Abstract

In recent years, an increasing number of studies has demonstrated that redox polymers can be used in simple and effective electrochemical sensing platforms due to their fast electron transfer and electrocatalytic ability. To develop more sensitive and selective electrochemical (bio)sensors, the electrocatalytic properties of redox polymers and the electrical, mechanical, and catalytic properties of various nanomaterials are combined. This review aims to summarize and contribute to the development of (bio)sensors based on polyphenazine or polytriphenylmethane redox polymers combined with nanomaterials, including carbon-based nanomaterials, metal/metal oxide, and semiconductor nanoparticles. The synthesis, preparation, and modification of these nanocomposites is presented and the contribution of each material to the performance of (bio)sensor has been be examined. It is explained how the combined use of these redox polymers and nanomaterials as a sensing platform leads to improved analytical performance of the (bio)sensors. Finally, the analytical performance characteristics and practical applications of polyphenazine and polytriphenylmethane redox polymer/nanomaterial–based electrochemical (bio)sensors are compared and discussed.

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

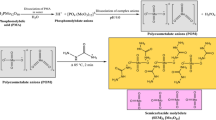

Redox polymers have been investigated since the 1970s. In the late 1980s, Degani and Heller [1] began to focus on research into electrochemical sensors based on redox polymers and developed a glucose biosensor using Os-complexes. In recent years, the use of redox polymers has increased in biofuel cells, biosensors, and energy storage technologies due to the fast rate of electron transfer. By acting as redox mediator, they facilitate the change of the electron state of their active site [2]. Among redox polymers, polyphenazine/polytriphenylmethane polymers have seen extensive use in electrochemical (bio)sensors over the past 30 years [3]. These polymers, formed by the electropolymerization of phenazine/triphenylmethane dyes on substrate electrodes, show monomer type redox activity after polymerization [4]. The polymerization is usually done by potential cycling (implemented as cyclic voltammetry (CV)), or at constant applied potential (implemented as fixed-potential amperometry) [3]. The electrochemically induced formation of the cation-radical at positive potentials and the structure of monomer affect the nature of the polymer formed [4]. In addition, since they have groups that can be protonated, pH plays a key role in the polymer electrochemical behaviour [3]. Thus, electropolymerization parameters such as the electrolyte, pH, monomer concentration, polymerization period, and scan rate are important for controlling the growth of the polymer film; by adjusting these parameters, the desired polymer film with the best electrochemical detection results can be obtained [5].

In addition to redox polymers, nanomaterials, which include carbon-based nanomaterials and metal/metal oxide/semiconductor nanoparticles, have been featured in many applications because they possess important mechanical, catalytic, and electrical features. Due to their excellent properties such as high surface activity and area, rapid electron transfer, and good biocompatibility, they have received growing interest in the field of electrochemical sensing [6]. Their properties can be easily altered by introducing chemical or physical modifications.

In recent years, there have been studies based on combining nanomaterials and polymers for the development of (bio)sensors in order to improve the sensing performance, normally in terms of selectivity and sensitivity. This has included conjugated conducting polymers which are not the subject of this review but represent an alternative strategy [7,8,9] and redox polymers [3, 6, 10]. Nanomaterial-based electrochemical (bio)sensors that include the formation of redox polymer films by electropolymerization have been reported in the literature [11,12,13]. Redox polymer/nanomaterial composites are good transducers for electrochemical sensors since they show features such as easy synthesis, varied morphology, large electroactive surface area, chemical stability, and excellent redox properties [6].

The aim of this review is to discuss the latest developments in electrochemical sensors and biosensors based on polyphenazine or polytriphenylmethane redox polymers and nanomaterials and their applications in the field of analytical chemistry, particularly since 2015, when a previous review on such polymers together with carbon nanotubes as electrode modifiers was published [3]. Nanomaterials considered include carbon-based nanomaterials, metal/metal oxide/semiconductor nanoparticles. The preparation and modification of these composites will be explained in detail. Due to the synergistic effects between the nanomaterials and redox polymers, the order of adding the components to form the modified electrode is very important and influences their performance characteristics [3]. Lastly, the analytical performance characteristics of these electrochemical (bio)sensors will be presented.

The general fabrication steps for redox polymer/nanomaterial-based electrochemical (bio)sensors are shown in Fig. 1. The polymer forms of phenazine and triphenylmethane dyes are designated as redox polymers due to the chemical structure of the monomer and the fact that the redox characteristics of the monomer continue after polymerization, which is very useful for (bio)sensor applications because they have the ability to change surface morphology and structure [14]. The phenazine/triphenylmethane dye monomers discussed in this review are presented in Fig. 2.

Nanocomposites of redox polymer/carbon materials

Nanocomposites based on redox polymers and carbon nanomaterials, including carbon nanotubes (CNT) (usually multiwalled carbon nanotubes (MWCNT)), graphene (GN), carbon quantum dots (CQD), and boronic acid functionalized carbon nanodots (B-CND), are promising as novel electrode materials for electrochemical applications. When a combination of carbon nanomaterials and redox polymers is used, the resulting nanocomposite provides many advantages due to its morphological and electrochemical features [6, 10]. Many studies have been reported in the literature [15,16,17,18,19,20,21,22,23,24,25,26,27,28,29,30,31,32,33,34,35,36,37].

Among carbon-based nanomaterials, CNT and GN are both significant and interesting for modification of the surface because they have advantageous and useful properties that provide an enhanced electrochemical response and faster electron transfer kinetics [38]. In order to achieve a uniform dispersion of CNT, a chemical treatment with concentrated acid is normally performed before their modification [39]. CNT is often purified and functionalized (f-CNT) by treatment with a mixture of the concentrated acids H2SO4 and HNO3 [22, 26, 29], with concentrated HNO3 [16, 18,19,20, 23, 25, 34, 37], or can be purchased purified or functionalized [15, 31, 32].

GN can be prepared from graphene oxide (GO) by high-temperature treatment [17]. GO can be obtained from graphite powder by the conventional [24, 27, 30] or modified Hummer method [28, 35]. In another procedure for GO, a mixture of concentrated H2SO4 and H3PO4 was added to a solution of graphite flakes and KMnO4 heated to 50 °C; after centrifuging the filtrate, the precipitate was dried to obtain GO [36].

B-CNDs, which are carbon materials, have been prepared by dissolving phenylboronic acid in H2O, adjusting the pH of the mixture to 9.0 using NaOH, removing oxygen, heating to 160 °C, centrifuging, and drying the supernatant to obtain B-CND [33]. For CQDs, citric acid was melted at 180 °C for 30 min and the formation of orange CQD was observed, adjusting the pH to 7.0 with NaOH [21].

It is crucial to use a suitable solvent to obtain a good dispersion [10]. Some examples are given here. CNT, f-CNT, or GN suspensions were prepared in chitosan (Chit) solution [18,19,20, 23, 25, 34, 37], phosphate buffer (PB) [26], water [17, 24, 31, 35, 36], or ethanol [32]. Another method of using CNT was the preparation of a modified electrode by mixing a known amount of CNT or f-CNT, graphite powder, and silicone oil [15, 22]. GO synthesized by the Hummer method was dispersed in water, sonicated for 30 min and then centrifuged, mixed with polyvinylpyrrolidone solution, and subsequently heated to 50 °C for 12 h. To obtain a reduced graphene oxide (rGO) suspension, hydrazine and NH3 were added into the dispersion, heated to 95 °C, centrifuged, and dried [30]. GO was mixed with monomer in water and the homogeneous solution was dropped on the electrode surface [27, 28]. B-CND were dispersed in water, and the electrode was immersed in this mixture to obtain B-CND-coated electrode [33]. A mixture of CQD and monomer solution in NaOH was used for potential cycling electropolymerization [21].

Polyphenazine or polytriphenylmethane/carbon nanomaterial composites have been prepared on the electrode surface in different ways:

-

(a)

A dispersion of carbon nanomaterials in a suitable solvent is dropped onto the electrode surface or the electrode is dipped into the solution. The modified electrode is then coated with polymer film by electropolymerization in the presence of monomer [16,17,18,19,20, 23,24,25,26, 30, 31, 34,35,36,37]. A typical electropolymerization profile for the formation of PNR and PBCB on MWCNT in aqueous solution [40] is presented in Fig. 3. An alternative strategy was used in [24], in which graphene oxide is reduced at the same time that methylene blue is oxidized. In another work, graphene flakes (GNF) were drop cast on fluorine-doped tin oxide (SnO2/F) coated glass and covered with PMB by electropolymerization [41]. For a biosensor, electropolymerization on a GN modified electrode surface was performed in monomer plus enzyme solution [28] by potential cycling.

-

(b)

The bare electrode is placed in a monomer solution for electrochemical polymerization by potential sweeping. The polymer-modified electrode is drop-coated with a suspension of nanomaterial [32], or is dipped in a homogenous suspension [33].

-

(c)

Carbon paste electrodes bulk-modified with carbon nanomaterial are placed in a monomer solution for electropolymerization [15, 22].

-

(d)

Electropolymerization is performed in a solution containing both carbon nanomaterials and monomer solution [21].

-

(e)

A solution with a mixture of carbon nanomaterials and monomer is dropped on the electrode surface. Potential cycling is used to form a carbon material-polymer-modified electrode [27].

-

(f)

Modifiers are prepared chemically and the electrode is then coated. For example, carbon nanotube/polymer nanowires were prepared by in situ oxidative polymerization; the resulting suspension was dispersed in ethanol and used to coat the electrode surface [29].

Electrochemical polymerization by potential cycling at 50 mV s−1 between a -1.0 and +1.0 V for neutral red in 1 mM NR, 0.025 M KPB, pH 5.5 + 0.1 M KNO3; b -0.6 and +1.0 V for brilliant cresyl blue in 0.1 mM BCB, 0.1 M NaPB, pH 7.0 + 0.1 M KNO3 at CNT-modified GCE. Insets show polymerization at bare glassy carbon electrodes. From [40], reprinted by permission of Springer

Redox polymer/carbon nanotubes

After the discovery of carbon nanotubes in 1991 [42], they became very promising as novel electrode materials for the construction of (bio)sensors due to their unique physicochemical properties, which differ from other carbon materials [43]. In recent years, the combination of redox polymers and CNT has become of great interest in electrochemical applications. The combined use of these materials leads to improving the operational characteristics because CNT provide high electrical conductivity and mechanical strength to the resulting nanocomposite and there is usually a synergistic effect between polymer and CNT [3].

Recent reports of redox polymer/carbon nanotube–based electrochemical sensors and biosensors are given in Table 1.

Sensors based on redox polymer PBG and conducting polymer PEDOT-modified carbon film electrodes (CFE), CNT/PBG/CFE, CNT/PEDOT/CFE were reported by Barsan et al. [19]. Glucose oxidase (GOx), alcohol oxidase, and alcohol dehydrogenase were immobilized on the modified CFE. The phenazine-based biosensor (CNT/PBG/CFE) exhibited the best sensing performance for the determination of both glucose and ethanol compared with conducting polymer-based biosensor (CNT/PEDOT/CFE) and other similar nanostructured architectures described in the literature. Ganesh et al. [15] developed a sensor based on the electropolymerization of BB on MWCNT/CPE. The sensor showed a well-defined electrochemical response to dopamine (DA) in the presence of ascorbic acid (AA) and uric acid (UA); analysis of DA was successfully carried out with the PBB-based sensor in the presence of common interferent species. A novel amperometric sensor was prepared by mixing a known amount of CNT, graphite, and silicone oil [22]; a film of PBCP was then deposited by electropolymerization. Combining PBCP and CNT significantly enhances the electron transfer ability, as a result of π-π conjugated bonds, large active surface area, and high electrical conductivity. Since the aromatic hydroxy group of tyramine can form hydrogen bonds with the oxygen atom of the BCP, the sensor showed an excellent electrocatalytic activity towards substrate and was successfully used for the determination of tyramine in milk and blood serum. A H2O2 sensor based on PNR and haemoglobin was prepared by electrodeposition on a CNT-modified electrode surface [26]; the formation of a hybrid composite of redox polymer and haemoglobin was significantly increased by CNT. The hybrid composite sensor showed electrocatalytic activity towards H2O2 with high sensitivity and selectivity. Barsan et al. [25] proposed new electrode platforms based on PMG and f-CNT with two architectures, PMG/f-CNT/GE and f-CNT/PMG/GE, for the sensing of acetaminophen and pyridoxine. The polymerization was better on the f-CNT-modified electrode than on the bare electrode, and the highest sensitivity for both species was obtained with PMG/f-CNT/GE. This is due to the interaction of the carboxylate groups of the CNT with the amino group and sulphur anion of PMG.

PTB was used for the determination of caesium(III) [29], nitrite [31], and DA [32]. Studies have shown that PTB is successfully formed onto the surface of OH-MWCNT/PTB nanowires [29], MWCNT/GCE [31], and MWCNT-COOH/PTB/GCE [32].

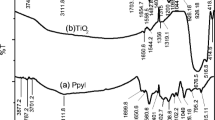

PBCB, PBG, PMB, and PTH were synthesized by potential cycling electropolymerization in the deep eutectic solvent ethaline (DES) on MWCNT-modified GCE [16, 18, 20, 23, 37]. The prepared nanostructured polymer films in ethaline-acid solution showed better sensing performances, improved morphological properties and behavioural diversity than those prepared in aqueous solution. In [16], the changes that occur in the morphology of the nanostructured polymer films electrodeposited in ethaline in the presence of acids as anion source were investigated by scanning electron microscopy (SEM) (see Fig. 4). MWCNT are uniformly embedded in the chitosan matrix, and show that it is suitable as platform for the polymerization of redox polymer due to its highly porous and regular surface morphology. The morphology of the PBCBaqu in Fig. 4b shows thin film formation on the MWCNT surface and this caused only minor changes in the size of the MWCNT. In Fig. 4b–f, the use of ethaline DES in the presence of HNO3 for BCB electropolymerization shows more uniform and smoother film than the other nanocomposite films. In [37], the sensor prepared by the polymerization of TH on MWCNT/GCE in ethaline DES was used for sensing of AA and biosensing of UA. It was shown that the proposed sensor is a promising approach for the analysis of AA and UA in real samples, with better analytical performance than in the literature.

SEM images of a MWCNT/GCE; b PBCBAqu/MWCNT/GCE; c PBCBEthaline-HNO3/MWCNT/GCE; d PBCBEthaline-H2SO4/MWCNT/GCE; e PBCBEthaline-HCl/MWCNT/GCE; f PBCBEthaline-HClO4/MWCNT/GCE. From [16], reprinted by permission of Elsevier

A new inhibition biosensor based on choline oxidase immobilized on PBCBDES-HNO3/MWCNT/GCE for the detection of dichlorvos pesticide was developed by da Silva et al. [18]. The biosensor detection limit was 1.6 nM and it showed superior analytical parameters to other inhibition biosensors for dichlorvos reported in the literature. This study showed clearly that the morphology of the polymer depends on both the polymerization solution composition and electropolymerization mode (potentiodynamic or potentiostatic). In another work, an enzyme inhibition biosensor was constructed by immobilizing GOx on PBG films formed in ethaline-acid solution on MWCNT/GCE [20]. The new biosensor was successfully applied to the monitoring of heavy metal ion species, with a nanomolar detection limit.

An analysis of Table 1 shows that the main applications of these sensors and biosensors in the last 5 years have been to pharmaceutical and clinical analytes with only a minority of applications to foods and beverages and contaminants in environmental samples.

Redox polymer/graphene

Graphene is a two-dimensional (2D) sheet of carbon monolayers with some attractive properties [44]. In relation to other carbon-based nanomaterials, graphene (GN) has a larger specific surface area, which allows the interaction of biomolecules with the surface. Graphene-based composite films have broad interest in the areas of electrochemistry application since they provide high thermal and electrical conductivity, excellent electron transferability, and strong mechanical strength [45]. The incorporation of redox polymers in the construction of GN-based sensors can improve properties such as redox activity, chemical stability, and biocompatibility [46]. In comparison with other carbon materials, GN can be a better support for polymerization due to its chemical structure [47].

GN-modified PBCB/GCE was developed for the analysis of epinephrine (EP) in the presence of the common interferents AA and UA in pharmaceutical formulations by Ding et al. [17]. Owing to the improved adsorption of EP at the GN-modified PBCB/GCE, the combined use of BCB and graphene exhibited excellent electrocatalytic activity towards EP oxidation.

A poly(Nile blue)-GN composite was synthesized by a one-step electrochemical method: after drop casting a mixture of NB and GN and drying, potential cycling was used to form PNB-GN [27]. GOx was immobilized on the surface of PNB-GN/GCE and then used for the sensing of glucose in serum samples. The biosensor had a satisfactory sensitivity to glucose due to the high surface area and conductivity of the PNB-GN nanocomposite. The authors reported that the nanocomposite could be a promising full-cell catalyst.

rGO is a good alternative to GN, because rGO demonstrates the properties of graphene and can be much easier to produce [36]. Gorle et al. [24] developed a dopamine-grafted rGO/PMB composite film for the detection of DA in the presence of AA and UA. It was shown that the developed nanocomposite acts as a catalytic platform. In another work, a hydroquinone (HQ) sensor based on PNMTh and rGO was synthesized by a two-step method, electrochemical reduction of drop-cast GO, followed by polymerization of NMTh in a strong acid medium [36]. The modified sensor was able to catalyze the redox reaction of HQ and showed an electrochemical response to HQ, with high sensitivity.

Biosensors based on horseradish peroxidase (HRP) are GCE modified with PTB-HRP/Toluidine Blue-GN [28], PTB-HRP-GOx/rGO [30], HRP/PTH/rGO [35]. A HRP inhibition biosensor based on electrodeposition of a PTH film over an rGO layer was developed. The biosensor was also used for monitoring chromium(VI) with a high sensitivity of 98.79 μA cm−2 μM−1 and a nanomolar detection limit of 20 nM [35]. Thionine is easily adsorbed on GO through π-π stacking interactions. The composite acts as an electron mediator to facilitate electron transfer between the enzyme and the modified electrode surface. In addition, the PTB-HRP-GOx/rGO bienzyme biosensor showed a strong affinity to glucose and H2O2 [30]. Due to GN’s unique electronic characteristics and with PTB as a redox mediator, the modified electrode was able to catalyze the oxidation of these substrates at a low potential, thus preventing potential interferences.

In general, there are two ways for the detection of glucose in a nanomaterial/redox polymer bienzymatic biosensor to occur, as shown in the scheme in Fig. 5. One is based on the determination of H2O2 generated in the presence of O2 during the enzymatic reaction (Fig. 5a). In Fig. 5b, the redox polymer (here PBCB) acts as a mediator to facilitate electron transfer between GOx and the modified electrode in the absence of O2.

GOx biosensor mechanism a in a bienzymatic configuration, when detection is based on the detection of peroxide formed in the first GOx enzymatic reaction and b based on the direct regeneration of FAD at polyphenazine mediator. From [3], reprinted by permission of Elsevier

A nanocomposite film with PMB formed by electropolymerization on graphene nanoflakes (GNF) deposited on fluorine-doped tin oxide coated glass was used for the determination of metformin in urine and serum [41]; the success of the developed sensor was attributed to the electrical properties of GNF and stable electron transfer of PMB.

Redox polymer/other carbon nanomaterials

Other carbon nanomaterials include carbon nanodots (CND) [48], carbon quantum dots (CQD), carbon nanoparticles (CNP), and carbon nanofibers. After the discovery of CNP by Iijima [42], the field of CNP research area has grown rapidly. CND can be obtained by purification of carbon nanotubes through electrophoresis [49] and they have attracted increasing interest due to their strong fluorescence [48]. CND/CQD are very useful and show advantages as part of sensor platforms, because of their low cost, easy solubility and preparation, high conductivity, biocompatibility, good photoluminescence properties, and efficient catalytic activity [33].

A novel PBCG/CQD nanocomposite film–modified GCE was prepared by electropolymerization [21]. GCE, CQD/GCE, PBCG/GCE, and PBCG/CQD/GCE were compared for the simultaneous determination of guanine and adenine by differential pulse voltammetry (DPV). Due to the synergistic effect of PBCG and CQD, the anodic peak currents of guanine and adenine at PBCG/CQD/GCE have much better-defined oxidation peaks than at all the other electrode platforms.

Li et al. [33] developed an enhanced modification procedure for B-CND and PTH on GCE for the electrochemical sensing of NADH. The B-CND/PTH/GCE sensor exhibited a response to NADH with high sensitivity and selectivity due to the functional boronic acid groups’ interaction with the cis-diol of NADH. Bairagi et al. [50] proposed a new electrode platform based on a Cu/Ni bimetal-dispersed carbon nanofiber/PMO nanocomposite for the determination of cholesterol in blood. The sensor showed excellent analytical performance, with high sensitivity, a wide linear working range, and a lower detection limit compared to reported cholesterol enzymatic biosensors and without the issues of enzyme stability.

In another study, PMB nanofilm was electrochemically grown on the surface of Cu-CNP/ACF [51], and was used for the sensing of creatinine biomarker. Due to the configuration properties and the synergistic contribution of the polymer-metal-carbon nanofiber nanocomposites, the modified electrode showed an excellent electrochemical response to creatinine over a wide concentration range.

Nanocomposites of redox polymer/metal, metal oxide nanoparticles

Metal/metal oxide and semiconductor nanoparticles (NP) have found application in the preparation of electrochemical sensing platforms with redox polymers, due to the favourable properties of polymer films grown on NP [12, 41, 52,53,54,55,56,57,58,59,60,61,62,63,64,65,66,67,68]. Recently reported redox polymer/metal or metal oxide nanoparticle–based sensors and biosensors are shown in Table 2.

The synthesis of NP in a size- or shape-selected and controlled manner is essential for NP to improve the (bio)sensing performance [55, 69]. Most AuNP are synthesized by reaction in aqueous HAuCl4 solution and then used as modifiers, as in [56], in which a PBCB polymer–modified electrode was immersed in AuNP solution for 6 h at 4 °C to decorate the polymer with AuNP. The synthesis of AuNP was carried out in HAuCl4 solution containing 0.5 M H2SO4 or 0.1 M KNO3 as supporting electrolyte at a constant applied potential [58] or by potential cycling (implemented as cyclic voltammetry (CV)) [62]. In another procedure, AuNP were formed by treating hot HAuCl4 with sodium citrate reducing agent [57, 63]. Mixing thionine monomer with HAuCl4 solution led to the formation of AuNP-polymer nanowires, in which HAuCl4 acted as oxidizing agent for TH polymerization and was itself reduced [60].

Synthesis of PtNP was performed in H2PtCl6 containing 0.01 M KCl as supporting electrolyte at a constant applied potential [55]. PtNP-nitrogen-doped graphene (NGE) was prepared by dissolving nitrogen-doped graphene in H2PtCl6 aqueous solution, adding AA and HCl, centrifuging, and drying the supernatant. PtNP-NGE and TH were mixed in N,N-dimethylformamide (DMF), sonicated for 4 h, and then centrifuged. The precipitate was dispersed in water and was dropped onto the electrode surface [61]. To obtain copper or nickel metal polymer–modified electrode, the polymer-modified electrode was immersed in copper nitrate [53] or nickel nitrate [54] solution.

Regarding metal oxide NP, and in order to obtain a uniform and stable suspension of NP, Fe2O3NP [12, 52, 66, 67] and CuONP [68] were dispersed in Chit solution and the modified electrode was prepared from a homogeneous suspension. Nickel (II) nitrate was dissolved in isopropanol-polyethylene glycol mixture to obtain NiONP after heating and chemical treatment. Then, a known amount of NiONP, graphite powder, and silicone oil were mixed to construct a modified carbon paste electrode [59].

Some sensors based on the combined use of carbon nanomaterials and metal/metal oxide NP have been developed [11, 13, 61, 70,71,72,73,74,75,76,77,78]. In [70, 72, 77], GO was synthesized following the modified Hummer method. rGO/AgNP were deposited on a PBB polymer-coated electrode [70] or, using the inverse order of coating, by electropolymerization of NR on a rGO/AuNP-modified GCE [77]. In [72], an aqueous dispersion of GO, AgNP, and MB monomer was prepared. GO/MB/AgNP paper was obtained by vacuum filtration of this mixture through a membrane. After separating from the membrane, and reduction to rGO by HI solution, rGO/PMB/AgNP paper was produced by surface-confined electropolymerization.

MWCNT and NP nanocomposites were used for the modification of different electrode surfaces. MWCNT suspension, prepared in a DMF:water mixture, was coated onto the electrode surface [11, 74, 76]. Polymerization was done by potential sweeping, to form PMB, and then HAuCl4 was reduced in 0.5 M H2SO4 acid solution at constant applied potential to form AuNP, the final architecture being AuNP/PMB/f-MWCNT/GE [11]. In [74, 76], a stable dispersion of AuNP was dropped onto an MWCNT-modified electrode to obtain AuNP/MWCNT/SPCE; PNR film was then formed by electropolymerization of NR on the AuNP/MWCNT surface. In another work, MWCNT aqueous dispersion was dropped onto the electrode surface, and then PTH was formed on the modified electrode surface by electrochemical polymerization. After electropolymerization, potentiostatic deposition was used to form PtNP on the MWCNT/PTH/GCE [13]. In a different approach, an MWCNT dispersion in ethanol was mixed with AgNP, and then this solution was drop cast on a PAMAM-coated electrode surface [75]. In [69, 71], the electrode surface was modified by electrodeposition of Au-MWCNT. Ni2+/PNR hybrid nanocomposites (HN) were synthesized by a reverse microemulsion method [78]. A known amount of Ni2+@PNR HN was mixed with MWCNT/Nafion solution and the homogeneous suspension was dropped on the GCE.

In summary, sensors based on redox polymer plus NP-modified electrodes can be prepared with different architectures, and thence different analytical properties, following methods that are similar to those employed with carbon nanomaterials.

-

(a)

A dispersion of NP in a suitable solvent is first dropped onto the electrode surface. The modified electrode is coated with a polymer film by electropolymerization in monomer solution (Fig. 6) [12, 52, 57, 66,67,68]. Typical cyclic voltammograms for electropolymerization of redox polymer onto a nanoparticle modified electrode are given in Fig. 7; this demonstrates clearly the fast electron transfer that can occur within the polymer film prepared in ethaline DES if nanomaterials, in this case, iron oxide NP, modified electrodes are used for polymer film growth. For biosensors, a NP-modified electrode is immersed in monomer solution and enzyme solution [62] or monomer solution [64] for electrochemical polymerization by potential sweeping.

-

(b)

The polymer/NP is obtained by dipping the polymer-coated electrode into the NP suspension or drop casting (Fig. 6), e.g. AuNP/PBCB/GCE [56].

-

(c)

Bulk-modified carbon paste electrodes are placed in an aqueous solution containing a monomer solution for electropolymerization, e.g. with NiONP [59].

-

(d)

A bare electrode is placed in a monomer solution for electropolymerization together with the NP precursor. As one example, a polymer-PtNP or polymer-AuNP modification layer is obtained by reductive electrodeposition in the presence of chloroplatinic acid (PAA-PtNP) [55] or chloroauric acid (PMB-AuNP) [58], respectively.

-

(e)

Monomer solution is dropped onto the bare electrode and a polymer film is then grown in buffer solution by potential cycling [53, 54]. The prepared polymer-modified electrode is immersed in a solution containing copper or nickel metal ions, which leads to the formation of metal NP on the surface.

-

(f)

A mixture of polymer and NP is dropped on the electrode surface and dried at room temperature [60]. In another example, a redox polymer/NP nanocomposite is prepared by one-step synthesis in solution: a precipitate of PTH/AuNP formed in this way is dispersed in DMF and dropped onto the electrode surface [63, 65].

Potential cycling electropolymerization on Fe2O3/GCE in ethaline DES / 1.0 M H2SO4, scan rate 50 mV s−1 of a 1 mM NR to form PNREthaline and b 1 mM MG to form PMGEthaline. Adapted from [66], reprinted by permission of Elsevier

Redox polymer with metal or metal oxide nanoparticles for sensing

The construction of new electrochemical (bio)sensors that include NP components has attracted considerable attention. NP with different morphologies show various kinds of electrical, optical, and catalytic properties due to their particle size, long-term stability, and high surface-to-volume ratio. NP often act as electrocatalysts because of their nanostructure and size [79]. The combined use of redox polymers and NP provides a synergistic interaction and allows the formed nanocomposite film to have the properties of each category of materials [80].

Examples of sensors based on AuNP are HRP/AuNP/PBCB/GCE [56], PCB/AuNP/GE [57], AuNP/PMB/PGE [58], MIP/Au-PTH/pABSA/GCE [60], HRP/PTH-MIP/MPBA/AuNP/GCE [62], PTH/AuNP/GCE [63], MIP/PTH/AuNP@ZIF-67/GCE [64], and PTH/AuNP/GCE [65]. The amine group of the redox polymer interacts with AuNP due to the cooperative electrostatic interaction between amines and AuNP. The construction of various redox polymer/AuNP formed on different electrode surfaces has been characterized by SEM. In [56, 58], differences in the SEM images of the polymer on AuNP-modified electrodes are large, but the AuNP are size-uniform in each case and highly dispersed on the polymer film surface, which is demonstrated in all studies involving examination by SEM.

Amperometric hydrogen peroxide sensors were developed based on AuNP and redox polymers [56, 57, 62]. It was found that the PTH-MIP/MPBA/AuNP/GCE show a low detection limit compared to other H2O2 (bio)sensors [56, 57], due to the specific interactions between boronate affinity–based MIP film and HRP [62].

Electrochemical (bio)sensors based on AuNP-PTH showed a strong affinity to the target analyte, due to PTH acting as an electroactive probe and an electron transfer mediator [60, 63,64,65]. A sensor based on the interaction between PTH and AuNP was constructed for the detection of epinephrine (EP) [63] and DA [65] with high sensitivity. In other studies, dual-signal electrochemical sensors were developed using AuNP/PTH and MIP composites for bisphenol A [60] or tyrosine [64].

PtNP are less used than AuNP in sensor applications but are nevertheless important, especially for the monitoring of H2O2. They allow reducing the working potential for the electrocatalytic reduction/oxidation of H2O2 to minimize the effects of interferences [81]. Jiménez-Pérez et al. [55] developed a PtNP-modified PAA/SPCE for the sensitive determination of H2O2. The non-enzymatic sensor showed a significant electrocatalytic effect towards H2O2 oxidation with a detection limit of 52 nM, better than other reports in the literature.

There are polymer nanocomposite films reported that are formed with different metal ions by adsorption. A novel H2O2 sensor was prepared by adsorption of Cu on PAA-Chit/GCE [53]. A Fenton type reaction between Cu2+ and H2O2 leads to the formation of hydroxyl radicals that oxidize PAA and cause a change in the reduction current of the polymer dye at the potential applied. PAA-Ni/GCE was developed by bonding nickel hydroxide/nickel oxide with PAA [54]; due to the Ni(II)/Ni(III) couple, the modified electrode exhibited well-defined redox peaks and an excellent electrocatalytic activity towards glucose oxidation.

Electrochemical sensors based on metal oxide NP were the modified electrodes AChE/PNRethaline-HNO3/Fe2O3/GCE [12], PBCB/Fe2O3/GCE, PNB/Fe2O3/GCE [52], and PSF/nano NiO/CPE [59]. A novel biosensor was prepared by PNR synthesized by electropolymerization on Fe2O3-modified GCE in ethaline DES [12]. Acetylcholinesterase (AChE) was immobilized on the PNRethaline-HNO3/Fe2O3/GCE for the detection of acetylcholine in synthetic urine. The PNR nanostructured films in ethaline-HNO3 had a low detection limit of 1.04 μM, better than reported in the literature. In [52], PBCB and PNB were formed on Fe2O3/GCE by potential cycling electropolymerization, and were used for the sensing of EP in adrenaline samples. PBCB/Fe2O3/GCE exhibited better sensitivity and selectivity to EP than PNB/Fe2O3/GCE configurations because the modified electrode allowed better access of analyte to the polymer. In another study, NiO/CPE was constructed by mixing graphite powder, silicone oil, and the synthesized NiONP [59]. The modified carbon paste electrode was coated with PSF film by electropolymerization of safranine to obtain PSF/NiO/CPE. The sensor could be applied to determine rutin in tea samples without interference effects. The performance parameters of the sensor for rutin were better than in the literature. This is probably due to the polymerization occurring at the electrode surface modified with homogeneously dispersed NiO that supplied high surface activity and area.

Redox polymer/metal, metal oxide nanoparticles with carbon nanomaterials

The combination of metal or metal oxide nanoparticles together with carbon nanomaterials has been shown to enhance electrocatalysis and sensitivity of sensors [82]: the prepared nanocomposites have the properties of each material category. Modified electrode sensors using the combination of metal/metal oxide NP and carbon nanomaterials as well as redox polymer have been reported in the literature [11, 13, 61, 70,71,72,73,74, 76, 77].

Gholivand et al. [11] described a new electrochemical sensor based on AuNP/PMB/f-MWCNT/GCE for the detection of nevirapine (NVN) as an anti-HIV drug, by differential pulse anodic stripping voltammetry. The modified electrode showed strong electrocatalytic activity towards NVN, at low working potentials, thus avoiding the interference effect of common electroactive species. Bollella et al. [71] reported the first mediated microneedle-based biosensor for the continuous monitoring of lactase in the dermal interstitial fluid. The biosensor was prepared by immobilizing lactate oxidase (LOx) on a PMB/Au-MWCNT film coated with Au microneedles. Practical application of the biosensor was successfully demonstrated in body fluids. The same authors also developed the first mediated microneedle-based biosensor array for the continuous and simultaneous sensing of lactate and glucose in body fluid [73]. Sensors were prepared by immobilizing glutamate dehydrogenase or LOx on the PMB/Au-MWCNT/Au microneedles. The authors proposed that the new biosensors could be used as a wearable device for the continuous monitoring of glucose and/or lactate.

In another work, amperometric sensors based on the use of PNR with AuNP and MWCNT were fabricated [74, 76]. Alcohol oxidase (AOx) and alcohol dehydrogenase (ADH) were immobilized on PNR/AuNP/MWCNT/SPCE for the analysis of ethanol, methanol, and their different mixtures. An ADH-based biosensor for ethanol and an AOx-based biosensor for methanol showed the best responses [76]. The NADH sensor was obtained by the modification of SPCE by MWCNT and then with AuNP and PMB [74]. A novel glucose amperometric biosensor based on rGO-AuNP/PNR nanocomposite was reported [77]; the modified electrode demonstrated good stability for 2 weeks. The authors also proposed that rGO-AuNP/PNR/GOx/GCE could be used in biofuel cell applications.

An electrochemical sensor based on the synthesis of a nanocomposite film of f-CNT, PTH, and PtNP was developed [13]. Due to the synergistic effect among f-CNT (superior electrical conductivity), PTH (excellent electron transfer mediator), and PtNP (good electrocatalytic performance), the three-dimensional nanocomposite sensor was successfully applied to the simultaneous determination of myricetin and rutin. Devi et al. [75] proposed a novel electrode platform based on PAMAM/AgNP/MWCNT/PNR for the sensing of paracetamol that had a detection limit of 0.053 μM. Due to the use of PAMAM 3-D dendrimer, stable immobilization of AgNP/MWCNT nanocomposite on the electrode surface was achieved. Huang et al. [61] developed a sensor platform of PtNP, nitrogen-doped graphene, MIP, and PTH on GCE for the electrochemical detection of patulin in juice samples; it showed a wide linear range (0.013–13 nM), and low detection limit (0.0065 nM).

In [72], see Fig. 8, a new highly flexible NADH amperometric sensor based on rGO/PMB/AgNP composite paper was developed, with a low detection limit and a wide linear working range for the determination of NADH. This is attributed to the electrostatic interactions between the negative charge of NADH and the positive charge of the PMB. A novel electrochemical sensor involving depositing rGO/AgNP on a PBB polymer-coated electrode was developed by El-Zahry [70]. The prepared sensor was successfully used for the ultra-trace level determination of rosuvastatin in human plasma.

Scheme of the preparation procedure of rGO/poly(MB)/AgNP composite paper for NADH determination. From [72], reprinted by permission of Wiley

Ran et al. [83] constructed an electrochemical sensor based on the combination of Fe3O4 and MWCNT drop cast on PBCG/GCE for the analysis of serotonin in human blood serum. The Fe3O4-MWCNT-PBCG nanocomposite had a good electrocatalytic effect on serotonin oxidation with a low detection limit, high selectivity, and sensitivity compared to other reported serotonin sensors. This was ascribed to MWCNT creating many active sites for catalyzing the oxidation of serotonin.

Chang et al. [78] prepared a new hybrid nanocomposite with Ni2+-doped PNR film. The GCE/Ni2+@PNR HN/MWCNT/Nafion-modified electrode for the analysis of glucose was fabricated based on electrostatic interactions between Ni2+@PNR HN and MWCNT. The sensor showed a strong electrocatalytic effect on the oxidation of glucose due to the synergistic effects between the modifier components.

As is the case for redox polymers with carbon nanomaterials, examination of Table 2 shows that the main applications of these sensors and biosensors in the last 5 years have been to pharmaceutical and clinical analytes with a just a third of the articles directed towards analysis of components in foods and beverages and to contaminants in environmental samples.

Conclusions, challenges, and perspectives

The synthesis, preparation, and application of polyphenazine and polytriphenylmethane redox polymers, together with nanomaterials, for the preparation of and application in electrochemical sensors have been reviewed. Figure 9 gives a breakdown of how much each of the polymers reported has been employed in sensors and biosensors. It is interesting that more than half of the reports employ poly(neutral red), poly(methylene blue), or polythionine, with poly(toluidine blue) and poly(brilliant cresyl blue) following with 9% each. In all of these reports, the combined use of redox polymers with favourable catalytic ability and nanomaterials with unique electrical, mechanical, and catalytic properties allow the construction of more sensitive and selective (bio)sensors due to synergistic effects.

Many of the studies in this review demonstrate better (bio)sensing performance, together with improved morphological and electrochemical properties than occurs with the use of just nanomaterials for sensors, reported in the literature. Current data show that redox polymers play an important role in the development of nanomaterial-based electrochemical (bio)sensors.

Redox polymers can be effective for incorporating the nanomaterial on the electrode surface and increasing the active surface area on electrode modification because of their highly porous structure. This can contribute to the improvement of the performance characteristics of the electrochemical sensors.

Polyphenazine and polytriphenylmethane redox polymers can also exhibit an electrocatalytic effect, permitting the detection of analytes by oxidation at less positive potentials, in this way reducing possible interference effects by common electroactive species. Also, the order of adding the components, polymer or nanomaterial, to construct the modified electrode can be important since it can influence the final morphology and access of the analyte to the modified electrode surface.

There are a number of challenges to be overcome for sensing applications of redox polymer/nanomaterial film–modified electrodes to be used more widely. Most importantly, the synthesis and purification steps of nanomaterial can be challenging and time-consuming and need to become faster and more efficient. Second is the preparation of redox polymer/nanocomposite film with a uniform distribution of nanomaterials which influences interaction effects in the polymer nanocomposite. Therefore, new strategies are needed to design and prepare simple and cost-effective nanocomposite films based on carbon nanomaterials and metal/metal oxide nanoparticles, whilst retaining the high reproducibility and repeatability.

It is also necessary to further evaluate alternative electropolymerization media in order to achieve more highly stable and sensitive electrochemical sensors, with lower limits of detection. At the same time, the toxicological effects on environmental and living systems, of all the sensor platform components and reagents used in their preparation, should not be forgotten. Due to the increasing demands for low toxicity, eco-friendly, and biocompatible solvents, green designer solvents such as DES have a growing interest in the preparation of electrochemical sensors. Synthesis of polymer films in DES, rather than in aqueous solution, has led to sensors with better analytical performances ascribed principally to improved morphological properties [15]. The use of DES media with acid dopant for the polymerization supplies good conductivity, with maximized strong hydrogen bonding interactions between donor and acceptor in binary mixtures. There is a wide range of H-bond donors that can be used with H-bond acceptors, such as choline chloride, giving rise to polymer films with even better properties [84, 85]. There is a very large number of DES that can be evaluated for this purpose and much research can be done in exploring these avenues.

Owing to synergistic effects between the nanomaterials and redox polymers, it is clear that carbon nanomaterials and metal/metal oxide nanoparticles will continue to be an important part of the next-generation development of sensors and biosensors. The advantage of combined redox polymer and nanomaterial nanocomposite will depend on the differences in electrical, mechanical, and catalytic properties of both materials and their interactions with each other.

Further studies are required to clarify the mechanism of redox polymer mediation. In addition to the traditional single polymer systems, more than one polymer combined with nanomaterials will pave the way for a new approach in future sensor technology.

In summary, and as emphasized in this review, it is clear that redox polymer/nanomaterial-based electrochemical sensors show much promise for future applications. It is seen that polyphenazine or polytriphenylmethane redox polymers combined with nanomaterials have considerable potential in the development of electrochemical (bio)sensors for the determination of common analytes with enhanced performance for two principal reasons. First, electrocatalysis by reducing the applied potential needed for the oxidation or reduction of the electroactive species to occur. Secondly, a higher current response due to the increased accessible modified electrode surface area, that leads to higher sensitivity and usually to lower detection limits. Applications range from detection of important components of or contaminants in food and beverages, to health and the environment. The on-going research in this area is expected to contribute to the design of more sophisticated, but simple to prepare, electrochemical sensors and biosensors in the near future.

References

Ruff A (2017) Redox polymers in bioelectrochemistry: common playgrounds and novel concepts. Curr Opin Electrochem 5:66–73

Yuan M, Minteer SD (2019) Redox polymers in electrochemical systems: from methods of mediation to energy storage. Curr Opin Electrochem 15:1–6

Barsan MM, Ghica ME, Brett CMA (2015) Electrochemical sensors and biosensors based on redox polymer/carbon nanotube modified electrodes: a review. Anal Chim Acta 881:1–23

Karyakin AA, Karyakina EE, Schmidt HL (1999) Electropolymerized azines: a new group of electroactive polymers. Electroanal 11(3):149–155

Ameer Q, Adeloju SB (2009) Development of a potentiometric catechol biosensor by entrapment of tyrosinase within polypyrrole film. Sens Actuat B-Chem 140:5–11

Shrivastava S, Jadon N, Jain R (2016) Next-generation polymer nanocomposite-based electrochemical sensors and biosensors: a review. TrAC-Trend Anal Chem 82:55–67

Aydemir N, Malmström J, Travas-Sejdic J (2016) Conducting polymer based electrochemical biosensors. Phys Chem Chem Phys 18(12):8264–8277

El-Said WA, Abdeslhakour M, Choi JH, Choi JW (2020) Application of conducting polymer nanostructures to electrochemical biosensors. Molecules 25(2):307

Lakard B (2020) Electrochemical biosensors based on conducting polymers: a review. Appl Sci 10(18):6614

El Rhazi M, Majid S, Elbasri M, Salih FE, Oularbi L, Lafdi K (2018) Recent progress in nanocomposites based on conducting polymer: application as electrochemical sensors. Int Nano Lett 8(2):79–99

Gholivand MB, Ahmadi E, Haseli M (2017) A novel voltammetric sensor for nevirapine, based on modified graphite electrode by MWCNs/poly(methylene blue)/gold nanoparticle. Anal Biochem 527:4–12

da Silva W, Brett CMA (2020) Novel biosensor for acetylcholine based on acetylcholinesterase/poly (neutral red)–deep eutectic solvent/Fe2O3 nanoparticle modified electrode. J Electroanal Chem 872:114050

Liu C, Huang J, Wang L (2018) Electrochemical synthesis of a nanocomposite consisting of carboxy-modified multi-walled carbon nanotubes, polythionine and platinum nanoparticles for simultaneous voltammetric determination of myricetin and rutin. Microchim Acta 185(9):414

Pauliukaite R, Ghica ME, Barsan MM, Brett CMA (2010) Phenazines and polyphenazines in electrochemical sensors and biosensors. Anal Lett 43(10–11):1588–1608

Ganesh PS, Swamy BK (2015) Sodium dodecyl sulphate/poly (brilliant blue)/multi walled carbon nanotube modified carbon paste electrode for the voltammetric resolution of dopamine in the presence of ascorbic acid and uric acid. J Anal Bioanal Tech 6(6):1

da Silva W, Ghica ME, Brett CMA (2019) Novel nanocomposite film modified electrode based on poly(brilliant cresyl blue)-deep eutectic solvent/carbon nanotubes and its biosensing applications. Electrochim Acta 317:766–777

Ding M, Zhou Y, Liang X, Zou H, Wang Z, Wang M, Ma J (2016) An electrochemical sensor based on graphene/poly(brilliant cresyl blue) nanocomposite for determination of epinephrine. J Electroanal Chem 763:25–31

da Silva W, Ghica ME, Brett CMA (2019) Choline oxidase inhibition biosensor based on poly (brilliant cresyl blue)–deep eutectic solvent/carbon nanotube modified electrode for dichlorvos organophosphorus pesticide. Sens Actuat B-Chem 298:126862

Barsan MM, Pifferi V, Falciola L, Brett CMA (2016) New CNT/poly (brilliant green) and CNT/poly (3, 4-ethylenedioxythiophene) based electrochemical enzyme biosensors. Anal Chim Acta 927:35–45

da Silva W, Ghica ME, Brett CMA (2020) Biotoxic trace metal ion detection by enzymatic inhibition of a glucose biosensor based on a poly (brilliant green)–deep eutectic solvent/carbon nanotube modified electrode. Talanta 208:120427

He S, He P, Zhang X, Zhang X, Li C, Dong F, Leia H, Liu D (2017) Poly (bromocresol green)/carbon quantum dots modified electrode for the simultaneous electrochemical determination of guanine and adenine. J Electroanal Chem 806:158–165

Shrestha S, Mascarenhas RJ, D’Souza OJ, Satpati AK, Mekhalif Z, Dhason A, Martis P (2016) Amperometric sensor based on multi-walled carbon nanotube and poly (bromocresol purple) modified carbon paste electrode for the sensitive determination of L-tyrosine in food and biological samples. J Electroanal Chem 778:32–40

Hosu O, Barsan MM, Cristea C, Săndulescu R, Brett CMA (2017) Nanocomposites based on carbon nanotubes and redox-active polymers synthesized in a deep eutectic solvent as a new electrochemical sensing platform. Microchim Acta 184(10):3919–3927

Gorle DB, Kulandainathan MA (2016) Electrochemical sensing of dopamine at the surface of a dopamine grafted graphene oxide/poly(methylene blue) composite modified electrode. RSC Adv 6(24):19982–19991

Barsan MM, Toledo CT, Brett CMA (2015) New electrode architectures based on poly(methylene green) and functionalized carbon nanotubes: characterization and application to detection of acetaminophen and pyridoxine. J Electroanal Chem 736:8–15

Lin KC, Syu JJ, Chen SM (2015) A hybrid nanocomposite of poly(neutral red) and hemoglobin codeposited on multi-walled carbon nanotubes for determination of hydrogen peroxide. Int J Electrochem Sci 10:6886–6899

Shervedani RK, Amini A (2015) Preparation of graphene/Nile blue nanocomposite: application for oxygen reduction reaction and biosensing. Electrochim Acta 173:354–363

Yang S, Ding S, Li L, Sun Q, Yang J, Cao Q (2017) Hydrogen peroxide biosensor based on graphene-toluidine blue/HRP-poly (toluidine blue). Int J Electrochem Sci 12:10838–10849

Khan AAP, Khan A, Alam MM, Asiri AM, Uddin J, Rahman MM (2019) SDBS-functionalized MWCNT/poly (o-toluidine) nanowires modified glassy carbon electrode as a selective sensing platform for Ce3+ in real samples. J Mol Liq 279:392–399

Wang F, Gong W, Wang L, Chen Z (2015) Enhanced amperometric response of a glucose oxidase and horseradish peroxidase based bienzyme glucose biosensor modified with a film of polymerized toluidine blue containing reduced graphene oxide. Microchim Acta 182(11–12):1949–1956

Dai J, Deng D, Yuan Y, Zhang J, Deng F, He S (2016) Amperometric nitrite sensor based on a glassy carbon electrode modified with multi-walled carbon nanotubes and poly (toluidine blue). Microchim Acta 183(5):1553–1561

Palakollu VN, Karpoormath R (2018) Enhanced electrochemical sensing of dopamine based on carboxylic acid functionalized multi-walled carbon nanotubes/poly (toluidine blue) composite. Synth Met 245:87–95

Li X, Kan X (2019) A boronic acid carbon nanodots/poly (thionine) sensing platform for the accurate and reliable detection of NADH. Bioelectrochem 130:107344

Ghica ME, Ferreira GM, Brett CMA (2015) Poly (thionine)-carbon nanotube modified carbon film electrodes and application to the simultaneous determination of acetaminophen and dipyrone. J Solid State Electrochem 19(9):2869–2881

Pandey SK, Sachan S, Singh SK (2019) Electrochemically reduced graphene oxide modified with electrodeposited thionine and horseradish peroxidase for hydrogen peroxide sensing and inhibitive measurement of chromium. Mater Sci Technol 2(3):676–686

Liu Y, Song N, Ma Z, Zhou K, Gan Z, Gao Y, Tang S, Chen C (2019) Synthesis of a poly (N-methylthionine)/reduced graphene oxide nanocomposite for the detection of hydroquinone. Mater Chem Phys 223:548–556

Dalkıran B, Fernandes IPG, David M, Brett CMA (2020) Electrochemical synthesis and characterization of poly(thionine)-deep eutectic solvent/carbon nanotube–modified electrodes and application to electrochemical sensing. Microchim Acta 187(11):1–11

Mittal G, Dhand V, Rhee KY, Park SJ, Lee WR (2015) A review on carbon nanotubes and graphene as fillers in reinforced polymer nanocomposites. J Ind Eng Chem 21:11–25

Esumi K, Ishigami M, Nakajima A, Sawada K, Honda H (1996) Chemical treatment of carbon nanotubes. Carbon 34:279–281

Ghica ME, Brett CMA (2010) The influence of carbon nanotubes and polyazine redox mediators on the performance of amperometric enzyme biosensors. Microchim Acta 170:257–265

Narang J, Malhotra N, Singhal C, Bhatia R, Kathuria V, Jain M (2017) Graphene nanoflakes on transparent glass electrode sensor for electrochemical sensing of anti-diabetic drug. Bioproc Biosystems Eng 40(4):537–548

Iijima S (2002) Carbon nanotubes: past, present, and future. Phys B Condens Matter 323(1–4):1–5

Zaporotskova IV, Boroznina NP, Parkhomenko YN, Kozhitov LV (2016) Carbon nanotubes: sensor properties. Mod Electron Mater 2(4):95–105

Ke Q, Wang J (2016) Graphene-based materials for supercapacitor electrodes–a review. J Mater 2(1):37–54

Suvarnaphaet P, Pechprasarn S (2017) Graphene-based materials for biosensors: a review. Sensors 17(10):2161

Salavagione HJ, Díez-Pascual AM, Lázaro E, Vera S, Gómez-Fatou MA (2014) Chemical sensors based on polymer composites with carbon nanotubes and graphene: the role of the polymer. J Mater Chem A 2(35):14289–14328

Shareena TPD, McShan D, Dasmahapatra AK, Tchounwou PB (2018) A review on graphene-based nanomaterials in biomedical applications and risks in environment and health. Nano-Micro Lett 10(3):53

Li H, Kang Z, Liu Y, Lee ST (2012) Carbon nanodots: synthesis, properties and applications. J Mater Chem 22(46):24230–24253

Xu XY, Ray R, Gu YL, Ploehn HJ, Gearheart L, Raker K, Scrivens WA (2014) Electrophoretic analysis and purification of fluorescent single-walled carbon nanotube fragments. J Am Chem Soc 126:12736–12737

Bairagi PK, Verma N (2018) Electrochemically deposited dendritic poly (methyl orange) nanofilm on metal-carbon-polymer nanocomposite: a novel non-enzymatic electrochemical biosensor for cholesterol. J Electroanal Chem 814:134–143

Pandey I, Bairagi PK, Verma N (2018) Electrochemically grown polymethylene blue nanofilm on copper-carbon nanofiber nanocomposite: an electrochemical sensor for creatinine. Sens Actuat B-Chem 277:562–570

Tomé LIN, Brett CMA (2019) Polymer/iron oxide nanoparticle modified glassy carbon electrodes for the enhanced detection of epinephrine. Electroanal 31(4):704–710

Liu T, Luo Y, Wang W, Kong L, Zhu J, Tan L (2015) Non-enzymatic detection of hydrogen peroxide based on Fenton-type reaction on poly(azure A)-chitosan/Cu modified electrode. Electrochim Acta 182:742–750

Liu T, Luo Y, Zhu J, Kong L, Wang W, Tan L (2016) Non-enzymatic detection of glucose using poly (azure A)-nickel modified glassy carbon electrode. Talanta 156:134–140

Jimenez-Perez R, Gonzalez-Rodriguez J, González-Sánchez MI, Gómez-Monedero B, Valero E (2019) Highly sensitive H2O2 sensor based on poly (azure A)-platinum nanoparticles deposited on activated screen printed carbon electrodes. Sens Actuat B-Chem 298:126878

Ahammad AS, Shaikh AA, Jessy NJ, Akter T, Al Mamun A, Bakshi PK (2015) Hydrogen peroxide biosensor based on the immobilization of horseradish peroxidase onto a gold nanoparticles-adsorbed poly (brilliant cresyl blue) film. J Electrochem Soc 162(3):B52–B56

Sangeetha NS, Narayanan SS (2019) Amperometric H2O2 sensor based on gold nanoparticles/poly(celestine blue) nanohybrid film. SN Appl Sci 1(7):732

Koyun O, Sahin Y (2018) Voltammetric determination of nitrite with gold nanoparticles/poly (methylene blue)-modified pencil graphite electrode: application in food and water samples. Ionics 24(10):3187–3197

Saritha D, Gupta VK, Reddy AVB, Agarwal S, Moniruzzaman M, Anitha K, Madhavi G (2019) Development of a simple, selective, stable and ultrasensitive poly (safranine/nano NiO) modified carbon paste electrode for selective detection of rutin in buckwheat and green tea samples. Int J Electrochem Sci 14:10093–10110

Chai R, Kan X (2019) Au-polythionine nanocomposites: a novel mediator for bisphenol A dual-signal assay based on imprinted electrochemical sensor. Anal Bioanal Chem 411(17):3839–3847

Huang Q, Zhao Z, Nie D, Jiang K, Guo W, Fan K, Zhang Z, Meng J, Wu Y, Han Z (2019) Molecularly imprinted poly (thionine)-based electrochemical sensing platform for fast and selective ultratrace determination of patulin. Anal Chem 91(6):4116–4123

Yang S, Bai C, Teng Y, Zhang J, Peng J, Fang Z, Xu W (2019) Study of horseradish peroxidase and hydrogen peroxide bi-analyte sensor with boronate affinity-based molecularly imprinted film. Can J Chem 97(12):833–839

Huang J, Xu W, Gong Y, Weng S, Lin X (2016) Selective and reliable electrochemical sensor based on polythionine/AuNPs composites for epinephrine detection in serum. Int J Electrochem Sci 11(10):8193–8203

Chen B, Zhang Y, Lin L, Chen H, Zhao M (2020) Au nanoparticles@ metal organic framework/polythionine loaded with molecularly imprinted polymer sensor: preparation, characterization, and electrochemical detection of tyrosine. J Electroanal Chem 863:114052

Zhao C, Jiang Z, Cai X, Lin L, Lin X, Weng S (2015) Ultrasensitive and reliable dopamine sensor based on polythionine/AuNPs composites. J Electroanal Chem 748:16–22

da Silva W, Queiroz AC, Brett CMA (2020) Nanostructured poly(phenazine)/Fe2O3 nanoparticle film modified electrodes formed by electropolymerization in ethaline-deep eutectic solvent. Microscopic and electrochemical characterization. Electrochim Acta:347–136284

da Silva W, Queiroz AC, Brett CMA (2020) Poly (methylene green)-Ethaline deep eutectic solvent/Fe2O3 nanoparticle modified electrode electrochemical sensor for the antibiotic dapsone. Sens Actuat B-Chem 128747

Dalkiran B, Brett CMA (2021) A novel nanostructured poly(thionine)-deep eutectic solvent/CuO nanoparticle film modified disposable pencil graphite electrode for determination of acetaminophen in the presence of ascorbic acid. Anal Bioanal Chem 413:1149–1157

Zeng S, Yong KT, Roy I, Dinh XQ, Yu X, Luan F (2011) A review on functionalized gold nanoparticles for biosensing applications. Plasmonics 6(3):491–506

El-Zahry MR, Ali MF (2019) Enhancement effect of reduced graphene oxide and silver nanocomposite supported on poly brilliant blue platform for ultra-trace voltammetric analysis of rosuvastatin in tablets and human plasma. RSC Adv 9(13):7136–7146

Bollella P, Sharma S, Cass AEG, Antiochia R (2019) Microneedle-based biosensor for minimally-invasive lactate detection. Biosens Bioelectron 123:152–159

Topçu E, Dağcı K, Alanyalıoğlu M (2016) Free-standing graphene/poly (methylene blue)/AgNPs composite paper for electrochemical sensing of NADH. Electroanal 28(9):2058–2069

Bollella P, Sharma S, Cass AEG, Antiochia R (2019) Minimally-invasive microneedle-based biosensor array for simultaneous lactate and glucose monitoring in artificial interstitial fluid. Electroanal 31(2):374–382

Sahin M, Ayranci E (2015) Electrooxidation of NADH on modified screen-printed electrodes: effects of conducting polymer and nanomaterials. Electrochim Acta 166:261–270

Devi CL, Narayanan SS (2019) Poly(amido amine) dendrimer/silver nanoparticles/multi-walled carbon nanotubes/poly (neutral red)-modified electrode for electrochemical determination of paracetamol. Ionics 25(5):2323–2335

Bilgi M, Ayranci E (2018) Development of amperometric biosensors using screen-printed carbon electrodes modified with conducting polymer and nanomaterials for the analysis of ethanol, methanol and their mixtures. J Electroanal Chem 823:588–592

Mazar FM, Alijanianzadeh M, Molaeirad A, Heydari P (2017) Development of novel glucose oxidase immobilization on graphene/gold nanoparticles/poly neutral red modified electrode. Process Biochem 56:71–80

Chang Z, Gao Z (2018) Study of the enzyme-free glucose biosensor based on Ni2+@ poly (neutral red) hybrid nanocomposites (Ni2+@PNR HN)/MWCNTs/Nafion modified electrode. Int J Electrochem Sci 13:1754–1772

George JM, Antony A, Mathew B (2018) Metal oxide nanoparticles in electrochemical sensing and biosensing: a review. Microchim Acta 185(7):358

Zhang H, Han J, Yang B (2010) Structural fabrication and functional modulation of nanoparticle–polymer composites. Adv Funct Mater 20(10):1533–1550

Ravi Shankaran D, Uehara N, Kato T (2003) A metal dispersed sol-gel biocomposite amperometric glucose biosensor. Biosens Bioelectron 18:721–728

Dalkiran B, Erden PE, Kiliç E (2017) Amperometric biosensors based on carboxylated multiwalled carbon nanotubes-metal oxide nanoparticles-7, 7, 8, 8-tetracyanoquinodimethane composite for the determination of xanthine. Talanta 167:286–295

Ran G, Chen X, Xia Y (2017) Electrochemical detection of serotonin based on a poly (bromocresol green) film and Fe3O4 nanoparticles in a chitosan matrix. RSC Adv 7(4):1847–1851

Tomé LIN, Baião V, da Silva W, Brett CMA (2018) Deep eutectic solvents for the production and application of new materials. Appl Mater Today 10:30–50

Abad-Gil L, Procopio JR, Brett CMA (2021) Binary and ternary deep eutectic solvent mixtures: influence on methylene blue electropolymerisation. Electrochem Commun 124:106967

Acknowledgements

B. Dalkiran thankfully acknowledges the Scientific and Technological Research Council of Turkey (TUBITAK 2219) for a postdoctoral fellowship.

Funding

The authors thank Fundação para a Ciência e a Tecnologia (FCT), Portugal, project PTDC/QEQ-QAN/2201/2014, in the framework of Project 3599-PPCDT, co-financed by the European Community Fund FEDER), and CEMMPRE, project UIDB/EMS/00285/2020 by FEDER funds through the program COMPETE – Programa Operacional Factores de Competitividade, and by national funds through FCT.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Dalkiran, B., Brett, C.M.A. Polyphenazine and polytriphenylmethane redox polymer/nanomaterial–based electrochemical sensors and biosensors: a review. Microchim Acta 188, 178 (2021). https://doi.org/10.1007/s00604-021-04821-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00604-021-04821-1