Abstract

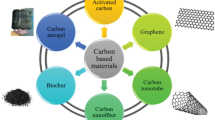

This review (with 168 refs) summarizes the progress that has been made on the field of microextraction of heavy metal ions using carbonaceous materials. Following an introduction into the features of such materials, we discuss the various kinds of sorption-based microextraction techniques (like solid phase extraction, micro solid phase extraction, solid phase microextraction, magnetic solid phase extraction, and dispersive solid phase extraction). The next section covers specific methods based on the use of carbon-based adsorbents (with subsections on uses of carbon nanotubes, graphene, fullerenes, activated carbon, carbon nanohorns, carbon nanofibers, graphitic carbon nitride, and their composites). The concluding section addresses current challenges, and gives an outlook on potential future trends.

Schematic of the variety of applications of carbonaceous sorbents in sorptive extraction methods including SPE, SPME, SBSE, DSPE, μSPE, D-μSPE, and MSPE for the extraction and enrichment of different heavy metals.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Heavy metal ions are released into the environment through different sources mainly including agricultural and industrial activities [1]. Some metal ions such as copper, zinc, and iron are vital for a healthy life at trace amounts; however, some other (e.g. Cd, Hg, As, and Pb) are considered very toxic and harmful even at trace levels of concentration [2]. Consequently, the development of promising techniques for the analysis of heavy metal ions is of great concern.

Various methods have been introduced and applied for the extraction of heavy metals from real matrices [3,4,5,6]. As conventional pretreatment techniques are time, reagents, and sample consuming, it has been tried to develop miniaturized analytical methods to minimize the consumption of reagents and energy. For instance, automation of pretreatment process, development of greener microextraction methods, and use of microwave and ultrasound radiation can be helpful to achieve this goal. Sorptive-based extraction methods are among the most successfull-employed methods for the enrichment of heavy metals from different complicated matrices.

As the type or nature of the sorbent is considered among the most critical factors that can influence the efficiency of the extraction procedure, it is important to use an appropriate material for the enrichment of the target metal ion [7, 8]. Lately, carbonaceous adsorbents and their hybrids with other nanoparticles have aroused considerable attraction in sorptive-based pre-concentration methods for the determination and analysis of hazardous metal ions. These sorbents show several notable properties including high sorption capacity, ease of surface modification, outstanding electrical/chemical and thermal properties [9, 10].

This review presents and highlights the recent applications (since 2010) of various classes of carbon-based compounds (namely activated carbon (AC), carbon nanotubes (CNTs), graphene (G), graphene oxide (GO), reduced graphene oxide (rGO), carbon nanohorns (CNHs), carbon nanofibers (CNFs), graphitic carbon nitride, and fullerenes) for the separation and pre-concentration of various heavy metals in the environmental, food, and biological samples. This review also emphasizes the current trends and developments in the synthesis and modification process of these sorbents in the sorptive-based techniques.

Different sorptive-based extraction techniques

Although a tremendous improvement has been occurred in modern analytical instruments, pretreatment methods are still commonly used to improve limits of detection (LODs) and reduce the matrix effect in the determination of heavy metals [11]. Normally, several factors like the type of analyte, the extraction procedure, and the extracting phase (either solvent or sorbent) should be taken into account before choosing a pretreatment technique [11]. Among numerous sampling methods, extraction and pre-concentration of analytes using sorptive-based enrichment techniques have been widely utilized for the potential analysis of various chemicals from several complicated matrices [12, 13]. The general principle in sorptive-based pretreatment techniques is that analytes are interacted with the extraction phase or sorbent and separated from the sample media. Then the sorbent is isolated (using centrifugation, filtration or external magnet) from the sample solution and the retained analytes are eluted from the sorptive phase for further instrumental analysis (Fig. 1).

Solid phase extraction (SPE) was first introduced in the 1970s to lessen the consumption of a large amount of toxic organic solvents in liquid-liquid extraction (LLE). SPE is still utilized as one of the most profitable choices for analyte pre-concentration in analytical chemistry [14]. In SPE, the solutes are adsorbed onto the solid sorbent, isolated from the interferences and enriched. The type of the adsorbent depends on not only the analyte of interest but also the interaction of the sorbent and the analyte. Accordingly, an appropriate sorbent can enormously enhance the efficiency of the extraction process. Various benefits involving low-cost, simplicity, small volume of organic solvents, and compatibility with many analytical instruments are associated with the SPE [12, 14].

In 1990, the miniaturization in solid phase extraction resulted in the development of solid phase microextraction (SPME) [15] and it has continued to date. The fundamental aims of miniaturization include reduction of the consumption of samples, chemicals, solvents, sorbents, as well as the extraction and sampling tools [11]. In SPME, the analytes of interest are extracted into the sorptive phase, which is coated on the surface of fused silica fiber (and/or stainless steel wire) or placed inside the needle-like device [16, 17]. It is worth mentioning that the stability, nature as well as the thickness of the coating sorbent can affect the efficiency of the pre-concentration procedure in SPME. The enriched target chemicals can be analyzed by either gas chromatography (GC) or liquid chromatography (LC) after thermal and solvent desorption, respectively. SPME is a cost-effective, and environmentally friendly pretreatment method.

In 1999, stir bar sorptive extraction (SBSE) was first applied as a new generation of miniaturized sorptive-based extraction technique [18]. An SBSE device is composed of a coated magnetic stir bar with a suitable sorbent (typically polydimethylsiloxane (PDMS)) which is placed inside the glass jacket. The magnetic bar is then exposed to the solution containing the analytes (either in the direct or headspace modes) for a certain duration. Afterward, the adsorbate is back-extracted from the sorptive phase using thermal desorption (TD) or solvent elution [19]. Depending on the nature of the target analyte and the sample matrix, different sorptive materials can be utilized in SBSE. For instance, metal-organic frameworks (MOFs), moleulary-imprinted polymers (MIPs), and carbonaceous material are among the most common sorptive phases in SBSE [20,21,22]. In comparison with SPME, the larger quantity of the sorptive phase in SBSE leads to lower limits of detection (LODs) and higher extraction recoveries [19].

Dispersive solid phase extraction (DSPE) is another form of SPE in which the adsorbent is exposed to the analytes via dispersion process to provide a large surface area and high sorption capacity. The following analysis of the analytes can be performed after isolation of the sorbent using centrifugation process [23]. DSPE possess several benefits including short equilibrium time, no need for conditioning stage, and high extraction recovery. Micro solid phase extraction (μSPE) and dispersive micro solid phase extraction (D-μSPE) are two other miniaturized forms of sorptive-based pretreatment methods. In both of these methods, the smaller quantity of sorbent is used compared to SPE and DSPE [23]. Until today, carbon-based sorbents have been continuously applied for the enrichment of heavy metals from diverse real samples using DSPE and D-μSPE [24,25,26].

Magnetic solid phase extraction (MSPE) is another alternative to general SPE in which an external magnet is used for the retrieval of the magnetic adsorbent from the aqueous sample. The extraction procedure can be performed by either functionalized magnetic nanoparticles (MNPs) or their composites with other materials such as CNTs, G, and GO [27]. The elimination of centrifugation and/or filtration step is the most notable superiority of this method that leads to the simplicity and rapidity of the enrichment process.

Carbon-based adsorbents and their characterization techniques

Contemporary trends in the development of sorptive-based enrichment methods have led to the synthesis and application of diverse range of solid materials (e.g. ion-imprinted polymers (IIPs), MOFs, CNTs, G, GO, metal, and metal oxide nanoparticles) for the enrichment of hazardous metals [28,29,30,31]. Several remarkable properties of carbonaceous sorbents mainly involving high sorption capacity, possibility for surface modification, reasonable extraction efficiency, and good conductivity make them be favorable among chemists and environmentalists for the isolation of harmful contaminants [32].

The elemental, structural, and chemical composition of carbon-based sorbents can be determined using diverse techniques including X-ray diffraction (XRD), scanning electron microscopy, energy dispersive X-ray spectroscopy (EDX), and Fourier transfers infrared spectroscopy. SEM allows the determination of the morphology of the prepared sorbent. In addition, SEM can confirm structural changes that may happen on the surface of the sorbent due to some phenomenon such as functionalization of the surface and adsorption/desorption of the analyte onto the surface of the adsorbent [33].

FT-IR is a proper technique to detect the present functionality of the prepared solid sorbent. For instance, the IR spectra can represent the incorporation of the diverse functional groups such as hydroxyl, amino, carboxyl, and carbonyl onto the surface of the modified carbonaceous materials.

In addition, the elemental analysis of the synthesized sorbent can be performed by EDX. Moreover, X-ray photoelectron spectroscopy (XPS) and XRD can confirm the chemical composition and crystal structure of the sorbent [33].

Moreover, the specific surface area of the applied sorbent is usually determined by the adsorption of N2 on the surface of the sorbent at 77 K [33, 34]. The Brunauer–Emmett–Teller (BET) and Barrett–Joyner–Halenda (BJH) theories aim to determine the surface area (m2 g−1) and the adsorption cumulative pore volumes (cm3 g−1) of the adsorbent, respectively. This section focuses on the several categories of carbon-based substances, their physicochemical properties, preparation, and modification methods in sorptive-based pretreatment area.

Activated carbon

Activated carbon (AC) is classified as a carbon-based material composed of graphite crystallites possesses heterogeneous and irregular surface. Chemical treatment or pyrolysis of materials like nutshells, wood, and coal leads to the production of AC. Several factors such as synthesis procedure and the kind of materials used for synthesis were found to affect the surface structure of activated carbon. Various functional groups (e.g. quinone, carboxyl, hydroxyl, and carbonyl) can be attached to the surface of AC through gas and liquid phase oxidation. However, oxidation can decrease the surface of AC [35].

The presence of functional acidic molecules in the surface of activated carbon is beneficial for the extraction and removal of metal ions. However, the heterogeneous surface of AC may reduce the reproducibility of this sorbent. Moreover the hydrophobic structure of activated carbon restricts the interaction of inorganic analytes (metal ions) with this sorbent and results in the increase of the adsorption time. Therefore, the surface of AC can be modified using different chelating agents such as 8-Hydroxyquinoline, diarylazobisphenol, and pyrocatechol violet (Fig. 2). The modification can enhance not only the selectivity but also the adsorption ability of this sorbent toward target heavy metal ions [36]. The adsorption efficiency of AC depends on pH, temperature, salt concentration, as well as interferences concentration; therefore, these factors should be controlled to achieve reasonable sorption capacity [37].

In 2010, a column-based SPE was performed using modified AC with 2-((2-aminoethylamino)methyl)phenol (AMP) for the enrichment of three metal ions (Fe3+, Cu2+, and Pb2+) followed by sensitive analysis using ICP-OES [36]. For this purpose, the adsorbed impurities on the surface of the AC were removed using HCl solution. Next, the COOH groups were added to the surface of the sorbent by interacting (at 60 °C for 5 h) with HNO3 solution (5 mol L−1). Then, 4.5 mg AC-COOH was interacted with 100 mL of ethylenediamine (EDA) under heating and stirring. The subsequent addition of N,N-dicyclohexylcarbodiimide (DCC) was lead to the production of AC-EDA. The AC-EDA was subsequently used for the preparation of AC-AMP using salicylaldehyde and sodium borohydride as the main precursors. Finally, an appropriate quantity of the synthesized sorbent was used to pack a polytetrafluoroethylene column. The influence of different parameters (e.g. pH, elution conditions, sorbent quantity, and flow rate) was then investigated to reach an optimum pre-concentration condition. High adsorption capacities (12.1–67.1 mg g−1) and large pre-concentration factors (50–100) are obtained for the analysis of the target metal ions in both water and biological matrices. In the same research work, modified activated carbon with 4-(8-hydroxyquinoline-azo)benzamidine (HQAB) was used as a solid adsorbent for the analysis of lead ions in environmental water samples [38]. Chemical modification of the AC surface with HQAB can improve the sorption capacity (53.58 mg g−1) and selectivity of the sorbent due to the presence of nitrogen and oxygen atoms in the structure of the ligand. The main advantages of these two reported methods are the reusability of the sorbents (up to 10 cycles for both) and large sorption capacity.

In 2012, a composite of gold nanoparticles (AuNPs) with AC and bis(4-methoxy salicylaldehyde)-1,2-phenylenediamine (BMSAPD) was reported [39] as a solid sorbent for the enrichment of Pb2+, Zn2+, Ni2+, Cu2+, Co2+ and Fe2+ from corundum sativa, olive, limon, and onion samples. The presence of AuNPs on the surface of AC allows the further modification of AC surface with the complexing agent. In addition, conjugation of AuNPs with AC leads to the enhancement of the sorbent selectivity toward the metal ions. The composite (AU-NP-AC-BMSAPD) provided trace analysis of the analytes (LODs: 1.4–2.6 μg L−1) with large sorption capacity (31.5–37.4 mg g−1) prior to FAAS analysis. The method combines the advantages of using AC and gold nanoparticles in the extraction procedure. However, desorption of heavy metals with a large volume of the eluent (6 mL of nitric acid 4 mol L−1) from the surface of adsorbent can be considered as a demerit of the procedure.

Lately, Mogolodi Dimpe et al. [34] prepared a novel composite of activated carbon with magnetic nanoparticles and manganese oxide nanoparticles for the following dispersive magnetic solid phase extraction of several toxic heavy metals (e.g. Sn, Ti, Ta, Sb, Mo, Hf, Zr, W, Ge, Nb, Hf, Te). The presence of MnO2 in the composite structure increases the affinity of the AC large surface area for the adsorption of target metals in water samples. The results were fitted into both Langmuir and Freundlich isotherm models; however, Langmuir model gave higher r2 value (0.997). The main objective of miniaturization in separation science is to reduce the amount of reagents, time, and sample tools. However, adsorption of analytes with large amount of sorbent (125 mg) compared to the conventional SPE can be considered as a disadvantage of this research work. On the other hand, this microextraction method revealed good analytical figures of merit. The low LODs (0.0004–0.02 μg L−1), high pre-concentration factors (PF: 396–920) and reasonable precision (RSD < 5%) proved the applicability of the sorbent for analysis of metal ions in the environmental water samples. Recent applications of AC in sorptive-based extraction methods for the enrichment of heavy metal ions are presented in Table 1. According to the Table, modified AC with different chelating agents have been used for the efficient enrichment of a variety of metal ions. This sorbent provides low limits of detection and high sorption capacity. Moreover, among diverse types of analytical instruments, FAAS and ICP have been the most common ones for determination of the target metals. Compared to other carbon-based sorbents, AC is cheap and more available. However, this adsorbent composed of larger carbon particles that are irregular in shape.

Graphitized carbon black

Graphitized carbon black (GCB) is a carbonaceous substance that has been used in SPE procedure for the first time in the 1980s. GCB can be produced by heating of carbon black at high temperature (about 2700–3000 °C) [40]. According to Corcia et al., [41] acidic compounds can be strongly adsorbed on the surface of graphitized carbon black due to the presence of some oxygenated groups such as quinones. The irreversible binding of target analytes onto the surface of the GCB can restrict the application of this sorbent in sorptive-based extraction techniques. To avoid this phenomenon, the sorbent can be treated by the solution of ascorbic acid in order to decrease the number of quinones groups on the surface of the GCB [40, 41].

Porous graphitized carbon (PGC) is another form of graphitized carbon possessing extremely homogeneous crystalline surface. The 2-D structure of PGC consists of sp2-hybridized carbon atoms. The impregnation of silica with phenol-formaldehyde mixture followed by polymerization and carbonization at 1000 °C leads to the production of PGC. Then, the silica can be removed by the subsequent treatment in a concentrated solution of KOH or NaOH [40, 42]. Both GCB and PGC can be employed as sorbents for the isolation and enrichment of heavy metals in sorptive-based pretreatment methods, however, no research article has reported since 2010.

Carbon nanotubes

In 1991, Iijima discovered an allotrope of carbon named carbon nanotubes [43]. These substances are cylindrical in shape with a diameter of about several nanometers. Based on the number of graphene layers in the tubular structure of CNTs, these materials are classified into two groups: single-walled carbon nanotubes (SWCNTs) and multi-walled carbon nanotubes (MWCNTs) [10].

Chemical vapor deposition, arc-discharge, and laser ablation are among the most typical synthesis procedures for the preparation of CNTs. Chemical vapor deposition is the most reliable method that leads to the high-scale production of pure CNTs. While laser ablation is frequently used for the synthesis of CNTs on a laboratory scale [35, 44].

Generally, non-covalent interactions including π-π interaction, van der Waals forces, and hydrophilic interactions are responsible for the adsorption of analytes onto the surface of CNTs. Carbon nanotubes can be oxidized through the interaction with several oxidizing agents (like sulfuric acid, nitric acid, and potassium permanganate) [10]. Oxidized CNTs are polar and can be easily dispersed into the aqueous media. The oxygenated functional groups on the surface of CNTs can interact with metal ions and lead to the efficient extraction of these analytes from complicated matrices [45].

Although SWCNTs have a larger surface area in comparison with MWCNTs, they have found lower applications in sorptive-based extraction techniques. The more complex synthesis process and resistance to functionalization and oxidation are the most important factors that confine the applications of SWCNTs in SPE methods [44].

In contrast to graphene-based sorbents, the inter walls of CNTs are not available for the analytes adsorption. Therefore, the main adsorption process is taken place on the outer surface of CNTs. In addition, the synthesis procedure for the preparation of graphene-based materials is easier than that one for the CNTs. In other words, no purification stages and complex instruments are needed for the production of graphene-based materials [45]. To date many toxic heavy metal ions have been separated and concentrated from different matrices (e.g. food, biological, and environmental samples) using CNTs as sorbent (Table 2).

In 2010, Ozcan et al. [46] packed an SPE column with MWCNTs for the subsequent enrichment of several heavy metals (Cu2+, Fe3+, Mn2+, and Pb2+) from the plant, water and food samples. The packed column was successfully applied for the extraction of the target metal ions with low LODs ranged from 3 to 8 μg L−1.

In another example, a composite of MWCNTs and magnetic nanoparticles were prepared and employed as an efficient sorbent for the magnetic solid phase extraction of Mn(II) and Pb(II) after FAAS analysis [47]. To obtain the magnetic sorbent, an appropriate quantity of MWCNT was dispersed in the solution of Fe2+/Fe3+ (1:2) under the inert atmosphere of argon. Then 20 mL of ammonium hydroxide solution was added gradually to the mixture and the reaction continued for 30 min at 50 °C. Finally, the synthesized composite was isolated using an external magnet and washed thoroughly with water and ethanol. The Fe3O4/CNT composite was used for the fast and convenient extraction of trace amounts of target metals (LODs: 0.6–1.0 μg L−1) in rice, cosmetic, and urine samples. In addition, the reported results from the analysis of the certified reference material (CRM) was in good agreement with the actual values and proved the validity of the reported method. Compared to the pure CNTs, the magnetic composites has better dispersion ability that can lead to the easier isolation of the adsorbent from the sample solution. In addition, the surface of MCNTs is prone to more modification with other nanoparticles or functional groups. Moreover, the lower volume of elution solvent (200 μL) is used for desorption of metal ions from the surface of the MCNTs. According to the article, the synthesized composite was regenerated using the mixture of acid/ethanol and reused in the SPE process eight times.

A novel sorbent was prepared by the combination of magnetic nanoparticles coated with silica shell, MWCNTs, and 1-(2-pyridylazo)-2-naphthol (PAN) for the MSPE of cobalt and lead ions from water samples before FAAS analysis [48]. The ease of surface functionalization and stability of silica makes it be a suitable shell to protect the surface of MNPs from oxidation and corrosion in the presence of oxygen and acidic solutions, respectively. To prepare magnetic CNTs, an appropriate quantity of the synthesized MNPs through co-precipitation technique was mixed with 1 g of MWCNT and heated at 60 °C in EtOH solution. Then, a solution of tetraethoxysilane (TEOS) was added to the prepared magnetic CNT (at 80 °C) to obtain SiO2@Fe3O4@MWCNT composite. After that, PAN (as chelating agent) was immobilized on the surface of the obtained composite to reach SiO2@Fe3O4@MWCNT-PAN. This sorbent was then utilized in the vortex-assisted MSPE procedure. Low LODs (0.55–1.76 μg L−1) and good precision (RSD%: 2.5–3.3) has proved the efficiency of this extraction method in the analysis of Pb and Co ions.

In one more case, modified MWCNTs with tricaprylmethylammonium chloride (Aliquat 336) was prepared as a solid material for the D-μSPE of Cr(VI) ions from water samples before total reflection X-ray fluorescence (TRXF) determination [49]. It is worth mentioning that the application of D-μSPE followed by TRXF analysis can provide the determination of the analyte of interest at trace levels of concentration. First, a solution containing 5% Aliquat 336 in methanol was interacted with MWCNTs (0.025 g) to obtain the modified CNTs with an anion exchanger. After the optimization of the extraction process, Cr6+ ions were enriched from the sample solution with high recoveries (101–108%) and low LOD (3.0 μg L−1). It should be pointed out that lower amount of the adsorbent (5 mg) and the desorption solvent (300 μL) were used in the extraction procedure which can prove the superiority of D-μSPE over the conventional SPE. In recent research work, the adsorption efficiency of U(VI) ions using MWCNTs and modified MWCNTs with 2-(5-Bromo-2-pyridylazo)-5-(diethylamino)phenol (Br-PADAP) has been compared [50]. According to the results, Br-PADAP/MWCNTs revealed faster adsorption equilibrium and high adsorption capacity compared to pure MWCNTs. This can be attributed to the presence of the chelating agent on the surface of MWCNTs. In fact, modification of CNTs surface by metal complexing agents can improve the selectivity of these sorbents toward the adsorption of metal ions.

Based on the information of Table 2, since 2010, CNTs and their different composites have been used in diverse solid phase-based pretreatment methods for the analysis of metal ions. This group of carbonaceous materials can be easily modified to facilitate the adsorption process of analytes. However, the insolubility of CNTs can cause high pressure in column-based SPE. As CNTs can provide the trace analysis (at μg L−1 and ng L−1 levels) of toxic heavy metals in different complex matrices, their application can be more extended in separation science in the future. Therefore, there is still a great room to develop more convenient modification methods and produce novel composites from CNTs.

Graphene, graphene oxide, and reduced graphene oxide

The 2-dimensional structure of graphene is produced from a single layer arrangement of carbon atoms with sp2 hybridization. Unlike other forms of carbonaceous materials (e.g. CNTs, and fullerenes), both sides of graphene planar sheets are available for analyte uptake in sample media [32, 51]. Compounds that contain aromatic rings (like pesticides, drugs, and polycyclic aromatic hydrocarbons) can be efficiently extracted using G, due to the interaction the π-electron system in the benzene ring of these substances with that one in graphene structure [32].

There are some synthesis methods for the production of graphene in both industrial and research scale. The micromechanical exfoliation of graphite can produce graphene. Although this method yields pure graphene, it is not applicable to large-scale production. Likewise, the exfoliation via ultrasonication process results in low-yield production of graphene [45]. The most promising scalable methods for preparation of G are the thermal decomposition of SiC and chemical vapor decomposition (CVD) of alcohols and hydrocarbons [45, 52]. In addition, the chemical reduction of graphene oxide using an appropriate reducing agent (e.g. hydrazine) is another typical method to produce graphene with high quality [53].

In 2012, Wang et al. [54] investigated the application of graphene as a sorbent in column-based SPE for the enrichment of the trace quantities of Pb2+ ions in different water (sea, tap, and river water) and vegetable (cucumber and tomato) samples. For this purpose, GO was synthesized through the Hummers method and then it was reduced with hydrazine to obtain graphene. An appropriate quantity of the synthesized sorbent (30 mg) was placed in an SPE column and utilized for the following enrichment of lead ions. The packed column was stable in more than 50 extraction/elution cycles and showed large sorption capacity (16.6 mg g−1). The π-π interaction between graphene and the benzene rings in the structure of the chelating agent (dithizone) can enhance the affinity of the sorbent toward the adsorption of lead ions.

The hybrid of graphene and other nanomaterials can reduce the aggregation of this sorbent in aqueous samples and improve the efficiency of the extraction procedure in SPE. For example, Yavuz et al. [55] reported a novel composite of graphene and cobalt oxide (G@Co3O4) for the pre-concentration of iron, lead, and copper ions from food and water samples. This composite showed high sorption capacity (58–78 mg g−1) and low limits of detection (LODs≤0.81 μg L−1). To prepare the composite, first cobalt oxide particles are chemically deposited onto the GO and then GO was reduced to G by adding the solution of sodium borohydride. This nano composite was applied in both batch and column-based solid phase extraction. According to the results, using low amount of G@Co3O4 (100 mg) is considered as the great advantage of the extraction process. However, based on the fast equilibrium time and large surface area of the sorbent, this amount of the composite is not low enough. Therefore, other analytical merits such as rapid kinetic (10 S), high sorption capacity and pre-concentration factor are considered among the most important characteristics of this sorbent.

In another case, Ezzodin et al., [56] found that the dispersion of magnetic graphene into the aqueous sample containing cadmium and lead ions offered an efficient extraction procedure for the enrichment of these ions prior to analysis by atomic absorption spectrometer. The conjugation of graphene with MNPs improved not only the dispersibility of the solid sorbent but also its sorption capacity. Extraction of the target analytes using 0.5 mg of magnetic graphene, which is much smaller than that in conventional SPE, is considered as the most notable feature of miniaturized SPE techniques.

Graphene oxide is a popular form of graphene-based substance among researchers in which many functional moieties containing an oxygen atom (hydroxyl, carboxyl, epoxide, and carbonyl) are incorporated. The addition of such groups make this sorbent be more hydrophilic in character [9]. In addition, the presence of functional groups in GO is responsible for electrical and hydrogen bonding interactions with metals and organic analytes. Likewise, modification of the GO surface is more possible due to the presence of polar oxygenated groups [9]. For instance, the aggregation of GO particles can be restricted by attachment of different nanomaterials such as SiO2, MNPs, and TiO2. On the other hand, the electrical and mechanical properties of GO is less than graphene due to the existence of many oxygen atoms in the structure of this sorbent [45, 57, 58].

The most typical procedure for the synthesis of GO is based on the oxidation of graphite via Hummers method. In this method, graphene oxide is produced by the gradual addition of potassium permanganate to the solution containing graphite, sodium nitrite, and sulfuric acid. The reaction is proceeded at 308 K for 2 h following the addition of hydrogen peroxide to produce the yellow product [59]. Despite the remarkable properties of graphene and graphene oxide in sorptive-based extraction methods, the softness of these sorbents can cause high pressure in column-based SPE and lead to the loss of the adsorbent [14]. In one case, the combination of GO with ethylenediamine (EDA) was utilized as a low-cost adsorbent for the simultaneous enrichment of several toxic heavy metals from water samples via D-μSPE [60]. Due to the presence of nitrogen heteroatoms in the structure of GO/EDA, no more chelating agent was used in the extraction process. According to the results, GO/EDA sorbent demonstrated the LODs in the range of 0.06–0.1 μg L−1.

Magnetic graphene oxide is a composite of GO that can be prepared through co-precipitation procedure [61] and be utilized as an efficient sorbent with high sorption capacity in MSPE. As an example, Seidi et al., [62] investigated the magnetic DSPE through immobilization of polythiophene (PTh) on the surface of MGO for the determination of Hg in seafood samples. Similar to other previously published research articles, magnetic GO was synthesized through co-precipitation technique and then thiophene was polymerized on the surface of the MGO. As mercury is considered as a soft acid, it can interact with the sulfur atoms of PTh and consequently can be isolated from the sample media. In addition, the presence of PTh can improve not only the sorption capacity but also the stability of the sorbent against oxidative reagents. Regarding the optimum experimental conditions and using the experimental design methodology a concentration range of 1–85 μg L−1 with LOD and RSD of 0.025 μg L−1 and 4.0%, respectively, were reported. In the same case, a composite of MGO with polyaniline (MGO@PANI) was synthesized as a novel sorbent for the per-concentration of toxic Cr6+ ions at trace concentration levels [63]. GO was synthesized by the Hummers method with slight modification. To this end, graphite was added to the cold mixture of sulfuric and phosphoric acids followed by addition of KMnO4 and hydrogen peroxide solutions. Next, MGO@PANI was prepared using several precursors including MGO, cetyltrimethylammonium bromide (CTAB), aniline, and Na2S2O8. The conversion process between two forms of polyaniline (emeraldine salt (ES) and emeraldine base (EB)) and the available forms of chromium ion depend on the pH value. At a pH of 5.6, Cr2O72− is the main form and it can interact with ES form of PANI and consequently can be extracted from the sample solution. Therefore, 5.6 was selected as an optimum pH to reach a maximum extraction efficiency. At more basic and acidic pHs, there is an adsorption competition between chromium ions with hydroxyl and anions of acids, respectively. The analytical performance of the extraction method for the analysis of Cr6+ included a wide linear range (0.015–0.3 μg L−1), low LOD (0.005 μg L−1), and high PF (40).

Reduced graphene oxide (rGO) is the third form of graphene, which can be synthesized via different methods including electrochemical, chemical, and thermal ones. Among these methods of preparation, chemical reduction of GO using common reducing agents (like ascorbic acid, lithium aluminum hydride, and hydrazine) is the most applicable one [52]. Like G and GO, reduced graphene oxide has been used as an extracting sorbent for the isolation and enrichment of metal ions in different samples. As an example, rGO was synthesized by heating the mixture containing GO, N2H4, and ammonia at 95 °C. Then, rGO was utilized as an adsorbent in a batch procedure for the determination of zinc ions in onion, potato, orange, and rock samples after FAAS analysis [64]. rGO was applied in 5 successive adsorption/desorption cycles by keeping it’s analytical performance. In other example, rGO was added to the structure of a soluble eggshell membrane protein (SEP) (rGO-SEP) and used as a new bio sorbent for the anodic stripping voltammetry (ASV) determination of Hg2+ in the concentration range of 0.50 to 80 μg L−1 [65]. rGO distributed uniformly into the porous structure of SEP and provided efficient adsorption and elution of mercury on the surface of the sorbent. To prove the adsorption ability of the prepared rGO-SEP in the SPE method, the efficiency of this composite was compared with SEP and rGO in the same experimental conditions. According to the reported results, the recovery of rGO-SEP was more than other two sorbents in the extraction process. It was attributed to the flexible structure of SEP that leads to more distribution and less aggregation of rGO. The column-based SPE revealed large sorption capacity (77 mg g−1) and low LOD (0.14 μg L−1) for the determination of mercury in water samples.

Moreover, a solid phase extraction method was reported by Aghagoli et al., [66] who employed a composite of molybdenum disulfide (MoS2) and rGO for the separation and enrichment of two heavy metal ions (Ni2+ and Pb2+) from both water and biological samples. The negatively charged surface of MoS2 can interact with the π-electron system in the structure of rGO to form a composite (MoS2@rGO) with high adsorption capacity. The composite was used in batch SPE and revealed high adsorption capacity (294–322 mg g−1) and low LODs (0.21–0.71 μg L−1) in the proposed extraction procedure. These great analytical features can prove the benefit of modification of rGO with MoS2 to reach an efficient extraction process. The applications of graphene-based sorbents for the extraction and enrichment of diverse heavy metals are covered in Table 3. Several notable merits including ease of modification, availability of both sides for the adsorption process, and simple synthesis process make graphene-based materials be superior sorbents in solid phase extraction. Low LODs and high sorption capacity obtained for the analysis of hazardous metal ions can prove these outstanding features of G, Go, and rGO. Compared to CNTs and AC, graphene-based materials are more applicable for metal extraction. It can be attributed to the larger surface area and the presence of oxygen containing groups on the surface of this class of sorbents.

Fullerenes

Fullerenes are buckyball carbon-based materials in which carbon atoms are attached to form penta- or hexagonal rings. Fullerenes consist of different isomers and homologous series from the most popular ones (e.g. C60 and C70) to the larger ones (e.g. C240 and C540) [44]. Fullerenes can be produced using several methods (such as laser ablation of carbon graphite, heating of carbon rods in vacuum and oxidative combustion of the mixture of benzene and argon) in laboratory. However, formation of some by-products like carbon-rich sot and poly aromatic hydrocarbons can decrease the purity of the main product. Therefore, separation techniques such as liquid chromatography or supercritical fluid chromatography should be applied to purify the produced fullerenes [67].

Fullerenes are known for their hydrophobic structure, large surface area, as well as ease of modification. The hydrophobicity of fullerenes makes them useful sorbents for the extraction of metal complexes with low polarity [1]. For instance, the low polar complexes of ammonium pyrolidine dithiocarbamate (APDC) and diethyldithiocarbamate (DDTC) with some heavy metal ions like Cd, Co, Cu, and Pb can be adsorbed onto the surface of fullerenes and be extracted from sample media [1]. In comparison with C18, C60 provides more selectivity toward the adsorption of metal ions due to the larger surface area and higher interstitial volume [67].

Several applications of fullerenes as sorbent for the isolation and pre-concentration of heavy metal ions have been reported before 2010 [68, 69]. The low aggregation tendency of fullerenes in both aqueous and organic solvents make them be potential sorbents in D-μSPE and DSPE. However, the low solubility of fullerenes can restrict their applications as coating materials in SPME [70].

Carbon nanofibers

Carbon nanofibers (CNFs) are cylindrical nanomaterials composed of graphene layers with a length of about 100 μm and diameters of around 600–200 nm [71]. The large surface area (up to 1877 m2 g−1) of CNFs makes them appropriate sorbents in solid phase-based extraction techniques. In addition, due to large dimensions, CNFs have lower tendency to aggregate in comparison to CNTs and G. Different functional moieties such as COOH, OH, and CO can be attached to the surface of CNFs to enhance their sorption capacity. CNFs can also be utilized as efficient coating layers in SPME due to the high chemical and thermal stability. Furthermore, high surface area of CNFs (up to 1870 m2 g−1) can provide the efficient enrichment of contaminants from real samples [72]. The fiber coated CNFs can be reused in several extraction cycles without losing its efficiency and morphology [73].

Among different techniques, (e.g. phase separation, drawing, and self-assembly) electrospinning is the most common technique for the fabrication of CNFs. In this method, nanofibers are produced from a viscoelastic solution (such as polyacrylonitrile (PAN)) via a repulsive electrostatic force [71]. The electrospun nanofibers can be used as a solid sorbent for the pre-concentration of different analytes from the sample solution.

Carbon nanohorns

Carbon nanohorns (CNHs) are another group of carbon-based nano materials that have been applied as a sorbent in sorptive-based enrichment methods. The carbon cage of these substances is made up of sp2-hybridized carbon atoms [44, 71]. Compared to CNTs, CNHs can be prepared in large quantity at room temperature. In addition, no hazardous metal catalysts and acid treatment are needed for their synthesis process. Laser ablation, arc discharge, and Joule heating are among the typical preparation techniques that have been applied for the production of CNHs. The surface of CNHs can be modified through chemical modification. As an example, oxygen-containing groups and organic molecules can be attached to the surface and sidewalls of CNHs via covalent and non-covalent interactions. In addition, several functional moieties such as biomolecules, thiols, amines, and alcohols can be added to the oxidized surface of CNHs to produce more hybrid adsorbents [74]. Then modified CNHs can be successfully used in solid phase-based treatment procedures.

Although carbon nanohorns have been used less than graphene-based sorbents and CNTs in sorptive-based enrichment methods, the potential application of this group of carbonaceous materials can be enormously exploited in pretreatment methods.

Graphitic carbon nitride

Graphitic carbon nitride (g-C3N4) is a stable form of carbon nitride materials with 2D structure composed of tri-s-triazine units that are linked by amine groups. g-C3N4 has unique properties including wonderful catalytic activity, chemical stability, ease of surface modification, and outstanding thermal and optical properties [75]. Among diverse synthetic methods (such as solvothermal method, chemical vapor deposition (CVD), thermal decomposition, and solid-state reaction), thermal decomposition is the most applied one for preparation of g-C3N4. In this technique, some nitrogen-rich substances (e.g. urea, cyanimide, thiourea, and melamine) are used in the synthesis process [76,77,78]. Several factors such as the type of nitrogen-containing reagents, pH of the sample solution, and temperature can influence the structure of the produced g-C3N4 via thermal decomposition technique [75].

The presence of nitrogen-containing groups (including –NH2, -NH, and = N-) in the structure of g-C3N4 make this sorbent a suitable candidate for the enrichment of metal ions. In addition, the delocalized electron system of g-C3N4 can interact with either organic or inorganic analytes [75]. On the other hand, the polar carbon-nitrogen bonds in the structure of g-C3N4 can decrease the aromaticity of this sorbent compared to graphene. Moreover, the hydrogen bonds that are responsible for the connection of linear graphitic carbon nitride molecules are weaker than the covalent bonds in the structure of graphene. Consequently, g-C3N4 has better dispersibility in a sample solution. The surface of g-C3N4 can be modified using several techniques like a soft/hard template, oxidation, and protonation to improve the adsorption efficiency and enhance the surface area of this sorbent [75].

Lately, Fahimirad et al. [79] reported the application of a composite of g-C3N4 with MNPs and ethylenediamine in magnetic D-μSPE of Cd(II) and Pb(II) ions with recoveries more than 99%. To produce g-C3N4, melamine was heated up to 520 °C for about 4 h. Next, appropriate quantities of magnetic SnFe2O4 particles and g-C3N4 were mixed and calcinated at 400 °C. After that, a solution of N-[3-(trimethoxysilyl) propyl] ethylenediamine (TPED) was added to the g-C3N4- SnFe2O4 in toluene at 110 °C in the presence of N2 atmosphere. The nano composite was then characterized using several techniques such as SEM, EDX, and FT-IR to confirm the structure. It is worth mentioning that this nano composite was prepared from low-cost and non-toxic chemicals. The sorbent was applied in the extraction procedure and the influence of different parameters on the extraction efficiency was investigated by experimental design. According to the results the lower quantity of the prepared adsorbent and less amount of the elution solvent were used in the enrichment process that made this technique more environmentally friendly.

Conclusions and remarks

Typically, the analysis of metal ions is done using analytical instruments such as FAAS, GFAAS, ETAAS, and ICP with different detectors (e.g. ICP-OES, ICP-AES, and ICP-MS). However, not all these instruments can detect the trace amounts of toxic metals directly in complex samples. Consequently, the development of efficient pretreatment techniques for the isolation of these inorganic pollutants from their matrices is important prior to instrumental analysis. The aim of this review is to give an overview of several carbonaceous sorbents and cover the recent applications of these materials in sorptive-based pretreatment methods (like SPE, SPME, DSPE, MSPE, and D-μSPE) for the environmental, food, and bio analysis of these target contaminants.

Carbonaceous sorbents and their composites have several outstanding features including chemical and thermal stability, large sorption capacity, the possibility of functionalization, wonderful optical and electronic properties, and large surface area. These outstanding characteristics make carbonaceous materials potential candidates in sorptive-based extraction methods for the enrichment of toxic metal ions. Among different carbon-based sorbents, graphene and carbon nanotubes have found more applications in sorptive-based pretreatment techniques due to the ease of preparation and functionalization. Therefore, since 2010 a great number of research articles have been published about the applications of these two class of sorbents in pretreatment of metal ions.

Although the number, of research papers that have used CNFs, fullerenes, CNHs, g-C3N4, and GCB in sorptive-based pretreatment methods is lower than graphene-based materials and CNTs, these sorbents offer some advantages in the extraction process. As an example, the large dimensions of CNFs can prevent the aggregation of this sorbent in SPE procedure and enhance the extraction efficiency without further modification. In addition, CNFs can be produced in large quantities via electrospinning. Moreover, the presence of several nitrogen-containing groups and the delocalized electron system in the structure of g-C3N4 make this sorbent be attractive in the enrichment of both organics and inorganics from sample solution.

Finally, carbon-based adsorbents have many superiorities over the conventional sorbents; however, the possible drawbacks of these adsorbents should not be ignored. For example, it is still important to develop carbonaceous sorbents with higher selectivity for the extraction of metal ions prior to analytical detection. Therefore, new modification methods are still required to diversify the surface of these materials and consequently enhance the sorption capacity and selectivity of the sorbenst. In addition, carbonaceous sorbents may cause some environmental contamination; therefore, recovery of these materials from sample solution is of great concern. Furthermore, it is important to develop novel synthesis procedures in which more environmentally friendly reagents are used for the preparation of different carbonaceous materials to reduce the hazardous impacts of toxic chemicals on both humans and the environment and consequently follow the rules of green chemistry.

Abbreviations

- AFS:

-

Hydride generation-atomic fluorescence spectrometer

- AMP:

-

2-((2-aminoethylamino)methyl)phenol

- ANS:

-

1-amino-2-naphthol-4-sulfonate

- APDC:

-

Ammonium pyrrolidine dithiocarbamate

- ASV:

-

Anodic stripping voltammetry

- AuNPs:

-

Gold nanoparticles

- BMSAPD:

-

Bis(4-methoxy salicylaldehyde)-1,2-phenylenediamine

- CRM:

-

Certified reference material

- DCC:

-

N,N-dicyclohexylcarbodiimide

- DI-SPME:

-

Direct immersion-solid phase microextraction

- DMG:

-

Dimethylglyoxime

- DPASV:

-

Differential pulse anodic stripping voltammetry

- EAAS:

-

Electrothermal atomic absorption spectrometry

- EBB:

-

Eriochrome blue black

- EDA:

-

Ethylenediamine

- EDXRF:

-

Energy-dispersive X-ray fluorescence spectrometry

- ES:

-

Emeraldine salt

- EB:

-

Emeraldine base

- FI-CV-AAS:

-

Flow injection-cold vapor-atomic absorption spectrometry

- FI-SCGD-AES:

-

Solution-cathode glow discharge-atomic emission spectrometry

- g-C3N4 :

-

Graphitic carbon nitride

- GFAAS:

-

Graphite furnace atomic absorption spectrometry

- GO-SBA-15:

-

Silica-grafted graphene oxide

- HF-SPME:

-

Hollow fiber-solid phase microextraction

- HG-AMPES:

-

Hydride generation-microwave plasma atomic emission spectrometry

- HG-DC-AFS:

-

Hydride generation-double channel atomic fluorescence spectrometry

- HPLC:

-

High performance liquid chromatography

- HQAB:

-

4-(8-hydroxyquinoline-azo)benzamidine

- ICP-AES:

-

Inductively coupled plasma-atomic emission spectroscopy

- IL:

-

Ionic liquid

- LIF:

-

Laser-induced fluorescence

- MPANI@GO:

-

Fe3O4@SiO2@polyaniline–graphene oxide

- MSPE:

-

Magnetic dispersive solid phase extraction

- MS-FAAS:

-

Micro sampling flame atomic absorption spectrometry

- NaDDTC:

-

Sodium diethyldithiocarbamate

- PAN:

-

1-(2-pyridylazo)-2-naphthol

- PAN-imp-ACC:

-

1-(2-Pyridylazo)-2-naphthol impregnated activated carbon cloth

- PANI:

-

Polyaniline

- PEI:

-

Polyethylenimine

- Phen@GO:

-

5-amino-1,10-phenanthroline

- PPy:

-

Polypyrrole

- 2-PTSC:

-

Pyridinecarboxaldehyde thiosemicarbazone

- REEs:

-

Rare earth elements

- SA-D-μSPE:

-

Syringe-assisted dispersive micro solid phase extraction

- SEP:

-

Soluble eggshell membrane protein

- TEOS:

-

Tetraethoxysilane

- TETA:

-

Triethylenetetramine

- TPED:

-

N-[3-(trimethoxysilyl) propyl] ethylenediamine

- TXRF:

-

Total-reflection X-ray fluorescence spectrometry

- USA-IL-LDMME:

-

Ultrasound-assisted, ionic liquid linked, dual-magnetic multiwall carbon nanotube microextraction

- WDXRF:

-

Wavelength-dispersive X-ray fluorescence analysis

- XRF:

-

X-ray fluorescence spectrometry

References

Wanekaya AK (2011) Applications of nanoscale carbon-based materials in heavy metal sensing and detection. Analyst 136:4383–4391

Lu F, Astruc D (2018) Nanomaterials for removal of toxic elements from water. Coord Chem Rev 356:147–164

Peng G, He Q, Zhou G, Li Y, Su X, Liu M, Fan L (2015) Determination of heavy metals in water samples using dual-cloud point extraction coupled with inductively coupled plasma mass spectrometry. Anal Methods 7:6732–6739

Sorouraddin SM, Farajzadeh MA, Okhravi T (2017) Cyclohexylamine as extraction solvent and chelating agent in extraction and preconcentration of some heavy metals in aqueous samples based on heat-induced homogeneous liquid-liquid extraction. Talanta 175:359–365

Hu B, He M, Chen B, Xia L (2013) Liquid phase microextraction for the analysis of trace elements and their speciation. Spectrochim Acta Part B 86:14–30

La Colla NS, Domini CE, Marcovecchio JE, Botté SE (2015) Latest approaches on green chemistry preconcentration methods for trace metal determination in seawater–a review. J Environ Manag 151:44–55

Smith SC, Rodrigues DF (2015) Carbon-based nanomaterials for removal of chemical and biological contaminants from water: a review of mechanisms and applications. Carbon 91:122–143

Habila MA, Alothman ZA, El-Toni AM, Al-Tamrah SA, Soylak M, Labis JP (2017) Carbon-coated Fe 3 O 4 nanoparticles with surface amido groups for magnetic solid phase extraction of Cr(III), co(II), cd(II), Zn(II) and Pb(II) prior to their quantitation by ICP-MS. Microchim Acta 184:2645–2651

Duru I, Ege D, Kamali AR (2016) Graphene oxides for removal of heavy and precious metals from wastewater. J Mater Sci 51:6097–6116

Yu G, Lu Y, Guo J, Patel M, Bafana A, Wang X, Qiu B, Jeffryes C, Wei S, Guo Z (2018) Carbon nanotubes, graphene, and their derivatives for heavy metal removal. Adv Compos Hybrid Mater 1:56–78

Tang S, Zhang H, Lee HK (2015) Advances in sample extraction. Anal Chem 88:228–249

Ahmadi M, Elmongy H, Madrakian T, Abdel-Rehim M (2017) Nanomaterials as sorbents for sample preparation in bioanalysis: a review. Anal Chim Acta 958:1–21

Hashemi B, Zohrabi P, Dehdashtian S (2018) Application of green solvents as sorbent modifiers in sorptive-based extraction techniques for extraction of environmental pollutants. Trends Anal Chem 109:50–61

Hemmati M, Rajabi M, Asghari A (2018) Magnetic nanoparticle based solid-phase extraction of heavy metal ions: a review on recent advances. Microchim Acta 185(3):160–192

Arthur CL, Pawliszyn J (1990) Solid phase microextraction with thermal desorption using fused silica optical fibers. Anal Chem 62:2145–2148

Souza Silva ÉA, Jiang R, Rodríguez Lafuente A, Gionfriddo E, Pawliszyn J (2015) A critical review of the state of the art of solid-phase microextraction of complex matrices I. environmental analysis. TrAC. Trends Anal Chem 71:224–235

Souza-Silva ÉA, Reyes-Garcés N, Gómez-Ríos GA, Boyacı E, Bojko B, Pawliszyn J (2015) A critical review of the state of the art of solid-phase microextraction of complex matrices III. Bioanalytical and clinical applications. Trends Anal Chem 71:249–264

Baltussen E, Sandra P, David F, Cramers C (1999) Stir bar sorptive extraction (SBSE), a novel extraction technique for aqueous samples: theory and principles. J Microcolumn Sep 11:737–747

Nogueira JMF (2015) Stir-bar sorptive extraction: 15 years making sample preparation more environment-friendly. TrAC Trends Anal Chem 71:214–223

Zhang N, Hu B (2012) Cadmium(II) imprinted 3-mercaptopropyltrimethoxysilane coated stir bar for selective extraction of trace cadmium from environmental water samples followed by inductively coupled plasma mass spectrometry detection. Anal Chim Acta 723:54–60

Xiao Z, He M, Chen B, Hu B (2016) Polydimethylsiloxane/metal-organic frameworks coated stir bar sorptive extraction coupled to gas chromatography-flame photometric detection for the determination of organophosphorus pesticides in environmental water samples. Talanta 156:126–133

Hu C, Chen B, He M, Hu B (2013) Amino modified multi-walled carbon nanotubes/polydimethylsiloxane coated stir bar sorptive extraction coupled to high performance liquid chromatography-ultraviolet detection for the determination of phenols in environmental samples. J Chromatogr A 1300:165–172

Khezeli T, Daneshfar A (2017) Development of dispersive micro-solid phase extraction based on micro and nano sorbents. Trends Anal Chem 89:99–118

Krawczyk M, Jeszka-Skowron M (2016) Multiwalled carbon nanotubes as solid sorbent in dispersive micro solid-phase extraction for the sequential determination of cadmium and lead in water samples. Microchem J 126:296–301

Feist B (2016) Selective dispersive micro solid-phase extraction using oxidized multiwalled carbon nanotubes modified with 1,10-phenanthroline for preconcentration of lead ions. Food Chem 209:37–42

Kocot K, Sitko R (2014) Trace and ultratrace determination of heavy metal ions by energy-dispersive X-ray fluorescence spectrometry using graphene as solid sorbent in dispersive micro solid-phase extraction. Spectrochim Acta Part B 94:7–13

Speltini A, Sturini M, Maraschi F, Profumo A (2016) Recent trends in the application of the newest carbonaceous materials for magnetic solid-phase extraction of environmental pollutants. Trends Environ Anal Chem 10:11–23

Zhang Z, Li J, Song X, Ma J, Chen L (2014) Hg2+ ion-imprinted polymers sorbents based on dithizone–Hg2+ chelation for mercury speciation analysis in environmental and biological samples. RSC Adv 4:46444–46453

Wang Y, Chen H, Tang J, Ye G, Ge H, Hu X (2015) Preparation of magnetic metal organic frameworks adsorbent modified with mercapto groups for the extraction and analysis of lead in food samples by flame atomic absorption spectrometry. Food Chem 181:191–197

Méndez JÁ, García JB, Crecente RMP, Martín SG, Latorre CH (2011) A new flow injection preconcentration method based on multiwalled carbon nanotubes for the ETA-AAS determination of cd in urine. Talanta 85:2361–2367

Pourjavid MR, Sehat AA, Arabieh M, Yousefi SR, Hosseini MH, Rezaee M (2014) Column solid phase extraction and flame atomic absorption spectrometric determination of manganese(II) and iron(III) ions in water, food and biological samples using 3-(1-methyl-1H-pyrrol-2-yl)-1H-pyrazole-5-carboxylic acid on synthesized graphene oxide. Mater Sci Eng C 35:370–378

de Toffoli AL, Maciel EVS, Fumes BH, Lanças FM (2018) The role of graphene-based sorbents in modern sample preparation techniques. J Sep Sci 41:288–302

Ibarra IS, Rodriguez JA, Galán-Vidal CA, Cepeda A, Miranda JM (2015) Magnetic solid phase extraction applied to food analysis. J Chem 2015:1–13

Dimpe KM, Nyaba L, Magoda C, Ngila J, Nomngongo PN (2017) Synthesis, modification, characterization and application of AC@Fe2O3@MnO2 composite for ultrasound assisted dispersive solid phase microextraction of refractory metals in environmental samples. Chem Eng J 308:169–176

Stafiej A, Pyrzynska K (2008) Solid phase extraction of metal ions using carbon nanotubes. Microchem J 89:29–33

He Q, Hu Z, Jiang Y, Chang X, Tu Z, Zhang L (2010) Preconcentration of cu(II), Fe(III) and Pb(II) with 2-((2-aminoethylamino) methyl) phenol-functionalized activated carbon followed by ICP-OES determination. J Hazard Mater 175:710–714

Sweetman M, May S, Mebberson N, Pendleton P, Vasilev K, Plush S, Hayball J (2017) Activated carbon, carbon nanotubes and graphene: materials and composites for advanced water purification. J Carbon Res 3(2):18–46

Tian H, Chang X, Hu Z, Yang K, He Q, Zhang L, Tu Z (2010) Activated carbon modified with 4-(8-hydroxyquinoline-azo) benzamidine for selective solid-phase extraction and preconcentration of trace lead from environmental samples. Microchim Acta 171:225–232

Karimipour G, Ghaedi M, Sahraei R, Daneshfar A, Biyareh MN (2012) Modification of gold nanoparticle loaded on activated carbon with bis(4-methoxysalicylaldehyde)-1,2-phenylenediamine as new sorbent for enrichment of some metal ions. Biol Trace Elem Res 145:109–117

Pyrzynska K (2007) Application of carbon sorbents for the concentration and separation of metal ions. Anal Sci 23:631–637

Di Corcia A, Marchetti M (1991) Multiresidue method for pesticides in drinking water using a graphitized carbon black cartridge extraction and liquid chromatographic analysis. Anal Chem 63:580–585

Hennion M-C (2000) Graphitized carbons for solid-phase extraction. J Chromatogr A 885:73–95

Iijima S (1991) Synthesis of carbon nanotubes; nature publishing group. Nature 354:56–58

Płotka-Wasylka J, Szczepańska N, de la Guardia M, Namieśnik J (2016) Modern trends in solid phase extraction: new sorbent media. Trends Anal Chem 77:23–43

Perreault F, De Faria AF, Elimelech M (2015) Environmental applications of graphene-based nanomaterials. Chem Soc Rev 44:5861–5896

Ozcan SG, Satiroglu N, Soylak M (2010) Column solid phase extraction of iron(III), copper(II), manganese(II) and lead(II) ions food and water samples on multi-walled carbon nanotubes. Food Chem Toxicol 48:2401–2406

Tarigh GD, Shemirani F (2013) Magnetic multi-wall carbon nanotube nanocomposite as an adsorbent for preconcentration and determination of lead(II) and manganese(II) in various matrices. Talanta 115:744–750

Khan M, Yilmaz E, Soylak M (2016) Vortex assisted magnetic solid phase extraction of lead(II) and cobalt(II) on silica coated magnetic multiwalled carbon nanotubes impregnated with 1-(2-pyridylazo)-2-naphthol. J Mol Liq 224:639–647

Bahadir Z, Bulut V, Hidalgo M, Soylak M, Marguí E (2015) Determination of trace amounts of hexavalent chromium in drinking waters by dispersive microsolid-phase extraction using modified multiwalled carbon nanotubes combined with total reflection X-ray fluorescence spectrometry. Spectrochim Acta Part B 107:170–177

Khamirchi R, Hosseini-Bandegharaei A, Alahabadi A, Sivamani S, Rahmani-Sani A, Shahryari T, Anastopoulos I, Miri M, Tran HN (2018) Adsorption property of Br-PADAP-impregnated multiwall carbon nanotubes towards uranium and its performance in the selective separation and determination of uranium in different environmental samples. Ecotoxicol Environ Saf 150:136–143

Nouri N, Khorram P, Sereshti H (2019) Applications of three-dimensional graphenes for preconcentration, extraction, and sorption of chemical species: a review. Microchim Acta 186(4):232

Khan A, Khuda F, Elseman AM, Aly Z, Rashad MM, Wang X (2018) Innovations in graphene-based nanomaterials in the preconcentration of pharmaceuticals waste. Environ Technol Rev 7:73–94

Sitko R, Zawisza B, Malicka E (2013) Graphene as a new sorbent in analytical chemistry. Trends Anal Chem 51:33–43

Wang Y, Gao S, Zang X, Li J, Ma J (2012) Graphene-based solid-phase extraction combined with flame atomic absorption spectrometry for a sensitive determination of trace amounts of lead in environmental water and vegetable samples. Anal Chim Acta 716:112–118

Yavuz E, Tokalıoğlu Ş, Şahan H, Patat Ş (2013) A graphene/Co3O4 nanocomposite as a new adsorbent for solid phase extraction of Pb(II), cu(II) and Fe(III) ions in various samples. RSC Adv 3(46):24650–24657

Ezoddin M, Majidi B, Abdi K, Lamei N (2015) Magnetic graphene-dispersive solid-phase extraction for preconcentration and determination of lead and cadmium in dairy products and water samples. Bull Environ Contam Toxicol 95:830–835

Sreeprasad T, Berry V (2013) How do the electrical properties of graphene change with its functionalization? Small 9:341–350

Suk JW, Piner RD, An J, Ruoff RS (2010) Mechanical properties of monolayer graphene oxide. ACS Nano 4(11):6557–6564

Hummers WS Jr, Offeman RE (1958) Preparation of graphitic oxide. J Am Chem Soc 80:1339–1339

Zawisza B, Baranik A, Malicka E, Talik E, Sitko R (2016) Preconcentration of Fe(III), co(II), Ni(II), cu(II), Zn(II) and Pb(II) with ethylenediamine-modified graphene oxide. Microchim Acta 183:231–240

Wang X, Liu B, Lu Q, Qu Q (2014) Graphene-based materials: fabrication and application for adsorption in analytical chemistry. J Chromatogr A 1362:1–15

Seidi S, Fotouhi M (2017) Magnetic dispersive solid phase extraction based on polythiophene modified magnetic graphene oxide for mercury determination in seafood followed by flow-injection cold vapor atomic absorption spectrometry. Anal Methods 9:803–813

Seidi S, Majd M (2017) Polyaniline-functionalized magnetic graphene oxide for dispersive solid-phase extraction of Cr(VI) from environmental waters followed by graphite furnace atomic absorption spectrometry. J Iran Chem Soc 14:1195–1206

Bahar S, Babamiri B (2014) Determination of Zn(II) in rock and vegetable samples after acidic digestion followed by ultrasound-assisted solid-phase extraction with reduced graphene oxide as novel sorbent, in combination with flame atomic absorption spectrometry. J Iran Chem Soc 11:1039–1045

Razmi H, Musevi SJ, Mohammad-Rezaei R (2016) Solid phase extraction of mercury(II) using soluble eggshell membrane protein doped with reduced graphene oxide, and its quantitation by anodic stripping voltammetry. Microchim Acta 183:555–562

Aghagoli MJ, Shemirani F (2017) Hybrid nanosheets composed of molybdenum disulfide and reduced graphene oxide for enhanced solid phase extraction of Pb(II) and Ni(II). Microchim Acta 184:237–244

Baena JR, Gallego M, Valcarcel M (2002) Fullerenes in the analytical sciences. Trends Anal Chem 21(3):187–198

Pereira M, Pereira-Filho E, Berndt H, Arruda M (2004) Determination of cadmium and lead at low levels by using preconcentration at fullerene coupled to thermospray flame furnace atomic absorption spectrometry. Spectrochim Acta Part B 59:515–521

Munoz J, Gallego M, Valcárcel M (2004) Solid-phase extraction–gas chromatography–mass spectrometry using a fullerene sorbent for the determination of inorganic mercury(II), methylmercury(I) and ethylmercury(I) in surface waters at sub-ng/mL levels. J Chromatogr A 1055:185–190

Mehdinia A, Aziz-Zanjani MO (2013) Recent advances in nanomaterials utilized in fiber coatings for solid-phase microextraction. Trends Anal Chem 42:205–215

Zhang B-T, Zheng X, Li H-F, Lin J-M (2013) Application of carbon-based nanomaterials in sample preparation: a review. Anal Chim Acta 784:1–17

Wen Y, Chen L, Li J, Liu D, Chen L (2014) Recent advances in solid-phase sorbents for sample preparation prior to chromatographic analysis. Trends Anal Chem 59:26–41

He M, Huang L, Zhao B, Chen B, Hu B (2017) Advanced functional materials in solid phase extraction for ICP-MS determination of trace elements and their species-a review. Anal Chim Acta 973:1–24

Karousis N, Suarez-Martinez I, Ewels CP, Tagmatarchis N (2016) Structure, properties, functionalization, and applications of carbon nanohorns. Chem Rev 116(8):4850–4883

Sun Y-P, Ha W, Chen J, Qi H-Y, Shi Y-P (2016) Advances and applications of graphitic carbon nitride as sorbent in analytical chemistry for sample pretreatment: a review. Trends Anal Chem 84:12–21

Liu J, Zhang T, Wang Z, Dawson G, Chen W (2011) Simple pyrolysis of urea into graphitic carbon nitride with recyclable adsorption and photocatalytic activity. J Mater Chem 21:14398–14401

Yan H, Chen Y, Xu S (2012) Synthesis of graphitic carbon nitride by directly heating sulfuric acid treated melamine for enhanced photocatalytic H2 production from water under visible light. Int J Hydrog Energy 37:125–133

Thomas A, Fischer A, Goettmann F, Antonietti M, Müller J-O, Schlögl R, Carlsson JM (2008) Graphitic carbon nitride materials: variation of structure and morphology and their use as metal-free catalysts. J Mater Chem 18:4893–4908

Fahimirad B, Asghari A, Rajabi M (2017) Magnetic graphitic carbon nitride nanoparticles covalently modified with an ethylenediamine for dispersive solid-phase extraction of lead(II) and cadmium(II) prior to their quantitation by FAAS. Microchim Acta 184:3027–3035

Zhang L, Chang X, Li Z, He Q (2010) Selective solid-phase extraction using oxidized activated carbon modified with triethylenetetramine for preconcentration of metal ions. J Mol Struct 964:58–62

Tavakkoli N, Habibollahi S, Amini Tehrani S (2012) Modified activated carbon as solid phase extraction adsorbent for the preconcentration and determination of trace as(III) in environmental samples by graphite furnace atomic absorption spectrometry. Chin J Chem 30:665–669

Aranda PR, Colombo L, Perino E, De Vito IE, Raba J (2013) Solid-phase preconcentration and determination of mercury(II) using activated carbon in drinking water by X-ray fluorescence spectrometry. X-Ray Spectrom 42:100–104

Feist B, Mikula B (2014) Preconcentration of heavy metals on activated carbon and their determination in fruits by inductively coupled plasma optical emission spectrometry. Food Chem 147:302–306

Alothman ZA, Yilmaz E, Habila M, Soylak M (2015) Solid phase extraction of metal ions in environmental samples on 1-(2-pyridylazo)-2-naphthol impregnated activated carbon cloth. Ecotoxicol Environ Saf 112:74–79

Zhang L, Li Z, Du X, Chang X (2011) Activated carbon functionalized with 1-amino-2-naphthol-4-sulfonate as a selective solid-phase sorbent for the extraction of gold(III). Microchim Acta 174:391–398

Albishri HM, Marwani HM, Batterjee MG, Soliman EM (2017) Eriochrome blue black modified activated carbon as solid phase extractor for removal of Pb(II) ions from water samples. Arab J Chem 10:S1955–S1962

Nekouei S, Nekouei F, Canselier JP (2017) Solid-phase extraction for simultaneous separation and preconcentration of Fe(III) and Zn(II) traces using three chelatants and Ramelak bark-derived activated carbon as a new bio-sorbent. Sep Sci Technol 52:824–833

Barfi B, Rajabi M, Zadeh MM, Ghaedi M, Salavati-Niasari M, Sahraei R (2015) Extraction of ultra-traces of lead, chromium and copper using ruthenium nanoparticles loaded on activated carbon and modified with N,N-bis-(α-methylsalicylidene)-2,2-dimethylpropane-1,3-diamine. Microchim Acta 182:1187–1196

Imyim A, Daorattanachai P, Unob F (2013) Determination of cadmium, nickel, lead, and zinc in fish tissue by flame and graphite furnace atomic absorption after extraction with pyrrolidine dithiocarbamate and activated carbon. Anal Lett 46:2101–2110

Mahmoud ME, Ahmed SB, Osman MM, Abdel-Fattah TM (2015) A novel composite of nanomagnetite-immobilized-baker’s yeast on the surface of activated carbon for magnetic solid phase extraction of hg(II). Fuel 139:614–621

Mohammadi S, Afzali D, Pourtalebi D (2010) Flame atomic absorption spectrometric determination of trace amounts of lead, cadmium and nickel in different matrixes after solid phase extraction on modified multiwalled carbon nanotubes. Cent Eur J Chem 8:662–668

Soylak M, Unsal YE (2010) Chromium and iron determinations in food and herbal plant samples by atomic absorption spectrometry after solid phase extraction on single-walled carbon nanotubes (SWCNTs) disk. Food Chem Toxicol 48:1511–1515

Yang B, Gong Q, Zhao L, Sun H, Ren N, Qin J, Xu J, Yang H (2011) Preconcentration and determination of lead and cadmium in water samples with a MnO2 coated carbon nanotubes by using ETAAS. Desalination 278:65–69

Vellaichamy S, Palanivelu K (2011) Preconcentration and separation of copper, nickel and zinc in aqueous samples by flame atomic absorption spectrometry after column solid-phase extraction onto MWCNTs impregnated with D2EHPA-TOPO mixture. J Hazard Mater 185:1131–1139

Li R, Chang X, Li Z, Zang Z, Hu Z, Li D, Tu Z (2011) Multiwalled carbon nanotubes modified with 2-aminobenzothiazole modified for uniquely selective solid-phase extraction and determination of Pb(II) ion in water samples. Microchim Acta 172:269–276

Aydemir N, Tokman N, Akarsubasi AT, Baysal A, Akman S (2011) Determination of some trace elements by flame atomic absorption spectrometry after preconcentration and separation by Escherichia coli immobilized on multiwalled carbon nanotubes. Microchim Acta 175:185–191

Wu H, Wang X, Liu B, Liu Y, Li S, Lu J, Tian J, Zhao W, Yang Z (2011) Simultaneous speciation of inorganic arsenic and antimony in water samples by hydride generation-double channel atomic fluorescence spectrometry with on-line solid-phase extraction using single-walled carbon nanotubes micro-column. Spectrochim Acta B At Spectrosc 66:74–80

Hu Z-J, Cui Y, Liu S, Yuan Y, Gao H-W (2012) Optimization of ethylenediamine-grafted multiwalled carbon nanotubes for solid-phase extraction of lead cations. Environ Sci Pollut Res 19:1237–1244

Aranda PR, Perino E, Bertolino FA, Raba J, De Vito IE (2012) Solid phase extraction of chromium(VI) using Aliquat336 immobilized on a thin film of multiwall carbon nanotubes. Microchim Acta 179:235–239

Alothman ZA, Habila M, Yilmaz E, Soylak M (2012) Solid phase extraction of cd(II), Pb(II), Zn(II) and Ni(II) from food samples using multiwalled carbon nanotubes impregnated with 4-(2-thiazolylazo) resorcinol. Microchim Acta 177:397–403

Cui Y, Hu Z-J, Yang J-X, Gao H-W (2012) Novel phenyl-iminodiacetic acid grafted multiwalled carbon nanotubes for solid phase extraction of iron, copper and lead ions from aqueous medium. Microchim Acta 176:359–366

Behbahani M, Bagheri A, Amini MM, Sadeghi O, Salarian M, Najafi F, Taghizadeh M (2013) Application of multiwalled carbon nanotubes modified by diphenylcarbazide for selective solid phase extraction of ultra traces cd(II) in water samples and food products. Food Chem 141:48–53

ALqadami AA, Abdalla MA, Alothman ZA, Omer K (2013) Application of solid phase extraction on multiwalled carbon nanotubes of some heavy metal ions to analysis of skin whitening cosmetics using ICP-AES. Int J Environ Res Public Health 10:361–374

Sitko R, Gliwinska B, Zawisza B, Feist B (2013) Ultrasound-assisted solid-phase extraction using multiwalled carbon nanotubes for determination of cadmium by flame atomic absorption spectrometry. J Anal At Spectrom 28:405–410

Soleimani M, Ghahraman Afshar M, Sedghi A (2013) Amino-functionalization of multiwall carbon nanotubes and its use for solid phase extraction of mercury ions from fish sample. ISRN Nanotechnol 2013:1–9

Yilmaz E, Soylak M (2014) Solid phase extraction of cd, Pb, Ni, cu, and Zn in environmental samples on multiwalled carbon nanotubes. Environ Monit Assess 186:5461–5468

Zhou Q, Xing A, Zhao K (2014) Simultaneous determination of nickel, cobalt and mercury ions in water samples by solid phase extraction using multiwalled carbon nanotubes as adsorbent after chelating with sodium diethyldithiocarbamate prior to high performance liquid chromatography. J Chromatogr A 1360:76–81

Nabid MR, Sedghi R, Behbahani M, Arvan B, Heravi MM, Oskooie HA (2014) Application of poly 1, 8-diaminonaphthalene/multiwalled carbon nanotubes-COOH hybrid material as an efficient sorbent for trace determination of cadmium and lead ions in water samples. J Mol Recognit 27:421–428

Taghizadeh M, Asgharinezhad AA, Samkhaniany N, Tadjarodi A, Abbaszadeh A, Pooladi M (2014) Solid phase extraction of heavy metal ions based on a novel functionalized magnetic multi-walled carbon nanotube composite with the aid of experimental design methodology. Microchim Acta 181:597–605

Moghaddam FH, Taher MA, Behzadi M, Naghizadeh M (2015) Modified carbon nanotubes as a sorbent for solid-phase extraction of gold, and its determination by graphite furnace atomic absorption spectrometry. Microchim Acta 182:2123–2129

Wang L, Zhou J-B, Wang X, Wang Z-H, Zhao R-S (2016) Simultaneous determination of copper, cobalt, and mercury ions in water samples by solid-phase extraction using carbon nanotube sponges as adsorbent after chelating with sodium diethyldithiocarbamate prior to high performance liquid chromatography. Anal Bioanal Chem 408:4445–4453

Gouda AA, Al Ghannam SM (2016) Impregnated multiwalled carbon nanotubes as efficient sorbent for the solid phase extraction of trace amounts of heavy metal ions in food and water samples. Food Chem 202:409–416

Zhu X, Cui Y, Chang X, Wang H (2016) Selective solid-phase extraction and analysis of trace-level Cr(III), Fe(III), Pb(II), and Mn(II) ions in wastewater using diethylenetriamine-functionalized carbon nanotubes dispersed in graphene oxide colloids. Talanta 146:358–363

Peng G, He Q, Lu Y, Huang J, Lin J-M (2017) Flow injection microfluidic device with on-line fluorescent derivatization for the determination of Cr(III) and Cr(VI) in water samples after solid phase extraction. Anal Chim Acta 955:58–66

Wadhwa SK, Tuzen M, Kazi TG, Soylak M (2013) Graphite furnace atomic absorption spectrometric detection of vanadium in water and food samples after solid phase extraction on multiwalled carbon nanotubes. Talanta 116:205–209

Zawisza B, Skorek R, Stankiewicz G, Sitko R (2012) Carbon nanotubes as a solid sorbent for the preconcentration of Cr, Mn, Fe, co, Ni, cu, Zn and Pb prior to wavelength-dispersive X-ray fluorescence spectrometry. Talanta 99:918–923

Chen S, Zhu L, Lu D, Cheng X, Zhou X (2010) Separation and chromium speciation by single-wall carbon nanotubes microcolumn and inductively coupled plasma mass spectrometry. Microchim Acta 169:123–128

Yuan C-G, Zhang Y, Wang S, Chang A (2011) Separation and preconcentration of palladium using modified multi-walled carbon nanotubes without chelating agent. Microchim Acta 173:361–367

Sahmetlioglu E, Yilmaz E, Aktas E, Soylak M (2014) Polypyrrole/multi-walled carbon nanotube composite for the solid phase extraction of lead(II) in water samples. Talanta 119:447–451

Savio M, Parodi B, Martinez LD, Smichowski P, Gil RA (2011) On-line solid phase extraction of Ni and Pb using carbon nanotubes and modified carbon nanotubes coupled to ETAAS. Talanta 85:245–251

Gouda AA (2014) Solid-phase extraction using multiwalled carbon nanotubes and quinalizarin for preconcentration and determination of trace amounts of some heavy metals in food, water and environmental samples. Int J Environ Anal Chem 94:1210–1222

Skorek R, Zawisza B, Marguí E, Queralt I, Sitko R (2013) Dispersive micro solid-phase extraction using multiwalled carbon nanotubes for simultaneous determination of trace metal ions by energy-dispersive X-ray fluorescence spectrometry. Appl Spectrosc 67(2):204–209

Skorek R, Turek E, Zawisza B, Marguí E, Queralt I, Stempin M, Kucharski P, Sitko R (2012) Determination of selenium by X-ray fluorescence spectrometry using dispersive solid-phase microextraction with multiwalled carbon nanotubes as solid sorbent. J Anal At Spectrom 27:1688–1693

Kocot K, Zawisza B, Marguí E, Queralt I, Hidalgo M, Sitko R (2013) Dispersive micro solid-phase extraction using multiwalled carbon nanotubes combined with portable total-reflection X-ray fluorescence spectrometry for the determination of trace amounts of Pb and cd in water samples. J Anal At Spectrom 28:736–742

Barfi B, Asghari A, Rajabi M, Sabzalian S, Khanalipoor F, Behzad M (2015) Optimized syringe-assisted dispersive micro solid phase extraction coupled with microsampling flame atomic absorption spectrometry for the simple and fast determination of potentially toxic metals in fruit juice and bio-fluid samples. RSC Adv 5:31930–31941

Grijalba AC, Escudero LB, Wuilloud RG (2015) Ionic liquid-assisted multiwalled carbon nanotube-dispersive micro-solid phase extraction for sensitive determination of inorganic as species in garlic samples by electrothermal atomic absorption spectrometry. Spectrochim Acta B At Spectrosc 110:118–123

Manoochehri M, Naghibzadeh L (2017) A nanocomposite based on Dipyridylamine functionalized magnetic multiwalled carbon nanotubes for separation and Preconcentration of toxic elements in black tea leaves and drinking water. Food Anal Methods 10:1777–1786