Abstract

A polyamidoamine dendrimer was synthesized, placed on magnetite nanoparticles, and the resulting material was then employed as a fiber coating for use in solid phase microextraction of chlorophenols. The polyamidoamine was expected to be an efficient extracting medium due to the presence of multipolar groups and its inner porosity. A thin stainless steel wire was coated with the dendritic polyamidoamine polymer via electrolysis and chemical reactions. The coated fiber was investigated in terms of headspace solid phase microextraction of chlorophenols from aqueous samples followed by GC-MS quantitation. The calibration plots are linear in the 2–1000 ng⋅L−1 chlorophenol concentration ranges. The LOD values (for an S/N ratio of 3) are between 0.6 and 10 ng⋅L−1. The relative standard deviations (RSDs) for spiked distilled water samples (for n = 3) are <7% at a level of 100 ng⋅L−1. The RSDs for fiber to fiber variations at the same concentration are <9%. The method was applied to spiked tap water, well water and Caspian Sea water samples. Relative recoveries are between 80 and 97%. The method shows good repeatability, sensitivity, long operational lifetime, and the fibers are physically stable.

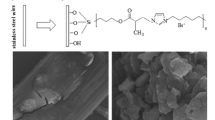

Schematic presentation of a polyamidoamine dendrimer with multipolar groups and highly inner porosity. It was placed on magnetic nanoparticles (MNP) and employed for headspace solid phase microextraction of chlorophenols.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Dendrimers are an interesting class of macromolecules with hyperbranched, homogeneous and spherical structure, with distinct properties such as multifunctional terminal surfaces and high density of accessible active sites, nanoscale size, monodispersity, host–guest potential, intensive internal porosity and moderate biocompatibility [1–4]. One interesting feature of these polymers is that their terminal surfaces can be chemically modified for any desired application. Polyamidoamine (PAMAM) dendrimers are the most common type of these materials which is due to their globular structure, imitating the three–dimensional structure of biomacromolecules, their convenient synthesis method, highly reactive primary amine terminal surfaces and good biocompatibility which make them suitable for many bio–oriented applications [4, 5]. Two major approaches have been implemented for synthesizing the desired dendrimers. In the first approach, called “divergent method”, the dendrimer grows from a central core in a stepwise manner which involves assembling monomeric modules in a radial, branch–upon–branch motif based on certain principles. In the second approach, convergent method, several dendrons are synthesized primarily and then they reacted with a multifunctional core to obtain the final product [6]. Dendrimers have found wide numbers of applications in drug delivery and medicinal applications [7–9], gene therapy [10], cancer diagnosis and therapy [11], catalysis [12], electrochemical sensors [13, 14], coatings [15], separating agents [16] and so on [17, 18] .

In the meantime, the high surface–to–volume ratio of nanostructured materials such as magnetic PAMAM provides more active sites for sorption, making an appropriate platform for efficient separation/extraction process [19].

Chlorophenols (CPs) are widely distributed in the environment due to their numerous industrial and agricultural applications [20]. Due to their toxic and carcinogenic properties, their determination has remained an important issue for environmental health. Since the concentrations of CPs in the environment are at ng⋅L−1 to μg⋅L−1 levels, their monitoring is highly important. Development of a rapid, sensitive, and convenient sample pretreatment method for their simultaneous determination is therefore essential [21, 22].

In this research, a synthesized dendritic polymer was chemically immobilized on the surface of a stainless–steel wire to be implemented as a fiber coating [23] for solid phase microextraction (SPME) of trace amounts of CPs from water samples.

Experimental

Chemicals

Ferric chloride hexahydrate, ferrous chloride tetrahydrate, ammonia (25% w/w), 3-aminopropyltriethoxysilane (APTS), methyl acrylate, salts of sodium chloride and sodium bicarbonate, hydrochloric acid, ethanol, methanol, pyridine, acetonitrile, acetone, thionyl chloride, hydrofluoric acid and chlorophenol compounds (4-chlorophenol, 2,4-dichlorophenol, ethanedial 40% (w/w) solution, sodium nitrite 2,6-dichlorophenol and 2,4,6-trichlorophenol) were supplied from Merck (www.merckmillipore.com). Acetic anhydride was purchased from Fluka (www.sigmaaldrich.com). Ethylenediamine provided from Loba Chemie (www.lobachemie.com). 4-aminophenyl acetic acid was purchased from Acros (www.acros.com). Standard solution of CPs compounds was prepared in methanol at a concentration of 1000 mg⋅L−1.

Instrumentation

The optimizing experiments were carried out by a gas chromatograph model 6820 (www.agilent.com) with a flame ionization detection system, a split/splitless injection port and a HP-5 analytical column (30 m, 0.25 mm id) with 0.25 μm film thickness (Hewlett- Packard, Palo Alto, CA, USA). The sample injection port was set on splitless mode for 4 min at 180 °C while the nitrogen carrier gas with the purity of 99.99% passed through the column at a flow rate of 2 mL⋅min−1. The temperature of detector was set at 290 °C. A gas chromatograph model HP 6890 from Hewlette Packard (HP, Palo Alto, USA) equipped with a split/splitless injection port and a HP 5973 mass–selective detector was used for the quantitation purposes and real samples analysis. The MS system was operated on electron impact (EI, 70 eV) mode. A capillary column, TRB–5MS (www.teknokroma.es) (30 m, 0.25 mm i.d.) with 0.25 μm film thickness, was used for separation of analytes. Helium gas with purity of 99.999% at a flow rate of 1 mL⋅min−1 was used as the carrier gas. The samples were injected into the GC (splitless mode) at 180 °C and the split valve was kept closed for 4 min. The temperature program of GC was started at 40 °C for 4 min, increased to 55 °C at the rate of 10 °C⋅min−1 and kept at this temperature for 2 min, then increased to 105 °C at a rate of 40 °C⋅min−1 and remained at this temperature for 2 min and finally raised to 200 °C at a rate of 40 °C⋅min−1 and remained at this temperature for 4 min. The GC-MS parameters were set at 270, 230 and 150 °C for the interface, ion source and quadrupole temperatures, respectively.

For each analyte, two ions with the highest intensities were selected for the time–scheduled selected ion monitoring (SIM) mode. Ions at m/z 128 and 170 were selected for 4-CP at tR = 12.04 min; m/z 162 and 164 for 2,4-DCP and 2,6-DCP at tR = 12.66 and 12.79 min; and m/z 196 and 198 for 2,4,6-TCP at 13.28 min. Water samples in the 19 mL glass vials with a PTFE faced septum and aluminum cap were heated in a water bath (www.thermo.com) while stirred with a Gerhardt Bonn (www.gerhardt.de) hot plate magnetic stirrer. FT-IR spectrometer model ABB Bomem MB–100 spectrometer (www.abb.com) was used for characterization and identification of PAMAM. The field emission–scanning electron microscopy (FE–SEM) images were obtained by TESCAN MIRA 3 LMU instrument (www.tescan.com).

Synthesis of magnetic PAMAM dendrimer

Synthesizing the PAMAM dendrimer was initiated by preparation of magnetic nanoparticles (MNPs) as the core moiety based on the iron salts co–precipitation method. Stoichiometric amounts of FeCl3.6H2O (5.2 g) and FeCl2.4H2O (2.0 g) were dissolved in 50 mL deaerated double distillated water at 70 °C under the nitrogen atmosphere. Then, 20 mL ammonia solution (25%) was added to the solution drop by drop with vigorous stirring. A black Fe3O4 MNPs precipitate was immediately formed and separated by the application of an external magnetic field. The produced MNPs were washed several times with double distillated water to remove all the chloride ions; then they were washed two times with methanol and dried under the nitrogen atmosphere at 45 °C. A mixture of MNPs was prepared by sonicating 2 g of dried Fe3O4 in 50 mL ethanol/water mixture (4:1) for 30 min. To functionalize the prepared MNPs, an excess amount of APTS (6 mL) was added into the mixture and kept it at 80 °C for 48 h. The amine functionalized MNPs were collected by a permanent magnet from cooled mixture and washed three times with methanol and dried under neutral atmosphere. An amount of 1.7 g of amine functionalized MNPs was dispersed in 30 mL of absolute methanol in sonication bath for 30 min. After addition of 2 mL methyl acrylate, the mixture was kept at 50 °C for one week (G0.5). Then MNPs@APTS were magnetically separated from the cooled mixture and washed 3 times with dry methanol; dried under the nitrogen atmosphere and then was suspended again in 50 mL of methanol. A volume of 3 mL ethylenediamine was added to the mixture and stirred at room temperature for a day. Then mixture was kept at 50 °C for one week. The PAMAM coated MNPs (G1) (MNP@PAMAM) was magnetically collected and then washed 3 times with absolute methanol, and dried as previously described. The synthesizing step was repeated for two more times using a 50–fold excess of methyl acrylate and a 125–fold excess of ethylenediamine with respect to the amount of amino groups. The third generation of PAMAM dendrimer (G3) is expected to be grown up on the surface of MNPs [4, 24]. The schematic steps for preparation of MNP@PAMAM dendrimer are shown in Fig. 1.

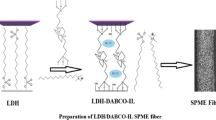

Preparation of PAMAM SPME fiber

A 2.0–cm stainless steel wire was etched by diluted hydrofluoric acid for 30 min and then washed and sonicated by acetone. The next step included primarily functionalizing the wire, involving the electrochemical reduction of 4–amino phenyl acetic acid for in situ generation of aryl diazonium cation [25, 26]. As it was previously reported, the functionalizing process proceeded by addition of sodium nitrite solution (2 mM) to 4–amino phenyl acetic acid (2 mM) in 0.05 M HCl solution under maximum stirring rate. Prior to the electrochemical functionalizing process, the solution was kept at room temperature for 5 min to ensure the completion of the reaction. Then, the wire was placed in the electrolyte solution, as the cathode, and a piece of aluminum foil was used as the anode while a constant potential of 1.5 V was applied for 15 min [27]. Then, the functionalized wire was immersed in SOCl2 for 12 h. For amidation reaction, the wire– substrate was immediately immersed in PAMAM suspension of pyridine for 6 h to chemically bond the first layer of PAMAM on the fiber. For adhesion of additional layers of PAMAM, the wire was immersed in PAMAM suspension in acetonitrile with 10 μL of 40% (w/w) solution of ethanedial as cross linker for 2 h [28, 29]. The prepared fibers were positioned in a laboratory–made SPME device for implementation of extraction process (Fig. 2). The prepared fiber was conditioned in the GC injection port under N2 stream at 150 °C for 2 h and raised to 180 °C and kept for 3 h.

Extraction procedure

After preparation of the PAMAM SPME fiber, it was used for headspace extraction of CPs from water samples. For derivatization of CPs, 3.0 g of sodium chloride, 0.2 g of sodium bicarbonate and 0.1 mL of acetic anhydride were added to 12 mL of spiked water/sample in a 19 mL vial and it was vigorously shaken until the CO2 gas formation was ceased. The vial was sealed with a PTFE–faced septum and an aluminum cap and stirred at maximum rate at 30 °C. In order to do extraction process, fiber coating was exposed to the headspace over the aqueous sample for 15 min at 30 °C. After extraction, the SPME fiber was transferred from the sample vial to the 180 °C GC injection port for 4 min.

Results and discussion

Synthesis and characterization of the PAMAM dendrimer

MNPs were chosen to be the first core due to their high surface to volume aspect ratio and magnetic property which is essential in separating the synthesized product in each steps of synthesis. Functionalizing MNPs by APTS led to the generation of amine groups on its surface, assisting the grown up of PAMAM dendrimer [30].

Fourier transform infrared spectroscopy (FTIR) is helpful to examine the synthesis process. Fig. 3a shows the FT-IR spectra regarding the two steps in one generation PAMAM synthesis on the surface of MNPs (G0.5 and G1.0, after methyl acrylate and ethylenediamine addition, respectively) and the stretching vibration of ester groups at 1744 cm−1 for G0.5 disappeared in the second step because of conversion of ester to amide groups. Also the FT-IR spectra of MNP, MNP@APTS and MNP@PAMAM (G3) are shown in Fig. 3b. The spectrum of bare MNP shows stretching vibration of Fe–O at 641 cm−1. Absorption peaks appearing at around 900–1200 cm−1 and 444 cm−1 are attributed to the Si–O–Metal, Si–OR and O–Si–O vibrations of the MNP@APTS spectrum and also the vibration peak at 1631 cm−1 shows N–H bending vibration of amino group of APTS. For MNP@PAMAM (G3), the dual peaks at 1635 and 1547 cm−1 are corresponding to amide C = O stretching and N–H bending vibrations, respectively. Absorption peaks at 2850–3000 and 3000–3600 cm−1 are attributed to the C–H and N–H stretching vibrations.

Fabrication and evaluation of the PAMAM SPME fiber coating

For fabrication of the PAMAM SPME fiber coating, the stainless steel wire was primarily functionalized by aryl diazonium layer. The primarily PAMAM dendrimer layer bonded to the substrate via intensification of the surface activity by thionyl chloride as an activating agent. The amidation reaction between PAMAM amino group and activated acyl group of diazonium layer was expected to occur. The PAMAM coating thickness was subsequently enhanced using ethanedial as a cross linker [12].

The surface characteristics of the PAMAM SPME fiber were investigated by FE–SEM. As Fig. 4a shows the stainless steel substrate demonstrates some small cavities which is due to the etching process. Figure 4b illustrates the functionalized diazonium layer is covering the cavities throughout the substrate while the formation of primarily PAMAM layers and subsequent cross–linking process are shown in Fig. 4c and 4d, respectively. Apparently, the final PAMAM dendrimer coating possess sufficient porosity, expecting to act as an appropriate candidate toward isolation of polar–oriented organic compounds.

Optimization

The extraction efficiency of the prepared coating was investigated by adapting a HS-SPME method to isolate some selected CPs from aqueous samples followed by GC–MS determination. Considering the relative volatility of acetylated chlorophenols and their adaptability for HS-SPME procedure, chlorophenols were derivatized. Initially, the cross linker volume was necessary to be optimized to find the most suitable fiber coating.

Ethanedial as a cross linker, plays a major role in increasing the PAMAM coating thickness. The effect of ethanedial on the PAMAM fiber performance was studied by its various contributions within the polymeric structure. The results demonstrates addition of ethanedial up to 10 μL led to thicker PAMAM coating and improving the extraction efficiency while, the excess amount of etanedial causes the deactivation of active sites. An amount of 10 μL of ethanedial was therefore used as the optimum quantity.

Eventually, the effects of influential parameters on the extraction and desorption efficiency including the ionic strength (A), extraction temperature (B) and time (C), desorption temperature (D) and time (E) were considered for optimization. Respective data and figures are given in the Electronic Supporting Material (Fig. 1S). We found the following experimental conditions to give the most appropriate results: a salt concentration of 25%, equivalent to 3 g of sodium chloride (A); extraction temperature of 30 °C (B); extraction time of 15 min (C); and desorption temperature of 180 °C (D) and its duration time of 4 min (E), while carry over remains negligible.

Method validation

The calibration curves show good linearity for most of the CPs with correlation coefficients ranging from 0.9935 to 0.9994. Limits of detection (LODs) and limits of quantification (LOQs) were obtained, based on the signal–to–noise ratio of 3 and 10, are in the range of 0.6 to 10.0 ng⋅L−1 and 2.0 to 30.0 ng⋅L−1, respectively. The relative standard deviation percentage (RSD%) values for intra–day, inter–day and fiber to fiber was calculated at 100 ng⋅L−1 concentration level and are less than 9% (the significant quantitative data are tabulated in Table 1). To evaluate the applicability of this method to real samples, Tehran drinking water, well and Caspian–sea waters were spiked with CPs at 100 ng⋅L−1 and analyzed under the optimized condition. The results show good relative recoveries for CPs in complex matrix such as sea water (Table 1). Also Table 2 shows a comparison between the analytical data obtained from the HS-SPME PAMAM fiber with other sorbents. The prepared PAMAM SPME fiber in comparison with other published methods shows lower LOD values and faster extraction time. The polarity of extraction media due to presence of amine functional groups leads to higher tendency for phenolic compounds. Moreover, the dendrimeric sorbent can be modified and functionalized desirably for extraction of other analytes and future purposes.

Conclusion

A new magnetic PAMAM fiber coating was synthesized and implemented to quantify traces of CPs in water samples. Possessing three–dimensional network which provides higher specific surface area, intense internal porosity and loading capacity, capability of the chemical structure of coating for contribution in hydrogen bonding and higher polarity led to the construction of a rather susceptible fiber for extracting polar–oriented organic compounds. Eventually, the chemical binding between substrate and the coating led to a chemically and thermally stable SPME fiber, while its thermal stability is not comparable with the sol-gel-based fiber coatings. In overall, the constructed dendritic SPME fiber coating exhibits appropriate extraction efficiency along with good relative recoveries for the selected CPs. The analysis of various samples such as drinking water, well and Caspian-sea waters led to low LOD and LOQ values, well below the allowable levels along with acceptable RSD%. The current SPME fiber can be used for more than 60 times at the 180 °C desorption temperature. These results confirm that the modified PAMAM dendrimer is an appropriate candidate as a SPME fiber coating for extracting polar–oriented compounds. Apparently, the dendritic polymers with plenty of flexible functional groups can be selectivity modified.Their inherent potential makes them suitable for further applications.

References

Zeng F, Zimmerman SC (1997) Dendrimers in supramolecular chemistry: from molecular recognition to self-assembly. Chem Rev 97:1681–1712

Astruc D, Boisselier E, Ornelas C (2010) Dendrimers designed for functions: from physical, photophysical, and supramolecular properties to applications in sensing, catalysis, molecular electronics, photonics, and nanomedicine. Chem Rev 110:1857–1959

Soleyman R, Adeli M (2015) Impact of dendritic polymers on nanomaterials. Polym Chem 6:10–24

Pourjavadi A, Hosseini SH, Hosseini ST, Aghayeemeibody SA (2012) Magnetic nanoparticles coated by acidic functionalized poly (amidoamine) dendrimer: effective acidic organocatalyst. Catal Commun 28:86–89

Choi Y, Thomas T, Kotlyar A, Islam MT, Baker JR Jr (2005) Synthesis and functional evaluation of DNA-assembled polyamidoamine dendrimer clusters for cancer cell-specific targeting. Chem Biol 12:35–43

Nanjwade BK, Bechra HM, Derkar GK, Manvi FV, Nanjwade VK (2009) Dendrimers: emerging polymers for drug-delivery systems. Eur J Pharm Sci 38:185–196

Khandare J, Calderón M (2015) Dendritic polymers for smart drug delivery applications. Nanoscale 7:3806–3807

Wu L, Ficker M, Christensen JB, Trohopoulos PN, Moghimi SM (2015) Dendrimers in medicine: therapeutic concepts and pharmaceutical challenges. Bioconjugate Chem 26(7):1198–1211

Sharma A, Kakkar A (2015) Designing dendrimer and miktoarm polymer based multi-tasking nanocarriers for efficient medical therapy. Molecules 20(9):16987–17015

Kobayashi A, Yokoyama Y, Osawa Y, Miura R, Mizunuma H (2016) Gene therapy for ovarian cancer using carbonyl reductase 1 DNA with a polyamidoamine dendrimer in mouse models. Cancer Gene Ther 23:24–28

Myung JH, Roengvoraphoj M, Tam KA, Ma T, Memoli VA, Dmitrovsky E, Freemantle SJ, Hong S (2015) Effective capture of circulating tumor cells from a transgenic mouse lung cancer model using dendrimer surfaces immobilized with anti-EGFR. Anal Chem 87:10096–10102

Ricciardi R, Huskens J, Verboom W (2015) Dendrimer-encapsulated Pd nanoparticles as catalysts for C–C cross-couplings in flow microreactors. Org Biomol Chem 13:4953–4959

Ning D, Zhang H, Zheng J (2014) Electrochemical sensor for sensitive determination of nitrite based on the PAMAM dendrimer-stabilized silver nanoparticles. J Electroanal Chem 18:29–33

Yin H, Zhou Y, Cui L, Liu T, Ju P, Zhu L, Ai S (2011) Sensitive voltammetric determination of rutin in pharmaceuticals, human serum, and traditional Chinese medicines using a glassy carbon electrode coated with graphene nanosheets, chitosan, and a poly (amido amine) dendrimer. Microchim Acta 173:337–345

de Jong ER, Deloch N, Knoll W, Turrin CO, Majoral J, Caminade AM, Koper I (2015) Synthesis and characterization of bifunctional dendrimers: preliminary use for the coating of gold surfaces and the proliferation of human osteoblasts (HOB). New J Chem 39:7194–7205

Kouketsu T, Duan S, Kai T, Kazama S, Yamada K (2007) PAMAM dendrimer composite membrane for CO2 separation: formation of a chitosan gutter layer. J Membr Sci 287(1):51–59

Divsar F, Nomani A, Chaloosi M, Haririan I (2009) Synthesis and characterization of gold nanocomposites with modified and intact polyamidoamine dendrimers. Microchim Acta 165:421–426

Lin Y, Dai H, Xu G, Yang T, Yang C, Tong Y, Yang Y, Chen G (2013) Enhanced luminol electrochemiluminescence triggered by an electrode functionalized with dendrimers modified with titanate nanotubes. Microchim Acta 180:563–572

Bagheri H, Roostaie A (2014) Electrospun modified silica-polyamide nanocomposite as a novel fiber coating. J Chromatogr A 1324:11–20

Fiamegos YC, Nanos CG, Pilidis GA, Stalikas CD (2003) Phase-transfer catalytic determination of phenols as methylated derivatives by gas chromatography with flame ionization and mass-selective detection. J Chromatogr A 983:215–223

Sun Y, Zhang WY, Xing J, Wang CM (2011) Solid-phase microfibers based on modified single-walled carbon nanotubes for extraction of chlorophenols and organochlorine pesticides. Microchim Acta 173:223–229

Abolghasemi MM, Yousefi V, Piryaei M (2015) Fabrication of a hierarchical dodecyl sulfate-layered double hydroxide nanocomposite on porous aluminum wire as an efficient coating for solid-phase microextraction of phenols. Microchim Acta 182:1177–1186

Aziz-Zanjani MO, Mehdinia A (2014) A review on procedures for the preparation of coatings for solid phase microextraction. Microchim Acta 181:1169–1190

Pourjavadi A, Hosseini SH, Alizadeh M, Bennett C (2014) Magnetic pH-responsive nanocarrier with long spacer length and high colloidal stability for controlled delivery of doxorubicin. Colloids Surf B: Biointerfaces 116:49–54

Breton T, Bélanger D (2008) Modification of carbon electrode with aryl groups having an aliphatic amine by electrochemical reduction of in situ generated diazonium cations. Langmuir 24:8711–8718

Marulanda J (2011) Carbon nanotubes applications on electron devices. InTech, Croatia

Bagheri H, Bayat P, Piri-Moghadam H (2013) Grafting the sol-gel based sorbents by diazonium salts: a novel approach towards unbreakable capillary microextraction. J Chromatogr A 1318:58–64

Montalbetti C, Falque V (2005) Amide bond formation and peptide coupling. Tetrahedron 61:10827–10852

Carey F, Giuliano R (2011) Organic chemistry. McGraw-Hill, New York

Bourque SC, Maltais F, Xiao W, Tardif O, Alper H, Arya P, Manzer LE (1999) Hydroformylation reactions with rhodium-complexed dendrimers on silica. J Am Chem Soc 121:3035–3038

Bagheri H, Aghakhani A, Baghernejad M, Akbarinejad A (2012) Novel polyamide-based nanofibers prepared by electrospinning technique for headspace solid-phase microextraction of phenol and chlorophenols from environmental samples. Anal Chim Acta 716:34–39

Bagheri H, Najarzadekan H, Roostaie A (2014) Electrospun polyamide-polyethylene glycol nanofibers for headspace solid-phase microextration. J Sep Sci 37:1880–1886

Abolghasemi MM, Yousefi V, Piryaei M (2015) Synthesis of carbon nanotube/layered double hydroxide nanocomposite as a novel fiber coating for the headspace solid-phase microextraction of phenols from water samples. J Sep Sci 38:1344–1350

Abolghasemi MM, Parastari S, Yousefi V (2016) A nanoporous anodized alumina wire with a nanosized hydroxyapatite coating for headspace solid-phase microextraction of phenol and chlorophenols. Microchim Acta 183:241–247

Acknowledgements

The Research Council (Grant number G940603) and Graduates School of Sharif University of Technology (SUT) are acknowledged for supporting this project.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The author(s) declare that they have no competing interests.

Electronic supplementary material

ESM 1

(DOC 253 kb)

Rights and permissions

About this article

Cite this article

Bagheri, H., Manouchehri, M. & Allahdadlalouni, M. A magnetic multifunctional dendrimeric coating on a steel fiber for solid phase microextraction of chlorophenols. Microchim Acta 184, 2201–2209 (2017). https://doi.org/10.1007/s00604-017-2220-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00604-017-2220-5