Abstract

Silica-bonded N-propylpiperazine sodium N-propionate is employed as a recyclable heterogeneous solid base catalyst for the synthesis of benzopyrano[2,3-d]pyrimidines through one-pot condensation reaction of salicylaldehydes, malononitrile, and secondary amines at room temperature under solvent-free conditions. The catalyst could be recycled several times without appreciable loss in catalytic activity.

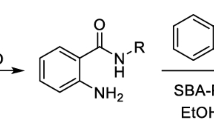

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Benzopyranopyrimidines have provided an important pharmacophore-synthesized research platform for chemists. This is because of their specific characteristics which consist of anti-inflammatory, analgesic, in vivo antitumor, in vitro anti-aggregating activities as well as cytotoxic activity against cancer cell lines, and causing significant perturbation in cell cycle kinetics [1–5]. In this respect, several pyrimidine derivatives such as compounds 1–3 showed good in vitro antiplatelet activity, being able to inhibit arachidonic acid (AA), ADP, and collagen-induced aggregation, together with a good in vivo antithrombotic effect (Fig. 1) [3, 6–9]. Some of these compounds were also found to be interesting as analgesic and/or antiphlogistic agents [6]. The basic function in benzopyranopyrimidine scaffold was also investigated and it was concluded that it has a pivotal role in the expression of antiphlogistic/analgesic activities without adverse gastrolesive effects [10].

In this respect, lots of methods have been developed for the preparation of benzopyranopyrimidine derivatives [1–5, 11–13] while none of them contain recyclable and reusable catalysts in their protocols. Bazgir and co-workers for the first time have reported the synthesis of benzopyrano[2,3-d]pyrimidines via pseudo-four-component reaction of salicylic aldehyde, malononitrile, and amine in the presence of LiClO4 in EtOH at room temperature for 24 h [14]. Very recently, this multi-component protocol has been developed by ionic liquid [Bmim]BF4 [15], Brønsted acidic ionic liquids [16], ZrOCl2∙8H2O [17], silica nanoparticles immobilized benzoylthiourea ferrous complex [18], manganese(III) salen complex immobilized on Fe3O4 magnetic nanoparticles [19], and choline chloride-based deep eutectic solvent [20].

Several types of propyl amine functionalized silica, hydrotalcites, and basic zeolites (microporous and mesoporous) have been synthesized and applied as an alternative to traditional amines in base catalyzing chemical transformations [21–30].

Recently, we prepared some silica immobilized amines such as, silica-bonded N-propylpiperazine sodium N-propionate (SBPPSP) [31], silica-bonded N-propylpiperazine (SBPP) [32], silica-bonded N-propylmorpholine (SBPM) [33], and 3-silicapropylamine (3-SPA) [34], and investigated their applications as heterogeneous solid bases in organic reactions [35] or using as ligand for stabilizing Pd nanoparticles [36–38] (Fig. 2).

In continuation our research on the design and application silica functionalized solid acids and bases as heterogeneous catalysts in organic transformations [26, 27, 31–40], we describe the application of silica-bonded N-propylpiperazine sodium N-propionate (SBPPSP) in the synthesis of benzopyrano[2,3-d]pyrimidine derivatives via pseudo four-component condensation of salicylaldehydes, malononitrile, and secondary amine at room temperature and solvent-free conditions. To the best of our knowledge, there is no other report about the synthesis of benzopyranopyrimidines via pseudo-four-component condensation reaction of salicylic aldehyde, malononitrile, and secondary amines using solid bases as catalysts.

Results and discussion

The catalytic activity of silica immobilized bases (SBPPSP, SBPP, SBPM, and 3-SPA) was investigated as a heterogeneous solid base catalysts in one-pot synthesis of benzopyranopyrimidines through pseudo-four-component reaction of salicylaldehyde, malononitrile, secondary amine and the results are summarized in Table 1.

For this purpose, the reaction between salicylaldehyde (2 mmol), malononitrile (1 mmol), and morpholine (1 mmol) was selected as a model reaction at room temperature in order to establish the feasibility of the strategy and optimize the reaction conditions. As shown in Table 1, the catalytic effect of solid amines SBPPSP, SBPP, SBPM, and 3-SPA was studied as a heterogeneous base catalysts. All of these silica immobilized propylamines were accomplished this pseudo-four-component condensation reaction at room temperature under solvent-free conditions. The model reaction was converted into corresponding product in a higher yield using solid base SBPPSP as catalyst (Table 1, entry 3). The lower amounts of SBPPSP (0.03 g) were converted the model reaction in longer reaction time and lower yield (Table 1, entry 5) and using higher amounts of the catalyst (0.07 g) did not improve the result to an appreciable extent (Table 1, entry 6). The model reaction was treated in solvents such as ethanol, water, toluene, and acetonitrile in the presence of 0.05 g SBPPSP as catalyst at room temperature (Table 1, entries 7–10), but the best result was under solvent-free conditions. Also, the model reaction was treated with commercially available bases such as triethylamine and morpholine the corresponding product was obtained in the presence of 0.30 mmol of these bases after 12 h in 58–60 % yields (Table 1, entries 11 and 12). The optimum conditions was α-hydroxybenzaldehyde (2 mmol), malononitrile (1 mmol), secondary amine (1 mmol), and SBPPSP (0.05 g) at room temperature under solvent-free conditions.

The reaction can tolerate α-hydroxybenzaldehydes and some of its derivatives carrying both electron-donating such as MeO and halogen such as Br and the results were reasonable (Table 2). Aliphatic amines such as diethylamine and dibutylamine did not react while the best results were achieved with cyclic secondary amines such as morpholine, piperidine, and pyrrolidine.

Proposed mechanism for the synthesis of benzopyranopyrimidine derivative 6 was described in Scheme 1 [18, 35]. The process represents a typical cascade reaction in which the catalyst facilitates the Knoevenagel condensation reaction through activate malononitrile for nucleophilic attack to the salicylic aldehyde. The catalyst can activate O–H groups so that the Pinner reaction occurs and intermediate II was formed. Next, the cyano group of intermediate II can be attacked by the amine to produce intermediate III. Finally, intermediate III reacts with another molecule of salicylic aldehyde followed by proton transfer to afford the final benzopyranopyrimidine 6. Also, catalyst could be able to facility of the capture and losing the proton process.

The possibility of recycling the catalyst SBPPSP was examined using by the reaction of salicylaldehyde, malononitrile, and morpholine under the optimized conditions. Upon completion, 10 cm3 ethanol was added and filtered. The remaining was washed with warm ethanol (2 × 5 cm3). The separated catalyst was dried and reused as such for subsequent experiments under similar reaction conditions. The results showed that the catalyst could be effectively used for at least four consecutive cycles without much appreciable loss in its catalytic activity (Fig. 3).

To show the advantages of these solid bases (3-SPA, SBPP, SBPPSP, and SBPM) as a catalyst in this pseudo-four-component reaction, our results and reaction conditions for synthesis of 2-(4-morpholino-5H-chromeno[2,3-d]pyrimidin-2-yl)phenol (6a) were compared with previously reported data as shown in Table 3. The results show that our method is quite comparable with the former methods in yields and reaction times. Moreover, the amounts of these solid bases are low and they could be recycled and reused again for several times while most of the former methods using catalyst which could not recyclable.

In conclusion, this work shows that silica-bonded solid bases which can be prepared by simple operation from commercially available and relative cheap starting materials efficiently catalyzed the synthesis of benzopyranopyrimidines. It could also be recovered and reused for several times without noticeable loss of reactivity.

Experimental

Chemicals were purchased from Merck and Aldrich chemical companies. For recorded 1H NMR spectra, we were using Bruker Ultrashield (400 MHz) in pure deuterated DMSO-d 6 solvent with tetramethylsilane (TMS) as internal standard. Melting points were determined in open capillary tubes in a Barnstead Electrothermal 9100 BZ circulating oil melting point apparatus. The reaction monitoring was accomplished by TLC on silica gel Poly Gram SILG/UV254 plates. All the products are known compounds and were characterized by comparison of their IR, 1H NMR, and 13C NMR spectroscopic data and their melting points with reported values [13–20]. Solid bases such as silica-bonded N-propylpiperazine sodium N-propionate (SBNPPSP) [31], silica-bonded N-propylpiperazine (SBNPP) [32], silica-bonded N-propylmorpholine (SBNPM) [33], and 3-silicapropylamine (3-SPA) [34] were prepared according to our previously reported procedure.

General procedure for the synthesis of benzopyranopyrimidines

A mixture of 2-hydroxybenzaldehyde derivative (2 mmol), malononitrile (1 mmol), secondary aliphatic amine (1 mmol), 0.05 g SBPPSP (4.3 mol %) [31], under solvent-free conditions was stirred at room temperature for 6 h (the progress of the reaction was monitored by TLC, by taking a small part of reaction mixture and solving in ethyl acetate). After completion, 10 cm3 warm ethanol was added and filtered. The remaining was washed with warm ethanol (2 × 5 cm3) in order to separate catalyst. After cooling the organic phase, the crude was precipitated and filtered to obtained products. For further purification the crude was recrystallized from ethanol (95 %). The recovered catalyst was dried and reused for subsequent runs.

3-Hydroxy-2-(8-hydroxy-4-morpholino-5H-chromeno[2,3-d]pyrimidin-2-yl)phenol (6j, C21H19N3O5)

White solid; m.p.: 172-174 °C; IR (KBr): = 3450, 3060, 2965, 2890, 2830, 1601, 1508, 1430, 1260, 1103 cm−1; 1H NMR (400 MHz, DMSO-d 6 ): δ = 3.55 (t, 4H, J = 3.8 Hz, N(CH2)2), 3.81 (t, 4H, J = 3.8 Hz, O(CH2)2), 4.00 (s, 2H, CH2), 6.71-6.76 (m, 2H, Ar), 6.81 (d, 1H, J = 6.3 Hz, Ar), 6.89–6.95 (m, 2H, Ar), 7.76 (d, 1H, J = 6.3 Hz, Ar), 8.56 (brs, 1H, OH), 9.50 (brs, 1H, OH), 13.09 (brs, 1H, OH) ppm; 13C NMR (100 MHz, DMSO-d 6 ): δ = 24.6, 47.9, 65.7, 97.1, 114.9, 117.7, 117.8, 118.2, 118.3, 118.5, 120.6, 123.9, 138.4, 145.1, 145.8, 148.6, 160.7, 163.2, 163.9 ppm.

References

O’Callagan CN (1980) J Chem Soc Perkin Trans 1:1335

Bruno O, Schenone S, Ranise A, Bondavalli F, Barocelli E, Ballabeni V, Chiavarini M, Bertoni S (2001) Bioorg Med Chem 9:629

Bruno O, Brullo C, Ranise A, Schenone S, Bondavalli F, Barocelli E, Ballabeni V, Chiavarini M, Tognolini M, Impicciatore M (2001) Bioorg Med Chem Lett 11:1397

Bruno O, Brullo C, Schenone S, Ranise A, Bondavalli F, Barocelli E, Magnanini F, Ballabeni V (2002) Farmaco 57:753

Bruno O, Brullo C, Schenone S, Bondavalli F, Ranise A, Tognolini M, Ballabeni V, Barocelli E (2004) Bioorg Med Chem 12:553

Bruno O, Schenone S, Ranise A, Barocelli E, Chiavarini M, Ballabeni V, Bretoni S (2000) Arzneim Forsch 50:140

Ballabeni V, Calcina F, Tognolini M, Bruno O, Manotti C, Barocelli E (2004) Life Sci 74:1851

Brullo C, Rocca M, Fossa P, Cichero E, Barocelli E, Ballabeni V, Flammini L, Giorgio C, Saccani F, Domenichini G, Bruno O (2012) Bioorg Med Chem Lett 22:1125

Chinnakali K, Sudha D, Jayagobi M, Raghunathan R, Fun HK (2009) Acta Crystallogr E65:o2907

Bruno O, Brullo C, Bondavalli F, Ranise A, Schenone S, Tognolini M, Ballabeni V, Barocelli E (2007) Med Chem 3:127

Bruno O, Brullo C, Schenone S, Bondavalli F, Ranise A, Tognolini M, Impicciatore M, Ballabeni V, Barocelli E (2006) Bioorg Med Chem 14:121

Borisov AV, Dzhavakhishvili SG, Zhuravel IO, Kovalenko SM, Nikitchenko VM (2007) J Comb Chem 9:5

Zonouzi A, Biniaz M, Mirzazadeh R, Talebi M, Ng SW (2010) Heterocycles 81:1271

Ghahremanzadeh R, Amanpour T, Bazgir A (2010) Tetrahedron Lett 51:4202

Gupta AK, Kumari K, Singh N, Raghuvanshi DS, Singh KN (2012) Tetrahedron Lett 53:650

Shaterian HR, Aghakhanizadeh M (2013) Res Chem Intermed 39:3877

Tavakoli HR, Moosavi SM, Bazgir A (2013) J Korean Chem Soc 57:260

Amirnejat S, Movahedi F, Masrouri H, Mohadesi M, Kassaee MZ (2013) J Mol Catal A: Chem 378:135

Sadeghzadeh SM, Daneshfar F, Malekzadeh M (2014) Chin J Chem 32:349

Azizi N, Mariami M, Edrisi M (2014) Dyes Pigm 100:215

Weitkamp J, Hunger M, Rymsa U (2001) Micropor Mesopor Mater 48:255

Zapf A, Beller M (2002) Top Catal 19:101

Kelly GJ, King F, Kett M (2002) Green Chem 4:392

King F, Kelly GJ (2002) Catal Today 73:75

Poliakoff M, Fitzpatrick JM, Farren TR, Anastas PT (2002) Science 297:807

Niknam K, Habibabad MS, Deris A, Aeinjamshid N (2013) Monatsh Chem 144:987

Niknam K, Abolpour P (2015) Monatsh Chem 146:683

Niknam K, Rashidian R, Jamali A (2013) Scientia Iran C 20:1863

Debecker DP, Gaigneaux EM, Busca G (2009) Chem Eur J 15:3920

Tanabe K, Holderich WF (1999) Appl Catal A 181:399

Niknam K, Jamali A (2012) Chin J Catal 33:1840

Niknam K, Deris A, Naeimi F, Majleci F (2011) Tetrahedron Lett 52:4642

Niknam K, Gharavi A, Hormozi-Nezhad MR, Panahi F, Sharbati MT (2011) Synthesis (10):1609

Niknam K, Saberi D (2009) Tetrahedron Lett 50:5210

Niknam K, Borazjani N, Rashidian R, Jamali A (2013) Chin J Catal 34:2245

Niknam K, Habibabad MS, Deris A, Panahi F, Hormozinejad MR (2013) J Iran Chem Soc 10:527

Niknam K, Deris A, Panahi F (2013) Chin J Catal 34:718

Niknam K, Deris A, Panahi F, Hormozinejad MR (2013) J Iran Chem Soc 10:1291

Niknam K, Mojikhalifeh S (2014) Mol Divers 18:111

Makvandi M, Abiar Dil F, Malekzadeh A, Baghernejad M, Niknam K (2013) Iran J Catal 3:221

Acknowledgments

We are thankful to the Persian Gulf University Research Council for the partial support of this work. Also, we are thankful to the School of Chemistry, Manchester University for running NMRs and Dr. Paul Mears for helpful comments.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Niknam, K., Borazjani, N. Synthesis of benzopyrano[2,3-d]pyrimidines using silica-bonded N-propylpiperazine sodium N-propionate as heterogeneous solid base catalyst under solvent-free conditions. Monatsh Chem 147, 1129–1135 (2016). https://doi.org/10.1007/s00706-015-1552-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00706-015-1552-2