Abstract

This work was focused on the development of an analytical method for determination of arsenic in liquid (aqueous solutions of arsenite) by UV-photochemical generation of its volatile compounds. The study contains the optimization, method characterisation and also a study of the influence of selected compounds on the signal measured. The method involves a combination of flow injection analysis, UV-photochemical generation of volatile compounds of arsenic in flow injection arrangement and atomic absorption spectrometry using an externally heated quartz tube atomizer. The attained absorbance was very low after the optimization. In the next step, the influence of selected compounds on UV-photochemical generation was investigated with the aim to find a suitable reaction modifier that would improve the sensitivity of arsenic determination. Bi(III) was found as the best reaction modifier not only for causing the increase of the signal of arsenic measured but also for its persisting effect. The activation with concentration of 10 mg dm−3 of Bi(III) increases the absorbance of arsenic approximately eleven times compared to signals without activation. Following method characteristics were achieved under the optimum experimental conditions: the limit of detection of 18 µg dm−3, the repeatability of 4.5 % expressed as % RSD at 200 µg dm−3, and linear dynamic range 60–500 µg dm−3 of arsenic.

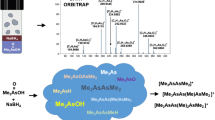

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

UV-photochemical generation of volatile compounds is important and well known technique in atomic spectrometry that can be used to determine metals, metalloids, or organometallic compounds. There are several approaches for conversion of the analyte from the aqueous phase into the gaseous phase. The chemical vapour generation (CVG) using borohydride as a reducing agent in the presence of mineral acid is the most popular way for the volatile compound forming elements. The common mixture is NaBH4/HCl used in CVG [1, 2]. The electrochemical generation is the other method in which the electric current is used for reduction of the analyte to the volatile species in presence of mineral acid medium [3, 4]. At last, the UV-photochemical vapour generation (UV-PVG) has been used [5, 6]. It is an alternative to the two previous methods. Volatile compounds are formed under the UV irradiation in presence of low molecular weight organic acid (formic, acetic, and propionic acid) [7–9] or other chemicals [10–12] in the UV generator. UV-photochemical generation can be combined with different detection such as AAS [13–17], AFS [10, 18–20], ICP-MS [5, 10, 18, 21, 22], ICP-OES [23, 24] or can be used as a derivatization unit for speciation analysis [20, 27–31] connected to the output of chromatographic column.

UV-photochemical generation of volatile compounds with various kinds of detection is one of the possible ways to determine arsenic [32] and also other hydride forming elements [25, 26] in the sample. This derivatization method is based on photolytic decomposition of low molecular weight organic acids (formic, acetic, propionic) to form hydrocarbons, radicals and CO2, according to the Eq. (1) [32].

Hydrocarbon radicals are taken up by trivalent arsenic to form stable substituted compounds as shown in Eq. (2) [32].

For a spontaneous release of the compounds generated from a solution it is necessary that the products formed are sufficiently volatile. Such compounds containing the determined element are formed by photolysis of formic acid, acetic acid, and propionic acid. Volatile arsenic species generated by UV irradiation of aqueous solutions of arsenite in various low molecular weight carboxylic acid media are identified in article [32]. Identification of arsenic alkylation products by UV irradiation in acetic acid solution was reported in detail in paper [33]. The authors concluded that the photoalkylation of arsenic in acetic acid by UV irradiation has not only formed trimethylarsine, but also a whole range of aqueous soluble species. They also presumed similar processes for other low molecular weight carboxylic acid media.

The aim of this work was to develop a method of UV-photochemical generation of volatile compounds (UV-PVG) employable for determination of arsenic with atomic absorption detection in an externally heated quartz tube (QT-AAS) in a flow injection analysis (FIA) mode. The method is based on a reaction of formic acid with arsenic compounds by UV irradiation. We looked for ions or compounds influencing the signal measured, especially in a positive way. The suitable reaction modifier was chosen based on these results. The developed analytical method was successfully used for determination of arsenic (III) compounds in model samples as a basis for the future investigation considering of speciation analysis.

Results and discussion

It was experimentally proved that evaluation from peak heights was more precise than evaluation from peak areas in FIA mode for this study. The peaks were usually high, narrow and nearly symmetrical with very small influence of analytical zone dispersion.

Optimization of working conditions

First, it was necessary to find the optimum conditions for UV-photochemical generation of volatile arsenic compounds. Following key parameters were optimized: the volume of sampling loop, the length of irradiated reaction coil (UV-photoreactor), the flow rate of carrier liquid, the concentration of formic acid in this solution, the flow rate and input/inlet position of gases (Ar, H2), and the temperature of the atomizer. The optimum experimental conditions were found to achieve a sufficient signals as well as the highest possible efficiency of the generation of volatile arsenic compounds. FIA instrumental set-up is introduced in Experimental part of this paper and it is shown in Fig. 6. The list of initial conditions is shown in Table 1. Each of these parameters was optimized to achieve the highest peak in FIA mode.

Influence of carrier gas flow rate connected before sampling valve

Argon was introduced as the carrier gas into the apparatus through PTFE tube and peristaltic pump. Its flow rate was controlled by the choice of suitable diameter of Tygon pumping tube. This kind of carrier gas introduction was used for segmentation of flow and prevention of spread zones of the injected sample. The tube with inner diameter of 0.51 mm and carrier liquid flow rate of 0.33 cm3 min−1 were chosen as optimum values of these parameters for further measurements.

Effect of carrier gas (Ar) total flow rate

It was found experimentally that the presence of carrier gas is necessary for the efficient release of volatile compounds of arsenic from a liquid phase and for their quantitative transport into the atomizer. The effect of the carrier gas total flow rate was studied from 16 to 110 cm3 min−1. It had a significant effect not only on the gas–liquid separation and on the analyte transport but the carrier gas flow rate also influenced the UV-PVG. The baseline was not stable at low values of flow rate of argon. It could have several causes. The explanation could be connected with the different composition of the gaseous phase transported from the gas–liquid separator; mixing the carrier gas with reaction gas and with the oxygen diffused from atmosphere surrounding the atomizer (insufficiently shielded by Ar). The effect of argon flow rate on peak width (approximately 30 s) was not significant, whereas peak height was influenced strongly. The absorbance increased rapidly with decreasing argon flow rate. Figure 1 shows the effect of carrier gas flow rate on the signal of arsenic. The total flow rate of 24 cm3 min−1 Ar was chosen for all the following experiments as the optimum.

Effect of argon total flow rate on the absorbance signal. Concentration of arsenic: 0.4 mg dm−3. Experimental conditions are given in Table 1

Effect of reaction gas (H2) flow rate

The presence of hydrogen radicals is necessary for UV-photochemical generation of volatile compounds of arsenic as well as for their atomization in the quartz tube atomizer. Therefore, it was investigated if added hydrogen into the UV-photoreactor can increase the signals (probably as well as the reaction rate) in FIA arrangement. Attained dependence is shown in Fig. 2. The absorbance first increased with the ascending hydrogen flow rate starting at 10 cm3 min−1, reached the maximum at 30 cm3 min−1, and then slowly decreased for higher flow rates. Reaction of the excess of hydrogen in the atomizer with atmospheric oxygen provided radicals as well as water and changed the atomization conditions. These changes resulted in a decrease of measured peak heights while the width was approximately constant. The introduction of the inert carrier gas instead of the reaction gas at the same flow rate by this channel did not lead to any increase of peaks.

Effect of hydrogen flow rate on absorbance. Concentration of arsenic: 0.4 mg dm−3. Other experimental conditions are given in Table 1

Dependence of the absorbance (peak height) on concentration of formic acid

Aqueous formic acid solution served as carrier liquid in this analytical method. Therefore, concentration of formic acid was the next optimized parameter. It was a key parameter for UV-photochemical generation because it is a source of radicals. The appropriate concentration of formic acid is needed for generation of volatile compounds of arsenic. The samples of arsenite were prepared in the solutions containing the same concentration of formic acid, as was the concentration in carrier liquid. The best signal absorbance was attained for 0.75 mol dm−3. Therefore, this concentration of formic acid was applied as an optimized condition for following experiments (Fig. 3). The optimum working conditions for the determination of arsenic by UV-photochemical generation with AAS detection are listed in Table 1.

Effect of concentration of formic acid (in carrier liquid). Concentration of arsenic: 1 mg dm−3. Other experimental conditions are given in Table 1

Effect of selected compounds

A hollow cathode lamp was replaced by a Superlamp at the beginning of this part of the study with the aim to improve the signal/noise ratio.

It is well known that some compounds can influence the UV-photochemical generation used for determination of arsenic. The effect of fifteen various compounds or ions on the arsenic determination by UV-PVG-AAS was investigated with the intended purpose to find a suitable reaction modifier which could make UV-PVG analytically usable. It was not the aim to do a detailed overview of interferences but just to find such substances and to compare their positive effect and experimental conditions at which they would increase the arsenic absorbance. The concentration of arsenic of 1 mg dm−3 was used for this study in model samples as well as the appropriate concentration of the compounds or ions tested in the range from 10−3 to 102 mg dm−3. Consequently, the signals of model samples enriched by various concentrations of selected compounds were measured.

Following substances were tested: transitions metals (Fe, Ni, Co, and Cu as common interferents for hydride generation), organic compounds (ethanol, 2-mercaptoethanol, triethanolamin, and acetonitrile as possible solvents or additives for HPLC with the intended use in speciation analysis), and other compounds [nitric acid, hydrochloric acid, sulfuric acid, titanium dioxide, l-cysteine, Se(IV), and Bi(III)] selected on the base of facts presented in published articles related to UV-PVG or to hydride generation. For example, 2-mercaptoethanol is used for UV-photochemical generation of mercury cold vapour because it increases the signal measured significantly [27, 34].

The tested compounds can be divided into three groups according to the results attained: compounds with a negative effect (in following text negative interferents), minimum interfering species and compounds with a positive effect on arsenic signal (positive interferents or potential reaction modifiers).

The higher was the concentration of each negative interferent the more intensive was the depression of arsenic signal. Negative interferents group includes: Ni(II) reducing the absorbance of arsenic more than three times from 0.01 mg dm−3, Cu(II) ions which significantly reduced the signal from 0.1 mg dm−3, chloride ions reducing absorbance more than a half from 0.01 mg dm−3, and 2-mercaptoethanol which was the most significant negative interferent and its concentration higher than 0.005 mg dm−3 caused a decrease of absorbance to zero.

The minimum interfering species like nitric acid, Fe(III), ethanol, sulfate ions, titanium dioxide, and l-cysteine had just an insignificant effect on the signal of As(III) in range of 0.01–1 mg dm−3. About one (HNO3, Fe(III), ethanol, l-cysteine) or two (sulfate ions, TiO2) order higher concentration of these substances (compared to the As(III) concentration) in model sample solutions had negative impact on arsenic absorbance which was proportional to its concentration too.

The positive interferents group includes: Co(II) increasing absorbance about 65 % in the concentration range from 0.01 to 0.1 mg dm−3, acetonitrile with a positive effect (about 50 %) in the entire concentration range (from 0.005 to 100 mg dm−3), triethanolamine which had a significant positive influence (about 20 %) also from 0.01 to 0.1 mg dm−3, Se(IV) which interfered positively (about 35 %) in the range from 0.005 to 0.1 mg dm−3, and bismuth ions which increased the absorbance most significantly at 10 mg dm−3. A very strong (up to 100 %) negative influence on arsenic absorbance was observed at concentrations of these substances higher than for above listed concentration ranges with positive effect.

The most interesting results were obtained with Bi(III). The enhancement of arsenic absorbance was about 86 % in the presence of 10 mg dm−3 of Bi(III). This was the best result achieved. For this reason, Bi(III) was chosen as the most suitable reaction modifier for the determination of arsenic using UV-photochemical generation of volatile compounds and AAS. The influence of Bi(III) on arsenic absorbance measured is displayed in Fig. 4 as a very important example of attained dependences. The concentration of Bi(III) is plotted in a logarithmic scale on horizontal axis and the normalized absorbance (with the reference value measured previously for 1 mg dm−3 As(III) without the presence of any studied compound indicated by a horizontal line) on vertical axis in Fig. 4. Similarly as chloride ions or Ni(II), Bi(III) caused peak height decrease more than a half since a concentration of 5–10 µg dm−3. Attained peaks became the same height as without the presence of Bi(III) when increasing its concentration to 1 mg dm−3. The addition of Bi(III) above this concentration lead to increase of arsenic signal. The presence of 100 mg dm−3 of Bi(III) lead to decrease of arsenic signal again.

Effect of Bi(III) concentration on the normalized absorbance (NA) of As. Concentration of arsenic: 1 mg dm−3. Used optimum experimental conditions are listed in Table 1

The following experiments have shown that it is not necessary to add Bi(III) into each sample solution but it is simply enough to flush the apparatus with a solution of 10 mg dm−3 of Bi(III) for a few minutes before the start of the measurements. This modified apparatus was consequently stable throughout the whole day of measurements. The localization and mechanism of acting would be a subject of a future investigation.

Figures of merit

The characterisation of analytical method for As(III) determination by UV-PVG/QT-AAS was performed after all the optimization experiments. First, the calibration in the concentration range from 0 to 1.6 mg dm−3 of As(III) was measured without previous activation by Bi(III) under the optimum working conditions. The established values of following parameters are summarized in Table 2. Limit of detection (LOD) and limit of quantification (LOQ) were calculated as the concentration causing a signal equal to three times (or ten times, respectively) the standard deviation of ten repeated measurements of the As(III) model solution with a concentration of 200 μg dm−3. The repeatability was expressed as the relative standard deviation (% RSD, n = 10) of results for 1.5 mg dm−3 of As(III). The calibration dependence is depicted in Fig. 5. The linear dynamic range (LDR) was relatively wide thanks to the low sensitivity.

Calibration dependences of As(III) without and after activation of the apparatus by Bi(III). Used optimum experimental conditions are listed in Table 1

Second, the calibration with long term modification (after the activation of the apparatus by Bi(III) but without addition of Bi(III) into the sample solution or carrier liquid) of the apparatus was measured again in concentration interval from 0 to 1 mg dm−3 of As(III). For comparison of both calibration dependences please see Fig. 5. The parameters characterizing this method were determined by the same procedure as the previous. An overview of their values is given in Table 2 for easy comparison between the approach without and after the activation. The LOD and LOQ [attained for concentration of 20 μg dm−3 of As(III)] moved to the lower concentration level as well as LDR after the activation. On the other hand, LDR became shorter in this case. From equations of the calibration lines, the signal enhancement factor (calculated as a ratio of both sensitivities) was calculated. Its value is 10.8.

Conclusions

A simple apparatus was constructed for determination of arsenite in model aqueous solutions by flow injection analysis. UV-photochemical vapour generation connected on-line with AAS detection in externally heated quartz tube atomizer was employed in this work. However, a very poor absorbance was attained after the optimization of the experimental conditions, which are usual for UV-PVG of other elements. Therefore, fifteen selected compounds were tested with the expectation to find a suitable reaction modifier with a positive effect for UV-photochemical generation of volatile arsenic compounds.

The most positive influence on arsenic absorbance (increase of 86 %) was observed in presence of 10 mg dm−3 of Bi(III) in a sample. Even more interesting is that Bi(III) became evident a long term modifier of internal surface of the apparatus. The localization and mechanism of this activity would be a subject of future investigation but it is a fact that this effect persisted for all the following measurements of the day after flushing the apparatus by the Bi(III) solution. Thus it is not needed to add Bi(III) into the routine or calibration samples.

The proposed method is distinguished by a detection limit of 18 µg dm−3 of arsenic, by a sensitivity of 1.1 × 10−3 dm3 µg−1 (nearly 11 times higher than without activation), by a repeatability of 4.5 % and by a linear dynamic range of 60–500 µg dm−3 under the optimum conditions and after the activation by bismuth(III).

Relevant data for comparison of method characteristic (combination of UV-PVG with QT-AAS) were not found in available published articles. For partly comparison, limit of detection of 0.09 µg dm−3 (peak height) was reported for determination of arsenic by high-pressure liquid flow injection to high-resolution continuum source hydride generation atomic absorption spectrometry [35]. Just about one order lower LOD was found for arsenical speciation analysis by HPLC-(UV)-HG-AFS [29]. About one and half order lower LOD reached by the same volatile compounds generation technique (UV-PVG) and atomic fluorescence detection [19]. About two orders lower detection limit was achieved for HG-AAS with preconcentration in a cryotrap [17]. It is necessary to mention that AFS is much more sensitive than AAS and cryotrapping can also improve LOD significantly.

On the other hand, no signal was observed for concentration higher than 5 μg dm−3 of 2-mercaptoethanol, an organic additive with the highest negative effect of all the studied compounds.

This work shows that UV-photochemical generation of arsenic volatile species is applicable as well as the other techniques of volatile compounds generation. A comparable sensitivity with the other vapour generation techniques, simplicity of the apparatus and an effortless measurement procedure are the advantages of this approach, which is also environmentally friendly.

Moreover, an applicability of this approach for arsenic speciation seems to be possible in future. It was confirmed experimentally that l-cysteine which is often used for sample preparation does not interfere and that acetonitrile (potential mobile phase component) even increase the signal of arsenic in studied concentration range.

Experimental

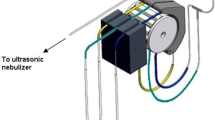

An analytical method for determination of arsenic using its UV-photochemical volatile compound generation was developed in this work. The arsenic volatile compounds were detected by atomic absorption spectrometer Varian SpectraAA-300A (Varian, Australia) after the atomization in a conventional T-shaped quartz tube (QT-AAS) which was externally heated to 950 °C (RMI, CZ). An arsenic hollow cathode lamp (Heraeus, Germany, current of 10 mA, λ = 193.7 nm) and a Superlamp (Photron, current of 18 mA, boosted by 20 mA, λ = 193.7 nm) served as sources of radiation. The used quartz tube atomizer (atomization tube had conventional dimensions) was unique because it had an integrated gas–liquid separator (GLS) with forced outlet at the ending of the inlet arm. The GLS inner volume was approximately 7 cm3. Both these parts were laboratory-made as one piece of quartz. A scheme of the instrumental set-up for UV-PVG/QT-AAS employed in flow injection mode is depicted in Fig. 6.

A scheme of the instrumental set-up for UV-PVG/QT-AAS (FIA). 1 reservoir bottle with solution of HCOOH, 2 peristaltic pump, 3 six-way injection valve, 4 UV-lamp with reaction coil, 5 gas–liquid separator with forced outlet integrated to, 6 externally heated quartz tube atomizer, 7 AAS, 8 waste bottle, 9 gas flow controller

Arsenic volatile compounds were generated in a flow-through UV-photoreactor consisting of a 2.5 m-long Teflon (PTFE) tube (1.0 mm ID, 1.4 mm OD) wrapped around a source of UV-radiation. A low-pressure mercury UV bench lamp (254 nm, 20 W, dimensions 610 × 152 × 108 mm) (purchased from Ushio, Japan) was used as the source of UV-radiation.

Formic acid was pumped to the UV-photochemical reactor using a MasterFlex programmable peristaltic pump with an eight-channel Ismatec head (Cole-Parmer, USA). The sample was injected into the flow of carrier liquid by a six-way injection valve via a 600 mm3 injection loop. Hydrogen was introduced to the apparatus before the UV-photochemical reactor and its flow rate was controlled by a flowmeter (Cole-Parmer, USA, model 32907-67, range 0–1000 cm3 min−1). A stream of argon was introduced to the apparatus into two different places (before the six-way injection valve and into the gas–liquid separator). A flowmeter (Cole-Parmer, USA, model N112-02) was used for regulation of total argon flow rate. Tygon and Teflon tubes of various inner diameters and lengths were used as a connection material in the apparatus.

Reagents and samples

Deionized water prepared in a MilliQplus system (18.2 MΩ cm; Millipore, USA) was used for dilution of all the solutions. The stock solution of As(III) was prepared by dissolving the appropriate amount of arsenic trioxide (>99.5 %, Sigma–Aldrich, USA) in slightly alkaline (solid KOH—89.0 %, Lach-Ner, CZ) solution. Formic acid (HCOOH, ≥98 %, Sigma–Aldrich, USA) was used as UV-photochemical reaction agent and its solutions were prepared fresh daily. Argon (99.998 %; Linde Gas, CZ) was used as the inert carrier gas during all the experiments. Hydrogen (99.998 %; Linde Gas, CZ) was used as the reaction gas during all the experiments.

The solutions of the studied compounds or ions were prepared from standard solution of Fe(III) (1002 ± 2 mg dm−3, Merck, Germany), Co(II) (1002 ± 2 mg dm−3, Merck, Germany), Ni(II) (1000 ± 5 mg dm−3, Analytika, CZ), Cu(II) (1000 ± 5 mg dm−3, Analytika, CZ), Se(IV) (1000 ± 2 mg dm−3, Analytika, CZ), Bi(III) (1001 ± 5 mg dm−3, Merck, Germany), SO4 2− (1000 ± 2 mg dm−3, Merck, Germany) and Cl− (1000 ± 2 mg dm−3, Merck, Germany), or diluted from stock solutions of HNO3 (≥65 %, Merck, Germany), ethanol (≥99.5 %, Merck, Germany), 2-mercaptoethanol (≥99.0 %, Sigma-Aldrich, USA), triethanolamine (≥98 %, Sigma-Aldrich, USA), acetonitrile (≥99.8 %, Sigma-Aldrich, USA) or by dissolving of solid l-cysteine hydrochloride monohydrate (≥98 %, Sigma-Aldrich, USA), TiO2 (≥99.5 %, size of nanoparticles ~21 nm, Aldrich, USA).

Determination of As(III) by UV-PVG/QT-AAS

Samples prepared in formic acid medium were injected by an injection valve via a 600 mm3 injection loop into the flow of carrier liquid (a solution of formic acid). Sample zone together with carrier liquid was pumped into the UV-photoreactor where arsenic volatile compounds had been formed under the UV irradiation. The reaction mixture with generated volatile products was transported into a gas–liquid separator. The liquid phase was pumped into the waste while the gaseous phase, which was flushed out by a stream of argon, entered the atomizer.

References

Marschner K, Musil S, Dědina J (2015) Spectrochim Acta 109:16

Rybínová M, Červený V, Hraníček J, Rychlovský P (2015) Microchem J 124:584

Sturgeon RE, Mester Z (2002) Appl Spectrosc 56:202

Červený V, Rychlovský P, Hraníček J, Šíma J (2009) Chem List 103:652

Quadros DPC, Borges DLG (2014) Microchem J 116:244

Silva CS, Oreste EQ, Nunes AM, Vieira MA, Ribeiro AS (2012) J Anal At Spectrom 27:689

Guo X, Sturgeon RE, Mester Z, Gardner GJ (2003) Anal Chem 75:2092

Guo X, Sturgeon RE, Mester Z, Gardner GJ (2003) Appl Organomet Chem 17:575

Guo X, Sturgeon RE, Mester Z, Gardner GJ (2003) Environ Sci Technol 37:5645

Zheng C, Wu L, Ma Q, Lv Y, Hou X (2008) J Anal At Spectrom 23:514

Hou X, Ai X, Jiang X, Deng P, Zheng C, Lv Y (2012) Analyst 137:686

Han C, Zheng C, Wang J, Cheng G, Lv Y, Hou X (2007) Anal Bioanal Chem 388:825

Zheng C, Sturgeon RE, Hou X (2009) J Anal At Spectrom 24:1452

Figueroa R, García M, Lavilla I, Bendicho C (2005) J Spectrochim Acta 60:1556

Nóbrega JA, Sturgeon RE, Grinberg P, Gardner GJ, Brophy CS, Garcia EE (2011) J Anal At Spectrom 26:2519

Matoušek T, Hernández-Zavala A, Svoboda M, Langrová L, Adair BM, Drobná Z, Thomas DJ, Stýblo M, Dědina J (2008) Spectrochim Acta 63:396

Musil S, Matoušek T (2008) Spectrochim Acta 63:685

Li H, Luo Y, Li Z, Yang L, Wang Q (2012) Anal Chem 84:2974

Zheng C, Ma Q, Wu L, Hou X, Sturgeon RE (2010) Microchem J 95:32

Cai Y (2000) Trend Anal Chem 19:62

Sun YC, Chang YC, Su CK (2006) Anal Chem 78:2640

Shih TT, Hsu IH, Wu JF, Lin CH, Sun YC (2013) J Chromatogr A 1304:101

Zheng C, Sturgeon RE, Brophy CS, He S, Hou X (2010) Anal Chem 82:2996

Santos EJ, Herrmann AB, Santos AB, Baika LM, Sato CS, Tormen L, Sturgeon RE, Curtius AJ (2010) J Anal At Spectrom 25:1627

Guo X, Sturgeon RE, Mester Z, Gardner GJ (2004) Anal Chem 76:2401

Sturgeon RE, Willie SN, Mester Z (2006) J Anal At Spectrom 21:263

Yin Y, Qiu J, Yang L, Wang Q (2007) Anal Bioanal Chem 388:831

Quadros DPC, Campanella B, Onor M, Bramati E, Borges DLG, D´Ulivo A (2014) Spectrochim Acta Part B 101:312

Šlejkovec Z, Kápolna E, Ipolyi I, Elteren JT (2006) Chemosphere 63:1098

Francesconi KA, Kuehnelt D (2004) Analyst 129:373

Schaeffer R, Francesconi KA, Kienzl N, Soeroes C, Fodor P, Váradi L, Raml R, Goessler W, Kuehnelt D (2006) Talanta 69:856

Guo X, Sturgeon RE, Mester Z, Gardner GJ (2005) J Anal At Spectrom 20:702

McSheehy S, Guo X, Sturgeon RE, Mester Z (2005) J Anal At Spectrom 20:709

Yin Y, Liu J, He B, Shi J, Jiang G (2009) Microchim Acta 167:289

Hesse S, Ristau T, Einax JW (2015) Microchem J 123:42

Acknowledgments

The authors acknowledge for financial support from the Charles University in Prague: GAUK152214, Project SVV260317 and Project UNCE204025/2012.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Linhart, O., Smolejová, J., Červený, V. et al. Determination of As by UV-photochemical generation of its volatile species with AAS detection. Monatsh Chem 147, 1447–1454 (2016). https://doi.org/10.1007/s00706-016-1808-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00706-016-1808-5