Abstract

Sensitive voltammetric method for α-lipoic acid determination based on glassy carbon electrode (GCE) modified with SnO2 nanoparticles (SnO2 NP) dispersion in cetyltriphenylphosphonium bromide (CTPPB) (SnO2 NP-CTPPB/GCE) has been developed. The comparison to other surface active compounds as dispersive agents has been performed. The electrodes surface has been characterized by scanning electron microscopy, electrochemical impedance spectroscopy, cyclic voltammetry, and chronoamperometry. Statistically significant decrease of charge transfer resistance (10.8 ± 0.4 kΩ vs. 181 ± 7 kΩ for GCE and 71 ± 3 kΩ for SnO2 NP-H2O/GCE) and higher effective surface area (13.7 ± 0.2 mm2 vs. 8.2 ± 0.3 mm2 for GCE and 12.1 ± 0.2 mm2 for SnO2 NP-H2O/GCE) has been obtained for SnO2 NP-CTPPB/GCE. α-Lipoic acid oxidation on SnO2 NP-CTPPB/GCE is a two-electron diffusion-controlled pH independent process leading to β-lipoic acid formation. Under conditions of differential pulse voltammetry in Britton–Robinson buffer pH 4.5, the linear dynamic ranges are 0.50–50 and 50–400 μmol dm−3 of α-lipoic acid with the limits of detection and quantification of 0.13 and 0.43 μmol dm−3, respectively. The method developed has been successfully applied for the pharmaceutical dosage form analysis.

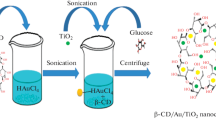

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

α-Lipoic acid (1,2-dithiolane-3-pentanoic acid) is an important bioactive compound playing a key role in cellular metabolism and intracellular antioxidant defense system in living organisms providing their resistance to the oxidative stress development and its negative effects [1, 2]. It is used in medicine as part of the drug therapy of neuropathy [3], liver pathologies of different genesis [4, 5], human immunodeficiency [6], ischemic injury [7], diabetes mellitus [8, 9], Alzheimer’s disease [10], etc. Like other low-molecular weight antioxidants, α-lipoic acid in high concentrations can promote free radical generation, i.e., acts as prooxidant. Its overdose can also lead to the intoxication (appeared as altered mental state and confusion due to the neurologic effects, metabolic acidosis, decreased blood pressure, tachycardia, and increased respiratory rate) [11]. Therefore, the administration dose of α-lipoic acid has to be strictly followed and determination of lipoic acid is necessary to control the quality of corresponding pharmaceutical dosage forms as well as for biochemical and pharmacokinetic studies.

Simple, express, and reliable methods of α-lipoic acid quantification are required for these purposes and various analytical methods are developed. Reversed-phased high-performance liquid chromatography with UV- [12,13,14], electrochemical [15,16,17], electrospray ionization mass-spectrometric [16, 17], and chemiluminescent [18] detection is usually used for the biological fluids and bioadditive analysis due to the complex matrix of the samples and the necessity of components separation. Another way for the determination of α-lipoic acid in dietary supplement is based on the capillary electrophoresis [19, 20]. Nevertheless, the tedious sample pretreatment is required in the most cases mentioned above as well as insufficient selectivity of determination is observed for some methods.

Disulfide bond in the structure of α-lipoic acid makes it electrochemically active that is successfully used in electroanalytical methods being a promising tool due to the simplicity, high accuracy, possibility of miniaturization and cost-efficiency. The analytical characteristics of α-lipoic acid electrochemical determination are summarized in Table 1. It should be noted that electrooxidation of α-lipoic acid on the traditional carbon-based and platinum electrodes occurs at high overpotentials and the fouling of the electrode surface with oxidation products takes place in most cases. The sensitivity of determination can be improved too. The best analytical characteristics are obtained on hanging drop mercury electrode but toxicity of mercury vapors and restriction of its application requires development of novel highly sensitive electrodes for the quantification of α-lipoic acid.

These drawbacks are overcome with application of chemically modified electrodes allowing improvement of the sensitivity and selectivity of the determination and registration of the analytical response at the lower oxidation potential. Carbon nanomaterials including the functionalized ones, metal oxide nanoparticles, and metal complexes as well as their combinations are common electrode surface modifiers. The nanoparticles of the inert titanium and tin oxides in combination with other modifiers are among the perspective ones.

Surface active compounds (SAC) are successfully used for the control of the analytical signal of target analytes in modern voltammetry [31]. Varying the nature of the SAC, the analytical characteristics enhancement and anti-fouling effect of the electrode surface have been obtained for a number of organic compounds [32]. Combination of SAC with metal oxide nanoparticles as electrode surface modifier has been successfully used for a range of phenolic antioxidants [33, 34]. Nevertheless, combination of SnO2 NP with SAC is almost out of consideration. The only sensor based on SnO2 NP and cetylpyridinium bromide (CPB) has been recently described for the voltammetric determination of vanillin [35]. Thus, the application of this type of electrodes (modified with SnO2 NP and SAC) in the electroanalysis of S-containing compound is of interest.

The aim of present work is the development of novel voltammetric method for the α-lipoic acid determination using GCE modified with combination of SnO2 NP and SAC. The special attention is paid to the effect of SAC nature on the response of α-lipoic acid. CTPPB has been investigated as electrode surface modifier for the first time and provided significant improvements in the α-lipoic acid analytical characteristics.

Results and discussion

Voltammetric behavior of α-lipoic acid on glassy carbon and SnO2 NP-modified electrodes

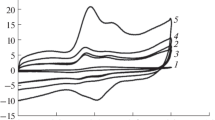

Voltammetric characteristics of α-lipoic acid oxidation have been investigated under conditions of cyclic voltammetry on GCE and SnO2-modified electrodes in Britton–Robinson buffer pH 7.0 (Fig. 1). There are no cathodic steps on the voltammograms confirming oxidation irreversibility on both types of the electrodes (Fig. 1, curves 2 and 3). Electrooxidation on GCE occurs at high potential (+ 1.12 V) and the shape of the analytical signal is stretched out complicating the peak current calculation, especially for the low concentrations of α-lipoic acid. A 260 mV cathodic shift of the oxidation potential and sixfold increase of the oxidation current are observed for the SnO2 NP-modified electrode in comparison to bare GCE. The shape of voltammograms is significantly improved too. These effects are caused by electrocatalytic effect of SnO2 NP and the changes in the effective surface area of the modified electrode.

Further improvement of the α-lipoic acid voltammetric characteristics can be achieved using SAC as electrode surface co-modifiers. The effect of SAC nature on the voltammetric response of α-lipoic acid has been investigated (Table 2). As one can see, the statistically significant increase of the α-lipoic acid oxidation currents is observed for the all SAC under investigation independently of their nature. Nonionic SAC (Triton™ X-100 and Brij® 35) shows similar oxidation currents of α-lipoic acid which are less than for another SAC under consideration. This behavior indirectly confirms the hydrophobic interaction between the SAC molecules and α-lipoic acid. In the case of anionic sodium dodecyl sulfate (SDS), the electrostatic repulsion between negatively charged SAC and α-lipoic acid (pKA = 4.70 [36]) occurs allowing conclusion that the oxidation current increase is caused by hydrophobic interactions.

The highest oxidation currents are obtained on the electrodes modified with cationic SAC (CPB, cetyltrimethylammonium bromide (CTAB), and CTPPB) due to the electrostatic attraction between positively charged heads of the SAC molecules and negatively charged at pH 7.0 α-lipoic acid. The oxidation potentials of α-lipoic acid are changed insignificantly (10–40 mV) excluding 100 mV anodic shift for the electrode modified with SnO2 NP dispersed in CTPPB. In general, the application of SAC as dispersive agents for SnO2 NP and electrode surface co-modifiers provides stabilization of the NP dispersion and improvement of the α-lipoic acid voltammetric characteristics.

To find the best combination of the electrode surface modifiers, the effect of cationic SAC and SnO2 NP concentration on the response of α-lipoic acid has been evaluated (Fig. 2). The results obtained clearly show the synergetic effect of co-modifiers (SnO2 NP and SAC) as far as statistically significant changes in the oxidation currents of α-lipoic acid are observed for the SAC/GCE and SnO2 NP-SAC/GCE. The higher oxidation currents are observed for all cationic SAC under investigation while SnO2 NP concentration grows up to 1.5 mg cm−3 that is caused by the increase of the effective surface area of the working electrode and number of active centers on it. Further increase of the SnO2 NP concentration does not lead to the response improvement. The oxidation potentials of α-lipoic acid do not change significantly. The changes in the cationic SAC concentration show different effects on the oxidation currents of α-lipoic acid. The gradual decrease of the oxidation currents is observed as CTAB concentration increases. On contrary, the oxidation currents are increased in the case of CPB and CTPPB until 0.5 mmol dm−3 concentration and then is decreased for 1 mmol dm−3 SAC. The best response of α-lipoic acid has been registered on the electrode modified with 1.5 mg cm−3 SnO2 NP dispersion in 0.5 mmol dm−3 CTPPB that has been chosen for further measurements.

Characterization of the electrodes surface by SEM and electrochemical methods

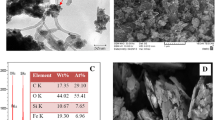

The electrodes surface morphology has been characterized by scanning electron microscopy (SEM, Fig. 3). GCE surface is relatively smooth and does not show high roughness. SnO2 NP layer consists of particles (22–35 nm) and their aggregates (40–100 nm) of spherical, ellipse, and rhomboid shape that are homogeneously distributed on the electrode surface forming porous coverage. The electrode surface morphology does not change significantly in the case of SnO2 NP-CTPPB/GCE showing similar distribution of nanomaterial but the number of bigger sized NP is less in comparison to SnO2 NP-H2O/GCE and the most of NP are of 20–40 nm confirming the stabilizing effect of CTPPB preventing the aggregation of SnO2 NP.

The electron transfer properties of the electrodes under consideration have been studied using electrochemical impedance spectroscopy (EIS) in the presence of 1.0 mmol dm−3 mixture of hexacyanoferrate(II)/(III) ions as a redox probe. The corresponding Nyquist plots are presented in Fig. 4a. As one can see, the semicircle diameter is gradually decreased for the modified electrodes in comparison to bare GCE confirming the lower charge transfer resistance, i.e., the higher electron transfer rate for them. The impedance spectra have been fitted using Randles’ equivalent circuits consisted of the electrolyte resistance Rs in series with the parallel combination of the constant phase element Q and charge transfer resistance Rct (for GCE and SnO2 NP-H2O/GCE) and also Warburg element W in the case of CTPPB/GCE and SnO2 NP-CTPPB/GCE. Good agreement of the experimental points and fitted curves in Fig. 4a indicates the correct choice of the equivalent circuit applied. The electrochemical impedance parameters obtained are presented in Table 3.

a Electrochemical impedance spectra as Nyquist plots (experimental (points) and fitted (lines)) for GCE (1), SnO2 NP-H2O/GCE (2), CTPPB/GCE (3), and SnO2 NP-CTPPB/GCE (4) in 1 mmol dm−3 [Fe(CN)6]3−/4− in 0.1 mol dm−3 KCl. Frequency range 10 kHz–0.04 Hz (in 12 frequency steps per decade) at polarization potential of 0.23 V and amplitude of 5 mV. b Cyclic voltammograms of 1 mmol dm−3 [Fe(CN)6]4− on GCE (curve 2), SnO2 NP-H2O/GCE (3), CTPPB/GCE (4) and SnO2 NP-CTPPB/GCE (5) in 0.1 mol dm−3 KCl (curve 1 on GCE). Potential scan rate is 50 mV s−1

SnO2 NP-H2O/GCE is characterized by 2.5-fold lower Rct in comparison to bare GCE. The presence of CTPPB on the electrode surface leads to dramatic decrease of the Rct (22.6- and 8.9-fold vs. GCE and SnO2 NP-H2O/GCE, respectively) and appearance of the Warburg element on the impedance spectra that is explained by electrostatic interactions of positively charged CTPPB and negatively charged hexacyanoferrate(II)/(III) ions. In the case of SnO2 NP-CTPPB/GCE, the Rct is a bit higher than for CTPPB/GCE due to the presence of SnO2 NP (10.8 ± 0.4 kΩ vs. 8.0 ± 0.2 kΩ, respectively) but 16.8- and 6.6-fold less than for GCE (181 ± 7 kΩ) and SnO2 NP-H2O/GCE (71 ± 3 kΩ) confirming the important role of CTPPB in the electrode surface modification. The Q values for the modified electrodes are 2.0–2.7-fold higher than for bare GCE due to the increase of the total surface charge as well as a porous structure of SnO2 NP-modified electrodes that is indirectly confirmed by the heterogeneity factor n. The EIS data clearly show the electron transfer improvement on SnO2 NP-CTPPB/GCE.

Cyclic voltammetry of hexacyanoferrate(II) ions in 0.1 mol dm−3 KCl has been applied for the characterization of electrodes’ effective surface area (Fig. 4b). Significant increase of the oxidation/reduction currents and decrease of the cathodic to anodic peak potential separation are observed for the modified electrodes in comparison to bare GCE. The shape of voltammograms on the modified electrodes is substantially improved too. However, cathodic to anodic peak potential separation (749 and 400 mV for GCE and SnO2 NP-H2O/GCE) and reduction to oxidation currents ratio confirm irreversible oxidation of hexacyanoferrate(II) ions on GCE and SnO2 NP-H2O/GCE. In the case of CTPPB-modified electrodes, the quasi-reversible oxidation is observed as far as reduction to oxidation currents ratio is 1.3–1.4 and peak to peak potential separation in more than 100 mV. Therefore, the chronoamperometry and Cottrell equation have been applied for the evaluation of the electrodes effective surface area (Fig. S1). The effective surface area of 8.2 ± 0.3 mm2 for GCE, 12.1 ± 0.2 mm2 for SnO2 NP-H2O/GCE, 8.0 ± 0.1 mm2 for CTPPB/GCE, and 13.7 ± 0.2 mm2 for SnO2 NP-CTPPB/GCE has been obtained. Statistically insignificant lower surface area for CTPPB/GCE vs. GCE is caused by SAC film that makes the surface smoother. The increase of the surface area of SnO2 NP-CTPPB/GCE in comparison to SnO2 NP-H2O/GCE agrees well with the SEM data as far as the smaller SnO2 NP cover the electrode surface in this case due to dispersive effect of CTPPB.

Electrooxidation of α-lipoic acid on SnO2 NP-CTPPB/GCE

The electrooxidation parameters of α-lipoic acid have been evaluated on the basis of supporting electrolyte pH and potential scan rate effect on the voltammetric characteristic.

The variation of Britton–Robinson buffer pH in the range of 2.0–11.0 has shown the irreversible oxidation of α-lipoic acid in the whole range of pH mentioned above (Fig. 5a). The oxidation potential is independent of the supporting electrolyte pH confirming nonparticipation of protons in the electrode reaction. The oxidation currents of α-lipoic acid are maximal at pH of 4.5 that is chosen for further measurements.

a Effect of supporting electrolyte pH on the α-lipoic acid voltammetric characteristics on SnO2 NP-CTPPB/GCE. b Cyclic voltammograms of 100 μmol dm−3 α-lipoic acid on SnO2 NP-CTPPB/GCE in Britton–Robinson buffer pH 4.5 (curve 1) at different scan rate (mV s−1): 10 (curve 2), 25 (3), 50 (4), 75 (5), 100 (6), 150 (7), 250 (8), and 300 (9)

The changes of the potential scan rate in the range of 10–300 mV s−1 (Fig. 5b) have shown the diffusion-controlled electrooxidation of α-lipoic acid as far as linear plots of oxidation current vs. square root of scan rate [Eq. (1)] and Napierian logarithms of oxidation current vs. scan rate with the slope of 0.62 [Eq. (2)] [37] are obtained.

The absence of the cathodic step on cyclic voltammograms confirms full irreversibility of the electrode reaction. In this case, the Eq. (3) can be applied for the calculation of the number of electrons participating in the reaction [38].

Taking into account that αa for a totally irreversible process equals to 0.5 [38], the number of electrons participating in the α-lipoic acid oxidation has been calculated as 2.0 that corresponds well to the reported earlier [27, 28]. Thus, electrooxidation of α-lipoic acid proceeds with participation of two electrons leading to the formation of β-lipoic acid (Scheme 1).

Differential pulse voltammetric determination of α-lipoic acid

Differential pulse voltammetry has been used for the quantification of α-lipoic acid. The pulse parameters effect on the analyte response has been evaluated varying modulation amplitude in the range of 25–100 mV and modulation time—25–100 ms (Fig. S2) in Britton–Robinson buffer pH 4.5. The oxidation potential is almost independent of the pulse parameters while the oxidation currents are significantly changed. The highest oxidation currents are obtained at modulation amplitude of 100 mV and modulation time of 50 ms.

Under conditions mentioned above, α-lipoic acid gives well-defined oxidation peak at 0.843 V that is increased as the analyte concentration grows (Fig. 6). Two linear dynamic ranges of 0.50–50 and 50–400 μmol dm−3 are obtained (Eq. (4) and (5), respectively) with the limits of detection and quantification of 0.13 and 0.43 μmol dm−3, respectively. These analytical characteristics are better than reported for other modified electrodes (see Table 1).

Baseline-corrected differential pulse voltammograms of 0.50 (curve 1), 0.75 (2), 1.00 (3), 2.5 (4), 5.00 (5), 7.50 (6), 10 (7), 25 (8), and 50 (9) a and 50 (curve 1), 75 (2), 100 (3), 250 (4), and 400 (5) b μmol dm−3 α-lipoic acid on SnO2 NP-CTPPB/GCE in Britton–Robinson buffer pH 4.5. Potential scan rate is 10 mV s−1, modulation amplitude is 100 mV, and modulation time is 50 ms

The accuracy of the determination has been checked by the added-found method (Table 4). Significant decrease of the α-lipoic acid oxidation currents on the second and further scans is observed. Therefore, the electrode working surface has to be renewed before each measurement. Thus, the RSD values less than 4% confirm high reproducibility of the α-lipoic acid determination.

Selectivity study

The interference effect of the different substances on the 1.0 μmol dm−3 α-lipoic acid response has been investigated. Inorganic ions (K+, Na+, Mg2+, Ca2+, NO3−, Cl−, and SO42−), saccharides (glucose, rhamnose, and sucrose) and polysaccharides (starch and cellulose derivatives) are electrochemically inactive in the potential window applied for the α-lipoic acid quantification and do not show interfering effect. It should be noted that saccharides and polysaccharides are the major co-existing components in the case of pharmaceutical dosage form analysis. As for the biosamples, the ascorbic and uric acids, neuromediators and other biothiols are the possible interferences. Ascorbic and uric acids as well as dopamine are oxidized at less positive potentials (0.242, 0.443, and 0.604 V, respectively) and do not affect the α-lipoic acid response even at 100-fold excesses. Sulfur-containing amino acids (cysteine, methionine) and glutathione are electrochemically inactive in the potential range of 0–1.1 V and do not interfere the α-lipoic acid quantification. Thus, SnO2 NP-CTPPB/GCE is characterized by high selectivity to α-lipoic acid that is important advantage in comparison to other electrodes [25, 27].

Real sample analysis

The applicability of voltammetric method developed to real samples has been shown on the α-lipoic acid pharmaceutical dosage forms. A clear oxidation peak of α-lipoic acid at 0.843 V has been obtained for all samples under investigation (Fig. S3). The results of α-lipoic acid quantification in real samples are presented in Table 5. The accuracy of the determination is confirmed by independent coulometric method [22]. t Test results show the absence of systematic errors of the measurements. F criteria are less than critical confirming the similar precision of the methods.

Conclusion

Sensitive and selective voltammetric approach for the α-lipoic acid quantification using GCE modified with SnO2 NP dispersed in CTPPB has been developed. The applicability of phosphonium salts as electrode surface co-modifier has been shown for the first time. The electrode is characterized by high effective surface area and electron transfer rate. The enhanced analytical characteristics of α-lipoic acid and high selectivity in comparison to existing methods are obtained allowing application of the electrode developed for the real sample analysis and pharmaceutical dosage forms quality control.

Experimental

Stock 10 mmol dm−3 solution of α-lipoic acid (99% purity) from Sigma (Germany) was prepared by dissolution of a definite amount in ethanol (rectificate) in 5.0 cm3 flasks. The exact dilution was used for the preparation of less concentrated solutions. Surfactants CPB (98% purity) and Triton™ X-100 from Aldrich (Germany), CTAB (99% purity) and Brij® 35 from Acros Organics (Belgium), SDS (Ph. Eur.) from Panreac (Spain), and CTPPB synthesized in the Department of Organoelement Compounds Chemistry of Kazan Federal University were used as electrode surface co-modifiers. Their stock solutions (5.0 mmol dm−3 for CPB and CTAB, 3.0 mmol dm−3 for CTPPB, and 10 mmol dm−3 for SDS, Brij® 35, and Triton™ X-100) were prepared dissolving an exact weight of the substance in distilled water in volumetric flasks. Tin dioxide nanopowder with < 100 nm particle size from Aldrich (USA) was used for the electrode modification. Its dispersion of 1.0–2.0 mg cm−3 in water or surfactant media was obtained using ultrasonic treatment for 10 min. Other reagents were of chemical purity and used without additional pretreatment.

Potentiostat/galvanostat µAutolab Type III with the GPES, version 4.9.005 software (Eco Chemie B.V., The Netherlands) was used for the voltammetric experiments. EIS was performed on the potentiostat/galvanostat Autolab 302N with FRA32M module and NOVA 1.10.1.9 software (Eco Chemie B.V., The Netherlands). The three-electrode cell with working GCE (3 mm diameter from CH Instruments Inc., USA) or modified electrodes, reference (silver–silver chloride saturated KCl) and counter (platinum wire) electrodes was used. pH measurements were carried out on the “Expert-001” pH meter (Econix-Expert Ltd., Russia). WiseClean WUC-A03H (DAIHAN Scientific Co., Ltd., Republic of Korea) ultrasonic bath was applied for the preparation of SnO2 dispersions. Coulometric titration was performed on “Exper-006” coulometric analyzer (Econix-Expert, Moscow, Russia) with four-electrode two-compartment electrochemical cell consisted of working electrode (platinum wire of 0.5 cm2 surface area), auxiliary platinum electrode and two polarized platinum electrodes (ΔE = 200 mV) in indicator chain. SEM measurements were carried out on the high-resolution field emission scanning electron microscope Merlin™ (Carl Zeiss, Germany).

Modified electrodes fabrication

The GCE surface was modified with dispersions of SnO2 NP using drop-casting of 5 mm3. The electrode surface was renewed after each measurement by polishing on alumina (0.05 µm) with further rinsing by acetone and distilled water.

Cyclic voltammetry

The supporting electrolyte (4.95 cm3 of BRB pH 2.0–11.0) and 50 mm3 of α-lipoic acid stock solution were inserted in the electrochemical cell and cyclic voltammograms were recorded in the potential ranges of 0.5–1.5 V or 0.3–1.3 V. The potential scan rate was varied.

Differential pulse voltammetry

Britton–Robinson buffer pH 4.5, aliquot portion of α-lipoic acid standard solution (25–200 mm3) and ethanol (up to 200 mm3) were added to the cell. Total volume of solution in the cell equaled to 5 cm3. Differential pulse voltammograms were registered from 0.4 to 1.2 V and scan rate of 10 mV s−1. The pulse parameters were varied. Baseline correction by moving average algorithm included in GPES software was used for the peaks characteristics calculation.

Electrochemical impedance spectroscopy

EIS was carried out in the presence of 1 mmol dm−3 mixture of hexacyanoferrate(II)/(III) ions in 0.1 mol dm−3 KCl at ambient temperature, applied sine potential of 5 mV and polarization potential of 0.23 V (calculated as a half-sum of the hexacyanoferrate reduction/oxidation potentials) in the frequency range of 10 kHz–0.04 Hz (in 12 frequency points per decade).

Scanning electron microscopy

SEM characterization of the electrodes surface was performed at 5 kV accelerating voltage and emission current of 300 pA.

Coulometric titration with electrogenerated bromine

Bromine electrogeneration was carried out in galvanostatic mode at the current density of 5 mA cm−2 providing 100% current yield. Coulometric titration was carried out in a 50 cm3 cell containing 20.0 cm3 of the supporting electrolyte (0.2 mol dm−3 KBr in 0.1 mol dm−3 H2SO4). Firstly, Br2 was generated until the certain value of the indicator current was achieved. Then, a 25–150 mm3 of pharmaceutical dosage form solution was inserted to the cell and the timer was started simultaneously. The titration end-point was detected by the achievement of the initial value of the indicator current. The timer was stopped and the generating circuit was turned off. The titration time was used for the calculation of α-lipoic acid quantity by Faraday formula.

Sample preparation

Pharmaceutical dosage forms and one bioactive supplement of α-lipoic acid available from pharmacies were used as real samples. The liquid form was 15-fold diluted with distilled water. Tablets were prepared according to Pharmacopoea [39]. Briefly, ten tablets were weighted (the average mass of the tablet was calculated) and thoroughly grinded in mortar. The exact weight (0.015 ± 0.005 g) of powder was taken, quantitatively dissolved in ethanol and used for the measurements after filtration.

Statistical analysis

The measurements were carried out in five replications and the 5% significance level was used for the data statistical treatment. The results were expressed as the average value ± the confidence interval. The relative standard deviation was calculated for the random error characterization. Regression analysis was performed using OriginPro 8.0 (OriginLab, USA) software.

References

Shay KP, Moreau RF, Smith EJ, Smith AR, Hagen TM (2009) Biochim Biophys Acta 1790:1149

Packer L, Witt EH, Tritschler HJ (1995) Free Radic Biol Med 19:227

Guo Y, Jones D, Palmer JL, Forman A, Dakhil SR, Velasco MR, Weiss M, Gilman P, Mills GM, Noga SJ, Eng C, Overman MJ, Fisch MJ (2014) Support Care Cancer 22:1223

Sadek KM, Saleh EA, Nasr SM (2018) Hum Exp Toxicol 37:142

Stanković MN, Mladenović D, Ninković M, Ðuričić I, Šobajić S, Jorgačević B, de Luka S, Vukicevic RJ, Radosavljević TS (2014) J Med Food 17:254

Jariwalla RJ, Lalezari J, Cenko D, Mansour SE, Kumar A, Gangapurkar B, Nakamura D (2008) J Altern Complement Med 14:139

Dong Y, Wang H, Chen Z (2015) Int J Endocrin 2015:903186

Gianturco V, Bellomo A, D’Ottavio E, Formosa V, Iori A, Mancinella M, Troisi G, Marigliano V (2009) Arch Gerontol Geriatr 49(S1):129

Henriksen EJ, Diamond-Stanic MK, Marchionne EM (2011) Free Radical Biol Med 51:993

Maczurek A, Hager K, Kenklies M, Sharman M, Martins R, Engel J, Carlson DA, Münch G (2008) G Adv Drug Delivery Rev 60:1463

Emir DF, Ozturan IU, Yilmaz S (2018) Am J Emerg Med 36:1125.e3

Aboul-Enein HY, Hoenen H (2004) J Liq Chromatogr Relat Technol 27:3029

Ezhilarasi K, Sudha V, Ramachandran G, Umapathy D, Rajaram R, Padmalayam I, Viswanathan V, Kumar AKH (2014) J Chromatogr Separat Techniq 5:6

Chwatko G, Krawczyk M, Iciek M, Kamińska A, Bilska-Wilkosz A, Marcykiewicz B, Głowacki R (2016) Arab J Chem. https://doi.org/10.1016/j.arabjc.2016.10.006

Siangproh W, Rattanarat P, Chailapakul O (2010) J Chromatogr A 1217:7699

Durrani AI, Schwartz H, Schmid W, Sontag G (2007) J Pharm Biomed Anal 45:694

Durrani AI, Schwartz H, Nagl M, Sontag G (2010) Food Chem 120:1143

Wolyniec E, Karpinska J, Losiewska S, Turkowicz M, Klimczuk J, Kojlo A (2012) Talanta 96:223

Sitton A, Schmid MG, Gubitz G, Aboul-Enein HY (2004) J Biochem Biophys Methods 61:119

Kodama S, Taga A, Aizawa S, Kemmei T, Honda Y, Suzuki K, Yamamoto A (2012) Electrophoresis 33:2441

Marin M, Lete C, Manolescu BN, Lupu S (2014) J Electroanal Chem 729:128

Ziyatdinova GK, Budnikov GK, Pogorel’tsev VI (2004) J Anal Chem 59:288

Corduneanu O, Garnett M, Brett AMO (2007) Anal Lett 40:1763

Alarfaj NA (2009) Int J Biomed Sci 5:54

Stanković DM, Mehmeti E, Kalcher K (2016) Anal Sci 32:847

Ziyatdinova GK, Grigor’eva LV, Budnikov GK (2009) J Anal Chem 64:185

Miranda MP, del Rio R, del Valle MA, Faundez M, Armijo F (2012) J Electroanal Chem 668:1

Ferreira APM, dos Santos Pereira LN, da Silva IS, Tanaka SMCN, Tanaka AA, Angnes L (2014) Electroanalysis 26:2138

Dos Santos Pereira LN, da Silva IS, Araújo TP, Tanaka AA, Angnes L (2016) Talanta 154:249

Sasikumar R, Ranganathan P, Chen S-M, Rwei S-P (2018) Sens Actuators B 255:217

Ziyatdinova GK, Ziganshina ER, Budnikov HC (2012) J Anal Chem 67:869

Ziyatdinova G, Budnikov H (2018) Carbon nanomaterials and surfactants as electrode surface modifiers in organic electroanalysis. In: Shtykov SN (ed) Nanoanalytics: nanoobjects and nanotechnologies in analytical chemistry. De Gruyter, Berlin, p 223

Ziyatdinova G, Ziganshina E, Nguyen Cong PH, Budnikov H (2017) Food Anal Meth 10:129

Ziyatdinova G, Ziganshina E, Romashkina S, Budnikov H (2017) Electroanalysis 29:1197

Ziyatdinova GK, Antonova TS, Mubarakova LR, Budnikov HC (2018) J Anal Chem 73:801

Krishnan CV, Garnett M (2011) Int J Electrochem Sci 6:3607

Scholz F (ed) (2002) Electroanalytical methods. Guide to experiments and applications. Springer-Verlag, Berlin Heidelberg

Bard AJ, Faulkner LR (2001) Electrochemical methods: fundamentals and applications, 2nd edn. Wiley, New York

European Pharmacopoeia (2016) Council of Europe, 9th edn. European Directorate for the Quality of Medicines and Healthcare, Strasbourg

Acknowledgements

The authors thank Prof. Irina Galkina (Kazan Federal University) for the synthesis and granting of CTPPB.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Ziyatdinova, G., Antonova, T., Vorobev, V. et al. Selective voltammetric determination of α-lipoic acid on the electrode modified with SnO2 nanoparticles and cetyltriphenylphosphonium bromide. Monatsh Chem 150, 401–410 (2019). https://doi.org/10.1007/s00706-018-2341-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00706-018-2341-5