Abstract

Tris(pentafluorophenyl)borane [B(C6F5)3] catalyzed simple, efficient and environmentally benign protocol has been developed for the Pechmann condensation using variety of phenols and β-ketoesters under solvent-free conditions to afford coumarin derivatives. The present protocol displayed significant advantages such as low catalyst loading, short reaction time, mild reaction conditions, low toxicity, easy work-up, high yields, and compatibility with other functional groups. In addition, it is a convenient, clean, and fast alternative approach for synthesizing variety of coumarin derivatives. Moreover, the applicability of this method towards large-scale synthesis demonstrated its suitability for the industrial application.

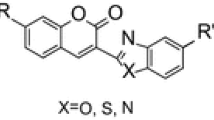

Graphic abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Coumarin and its derivatives constitute an important class of heterocycles, occupying an important place in the realm of natural products and synthetic organic chemistry [1]. They are widely used as additives in food, agrochemicals, perfumes, cosmetics, pharmaceuticals, insecticides, optical brightener, laser dyes, and in the preparations of dispersed fluorescent [2, 3]. The widespread biological activities of coumarins such as anticancer, anti-psoriasis, anti-coagulant, anti-HIV, anti-inflammatory, and antibiotic activities have aroused great interest in the area of pharmacology and synthetic chemistry [4,5,6,7,8,9]. Coumarins have been synthesized by several methods, including Pechmann, Perkin, Reformatsky, Knoevenagel, and Wittig reactions [10,11,12,13,14,15].

Pechmann reaction is one of the most common methods for the synthesis of coumarin and its derivatives. This method involves the reaction between phenols and β-ketoester by employing various catalysts such as H2SO4, P2O5, FeCl3, ZnCl2, TiCl4, POCl3, AlCl3, PPA, In(OTf)3, HCl, samarium(III) nitrate, phosphoric acid, and trifluoroacetic acid [16,17,18,19,20,21,22,23].

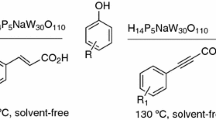

Similarly, several heterogeneous catalysts were utilized to carry out Pechmann condensation such as Al-SBA-1 molecular sieve, Al-MCM-4, heteropolyacids, H14[NaP5W30O110], Keggin structures, mesoporous zirconium phosphate, silica triflate, melamine–formaldehyde resin supported H+, ZrOCl2·8H2O/SiO2, PEG-SO3H, poly(4-vinylpyridine)-supported copper iodide, PVP supported phosphotungstic acid montmorillonite, and other clays [24,25,26,27,28,29,30,31,32,33]. In recent years, several researchers are also involved in exploring the utility of nanomaterial based catalyst for the synthesis of substituted coumarins [34,35,36,37,38,39,40,41,42]. In addition, ionic liquids, microwave irradiations, Nafion-H have also been well documented for the Pechmann condensation [43,44,45,46,47,48]. However, in the current context of environmental bang, many of the reported protocols are not attractive as they require high catalyst loading (e.g., sulfuric acid in 10–12 equivalents, phosphorus pentoxide in five-fold excess, trifluoroacetic acid in three to four equivalents), use of organic solvents, sometimes longer reaction time, low yields and very often temperature to the extent of 150 °C [49,50,51]. Despite extensive researches on coumarin synthesis, it is still an active research area which is in need to develop, and demands novel synthetic methodologies, which simplifies the synthesis and minimizes the drawbacks.

In this regard, tris(pentafluorophenyl)borane [B(C6F5)3] has emerged as a powerful Lewis acid and is gaining significance because of its no-toxicity, thermal stability, water tolerant and requires no special care during its handling. The potential of B(C6F5)3 in various organic transformations such as Ferrier azaglycosylation, epoxide ring opening, Friedel–Crafts alkylation of activated arenes, polymethylhydrosiloxane (PMHS) activation for reduction of different functional groups, etc. have been explored [17, 52,53,54,55]. Recently, an efficient protocol for [3 + 2] cycloaddition, acylation, oxidative esterification, reductive amination, and Biginelli reaction have been reported using B(C6F5)3 as catalyst [56,57,58,59,60]. The versatility of tris(pentafluorophenyl)borane encouraged us to study its utility for the Pechmann condensation to achieve various coumarin derivatives. We herein disclose the remarkable catalytic activity of B(C6F5)3, for the efficient synthesis of coumarins, under solvent-free conditions (Scheme 1). To the best of our knowledge, this is the first demonstration of Pechmann condensation by employing B(C6F5)3 as catalyst.

Results and discussion

To investigate the catalytic efficiency of B(C6F5)3 and to determine the most appropriate reaction conditions for the synthesis of coumarins, a model reaction was performed comprising a mixture of phenol (1a) and ethyl acetoacetate (2a) in a sealed tube, under various reaction conditions and the results are summarized in Table 1.

Initially, the reaction did not proceed satisfactorily, when the reaction was carried out with 1 mol% of B(C6F5)3 at 0 °C—room temperature (Table 1, entry 1). However, 42% yield of coumarin 3a was isolated, when the reaction temperature was raised to 50 °C for 45 min (Table 1, entry 2). In an attempt to improve the conversion and yield, the reaction was repeated using 5 mol% of B(C6F5)3 as catalyst. Pleasingly, this resulted in complete conversion of 1a into 3a within 30 min gave 94% of product yield (Table 1, entry 3). Further improvement was not observed in terms of reaction time/yield either on increasing the catalyst loading or temperature (Table 1, entries 4 & 5). Interestingly, the yields remained considerably high even when the quantity of B(C6F5)3 was reduced from 5 mol% to 3 mol% (Table 1, entry 6). Further reductions in the amount of catalyst led to protracted reaction time and declined yields (Table 1, entry 7). The influence of other solvents such as EtOH, water, and THF have also been evaluated and the results revealed that neat condition was superior to give excellent yield of the product rather than using solvent (Table 1, entries 8–10). The reaction was unfruitful in the absence of catalyst, signifying the crucial role of the B(C6F5)3 catalyst in Pechmann condensation process (Table 1, entry 11). Based upon these results, 3 mol% of B(C6F5)3 under neat conditions was considered to be optimum concentration of catalyst for this reaction.

To establish the generality and scope of present methodology, we evaluated a variety of phenols under the optimal reaction conditions and the results are presented in Table 2. In all the cases, the Pechmann condensation progressed well to afford the corresponding coumarin derivatives 3 in good to excellent yields (78–96%) in a short reaction time (Table 2, entries 1–17). The results indicated that the phenols bearing electron-donating groups were well tolerated under the optimal reaction conditions and provided the corresponding coumarin derivatives 3b–3d in excellent yields (Table 2, entries 2–4). However, the phenols tethered with electron withdrawing groups decreased the rate of reaction and afforded desired product in less yields relatively (Table 2, entries 5 & 6). The reaction of resorcinol (1g) with 2a was successfully accomplished within 25 min to achieve 7-hydroxy-4-methyl-2H-chromen-2-one (3g) in 95% yield (Table 2, entry 7). Whereas, orcinol (1h) reacted in sluggish manner under the standard reaction condition, which could be due to the steric hindrance of the methyl group ortho to the position of hydroxyl alkylation (Table 2, entry 8).

The reactivity of phloroglucinol (1i) with ethyl acetoacetae (2a) was found to be superior to pyrogallol (1j) (Table 2, entries 9 & 10). This might be due to the presence of two hydroxyl groups at meta position in 1i, which promote the activation of aromatic ring. Similarly, catechol (1k) could also be used under the optimal reaction conditions to obtain 3k in 86% yield (Table 2, entry 11). Furthermore, we explored the reactions of 2-naphthol (1l) with ethyl acetoacetate using 3 mol% of B(C6F5)3, which proceeded smoothly to afford 3l in 90% yields (Table 2, entry 12), however, 1m took longer reaction time for the completion of reaction and gave 78% of product yield (Table 2, entries 13). Interestingly, 3-aminophenol (1n) also reacted well, under standard reaction condition to afford 3n in 88% yield (Table 2, entry 14).

Additionally, the scope of this protocol was further investigated using different β-keto esters 2b-2d with 1g under the optimized reaction conditions. As expected, the reaction of 1g with methyl acetoacetate (2b) under optimal reaction conditions gave 92% of product yield (Table 2, entry 15). Similarly, 1g was reacted efficiently with ethyl benzoylacetate (2c) and ethyl 4‐chloroacetoacetate (2d) to afford corresponding coumarins 3p, 3q in excellent yields (Table 2, entries 16 & 17). The above results clearly indicate the scope and generality of B(C6F5)3 catalyst for the synthesis of substituted coumarins using various phenols without affecting the presence of other functional groups and the Pechmann condensation proceeds well, irrespective of the position and electronic nature of the substituents.

In the light of above finding, we extended the scope of present protocol towards the large-scale synthesis of 7-hydroxy-4-methyl-2H-chromen-2-one (3g). On large-scale operation, the reaction of resorcinol (1g) (5.0 g, 1 equiv.) with equimolar amounts of ethyl acetoacetate (2a, 5.9 g, 1 equiv.) by employing 3 mol% (0.69 mg) of B(C6F5)3 under neat condition at 70 ºC for 45 min to obtain 3g in 94% yield (Scheme 2).

The plausible mechanism for the synthesis of substituted coumarin in the presence of B(C6F5)3 under solvent-free conditions is shown in Scheme 3. The catalyst allows the Pechmann condensation by the activation of 2a, which makes the carbonyl group more susceptible towards nucleophilic attack by phenol and favor the trans-esterification followed by an attack to the activated carbonyl by the aromatic ring at ortho-position to form the coumarin skeleton. Finally, subsequent re-aromatization and elimination of water give the desired product.

Conclusion

In summary, we have developed an efficient and facile method for the synthesis of various coumarins derivatives via Pechmann condensation using catalytic amount of B(C6F5)3. The advantages of this method are environmental benign, low catalyst loading, less-toxicity of catalyst, solvent-free condition, high yields of the desired products, and simple experimental procedure. Moreover, the applicability of the present protocol for large-scale synthesis highlights its possibility for bulk synthesis. Further work to explore the utility of B(C6F5)3 as catalyst in other organic transformations is in progress.

Experimental

General experimental procedure

In a sealed tube, a mixture of 100 mg phenol (1.06 mmol) and 138.28 mg ethyl acetoacetate (1.06 mmol) was heated (70 °C) in the presence of 16.32 mg B(C6F5)3 (0.03 mmol). After the completion of reaction, as indicated by TLC analysis, the reaction mixture after being cooled to room temperature, was poured onto 40 g crushed ice and stirred for 5–10 min. The solid products were filtered off, washed with ice-cold water, and recrystallized from hot ethanol to afford pure coumarin derivatives 3. The known compounds were identified by comparison of their spectral data and physical properties with the reported literature.

References

Murray R (1995) Nat Prod Rep 12:477

Scheel LD (1972) Microbiol Toxins 8:47

Sun WC, Gee KR, Haugland RP (1998) Bioorg Med Chem Lett 8:3107

Wang CJ, Hsieh YJ, Chu CY, Lin YL, Tseng TH (2002) Cancer Lett 183:163

Bravic G, Gaultier J, Hauw C (1968) C R Acad Sci. Paris Ser IIc: Chim 267:1790

Arora RB, Mathur CN (1963) Br J Pharmacol Chemother 20:29

Palmer CJ, Josephs JL (1995) J Chem Soc Perkin Trans 1:3135

Maddi V, Kallur RS, Rao MNA (1992) J Pharm Sci 81:964

Musiciki B, Periers AM, Laurin P, Ferroud D, Benedetti Y, Lachaud S, Chatreaux F Haesslein JL, LLtis A, Pierre C, Khider J, Tessol N, Airault M Demassey J, Dupuis-Hamelin C Lassaigne P, Bonnefoy A, Vicat P, Klich M (2000) Bioorg Med Chem Lett 10:1695

Pechmann HV, Duisberg C (1884) Ber Dtsch Chem Ges 17:929

Johnson JR (1942) Org React 1:210

Shirner RL (1942) Org React 1:1

Brufola G, Fringuelli F, Piermatti O, Pizzo F (1996) Heterocycles 43:1257

Yavari I, Hekmat-Shoar, Zonouzi A (1998) Tetrahedron Lett 39:2391

Molnar M, Lončarić M, Kovač M (2020) Curr Org Chem 24:4

Appel H (1935) J Chem Soc 1031

Woods LL, Sapp J (1962) J Org Chem 27:3703

Ahmad ZS, Desai RD (1937) Proc Indian Acad Sci Chem Sci 5:277

Robinson R, Weygand F (1941) J Chem Soc 386

Nadkarni AJ, Kudav NA (1981) Ind J Chem Sect B 20:719

Valizadeha H, Shockravi A (2005) Tetrahedron Lett 46:3501

Bahekar SS, Shinde DB (2004) Tetrahedron Lett 45:7999

Karami B, Kiani M, Hoseini MA (2014) Chin J Catal 35:1206

Peng MM, Hemalatha P, Ganesh M, Palanichamy M, Jang HT (2014) J Ind Eng Chem 20:953

Sudha S, Venkatachalam K, Vishnu Priya S, Herbert Mabel J, Palanichamy M, Murugesan V (2008) J Mol Catal A: Chem 291:22

Heravi MM, Khorasani M, Derikvand F, Oskooie HA, Bamoharram FF (2007) Catal Commun 8:1886

Torviso R, Mansilla D, Belizan A, Alesso E, Moltrasio G, Vazquez P, Pizzio L, Blanco M, Caceres C (2008) Appl Catal A 339:53

Shirini F, Marjani K, Nahzomi HT (2007) Chin Chem Lett 18:909

Rezaei R, Dorosty L, Rajabzadeh M, Khalifeh R (2011) Chin Chem Lett 22:1313

Karami B, Kiani M (2011) Catal Commun 14:62

Nazeruddin GM, Pandharpatte MS, Mulani KB (2012) C R Chim 15:91

Albadi J, Shirini F, Abasi J, Armand N, Motaharizadeh T (2013) C R Chim 16:407

Li S, Qi X, Huang B (2016) Catal Today 276:139

Li TS, Zhang ZH, Yang F, Fu CG (1998) J Chem Res (S) 38

Abbasi Z, Rezayati S, Bagheri M, Hajinasiri R (2017) Chin Chem Lett 28:75

Sharma RK, Monga Y, Puri A (2013) Catal Commun 35:110

Zareyee D, Serehneh M (2014) J Mol Catal A: Chem 391:88

Yadav GD, Ajgaonkar NP, Varma A (2012) J Catal 292:99

Ahmed AI, El-Hakam SA, Khder AS, Abo El-Yazeed WS (2013) J Mol Catal A: Chem 366:99

Reddy BM, Patil MK, Lakshmanan P (2006) J Mol Catal A: Chem 256:290

Naik MA, Mishra BG, Dubey A (2008) Colloids Surf A 317:234

Ghodke S, Chudasama U (2013) Appl Catal A 453:219

Jadhav NH, Sakate SS, Rasal NK, Shinde DR, Pawar RA (2019) ACS Omega 4:8522

Potdar MK, Mohile SS, Salunkhe MM (2001) Tetrahedron Lett 42:9285

Frere S, Thiery V, Besson T (2001) Tetrahedron Lett 42:2791

Romanelli GP, Bennardi D, Ruiz DM, Baronetti G, Thomas HJ, Autino JC (2004) Tetrahedron Lett 45:8935

Laufer MC, Hausmann H, Holderich WF (2003) J Catal 218:315

Khaligh NG (2012) Catal Sci Technol 2:1633

Maheswara M, Siddaiah V, Damu GLV, Rao YK, Rao CV (2006) J Mol Catal A: Chem 255:49

Russell A, Frye JR (1941) Org Synth 21:22

Simmonis H, Remmert P (1914) Chem Ber 47:2229

Chandrasekhar S, Reddy CR, Chandrashekar G (2004) Tetrahedron Lett 45:6481

Chandrasekhar S, Reddy CR, Babu BN, Chandrashekar G (2002) Tetrahedron Lett 43:3801

Thirupathi P, Neupane LN, Lee KH (2011) Tetrahedron 67:7301

Chandrasekhar S, Chandrashekar G, Vijeender K, Reddy MS (2006) Tetrahedron Lett 47:3475

Chandrasekhar S, Reddy CR, Babu BN (2002) J Org Chem 67:9080

Prajapti SK, Nagarsenkar A, Babu BN (2014) Tetrahedron Lett 55:3507

Prajapti SK, Nagarsenkar A, Babu BN (2014) Tetrahedron Lett 55:1784

Guggilapu SD, Prajapti SK, Babu BN (2015) Tetrahedron Lett 56:889

Nagarsenkar A, Prajapti SK, Babu BN (2015) J Chem Sci 127:711

Prajapti SK, Gupta KK, Babu BN (2015) J Chem Sci 127:1047

Acknowledgements

The authors thank to NIPER, Hyderabad & Inovine Pharma Research Solution, Raipur for the scientific and instrumental support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Prajapti, S.K., Rao, S.P. B(C6F5)3-catalyzed synthesis of coumarins via Pechmann condensation under solvent-free conditions. Monatsh Chem 152, 469–473 (2021). https://doi.org/10.1007/s00706-021-02747-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00706-021-02747-1