Abstract

The growing importance of siloxanes in various industrial areas, e.g., health care, cosmetics, automotive and construction industries requires further method development of analysis techniques. In addition, and complementing gas chromatography analysis, a polymer liquid chromatography method for separation of linear and cyclic (poly)dimethylsiloxanes was developed and optimized. By an appropriate choice of mobile and stationary phase combinations, separations of up to 30 monomeric units were achieved. Therefore, various HPLC columns were investigated concerning physical and chemical properties, e.g., pore size, silica base material, and column functionality. Furthermore, solubility properties of siloxanes in adsorption- and desorption-promoting solvents were investigated and taking these results into account, the separation was optimized applying a mixture of methanol:water (75:25, v/v) and acetone. The findings indicate that precipitation/re-dissolution effects superimposed by adsorption chromatography play an important role for the efficient separationof a high number of monomer units. Besides method development on an analytical scale, linear poly(dimethylsiloxane) oligomers were separated with preparative polymer HPLC. These fractions of single oligomers allow further investigations of different material properties beyond polymer HPLC.

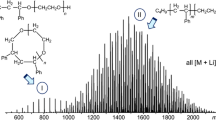

Graphical abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Siloxanes show a broad variety of application areas, because of their exceptional polymer structure. Various applications in cosmetics, medicine, automotive or construction industry depend on low intermolecular forces between methyl groups, high flexibility in the polymer backbone or low surface energies. The usage in antifoams, shock absorbers or release agents only depicts some examples [1, 2]. In this study, the important class of poly(dimethylsiloxanes) (PDMS) is separated according to its molecular architecture. The PDMS nomenclature depends on the nominal number of oxygen bonded to silicon: the basic building blocks M, D, T, and Q represent one, two, three, or four oxygen(s) bonded to silicone, respectively. Consequently, cyclic PDMS are unambiguously described by the amount of [D]-building blocks, e.g., D4 stands for the cyclic tetramer octamethylcyclotetrasiloxane [3, 4]. Additionally, in this publication, the short cut “Si” is used with the appropriate number of oligomers as label for linear PDMS oligomers.

Especially, for low molecular weight (up to 8 [D]-blocks), linear and cyclic PDMS analysis is predominantly performed with gas chromatography [5, 6]. But with increasing molecular weight, liquid chromatographic techniques such as size-exclusion chromatography (SEC), liquid chromatography at critical conditions (LCCC) or polymer HPLC become more favorable. SEC provides separation according to hydrodynamic volume or rather molar mass of the investigated polymers. This analytical method is primarily based on changes of entropic interactions of the polymer with the separation system. Therefore, typical SEC stationary phases consist of particles with different pore diameters for achieving successful separation due to differences in molecular size, but any chemical interaction between polymer and stationary phase must be prevented [7,8,9]. In LCCC, separations solely according to chemical functionalities of polymers are possible. Therefore, enthalpic and entropic energy changes must balance each other for a separation independent of molar mass effects. However, this technique is typically applied for higher molecular weight masses in contrast to the separation of linear and cyclic PDMS oligomers up to 30 [D]-block units as required in this study. Moreover, LCCC compromises some challenges, such as, e.g., high susceptibility to small changes in analytical conditions or small variations of the investigated polymer sample [12].

In polymer HPLC, the separation is generally based on molar mass differences as well as on variation of chemical functionalities. Compared to HPLC of small molecules, the major differences are small diffusion coefficients and reduced solubility of polymers in solution. Apart from this, polymer elution may occur due to several different separation mechanisms, like adsorption or precipitation/re-dissolution chromatography. The main distinctive feature is the injection of a polymer sample: Assuming an impaired polymer solubility, the well-dissolved sample is injected at a stationary phase pre-conditioned with a typically very weak (or so-called adsorption-promoting) solvent. Thus, subsequent to polymer injection, precipitation or at least very strong adsorption on top of the column takes place. Consequently, a programmed gradient is usually used to elute the withheld sample, driven by increasing amounts of desorption-promoting solvent [7, 14,15,16,17].

The choice of a suitable detector for PDMS is limited because of the lack of chromophores and the need of gradient elution. Therefore, an evaporative light scattering detector (ELSD) is a good choice, permitting gradient elution and a universal detection. Mojsiewicz-Pieńkoswka [22] already described the application of this detection technique for the analysis of PDMS with SEC. Based on these investigations, Durner et al. [13] optimized the detector performance for linear and cyclic PDMS. In this study, method development and optimization for separation of linear and cyclic PDMS oligomers with polymer HPLC are shown.

Results and discussion

Alkyl chain stationary phases in combination with acetonitrile as adsorption-promoting and tetrahydrofuran (THF) as desorption-promoting solvent are used for PDMS analysis, based on common reversed-phase polymer HPLC [10, 11]. Hence, method development was started comparing four stationary phases with different alkyl chain lengths (C4 (a), C8 (b), C18 (c), C30 (d), see Fig. 1)

Apart from the C30 column, all other stationary phases showed at least partial separation of several linear and cyclic oligomers. However, the separation performance in all cases was insufficient. Aside from this, ELS detection of the measurement series (Fig. 1a–d) was performed over a period of three weeks using a concentric glass nebulizer. During this time, a continuous decrease in signal intensity was observed comparing the initially used C4 column and the finally used C30 column. The improvement of ELSD performance was already published elsewhere [13] and as described there, especially for PDMS analysis, the use of an enhanced poly(tetrafluoroethylene) (PTFE) parallel-path nebulizer is useful. Consequently, for all further measurements, an enhanced PTFE nebulizer was used improving the detector long-term stability and signal intensity. As shown in [18], for PDMS analysis, an optimization in oligomer separation could be achieved by applying a C8 column and using a convex gradient with extended total runtime. Whereby, even this improvement showed repeated changes in the elution order of linear and cyclic oligomers. For this reason, a change in the separation system concerning stationary and mobile phase was necessary. Applying a pentafluorophenyl column seemed appropriate because of its very different selectivity and the possibility of stereoisomer separation [19]. Beside electron donor/acceptor interactions, presumably, the π–π interactions of the aromatic pentafluorophenyl group led to a change of the separation of linear and cyclic PDMS oligomers (Fig. 2).

Acetonitrile with its triple bond blocks this π–π stacking effects and had to be replaced with a different proper adsorption-promoting solvent. Thus, a mixture of methanol and water (75:25, v/v) was used to adjust a similar elution strength as pure acetonitrile [20, 21]. Furthermore, in place of THF, acetone was found to be a suitable desorption-promoting solvent when using pentafluorophenyl columns. These modifications of the separation system showed increased separation performance without crossed elution of linear and cyclic PDMS up to 17 [D] repetition units. Beside the improved separation result, a major drawback using a Phenomenex Kinetex PFP column was the stationary phase’s batch-to-batch reproducibility (see Fig. 2a–c). Applying other pentafluorophenyl columns from other manufactures, e.g., Agilent Poroshell PFP, Phenomenx Luna PFP (2), or Phenomenex Kinetex F5 resulted in a decreased separation performance. Thus, further optimization had to be done and the lack of separation performance comparing various pentafluorophenyl columns showed that presumably not only the modification of the stationary phase determined the separation. Because of these findings, modifications of the mobile phase components were investigated applying linear alkyl chain columns.

Furthermore, the LC flow rate was increased from 1.0 to 2.0 cm3 min−1 decreasing run time without losing separation performance. This change showed a substantial improvement in peak separation when using an Accucore C30 column (see Fig. 3b, c). Figure 3b, c only differ in the gradient slope of acetone (i.e., the acetone volume ratio change per minute) from 12.5 × 10−3 min−1 for (b) to 3.125 × 10−3 min−1 for (c). Consequently, beside the increase in separation performance, the flattening of the gradient slope led to an increased measurement time. Nevertheless, an effective gradient runtime of 160 min (Fig. 3c) was a good compromise between total runtime and separation performance.

Comparison of two C30 columns with methanol:water (75:25, v/v) as adsorption-promoting solvent and acetone as desorption-promoting solvent: a YMC carotenoid C30 (100 × 4.6 mm) and b Accucore C30 (50 × 4.6 mm) with an effective linear gradient of 40 min duration; c Accucore C30 with an effective linear gradient of 160 min and a LC flow rate of 2.0 cm3 min−1

The comparison to another C30 column (YMC Carotenoid C30, 100 × 4.6 mm, Fig. 3a) showed no separation of cyclic and linear oligomers at all. This result revealed that apart from the chemical modification of the stationary phase, presumably the manufacturing process itself and the type of particles may have an important impact.

Consequently, additional stationary phases (Fig. 4, Table 1) were compared to investigate separation differences and dependencies on further column characterizing parameters, e.g., particle diameter or C18 base silica material. Each subsequent measurement was carried out with methanol:water (75:25, v/v) as adsorption-promoting solvent, acetone as desorption-promoting solvent, and an effective linear gradient of 40 min (on a column with 50 × 4.6 mm, 2.6 µm) adapted to the different column dimensions, respectively. As quality criterion for separation, the last baseline-separated cyclic and linear PDMS oligomer was used. The comparison of C18 columns showed no considerable tendencies regarding particle diameter or other column-specific parameters—only larger column pore sizes seemed to be having an effect (e.g., 16-Hypersil BDS C18, 18-HyPurity C18, 4-Accucore C30). Even the comparison of various C18 columns with 4-Accucore C30, 1-Accucore C4 or a pentafluorophenyl column showed no direct correlation. As consequence, minor differences in the physics and chemistry of the column could result in major differences in the separation of polymer HPLC. Beside this, three stationary phases—16-Hypersil BDS C18 (100 × 4.6 mm), 18-HyPurity C18 (150 × 4.6 mm) and 4-Accucore C30 (50 × 4.6 mm)—showed the best separation results. Comparing these three stationary phases with each other regarding total runtime, the Accucore C30 was shorter in length and, consequently, offered shorter runtimes. Nonetheless, all three stationary phases provided a good separation performance for linear and cyclic PDMS oligomers.

Separation performance of various stationary phases, assessed according to the last separated pair of cyclic and linear PDMS oligomers, all measurements were performed applying an effective linear gradient of 40 min with methanol:water (75:25, v/v) as adsorption-promoting solvent and acetone as desorption-promoting solvent

For further investigations of the influence of column pore size on separation quality, an additional measurement series was performed using four C18 columns from the same manufacturer (Macherey–Nagel) while only varying mean pore sizes from 50 up to 1000 Å (see Table 2).

Except of mean pore size, the column’s carbon content C%, silica surface area S and binding density db were under investigation, too. Calculation of the binding density was done according to Eq. (1) [23] taking the molar mass M and number of carbon atoms per ligand nc into account.

Equation (1) showed that mean pore size, carbon content, and surface area were depending on each other for different columns. Figure 5 depicts a plot comparing the retention times of cyclic PDMS with respect to the mean pore size. Generally, with increasing pore size, the retention times of the oligomers decreased, while the separation performance in case of 1000 Å was found insufficient for cyclic oligomers. Thus, the separation performance decreased with increasing pore size. However, it was not possible to determine whether the separation quality was affected by pore size or other parameters.

Dependence of the retention time of cyclic PDMS oligomers (D11–D17) on the mean pore size; the right y-axis depicts the characteristics of carbon content in context to mean pore size. The measurements were done with methanol:water (75:25, v/v) as adsorption-promoting solvent and acetone as desorption-promoting solvent and an effective linear gradient of 40 min on four different Nucleosil C18 EC columns described in Table 2

Like the choice of stationary phase, as already discussed, the optimization of the mobile phase composition had decisive influence on the separation quality. Therefore, the combination of various common HPLC solvents was investigated. Using pure solvents, like acetonitrile as adsorption-promoting solvent or THF as desorption-promoting solvent, led to insufficient separation of linear and cyclic PDMS oligomers, as depicted in Fig. 1. For the examined low-molecular weight PDMS samples, methanol was a partial solvent and therefore, using pure methanol as adsorption-promoting solvent was not an option. Furthermore, water was a too strong non-solvent and resulted in longer retention times for PDMS in combination with a minimization of the elution range. Taking these results and the aforementioned constraints of pentafluorophenyl columns for acetonitrile into account, a solvent mixture of methanol and water with a mixing ratio of 75:25 (v/v) was found considerably improving the separation quality (see Fig. 3). Additionally, the desorption-promoting solvent THF showed overtightened dissolving properties, so that a less stronger solvent was needed for low-molecular mass PDMS. For PDMS with up to 30 [D-] repetition units, acetone was found to be an appropriate compromise. Substituting acetone with the next higher homologue 2-butanone (containing one methyl group more) showed a considerable decrease in separation of oligomers (see Fig. 6c).

Variation of mobile phase components (adsorption-promoting solvent| desorption-promoting solvent) on a Accucore C30 (50 × 4.6 mm) column: a acetonitrile: water (50:50, v/v)| acetone, b acetone: water (75:25, v/v)| acetone, c methanol:water (75:25, v/v)| 2-butanone; cyclic PDMS orange, mixture of linear and cyclic PDMS green

All subsequently discussed data referring to pre-mixed mobile phase components present the best separation result for the appropriate pair of solvent mixtures. Figure 6a depicts an inadequate separation quality by using a mixture of acetonitrile and water (50:50, v/v) in combination with acetone. Substituting the acetonitrile–water mixture with acetone and water (75:25, v/v) in combination with pure acetone as desorption-promoting solvent resulted in a partial separation of linear and cyclic PDMS oligomers (Fig. 6c). However, none of these modifications of the mobile phase composition could improve the performance compared to methanol:water (75:25, v/v) and acetone at a C30 column.

Regarding the separation mechanism, polymer liquid chromatography provides various interactions between polymer and stationary phase, e.g., size-exclusion effects, adsorption chromatography or precipitation/re-dissolution chromatography [17]. Based on the comparison of column pore size and the parameters carbon content and surface area, the influence of actual size-exclusion effects should be circumstantial. As mentioned in [17, 24,25,26], an unambiguous differentiation between adsorption and precipitation/re-dissolution effects was difficult for the investigated low-molecular weight PDMS oligomers. In ideal precipitation/re-dissolution chromatography, altering the stationary phase should not result in different retention times for a polymer. As shown by comparing various stationary phases, the separation performance remarkably differs for cyclic and linear PDMS oligomers. Thus, adsorption chromatography had a major impact on oligomer separation of PDMS. However, the superordinate influence of the mobile phase composition indicated a slight overlay with precipitation/re-dissolution effects.

In addition to analytical separation of PDMS oligomers, preparative polymer HPLC was used to fractionate pure linear PDMS oligomers. Therefore, a mixture of silicone oils, containing linear oligomers only, with viscosities of 5:10:20 mPa s at a mixing ratio of 1:1:4, without any solvent was directly injected on an Accucore C30 column (150 × 4.6 mm). Again, a mixture of methanol:water (75:25, v/v) was used as adsorption-promoting solvent and THF as desorption-promoting solvent with a multi-linear gradient shown in Table 3. After injecting 1.0 cm3 of the PDMS mixture, linear PDMS oligomers from Si9 up to Si48 (depicted in Table 4) were obtained by fraction collection. The purity of each fraction was analyzed with LC–MS and for most fractions, purities above 95 or 99% were found. The major impurities were hydroxy-terminated linear PDMS and low amounts of cyclic silicones. The results of semi-preparative studies showed a good applicability of the analytical separation approach. Moreover, combining preparative polymer HPLC with other analytical methods may improve the understanding of varying behaviors of different linear PDMS oligomers in future investigations.

Conclusion

A polymer HPLC method for separation of linear and cyclic PDMS was developed and optimized. The new method offers complementary information to gas chromatography for low-molecular weight PDMS oligomers and expanded the analytical range of baseline-separated linear and cyclic oligomers up to 30 [D]-block units. Therefore, stationary phase and mobile phase were optimized investigating several parameters. On the one hand, the chemical and physical properties, like pore size, carbon content, silica basis material or phase modification of the stationary phase were adjusted achieving an efficient separation system. On the other hand, various mobile phase compositions showed the dependence on oligomer separation regarding minor changes in polymer solubility and elution strength. Taking all parameters together, the separation mechanism may be primarily driven by adsorption effects superimposed with solubility or rather precipitation/re-dissolution effects. In addition to the analytical method development, preparative separation of linear PDMS oligomers was investigated and the appropriate oligomers were isolated for the first time. Fractions containing only a single oligomer were obtained allowing further investigations of these isolated species with other analytical techniques, such as mass spectrometry and nuclear magnetic resonance spectrometry.

Experimental

All solvents used were HPLC grade. Acetonitrile, acetone, 2-butanol, methanol, and non-stabilized tetrahydrofuran were purchased from Merck (Darmstadt, Germany) and used without further purification. Water was obtained from a Milli-Q-Advantage A10 water system (Merck Millipore). All applied poly(dimethylsiloxane) standards were obtained from Wacker Chemie AG (Burghausen, Germany). The used stationary phases for method development and analytical as well as preparative measurements are summarized in Table 1. For preparative analysis, a mixture of silicone oils with viscosities of 5:10:20 mPa s at a mixing ratio of 1:1:4 without any solvent dilution was used.

Instrumentation

All investigations on analytical scale were performed on a 1100 series LC System of Agilent (Waldbronn, Germany) with a tetrahydrofuran-resistant 3215α degasser from ERC (Riemerling, Germany) and a 385 ELSD of Agilent equipped with an enhanced parallel-path MiraMist® poly(tetrafluoroethylene) nebulizer from Burgener Research (Mississauga, Ontario, Canada) at optimized conditions [13] of 40 °C evaporator temperature, 90 °C nebulizer temperature and 1.2 SLM (standard liter per minute) gas flow, unless otherwise mentioned. Chromeleon 7.2 was used as chromatography software for all measurements. All optimization measurements were performed from 100% A to 100% B in a linear gradient of 40 min and a LC flow of 1.0 cm3 min−1 for column dimensions of 100 × 4.6 mm, 2.6 µm particles, unless otherwise mentioned. For all analytical stationary phases with different dimensions, the gradient settings were adapted to obtain the same effective linear gradient (40 min at 100 × 4.6 mm column). The optimized method for analytical separation of linear and cyclic PDMS was performed on an Accucore C30 (50 × 4.6 mm, 2.6 µm) with a linear gradient starting at (methanol:water (75:25, v/v)): acetone 50:50 and ending at 100% acetone in 160 min and a LC flow rate of 2.0 cm3 min−1.

Preparative HPLC measurements were performed on an Agilent 1260 Infinity II LC system equipped with a TCC 6000 PSS (Mainz, Germany) column oven, a tetrahydrofuran-resistant PSS degasser, and an Agilent 35900 E analog/digital converter and a PL ELS 1000 as detector. For fraction collection, an Agilent 1260 Infinity II fraction collector was used. Open Lab CDS C.01.08 was used as chromatography software. A mixture of methanol:water (75:25, v/v) was used as adsorption-promoting solvent and acetone as desorption-promoting solvent. The used gradient settings are summarized in Table 3. For monitoring the purity of the collected fractions, a Bruker (Bremen, Germany) amazon SL ion trap liquid chromatography mass spectrometer, equipped with an electrospray ionization interface, was used.

References

Rapra (ed) (2013) Silicone elastomers 2013: 10–12 June, Hilton Munich City, Munich. Smithers Information, Shawbury, Shrewsbury, Shropshire, Germany

Lambrecht J, Brünnig M (2012) Advantages of silicones and future challenges in the world of T&D. In: Rapra (ed) Silicone Elastomers 2012: 27–28 March; Berlin, Germany. Smithers Rapra Technology Limited, Berlin

Noll W (1968) Chemie und Technologie der Silicone. Verlag Chemie GmbH, Weinheim

Liu Y (ed) (2017) Silicone dispersions. Surfactant science series, vol 159. CRC Press, Boca Raton

Brothers HM, Boehmer T, Campbell RA (2017) Int J Cosmet Sci 39:580

Bletsou AA, Asimakopoulos AG, Stasinakis AS (2013) Environ Sci Technol 47:1824

Belenki BG, Vilenchik LZ (eds) (1983) Modern liquid chromatography of macromolecules. Journal of Chromatography Library, vol 25. Elsevier, Amsterdam

Berek D (2010) J Sep Sci 33:315

Striegel AM, Yau WW, Kirkland JJ (2009) Modern size-exclusion liquid chromatography: practice of gel permeation and gel filtration chromatography, 2nd edn. Wiley, Hoboken

Krüger R-P, Much H, Schulz G (1999) Monatsh Chem 130:163

Macko T, Hunkeler D (2003) Liquid chromatography under critical and limiting conditions: a survey of experimental systems for synthetic polymers. In: Abe A, Albertsson A-C, Cantow H-J (eds) Liquid Chromatography/FTIR Microspectroscopy/Microwave Assisted Synthesis. Springer, Berlin

Berek D (2016) J Sep Sci 39:93

Durner B, Ehmann T, Matysik F-M (2018) J Chromatogr A 1564:214

Pasch H, Trathnigg B (1998) HPLC of polymers. Springer laboratory, Springer

Glöckner G (1982) Polymercharakterisierung durch Flüssigkeits-Chromatographie: Chromatographische Methoden. Hüthig, Heidelberg

Berek D (2010) Polymer HPLC. In: Corradini D (ed) Handbook of HPLC, 2nd edn. Taylor and Francis, Boca Raton, p 447

Brun Y, Rasmussen CJ (2017) Interaction polymer chromatography. In: Fanali S, Haddad PR, Poole CF (eds) Liquid chromatography: fundamentals and instrumentation, 2nd edn. Elsevier, Amsterdam, p 275

Durner B, Ehmann T, Matysik F-M (2018) Separation of linear and cyclic poly(dimethylsiloxanes) with interactive chromatography. In: Nesmerak K (ed), Proceedings of the 14th International Students Conference “Modern Analytical Chemistry”, Prague, 20–21 September 2018. Cataloguing in Publication

Long W, Horton J (2014) Analysis of positional isomers with Agilent Poroshell 120 PFP columns: application note

Valkó K, Snyder LR, Glajch JL (1993) J Chromatogr A 656:501

Kromidas S, Mladek C. HPLC für Neueinsteiger: http://www.kromidas.de/publikationen/artikel-diverses/dokumente. Accessed 23 Jan 2019

Mojsiewicz-Pieńkowska K (2010) J Pharm Biomed Anal 53:503

LoBrutto R, Kazakevich Y (eds) (2007) HPLC for pharmaceutical scientists. Wiley-Interscience, Hoboken

Philipsen H, Klumperman B, German AL (1996) J Chromatogr A 746:211

Philipsen H, de Cooker MR, Claessens HA, Klumperman B, German AL (1997) J Chromatogr A 761:147

Philipsen H, Oestreich M, Klumperman B, German AL (1997) J Chromatogr A 775:157

Acknowledgements

The authors thank the group Process Chemistry Polymer and Fluids of the Business Unit Basics and Intermediates at Wacker Chemie AG Burghausen for support with silicone oils.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Durner, B., Ehmann, T. & Matysik, FM. Separation of linear and cyclic poly(dimethylsiloxanes) with polymer high-performance liquid chromatography. Monatsh Chem 150, 1603–1610 (2019). https://doi.org/10.1007/s00706-019-02389-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00706-019-02389-4