Abstract

Objectives

To evaluate the marginal and internal fit of CAD/CAM-generated frameworks for 4-unit, fixed dental prostheses (FDPs) from zirconia (Z) and cobalt-chromium alloy (C) made with conventional (CI) and digital impressions (DI).

Materials and methods

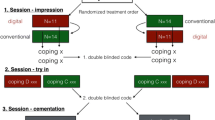

A titanium model was digitized with an intraoral scanner (DI, LAVA™ C.O.S.; 3M ESPE; Seefeld, Germany; n = 12). Additionally, 12 conventional impressions were taken, and referring plaster casts were digitized by a laboratory-scanner (CI, LAVA™ Scan ST; 3M ESPE; n = 12). Frameworks were fabricated (3M ESPE) from cobalt-chromium (DI-C, n = 12; CI-C, n = 12) and zirconia (DI-Z, n = 12; CI-Z, n = 12) from the same datasets. A replica technique was applied to measure the accuracy. The Mann–Whitney U statistical test was applied to detect statistical differences between each material and methodology groups in terms of fit.

Results

Frameworks from DI-C (median 19.07 μm) showed significantly better marginal fit than CI-C (median 64.64 μm, p < 0.001). Frameworks from DI-Z (median 52.50 μm) showed significantly better marginal fit than CI-Z (median 72.94 μm, p = 0.001). Additionally, frameworks from DI-C showed a significantly better marginal fit than DI-Z (p < 0.001).

Conclusions

CI and DI led to a clinically acceptable marginal fit of 4-unit FDPs from cobalt-chromium and zirconia. DI leads to better marginal fit of the cobalt-chromium frameworks; however, no effect on zirconia was found.

Clinical relevance

The results indicate that DI is suitable for fabricating 4-unit, cobalt-chromium and zirconia frameworks with regard to fit requirements.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Conventional impression techniques and impression materials, such as hydrocolloids, polyether, and vinyl polysiloxane, exhibit adequate stability and precision and, therefore, define the current standard in general dental practice [1, 2]. However, some drawbacks are associated with this well-known procedure like the influence of the impregnated debris, tearing of the impression material, and indistinct preparation margins, which might affect the quality of conventional impressions [3]. Consequently, low-quality impressions are inadequate for the manufacture of precise, well-fitting, indirect restorations. However, the internal and marginal fit influences the longevity of indirect restorations and is a prerequisite for clinical success [4]. Poor marginal fit of dental restorations increases plaque retention and changes the distribution of the microflora. This leads to the occurrence of microleakage, secondary caries, and endodontic inflammation, and can induce the onset of periodontal diseases [5–7]. It has also been demonstrated that an excessively thick cement space is capable of initiating cracks in the veneering porcelain in zirconia crowns [8]. Sizable marginal discrepancies can expose the luting material to the oral environment, leading to a more aggressive rate of cement dissolution, caused by oral fluids and chemo-mechanical forces [9]. Against this background and with regards to the current literature, there seems to be a consensus that marginal openings less than 120 μm are clinically acceptable [9–11].

It could be shown that the fit of the restoration is dependent on the quality of the impression method, on the subsequent workflow and the fabrication method of the indirect restoration, and also on the applied restoration materials [12]. With the direct digitalisation of the clinical situation using intraoral scanners, an alternative to conventional impression-taking has been available for a few years. Several advantages associated with this new procedure have been described; however, there is scant data regarding the performance of devices and the capability of the connected digital workflows, including computer-aided design (CAD) and computer-aided manufacturing (CAM) processes [13]. The conventional workflow, based on conventional impressions, plaster casts, and indirect digitalisation in the dental lab, which is the current standard for CAD/CAM restorations, has to serve as a reference.

The Lava™ Chairside Oral Scanner (Lava™ C.O.S., 3M ESPE, Seefeld, Germany) system is one of several intraoral scanning devices that has shown a good performance in a previous study [14]. This intraoral scanner is based on the principle of active wavefront sampling, which generates the 3D information from a single-lens imaging system by measuring the depth based on the defocus of the primary optical system [15]. It has been shown that all-ceramic crowns fabricated by Lava™ C.O.S. demonstrate better marginal fit when compared to all-ceramic crowns fabricated on conventional impressions [16]. Furthermore, Almeida et al. [17] described that the marginal fit of 4-unit, zirconia FPDs, fabricated after digital impression using the Lava™ C.O.S., was similar to the FPDs fabricated after conventional impression. Assuming that the data after direct digitalization are more accurate than data after indirect digitalization [14], the question arises why more accurate datasets do not lead to better-fitting zirconia restorations. One explanation could be the sintering process, as zirconia restorations are mostly milled in a pre-sintered stage, which means that the sintering process might influence the accuracy of fit of the resulting restorations [18]. On the other hand, milled metal restorations (e.g., cobalt-chromium alloy) do not need further sintering processes.

To date, no studies have been published concerning the marginal and internal fit of 4-unit, fixed dental prostheses (FDP) made of cobalt-chromium alloy (CoCr) and zirconia generated from conventional and digital impressions using the Lava™ C.O.S. scanner.

The aim of this in vitro study was to assess the marginal and internal fit of CAD/CAM-generated frameworks of 4-unit FDPs from indirect digitalization (Lava™ ScanST, 3M ESPE) after conventional impression and direct digitalization by digital impression using an intraoral scanning system (Lava™ C.O.S.). Therefore, frameworks from cobalt-chromium alloy and from zirconia fabricated from the same datasets were compared to evaluate the influence of different materials and impression method on the fit of the resulting restoration. The null hypotheses were that (1) the method of impression (conventional = CI or digital = DI) and (2) the material (CoCr alloy = C or zirconia = Z) used for manufacturing the restoration does not influence the marginal fit of CAD/CAM-fabricated frameworks of 4-unit FDPs.

Materials and methods

In this study, a titanium model (Basic Study Model, Kavo Dental GmbH, Biberach, Germany) with a prepared premolar (FDI 14) and molar (FDI 17) representing a 4-unit FDP was used as the basic model. Anchor teeth presented an occlusal reduction of 2.0 mm, an axial reduction of 1.5 mm and a 360° chamfer with a convergence angle of 6° for the abutment teeth (Fig. 1).

Once the preparations had been powdered with titanium dioxide particles (Lava™ Powder;, 3 M ESPE,), the model was scanned with the Lava™ C.O.S. intraoral scanner (3M ESPE; software version 3.0.2, n = 12). Prior to every scan, the base model was cleaned, and powdering was repeated. Scanned data were saved, and complementary scans of the lower jaw were performed so that the software could perform occlusion registration. The 12 datasets were electronically submitted to the authorized laboratory for digital die sectioning and the detection of margins. From each dataset, two frameworks were designed using CAD software (Lava™ Design, 3M ESPE), resulting in 12 frameworks from cobalt-chromium alloy (DI-C) and 12 from zirconia (DI-Z). CAD settings are given in Table 1.

Twelve conventional impressions with a polyether (Impregum Penta, 3M ESPE) of the basic model were made using custom trays. According to the manufacturer, the impression material requires 6 min after starting to mix to be fully set. Due to the controlled room temperature of this in vitro study, the setting time was extended about 2 min to a total time of 8 min. Twenty-four hours later, the impressions were poured in a Class IV stone (Fujirock white, GC Europe). Forty-eight hours after cast fabrication, the 12 plaster casts were digitized using an optical scanning device (Lava™ Scan ST, 3 M ESPE). Subsequently, the design of the 24 frameworks was performed (Lava™ Design): 12 for the production of frameworks from cobalt-chromium alloy (CI-C) and 12 for the production from zirconia (CI-Z).

The complete CAM process of the 48 frameworks took place in a fabrication centre (3M ESPE) using a 5-axes milling machine (Lava™ CNC 500, 3M ESPE). Zirconia frameworks were sintered in a sintering furnace (Lava™ Furnace 200, 3M ESPE) at a temperature of 1500 °C to full density.

To analyze the marginal and internal fit of the frameworks, the replica-technique was applied (Figs. 1 and 2) [19, 20]. No manual adjustments were performed on the frameworks. The retainers were filled with light body silicon (Virtual Light Body, Ivoclar Vivadent, Schaan, Liechtenstein, LOT: NL4015) and were placed onto the abutment teeth of the titanium model with finger pressure. After the light body silicon had set, the frameworks were removed with the thin silicon remaining on the abutment teeth. Subsequently, a heavy-body material (Virtual Putty, Ivoclar Vivadent, LOT: 4109) was circumferentially put onto the thin silicon. After setting the heavy-body material, the replica specimen was removed from the titanium base model. The replicas were segmented with a razor blade at the centre of the premolar and then at the centre of the molar in oro-vestibular and mesio-distal directions.

Measurement of the space between the abutment teeth and the frameworks. a Single image of the replica after being merged together by the software from eight single pictures. b Greyscale image of the original image as the basis for analysis. c Marked points on the inner and outer surface of the low viscosity silicone. d Perpendicular lines are dropped (in red) to measure the gap between inner and outer surface representing the inner and marginal gap (μm). e Image after measuring gap width

The replicas were examined at ×50 magnification (ocular ×10/23, lens ×5/0.13) under a reflected light microscope (Axioscope 2, Zeiss, Oberkochen, Germany). A picture of every cross-sectional specimen was taken with a digital camera (D90, Nikon, Tokyo, Japan) attached to the microscope. Eight to ten digital images were made of each cross section, which were further merged by image processing software (Adobe Photoshop CS, Adobe Systems Inc., San Jose, CA, USA), so that one single image for one cross-section could be obtained (Fig. 2a). Then, the completed colour image was converted into greyscale (Fig. 2b).

Quantification of the marginal and internal fit of the frameworks was conducted with imaging data software (Optimas 6.5, Media Cybernetics, Silver Spring, MD, USA). The images were imported, and a series of points was marked at the outer boundary between light and heavy body silicone and at the inner boundary between light body silicone and abutment tooth. The length of the perpendicular measurements represented the internal and marginal gap. In every plane, about 5000 perpendiculars were measured (Fig. 2c–e). For each framework, the following four measurement locations were analyzed: (1) marginal opening (MO), (2) chamfer area (CA), (3) axial wall (AW) and (4) occlusal area (OC) (Fig. 3). In total, 1536 measurements were performed on the 48 frameworks.

Descriptive statistics (mean, standard deviation, minimum, median, maximum, and the 95 % confidence interval) were computed. Kolmogorov-Smirnov and Shapiro-Wilk tests were applied to test data in normal distribution within the groups. To detect statistical influence of the type of impression and the restorative material, the Mann–Whitney U test was applied at all four measurement locations. For data analysis, the Statistical Package for the Social Sciences Version 20 (SPSS Inc., Chicago, US) was used. The level of significance was set at 5 % (p < 0.05).

Results

Kolmogorov-Smirnov and Shapiro-Wilk tests revealed that the values were not normally distributed. Therefore, minimum, median and maximum together with mean, standard deviation and 95 % confidence interval are given in Table 2. Boxplots for the single tested groups are depicted in Figs. 4 and 5.

Impact of impression method

Within one framework material, different impression methods resulted in different distances between the manufactured frameworks and the titanium model. For frameworks of CoCr-alloy, DI-C showed significantly lower values than CI-C at all measurement locations: MO (p < 0.001), CA (p < 0.001), AW (p < 0.001) and OC (p < 0.001). For zirconia frameworks, DI-Z also showed significantly lower distances than CI-Z at all measurement locations: MO (p = 0.001), CA (p < 0.001), AW (p = 0.001) and OC (p < 0.001).

Impact of restorative material

For FDPs after digital impression, DI-C showed significantly lower values than DI-Z at MO (p < 0.001), CA (p < 0.001) and AW (p = 0.037), while no significant differences were found for OC (p = 0.868). Concerning the conventional impression, CI-C showed only significant lower values than CI-Z at CA (p = 0.016). For MO (p = 0.199), AW (p = 0.234) and OC (p = 0.569), no significant differences could be found.

Discussion

With respect to the requirements of marginal fit, the gap widths of all groups showed clinically satisfactory results [9–11]. Nevertheless, frameworks milled from CoCr after DI showed a better marginal fit than frameworks fabricated from CoCr after CI and frameworks from zirconia after DI. Therefore, both null hypotheses have to be rejected.

In the present study, the marginal and internal fits were investigated using the cross-sectioning replica-technique with silicone impression materials. Based on the benefit of comparing different frameworks on the same basic model with this non-destructive and non-invasive method, and because this method can be applied both in vivo and in vitro, the authors selected this technique for the present study [16, 19, 20]. Additionally, the measurement method used captured approximately 6000 values (perpendiculars) per cross-sectional specimen, which provided a reliable dataset for acquiring representative values for each measurement location [4]. Also, for the equal treatment of all tested groups, manual adjustments of the frameworks were abandoned to avoid bias of the results by human influence and to guarantee comparability of the different workflows.

Frameworks from CoCr and zirconia showed better marginal and internal fit after digital impressions compared to frameworks after conventional impressions. Further on, frameworks from group DI-C showed a better marginal fit than ones from group DI-Z, despite being fabricated on the same datasets. The different fabrication mode of CoCr and zirconia and the tool path of the milling machines might explain these differences. After milling, the semi-sintered zirconia blanks applied in the present study had to be sintered to achieve final density and maximum strength of the material. This sintering process is characterized by a sintering shrinkage of about 20–30 %, which has to be compensated for in the milling procedure. The extent of the shrinkage exerts an extra challenge to the software that has to accurately calculate the milling of a 20–30 % enlarged framework that will shrink precisely to the required dimension during sintering [21]. This procedure might negatively influence the final dimension of the restoration [22]. On the other hand, CoCr blanks are milled in their original size without a sintering process.

Regarding the fit of restorations on their abutments, further enhancements might be clinically achieved by adjusting the design- and milling parameters, optimizing the sintering process, and, finally, through manual adaptation by the dental professional. Future software-applications with superimposition-algorithms might help to identify the interfering areas to be reduced in a standardized manner.

Almeida et al. [17] compared the marginal fit of 4-unit, zirconia frameworks produced on the basis of digital impressions (Lava™ C.O.S., 3M ESPE) against the fit after conventional impressions, plaster cast and scanning with a laboratory-based optical scanning device (Lava™ Scan ST, 3M ESPE). This resulted in no significant differences between the investigated systems (Lava™ C.O.S. mean, 63.96 μm; Lava™ Scan ST mean, 65.33 μm). In the present study, zirconia FDPs after DI presented comparable results (mean, 62.85 μm; median, 52.50 μm), whereas for the zirconia FDPs after conventional impressions, wider marginal gaps (mean, 86.51 μm; median, 72.94 μm) could be observed. This might be explained by the complex, error-prone and person-dependent process of conventional impression taking, even under in vitro conditions.

Another study investigated the marginal fit of 3-unit, CoCr frameworks produced on the basis of digital impressions by an intraoral scanner (iTero, Align Technology, Carlstadt, US) and conventional impressions with an optical scanning device (Straumann CARES Scanner, Straumann, Basel, Switzerland). In that case, no significant differences were seen between the investigated systems (iTero mean, 142 μm; Straumann CARES mean, 147 μm) [23]. Keul et al. [12] investigated the marginal opening of 4-unit CoCr and zirconia frameworks also using the iTero and Straumann CARES system: CoCr frameworks from digital impressions showed significantly lower mean values for marginal fit than ones from conventional impressions (digital impression mean, 56.90 μm; conventional impression mean, 90.64 μm; p < 0.001). On the other hand, zirconia frameworks showed no statistically significant difference between digital impressions and conventional impressions (digital impression mean, 127.23 μm; conventional impression mean, 141.08 μm; p = 0.481) [12]. This tendency in the results seems to be comparable to the results of the present study, although different scanning devices and production workflows have been applied. This supports the assumption that the applied scanning system, the choice of material and the fine-tuning of the interfaces of the fabrication workflow is decisive for the quality and fit of the final restoration.

This trend goes in line with the study results of van de Meer et al. [24], who compared the accuracy of the three intraoral scanners CEREC bluecam (Sirona Dental System GmbH, Bensheim, Germany), iTero (Cadent) and Lava™ C.O.S. (3M ESPE) [22]. The results indicated that the Lava™ C.O.S. resulted in the smallest and most consistent deviations. Also, the available data indicate that there might be a higher level of reproducibility of digital impressions using the Lava™ C.O.S. than with the iTero.

This in vitro study enabled a comparison of the technical potential of direct and indirect digitalization, including their respective workflows. Nevertheless, the results of the present study might not reflect the reality of in vivo conditions, as more influential factors might have an impact on the scanning accuracy. Therefore, further clinical studies are necessary to determine the effect of the digital and conventional impression in vivo under various clinical conditions. Furthermore, it has to be mentioned, that the evaluated intraoral scanning system is no longer produced, as it was replaced by a system using a similar technology from the same distributor. However, the investigated system is still widely utilized in clinical service, and it can be assumed that the successor system performs equally well or even better. Nevertheless, this has to be proven in further studies.

Conclusions

Within the limitations of this study the following conclusions can be drawn:

-

1.

Frameworks of cobalt-chromium alloy and zirconia fabricated from digital and conventional impressions showed a clinically acceptable marginal fit.

-

2.

Frameworks milled from cobalt-chromium alloy after digital impressions showed a significantly better marginal fit than after conventional impressions.

-

3.

The marginal fit from cobalt-chromium alloy frameworks after digital impressions showed significantly lower mean values than zirconia frameworks after digital impressions.

References

Hondrum SO (2001) Changes in properties of non-aqueous elastomeric impression materials after storage of components. J Prosthet Dent 85:73-81.

Thongthammachat S, Moore BK, Barco MT 2nd, Hovijitra S, Brown DT, Andres CJ (2002) Dimensional accuracy of dental casts: influence of tray material, impression material, and time. J Prosthodont 11:98-108.

Wassell RW, Barker D, Walls AW (2002) Crowns and other extra-coronal restorations: impression materials and technique. Br Dent J 192:679–84, 687-690.

Beuer F, Naumann M, Gernet W (2009) Precision of fit: zirconiathree-unit fixed dental prostheses. Clin Oral Invest 13:343-349.

Reich S, Wichmann M, Nkenke E, Proeschel P (2005) Clinical fit of all-ceramic three-unit fixed partial dentures, generated with three different CAD/CAM systems. Eur J Oral Sci 113:174-179.

Reich S, Kappe K, Teschner H, Schimitt J (2008) Clinical fit of four-unit zirconia posterior fixed dental prostheses. Eur J Oral Sci 116:579-584.

Kohorst P, Brinkmann H, Li J, Borchers L, Stiesch M (2009) Marginal accuracy of four-unit zirconia fixed dental prostheses fabricated using different computer-aided manufacturing systems. Eur J Oral Sci 117:319-325.

Rekow D, Thompson VP (2005) Near-surface damage—a persistent problem in crowns obtained by computer-aided design and manufacturing. Proc Inst Mech Eng 219:233-243.

Beschinidt SM, Strub JR (1999) Evaluation of the marginal accuracy of different all-ceramic crown systems after simulation in the artificial mouth. J Oral Rehab 26:582-593.

Sulaiman F, Chai J, Jameson LM, Wozniak WT (1997) A comparison of the marginal fit of In-Ceram, IPS Empress and Procera crowns. Int J Prosthodont 10:478-484.

Bader JD, Rozier RG, McFall WT Jr, Ramsey DL (1991) Effect of crowns margins on periodontal conditions in regularly attending patients. J Prosthet Dent 65:75-79.

Keul C, Stawarczyk B, Erdelt KJ, Beuer F, Edelhoff D, Güth JF (2014) Fit of 4-unit FDPs made of zirconia and CoCr-alloy after chairside and labside digitalisation-a laboratory study. Dent Mater 30:400-407.

Tamim H, Skjerven H, Ekfeldt A, Rønold HJ (2014) Clinical evaluation of CAD/CAM metal-ceramic posterior crowns fabricated from digital impressions. Int J Prothodont 27:331-337.

Güth JF, Keul C, Stimmelmayr M, Beuer F, Edelhoff D (2013) Accuracy of digital models obtained by direct and indirect data capturing. Clin Oral Investig 17:1201-1208.

3M Espe; Lava™ Chairside Oral Scanner C.O.S. Technical Datasheet. 3M ESPE (2009). Accessed 8 August 2014 from: http://multimedia.3m.com/mws/media/632323O/lava-cos-technical-data-sheet.pdf

Syrek A, Reich G, Ranftl D, Klein C, Cerny B, Brodesser J (2010) Clinical evaluation of all-ceramic crowns fabricated from digital impressions based on the principle of active wavefront sampling. J Dent 38:553-559.

Almeida E, Silva JS, Erdelt K, Edelhoff D, Araújo E, Stimmelmayr M, Vieira LC, Güth JF (2014) Marginal and internal fit of four-unit zirconia fixed dental prostheses based on digital and conventional impression techniques. Clin Oral Invest 18:515-523.

Beuer F, Schweiger J, Edelhoff D (2008) Digital dentistry: an overview of recent developments for CAD/CAM generated restorations. Br Dent J 204:505-511.

Molin M, Karlsson S. (1993) The fit of gold inlays and three ceramic inlay systems. A clinical in vitro study. Acta Odontol Scand 51:201-206.

Boening KW, Wolf BH, Schmidt AE, Kästner K, Walter MH (2000) Clinical fit of Procera All-Ceram crowns. J Prosthet Dent 84:419–424.

Kunii J, Hotta Y, Tamaki Y, Ozawa A, Kobayashi Y, Fujishima A, Miyazaki T, Fujiwara T (2007) Effect of sintering on the marginal and internal fit of CAD/CAM-fabricated zirconia frameworks. Dent Mater J 26:820-826.

Reich S, Wichmann M, Nkenke E, Proeschel P (2005) Clinical fit of all ceramic three-unit fixed partial dentures, generated with three different CAD/CAM systems. Eur J Oral Sci 113:174-179.

Svanborg P, Skjerven H, Carlsson P, Eliasson A, Karlsson S, Ortorp A (2014) Marginal and internal fit of cobalt-chromium fixed dental prostheses generated from digital and conventional impressions. Int J Dent 2014:1-9. doi: 10.1155/2014/534382

van der Meer WJ, Andriessen FS, Wismeijer D, Ren Y (2012) Application of intra-oral dental scanners in the digital workflow of implantology. PLoS One 7:e43312.

Conflict of interest

The authors declare that they have no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ueda, K., Beuer, F., Stimmelmayr, M. et al. Fit of 4-unit FDPs from CoCr and zirconia after conventional and digital impressions. Clin Oral Invest 20, 283–289 (2016). https://doi.org/10.1007/s00784-015-1513-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00784-015-1513-5