Abstract

A bismuth-film electrode prepared ex situ on the glassy carbon electrode support exhibited favorable electroanalytical performance for voltammetric measurement of folic acid. The reduction behavior of this substance was studied in aqueous solutions within the pH 1−7, the highest response being obtained in Britton–Robinson buffer with pH 2. In the differential pulse voltammetry, the bismuth-film electrode showed a linear dynamic range from 2.5 × 10−8 to 3 × 10−5 mol dm−3 folic acid, when reaching an extraordinary repeatability of measurements [RSD(11) = 1.03 %], of determination [RSD(5) ≤ 0.87 %], or detection capabilities (LOD = 4.1 × 10−9 mol dm−3). After optimization of key experimental and instrumental parameters, the respective method was tested by analyzing vitamin preparations and fruit juice, when the results agreed well with the declared content. Thus, the method for the determination of folic acid with a bismuth-film electrode can be proposed as an alternative to those employing mercury and amalgam electrodes, previously applied for the same purpose by our group.

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Since the year 2000, bismuth-film electrodes (BiFEs) have become an attractive configuration in electro-analysis as a potentially suitable replacement for mercury electrodes due to its environmentally friendlier nature [1]. BiFEs present valuable electrochemical characteristics, such as a wide potential window in the cathodic range, negligible interference from dissolved oxygen, and most importantly, rather similar electrochemical behavior compared to mercury-based electrodes [2]. BiFEs can be prepared by depositing a thin bismuth film on a suitable substrate material, such as the glassy carbon electrode (GCE) [1, 3–6], boron-doped diamond electrode (BDDE) [7], carbon paste electrodes (CPEs) [8–10], carbon fiber [1, 11], screen-printed electrodes (SPE) [12], or silver solid amalgam electrodes (AgSAE) [13, 14]. The film can be deposited electrochemically at a constant potential either in situ (in model or sample solution) [1, 7, 15] or ex situ by pre-deposition in a special plating solution [16, 17]. Besides the above described BiFE, bismuth bulk (disc) electrode (BiBE) and various electrode materials with the blended Bi powder (e.g., Bi-CPE), there is also a new perspective type of the bismuth sensor, being based on sputtering of silicon wafer with a thin film of bismuth [18]. The wide use of Bi electrodes is especially due to their effective performance in the determination of metals at the trace concentration level, which can be documented by many papers [1, 2, 4–12, 15, 16, 19–22]. The utilization of BiFEs in organic analysis is not so common because of the limited cathodic range and rather complicated surface morphology of bismuth crystals that form the film and may, e.g., affect adsorption onto the electrode surface in comparison with Hg electrodes [19]. Up until now, only a few organic compounds have been analyzed [16–18, 23–35].

In this paper, we demonstrate the applicability of a BiFE for voltammetric analysis of folic acid (FA, CAS: 59-30-3, Scheme 1), known also as pteroyl-l-glutamic acid (chemically: N-[4-[[(2-amino-4-oxo-1,4-dihydropteridin-6-yl)methyl]amino]benzoyl]-l-glutamic acid). FA is a widely distributed vitamin (called “vitamin BC, vitamin M or vitamin B9”), incorporating purine and pyrazine rings (together with the pterin structure) with two amino acids present on the pyrazine ring as a side chain. Folates represent an important class of water-soluble B vitamins that helps to build healthy cells, having a major role in biological functions of cell metabolism like DNA replication, repair and methylation, and synthesis of nucleotides, vitamins, amino acids, etc. The FA deficiency causes growth weakness in mammals, different kinds of anemia, devolution of mentality, and psychosis [36, 37], being also a very important nutrient especially for women planning pregnancy. The recommended daily intake of FA is 0.2 mg (0.453 µmol) for adults and 0.4 mg (0.906 µmol) for pregnant women [38, 39].

Considering the possibilities of determining FA, various analytical procedures have been reported. The respective methods include chromatography in various arrangements, such as high-performance liquid chromatography (HPLC) in combination with fluorescence and ultraviolet detectors [40] or diode array detector [41], liquid chromatography (LC) with electrospray ionization mass spectrometry [42], tandem mass spectroscopy [43], and microemulsion electrokinetic chromatography [44]. Besides chromatographic methods, capillary electrophoresis with chemiluminescence detection [45], biosensor-based determination [46], or disposable microfluidic ELISA (enzyme-linked immunosorbent assays) [47] were used for determination of FA.

Also various electrochemical approaches have been employed to study and determine FA. As shown, electroanalysis can be a suitable alternative to the above-mentioned techniques, particularly due to the miniaturization, relatively low costs of instrumentation, and relatively rapid and simple analysis. The electrochemical behavior of FA was first studied with mercury electrodes and the mechanism of its reduction proposed by Kretzschmar and Jaenicke [48], being confirmed also by Gurira et al. [49]. It was found that FA undergoes three two-electron/two- proton reduction steps in acidic media and one in an alkaline solution. The first step represents a quasi-reversible reduction of FA to 7,8-dihydro-FA via a transient 5,8-hydro-FA derivative, while the second and third ones involve the electrochemical cleavage of the C(9)-N(10) bond of 7,8-dihydro-FA to 6-methyl-7,8-dihydropterin and p-aminobenzoyl-glutamic acid and irreversible reduction of 6-methyl-7,8-dihydropterin to 6-methyl-5,6,7,8-tetrahydropterin. In alkaline medium, only a single reduction step is observed, representing the conversion of the molecule of FA to 5,8-dihydro-FA [49].

In subsequent years, various polarographic and voltammetric methods in connection with mercury electrodes have been described for FA determination: among others, a.c. polarography with the dropping mercury electrode (DME) [50], adsorptive stripping voltammetry (AdSV) with the hanging mercury drop electrode (HMDE) [51–53], or square wave voltammetry (SWV) with the static mercury drop electrode (SMDE) [54]. A similar voltammetric behavior was also confirmed on mercury meniscus modified and polished silver solid amalgam electrodes (m-, p-AgSAE) [55, 56]. Along with the reduction of FA on mercury and amalgam electrodes, the oxidation of this substance could also be successfully used [57–63].

Considering the importance of FA in the organism, it is necessary to have simple and sensitive methods for its determination in biological or pharmaceutical samples. The voltammetric behavior of folic acid on HMDE and AgSAEs has been described in our previous papers [55, 56]. In this article, it is shown that a BiFE can be another possible replacement for mercury electrodes; moreover, fulfilling the latest requirements for ecological materials and procedures [64]. The aim of this work was not only to develop method for the determination of FA using BiFE, but also to compare the voltammetric behavior and analytical results with AgSAE, resp. HMDE.

Results and discussion

Voltammetric behavior of FA on BiFE dependent on pH

The conditions for preparation of BiFE for the initial experiments were taken from the previous study [16]. The bismuth film was prepared ex situ in a plating solution containing 0.05 mol dm−3 acetate buffer (AcB, pH 4.5) +10 mg dm−3 of Bi(III) and in the presence of dissolved oxygen by applying a constant potential of −1000 mV for 360 s and under stirring.

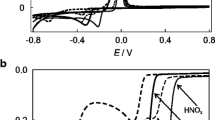

At first, the cyclic voltammogram of FA was measured in AcB (pH 4.5) and the relevant parts of the corresponding curve are shown in Fig. 1. The voltammetric behavior of FA has been previously studied on the HMDE and AgSAEs [56] and it was found that the cathodic reduction of the FA molecule provides three reduction peaks at about the potentials of −480, −850, and −1080 mV in Britton–Robinson buffer (BRB, pH 5). In the experiment with the BiFE presented herein, it was ascertained that FA gave rise to a single reduction response at about −450 mV, whereas the second and third anticipated signals did not appear, probably due to a narrower potential window available at BiFE, when the most negatively situated peaks remained overlapped by the signal of electrolyte decomposition. No oxidation signal was recorded under the working conditions used (Fig. 1), suggesting the irreversible pathway of the studied electrode process.

Generally, the selection of a suitable supporting electrolyte is an important step in the voltammetric analysis, because the type of medium might seriously influence the electrode processes. Because of the absence of the anodic signal, the influence of pH of the supporting electrolyte was studied using direct current voltammetry (DCV). The effect of HNO3 (pH 1) and BRB with pH varying from 2.0 to 7.0 on the voltammetric behavior of 1 × 10−5 mol dm−3 FA was investigated. It was found that the reduction signal of interest recordable on the BiFE could be observed from pH 1.0 to 6.0. As can be seen in Fig. 2, the highest current response was observed in the BRB with pH 2.0, and then the peak slowly decreased.

Figure 2 shows also the dependence of peak position (E p) on pH of the supporting electrolyte, resulting in a trend when the cathodic signal has shifted toward more negative potentials with the increasing pH. It is an indubitable proof that protons represent an important participator in the reduction process of FA at the BiFE. This dependence is linear over the whole pH range studied and can be characterized by the following Eq. (1):

The slope (−0.0599 V) is almost identical with the theoretical value from Nernst equation (−0.0592 V), which corresponds to a mechanism involving the same number of the electrons and protons. This could confirm a reduction pathway of FA to 7,8-dihydro-FA via a transient 5,8-hydro-FA derivative via the well-known two-electron/two-proton mechanism [49]. Based on the results described, BRB of pH 2.0 was chosen as the supporting electrolyte for all further measurements of FA using BiFE.

The effect of scan rate

The influence of scan rate (v) on the voltammetric response of FA was studied using a model solution of 5 × 10−6 mol dm−3 FA in BRB (pH 2.0), when applying the DCV mode. The values of v were changed from 25 to 400 mV s−1. The voltammetric curves obtained are depicted in Fig. 3a. It was found that the signal of FA enlarged with the increasing v, but the current response did not increase proportionally. A linear dependence between the I p and the square root of the scan rate (v 1/2) was obtained, which is evident from Fig. 3b and Eq. (2) with the corresponding coefficient of determination:

Thus, it can be assumed that the cathodic process is diffusion controlled. Moreover, as can be seen from parameters of the “log(I p)–log(v)” analysis, the value of 0.5 is not included in the confidence interval with a slope 0.5401 ± 0.0077 (p = 0.05), so the process is controlled by the diffusion transport with the likely slight participation of adsorption. Also, the position of the signal recorded moved to more positive potentials with the increasing scan rate, confirming the irreversible electrode process.

Optimization of the preparation of the BiFE

Due to particular requirements for ex situ BiFE preparation from a separate plating solution, the parameters for bismuth deposition onto the GCE (i.e., plating potential and time) were carefully optimized for the detection of FA. Firstly, the dependence of the I p of FA on deposition potential (E dep) was studied using DPV. The value of E dep was changed from −400 to −1400 mV and plating time (t dep) held constant (180 s). As illustrated by Fig. 4, the highest current response was observed for E dep close to −1000 mV and then the peak decreased. This behavior has indicated the proper film formation for potentials positioned negatively at about −1000 mV, which is related to the reduction of bismuth taking place beyond −300 mV at the GCE under these conditions. Thus, a value of E dep −1000 mV was chosen for each BiFE prepared ex situ in this work.

Effect of depositing potential and time on height of DPV peak of FA at BiFE. Method: DPV, electrolyte: BRB (pH 2.0), E in = −100 mV, E fin = −900 mV, v = 20 mV s−1, pulse height −50 mV, pulse width 80 ms, c FA = 1 × 10−5 mol dm−3; plating electrolyte: AcB (pH 4.5) + 10 mg dm−3, E dep = −400 to −1400 mV, resp. −1000 mV, t dep = 180 s, resp. 40–140 s

After that, the t dep was studied. When this time period was changed from 40 to 140 s, and the remaining parameters held constant (at E dep = −1000 mV), the signal recorded increased rapidly until the value of 80 s, followed by moderate decrease to the value of 140 s (Fig. 4). In this case, the optimum parameters for ex situ Bi-film deposition were determined to be E dep = −1000 mV and t dep = 80 s, when using AcB (with pH 4.5) as a plating electrolyte containing 10 mg dm−3 of Bi(III).

Determination of FA in model solutions

Differential pulse voltammetry (DPV) in connection with the BiFE was the technique of choice for determination of FA in model solutions. All the following experiments aimed at optimized conditions for DPV were carried out in BRB (pH 2.0) at the concentration level of 1 × 10−6 mol dm−3 FA.

Firstly, the procedure of electrochemical regeneration of the working electrode surface was studied with two different mechanisms tested. It was (a) application of one negative potential (−900 mV) for 20 s, and (b) imposition of 30 potential “jumps” (cycling) between −100 and −900 mV, where the limiting potentials were kept for 0.3 s. Application of −900 mV for 20 s was found the most appropriate for the BiFE regeneration, which was confirmed by a low value of the relative standard deviation of 11 repeated measurements [RSD(11) = 2.72 %]. Also, the possibility of omission of the regeneration step was investigated, but caused an undesirable decrease in the repeatability of measurements [RSD(11) = 4.89 %].

Subsequently, the working parameters (v, pulse height, and pulse width) of DPV were examined. When the value of v was changed from 5 to 100 mV s−1, and the remaining parameters were constant (E in = −100 mV, E fin = −900 mV, the pulse height −50 mV, pulse width 50 ms), the signal recorded increased but deformed at higher v, the value of 20 mV s−1 being chosen for the next experiments. The influence of pulse height was studied in the range from −10 to −130 mV (the remaining parameters: E in = −100 mV, E fin = −900 mV, v = 20 mV s−1, pulse width 50 ms). The signal of FA rapidly increased up to −50 mV, then decreased and deformed. Thus, the pulse height of −50 mV was chosen for all the following experiments. When the pulse width was changed from 10 to 150 ms (E in = −100 mV, E fin = −900 mV, v = 20 mV s−1, pulse height −50 mV), the peak current decreased with the increasing pulse width. In this case, the pulse width of 20 ms was selected for all the subsequent experiments.

A possibility to accumulate FA onto the electrode surface was studied as well. Firstly, the influence of accumulation potential (E acc) on I p was tested, and it was found that the changes of E acc in the range from 0 to −150 mV have no significant effect on the response to FA. Therefore, the value of E acc −100 mV (E acc = E in) could be chosen for the following experiments. The accumulation time (t acc) was changed from 0 to 140 s (c FA = 5 × 10−7 mol dm−3). Figure 5 shows the dependence of the I p on t acc and relevant voltammetric curves. The respective experiments revealed that the dependence is linear from 0 to 70 s and this linear dependence can be characterized by the equation being inserted in Fig. 5b. The reduction was previously described as diffusion controlled with negligible contribution of adsorption. FA was fractionally adsorbed on the working surface; therefore, the sensitivity of the determination could be improved by applying the AdSDPV mode.

DP voltammograms of FA recorded on BiFE at various t acc (a) with the appropriate dependence of I p on t acc (b). Method: DPV, electrolyte: BRB (pH 2.0), E in = −100 mV, E fin = −900 mV, v = 20 mV s−1, E reg = −900 mV, t reg = 20 s, pulse height −50 mV, pulse width 20 ms, E acc = −100 mV, t acc = 0–130 s, c FA = 5 × 10−7 mol dm−3

The repeatability of measurements for the reduction of FA under optimized conditions was studied again by application of replicate measurements and RSD(11) calculated as 1.03 % for a concentration of 5 × 10−7 mol dm−3 FA. This result had indicated a very good repeatability when confirming also an appropriate choice of the operational parameters of DPV. As already stated above, this technique with optimized parameters was applied to measure various concentrations of FA in model solutions. An example of a particular dependence in the concentration range from 5 × 10−8 to 3 × 10−7 mol dm−3 FA (with t acc = 20 s) and the corresponding voltammograms is shown in Fig. 6. The dependence depicted is linear and can be characterized by the equation with the respective coefficient of determination shown in Fig. 6b. The linear dynamic range (LDR) of the reduction peak observed was obtained in an interval from 2.5 × 10−8 to 3 × 10−5 mol dm−3. The value of t acc was changed in dependence of the concentration. From this reason, the whole LDR could not be measured in one single experiment.

DP voltammograms of FA at various concentrations (a) with the appropriate dependence of I p on c FA (b). Method: DPV, electrolyte: BRB (pH 2.0), E in = −100 mV, E fin = −900 mV, v = 20 mV s−1, E reg = −900 mV, t reg = 20 s, pulse height −50 mV, pulse width 20 ms, E acc = −100 mV, t acc = 20 s, c FA = 5 × 10−8–3 × 10−7 mol dm−3

The applicability of the proposed method was verified by repeated determinations of FA at three concentration levels. Each determination was repeated five times and the values of RSD(5) calculated. The obtained results are summarized in Table 1 and it is evident that the values achieved do not exceed 1.7 %. The results obtained confirmed the high accuracy, recovery, and good repeatability of the determinations of FA in model solutions under the experimental conditions used. Finally, some statistical parameters, such as limit of detection (LOD) and limit of quantification (LOQ), were calculated. The LOD was estimated to be about 4.1 × 10−9 mol dm−3 (t acc = 30 s), whereas the LOQ ca. 1.4 × 10−8 mol dm−3, which can be described as sufficiently low for analyzing pharmaceutical and vitamin preparations, as well as fruit beverages and selected food samples.

Voltammetric analysis of vitamin preparations and fruit juice

The operational conditions for DPV optimized on model solutions of FA were subsequently applied to the voltammetric determination of FA in vitamin preparations [Folic Acid Forte—Naturvita (FAFN); Folic Acid—Dr. Max (FADM)] and in fruit juice (Dizzy Multivitamin). The respective solutions were prepared and analyzed as described below. The results obtained are summarized in Table 2. These results could be considered as accurate and repeatable, which corresponds to an extraordinary RSD(5). A typical example of determination of FA in tablet is shown in Fig. 7.

Analogically, the FA content in fruit juice was determined, when the applicability of DPV to the juice analysis had initially been tested on the determination of FA in the spiked juice. The recovery values calculated for five replicate analyses ranged from 99.7 to 102.0 %, indicating a very good recovery in the matrix of the fruit beverage analyzed. Then, 0.5 cm3 of juice was added into the electrochemical cell with the supporting electrolyte (10 dm3) and the content of FA in juice was repeatedly determined by the standard addition method. The FA contents determined and the respective values of RSD(5) are shown in Table 2.

A comparison of the results obtained with BiFE, HMDE, and AgSAEs

One of objectives of this work was to compare the voltammetric behavior of FA on BiFE with the previously published results obtained with the HMDE, m-AgSAE, and p-AgSAE. Amalgam electrodes are often mentioned as an alternative to mercury electrodes. They exhibit very similar electrochemical properties, including high hydrogen overvoltage. They can often be used instead of mercury electrodes by applying the same conditions when these analyses give similar signals about the same values of potentials [65]. Nevertheless, this electrode material still contains mercury. Although, the mercury is bound in solid amalgam (i.e., non-liquid, non-toxic form), its use in the future has to be discussed with respect to the restrictions connected with the use of mercury as such [66]. On the other hand, bismuth (non-mercury alternative to mercury electrodes) is not a completely non-toxic material. As described in the literature, the poisoning with the bismuth compounds has similar symptoms, like those known for lead or mercury poisoning. Another similarity is that the organometallic derivatives of bismuth are the most toxic Bi-compounds. Nevertheless, it should be noted that elemental bismuth is not toxicologically rated and its compounds cause severe poisoning only at higher doses [20, 67].

The width of the potential window in the cathodic area was investigated first with all three working electrodes examined. This comparison was accomplished under the conditions in BRB (pH 6). The cathodic potential limit was defined via the current value reaching the level of −150 nA. The highest hydrogen overvoltage was identified with the HMDE, i.e., the widest negative potential window, allowing one to polarize this electrode down to −1360 mV vs. reference. Using the amalgam-based electrodes, the applicable cathodic potential was −1280 mV (for m-AgSAE) and −1155 mV (p-AgSAE), respectively. This implies that the hydrogen overvoltage gradually decreases from the HMDE via m-AgSAE, down to p-AgSAE, which is due to the decrease of mercury content in the electrode material. On the other hand, both types of amalgam electrodes exhibit the potential window in the cathodic region about a few hundreds of mV wider than that for BiFE, which enables us to observe the reduction processes down to the potentials at about −900 mV in BRB (pH 6).

The voltammetric behavior of FA has been compared on the three types of electrodes mentioned. Using CV in combination with the HMDE, three well-separated cathodic peaks and one anodic peak in acidic medium and only single reduction signal, as well as one oxidation peak in alkaline medium, were obtained. The curves recorded at m-AgSAE were similar, i.e., three reduction peaks and one oxidation peak obtained in acidic medium. However, the current signals observed at m-AgSAE were less intensive than those recorded using HMDE. This phenomenon can probably be explained by smaller surface area of the m-AgSAE in comparison with the HMDE. At the p-AgSAE, only two cathodic peaks corresponding to the reduction and one anodic peak corresponding to the oxidation process were observed in an acidic medium. The third reduction signal was already overlapped by a signal that corresponded to the hydrogen evolution. Finally, the BiFE provides only the first signal, i.e., the most positive reduction peak of FA, and it was not possible to register the second and third cathodic peaks, most probably due to a lower hydrogen overvoltage of the BiFE compared to the mercury-containing electrodes. Regarding the corresponding anodic signal, it was not observed when using BiFE, which indicates a considerably lower degree of reversibility of the electrode reaction of interest.

Last but not least, the statistical parameters calculated from experimental data characterizing the determination of FA at all electrodes tested were compared, when applying the same DPV method described above. The corresponding values of LOD, RSD(5), and RSD(11) are summarized in Table 3. By comparing the individual data, it can be stated that the LOD for BiFE is sufficiently low to analyze various pharmaceutical preparations, nutritional supplements, or fruits beverages. However, when considering the previously published results with mercury and amalgam electrodes [55, 56], measurements with the BiFE exhibit a higher value of LOD. On the other hand, the values of RSD for BiFE are very low and confirmed a very good repeatability. Also thanks to this, the BiFE, similarly to the HMDE and AgSAEs, could be successfully used to analyze real samples.

Time consumption and complications connected with electrode handling are other important aspects which should be considered before a working electrode is to be selected for particular use. In this respect, HMDE represents a very simple and rapid tool for electroanalytical measurements with continually renewable electrode surface. Both modifications of AgSAE require a renovation of their surfaces (by polishing or via forming of mercury meniscus) once or twice a week and, eventually, electrochemical regeneration of the surface before almost each measurement. These steps are usually simple, fast, and in most cases being even sufficient to obtain satisfactory results. Compared to this, also BiFEs require some care and the respective experiments may involve demanding and/or time-consuming operations. For instance, already the process of ex situ deposition of Bi film was not reproducible enough because the corresponding electrochemical characteristics (e.g., potential window, current responses) were poorly repeatable/reproducible. In some cases, the whole procedure of electroplating had to be completely repeated. Also, the BiFE prepared was unstable and its properties deteriorated with the continuing experiments. Based on these experiences, the new Bi film at the GCE surface had to be prepared after every three series of measurements. The repeatability of the signal measured was slightly improved by adding a regeneration step similar to that for AgSAEs, i.e., a negative potential imposed for several tens of seconds. After adopting these specific conditions, a very sensitive method of FA determination using BiFE was developed and well repeatable results obtained; nevertheless, the time consumption of analysis somewhat increased in comparison with those being typical for the HMDE and AgSAEs, respectively.

Conclusion

In the paper presented above, a BiFE has been used to investigate the electrochemical behavior of folic acid (FA) and to determine this substance in selected samples. The BiFE was prepared ex situ by predeposition in a plating solution based on acetate buffer (pH 4.5) and containing the Bi3+ ions. The electrode reaction studied at BiFE was identified as the diffusion-controlled process with a slight participation of adsorption. The BRB with pH 2.0 was the supporting electrolyte of choice for the determination of FA, when the key experimental and instrumental conditions and parameters were optimized for measurements in the DPV mode. The method developed characterized by the LOD of about 4.1 × 10−9 mol dm−3 was successfully applied to the determination of FA in pharmaceutical preparations and a sample of fruit juice. The results obtained were compared with the previously published outcomes achieved with the HMDE and two types of amalgam electrodes (m- and p-AgSAE). Regarding the new method with BiFE, it was found that the respective measurements offer somewhat lower sensitivity compared to HMDE and both AgSAEs, but the bismuth based electrode can still be reliably used for the determination of FA in selected real samples.

It can be concluded that the use of ex situ operated BiFE can be recommended for the determination of folic acid as a possible alternative to mercury electrodes, contributing also to the hitherto quite narrow spectrum of methods employing the bismuth-based electrodes and applicable to organic substances and biologically active compounds.

Experimental

Chemicals

All chemicals used for preparation of the supporting electrolyte, standard solutions and other stock solutions were of p.a. purity. FA (98 % declared by producer, Sigma-Aldrich) was used as obtained without any further purification. The stock solution of FA (c = 0.01 mol dm−3) was prepared by dissolving the appropriate weight of the substance in 0.01 mol dm−3 NaOH (Lachema, Brno, Czech Republic) and it was stored in the dark in a refrigerator. The BRB of a pH value from 2.0 to 7.0 was prepared by mixing an alkaline component of 0.2 mol dm−3 NaOH and an acidic component consisting of 0.04 mol dm−3 H3PO4, 0.04 mol dm−3 H3BO3, and 0.04 mol dm−3 CH3COOH (all these chemicals from Lachema, Brno, Czech Republic). HNO3 (0.1 mol dm−3, pH 1.0) served also as the supporting electrolyte and 0.5 mol dm−3 HNO3 was used for electrochemical removal of the bismuth film. These solutions were diluted from the concentrated acid (Penta, Prague, Czech Republic). The acetate buffer (0.1 mol dm−3, AcB) of pH value 4.5 was prepared by mixing solutions of CH3COOH and NaOH. The bismuth(III) ion stock solution (1 g dm−3, Analytika Co. Ltd., Prague, Czech Republic) was used for deposition of the bismuth film. Two types of the practical samples were analyzed: commercially available pharmaceutical preparations with the declared content of FA 200 µg/tablet (Folic acid forte—Naturvita) and 800 µg/tablet (Folic acid—Dr. Max), respectively, and fruit juice (Dizzy Multivitamin) containing FA too.

Instrumentation

Voltammetric measurements were carried out using computer-controlled Eco-Tribo Polarograph (Polaro-Sensors, Praha, Czech Republic), equipped with POLAR-PRO software for Windows. Voltammetric curves were obtained using a three-electrode system in an electrochemical cell. Bismuth film deposited onto a surface of GCE (L-Chem, Olomouc, Czech Republic) served as working electrode, and Ag|AgCl|KCl(satur.) as a reference and platinum wire as an auxiliary electrode (both from Monokrystaly, Turnov, Czech Republic). The measurements were performed at laboratory temperature (23 ± 2 °C). Oxygen was removed from the measured solutions by bubbling with nitrogen (purity class 4.0, Linde Gas, Prague, Czech Republic) for 5 min. All pH values were measured using pH-meter Hanna 221 (Hanna Instruments, USA). The solutions of FA tablets were prepared by applying an ultrasonic bath Bandelin Sonorex (Schalltec GmbH, Germany).

Procedures

Cyclic voltammetry (CV) and DCV, respectively, were used for the first set of studies on voltammetric behavior of FA at the BiFE depending on the pH of the supporting electrolyte and a scan rate (v). CV measurements were performed in the potential range from −200 to −1200 mV with a v of 100 mV s−1, and DCV measurements of voltammetric behavior of FA depending on pH of the supporting electrolyte were carried out from −50 to −800 mV with a v of 100 mV s−1. The influence of the scan rate was studied in the potential range from −100 to −900 mV with values varying from 25 to 400 mV s−1. DPV was utilized for the quantification of FA with the following parameters: initial potential (E in), −50 mV; final potential (E fin), −900 mV; pulse height, −50 mV; pulse width, 20 ms; v, 20 mV s−1; potential of regeneration (E reg), −900 mV; and time of regeneration (t reg), 20 s. An accumulation step was inserted into the measuring procedure for lower concentration levels of FA to increase the sensitivity of the adsorptive stripping mode, with the parameters for these measurements being as follows: potential of accumulation (E acc), −50 mV, whereas time of accumulation (t acc) was changed depending on the FA concentration. The current signals obtained were evaluated from the straight line by connecting the minima before and after the peak.

The LOD was calculated as three times and LOQ as ten times, respectively, of the standard deviation for the blank solution and divided by the slope of the calibration curve. The parameters of the calibration curve (e.g., slope and intercept) were calculated using OriginPro 9 software (OriginLab Corporation, USA). The confidence intervals were calculated at the level of significance 1 − α = 0.05.

Before use, the glassy carbon substrate was mechanically polished using a polishing kit (Electrochemical Detectors, Turnov, Czech Republic) consisting of a polishing polyurethane pad, Al2O3 suspension (with particle size of 1.1 mm), and a soft polishing Al2O3 powder (p.s.: 0.3 mm). The substrate was rinsed with distilled water and ethanol and placed in an ultrasonic bath for 5 min. The ex situ electroplating of the bismuth film was then performed in an air-saturated solution. The bismuth film was prepared by applying a constant potential −1000 mV during a fixed time 80 s in 0.1 mol dm−3 AcB (pH 4.5) containing 10 mg dm−3 Bi(III) while stirring the plating solution. To remove the bismuth film, an electrochemical step was carried out by applying a potential of +400 mV for 15 s in an acidic solution of 0.5 mol dm−3 HNO3. Due to the passivation of the electrode surface, a new film had to be prepared after a few voltammetric experiments.

Preparation and analysis of practical samples

Two types of real samples, commercially available pharmaceutical preparations and fruit juice, were analyzed. The stock solutions for the quantitative experiments were prepared always from one tablet of pharmaceutical preparations with the declared content of FA: 200 µg/tablet (Folic acid forte—Naturvita), resp. 800 µg/tablet (Folic acid—Dr. Max). Always one tablet of preparation was powdered in a grinding mortar and then the whole powdered amount was transferred into a 50 cm3 standard flask and dissolved in 0.1 mol dm−3 NaOH. The solution was filtered after 60 min of sonication. The clear filtrate solution was filled to 50 cm3 with 0.1 mol dm−3 NaOH and so used for experimentation. 276 mm3 of solution of “Folic acid forte–Naturvita” or 138 mm3 of solution of “Folic acid—Dr. Max” was added to 10 mL of B–R buffer (pH 2) to the polarographic cell for analysis. The standard addition method (SAM) was then applied to the FA determination when 25 or 50 mm3 of standard FA solution (c FA = 1 × 10−4 mol dm−3) were added as standard additions.

Regarding the fruit juice, there was no pretreatment before measurement. In the first step, the applicability of DPV was tested by addition of a known amount of FA to the juice sample. The electrolyte (9.5 cm3) with the juice sample (0.5 cm3) was taken as blank and 100 mm3 of standard FA solution (c FA = 1 × 10−4 mol dm−3) added as an analyte. After the application of SAM, the recovery of the FA determination was calculated. After that, a volume of 500 mm3 of fruit juice was added into the electrochemical cell with 10 cm3 of B–R buffer (pH 2) and the content of FA determined. In this case, 25 mm3 of standard solution of 1 × 10−4 mol dm−3 FA was used as a standard addition. Utilizing the SAM for quantification, at least two (subsequent) standard additions were made. Each determination was made in five replicates and the respective average values together with appropriate confidence intervals and the relative standard deviations (RSD(5)) calculated.

References

Wang J, Lu J, Hočevar SB, Farias PAM, Ogorevc B (2000) Anal Chem 72:3218

Economou A (2005) Trends Anal Chem 24:334

Hutton EA, Ogorevc B, Hočevar SB, Weldon F, Smyth MR, Wang J (2001) Electrochem Commun 3:707

Kefala G, Economou A, Voulgaropoulos A, SofoniouM (2003) Talanta 61:603

Hutton EA, Elteren TV, Ogorevc B, Smyth RM (2004) Talanta 63:849

Charalambus A, Economou A (2005) Anal Chim Acta 547:53

Banks CE, Kruusma J, Moore RR, Tomčík P, Peters J, Davis J, Komorsky-Lovrić Š, Compton RG (2005) Talanta 65:423

Vytřas K, Švancara I, Metelka R (2002) Electroanalysis 14:1359

Kefala G, Economou A, Sofoniou M (2006) Talanta 68:1013

Królicka A, Pauliukaite´ R, Švancara I, Metelka R, Bobrowski A, Norkus E, Kalcher K, Vytřas K (2002) Electrochem Commun 4:193

Hutton EA, Ogorevc B, Hočevar SB, Smyth MR (2006) Anal Chim Acta 557:57

Wang J, Lu J, Hočevar SB, Ogorevc B (2001) Electroanalysis 13:13

Deýlová D, Vyskočil V, Economou A, Mansfeldová V, Barek J (2014) Int J Electrochem Sci 9:4653

Deýlová D, Vyskočil V, Barek J, Economou A (2012) Talanta 102:68

Guo Z, Feng F, Hou Y, Jaffrezic-Renault N (2004) Talanta 65:1052

Nigović B, Šimunić B, Hočevar SB (2009) Electrochim Acta 54:5678

de Figueiredo-Filho LCS, dos Santos VB, Janegitz BC, Guerreiro TB, Fatibello-Filho O, Faria RC, Marcolino-Junior LH (2010) Electroanalysis 22:1260

Kokkinos C, Economou A, Raptis I, Efstathiou CE, Speliotis T (2007) Electrochem Commun 9:2795

Švancara I, Prior C, Hočevar S, Wang J (2010) Electroanalysis 22:1405

Švancara I, Vytřas K (2006) Chem Listy 100:90

Pauliukaite R, Metelka R, Švancara I, Królicka A, Bobrowski A, Vytřas K, Norkus E, Kalcher K (2002) Anal Bioanal Chem 374:1155

Švancara I, Metelka R, Stibůrková M, Seidlová G, Vytřas K, Pihlar B (2002) Sci Pap Univ Pardubice 8:19

Claux B, Vittori O (2007) Electroanalysis 19:2243

Asbahr D, Figueiredo-Filho LCS, Vicentinia FC, Oliveira GG, Fatibello-Filho O, Banks CE (2013) Sens Actuators, B 188:334

Hutton EA, Ogorevc B, Smyth MR (2004) Electroanalysis 16:1616

Campestrini I, de Braga OC, Vieira IC, Spinelli A (2010) Electrochim Acta 55:4970

Figueiredo-Filho LSC, Azzi DC, Janegitz BC, Fatibello-Filho O (2012) Electroanalysis 24:303

Moreno M, Bermejo E, Chicharro M, Zapardiel A, Arribasa AS (2009) Electroanalysis 21:415

Arribas AS, Bermejo E, Chicharro M, Zapardiel A (2006) Electroanalysis 18:2331

Du D, Ye X, Zhang J, Liu D (2008) Electrochim Acta 53:4478

Tutunaru B, Samide A, Moanţă A, Ionescu C, Tigae C (2015) Int J Electrochem Sci 10:223

Guzsvány V, Kádár M, Papp Z, Bjelica L, Gaál F, Tóth K (2008) Electroanalysis 20:291

Guzsvány V, Kádár M, Gaál F, Bjelica L, Tóth K (2006) Electroanalysis 18:1363

Sá ES, da Silva PS, Jost CL, Spinelli A (2015) Sens Actuators, B 209:423

Kreft GL, de Braga OC, Spinelli A (2012) Electrochim Acta 83:125

Blakley RL (1969) The biochemistry of folic acid and related pteridines. American Elsevier, New York

Tyagi A, Penzkofer A (2010) Chem Phys 367:83

Vávrová J, Pechová A, Wilhelm Z, Kazda A, Friedecký B, Jambor A (2007) In: Racek J, Dastych M (eds) Vitaminy a stopové prvky 2007, Česká společnost klinické biochemie ČLS JEP. Czech Republic, Pardubice, p 46

Vecchia CL, Negri E, Pelucchi C, Franceschi S (2001) Int J Cancer 102:545

Vahteristo L, Lehikoinen K, Ollilainen V, Varo P (1997) Food Chem 59:589

Breithaupt DE (2001) Food Chem 74:521

Patring JDM, Jastrebova JA (2007) J Chromatogr A 1143:72

Nelson BC, Sharpless KE, Sander LC (2006) J Chromatogr A 1135:203

Aurora-Prado MS, Silva CA, Tavares MFM, Altria KD (2004) J Chromatogr A 105:291

Zhao S, Yuan H, Xie C, Xiao D (2006) J Chromatogrr A 1107:290

Caselunghe MB, Lindeberg J (2000) Food Chem 70:523

Hoegger D, Morier P, Vollet C, Heini D, Reymond F, Rossier JS (2007) Anal Bioanal Chem 387:267

Kretzschmar K, Jaenicke W (1971) Z Naturforsch B 26:225

Gurira RC, Montgomery C, Winston R (1992) J Electroanal Chem 333:217

Jacobsen E, Wiesebjornsen M (1978) Anal Chim Acta 96:345

Alvarez JMF, Garcia AC, Ordieres AJM, Blanco PT (1987) J Electroanal Chem 225:241

Prokopová B, Heyrovský M (1996) Bioelectrochem Bioenerg 41:209

Villamil MJF, Ordieres AJM, García AC, Blanco PT (1993) Anal Chim Acta 273:377

Çakir S, Atayman I, Çakir O (1997) Microchim Acta 126:237

Bandžuchová L, Šelešovská R (2011) Acta Chim Slov 58:776

Bandžuchová L, Šelešovská R, Navrátil T, Chýlková J (2011) Electrochim Acta 56:2411

Cinková K, Švorc Ľ, Šatkovská P, Vojs M, Michniak P, Marton M (2015) Anal Lett 49:107

Ensafi AA, Karimi-Maleh H (2010) J Electroanal Chem 640:75

Kalimuthu P, John SA (2009) Biosens Bioelectron 24:3575

Xiao F, Ruan C, Liu L, Yan R, Zhao F, Zeng B (2008) Sens Actuators, B 134:895

Revin SB, John SA (2012) Electrochim Acta 75:35

Mazloum-Ardakani M, Beitollahi H, Amini MK, Mirkhalaf F, Abdollahi-Alibeik M (2010) Sens Actuators 151:243

Beitollahi H, Sheikhshoaie I (2011) Electrochim Acta 56:10259

Yáñez-Sedeño P, Pingarrón JM, Hernández L (2012) Bismuth electrodes. In: De la Guardia M, Garrigues S (eds), Handbook of green analytical chemistry. Wiley, New York, pp 262, 282

Yosypchuk B, Barek J (2009) Crit Rev Anal Chem 39:189

European parliament: Regulation (ec) no 1907/2006 of the European Parliament and of the Council of 18 December 2006 concerning the Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH), establishing a European Chemicals Agency, amending Directive 1999/45/EC and repealing Council Regulation (EEC) No 793/93 and Commission Regulation (EC) No 1488/94 as well as Council Directive 76/769/EEC and Commission Directives 91/155/EEC

Matrka M, Rusek V (1998) Průmyslová toxikologie. University of Pardubice, Pardubice

Acknowledgments

This work was supported by the University of Pardubice (Project No. SGS_2016_002).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Štěpánková, M., Šelešovská, R., Janíková, L. et al. Sensitive electrochemical sensor for the determination of folic acid based on a bismuth-film electrode. Monatsh Chem 148, 423–433 (2017). https://doi.org/10.1007/s00706-016-1849-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00706-016-1849-9