 67:841–845

Lai JH, Johnson AE (1993) Measuring polymerization shrinkage of photo-activated restorative materials by a water-filled dilatometer. Dent Mater 9:139–143

Davidson CL, Feilzer AJ (1997) Polymerization shrinkage and polymerization shrinkage stress in polymer-based restoratives. J Dent 25:435–440

Ferracane JL (2011) Resin composite-state of the art. Dent Mater 27:29–38

Park J, Chang J, Ferracane J, Lee IB (2008) How should composite be layered to reduce shrinkage stress: incremental or bulk filling? Dent Mater 24:1501–1505

Benetti AR, Havndrup-Pedersen C, Honoré D, Pedersen MK, Pallesen U (2015) Bulk-fill resin composites: polymerization contraction, depth of cure, and gap formation. Oper Dent 40:190–200

Ilie N, Stark K (2015) Effect of different curing protocols on the mechanical properties of low-viscosity bulk-fill composites. Clin Oral Investig 19:271–279

Ilie N, Stark K (2014) Curing behaviour of high-viscosity bulk-fill composites. J Dent 42:977–985

Van Ende A, De Munck J, Van Landuyt KL, Poitevin A, Peumans M, Van Meerbeek B (2013) Bulk-filling of high C-factor posterior cavities: effect on adhesion to cavity-bottom dentin. Dent Mater 29:269–277

Shortall AC, Palin WM, Burtscher P (2008) Refractive index mismatch and monomer reactivity influence composite curing depth. J Dent Res 87:84–88

Fujita K, Nishiyama N, Nemoto K, Okada T, Ikemi T (2005) Effect of base monomer’s refractive index on curing depth and polymerization conversion of photo-cured resin composites. Dent Mater J 24:403–408

Taira M, Suzuki H, Toyooka H, Yamaki M (1994) Refractive index of inorganic fillers in seven visible-light-cured composite resins. J Mater Sci Lett 13:68–70

Ilie N, Bucuta S, Draenert M (2013) Bulk-fill resin-based composites: an in vitro assessment of their mechanical performance. Oper Dent 38:618–625

Moszner N, Fischer UK, Ganster B, Liska R, Rheinberger V (2008) Benzoyl germanium derivatives as novel visible light photoinitiators for dental materials. Dent Mater 24:901–907

Behery H, El-Mowafy O, El-Badrawy W, Saleh B, Nabih S (2016) Cuspal deflection of premolars restored with bulk-fill composite resins. J Esthet Restor Dent 28:122–130

Moorthy A, Hogg CH, Dowling AH, Grufferty BF, Benetti AR, Fleming GJ (2012) Cuspal deflection and microleakage in premolar teeth restored with bulk-fill flowable resin-based composite base materials. J Dent 40:500–505

Rosatto CM, Bicalho AA, Veríssimo C, Bragança GF, Rodrigues MP, Tantbirojn D, Versluis A, Soares CJ (2015) Mechanical properties, shrinkage stress, cuspal strain and fracture resistance of molars restored with bulk-fill composites and incremental filling technique. J Dent 43:1519–1528

Leprince JG, Palin WM, Vanacker J, Sabbagh J, Devaux J, Leloup G (2014) Physico-mechanical characteristics of commercially available bulk-fill composites. J Dent 42:993–1000

Kim KH, Ong JL, Okuno O (2002) The effect of filler loading and morphology on the mechanical properties of contemporary composites. J Prosthet Dent 87:642–649

Arikawa H, Kanie T, Fujii K, Takahashi H, Ban S (2007) Effect of filler properties in composite resins on light transmittance characteristics and color. Dent Mater J 26:38–44

Emami N, Sjodahl M, Soderholm K-JM (2005) How filler properties, filler fraction, sample thickness and light source affect light attenuation in particulate filled resin composites. Dent Mater 21:721–730

Musanje L, Darvell BW (2005) Curing-light attenuation in filled-resin restorative materials. Dent Mater 22:804–817

Watts DC, Cash AJ (1994) Analysis of optical transmission by 400-500 nm visible light into aesthetic dental biomaterials. J Dent 22:112–117

Richerson DW (1982) Modern ceramic engineering. Marcel Dekker, New York

Fujita K, Ikemi T, Nishiyama N (2011) Effects of particle size of silica filler on polymerization conversion in a light-curing resin composite. Dent Mater 27:1079–1085

Hirabayashi S, Hirasawa T (1990) Improvements to light transmittance in light-cured composite resins by the utilisation of low refractive index dimethacrylates. Dent Mater J 9:203–214

Ogunyinka A, Palin WM, Shortall AC, Marquis PM (2007) Photoinitiation chemistry affects light transmission and degree of conversion of curing experimental dental resin composites. Dent Mater 23:807–813

Zorzin J, Maier E, Harre S, Fey T, Belli R, Lohbauer U, Petschelt A, Taschner M (2015) Bulk-fill resin composites: polymerization properties and extended light curing. Dent Mater 31:293–301

Gonçalves F, Kawano Y, Braga RR (2010) Contraction stress related to composite inorganic content. Dent Mater 26:704–709

Miyasaka T, Okamura H (2009) Dimensional change measurements of conventional and flowable composite resins using a laser displacement sensor. Dent Mater J 28:544–551

Salgado VE, Cavalcante LM, Silikas N, Schneider LF (2013) The influence of nanoscale inorganic content over optical and surface properties of model composites. J Dent 41:e45–e53

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

All authors declare that they have no conflict of interest.

Funding

The work has no source of funding to report.

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Informed consent

For this type of study, formal consent is not required.

Rights and permissions

About this article

Cite this article

Son, SA., Park, JK., Seo, DG. et al. How light attenuation and filler content affect the microhardness and polymerization shrinkage and translucency of bulk-fill composites?. Clin Oral Invest 21, 559–565 (2017). https://doi.org/10.1007/s00784-016-1920-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00784-016-1920-2