Abstract

Electrochemical sensor technology is an integral part of modern analytical chemistry that has attracted great attention. It is multifaceted and rapidly progressing because of its high demand and continuous technological advancements. Electrochemical sensors offer several advantages over traditional analytical methods, including selectivity, sensitivity, robustness, ease of operation, short-time measurement, portability, low cost, etc. Interestingly, some of such features are possible to engineer toward a better performance improvement by adjusting to the assay needs. This review article comprehensively discusses the components, configuration, and tailoring of electrochemical sensors. The electrode surface modification and its importance in performance enhancement, especially in terms of selectivity and sensitivity, are discussed. The immobilization strategies, their advantages, and limitations, as well as the influential factors in surface engineering, are also highlighted. In addition, state-of-the-art electrochemical sensors either based on the immobilization matrices or recognition elements for a diverse range of target analytes are discussed. Challenges and future aspects are briefly reviewed. The author believes the insights presented here will spark extra efforts to further understand and in turn, develop electrochemical sensors.

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

A chemical sensor is a device that analyzes substances by converting the recorded data into observable or quantifiable signals [1]. This subject is an emerging field established from different scientific studies, such as chemistry, biology, acoustics, electricity, mechanics, optics, thermology, semiconductors, microelectronics, and membranes. Despite a relatively new discipline, chemical sensors have come a long way, fundamentally driven by commercial demands. The chemical sensors have many excellent features like small size, good selectivity, sensitivity, wide detection range, low cost, and ease of realizing automatic measurement and online or in situ as well as continuous monitoring, all of which have gained increasing attraction for a wide variety of applications. Thanks to these advantages, they have become among the most active and effective directions of modern sensor technology [2,3,4,5,6].

The need for accurate detection platforms has opened up the possibility of advancing sensor technology toward a versatile device that can be applied to all aspects of life [7]. Among the chemical sensors which include electrochemical, optical, magnetic, mass, and thermal [8], the electrochemical sensors offer a cheaper and more convenient solution for an assay. Most importantly, they also provide good reliability for the detection of a wide range of analytes [9]. Since reliable sensing of chemicals is a very important facet, electrochemical sensors have been broadly applied in agriculture [10], food [11], environment [12], healthcare [13, 14], etc. The advantages of chemical and electrochemical sensors, in general, indicate that this technology is superior to traditional analytical methods or even other methods such as ELISA, quantitative real-time PCR, immunohistochemistry, and colorimetric assays [14, 15]. A large number of studies reported in the literature indicate that the electrochemical sensor is a potential device to be developed commercially.

This review discusses a detailed account of the fundamentals and engineering of an electrochemical sensor with the knowledge of electrode surface modification for improving assay efficiency. State-of-the-art methodologies of different types of electrochemical sensors are also discussed. Additionally, the challenges and future perspectives associated with the future of electrochemical sensor technology are incorporated into the text.

Electrochemical sensor

An electrochemical sensor is a standalone integrated tool that translates the information associated with electrochemical reactions into analysis-ready signals. It is useful to provide specific quantitative or semi-quantitative analytical data employing a chemical recognition element (receptor) that is fixed in direct spatial contact with the electrode [8]. In electrochemical sensors, the most common electrode system is the two-electrode (2E)-based and three-electrode (3E)-based systems. The cell based on a 3E system contains reference, counter, and working electrodes, while the 2E system only contains reference and working electrodes. The use of 2E and 3E systems is dependent on the condition of the electrolyte solution, the amount of the current passed through the electrode–solution interface, and the employed electrochemical technique. In a measurement, current flows across the working electrode and some other electrode (generally two leads require to complete the current circuit). This other electrode refers to the reference or some other third electrode. When the reference electrode is used as the current-carrying electrode, its potential will change, and finally, it is no more a reference electrode. Thus, using a reference electrode as a current-carrying electrode should be avoided. Indeed, a third electrode called the counter or auxiliary electrode is required, in which its main purpose is to complete the circuit to carry current. More explicitly, the 2E system can be employed just in case the current passed is so small and the solution resistance is also tiny. The 2E system is usually applied in polarography, where the concentration of the electroactive compound is low and a high concentration of the supporting electrolyte is used for the reduction of the charging current. Otherwise, the 3E system is required for most of the electrochemical techniques such as linear sweep voltammetry (LSV) and cyclic voltammetry (CV), in which the accurate control and monitoring of the working electrode potential is necessary. In the 3E system, the potential is applied between the working electrode and counter electrode yet is controlled with respect to the reference electrode, so that its potential stays constant all the time. In this system, there is no limitation for the amount of current passed, and no wonder it is widely used in most electrochemical investigations [16, 17].

Based on the type of measurements, electrochemical sensors are grouped into potentiometric, conductometric, voltammetric/amperometric, coulometric, and impedimetric. The potentiometric sensors measure the potential difference between the indicator and reference electrodes under conditions in which no current flow. They function under equilibrium conditions and monitor the accumulation of charge caused by selective binding. Such sensors can be realized into biosensors by modifying the electrode with biological materials like an enzyme that catalyzes the reaction to generate ions that are eventually sensed when the ions bind to a suitable ion exchange membrane [18]. The conductometric sensors involve the measurement of a solution’s ability to conduct an electrical current. They rely upon alterations in the electrical conductivity of a film or mass affected by the conductivity of the present analyte. In conductometric detection, a change in the concentration of the ionic species leads to a change in the electrical conductivity. The conductivity electrodes can be in direct contact with the solution, or alternatively, can be insulated using a thin layer. In contact-mode conductivity detection, good sensitivity and lesser response time can be obtained; however, it raises the risk of the electrodes breaking down and the samples becoming contaminated. Otherwise, such risks will not be observed in the contactless conductivity measurements since the electrodes are separated from the sample employing a thin film of insulation. To afford the best capacitive coupling, the insulation layer requires to be as thin as possible [19].

The voltammetric sensors record the current as a function of potential. In the measurement, the potential is variously applied either step by step or continuously to obtain a voltammogram. Several electrochemical sensors based on the voltammetry technique include cyclic, differential pulse, square wave, linear sweep, stripping, and hydrodynamic. These types of measurement have been commonly employed for the analysis of a diverse range of samples including clinical samples, pharmaceutical formulations, environmental samples, and so on. Similar to the voltammetry, the amperometric sensors measure the response current at a given potential, yet, in this case, the applying potential is kept constant. In other words, the amperometric technique involves the measurement of changes in current at a fixed potential. In the amperometric sensors, the constant voltage applied to the working electrode causes a current to flow, which is then recorded as a function of time. Since relying on the specific potential for a given analyte, the amperometric sensors offer a sensitive and selective measurement [20]. The coulometric sensors are a physicochemical method that does not use signal dependence on the analyte concentration. Coulometry is an absolute method that requires no chemical standard or calibration. The mass of the analyte is proportional to the amount of electricity consumed for electro-reduction/oxidation [21]. The impedimetric sensors involve the measurement of the resistance, capacitance, and inductance by a small-amplitude AC potential. The spectrum is gained from frequency variations in a wide range. Then, resistive and capacitive components are mostly obtained by the determination of in- and out-phase AC current. This technique can be used to develop affinity biosensors since they allow monitoring of impedance variation by the charge and mass transfer of analyte at the sensor surface [22].

Figure 1 shows the electrochemical sensor configuration and its basic principles.

The configuration and working principle of an electrochemical sensor. The target analyte in a sample is recognized by the receptors fixed on the electrode surface, resulting in a catalytic or binding event. The signal output is generated from the translation of the physicochemical changes due to target–receptor interactions, which can be displayed in the different electrochemical data depending on the types of measurement

Electrode surface modification

Since the electrochemical reactions occur on the working electrode surface, this electrode, thus, takes a crucial role in the sensor system. To improve the sensor performance, especially in terms of selectivity and sensitivity, the working electrode is usually modified with chemically stable substrates, such as nanomaterials, polymers, or composite materials. Mostly, the modified electrodes are evaluated on their capability both to sense the target of interest in a complex sample and to detect a very small amount of the analyte, which, respectively, represent the selectivity and sensitivity. On occasion, the sensitivity reflects the limit of detection (LOD). Note that the LOD is the lowest response, or the lowest quantity possibly to be determined, that can be estimated with a sufficient degree of statistical significance [21]. The physicochemical basis for the role of electrode surface modification can be explored by modifying an electrode for use in the selectivity study, enabling easier sensing in real samples. Generally, if the modified electrodes have a strong affinity to interact with the target, it will afford a good specificity. Yin et al. [22] electrochemically modified a carbon disulfide-functionalized graphene oxide (GOCS) composite electrode with cadmium ion-imprinted polymer (IIP) and then it was applied to detect Cd(II) by differential pulse voltammetry (DPV) technique in food samples. Since the IIP had a binding affinity to the target, the modified electrode demonstrated excellent sensing selectivity. Another feature of the electrode surface modification is an increased surface area that results in the enhancement of sensitivity. For instance, Ma et al. [24] tailored an electrode using graphene frameworks with a porous structure and high surface area. It was applied for electrochemical sensing of catechol, showing good performance with a low LOD of 0.19 µM. One of the claims made about electrode modification is that it leads to significant amplification of the analytical signal through altered electron-transfer kinetics. However, this was proved in many reported works [23,24,25,26,27].

Immobilization matrices

As previously mentioned, the working electrode defines the sensor performance, on which its modification with a different type of electrode substrates results in distinct electrochemical behaviors. The materials generally used in the electrochemical sensor fabrication are classified as (1) supporting substrates or immobilization matrix, (2) electroanalytical performance-enhancing material, and (3) recognition elements/receptors [28]. The classifications 1 and 2 are not sturdily defined in particular cases, especially for the electrochemical detection platforms that require no redox active indicators to generate the signals. In this regard, the materials that act as the immobilization matrix typically also enhance the electroanalytical performance, and vice versa. For instance, Noh et al. [29] devised a detection platform for cytokines using MXene nanosheet that functions as the detection sensitivity amplification as well as immobilization matrix for the aptamers. In a completely different case, the electrode materials can serve as a catalytic agent to conduct an electrochemical reaction. The sensing platforms that utilize catalytic materials for the electrode surface modification are also known as catalytic sensors as reported by Jannath and Akhtar et al. [30], while the sensor incorporating receptor molecules with a high deferential selectivity are known as affinity sensors. In general, the electrochemical affinity sensors involve the immobilization matrices for receptor attachment.

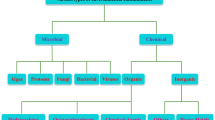

The immobilization matrices are substantial in the electrode surface modification. Mostly, they have high conductivity, a wide potential window, and are free of any electroactive species. In the past decades, significant advances have been made since new platforms, such as nanostructured architectures and nanotechnological materials, were introduced [31]. Nanomaterials have a remarkable impact on the electrochemical sensor application owing to their properties, such as improved electrical conductivity, stability, and chemical reactivity granted by increased surface area per unit weight. When applied as electrochemical labels, they push the LOD down and increase sensor sensitivity as well. The commonly used materials for immobilization purposes of the recognition elements include metal nanoparticles (MNPs), metal oxide NPs (MONPs), metal chalcogenides, metal–organic frameworks (MOFs), polymers, conducting polymers (CPs) or functionalized CPs, carbon nanomaterials (diamond, graphite, amorphous, fullerene C60 and C540, carbon onions, graphene, GO and its derivative, carbon nanotubes), nanocomposite materials (metallic, metal oxide and hydroxide, carbon, CP composites), etc. [28, 32]. Among them, the CP composites have received much attention because of their outstanding characteristics such as large surface area, strong catalytic efficiency, and good stability. Furthermore, they allow the receptors to be attached in multiple strategies. In addition, the CP composites also improve the mechanical strength of electrode interfaces with stability, preventing the leaking of the materials and antifouling. The antifouling property probably was due to the polymerization of the CPs that can reduce surface roughness and pore size. These advantages deliver a prodigious possibility of discovering excellent electrode substrates for advancing electrochemical sensors. Therefore, no wonder numerous electrochemical sensors reported nowadays are based on CP composite materials [33, 34]. Figure 2 presents different types of materials that are commonly used in the fabrication of electrochemical sensors.

Recognition elements

Recognition elements (REs), also known as receptors, are a substance integrated into a sensor device that specifically interacts with the molecules of interest in a sample. They are fixed on a modified sensing surface in a desired manner dependent on the immobilization matrices. The attachment of REs is a pivotal process to develop a high-specificity and stable-reusability sensor. The most critical part of this stage is to preserve the ability of REs to interact with the targets perfectly. Furthermore, the immobilization requires not only a speedy process but must load a large number of REs on the sensing surface as well [35]. In bioelectrochemical sensors, the recognition elements are classified into biocatalytic receptors such as enzyme and bioaffinity recognition elements such as antibodies, chemical antibodies (aptamers), and nucleic acid sequences. Other well-known REs commonly utilized in biosensing are cells or tissues and molecularly imprinted polymers (MIPs).

In fact, a selective and sensitive RE is not always used, yet a careful balance in terms of sensitivity, selectivity, reusability, reproducibility, physical parameters, ease of synthesis, etc. is maintained [36, 37]. Nanomaterials and their composites can be an alternative in electrochemical sensing because they have catalytic properties, in spite of the lack of specificity. As an example, a graphene oxide-anchored functionalized poly-aminopyrimidyl terthiophene (polyPAT) composite electrode was used to detect heavy metal ions Zn(II), Cd(II), Pb(II), Cu(II), and Hg(II) simultaneously in water samples [38]. In the interference study, the sensor demonstrated a reduced peak current of ≥ 5.0% in the presence of other metal ions which indicates its relatively low specificity toward the target metal ions. Another example is a recently published paper that reported the success of using the AuCo dendrite-anchored conductive polymer for the detection of saccharides. In this regard, the dendrite electrode showed electrocatalytic activity for the oxidation of sugars, where the LSV peaks were observed at + 0.07, + 0.04, + 0.02, + 0.01, + 0.04, + 0.01, + 0.04, and + 0.04 V for glucose, fructose, galactose, mannose, xylose, sucrose, maltose, and lactose, respectively. Since the sensor could not discriminate different types of saccharides, the platform utilized an electrodynamic microfluidic channel to separate them prior to the detection [39].

Considering several factors that may influence the analytical performance, it is of great importance to refer to a systematic decision map as shown in Fig. 3 for the receptor selection in designing an electrochemical sensor.

The systematic decision map established by Morales and Halpern for assisting the receptor selection in the initial design of electrochemical sensors [37].

Enzymes

One of the key biorecognition elements employed in the electrochemical sensors is an enzyme. It is a biological catalyst produced by living organisms, which can speed up the rate of certain chemical reactions in cell metabolism by a factor of at least 10 million. In a chemical reaction, enzymes are not destroyed, and therefore they can be used over and over. They specifically interact with substrates at the active sites to form an enzyme–substrate complex [40]. Generally, enzymes have better efficiency than those of the synthesized catalysts operating at the same experimental conditions. Thanks to their superior characteristics, enzymes have been broadly utilized in the development of electrochemical sensors. The enzyme-based electrochemical sensors (enzymatic sensors) are devised by attaching enzymes to an electrode and then applied to detect the matching substrate. To enhance signal generation, enzymes are commonly embedded in conductive materials or nanomaterials. The electrochemical enzymatic sensors offer distinct advantages, such as good selectivity and sensitivity as well as the possibilities for portability and point-of-care testing (POCT) devices. Such features make them more attractive for applications in food safety control, clinical analysis, or health monitoring [41, 42].

Antibody

An antibody is a protective protein designed by the immune system in response to a foreign substance. The antibodies are a large protein arranged in three globular regions that form a Y-shaped structure (Fig. 4). Each Y consists of two different identical pairs of polypeptide chains, including a heavy chain and light chain with MW of ~ 50 kDa and ~ 25 kDa, respectively. In the immune mechanism, antibodies identify and attach to specific antigens via antigen–antibody reaction with the purpose of eliminating them from the body. Types of interactions between antibodies and antigens include hydrophobic interactions, van der Waals forces, electrostatic forces, and hydrogen bonds. Antibodies have been broadly used in sensing applications as a recognition element thanks to their inherent characteristics [43, 44].

The structure of the antibody. Heavy and light chains connected by S–S bond to form the Y-shaped structure. –S–S– disulfide bridges, LC light chain, HC heavy chain, CR constant region, VR variable region [45].

Aptamers

The utilization of aptamers as a recognition agent for electrochemical sensing is strongly favored. Aptamers demonstrate comparable affinity to antibodies for binding to the targets. They are easy to immobilize on the electrode surface resulting in a longer shelf life (long-term stability), higher reproducibility, resistance to temperature changes and pH, and low immunogenicity. Additionally, aptamers offer a simple and low-cost synthesis process in a relatively short time. In the selection of aptamers, it involves the systematic evolution of ligands by exponential enrichment (SELEX) technology from a large and assortment collection of nucleic acids [46, 47].

Nucleic acids

Nucleic acids are a biopolymer formed from nucleotides that combine with each other. They can bind non-nucleic acid targets as well as catalyze chemical reactions. Hence, it is possible to use nucleic acids as the REs (in hybridization probes and aptamers) or enzymes (DNAzymes and ribozymes). In addition, the nucleic acids are easily modified with other molecules, making them ideally suited for use in the development of electrochemical sensors [48].

Cells

Living cells can act as a recognition layer in the electrochemical sensors by immobilizing them on the modified surface. They are useful for the study of the typology and activity of different cells since modifying the physiological state and behavior of the living cells under a specific stimulation is possible. Cell fixation is a very important step for achieving sensor stability and reliability. Among the cell immobilization methods, the most common one is to form a uniform adhesion layer using extracellular matrices like collagen, laminin, peptides, and self-assembled monolayers [49].

Molecularly imprinted polymers

Over the past few decades, molecularly imprinted polymers (MIPs) have emerged as alternative receptors substituting antibodies in the development of electrochemical sensors. They are synthetic polymers with specific and selective recognition elements bearing the advantages of durability under different environmental conditions and low fabrication costs [50, 51].

Immobilization strategies

The pillar of an electrochemical sensor is the chemical reaction that takes place on the transducer surface between the REs and targets to bring about a signal response. Accordingly, receptor immobilization in manufacturing a sensor becomes the most crucial stage. This process is affected by some factors, including electrode surface properties (physical and chemical), immobilization conditions (solution, pH, temperature, etc.), receptor characteristics, receptor orientation and density, and immobilization strategies. Typically, the strategies of receptor immobilization are classified into two categories, i.e., non-covalent (adsorption, entrapment, or affinity) and covalent or cross-linking [52, 53]. Covalent immobilization is a chemical attachment method that allows the REs to be vertically oriented, thereby facilitating a greater interaction with the target of interest. Although the matrix is not regenerable in this strategy owing to a non-reversible immobilization, it is preferred to adsorption especially when a stable attachment is required by a continuous flow rate and associated shear forces [54]. In general, non-covalent immobilization includes physisorption and bioaffinity interactions. The physisorption is specifically realized for physical encapsulation and entrapment of the REs in which no complex chemistry is involved. This interaction is dependent on the environments and demonstrates weak intermolecular forces like hydrophobic, van der Waals, electrostatic, and hydrogen bonds. On the other hand, bioaffinity relies on certain binding phenomena found in nature. This method provides specific interaction, orientation control, and good steric access to binding partners. The most employed partners in the bioaffinity-based interactions are avidin–biotin and streptavidin–biotin because the ligand–receptor possesses a very strong affinity and can mediate the attachment of numerous REs with preserving their functionality [55].

Table 1 presents the highlights of key advantages and disadvantages of using each immobilization strategy.

State-of-the-art electrochemical sensors

Electrochemical sensor classification based on immobilization matrices

Metal nanoparticle-based electrochemical sensors

In the electrochemical sensors, the main role of metal nanoparticles (MNPs), including noble metal and metal oxide NPs, involves toughening of the conductive sensor interface, on which their electrochemical behaviors enable the electrical contact of redox centers in the target of interest with the transducer surface. The biocompatible of these materials is demanded the immobilization of molecules or biomolecules in the fabrication of electrochemical immunosensors, genosensors, enzyme sensors, bacteriophage sensors, etc. [56, 57].

Because of their unique electrocatalytic properties, noble metal NPs have captured the vast attention of researchers. Their superiority lies in low-cost compared to bulk metal catalysts, high surface area, and selectivity. Furthermore, their electrocatalytic activity can be tuned and tailored according to their size and shape. In electrochemical sensor development, noble MNPs are considered electrode materials due to their high stability and sensitivity [56]. One of the most commonly used noble MNPs in electrochemical sensor development is Au nanoparticles. This nanomaterial has high electrical conductivity, chemical stability, volume-to-surface ratio, and loading capacity as well as ease of synthesis by a green and cost-effective method. Moreover, the Au nanoparticles have good biocompatibility which is beneficial for use in the development of electrochemical sensors that involve the analysis of living cells [58]. In a lung cancer study, AuNPs were used to fabricate an ultrasensitive amperometric nanobiosensor for the detection of A549 non-small cell lung cancer (NSCLC) cells. The AuNPs served as an immobilization matrix for aptamer attachment by compositing with poly(2,2′:5′,2″-terthiophene-3′-(p-benzoic acid)) (polyTBA). On the other side, they were also used to prepare a bioconjugate attached to another aptamer and hydrazine. The sensing platform performed a simple, low-cost, biocompatible, and sensitive analysis of NSCLC [59]. In a different investigation, an electrochemical sensor based on AuNPs was devised for the detection of annexin II and MUC5AC, which are biomarkers for lung cancer early detection. Two-step depositions of Au nanoparticles were aimed at improving the sensing performance. The first step of AuNP deposition was conducted on the surface of the GC electrode, while the second step of deposition of AuNPs was carried out by doping them onto the dendrimer. By chronoamperometric (CA) technique, the proposed immunosensor was successfully applied to determine the targets in the apical surface fluids of squamous metaplastic epithelial cells [60].

Besides the AuNPs, Pd nanoparticles are also among the most common metal NPs in the fabrication of electrochemical sensors. The PdNPs possess catalytic activities and strong chemical resistance. These characteristics are probably due to quantum size effects, large surface-to-volume ratio, structural robustness, and good biocompatibility [61]. An example of the utilization of Pd nanoparticles in electrochemical sensing was reported by Cao and Wei’s group [62]. The Zn2SiO4 spheres loaded with PdNPs were synthesized and then used as dual-functional labels in the electrochemical sensing of insulin. The CA signal was generated from the reduction current of H2O2 by the Zn2SiO4–PdNPs, showing a highly sensitive insulin detection under the optimized experimental conditions. Another PdNPs-based sensor was reported for the detection of alpha-fetoprotein (AFP) based on a sandwich-type format [63]. In this work, PdNPs were loaded on Fe3O4@C, utilizing electrostatic attraction to form a core–shell structure. The amperometric signal amplification was based on the noble metal Pd nanoparticles that exhibited electrocatalytic properties toward H2O2 reduction.

Metal oxide nanoparticle-based electrochemical sensors

When coupled with the recognition molecules, metal oxide NPs have proven a better selectivity. The metal oxide NPs demonstrate good electrochemical properties owing to their size, high surface area, and stability [57]. For instance, a NiO NP was modified with a CeCuOx-modified electrode for the determination of lipocalin 2 (LCN 2), a biomarker for acute kidney injury (AKI), in serum. The high surface-to-volume ratio of NiO NPs/CeCuOx facilitated the successful attachment of antibodies. By voltammetric technique, the sensor exhibited a high selectivity and recovery rate in LCN 2-spiked serum, which confirmed its feasibility to use in real clinical samples [64]. In a different report, a CeO2 NP or nanoceria was utilized in the fabrication of a disposable electrochemical total antioxidant capacity (TAC) sensor using square wave voltammetry (SWV) measurement [65]. The simple modification method by drop-coating the nanoceria on the screen-printed electrode was conducted to manufacture the proposed sensor. In terms of performance, it showed comparable results to that of the other method like spectrophotometric. Overall, the TAC sensing platform offered portability with ease of use and cost-effectiveness.

Metal chalcogenide-based electrochemical sensors

Transition metal chalcogenides (TMCs) possess distinctive characteristics which are suitable for catalytic applications. They include excellent charge transfer ability, large surface-to-volume ratio, controllable energy band gap, strong interaction with light, and mechanical robustness. These unique features make TMCs superior electrode materials for the development of electrochemical sensing platforms [66]. Recently, a transition metal dichalcogenide-based sensor was developed using MoS2 nanoflowers supported with AuNPs [67]. The MoS2–AuNPs-modified GC surface acted as a DPV signal amplification for the cancer antigen 72-4 (CA72-4) sensing. A simple electrochemical sensing platform for lactic acid (LA) based on TMCs was reported by Arivazhagan et al. [68]. In this work, they electrochemically deposited a hollow sphere of HS-NiS nanostructures on the nickel foam (NiF) substrate to form NiF/HS-NiS electrodes for LA sensing. By employing the amperometry technic, the enzyme mimic sensor performed an excellent electrocatalytic oxidation and detection ability toward LA. Most importantly, it exhibited practicality by sensing LA in urine samples. In their different LA detection work, an NiS nanocluster on NiS microsphere/bare NiF was prepared via a one-step electrochemical strategy. A high-performance amperometric detection of LA was achieved due to the uniform and good dispersion of small NiS-NC, abundant active sites, and improved mass transfer kinetics [69]. A layered metal chalcogenide of SnSe was composited with 2D-hexagonal boron nitride (h-BN) and then used for amperometric detection of nitrofurazone (NF) [70]. The SnSe/h-BN electrode demonstrated superior performance because of its high surface area and electron-transfer kinetics.

Metal–organic framework-based electrochemical sensors

MOFs have been applied for electrochemical sensors due to their abundant mesoporous, large surface area, designability, and diverse functional groups. The MOFs constitute ultrahigh porosity material that offers a favor for the sensing platform development. The intrinsic MOF characteristic affords more active sites for signal recognition molecules [71]. An example of work involving the use of MOFs was reported by Daut et al. [72]. They proposed an alternative approach for long-term monitoring of glucose employing an amperometric enzyme-free sensor. In the development, Ni–BDC–NH2 permitted diffusion for glucose entrapment by a multi-layered sheet-like structure and glucose adsorption by a BDC linker-attached –NH2 group.

Polymer-based electrochemical sensors

In electrochemical sensor configuration, polymers generally enhance the mechanical strength of electrode interfaces with stability. They also can directly involve in the sensing mechanism, or be as an immobilization matrix for specific receptor immobilization. A wide variety of polymers known to date can be grouped into two types, namely natural polymers (agar, cellulose, chitosan, glucomannan, inulin, pectin, etc.) and synthetic polymers (biocompatible, ethylene vinyl alcohol/EVOH, acrylic, conducting polymers, etc.). The polymer-based matrix platforms provide both non-covalent and covalent immobilization strategies. The non-covalent strategy is realized for the entrapment of the molecules within the polymers, while covalent immobilization is achieved by bonding the molecules/biomolecules to the polymers employing EDC/NHS chemistry, glutaraldehyde cross-linking, etc. Although offering the possibility of chemical modification that results in the sensor reactivity, flexibility, resistance to degradation, and good biocompatibility, the use of polymers can reduce the electrode conductivity owing to their semi-conductive property. Naturally, they are semi-conductive with low electrical conductivity. Despite this disadvantage, polymers have been still demanded for electrochemical sensor fabrication. The researchers overcome such limitations by incorporating them with conductive materials to obtain polymer composites as discussed in “Immobilization matrices” [33, 73].

One reported the development of a shrink polymer-based sensor for POCT of prostate-specific antigen (PSA) biomarkers. The poly(l-lysine hydrobromide) (PLL) was fixed on the graphene electrode followed by the attachment of an antibody to obtain the probe. The sensing mechanism was based on the DPV signal attenuation due to the steric hindrance of PSA captured on the probe, proportionate to the concentration of PSA in the samples. The sensor showed a short time of analysis, high selectivity, repeatability, precision, and long-term stability. Additionally, the analytical results obtained using the developed sensor were in good agreement with the commercial chemiluminescence instrument, suggesting the feasibility of the sensor in clinical diagnosis [74]. In a different research, the CP precursor TBA was electrochemically polymerized on the electrode surface and used as an immobilization matrix for the development of an electrochemical thrombin sensor. The amperometric signal originated from the redox indicator toluidine blue O (TBO) fixed on magnetic NPs along with an anti-thrombin antibody. The detection mechanism was based on sandwich-type immunoreaction, on which the target thrombin was sandwiched between the probe and bioconjugate. The sensor performed reliable results with good recovery in the range of 93.8–103.6% toward human serum samples spiked with thrombin [75].

Carbon nanomaterial-based electrochemical sensors

Carbon nanomaterials can be easily exploited in the industrialization of advanced technology for sensing applications owing to their built-in features that include a wide potential window, very small background current, good biocompatibility, and low production cost [76]. Poh et al. utilized nanoporous carbon for DPV detection of multiple biomarkers such as ascorbic acid, DNA bases, dopamine, NADH, and nitroaromatic explosives. This material consistently demonstrated superior performance compared to the bare GC electrode, graphite microparticles, and carbon nanotubes (CNTs) [77]. Carbon nanomaterials are also used in combination with a polymer as reported by Shim’s group [78]. An N,S-doped porous carbon (DPC) was modified on the GC electrode, then electropolymerized with a bi-functionalized 3-[(2,2′:5′,2″-terthiophen)-3′-yl]-5-aminobenzoic acid (TABA) monomer. The carboxyl and amine functional groups of pTABA were used to covalently attach NAD+ and LDH, respectively. When the samples containing lactate were introduced into the sensor system, an increase in amperometric currents was observed. The amperometric signals were ascribed to the LA level in the sample.

Composite-based electrochemical sensors

Ghalkhani et al. [79] developed an electrochemical raloxifene (RLX) sensor by a facile and cost-effective procedure. The sensor was fabricated using an rGO–CNT composite fixed on a GC electrode. It demonstrated high electrocatalytic efficiency and stability for the voltammetric determination of RLX in plasma and pharmaceutical samples. Zhu et al. [80] detected kanamycin employing a label-free LSV sensing platform based on a nanocomposite that consists of aptamer, functionalized CPs, and Au nanoparticles. The probe was fabricated by depositing self-assembled DPB on the electrode surface, followed by electropolymerization and covalent attachment of aptamers on the polyDPB(AuNP) composite electrode. The sensor was highly selective toward kanamycin and stable for up to two months. Abdelwahaba and Shim [81] deposited AgNPs on the Ox-polyTBA/MWCNT nanocomposite electrode for use in amperometric sensing of H2O2. Interestingly, it showed a very fast response time of < 5 s and sensitive detection with a LOD of 0.24 µM. Chung et al. [82] fabricated a sensing platform for dopamine and serotonin by anchoring Pd(C2H4N2S2) complex to the polyTBA layer on the employed AuNPs surface. Using a SWV technique, it was observed that the sensor performed a simple, rapid, selective, and precise analysis for real samples. Gopal et al. [83] developed a non-enzymatic method for amperometric sensing of glucose based on MXene-based nanocomposite. Simply, the sensor was fabricated by drop-coating MXene–Cu2O (Ti3C2Tx–Cu2O) nanocomposite on a GC electrode. The nafion was finally coated on the MXene–Cu2O (Ti3C2Tx)/GCE as a binder.

Table 2 summarizes the classification of electrochemical sensors based on immobilization matrices.

Electrochemical sensor classification based on recognition elements

Enzymatic/non-enzymatic electrochemical sensors

Enzymatic electrochemical sensors operate by utilizing enzymes fixed on the transducer surface for the catalytic process. Contrarily, enzyme-free electrochemical sensors or non-enzymatic electrochemical sensors do not require enzymes for the sensing mechanism. Instead of enzymes, they use certain materials that have the ability to catalyze the target of interest. An example of an enzyme-based electrochemical sensor is the use of GOx for the development of amperometric glucose sensors as reported by Kim et al. [84]. The sensor was fabricated using the conducting TCA monomer electrochemically polymerized on a gold-coated microneedle (AuMN) surface. The GOx enzyme was covalently attached to the polyTCA layer through amide bond formation between the –COOH group of pTCA and the –NH2 group of enzymes. One study reported the development of enzymatic and non-enzymatic amperometric glucose sensors in a single experimental setting [85]. For the non-enzymatic sensor, the mere hierarchical Au–Ni alloy was used. Meanwhile, for the enzymatic sensor, the conducting polyTBA was modified on the same alloy layer and then used as an immobilization matrix for the covalent attachment of GOx. In this study, the enzymatic sensor demonstrated a better analytical performance (sensitivity of 1.4 times higher, LOD of 20.1 lower, and stability of 12 days longer) than that of non-enzymatic sensor, due to the use of stable CP. However, enzymes are typically prone to environmental changes that can impact the stability of a sensor being developed. Besides, the immobilization technique and electrode matrices used may also affect this parameter. Otherwise, nanozymes are relatively stable and easy to prepare at a low cost.

Nanozyme-based electrochemical sensors

Nanozymes refer to a group of nanomaterials with enzyme-like characteristics that can perform catalytic reactions similar to those carried out by natural enzymes. They are also known as artificial enzymes. Nanozymes can be composed of metal and MONPs, metal nanoclusters (NCs), quantum and carbon dots, nanotubes (NTs), nanowires, or MOFs. They offer numerous advantages such as high operational robustness, stable shelf life, and low cost of synthesis. Most importantly, nanozymes exhibit comparable catalytic activities to those of natural enzymes [86].

Gold-loaded nanoporous ferric oxide nanocubes (Au–NPFe2O3NCs) were used for the fabrication of autoantibody sensors, exhibiting improved electrocatalytic and colorimetric detection of p53-specific autoantibodies [87]. The Au–NPFe2O3NCs nanozyme assisted the catalytic oxidation of 3,3′,5,5′-tetramethylbenzidine (TMB) in the presence of H2O2 via the Fenton reaction mechanism. An excellent sensing sensitivity with LOD of 0.08 U/cm3 and reproducibility (RSD) of ≤ 5.0% were obtained in the determination of p53-specific autoantibodies employing the CA technique. A nanocomposite of Au–CuO was labeled with CD62E and then reacted with the poly(azure A)/antibody electrode to form PAA/Ab/CD62E–Au–CuO layer. The enzyme-like activity possessed by the modified electrode was observed to improve the electrocatalytic process, resulting in a high DPV cathodic peak current. The introduction of the target E-selectin in the sensor system inhibited the assembly due to competitive immunoreaction. The linear dynamic range was from 0.5 to 500 ng/cm3 with an estimated detection limit of 226 pg/cm3 [88]. The functionalized nanozymes based on Prussian Blue (PB) and azidomethyl-substituted poly(3,4-ethylenedioxythiophene) (azidomethyl-PEDOT) were utilized as electrocatalytic labels for RNA/DNA sensors [89]. The direct electrocatalytic amperometric current of H2O2 reduction is the signal response that is proportional to the concentration of the hybridized sequences. The use of advanced PB-based electrocatalytic labels has opened a new avenue for POC RNA/DNA detection. Single-atom nanozymes of Co–N–C were embedded in rGO aerogel for amperometric sensing of H2O2 in living cells. The electrocatalytic performance of Co–N–C was enhanced thanks to the unique 3D layered rGA structure that has excellent electrical conductivity and high material loading [90]. Another single-atom nanozyme-based H2O2 sensor was reported [91]. In this case, a single-atom Au catalyst was loaded on CeO2 since it has the ability to accommodate more Au atoms. The A549 cells-released H2O2 was detected through the DPV technique employing a highly catalytic and stable sensor with a LOD of 1.4 nM.

Electrochemical immunosensors

An electrochemical immunosensor is a class of biosensors that is based on the interactions between an antibody and antigen occurring on the surface of an electrode (transducer). In the sensor configuration, either antibody or antigen can be the species fixed on the transducer surface which serves as a recognition element. Since antibodies and antigens have strong binding forces, the immunosensors offer high selectivity and sensitivity which make them attractive for use in various health applications, especially as a POCT [45].

An amperometric immunosensor for granzyme B (GzmB) detection was developed in a sandwich-type architecture [14]. An anti-GzmB monoclonal antibody and anti-GzmB polyclonal antibody were covalently immobilized on the CP layer to obtain a sensing probe and bioconjugate, respectively. The sensor demonstrated wide linearity, low LOD, high selectivity, reproducibility, and long-term stability as well as excellent detection precision. Moreover, the developed GzmB immunosensor was successfully applied to monitor the patients’ cancer progression while undergoing targeted therapy. In a different study, a label-free electrochemical cancer antigen 72-4 (CA72-4) immunosensor based on a signal amplification strategy of AuNPs-supported MoS2 was fabricated [67]. The receptor was attached to the composite layer utilizing the interaction between NH3+ in the antibody molecules and Au nanoparticles to form an amine–gold bond. The investigation provided a theoretical basis for the ultrasensitive DPV detection of cancer biomarkers in biological samples. Another tumor marker, carbohydrate antigen 199 (CA19-9), was successfully detected using a sandwich-type immunosensor based on a controlled release strategy [92]. By DPV technique, the immunosensor exhibited a wide linear concentration toward standard CA19-9 in the range of 0.001–100 U/cm3 with a detection limit of 0.0005 U/cm3. Since the outbreak of the coronavirus disease (COVID-19) attacked in early 2020, a huge research in the electrochemical immunosensors had been carried out for patients’ diagnosis. For instance, an electrochemical immunosensor for rapid determination of antibodies against the syndrome coronavirus 2 (SARS-CoV-2) spike protein was developed [93]. In this case, the receptor ScoV2-Rs was modified on the phytic acid-doped polyaniline (PANI-PA) films and then used to detect antibodies in the patient’s serum samples by means of impedance technique. Another electrochemical SARS-CoV-2 immunosensor was tailored using anti-spike antibodies functionalized on a graphene working electrode [94]. The sensor could detect SARS-CoV-2 using SWV measurement at the concentration of 5.5 × 105 PFU/cm3. Interestingly, it demonstrated a significantly faster analysis than that of the standard qPCR and was miniaturized in the form of a portable device that is possible for use in on-site infection diagnosis.

Electrochemical aptasensors

A functionalized bimetallic MOF-based dual signal aptasensor was developed for DPV detection of HER2 [95]. The aptamer was physically adsorbed on the Zn–Co–MOF@Fc/ITO electrode. Using Apt/Fe–Co–MOF@MB as labels, two peaks of the electrochemical signal were observed, which obviously originated from Fc and MB. A simple, fast, and accurate sensing of HER2 with the linearity from 0.75 to 250 pg/cm3 and LOD of 0.37 pg/cm3 were based on the ratio of signal peaks. In a study, a label-free electrochemical DPV sensing strategy was devised for thrombin [96]. The aptamer supported by conductive GNPs/CNO/CS nanocomposite demonstrated a promising quantitative determination of thrombin in human serum with superior sensitivity, specificity, and reproducibility. In addition, the aptasensor was useful in the biomedical field as well as for clinic applications. A sandwich-type electrochemical aptasensor based on the tyramide signal amplification (TSA) technology was used to detect Pseudomonas aeruginosa bacteria. The primary aptamer SA37 was used to capture the bacteria cells, while the secondary aptamer SA81 labeled with HRP was the catalytic probe. A TSA-based signal enhancement comprising biotinyl-tyramide and streptavidin-HRP is utilized as signal tags for improving the amperometric sensing sensitivity [97].

Electrochemical genosensors

A sensor that recognizes the target nucleic acids based on a hybridization reaction is called a genosensor. This approach is different compared to aptasensor which utilizes high affinity and specificity to bind a target molecule. In genosensors, DNA or RNA targets are detected through the hybridization reaction between DNA or RNA and single-stranded DNA (ssDNA) sensing element. Two common strategies applied in genosensing include sandwich and competitive formats and direct format. The sandwich and competitive formats use a recognition that consists of the mixture of DNA target and incubated ssDNA probe on the sensor surface through a specific label. Meanwhile, the direct format is principally based on the label-free detection by attachment of ssDNA on the modified electrodes. Although the direct format is comparatively simpler than that of the competitive format, sometimes the ssDNA probe-target DNA complex on the sensor surface produces no desirable changes in the transduction values. Therefore, the sandwich and competitive formats are a preferred approach to improve sensitivity [98].

An interesting electrochemical genosensor based on magnetic actuation and multiplex double tagging was utilized to detect interferon-gamma (IFN-γ) transcript on T cells [99]. Using the CA technique, the sensor performed highly sensitive and specific detection of IFN-γ. Moreover, it was a promising platform as an alternative IFN-γ release assay test for use in screening out populations at primary health care. In a lung cancer study, an exosomal microRNA array sensor was used as a sensing platform to simultaneously detect miRNA-21, miRNA-155, miRNA-205, and miRNA-let-7b in cell line models as well as NSCLC patient serum [100]. The multiplexed sensor was constructed using the conducting polyTBA for harboring DNA P-1 that hybridizes to the 5′ end of the chimera, followed by the hybridization of DNA P-2 to the 3′ end of the chimera, resulting in the binding site for p53 protein. The amperometric signal was achieved through the reduction of H2O2 by hydrazine fixed on Au nanoparticles along with the sequence recognition p53 protein. The development of a genosensor for electrochemical sensing of miR-200a was reported [101]. The probe was constructed using an NH2–CuONPs–MnO2NRs composite on the GC electrode. With ferrocene-functionalized graphene oxide (Fc–GO) nanosheets as a label, miR-200a was detected in the range of 1.0 fM to 0.1 µM with an LOD of 0.29 fM employing DPV. Since miR-184 expression is downregulated in elderly individuals with late-life depression (LLD), it becomes a potential marker in the LLD diagnosis. A work reported a novel and facile approach based on an electrochemical genosensor for this issue [102]. The sensor proved an efficient LLD diagnosis with accurate quantification of miR-184 via the DPV technique in real biological samples. A genosensor was developed for amperometric quantification of the circulating long noncoding RNA CCAT1 aimed at diagnosing colorectal cancer [103]. The developed sensor demonstrated high sensitivity toward CCAT1 indicated by a low detection limit of 990 fM.

Cell-based electrochemical sensors

An electrochemical sensor based on cells for the sensing of milk allergen casein was reported by Jiang et al. [104]. The rat basophilic leukemia (RBL-2H3) mast cells were immobilized on a highly conductive and biocompatible sensing interface fabricated using a graphene/carbon nanofiber/gelatin methacryloyl (GN/CN/GelMA) composite. By employing the DPV technique, the cell sensor showed linearity for casein in the range of 1.0 × 10–7–1.0 × 10–6 g/cm3 with LOD of 3.2 × 10–8 g/cm3. The developed sensor demonstrated good accuracy, stability, and reproducibility. Another example of a cell-based sensor was reported by Hao et al. [105]. HepG2 cells were fixed on the l-cysteine/AuNFs layer via a 3D cell culture, where sodium alginate/gelatin hydrogel is used to create such a system. Using the DPV technique, the sensor was applied for the detection of hydroxy-α-sanshool and demonstrated good performance. Wei et al. [106] constructed a sensing platform for evaluating the immunomodulatory effects using living cells as biorecognition elements. RAW264.7 cells were encapsulated in GelMA hydrogel to form a 3D cell cultivation system, which was then fixed on the modified electrode. The sensor performed satisfactory results via the DPV measurement of atrazine and its metabolites, indicating its potential for in vitro tests.

Bacteriophage-based electrochemical sensors

Bacteriophages are viruses that contain DNA or RNA encapsulated in a protein coat. They can infect the bacteria cells and then replicate within them; however, they invade no other cells. By modifying bacteriophages genetically to provide a peptide on their surface, the bacteriophages can bind to desired target molecules. This modification enables the bacteriophages for used in the sensor fabrication by immobilizing them on the modified electrode. For instance, M13 phages were covalently attached to a gold electrode and then used for the electrochemical detection of ovomucoid. Two different coupling chemicals of MUA-EDC/NHS and Sulfo-LC/SPDP were employed in the immobilization process. This sensing approach is an efficient alternative way with good sensitivity, selectivity, and stability since it employed electrochemical impedance spectrometry (EIS) and SWV [107]. A study reported the electrochemical DPV detection of E. coli using a wild-type T4 bacteriophage-based sensor [108]. The phages were immobilized on the electrode for the target recognition probe. An interesting feature of this sensor was its ability to differentiate between viable and dead bacteria.

MIP-based electrochemical sensors

Recently, a novel MIP-based electrochemical detection platform was fabricated for the determination of vacuolating cytotoxin A (VacA). The SiO2 NPs-modified surface was electropolymerized by MIP using VacA antigen as a template. Using the voltammetric technique, the SPE/SiO2 NPs/MIP sensor showed high sensitivity toward VacA in the samples with a low LOD of 0.01 ng/cm3 [109]. Another MIP-based electrochemical sensor was devised by integrating AuNPs into the MIP membrane and then applied for the impedance detection of norfloxacin. A rapid and precise determination of the target in real samples makes the sensor useful for routine screening of aquacultures and pharmaceutical processes [110]. A SARS-CoV-2 spike protein was imprinted in the thin film via a surface imprinting strategy. In this study, an MIP synthetic receptor was used for the detection of SARS-CoV-2 spike protein subunit S1 (ncovS1) through SWV measurement. The sensor demonstrated a satisfactory performance with rapid analysis (sample-to-answer of 15 min) [111]. An MIP-based electrochemical DPV milk amyloid A (MAA) sensor was constructed using AuNPs@rGO composite electrode. The template protein was electropolymerized with pyrrole to achieve a molecular imprinting film that has the capability for MAA signaling qualitatively and quantitatively [112]. Electrochemical detection of cytokine interleukin-1β (IL-1β) was carried out employing an impedimetric MIP sensor [113]. The IL-1β biomacromolecule was used as a template in the modification of MIP film which was formed from a double layer of poly(o-phenylenediamine) and poly(chromotrope 2R). The sensor showed a sensitive and selective detection for the trace IL-1β. A low detection limit of 0.23 pg/cm3 was estimated in this regard.

Table 3 summarizes the classification of electrochemical sensors based on recognition elements.

Summary

Electrochemical sensors can serve as semi-quantitative or quantitative assays. In their fabrication, these analytical devices are constructed from an electrochemical transducer modified with materials that can function either as a catalytic agent for the target of interest, or immobilization matrix for the recognition elements, or even both. Such materials include metal NPs, metal oxide NPs, metal chalcogenides, MOFs, polymers, CPs or functionalized CPs, carbon-based materials (diamond, graphite, amorphous, fullerene C60 and C540, carbon onions, graphene, GO or rGO, CNTs), nanocomposite materials (metallic, metal oxide and hydroxide, carbon, and CP composites), etc. The modification of the transducer surface with the electrode materials is aimed at enhancing the sensor performance, particularly in selectivity and sensitivity. Catalytic sensors directly detect the target molecules through an electrocatalytic mechanism performed by the corresponding materials fixed on the electrode surface. Otherwise, electrochemical sensors that utilize the binding affinity (known as affinity sensors) necessitate a recognition molecule to sense the target in a complex sample. The availability of various electrode materials, recognition elements, and immobilization strategies has led attempts to at various types of electrochemical sensors. Herein, the author classifies electrochemical sensors based on the electrode materials consisting of metal nanomaterials (MNPs, MONPs, metal chalcogenides, MOFs), carbon materials, polymers, and composites based electrochemical sensors; and based on the recognition elements including enzymatic/non-enzymatic, nanozymes, immunosensors, aptasensors, genosensors, cells based, bacteriophage-based, and MIPs based electrochemical sensors. State-of-the-art methodologies of these electrochemical sensors are discussed.

Challenges and future aspects

Electrochemical sensors are a promising and challenging research area. In spite of offering several merits, such as selectivity, sensitivity, robustness, ease of use, short-time measurement, miniaturization, and cost-effectiveness, they suffer from narrow or limited temperature ranges. Therefore, keeping electrochemical sensors and the samples at appropriate temperatures as stable as possible is the way to solve this issue. Furthermore, electrode surface engineering in the development of electrochemical sensors is still a major challenge. The rapid development of nanostructured materials, availability of different types of recognition elements, and employable modification strategies may open the possibility for advancing electrochemical sensors. The furtherance of electrochemical sensors in medical applications has greatly progressed, providing advantages such as selectivity, sensitivity, real-time analysis, and non-invasiveness that benefit future industries. Consequently, adaptable electrochemical sensors may be employed as a POCT device in advanced large-scale systems for diagnosis and health monitoring purposes. Electrochemical sensors also show notable progress in other applications, such as the use of arrays for environmental monitoring, and flow injection and online monitoring systems for various contaminants. Machine learning and chemometrics can be implemented in the electrochemical sensors to achieve chemical sustainability, performance improvement, and acceleration of complex system applications. The future prospects of electrochemical sensors are industrializing portable and multiplexed devices for cost-efficient applications.

Data availability

No new data were created or analysed during this study. Data sharing is not applicable to this article.

References

Fraden J (2004) Handbook of modern sensors: physics, designs, and applications. Springer, New York

Janata J (2008) Chem Rev 108:327

Wen W (2016) Progresses in chemical sensor. InTechOpen, Rijeka

Bi H, Han X (2019). In: Mitsubayashi K, Niwa O, Ueno Y (eds) Chemical, gas, and biosensors for internet of things and related applications. Susan Dennis, Chennai

Arakawa T, Dao K, Mitsubayashi DV (2022) IEEJ Trans Electr Electron Eng 17:626

Eddaif L, Shaban A (2023). In: Barhoum A, Altintas Z (eds) Advanced sensor technology: biomedical, environmental, and construction applications. Susan Dennis, Chennai

Regan F (2019) Encycl Anal Sci 2015:172

Hulanicki A, Glab S, Ingman F (1991) Pure Appl Chem 63:1247

Karimi-Maleh H, Karimi F, Alizadeh M, Sanati AL (2020) Chem Rec 20:682

Chugh B, Thakur S, Singh AK, Joany RM, Rajendran S, Nguyen TA (2022). In: Denizli A, Rajendran S, Nadda AK, Nguyen TA, Yasin G (eds) Nanosensors for smart agriculture. Matthew Deans, Chennai

Hartati YW, Suryani AA, Agustina M, Gaffar S, Anggraeni A (2019) Food Anal Methods 12:2591

Firdaus ML, Fitriani I, Wyantuti S, Hartati YW, Khaydarov R, Mcalister JA, Obata H, Gamo T (2017) Anal Sci 33:831

Chung JH, Yoon SH, Jeon D, Choi HJ, Moon K, Kwon S, Saputra HA, Kim YS, Shim Y-B (2022) Ann Transl Med 10:1

Saputra HA, Chung JH, Yoon SH, Seo K-D, Park D-S, Shim Y-B (2022) Biosens Bioelectron 198:113846

Bobacka J (2020) J Solid State Electrochem 24:2039

Bard AJ, Faulkner LR, Wiley J (2001) Electrochemical methods: fundamentals and applications. Wiley, New York

Baranwal J, Barse B, Gatto G, Broncova G, Kumar A (2022) Chemosensors 10:363

Yunus S, Jonas AM, Lakard B (2013). In: Roberts GCK (ed) Encyclopedia of biophysics. Springer, Berlin

Janata J (2009). In: Janata J (ed) Principles of chemical sensors. Springer, Boston

Aoki KJ, Chen J (2018). In: Maxakato NW (ed) Voltammetry. InTechOpen, London

Tanner EEL, Compton RG (2018) Electroanalysis 30:1336

Yin F, Mo Y, Liu X, Yang H, Zhou D, Cao H, Ye T, Xu F (2023) Food Chem 410:135293

Ma X, Huang M, Jia J, Wang H, Wang J, Zhu Y (2023) Microchem J 187:108441

Kozub BR, Rees NV, Compton RG (2010) Sens Actuators B Chem 143:539

Huang X, Li Y, Chen Y, Wang L (2008) Sens Actuators B Chem 134:780

Streeter I, Wildgoose GG, Shao L, Compton RG (2008) Sens Actuators B Chem 133:462

Keeley GP, Lyons MEG (2009) Int J Electrochem 4:794

Săndulescu R, Tertis M, Cristea C, Bodoki E (2015). In: Rinken T (ed) Biosensors: micro and nanoscale applications. InTechOpen, Rijeka

Noh S, Lee H, Kim J, Jang H, An J, Park C, Lee M-H, Lee T (2022) Biosens Bioelectron 207:114159

Jannath KA, Akhtar MH, Gurudatt NG, Park D-S, Kim KB, Shim Y-B (2022) J Mater Chem B 10:728

Moldoveanu I, van Stefan-Staden R-I, van Staden JF (2015). In: Aliofkhazraei M, Makhlouf A (eds) Handbook of nanoelectrochemistry. Springer, Berlin

Guth U, Zosel J, Riedel J, Tran TN, Berthold M, Vonau C, Sasum U, Shuk P, Paramasivam M, Vashook V (2013). In: Mukhopadhyay S, Jayasundera K, Fuchs A (eds) Advancement in sensing technology. Springer, Berlin

Naveen MH, Gurudatt NG, Shim Y-B (2017) Appl Mater Today 9:419

Moon JM, Thapliyal N, Hussain KK, Goyal RN, Shim Y-B (2018) Biosens Bioelectron 102:540

Justino CIL, Freitas AC, Pereira R, Duarte AC, Rocha Santos TAP (2015) TrAC Trends Anal Chem 68:2

Ravina X, Kumar D, Prasad M, Mohan H (2022). In: Maruccino G, Narang J (eds) Electrochemical sensors: from working electrodes to functionalization and miniaturized devices. Matthew Deans, Chennai

Morales MA, Halpern JM (2018) Bioconjug Chem 29:3231

Park M-O, Noh H-B, Park D-S, Yoon J-H, Shim Y-B (2017) Electroanalysis 29:514

Hossain MMD, Kim KB, Jannath KA, Park D-S, Shim Y-B (2023) Sens Actuators B Chem 389:133843

Britannica (2023) Enzyme | definition, mechanisms, & nomenclature. https://www.britannica.com/science/enzyme. Accessed 14 Apr 2023

Luka G, Ahmad S, Falcone N, Kraatz HB (2019). In: Pall K, Kraatz H-B, Khasnobish A, Bag S, Banerjee I, Kuruganti U (eds) Bioelectronics and medical devices: from materials to devices—fabrication, applications and reliability. Matthew Deans, Chennai

Newman JD, Setford SJ (2006) Mol Biotechnol 32:249

Medicine LibreTexts (2023) Structure and function of antibodies. https://med.libretexts.org/Bookshelves/Anatomy_and_Physiology/Anatomy_and_Physiology_(Boundless)/20%3A_Immune_System/20.6%3A_Humoral_Immune_Response/20.6B%3A_Structure_and_Function_of_Antibodies. Accessed 14 Apr 2023

Rishpon J, Buchner V (2005) Compr Anal Chem 44:329

Felix FS, Angnes L (2018) Biosens Bioelectron 102:470

Lakhin AV, Tarantul VZ, Gening LV (2013) Acta Nat 5:34

Zhang J, Cao Y (2019). In: Li G (ed) Nano-inspired biosensors for protein assay with clinical applications. Susan Dennis, Chennai

Zhang Z, Sen P, Adhikari BR, Li Y, Soleymani L (2022) Angew Chem Int Ed 61:1

Gupta N, Renugopalakrishnan V, Liepmann D, Paulmurugan R, Malhotra BD (2019) Biosens Bioelectron 141:111435

Belbruno JJ (2019) Chem Rev 119:94

Culver HR, Peppas NA (2017) Chem Mater 29:5753

Bhardwaj T (2014) Int J Eng Res Technol 3:294

Salva ML, Rocca M, Niemeyer CM, Delamarche E (2021) Micro Nano Eng 11:100085

Welch NG, Scoble JA, Muir BW, Pigram PJ (2017) Biointerphases 12:02D301

Kim D, Herr AE (2013) Biomicrofluidics 7:041501

Sannegowda LK (2021). In: Hussain CM, Kailasa SK (eds) Handbook of nanomaterials for sensing applications. Matthew Deans, Chennai

George JM, Antony A, Mathew B (2018) Microchim Acta 185:358

Petrucci R, Bortolami M, Matteo PD, Curulli A (2022) Nanomaterials 12:959

Mir TA, Yoon J-H, Gurudatt NG, Won M-S, Shim Y-B (2015) Biosens Bioelectron 74:594

Kim D-M, Noh H-B, Park S, Ryu S-H, Koo JS, Shim Y-B (2009) Biosens Bioelectron 25:456

Zhao Q, Yu H, Hu D, Li L-L, Jin J, Ai M-J, Wei J, Song K (2022) Chin J Anal Chem 50:100144

Li Y, Tian L, Liu L, Khan MS, Zhao G, Fan DD, Cao W, Wei Q (2018) Talanta 179:420

Ji L, Guo Z, Yan T, Ma H, Du B, Li Y, Wei Q (2015) Biosens Bioelectron 68:757

Chakraborty T, Das M, Lin CY, Lei KF, Kao CH (2022) Anal Chim Acta 1205:339754

Tortolini C, Bollella P, Zumpano R, Favero G, Mazzei F, Antiochia R (2018) Biosensors 8:108

Tajik S, Dourandish Z, Nejad FG, Beitollahi H, Jahani PM, Bartolomeo AD (2022) Biosens Bioelectron 216:114674

Yan Q, Wu R, Chen H, Nan W (2023) J Saudi Chem Soc 27:101612

Arivazhagan M, Shankar A, Maduraiveeran G (2020) Microchim Acta 187:468

Arivazhagan M, Maduraiveeran G (2020) J Electroanal Chem 874:114465

Thirumalraj B, Sriram B, Muthukutty B, Zheng L, Wang S-F, Choe H, Kwon K (2023) Chem Eng J 455:140521

Yin M, Zhang L, Wei X, Sun J, Xu D (2022) Microchem J 183:107946

Daud AD, Lim HN, Ibrahim I, Endot NA, Gowthaman NSK, Jiang ZT, Cordova KE (2022) J Electroanal Chem 921:116676

Alberti G, Zanoni C, Losi V, Magnaghi LR, Biesuz R (2021) Chemosensors 9:108

He W, Liu L, Cao Z, Lin Y, Tian Y, Zhang Q, Zhou C, Ye X, Cui T (2023) Biosens Bioelectron 228:115193

Chung S, Moon J-M, Choi J, Hwang H, Shim Y-B (2018) Biosens Bioelectron 117:480

Kour R, Arya S, Young S-J, Gupta V, Bandhoria P, Khosla A (2020) J Electrochem Soc 167:037555

Poh HL, Pumera M (2012) Chem Asian J 7:412

Hussain KK, Gurudatt NG, Akthar MH, Seo K-D, Park D-S, Shim Y-B (2020) Biosens Bioelectron 155:112094

Ghalkhani M, Shahrokhian S, Navabi M (2021) Mater Chem Phys 263:124131

Zhu Y, Chandra P, Song KM, Ban C, Shim YB (2012) Biosens Bioelectron 36:29

Abdelwahab AA, Shim Y-B (2014) Sens Actuators B Chem 201:51

Chung S, Akhtar MH, Benboudiaf A, Park D-S, Shim Y-B (2019) Electroanalysis 32:521

Gopal TS, Jeong SK, Alrebdi TA, Pandiaraj S, Alodhayb A, Muthuramamoorthy M, Grace AN (2022) Mater Today Chem 24:100891

Kim K-B, Lee W-C, Cho C-H, Park D-S, Cho S-J, Shim Y-B (2019) Sens Actuators B Chem 281:14

Lee W-C, Kim K-B, Gurudatt NG, Hussain KK, Choi CS, Park D-S, Shim Y-B (2019) Biosens Bioelectron 130:48

Mahmudunnabi RG, Farhana FZ, Kashaninejad N, Firoz SH, Shim Y-B, Shiddiky MJA (2020) Analyst 145:4398

Masud MK, Yadav S, Islam MN, Nguyen N-T, Salomon C, Kline R, Alamri HR, Alothman ZA (2017) Anal Chem 89:11005

Zhao L, Zhang N, He M, Luo P, Tan L (2022) Microchim Acta 189:406

Komkova MA, Shavokshina VA, Zarochintsev AA, Melnik DM, Aparin IO, Zatsepin TS, Karyakin AA (2023) Talanta 257:124337

Liu Y, Zhao P, Liang Y, Chen Y, Pu J, Wu J, Yang Y, Ma Y, Huang Z, Luo H, Huo D, Hou C (2023) Talanta 254:124171

Wu J, Wu Y, Lu L, Zhang D, Wang X (2021) Talanta Open 4:100075

Li B, Li Y, Li C, Yang J, Liu D, Wang H, Xu R, Zhang Y, Wei Q (2023) Biosens Bioelectron 227:115180

Drobysh M, Ramanavicius A, Baradoke A (2023) Sci Total Environ 862:160700

Mojsoska B, Larsen S, Olsen DA, Madsen JS, Brandslund I, Alatraktchi FA (2021) Sensors 21:390

Zhang Y, Xu Y, Li N, Ma W, Yang M, Hou C, Huo D (2023) Int J Hydrogen Energy 48:24548

Ansari MA, Liew WJ, Kurup CP, Ahmed MU (2023) J Electroanal Chem 937:117422

Nguyen TT-Q, Gu MB (2023) Biosens Bioelectron 228:115199

Babaei A, Pouremamali A, Rafiee N, Sohrabi H, Mokhtarzadeh A, de la Guardia M (2022) Trends Anal Chem 155:116686

Carinelli S, Xufré C, Martí M, Pividori MI (2018) Biosens Bioelectron 117:183

Mahmudunnabi RG, Umer M, Seo K-D, Park D-S, Chung JH, Shiddiky MJ, Shim Y-B (2022) Biosens Bioelectron 207:114149

Moazampour M, Zare HR, Shekari Z, Moshtaghioun MS (2023) Microchem J 185:108202

Guedes PHG, Brussasco JG, Moço ACR, Moraes DD, Segatto M, Flauzino JMR, Mendes-Silva AP, Vieira CU, Madurro JM, Brito-Madurro AG (2023) Talanta 258:124342

Sánchez-Salcedo R, Miranda-Castro R, de-los-Santos-Álvarez N, Fernández-Martínez D, García-Flórez LJ, Lobo-Castañón MJ (2023) Sensors Actuators B Chem 376:132940

Jiang D, Ge P, Wang L, Jiang H, Yang M, Yuan L, Ge Q, Fang W, Ju X (2019) Biosens Bioelectron 130:299

Hao M, Li Z, Huang X, Wang Y, Wei X, Zou X, Shi J, Huang Z, Yin L, Gao L, Li Y, Holmes M, Tahir HE (2023) Food Chem 418:135941

Wei X, Liu C, Li Z, Zhang D, Zhang W, Li Y, Shi J, Wang X, Zhai X, Gong Y, Zou X (2022) Biosens Bioelectron 203:114015

Shin JH, Park TJ, Hyun MS, Park JP (2022) Food Chem 378:132061

Xu J, Zhao C, Chau Y, Lee Y-K (2020) Biosens Bioelectron 151:111914

Saxena K, Chauhan N, Malhotra BD, Jain U (2023) Process Biochem 130:87

Vu OT, Nguyen QH, Phan TN, Luong TT, Eersels K, Wagner P, Truong LTN (2022) ACS Omega 8:2887

Ayankojo AG, Boroznjak R, Reut J, Öpik A, Syritski V (2022) Sens Actuators B Chem 353:131160

Zhang Z, Chen S, Ren J, Han F, Yu X, Tang F, Xue F, Chen W, Yang J, Jiang Y, Jiang H, Lv B, Xu J, Dai J (2020) Microchim Acta 187:642

Choi DY, Yang JC, Hong SW, Park J (2022) Biosens Bioelectron 204:114073

Acknowledgements

The author thanks the colleagues for their expertise and assistance throughout all aspects of the study and for their help in writing the manuscript.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Heru Agung Saputra is a Independent Scholar.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Saputra, H.A. Electrochemical sensors: basic principles, engineering, and state of the art. Monatsh Chem 154, 1083–1100 (2023). https://doi.org/10.1007/s00706-023-03113-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00706-023-03113-z