Abstract

α-Quaternary α-ethynyl α-amino acids are an important class of non-proteinogenic amino acids that play an important role in the development of peptides and peptidomimetics as therapeutic agents and in the inhibition of enzyme activities. This review provides an overview of the literature concerning synthesis and applications of α-quaternary α-ethynyl α-amino acids covering the period from 1977 to 2015.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Amino acids and their derivatives play a central role in the design of life. The relevance of the 20 proteinogenic l-amino acids as building blocks in peptides and proteins is self-evident, but the class of quaternary α-amino acids also called α,α-disubstituted amino acids has attracted the interest of organic chemists due to their biological importance. They play a crucial role in the development of peptides and peptidomimetics as therapeutics agents (Avenoza et al. 2001, 2003; Cativiela and Díaz-de-Villegas 1998, 2000, 2007; Hruby et al. 1997; Olma et al. 2012; Sawyer 1997). Thus, quaternary α-amino acid residues such as α-aminoisobutyric acid and isovaline are present in peptaibol and peptaibiotics which constitute a family of peptide antibiotics of fungal origin. Peptaibiotic could destabilize the membrane by formation of pores in the bilayer membrane (Degenkolb et al. 2003, 2006). The additional alkyl substituent could inhibit the free rotation of the peptide backbone leading to unique folding when incorporated into peptides. They can restrict the conformational freedom of the peptides and provide key information concerning the conformation responsible for biological recognition (Tanaka 2007; Venkatraman et al. 2001).

Moreover, peptides containing α,α-disubstituted amino acid residues also tend to have an increased hydrophobicity, as well as an increased stability toward both chemical (O’Connor and Liu 2003; Polinelli et al. 1992) and enzymatic degradations (Almond et al. 1962; Khosla et al. 1981). Therefore, the demand for efficient sources of unusual amino acids useful for the high-throughput synthesis of customized peptides is of crucial interest to date (Hughes 2009).

In this field, unsaturated α-amino acids have turned out to be especially important building blocks for incorporation in the protein structure due to the diverse reactivities of the multiple bonds and their ability to introduce biologically active functionalities (Berkowitz et al. 2006; Rutjes and Schoemaker 1997). These compounds are often used in peptide chemistry to confer β-turn secondary structure to induce new properties (Duggan et al. 2005). Several unsaturated amino acids were used as enzyme inhibitors (Berkowitz et al. 2004; Keith et al. 1975; Metcalf and Jund 1977; Rando 1974, 1984; Tolman and Sedmera 1988), in particular β,γ-unsaturated amino acid derivatives. For example, α-vinyl glycine inhibits pyridoxal phosphate-dependant enzymes (Berkowitz et al. 2006; Danzin et al. 1981; Feng and Kirsch 2000; Maycock et al. 1979; Tendler et al. 1987) and α-ethynyl glycine is a suicide substrate for alanine racemase (Kuroda et al. 1980a, b; Meffre and Le Goffic 1996; Walsh 1979). Some unsaturated amino acids are constituents of antibiotic (Yonezawa et al. 2000) or markers, such as 2-amino-4-hexynoic acid (Sasaki et al. 1988).

Finally, unsaturated amino acids can be functionalized by various chemical processes such as Diels–Alder reactions (Kotha 2003; Kotha and Ghosh 2004), [2 + 2] cycloadditions (Avenoza et al. 2005), and catalytic transformations including hydroformylation (Ojima et al. 1995), metathesis (Biagini et al. 1998; Gardiner et al. 2004; Hassan and Brown 2010; Kaul et al. 2005; Nolen et al. 2003; Rutjes and Schoemaker, 1997), Heck (Collier et al. 2002; Crisp and Gebauer 1996; Gurjar and Talukdar 2002) or Suzuki–Miyaura cross-coupling reactions (Krebs et al. 2004).

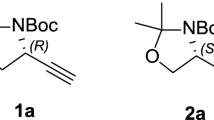

Quaternary α-vinyl amino acids (Fig. 1a) have been reviewed as part of reports concerning quaternary α-amino acids (Berkowitz et al. 2001, 2004; Cativiela and Di´az-de-Villegas 1998, 2007).

This review will provide an overview of different syntheses of quaternary α-ethynyl amino acids (Fig. 1b) covering the literature from 1977 to 2015. Most of the compounds are actually free or (N,O)-protected α-ethynyl derivatives of naturally occurring α-amino acids: phenylglycine, phenylalanine, α-ethynyl-3,4-dihydroxyphenylalanine (α-ethynyl-DOPA), alanine, glutamic acid, and ornithine.

Synthesis of α-ethynyl phenylglycine derivatives

Hata et al. (2011) described the synthesis of 7 which uses the nucleophilic addition of Grignard reagents to iminium salts generated from amino ketene silyl acetals (Fig. 2). Ethyl 2-(dibenzylamino)-2-phenylacetate 2 was prepared in two steps by α-bromination with ethyl 2-phenylacetate 1, N-bromosuccimide (NBS) and benzoyl peroxide followed by the substitution by dibenzylamine. Treatment of 2 with KHMDS followed by silylation led to amino ketene silyl acetal 3 in 48 % yield. The amino ester 7 was prepared in a one pot reaction starting from 3 in 82 % yield. Oxidation of 3 by N,N-dibromodimethylhydantoin (DBDMH) led to intermediate iminium salt 5 (not isolated), which was then immediately reacted with ethynylmagnesium bromide 6 and Lewis acid BF3.OEt2 to give the amino ester 7.

Synthesis of the protected α-ethynylphenylglycine 7 (Hata et al. 2011)

A mechanism was proposed by the authors. The oxidation of amino ketene silyl acetal 3 gave α-bromoester 4, and the BF3 Lewis acid-induced elimination of the bromide ion led to the formation of the iminium salt 5 (Fig. 3).

Synthesis of α-ethynylphenylalanine derivatives

To the best of our knowledge, three methods for the synthesis of racemic α-ethynylphenylalanine backbone (as free or protected form) have been described in the literature.

Casara and Metcalf claimed the synthesis of the fully protected α-ethynylphenylalanine 11 as well as the free amino acid starting from acetylenic glycinate derivative 10 (Casara and Metcalf 1978). Compound 10 is readily prepared by the amidoalkylation of bis-(trimethylsilyl)-acetylene 8 with the 2-chloro-N-carboethoxy glycinate 9, using Friedel–Crafts conditions (Newman 1973; Walton and Waugh 1972). The regioselective alkylation begins by deprotonation of 10 with an excess of lithium diisopropylamide in hexamethylphosphoramide (LDA/HMPA) at −70 °C, followed by the addition of benzyl bromide in THF to give 11 in 75 % yield after chromatography and recrystallization. Finally, α-ethynylphenylalanine 12 is synthesized by alkaline hydrolysis followed by ion exchange chromatography (Fig. 4). No experimental details or detailed analysis were described.

Synthesis of α-ethynylphenylalanine 12 (Casara and Metcalf, 1978)

Mechanistic considerations suggest the use of 12 as potential enzyme-activated irreversible inhibitors of the corresponding α-amino acid decarboxylase.

More recent papers report the synthesis of racemic N,O-protected α-ethynylphenylalanine and show the interest and the difficulties to synthesize a β,γ-unsaturated α-alkyl amino acid (Fernández González et al. 2010; Finkbeiner et al. 2014).

Gonzalez et al. described the direct ethynylation of 2-nitro-3-phenyl propanoate 13 using the hypervalent iodine reagent ethynyl-1,2-benziodoxol-3(1H)-one (EBX) generated in situ from bench-stable trimethylsilyl-ethynyl-1,2-benziodoxol-3(1H)-one (TMS-EBX, 14) in the presence of tetrabutylammonium fluoride (TBAF) under mild conditions to give 15 (Fernández González et al. 2010). Reduction of the nitro group in 15 to hydroxylamine 16 was conducted using Zn dust/NH4Cl. The selective reduction of hydroxylamine 16 into the corresponding amine was possible using SmI2 in THF/tBuOH. However, the purification of the free amine was difficult, but quenching the reaction with trifluoroacetic anhydride (TFAA) allowed the isolation of the corresponding trifluoroamide 17 in 67 % yield (Fig. 5).

Synthesis of the protected α-ethynylphenylalanine 17 (Fernández González et al. 2010)

The mechanism envisaged by the authors for this reaction is a conjugate addition of enolate anion to the alkyne derivative, followed by an elimination and 1,2-hydride shift. The use of 13C-labeled reagent 19 with keto ester 18 led to the intermediate 20 which generates alkylidenecarbene 21 by elimination of aryliodine. Finally, migratory aptitude of the β-hydrogen of alkylidenecarbene 21 led to 22. The acetylene transfer proceeds through a 1,2-hydride shift mechanism similar to the one proposed for alkynyliodonium salts (Ochiai et al. 1990) (Fig. 6).

Possible mechanisms for the ethynylation reaction and labeling experiment (Ar = phenyl-2-carboxylate) (Ochiai et al. 1990)

For reasons of synthetic accessibility, the labeled TIPS-EBX reagent 19 was used. Generally, TIPS-EBX was as efficient as TMS-EBX 14 as the reagent precursor, although the silyl group removal was slightly slower.

Finkbeiner and co-workers (2014) developed a direct electrophilic alkynylation of azlactones. Azlactones are versatile Cα-tetrasubstituted α-amino acids precursors which are easily accessible from α-amino acids via cyclodehydration and α-functionalization. They can be converted back into the open chained efficient form through base-induced ring opening.

The N-benzoylated amino acid 23 reacted with acetic anhydride to give azlactone 24 by cyclodehydration in 90 % yield (Macovei et al. 2012). The direct ethynylation of 24 with TMS-ethynyl (phenyl)-iodonium tosylate 25 gives the tetrasubstituted azlactone 26 in 94 % yield. The ring opening and deprotection of azlactone 26 by KF in methanol give the racemic (N,O)-protected α-ethynylphenylalanine 27 in 98 % yield (Fig. 7).

Synthesis of the protected α-ethynylphenylalanine 27 (Finkbeiner et al. 2014)

Full deprotection of 26 under acidic conditions failed due to an undesired decarboxylative hydration of the triple bond.

Benfodda and co-workers (Benfodda et al. 2015) described the synthesis of racemic protected α-ethynylphenylalanine 36, the separation of two enantiomers by chiral HPLC and the determination of their absolute configuration (Fig. 8). Oxazolidine 29 was prepared in three steps starting from commercially DL-2-benzylserine 28 in good overall yield. Compound 29 was reduced with LiBH4 into alcohol 30, which was oxidized under Swern conditions to afford the desired protected aldehyde 31 in good yield. Compound 31 was converted into alkyne 32 by Bestmann–Ohira reagent. Compound 32 was hydrolyzed by HCl 6N to afford the amino alcohol hydrochloride 33. Amino protection was conducted with Boc2O in the presence of TEA to give 34. The alcohol 34 was oxidized under Dess–Martin and Pinnick conditions to afford 35 in 32 % yield. The quaternary amino acid 35 was esterified by TMSCHN2 to give 36.

Enantiomers of 36 were successfully separated under analytical conditions and under semipreparative conditions. The absolute configuration of the separated enantiomers of 36 was determined by vibrational circular dichroism.

Synthesis of α-ethynyl-3,4-dihydroxyphenylalanine (α-ethynyl-DOPA)

Two methods have been described for the synthesis of this compound.

Taub and Patchett (1977) described the synthesis of hydrochloride of α-ethynyl-DOPA 42 starting from 37. Alkylation of 37 with 38 led to 39 in quantitative yield. The acylation of 39 with lithium diisopropylamide (LDA) and methyl chloroformate followed by Schiff base cleavage gave the trimethylsilyl amino ester 40 in 20–25 % yield starting from 37. Desilylation of 40 was performed by treatment with sodium methoxide in methanol to give the ethynyl amino ester 41 in 70 % yield. Finally, deprotection of 41 was accomplished using 6N HCl to give hydrochloride of α-ethynyl-3,4-dihydroxyphenylalanine 42 in 90 % yield (Fig. 9).

Synthesis of hydrochloride α-ethynyl-3,4-DOPA 42 (Taub and Patchett 1977)

Metcalf and Jund (1977) described the synthesis of α-ethynyl-3,4-dimethoxyphenylalanine 46 from 37 in 50 % overall yield. The alkylation of 37 with 3,4-dimethoxybenzyl bromide 43 led to 44. The use of LDA instead of BuLi avoids the extensive dialkylation. The acylation of 44 with methyl chloroformate gave 45. Compound 45 was converted into α-ethynyl-3,4-dimethoxyphenylalanine 46 using PhNHNH2 followed by KOH (Fig. 10).

Synthesis of of α-ethynyl-3,4-dimethoxyphenylalanine 46 (Metcalf and Jund 1977)

In the same paper, the authors synthesized α-ethynyl-DOPA 48 in the same way as described above (Fig. 11). The alkylation of 37 was realized with 3,4-isopropylidene benzyl bromide 38. Acid hydrolysis of 47 gave 48 in 24 % overall from 38.

Synthesis of α-ethynyl-DOPA 48 (Metcalf and Jund 1977)

Synthesis of α-ethynylalanine derivatives

Synthesis of a racemic derivative of α-ethynylalanine

In 2011, Maity and Lepore described the synthesis of non-racemic azaproline derivatives by cyclization of β-alkynyl hydrazines 54 or 55 (Maity and Lepore, 2011). Over the last decade, azaprolines have taken on an increasingly important role in bioorganic (Liu et al. 2003) and medicinal chemistry (Lange et al. 2006).

The addition of propargyl ester 49 to azidodicarboxylates 50 and 51 catalyzed by DBU (1,8-diazabicyclo[5.4.0]undec-7-ene) gave the desired beta-alkynyl hydrazines 52 and 53 in good yield (87 and 67 % respectively). The silyl deprotection was performed using tetra-n-butylammonium fluoride (TBAF) in isopropanol. After silica gel column chromatography, the products 54 and 55 were obtained in very good yield (Fig. 12).

Synthesis of β-alkynyl hydrazine 54 and 55 (Maity and Lepore 2011)

Enantioselective synthesis of both enantiomers of protected α-ethynylalanine

To the best of our knowledge, four methods for the asymmetric synthesis of α-ethynylalanine (as free or protected form) have been described in the literature.

The first method described in the literature is an asymmetric synthesis of the amino acid by the bis-lactim ether method. With this method, Schöllkopf et al. reported the first synthesis of (R)-α-ethynylalanine methyl ester (Schöllkopf et al. 1988).

The bis-lactim ether 56 reacts with BuLi or LDA in tetrahydrofuran at −70 °C to give the lithiated bislatim ethers 57. To obtain the α-ethynylalanine product 64, two different ways were envisaged. In the first case, the lithiated bislatim ether 57 reacts with acetyl chloride in THF to give 58 in 86 % yield and N-acylated isomer 59 as a by-product in a small proportion. In the second case, the lithium compound 57 reacts with paraformaldehyde to give the alcohol 60 product in 95 % yield (Fig. 13).

Synthesis of 58 and 60. Reagents and conditions: a acetylchloride, THF, −78 °C, 58: 86 %; b paraformaldehyde, THF, −78 °C, 60: 95 %. (Schöllkopf et al. 1988)

The compounds 58 and 60 are the key intermediates for the synthesis of (R)-α-ethynylalanine methyl ester 64.

Oxidation of carbinol 60 was realized under Swern conditions in 95 % yield followed by Corey–Fuchs transformation to yield alkyne 61 in 67 % yield (Corey and Fuchs, 1972) (Fig. 14).

Synthesis of the alkyne 61 starting from carbinol 60 (Schöllkopf et al. 1988)

Compound 61 could be also synthesized by “one-pot” treatment starting from 58.

First, 58 was treated with LDA and diethyl chlorophosphate at −78 °C in THF to give the enol phosphate 62, which was not isolated. The solution of 62 in THF was again cooled to −78 °C. An excess of LDA (2.2 eqs.) was added and the resulting solution was stirred at −78 °C during 3 h. At this stage, the solution of 62 was allowed to warm to room temperature and two different methods were used to obtain the acetylenic derivative. If a phosphate buffer was added, the product 61 was obtained in 23 %, whereas the addition of trimethylsilane at −30 °C allowed the formation of compound 63 in 28 % (Fig. 15).

Synthesis of 61 and 63 starting from 58. Reagents and conditions: a LDA in THF at −78 °C (3 h) then phosphate buffer (pH = 7) at room temperature. 61: 23 %; b LDA in THF at −78 °C (3 h) then chlorotrimethylsilane at −30 °C, 63: 28 %.(Schöllkopf et al. 1988)

Finally, acid hydrolysis of 61 and 63 with HCl (0.25 N) was performed for 3 days at room temperature to obtain (R)-α-ethynylalanine methyl ester 64 in 49 % yield (Fig. 16).

Synthesis of (R)-α-ethynylalanine methyl ester 64 (Schöllkopf et al. 1988)

In 1989, Schmidt et al. reported the first synthesis of (R)-N-Boc protected α-ethynylalanine 71 (Schmidt et al. 1989). They described the conversion of optically active 2,3-epoxide alcohols into amino acids (Fig. 17). The epoxide intermediate 66 was obtained by Sharpless epoxidation of (E)-3-methylpent-2-en-4-yn-1-ol 65. The epoxy alcohol 66 reacted with trichloroacetonitrile in the presence of DBU to give the imidic ester 67 in 91 % yield. Then, an intramolecular opening of the epoxide ring with boron trifluoride diethyl etherate led to the formation of dihydrooxazine 68. Treatment with hydrochloride acid (2N) followed by a protection step with (Boc)2O afforded the aminodiol 69 in 87 % yield. Sodium periodate oxidative cleavage of the vicinal diol 69 allowed the formation of the aminoaldehyde 70. Finally, N-Boc protected alpha-ethynylalanine 71 was obtained by Pinnick oxidation in 62 % yield (Fig. 17). In this case, the oxidation of aminodiol 69 to amino acid is not possible using potassium permanganate due to the presence of the triple bond.

Synthesis of (R)-N-Boc protected α-ethynylalanine 71 (Schmidt et al. 1989)

In 1993, Colson and Hegedus described the first synthesis of the free α-ethynylalanine (Colson and Hegedus 1993) (Fig. 18). In this work, the original approach is the synthesis of an optically active β-lactam ring by a photochemical reaction to obtain an α-alkyl-α-amino acid. The oxazolidine ring of 74 was converted to an oxazolidinone ring by hydrolysis with hydrochloride acid (0.2 N) followed by recyclization with triphosgene. Compound 75 obtained was then alkylated with retention of stereoselectivity using KHMDS and iodomethane to give compound 76 in 80 % yield with very high diastereoselectivity (≥97 % de). For this reaction, the use of lithium bases (tert-BuLi or LDA) showed lower yield due to degradation. Then, the β-lactam ring was cleaved by gaseous HCl in methanol to yield ester 77, which was used without purification. Cyclic aminal 77 was cleaved using aqueous solution of hydrochloric acid (1 N) for 2 days to give aldehyde 78 in 50–55 % yield.

First synthesis of the free α-ethynylalanine 81 (Colson and Hegedus 1993)

Compound 78 was converted into the bromoalkyne 80 via dibromovinyl alkene 79 by treatment with carbone tetrabromide and triphenylphosphine, followed by elimination with KOH. Finally, α-ethynylalanine 81 was synthesized by reductive cleavage of oxazolidinone ring and metal–halogen exchange of the acetylenic halide followed by ion exchange chromatography (Fig. 18).

Avenoza and co-workers (1999b) developed a straightforward synthetic route to obtain pure (S)- and (R)-α-ethynylalanine starting from (S)- and (R)-α-methylserinals, 84 and 85, respectively (Fig. 19). The two building blocks 84 and 85 were prepared starting from the same product (R)-2-methylglycidol 82 (94 % ee) which was transformed into the corresponding compound 83 in five steps with an overall yield of 75 % (Hatakeyama et al. 1997). Then, compound 83 was converted in three steps (82 %) to (S)-α-methylserinals 84 and in five steps (48 %) to (R)-α-methylserinal 85 (Avenoza et al. 1999a) (Fig. 19).

Synthesis of both building blocks 84 and 85 (Avenoza et al. 1999a)

The conversion of aldehyde 84 to acetylene 88 was performed by a Corey–Fuchs transformation. In the first step, the dibromoolefin 86 was obtained by preparation of the dibromomethyl phosphorene using bromoform (CHBr3) and potassium tert-butoxide in the presence of triphenylphosphine. The acetylenic function was obtained by treatment of 86 with two equivalents of BuLi. Then, the oxazolidine ring was cleaved by the action of conc. hydrochloric acid to give 1,2-amino alcohol hydrochloride. The protection of amine function was performed with (Boc)2O in the presence of sodium carbonate to give 87 from 86 in 54 % yield. To transform compound 87 in the desired (R)-α-ethynylalanine derivative (R)-88, the alcohol function was oxidized with Jones reagent, followed by hydrolysis with conc. hydrochloric acid at room temperature and finally treated by propylene oxide in ethanol at reflux (Fig. 20). The other enantiomer (S)-α-ethynylalanine (S)-88 was obtained using the same strategy, but starting from (R)-α-methylserinal 85 (Fig. 21). The synthesis of (R)-88 and (S)-88 was described in seven steps with an overall yield of 32 % from 84 and 85, respectively. The authors confirmed the same identical spectral data with an optical rotation of opposite sign between (R)-88 and (S)-88.

Synthesis of (R)-enantiomers of α-ethynylalanine 88 (Avenoza et al. 1999a)

Synthesis of (S)-enantiomers of α-ethynylalanine 88 (Avenoza et al. 1999b)

Synthesis of racemic N-protected α-ethynyl 2-(3,3,3-trifluoro) alanine methyl ester

The first synthesis of a racemic α-trifluoromethyl substituted acetylenic α-amino acid is described by Burger and Sewald (1990). The addition of amino group of carbamate 90 to methyl trifluoropyruvate 89 gave carbamate 91, which was obtained in 80 % yield as a crystalline solid in analytical quality. Dehydration of 91 was performed with trifluoroacetic anhydride in pyridine at 0 °C to give 92 in 68 % (Fig. 22).

Synthesis of imine 92 (Burger and Sewald 1990)

Treatment of imine 92 with sodium acetylide followed by hydrolysis led to the desired α-ethynyl 2-[N-benzyloxycarbonyl]-2-(trifluoromethyl)alanine methyl ester 93 in 80 % yield (Fig. 23).

Synthesis α-ethynyl 2-[N-benzyloxycarbonyl]-2-(trifluoromethyl)alanine methyl ester 93 (Burger and Sewald 1990)

The same type of Michael addition was used by Sémeril et al. (2001) and Shchetnikov et al. (2008, 2010) to obtain the same product 93 or analogs with different protective groups on the amine function. The products described by the two authors are listed in the Table 1.

In 2001 and 2008, Séméril and Shchetnikov described the N-alkylation of carbamate 94 and sulfonamide 93 in the same conditions. Treatment of the two compounds by sodium hydride at 0 °C in DMF followed by the addition at room temperature of allyl bromide or propargyl bromide gives the desired N-fully protected compounds 96 and 97 in 40 and 50 % yield, respectively (Fig. 24).

Synthesis of (S)-α-ethynyl 3,3,3-trifluoro alanine ethyl ester

To the best of our knowledge, the synthesis of (S)-α-ethynyl 3,3,3-trifluoro alanine ethyl ester reported by Crucianelli et al. (2004) is the first synthesis of a non-racemic form of an amino acid with a trifluoromethyl group and ethynyl substituents in the alpha position. The introduction of CF3 substituent in the alpha position to non-racemic amino acids is a challenge for the chemist and often requires complex and tedious protocols. This strategy is based on the reaction of an enantiomerically pure sulfinimine of trifluoropyruvate with Grignard reagents.

The iminophosphorane 98 was prepared according to the procedure described by Asensio and Bravo (Asensio et al. 2001; Bravo et al. 1998). Then, both diastereoisomers 100 and 101 were prepared in one-step synthesis. Staudinger reaction between 98 and trifluoropyruvate gave the sulfinimine 99 without isolation, followed by the addition of a solution of ethynyl magnesium bromide (0.5 M in THF) at −70 °C. Both diastereoisomers were obtained with 75 % overall yield. Major diastereoisomer 100 presents an e.e. of 97.5 % (Fig. 25).

Synthesis of both diastereoisomers 100 and 101 (Crucianelli et al. 2004)

Desulfonylation of 100 was realized by treatment with TFA/MeOH at 0 °C to give (S)-α-ethynyl 3,3,3-trifluoro alanine ethyl ester 102 in 72 % yield (Fig. 26).

Synthesis of (R)-methyl 2-((2-methoxyphenyl)amino)-2-(trifluoromethyl)but-3-ynoate

In 2011, Huang et al. (2011) described a second synthesis of a non-racemic form of trifluoromethyl amino acid derivatives. The original strategy was based on highly enantioselective alkynylation of ketoimine 103 via zinc/BINOL catalyzed process (Fig. 27). The proceeding afforded a facile access to optically active quaternary amino acids with high enantiomeric excess (e.e = 91.9–99.6 %).

Synthesis of (R)-methyl 2-((2-methoxyphenyl)amino)-2-(trifluoromethyl), but-3-ynoate (R)-106 (Huang et al. 2011)

The addition of trimethylsilylacetylene to α-CF3 ketoimine ester 103 was performed with dimethylzinc and BINOL derivative (R)-104 to give (R)-105 (97.7 % ee) in 84 % yield. The terminal alkyne (R)-106 was obtained in 92 % yield by treatment of (R)-105 with the TBAF solution (1.0 M in THF).

Synthesis of α-ethynyl glutamic acid hydrochloride and α-ethynylornithine

Previously in this review (see “Synthesis of α-ethynylphenylalanine derivatives” of this review), we described the synthesis of α-ethynylphenylalanine by Casara and Metcalf in 1978. In the same paper, the two authors reported the synthesis of α-ethynyl glutamic acid hydrochloride by the same method (Fig. 28).

Synthesis of α-ethynyl glutamic acid hydrochloride 108 (Casara and Metcalf 1978)

Michael addition of the anion derived from 10 on methyl acrylate gives the compound 107 in 65 % yield. The deprotection of 107 led to compound 108 with no yield indicated. The authors claimed that the NMR analysis, IR spectra and elemental analysis are in agreement with the structure.

The first step of this method was utilized by Danzin in 1981 (Danzin et al. 1981) to synthesize α-ethynylornithine 111 as potential enzyme-activated inhibitors of mammalian ornithine decarboxylase (Fig. 29).

Synthesis of α-ethynylornithine 111 (Danzin et al. 1981)

The regioselective alkylation of 10 was accomplished with lithium diisopropylamide and 1-iodo-3-benzaldiminopropane to give the non-isolated intermediate 109. The δ-lactam 110 was obtained by cyclization of 109 in mild acidic conditions. Then, the free amino acid was synthesized by alkyne hydrolysis of the TMS group and of the lactam ring. Finally, α-ethynylornithine 111 was obtained by ion-exchange chromatography and recrystallization in a mixture of ethanol and water in 59 % yield (Fig. 29).

Synthesis of fully protected optically active α-ethynyl serine

In 2003, Brennan et al. (2003) described the synthesis of the intermediate (S)-121 which is used in the total synthesis of (+)-lactacystin 112 described by Corey et al. (Corey et al. 1998) (Figs. 30, 31).

Synthesis of (S)-enantiomer 121 (Brennan et al. 2003)

2-Ethynylpropenol 115 was transformed into the chiral epoxide 116 (90 % ee) in 66 % yield using Sharpless epoxidation. Treatment of the epoxide alcohol 116 with trichloroacetonitrile in the presence of DBU gave the acetamidate 117 in 65 % yield. The cyclization of 117 was performed using Et2AlCl to give oxazoline alcohol 118.

The alcohol function of 118 was protected with TBSOTf using 2,6-lutidine as a base to give 119 in 92 % yield. The oxazoline ring was cleaved by treatment with dilute hydrochloric acid (1 N) to give 2-ethynyl-2-amino alcohol which was not isolated and immediately converted into a mixture of epimers of the amide 120 with racemic 2-bromopropionoyl chloride in 76 % yield. Dess–Martin oxidation, Pinnick oxidation and esterification with (trimethylsilyl)diazomethane led to the final compound (S)-121 in 60 % overall yield for these final three steps (Fig. 31).

In 2007, Bennett et al. (2007) described the (R) enantiomer of compound 121 (Fig. 32). This molecule is an intermediate in the synthesis of a common precursor to both the β-lactone and γ-lactone pyrrolidinone ring systems, found in oxazolomycin A 113 and neooxazolomycin 114 (Fig. 30).

Synthesis of (R)-enantiomer 121 (Bennett et al. 2007)

The synthesis described by Bennett and co-workers differs from the one of Brennan et al. described above (Fig. 31) with small modifications. In the first case, the epoxide alcohol (R)-116 (83 % ee) was prepared by the reaction between 115 and (−)-diisopropyl d-tartrate in 77 %. The reaction gives the (R) enantiomer of 116 a smaller enantiomeric excess (83 % ee). In the second step, the protection of the alcohol function of (R)-118 was performed using imidazole as a base in 83 %. Finally, the first oxidation step of (R)-120 was performed using a combination of NMO (N-methylmorpholine-N-oxide) and TPAP (tetrapropylammonium perruthenate) allowing to obtain (R)-121 in 55 % yield from (R)-120 (Fig. 32).

Miscellaneous

In 2006, Fukumoto and co-workers reported the first total synthesis of (+)-β-erythroidine 122, a non-aromatic dienoid-type Erythrina alkaloid (Fukumoto et al. 2006). Erythrina plant species are the main source of tetracyclic alkaloids. This family is classified into two groups depending of the nature of D rings: D rings are non-aromatic (structure 122) or aromatic (structure 123). Compound 122 contains a non-aromatic unsaturated lactone and is called a lactonic alkaloid (Amer et al. 1991) (Fig. 33).

Structure of β-erythroidine 122 and general structure of aromatic erythrina alkaloid 123 (Fukumoto et al. 2006)

Over the last decades, the Erythrina alkaloids have received considerable attention due to their intriguing biological activity. Some members of this family showed pharmacological effects such as sedative, hypotensive, neuromuscular blocking, antidiarrheal and central nervous system activity (Padwa et al. 1998).

The authors described the synthesis of ethynylated amino acid fragment 136, a key intermediate in the synthesis of (+)-β-erythroidine 122.

Treatment of 2,3-O-isopropylidene-d-threitol 124 with p-toluenesulfonyl chloride followed by treatment with trifluoromethanesulfonic acid gave 125 in 87 % yield. The acetylenic product 126 was obtained by reaction of 125 with lithiated propargyl tetrahydropyranyl ether in 88 % yield. Iodination of 126 by nucleophilic substitution with sodium iodide in DMF gave 127 in 87 % yield. Reductive cleavage of iodide derivative 127 with activated Zn and acetic acid afforded alcohol 128 in 90 % yield. The alcohol 128 reacted with iodomethane followed by subsequent removal of THP protecting group with pyridinium p-toluenesulfonate to get 129 in 98 %. Successive treatment of 129 with Red-Al® (sodium bis(2-methoxyethoxy)aluminum hybride: 65 % in toluene) and iodine give the regioselective Z-alkene 130. A Sonogashira coupling with trimethylsilylacetylene followed by the removal of TMS group with potassium carbonate led to alcohol 131 in 81 % yield (3 steps from 129).

In the first attempt to obtain epoxide 132, Katsuki–Sharpless conditions were used but gave poor distereoselectivity. The second attempt was performed with mCPBA and allowed to furnish an inseparable mixture of α and β diastereoisomers, but with excellent diastereoselectivity (6:94, respectively). The high diastereoselectivity was explained with a transition state where mCPBA was oriented to the β-face by hydrogen bonding.

Treatment of the alcohol function in 132 with trichloroacetonitrile in the presence of DBU and molecular sieves (4 Å) gave the acetamidate 133, which was used for the next step without purification. Cyclization of this compound was performed with Lewis acid (BF3–OEt2) in methylene chloride at −20 °C to give six-membered 134 with quaternary center in 93 % (two steps). Hydrolysis with diluted hydrochloric acid solution (1 N) followed by N-Boc protection with (Boc)2O and sodium carbonate gave diol 135 in quantitative yield.

Finally, a sequence of four steps was realized to obtain the desired ethynylated amino acid derivative with the free amine. An oxidative cleavage was performed with sodium periodate followed by a Pinnick oxidation to give the carboxylic acid function. Then, the esterification was accomplished with diazomethane and the Boc protecting group was removed by treatment with TFA in methylene chloride to give 136 in 79 % overall yield from 135 (Fig. 34).

Synthesis of methyl (2S,4R)-2-amino-2-ethynyl-4-methoxyhex-5-enoate 136 (Fukumoto et al. 2006)

At this stage, a two-step sequence was performed to obtain the dialkylated tertiary amine 138 derived from 136 in good yield. A reductive amination was realized with methyl 3-formylpropanoate and sodium triacetoxyborohydride to give 137 in 86 % yield. Then, the secondary amine 137 was allylated in the presence of allyl bromide and potassium carbonate to give α-ethynyl N,N-dialkylated amino acid derivative 138 (Fig. 35).

Synthesis of α-ethynyl N,N-dialkylated amino acids derivative 138. (Fukumoto et al. 2006)

Conclusion

α-Alkyl α-ethynyl amino acids are an important class of non-proteinogenic amino acids that play an important role in the development of peptides and peptidomimetics as therapeutic agents, and in the inhibition of enzyme activities. Their extensive use is limited by the availability of enantiomerically pure compounds in large quantities. As we have shown in this review, a wide variety of synthetic approaches to these compounds has been developed, most based on racemic syntheses and some syntheses lead to optically active compounds (ethynylalanine, ethynyl phenylalanine, trifluoroalanine and ethynyl serine).

References

Almond HR, Manning DT, Niemann C (1962) Interaction of alpha-chymotrypsin with several alpha-methyl-alpha-acylamino acid methyl esters. Biochem (Mosc.) 1:243–249

Amer ME, Shamma M, Freyer AJ (1991) The tetracyclic Erythrina alkaloids. J Nat Prod 54:329–363. doi:10.1021/np50074a001

Asensio A, Bravo P, Crucianelli M, Farina A, Fustero S, Soler JG, Meille SV, Panzeri W, Viani F, Volonterio A, Zanda M (2001) Synthesis of nonracemic α-trifluoromethyl α-amino acids from sulfinimines of trifluoropyruvate. Eur J Org Chem 2001:1449–1458

Avenoza A, Cativiela C, Corzana F, Peregrina JM, Zurbano MM (1999a) Preparation and synthetic applications of (S)- and (R)-N-Boc-N, O-isopropylidene-α-methylserinals: asymmetric synthesis of (S)- and (R)-2-amino-2-methylbutanoic acids (Iva). J Org Chem 64:8220–8225

Avenoza A, Cativiela C, Peregrina JM, Sucunza D, Zurbano MM (1999b) A straightforward synthesis of both enantiomers of α-vinylalanine and α-ethynylalanine. Tetrahedron Asymmetry 10:4653–4661

Avenoza A, Cativiela C, Corzana F, Peregrina JM, Sucunza D, Zurbano MM (2001) Enantioselective synthesis of (S)- and (R)-α-methylserines: application to the synthesis of (S)- and (R)-N-Boc-N, O-isopropylidene-α-methylserinals. Tetrahedron Asymmetry 12:949–957

Avenoza A, Busto JH, Cativiela C, Peregrina JM, Sucunza D, Zurbano MM (2003) Synthesis of enantiopure (αMe)Dip and other α-methylated β-branched amino acid derivatives. Tetrahedron Asymmetry 14:399–405

Avenoza A, Busto JH, Canal N, Peregrina JM, Pérez-Fernández M (2005) Selective Michael–Aldol reaction by use of sterically hindered aluminum aryloxides as Lewis acids: an easy approach to cyclobutane amino acids. Org Lett 7:3597–3600

Benfodda Z, Bénimélis D, Jean M, Naubron J-V, Rolland V, Meffre P (2015) Synthesis, resolution, and determination of absolute configuration of protected α-ethynylphenylalanine enantiomers. Amino Acids 47:899–907

Bennett NJ, Prodger JC, Pattenden G (2007) A synthesis of a common intermediate to the lactone–pyrrolidinone ring systems in oxazolomycin A and neooxazolomycin. Tetrahedron, Tetrahedron 50th anniversary symposium-in-print (part 2) 63: 6216–6231

Berkowitz DB, Chisowa E, McFadden JM (2001) Stereocontrolled synthesis of quaternary β, γ-unsaturated amino acids: chain extension of d- and l-α-(2-tributylstannyl)vinyl amino acids. Tetrahedron 57:6329–6343. doi:10.1016/S0040-4020(01)00499-9

Berkowitz DB, de la Salud-Bea R, Jahng W-J (2004) Synthesis of quaternary amino acids bearing a (2‘Z)-fluorovinyl α-branch: potential PLP enzyme inactivators. Org Lett 6:1821–1824

Berkowitz DB, Charette BD, Karukurichi KR, McFadden JM (2006) α-Vinylic amino acids: occurrence, asymmetric synthesis, and biochemical mechanisms. Tetrahedron Asymmetry 17:869–882

Biagini SCG, Gibsoné Thomas SE, Keen SP (1998) Cross-metathesis of unsaturated α-amino acid derivatives. J Chem Soc Perkin 1:2485–2500

Bravo P, Crucianelli M, Vergani B, Zanda M (1998) Sulfinimines of trifluoropyruvate: novel intermediates for chiral non racemic α-trifluoromethyl α-amino acids. Tetrahedron Lett 39:7771–7774

Brennan CJ, Pattenden G, Rescourio G (2003) Formal synthesis of (+)-lactacystin based on a novel radical cyclisation of an α-ethynyl substituted serine. Tetrahedron Lett 44:8757–8760

Burger K, Sewald N (1990) α-Trifluormethyl-substituierte Aminosäuren mit Acetylenfunktionen in der Seitenkette. Synthesis 1990:115–118

Casara P, Metcalf BW (1978) Trimethylsilylacetylene-N-carboethoxy glycinate dianion—a general synthon for α-acetylenic α-amino acids. Tetrahedron Lett 19:1581–1584

Cativiela C, Díaz-de-Villegas MD (2007) Recent progress on the stereoselective synthesis of acyclic quaternary α-amino acids. Tetrahedron Asymmetry 18:569–623

Cativiela C, Dı́az-de-Villegas MD (1998) Stereoselective synthesis of quaternary α-amino acids. Part 1: acyclic compounds. Tetrahedron Asymmetry 9:3517–3599

Cativiela C, Dı́az-de-Villegas MD (2000) Stereoselective synthesis of quaternary α-amino acids. Part 2: cyclic compounds. Tetrahedron Asymmetry 11:645–732

Collier PN, Patel I, Taylor RJK (2002) Heck reactions of amino acid building blocks: application to the synthesis of pyrrololine analogues. Tetrahedron Lett 43:3401–3405

Colson PJ, Hegedus LS (1993) Asymmetric synthesis of.alpha.-alkyl-.alpha. amino acids from chromium-carbene-complex-derived. beta.-lactams. J Org Chem 58:5918–5924

Corey EJ, Fuchs PL (1972) A synthetic method for formyl → ethynyl conversion (RCHO → RC CH or RC CR′). Tetrahedron Lett 13:3769–3772

Corey EJ, Li W, Nagamitsu T (1998) An efficient and concise enantioselective total synthesis of lactacystin. Angew Chem Int Ed 37:1676–1679

Crisp GT, Gebauer MG (1996) Heck couplings of non-activated alkenes. Tetrahedron 52:12465–12474

Crucianelli M, Angelis FD, Lazzaro F, Malpezzi L, Volonterio A, Zanda M (2004) Synthesis of enantiomerically pure α-ethyl, α-vinyl and α-ethynyl 3,3,3-trifluoro alaninates. J Fluor Chem 125:573–577 (special issue on fluorinated synthons)

Danzin C, Casara P, Claverie N, Metcalf BW (1981) alpha.-Ethynyl and. alpha.-vinyl analogs of ornithine as enzyme-activated inhibitors of mammalian ornithine decarboxylase. J Med Chem 24:16–20

Degenkolb T, Berg A, Gams W, Schlegel B, Gräfe U (2003) The occurrence of peptaibols and structurally related peptaibiotics in fungi and their mass spectrometric identification via diagnostic fragment ions. J. Pept. Sci. Off. Publ. Eur. Pept. Soc. 9:666–678

Degenkolb T, Gräfenhan T, Nirenberg HI, Gams W, Brückner H (2006) Trichoderma brevicompactum complex: rich source of novel and recurrent plant-protective polypeptide antibiotics (peptaibiotics). J Agric Food Chem 54:7047–7061

Duggan HME, Hitchcock PB, Young DW (2005) Synthesis of 5/7-, 5/8- and 5/9-bicyclic lactam templates as constraints for external beta-turns. Org Biomol Chem 3:2287–2295

Feng L, Kirsch JF (2000) l-Vinylglycine is an alternative substrate as well as a mechanism-based inhibitor of 1-aminocyclopropane-1-carboxylate synthase. Biochem (Mosc.) 39:2436–2444

Fernández González D, Brand JP, Waser J (2010) Ethynyl-1,2-benziodoxol-3(1 H)-one (EBX): an exceptional reagent for the ethynylation of keto, cyano, and nitro esters. Chem Eur J 16:9457–9461

Finkbeiner P, Weckenmann NM, Nachtsheim BJ (2014) Alkynyliodonium salt mediated alkynylation of azlactones: fast access to C(α)-tetrasubstituted α-amino acid derivatives. Org Lett 16:1326–1329

Fukumoto H, Takahashi K, Ishihara J, Hatakeyama S (2006) Total synthesis of (+)-β-erythroidine. Angew Chem Int Ed 45:2731–2734

Gardiner J, Anderson KH, Downard A, Abell AD (2004) Synthesis of cyclic β-amino acid esters from methionine, allylglycine, and serine. J Org Chem 69:3375–3382

Gurjar MK, Talukdar A (2002) Heck Reaction of (S)-N-Cbz-allyl glycine t-butyl ester with aromatic halides. Synthesis 2002:315–316

Hassan HMA, Brown FK (2010) A convenient approach to acyclic unsaturated amino acids via ring-closing metathesis. Chem Commun 46:3013–3015

Hata S, Koyama H, Shimizu M (2011) Synthesis of α, α-disubstituted α-amino esters: nucleophilic addition to iminium salts generated from amino ketene silyl acetals. J Org Chem 76:9670–9677

Hatakeyama S, Matsumoto H, Fukuyama H, Mukugi Y, Irie H (1997) Et2AlCl-catalyzed cyclization of epoxytrichloroacetimidates for the synthesis of α-substituted serines. J Org Chem 62:2275–2279

Hruby VJ, Li G, Haskell-Luevano C, Shenderovich M (1997) Design of peptides, proteins, and peptidomimetics in chi space. Biopolymers 43:219–266

Huang G, Yang J, Zhang X (2011) Highly enantioselective zinc/BINOL-catalyzed alkynylation of α-ketoimine ester: a new entry to optically active quaternary α-CF3 α-amino acids. Chem Commun 47:5587–5589

Hughes A (2009) Amino acids, peptides, and proteins in organic chemistry. Wiley-VCH, Weinheim

Kaul R, Surprenant S, Lubell WD (2005) Systematic study of the synthesis of macrocyclic dipeptide β-turn mimics possessing 8-, 9-, and 10- membered rings by ring-closing metathesis. J Org Chem 70:3838–3844

Keith DD, Tortora JA, Ineichen K, Leimgruber W (1975) The total synthesis of rhizobitoxine. Tetrahedron 31:2633–2636

Khosla MC, Stachowiak K, Smeby RR, Bumpus FM, Piriou F, Lintner K, Fermandjian S (1981) Synthesis of [alpha-methyltyrosine-4]angiotensin II: studies of its conformation, pressor activity, and mode of enzymatic degradation. Proc Natl Acad Sci USA. 78:757–760

Kotha S (2003) The building block approach to unusual α-amino acid derivatives and peptides. Acc Chem Res 36:342–351

Kotha S, Ghosh AK (2004) The Diels-Alder Approach for the synthesis of tetralin-based α-amino acid derivatives and their modification by the Suzuki-Miyaura cross-coupling reaction. Synthesis 558–567

Krebs A, Ludwig V, Pfizer J, Dürner G, Göbel MW (2004) Enantioselective synthesis of non-natural aromatic α-amino acids. Chem Eur J. 10:544–553

Kuroda Y, Okuhara M, Goto T, Kohsaka M, Aoki H, Imanaka H (1980a) FR-900130, a novel amino acid antibiotic. II. Isolation and structure elucidation of the acetyl derivative of FR-900130. J. Antibiot. (Tokyo) 33:132–136

Kuroda Y, Okuhara M, Goto T, Yamashita M, Iguchi E, Kohsaka M, Aoki H, Imanaka H (1980b) FR-900148, a new antibiotic. I. Taxonomy, fermentation, isolation and characterization. J. Antibiot. (Tokyo) 33:259–266

Lange UEW, Baucke D, Hornberger W, Mack H, Seitz W, Höffken HW (2006) Orally active thrombin inhibitors. Part 2: optimization of the P2-moiety. Bioorg Med Chem Lett 16:2648–2653

Liu B, Brandt JD, Moeller KD (2003) Constrained peptidomimetics: building bicyclic analogs of pyrazoline derivatives. Tetrahedron 59:8515–8523

Macovei C, Vicennati P, Quinton J, Nevers M-C, Volland H, Créminon C, Taran F (2012) Polyclonal antibodies: a cheap and efficient tool for screening of enantioselective catalysts. Chem Commun 48:4411–4413

Maity P, Lepore SD (2011) Catalytic synthesis of nonracemic azaproline derivatives by cyclization of β-alkynyl hydrazines under kinetic resolution conditions. Angew Chem Int Ed 50:8338–8341

Maycock A, Aster S, Patchett A (1979) A suicide inactivation of decarboxylases. Dev Biochem 115

Meffre P, Le Goffic F (1996) β, γ-Alkynylα-amino acids: a synthetic challenge. Amino Acids 11:313–328

Metcalf BW, Jund K (1977) Synthesis of β, γ-unsaturated amino acids as potential catalytic irreversible enzyme inhibitors. Tetrahedron Lett 18:3689–3692

Newman H (1973) Preparation of α, β-unsaturated aldehydes from acid chlorides. J Org Chem 38:2254–2255

Nolen EG, Kurish AJ, Wong KA, Orlando MD (2003) Short, stereoselective synthesis of C-glycosyl asparagines via an olefin cross-metathesis. Tetrahedron Lett 44:2449–2453

O’Connor SJ, Liu Z (2003) A concise synthesis of sterically hindered 3-amino-2-oxindoles. Synlett 2135–2138

Ochiai M, Ito T, Takaoka Y, Masaki Y, Kunishima M, Tani S, Nagao Y (1990) Synthesis of ethynyl(phenyl)iodonium tetrafluoroborate. A new reagent for ethynylation of 1,3-dicarbonyl compounds. J Chem Soc Chem Commun 118–119

Ojima I, Tzamarioudaki M, Eguchi M (1995) New and efficient route to pipecolic acid derivatives by means of Rh-catalyzed intramolecular cyclohydrocarbonylation. J Org Chem 60:7078–7079

Olma A, Lasota A, Kudaj A (2012) A convenient route to optically pure α-alkyl-β-(sec-amino)alanines. Amino Acids 42:2525–2528

Padwa A, Hennig R, Kappe CO, Reger TS (1998) A triple cascade sequence as a strategy for the construction of the erythrinane skeleton. J Org Chem 63:1144–1155

Polinelli S, Broxterman QB, Schoemaker HE, Boesten WHJ, Crisma M, Valle G, Toniolo C, Kamphuis J (1992) New aspartame-like sweeteners containing l-(αMe)Phe. Bioorg Med Chem Lett 2:453–456

Rando RR (1974) Irreversible inhibition of aspartate aminotransferase by 2-amino-3-butenoic acid. Biochem (Mosc.) 13:3859–3863

Rando RR (1984) Mechanism-based enzyme inactivators. Pharmacol Rev 36:111–142

Rutjes FPJT, Schoemaker HE (1997) Ruthenium-catalyzed ring closing olefin metathesis of non-natural α-amino acids. Tetrahedron Lett 38:677–680

Sasaki NA, Potier P, Savignac M, Jaouen G (1988) Organometallic derivatives of peptides: application to peptide receptor analysis. Tetrahedron Lett 29:5759–5762

Sawyer K (1997) Structure-based drug design: disease, targets, techniques and developments. Veerapandian P (eds) Marcel Dekker, New-York, p 559

Schmidt U, Respondek M, Lieberknecht A, Werner J, Fischer P (1989) Amino acids and peptides; 70. 1 optically active α-amino acids, N -Boc-aminoaldehydes and α-amino-β-hydroxy Acid from 2,3-epoxy alcohols. Synthesis 1989:256–261

Schöllkopf U, Westphalen K-O, Schröder J, Horn K (1988) Asymmetric syntheses via heterocyclic intermediates, XL. Studies on the acylation of lithiated bislactim ethers of cyclo(-L-Val-Ala-) and cyclo(-L-Val-Gly-) Asymmetric synthesis of (R)-α-alkenyl and (R)-α-ethinyl alanine methyl esters by the bislactim ether method. Liebigs Ann Chem 1988:781–786

Sémeril D, Nôtre JL, Bruneau C, Dixneuf PH, Kolomiets AF, Osipov SN (2001) Fluorine-containing α-alkynyl amino esters and access to a new family of 3,4-dehydroproline analogues. New J Chem 25:16–18

Shchetnikov G, Osipov S, Bruneau C, Dixneuf P (2008) Ruthenium-catalyzed cyclotrimerization of 1,6- and 1,7-azadiynes: new access to fluorinated bicyclic amino acids. Synlett 2008:578–582

Shchetnikov GT, Zotova MA, Bruneau C, Dixneuf PH, Osipov SN (2010) Synthesis of α-alkynyl-β, β, β-trifluoroalanine derivatives by Sonogashira cross-coupling reaction. Eur J Org Chem 2010:1587–1592

Tanaka M (2007) Design and synthesis of chiral alpha, alpha-disubstituted amino acids and conformational study of their oligopeptides. Chem Pharm Bull (Tokyo) 55:349–358

Taub D, Patchett AA (1977) Syntheses of α-ethynyl-3, 4-dihydroxyphenylalanine and α-vinyl-3, 4-dihydroxyphenylalanine. Tetrahedron Lett 18:2745–2748

Tendler SJ, Threadgill MD, Tisdale MJ (1987) Activities of serine hydroxymethyltransferase in murine tissues and tumours. Cancer Lett 36:65–69

Tolman V, Sedmera P (1988) Unsaturated amino acids: synthesis of trans-3,4-didehydro analogues of l-ornithine and l-arginine. Tetrahedron Lett 29:6183–6184

Venkatraman J, Shankaramma SC, Balaram P (2001) Design of folded peptides. Chem Rev 101:3131–3152

Walsh C (1979) Enzymatic reaction mechanisms. W H. Freeman, San Francisco

Walton DRM, Waugh F (1972) Friedel-crafts reactions of bis(trimethylsilyl)polyynes with acyl chlorides; a useful route to terminal-alkynyl ketones. J Organomet Chem 37:45–56

Yonezawa Y, Shimizu K, Yoon K, Shin C (2000) Facile synthesis of l-3,4-didehydrovaline constituting an antibiotic, phomopsin A. Synthesis 2000:634–636

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Funding

We gratefully thank the French “ministère de l’éducation nationale, de l’enseignement supérieur et de la recherche” and the University of Nîmes for their financial support.

Ethical standards

The manuscript does not contain clinical studies or patient data.

Additional information

Handling Editor: J. D. Wade.

P. Meffre and Z. Benfodda jointly supervised this work.

Rights and permissions

About this article

Cite this article

Boibessot, T., Bénimélis, D., Meffre, P. et al. Advances in the synthesis of α-quaternary α-ethynyl α-amino acids. Amino Acids 48, 2081–2101 (2016). https://doi.org/10.1007/s00726-016-2276-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00726-016-2276-2