Abstract

A new, convenient, and green procedure for the synthesis of naphthopyranopyrimidine-diones is described using a one-pot multi-component reaction of β-naphthol, 1,3-dimethylbarbituric acid, and various aryl aldehydes in the presence of ZnO nanoparticles, an effective and recyclable heterogeneous catalyst, under solvent-free conditions. This method provides excellent advantages, such as waste-free, simple work-up procedure, and excellent yield with high selectivity. The stability of the catalyst was investigated by determining its activity after recycling for six times without significant loss of its catalytic activity.

Graphical abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Nanocrystalline metal oxides are considered as efficient catalysts in many organic reactions due to their large surface-to-volume ratio, which provides a greater number of active sites per unit area in comparison with their heterogeneous counter sites [1, 2]. One of the extensively used materials for many chemical applications, such as gas sensors [3], photoactivity, flame-retardancy [4], solar cells [5], semiconductors [6], miniaturized lasers, light sources, piezoelectric elements for self-powered nano systems, transparent electrodes [7–9], and cosmetic and sunscreen to protect against UV-induced skin damage [10, 11] is nanocrystalline zinc oxide. During the last decade, ZnO nanoparticles (NPs) were used as an active catalyst in the synthesis of β-phosphonomalonates [12], benzimidazoles [13], as well as Mannich reactions [14].

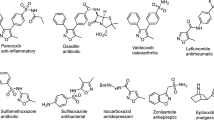

In recent years, design and synthesis of pharmacologically active molecules is one of the principal challenges in medicinal chemistry. So, numerous efforts have been directed towards the development of new and green methods for the synthesis of heterocyclic compounds because of their potential importance in the pharmaceutical and agricultural field. Among others, naphthopyranopyrimidine and its derivatives have attracted interest due to the fact that structural motifs of these compounds are very useful in medicinal and biological chemistry [15, 16]. Also these compounds exhibit promising physiological [17], anticonvulsant behavior [18], hypotensive effect [19], analgesic [20], fungicidal [21, 22], antibacterial [23–26], antitumor [27, 28], hypolipidemic [29], molluscicidal [30], and antifungal activities [31–33]. Lately, the biological activity of these molecules for the treatment of sleep, anxiety, and addiction disorders has been reported [34].

Recently, multi-component reactions (MCRs) have attracted much attention due to their wide domain of applications in pharmaceutical chemistry, synthetic and practical efficiency, reduction of isolation and purification steps, minimization of costs, energy, time, and waste production [35–37]. Multi-component reactions are also one-pot reactions in which three or more substrates together react in a single vessel to form the desired product [38].

Besides, solvent-free reactions lead to environmentally benign procedures that save resources and energy. “Green chemistry” suggests these kinds of reactions due to great attention in economical and synthesis point of view. In addition, solvent-free reactions possess some benefits over traditional reactions in organic solvents, for instance they not only reduce the burden of organic solvent disposal, but also enhance the rate of many organic reactions.

The synthesis of 8,10-dimethyl-12-aryl-12H-naphto[1′,2′:5,6]pyrano [2,3-d]pyrimidine-9,11-diones and its derivatives via previous methods has been reported so far using formic acid [39], indium(III) chloride [40], and iodine catalysts [41]. The majority of these methods have low yields, consumption of huge amount of catalyst or long reaction times. As well toxicity and non-recoverability of the catalyst are drawbacks of these methods. Accordingly, for solving these problems there was a need to develop flexible and green protocol for the synthesis of these compounds.

To the best of our knowledge, this is the first report on the synthesis of 8,10-dimethyl-12-aryl-9H-naphto[1′,2′:5,6]pyrano[2,3-d]pyrimidine-9,11-dione derivatives 4 (Scheme 1) in the presence of ZnO NPs as catalyst under solvent-free conditions via three component reaction. The products can be simply separated from the catalyst by filtration, and in particular, the catalyst can be recycled for several times without noticeable decrease of the catalyst activity.

Considering the above factors, we report a one-pot synthesis of 4a–4k in high to excellent yields using mixture of an aromatic aldehyde 1 and β-naphthol (2) with 1,3-dimethylbarbituric acid (3) by ZnO NPs under solvent-free condition (Scheme 1).

Results and discussion

In the beginning treatment of 4-nitrobenzaldehyde (1), (2), and (3) was chosen as the standard reaction to test various catalysts to yield 4b. Accordingly, the catalytic behaviors of some catalysts are compared in Table 1.

Initially, we found that in absence of any catalyst the reaction could not be achieved at all (Table 1, entry 1). These results in Table 1 clearly indicate that among the various catalysts, such as FeCl3, CH3COOH, HCl, CuI, and AgBr the yields of reaction are moderate. The best yield was observed when the reaction was carried out with ZnO (Table 1, entry 8). Notably, ZnO NPs (Table 1, entry 9) is an advantageous catalyst characterized with high reaction rate and yield.

Expectedly, the yield of reaction is influenced by different factors, such as the nature of aldehydes, solvent system, amount of catalyst, and temperature. A set of experiments in the presence of different amounts of ZnO NPs was performed to derive the optimal reaction conditions. As shown in Table 1, entries 9–12, the yields of product were improved when the amount of ZnO NPs was increased from 1 to 3 mol% (Table 1, entries 9 and 10). Also when mole percent was further increased to 5 mol% (Table 1, entry 11) the yield was stable and no evident influence was observed on this reaction. Thus, 3 mol% was chosen for future experiments.

Scanning electron microscopy (SEM) was used to characterize morphology of the nanocatalyst and its particle diameter. The SEM image (Fig. 1) shows ZnO NPs as white particles with diameters in the range of 10–15 nm. In addition, the size and morphology of zinc oxide nanoparticles were analyzed by transmission electron microscopy (TEM) (Fig. 2). The results show that the catalyst contains spherical particles with a crystallite size between 10 and 15 nm.

Moreover, the crystalline structure of ZnO NPs was verified by its X-ray diffraction pattern (XRD). The peaks in Fig. 3b show a pure hexagonal phase, and by means of the Debye–Scherrer formula (d = Kλ/β cosθ) where K is the dimensionless shape factor, which typically has a value of about 0.9, λ is the X-ray wavelength (1.5406 Å for Cu Kα), β is the full-width at half maximum or half-width in radian, and θ is the Bragg angle. The diameter (d) of crystalline size of ZnO NPs was thus computed to be 10 nm. The stoichiometry of the sample and its chemical purity was checked by EDAX studies that are shown in Fig. 3 revealing that zinc and oxygen are the only elementary components of ZnO NPs.

To find the optimum solvent, the reaction was investigated under solvent-free conditions and using water, THF, EtOH, AcOH, ethylene glycol, DMF, and acetonitrile as solvents. The outcomes of this screening are presented in Table 2. The desired product was not formed in water and CH3CN. In the case of ethanol and AcOH only low yield was obtained. When ethylene glycol, THF, and DMF were selected, the product 4b was obtained in relatively good yield, whereas under solvent-free conditions the product 4b was achieved with the best yield and the lowest reaction time.

Keeping these results in mind, this reaction was carried out under solvent-free conditions at temperatures between 50 and 120 °C to choosing the best reaction temperature. The results are summarized in Table 3. Thus, the reaction did not occur at temperatures less than 100 °C. As shown in Table 3 the best yield of 4b was obtained at 110 °C (Table 3, entries 2 and 3).

With optimized conditions in hand we explored scope and limitations of the method. Thus, the reaction was carried out with a wide diversity of aromatic aldehydes (either electron-donating or electron-withdrawing group) for providing 4a–4k. In all experiments, higher yields were obtained with electron-withdrawing groups. The results are summarized in Table 4.

A proposed reaction mechanism is demonstrated in Scheme 2. This mechanism consists of reaction sequences of addition, condensation, cyclization, and dehydration. The catalyst ZnO NPs interacts as the Lewis acid with the carbonyl group to improve cyclization. At first condensation between 1 and 2 provides intermediate 6. This is by a Michael addition with 3 gives intermediate 8. Then cyclization of 8 gives 9 and subsequent dehydration resulted in the desired product 4.

Then the same reaction using the recovered catalyst was done six times consequently to check the reusability of catalyst. It was found that the yield up to six times use did not substantially decrease the activity of the catalyst (Fig. 4).

Conclusion

In conclusion, the main aim of our research was based on a method for the synthesis of new 8,10-dimethyl-12-aryl-9H-naphto[1′,2′:5,6] pyrano[2,3-d]pyrimidine-9,11-dione derivatives in the presence of catalytic ZnO NPs under solvent-free conditions which provided in addition to several known compounds also a novel one of perhaps biological activity. The present method has many advantages, such as short reaction times, easy workup and excellent yields. High selectivity, mild reaction conditions, and a waste-free procedure are also benefits of this method. Especially ZnO nanoparticles are a green, recyclable heterogeneous and non-toxic catalyst that could be used for this purpose in the future and might be applied to obtain analogous targets.

Experimental

Chemicals of commercial reagent grade and without further purification were obtained from Sigma-Aldrich and Merck. All of melting points were determined in capillary tubes on Boetius melting point microscope. 13C NMR and 1H NMR spectra were measured on Bruker 400 MHz spectrometer with CDCl3 as solvent using TMS as internal standard, the chemical shift magnitudes are in δ. FT-IR spectrum were recorded on a Magna-IR, spectrometer 550 Nicolet in KBr pellets in the range of 400–4,000 cm−1. The elemental analyses (C, H, N) were obtained by means of a Carlo ERBA Model EA 1108 analyzer; the results were in good agreement with the calculated values. Scanning electron microscopy (SEM) images were obtained on a Philips EM208 instrument. The TEM image was obtained on Philips EM208 transmission electron microscope with an accelerating voltage of 100 kV. The energy-dispersive X-ray spectroscopy (EDAX) measurements were performed on the PV9100 instrument. Powder X-ray diffraction (XRD) was performed on a Philips diffractometer of X’pert Company. The ZnO NPs were prepared according to Ref. [42].

General procedure for the synthesis of 8,10-dimethyl-12-aryl-9H-naphto[1′,2′:5,6]pyrano[2,3-d]pyrimidine-9,11-dione derivatives

A mixture of 1.1 mmol aromatic aldehyde, 0.144 g 2 (1 mmol), 0.156 g 3 (1 mmol), and 0.01 g ZnO NPs (10 mol%) in a round bottom flask was heated in an oil bath at 110 °C for 20–35 min. During the reflux the reaction was monitored by TLC (eluent: n-hexane: ethyl acetate, 1:1). After completion of the reaction the mixture was cooled to room temperature, then the reaction mixture was dissolved in dichloromethane and stirred for 5 min. The suspended solution was filtered and then heterogeneous nanocatalyst was recovered. Then solvent was evaporated and the solid was recrystallized from methanol to afford the pure product 4.

Recycling and reusing of the catalyst

After completion of the reaction, the CH2Cl2-insoluble catalyst could be recycled by an easy filtration. The recovered catalyst from the experiment was washed two to three times with water and acetone (3 × 5 cm3) and dried at 60 °C for 24 h.

12-(2-Methoxyphenyl)-8,12-dihydro-8,10-dimethyl-9H-naphtho[1′,2′:5,6]pyrano[2,3-d]pyrimidine-9,11(10H)-dione (4 k, C24H20N2O4)

White solid; m.p.: 295–297 °C; IR (KBr): \(\bar{\nu}\) = 3,058, 2,952, 1,710, 1,652, 1,596, 1,482 cm−1; 1H NMR (400 MHz, CDCl3): δ = 8.03 (d, J = 8.4 Hz, 2H), 7.78–7.74 (m, 2H), 7.48–7.36 (m, 2H), 7.29–7.10 (m, 4H), 5.93 (s, 1H), 3.87 (s, 3H), 3.64 (s, 3H), 3.33 (s, 3H) ppm; 13C NMR (100 MHz, CDCl3): δ = 28.1, 29.0, 35.1, 57.50, 90.3, 115.5, 116.1, 123.2, 123.7, 125.4, 127.6, 128.4, 128.7, 129.0, 130.1, 130.3, 131.5, 143.2, 146.4, 147.0, 150.2, 150.8, 152.3, 161.3 ppm; MS (EI): m/z = 400.

References

Bing Z, Scott H, Raja R, Somorjai GA (eds) (2007) Nanotechnology in Catalysis. Springer, New York

Kassaee MZ, Mohammadi R, Masrouri H, Movahedi F (2011) Chin Chem Lett 22:1203

Zhang Q, Xie C, Zhang S, Wang A, Zhu B, Wang L, Yang Z (2005) Sens Actuators B 110:370

Fallah MH, Fallah SA, Zanjanchi MA (2011) Chin J Org Chem 29:1239

Matsubara K, Fons P, Iwata K, Yamada A, Sakurai K, Tampo H, Niki S (2003) Thin Solid Films 431:369

Janotti A, Van de Walle CJ (2009) Rep Prog Phys 72:126501

Willander M, Nur O, Zhao QX, Yang LL, Lorenz M, Cao BQ, Perez JZ, Czekalla C, Zimmermann G, Grundmann M, Bakin A, Behrends A, Al Suleiman M, El Shaer A, Mofor AC, Postels B, Waag A, Boukos N, Travlos A, Kwack HS, Guinard J, Dang DLS (2009) Nanotechnology 20:332001

Dijken AV, Makkinje J, Meijerink A (2001) J Luminescence 92:323

Sultana K, Hassan K, Tzamalis G, Nur O, Willander M (2010) Phys State Solidi A 207:67

Nohynek GJ, Dufour EK, Roberts MS (2008) Skin Pharmacol Physiol 21:136

Nohynek GJ, Lademann J, Ribaud C, Roberts MS (2007) Crit Rev Toxicol 37:251

Sarvari M, Etemad S (2008) Tetrahedron 64:5519

Alinezhad H, Salehian F, Biparva P (2012) Synth Commun 42:102

Ma Gee DI, Dabiri M, Salehi P, Torkian L (2011) Arkivoc 11:156

Brunavs M, Dell CP, Gallagher PT, Owton WM, Smith CW (1993) 4H-Naphtho[1,2-b]pyran cell antiproliferation agents. European Patent EP 557,075, 25 Aug, 1994 Chem Abstr 120:106768

Kuo SC, Huang LJ, Nakamura H (1984) J Med Chem 27:539

Radi M, Schenone S, Botta M (2009) Org Biomol Chem 7:2841

Bedair AH, El-Hady NA, El-Latif MSA, Fakery AH, El-Agrody AM (2000) Farmaco 5:708

Tandon VK, Vaish M, Jain S, Bhakuni DS, Srimal RC (1991) Indian J Pharm Sci 53:22

Regnier GL, Canevari RJ, Le Douarec JC, Holstorp S, Daussy J (1972) J Med Chem 15:295

Metolcsy G (1971) World Rev Pest Contr 10:50

Metolcsy G (1972) Chem Abstr 76:82031s

Joshi KC, Jain R, Sharma KJ (1988) Indian Chem Soc 45:202

Zamocka J, Misikova E, Durinda J (1992) Cesk-Farm 41:170

Zamocka J, Misikova E, Durinda J (1992) Chem Abstr 116:106031q

Pershin GN, Shcherbakova LI, Zykova TN, Sokolova VN (1972) Farmakol Toksikol 35:466

Mohr SJ, Chirigos MA, Fuhrman FS, Pryor JW (1975) Cancer Res 35:3750

Suguira K, Schmid FA, Schmid MM, Brown GF (1973) Cancer Chemother Rep Part 2(3):231

Banzatti C, Branzoli U, Lovisolo PP, Melloni P, Salvadori P (1984) Arzneim Forsch 34:864

Nawwar GA, Abdelrazek FM, Swellam RH (1991) Arch Pharm 324:875

Heckler RE, Jourdan GP (1991) Condensed pyrimidine derivatives and their use as fungicides, insecticides, and miticides. European Patent EP 414386, Feb 27, 1991

Heckler RE, Jourdan GP (1991) Chem Abstr 115:71630

Ohira T, Yatagai M (1993) J Jpn Wood Res Soc 39:237

Pañeda C, Huitron-Resendiz S, Frago LM, Chowen JA, Picetti R, de Lecea L, Roberts AJ (2009) J Neurosci 29:4155

Anary-Abbasinejad M, Saidipoor A (2008) Synth Commun 38:354

Ghosh R, Maiti S, Maiti SK, Roy S (2008) Synth Commun 38:1958

Habibi A, Mousavifar L, Yazdanbakhsh MR, Yavari S (2008) Synth Commun 38:873

Dömling A, Ugi I (2000) Angew Chem Int Ed 39:3169

Bedair AH, Emam HA, El-Hady NA, Ahmed KAR, El-Agrody AM (2001) Farmaco 56:965

Ganesh CN, Subhasis S, Ram K, Singh MS (2009) Tetrahedron 65:7129

Praveen Kumar K, Satyanarayana S, Lakshmi Reddy P, Narasimhulu G, Ravirala N, Subba Reddy BV (2012) Tetrahedron Lett 53:1738

Safaei-Ghomi J, Ghasemzadeh MA (2014) S Afr J Chem 67:27

Jalde SS, Chavan HV, Adsul LK, Dhakane VD, Bandgar BP (2014) Synth React Inorg Met Org Chem 44:623

Acknowledgments

The authors are grateful to Islamic Azad University, Qom Branch, Qom, I. R. Iran. Also authors are grateful to Dr. Raheleh Teymuri and Dr. Hossein Shahbazi-Alavi for their helps.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mohaqeq, M., Safaei-Ghomi, J. A flexible one-pot synthesis of 8,10-dimethyl-12-aryl-9H-naphto[1′,2′:5,6]pyrano[2,3-d]pyrimidine-9,11-diones catalyzed by ZnO nanoparticles under solvent-free conditions. Monatsh Chem 146, 1581–1586 (2015). https://doi.org/10.1007/s00706-015-1411-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00706-015-1411-1