Abstract

The complex behaviours of rocks and rock masses have presented paradoxes to the rock engineer, including the fracturing of seemingly strong rock under low stress conditions, which often occurs near excavation boundaries. The extension strain criterion was presented as a fracture initiation criterion under these conditions (Stacey in Int J Rock Mech Min Sci 18:469–474, 1981). This criterion has been used successfully by some and criticised by others. In this paper, we review the literature on the extension strain criterion and present a case for the correct interpretation of the criterion and the conditions suitable for its use. We argue that the extension strain criterion can also be used to provide an indication of damage level under conditions of relatively low confining stress. We also present an augmentation of the criterion, the ultimate extension strain, which is applicable under extensional loading conditions when σ 2 is similar in magnitude to σ 1.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The complex behaviours of rocks and rock masses have, for long, presented paradoxes to the rock engineer; one of which is the fracturing of seemingly strong rock under low stress conditions (Stacey and Yathavan 2003; Stacey et al. 2007). These conditions often occur near excavation boundaries where the confining stress is low. Understanding of the phenomenon of rock fracture and failure under such conditions is important for prediction of failure around excavations and for design of rock support to inhibit or prevent instability. A simple extension strain criterion for fracture of rock arose from such conditions (Stacey 1981). In the analysis of fracturing around a deep level tunnel boring situation, a limiting tensile strain criterion was found to be successful for predicting both the extents and the orientations of fractures observed around the bored tunnel. In contrast, conventional criteria for prediction of fracture and failure were unsuccessful (Stacey and de Jongh 1977).

It is quite logical to expect that any material, even perfect “flawless” material, will fail when it is stretched (i.e. subjected to extension) beyond a certain limit, as suggested by Bridgman (1912). The extension strain criterion is correspondingly reasonable and is elegantly simple, being able to take into account the three-dimensional stress condition (automatically including the intermediate principal stress σ 2) using a single equation from elastic theory.

The extension strain criterion has been used effectively in many applications, but it has also received criticism. This paper will provide a review of both the support for, and criticism of, the criterion. It is believed that use of the criterion has been limited by misunderstanding of its meaning and applicability, and one of the aims of this paper is to rectify this with further clarification and discussion.

2 Extension Strain Criterion: A Review

The extension strain criterion (Stacey 1981) may be expressed simply as follows: fracture initiates when

where ε c is the critical value of extension strain.

It is important to note that this original statement of the criterion dealt with prediction of fracture initiation, and emphasis on the word “initiate” appeared in the original publication.

The conclusions of the original publication stated, “Since fracture is dependent on the extension strain, the criterion will be applicable in areas of low confinement which, logically, are in the vicinity of excavations in rock. It is in these locations where prediction of fracturing is often required for the purposes of support design”.

2.1 Studies Reporting Successful Use of the Extension Strain Criterion

Since its inception in 1981, several researchers have reported the successful application of the criterion under varying conditions. Early reports of successful use were, naturally, limited to Stacey and his co-workers (Waldeck 1979; Stacey 1982, 1989; Stacey and Harte 1989; Stacey et al. 2003), but the criterion has also received other support from laboratory studies, in situ studies and numerical investigations.

2.1.1 Laboratory Studies

The response of elastic–brittle rock samples to loading by conical-, wedge- and hemispherical-indenter shapes representing jackhammer bit tips was studied by Pang and Goldsmith (1990). They performed pseudo-static loading experiments using an MTS machine, and dynamic percussion on an encased circular target disc of Sierra granite. The damage pattern consisted of a crater, a crushed zone and a region of multiple minor cracks, as well as some longer fissures. They found that the extension strain criterion was able to predict both the orientation and extent of fracturing in the specimens.

Li et al. (2011) made the interesting observation that, in Brazilian tests, slabbing fractures parallel to the loading direction initiated at a critical extension strain. This critical extension strain was about equal to the maximum tensile strain of the rock, as measured by lateral strain gauges on the specimen surface when subjected to the Brazilian test. Later, the crack initiation point of the Brazilian disc was intensively investigated by Li and Wong (2013), and they concluded that the extension strain criterion appears to be promising in explaining crack initiation and propagation in the Brazilian test.

2.1.2 In Situ Studies

Alber and Heiland (2001a, b) described a pillar failure in a limestone open-pit mine. They described the recent formation of sub-vertical fractures in individual blocks within these pillars and detachment of the immediate roof of the drifts, which indicates mainly gravitational loading. An extensive laboratory testing programme and field mapping were performed to facilitate back analysis. Alber and Heiland found that applications of the Mohr–Coulomb and Hoek–Brown failure criteria were inadequate for explaining the formation of sub-vertical fractures. They stated that whilst the strength criteria do not offer a reason for failure of the pillar, the application of Stacey’s (1981) extension strain concept focused on the fracture mechanisms and offered a plausible explanation for the observed sub-vertical fractures in the rock. They prudently pointed out that as it is a fracture initiation criterion, the extension strain criterion does not offer any insight into the further development and propagation of the initial fractures.

Simmons (2011) and Simmons and Simpson (2007) investigated the occurrence of unexpected failure of bedded coal mine rock slopes. Such failures occurred on composite failure surfaces involving surfaces that were not observed in site investigations prior to failure. It was considered that such surfaces could be due to extension strain fracturing. Numerical modelling that was carried out predicted such fractures. Microseismic monitoring gave evidence that unloading by excavation initiated extensional fracturing towards the base of the highwall.

Ndlovu (2006) and Ndlovu and Stacey (2007) investigated the occurrence of guttering in a coal mine and found that the extension strain criterion was successful in predicting the onset of such guttering, in contrast with the lack of success using other more conventional criteria. Numerical analyses using the extension strain criterion predicted failure mainly at the roof–pillar contact area. The depths and widths of failure were successfully predicted. High extension strain values were predicted at the centre of the road position ahead of the coal face, indicating that fracture initiation could be taking place in the roof rock ahead of the coal face. This suggested the following mechanism of failure: on blasting, the rock that has been fractured ahead of the face due to the induced extension strains is exposed and then physically able to fail. In the process, a gutter is formed at the centre of the road.

Andersson et al. (2009) performed what was termed the Äspö pillar stability experiment. A pillar was created in a rock mass containing some water-bearing fractures where the far-field maximum principal stress was only approximately 15 % of the UCS. By using both excavation-induced and thermal-induced stresses, the pillar was brought to yielding level in a controlled manner. The stress magnitude to initiate yielding was assessed from extensive instrumentation and visual observations. The progressive yielding process was also studied. Back calculations of the observations of spalling during the heating phase indicated that the tangential stress required to initiate spalling had to exceed 0.59 UCS. Andersson et al. (2009) showed that the crack initiation stress in laboratory samples provides a reasonable, lower-bound approximation for the rock mass spalling strength in the absence of in situ data. They did, however, point out that a reliable critical extension strain from laboratory axial versus lateral strain curves was difficult to obtain and that the methodology suggested by Stacey (1981) appeared to be too conservative for the Äspö Diorite.

Nicksiar and Martin (2012) subsequently reviewed five strain-based methods for establishing the onset of cracking in laboratory compression tests and compared the results to a newly proposed lateral strain response method. They performed ten tests on Äspö Diorite, applying each of the six techniques to it. A statistical evaluation of the results showed that any of the strain methods (including that of Stacey 1981) provided statistically accurate results. The laboratory crack initiation stress obtained by Nicksiar and Martin (2012) compares well with the in situ obtained spalling initiation strength from Andersson et al. (2009).

In a longhole stoping mining operation, Louchnikov (2011) used the extension strain criterion to predict fracturing around stopes for the purposes of designing appropriate rock support. The criterion was calibrated for site-specific conditions by simple measurement of the depth and condition of fracturing in blast holes prior to blasting. Such fracturing defined the extent of the potential failure zone around the stope and, therefore, the volume of rock that required support.

2.1.3 Numerical Studies

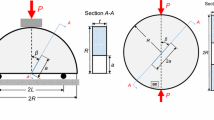

Steffanizzi et al. (2007) analysed the development of fractures in layered media with the ELFEN code (2006) using a Rankine rotating fracture model. The three layered model geometry and the final result of the model when fracture saturation occurred are shown in Fig. 1. Steffanizzi et al. (2007) pointed out that, based on the maximum principal stress distribution, it was not possible to locate where a tensile fracture will open. The extension strain distribution, however, is not uniform, and fracture initiation occurs when the extension strain that is generated exceeds a limit value that, for the particular model, is equal to 150 µε. As a fracture opens, the value of the extension strain drops, whilst increasing in the surrounding area, giving the opportunity for a new fracture to initiate. When this increase in extension strain is insufficient to reach the critical strain value, no new fracture initiates, and this explains the regular jointing patterns observed in bedded rock formations. Steffanizzi et al. (2007) concluded, “Fracture formation and spacing are controlled by extension strain localization. This is an indirect validation of Stacey’s empirical strain criterion”.

Prediction of fracturing in layered media (Steffanizzi et al. 2007)

2.2 Studies Advising Against the Use of the Extension Strain Criterion

Kwasniewski and Takahashi (2010) investigated two strain-based failure criteria for rocks. Results of experimental studies on the behaviour of fine-grained Rozbark sandstone samples under uniaxial compression, conventional triaxial compression and polyaxial compression conditions were used to verify these two proposed criteria, one of which is the extension strain criterion. They concluded that the extension strain criterion was not supported by the test results. They further pointed out that the largest extensional strain at strength failure is not constant under triaxial compression conditions, but that it assumes different values depending on the magnitude of confining pressure in conventional triaxial compression tests, or the magnitudes of the intermediate and minimum principal stresses in polyaxial compression tests. Although pointing out that the extension strain criterion does not predict the failure condition well, Kwasniewski and Takahashi (2010) conceded that it may find application in conditions of low confinement.

In their textbook on rock mechanics for tabular hard rock mines, Ryder and Jager (2002) reviewed the extension strain criterion. They presented the extension strain criterion, reformulated in terms of stress, in the form shown in Fig. 2a, and pointed out that the extension strain hypothesis predicts a halving of the strength in “extension” mode (σ 2 = σ 1), resulting from the increased lateral dilation due to the higher values of σ 2. This, they claim, is at variance with the findings of laboratory polyaxial testing in which an increase in strength is observed, whereas the extension strain criterion implies a decrease (Fig. 2b, c). This led them to conclude that, “…the extension strain hypothesis has little connection with reality, and in fact (at least in its present form) should not be used”.

These latter claims seem to be at odds with the earlier mentioned support for the extension strain criteria, indicating that further investigation and clarification are necessary.

3 Resolving the Apparent Discrepancy

Based on the empirical evidence of several authors mentioned previously, it is reasonable to assume that fractures will initiate in rock at a critical magnitude of extension strain. Further development of fracturing will occur at greater magnitudes of extension strain, provided that the confining stress conditions permit this development. At yet greater magnitudes of extension strain, failure may occur if the physical conditions allow such failure to occur. Therefore, whilst the criterion is suitable for predicting fracture initiation, it is only under suitable physical conditions that the criterion will be applicable for failure prediction. Extension fractures may form in an environment of triaxial compressive stress, but, during laboratory testing and in many field situations, there may be no direct physical evidence of such fracture development; that is, no failure appears to have occurred. When access after the fact reveals shear failure occurring, this may well be the result of subsequent damage due to other mechanisms after the initial extensional fracturing. This notion is supported by the microseismic monitoring studies, as for example, described by Martin (1993). Such fracturing may only be observed after unloading of the laboratory test specimen, as was illustrated very clearly by the early laboratory tests referred to by Bridgman (1912, 1938, 1947), in which extension fractures which formed normal to a substantial magnitude of compressive stress: “… the net stress across the plane on which the tensile break occurred was a compressive stress of 15,000 kg/cm2” (Bridgman 1947); disc fracturing in rock specimens normal to the axis was only observed when the test had been completed and the test specimen removed from the test apparatus (Bridgman 1938).

Therefore, in field conditions under confinement in a rock mass, the criterion can predict the initiation of extension fracturing even under significant compressive stress conditions. Under such conditions, it is possible that there may be no indication that any fracturing has occurred: there may be no change in the strength or deformability of the rock or rock mass to indicate any “weakening” or “failure” that might have developed. When the confining conditions are reduced or the three-dimensional stress field changed (for example, by excavation), the influence of the extension fracturing is more likely to be observed.

The mechanism of failure development is illustrated well in the descriptions of the micromechanical behaviour by Haimson and Chang (2000) and Lee and Haimson (2011). These confirm the occurrence of extension fracture development parallel to the σ 1 direction, and subsequent coalescence of such fractures to form a main fault or failure surface. In conventional triaxial testing of brittle rocks, ultimate failure usually occurs on an inclined shear plane formed by the coalescence of extension fractures. The true triaxial test results of Mogi (2007), and additional results published by Colmenares and Zoback (2002), Benz et al. (2008) and Lee and Haimson (2011), show this behaviour. Thus, under significantly confined conditions, the extension strain criterion may predict the occurrence of fractures but generally not actual failure.

From observations of rockburst ruptures by Ortlepp (1997) and the interpretation of this behaviour by Tarasov and Randolph (2011), referring to research by Reches (1999), Cox and Scholz (1988) and Reches and Lockner (1994), it is apparent that the initial formation of extension fractures (referred to in these references as tensile fractures) provides conditions that allow ultimate failure to occur by other mechanisms. The interpretation by Tarasov and Randolph (2011) is that rotation of a series of narrow slabs, formed by parallel extension fractures, results in frictionless shear failure to form the rupture surface.

In contrast with the above cases dealing with confined conditions, suitable conditions for failure due to extension fracturing are situations in which there is low confinement, such as close to the surfaces of excavations, and, in addition, where there is freedom for the fracture-defined slabs or blocks of rock to fallout. Thus, failure due to extension strain is not likely to be possible in polyaxial test equipment, even with σ 3 = zero, since the rock remains physically constrained from moving by the jacket. Hence, whilst laboratory polyaxial compressive testing can produce conditions that allow extension fractures to occur, it is unlikely to provide the conditions that would allow extension failure to occur. The physical confinement in such testing, even in the case of zero confining stress, simply will not allow extension failure to develop. Similarly, extension failure in the floor of an excavation will be inhibited compared with that in the roof (Martin 1993) even though extension fracturing may be pervasive. In contrast, in the same excavation, failure may occur in the roof or sidewalls (if unconstrained by rock support), and the loose rock may fall, for example as described by Martin (1993).

In such unconstrained conditions, the failure mechanism could be buckling of sidewalls if the σ 3 direction is sub-horizontal. If the field stress σ 3 direction is sub-vertical, it is possible that failure of the rock in the roof will occur by progressive falling-out of fragments formed by the extension fractures. This process will also occur in the floor with mechanical removal of fractured material. Similarly, in ore passes, which are usually steeply inclined, passage of the dumped rock will disturb fractured material, converting fractured rock into failed rock and allowing further fracturing to develop. Numerous cases of major growth in ore pass size have been reported, with many passes, excavated at a diameter of 3 m or less, growing, in some cases, to very large spans (for example, Minney 1990).

The extension strain criterion predicts a greater magnitude of extension strain and therefore, greater potential for failure in triaxial compression, for a constant σ 3, with increased magnitudes of σ 1 and σ 2. This is likely to be true if failure can physically occur. Further, by the same reasoning, the criterion predicts a lesser potential for failure in triaxial tension than in biaxial or uniaxial tension.

There are many reports of cases in which failure of excavations occurred at inexplicably low stresses, and such failure cannot be explained satisfactorily by strength-based criteria (Stacey 1989; Stacey and Harte 1989; Stacey and Yathavan 2003; Stacey et al. 2007). A strong case for these somewhat counter-intuitive results can be made by investigating the work performed by Dyskin et al. (1999) and Sahouryeh et al. (2002). They performed uniaxial and biaxial loading of penny-shaped cracks in brittle, clear resin specimens. Under uniaxial loading, two branches (wings) emerged from the upper and lower parts of the crack contour at about one-third of the uniaxial compressive strength (UCS) and grew in a stable manner (stepwise) upon further loading. The tensile wing cracks (Griffith 1920) grew from the original penny-shaped crack and curled inwards, wrapping around the vertical axis (σ1-axis) of the test sample (Fig. 3). These wing cracks grew to a size comparable with the original crack and could not grow sufficiently to split the sample. In contrast, the wing cracks under biaxial loading grew towards both loading axes. Both wing cracks grew extensively in all directions in the plane of loading, causing splitting of the sample (Fig. 4) under loading conditions much lower than the UCS. These failure mechanisms for the resin samples were verified using concrete (Fig. 5) and sandstone samples.

Shape of wing cracks under uniaxial loading (Sahouryeh et al. 2002)

Extensive wing crack growth causing splitting under biaxial loading (Sahouryeh et al. 2002). Arrows showing biaxial loading direction

Splitting of concrete sample under biaxial loading (Sahouryeh et al. 2002). Arrows showing biaxial loading direction

Sahouryeh et al. (2002) reported the resin to have a UCS of 140 MPa. With this information, one can plot the data from the resin test as shown in Fig. 6 (similar format to Fig. 2a). Also shown on the graph are the Mohr–Coulomb failure criterion and the extension strain criterion.

It is evident from this figure that, under these specific conditions, the extension strain criterion gives a much better prediction of failure of the sample than the Mohr–Coulomb and Hoek–Brown criteria or any other criterion that does not take into account the weakening effect of the intermediate stress.

Perhaps the most important aspect of the extension strain criterion is that it allows the prediction of a zone of fracturing, which then facilitates failure by mechanisms other than extension fracturing, for example, coalescence of extension fractures to form a continuous shear failure surface (Lee and Haimson 2011) and formation of parallel macro-fractures resulting in transverse anisotropy that could facilitate failure by a buckling mechanism. Having said this, however, the tests on brittle resin described above indicate that, under low stress confinement conditions in brittle rock, the extension strain criterion may also be successful as a failure and a damage criterion.

4 The Extension Strain Criterion as a Damage Criterion

In attempting to predict the development of rock mass damage around an excavation, it is important that the correct mechanisms of failure are taken into account. If the mechanism of failure is one of extension, for example, it is not appropriate to use a shear–stress-based criterion to predict the damage. Spalling in a massive hard rock environment is usually an example of extension fracture and failure of the rock.

Hadjiabdolmajid et al. (2002) proposed the use of a cohesion softening and friction hardening model under these circumstances. Although these models are practically useful, it is a shear model based on a Mohr criterion which does not take the influence of the intermediate principal stress into account. The Mohr theory predicts that shear fractures orientated at 45° to the major and minor principal stress axes. The reality, however, is extension fracturing occurring, orientated along the major principal stress direction.

Simple three-dimensional elastic modelling was successfully used by Louchnikov (2011) in a hard rock, longhole open stoping environment to correlate calculated extension strain magnitudes with observed extents of fracturing. Uniaxial compressive strengths determined in the laboratory for ore, footwall and hangingwall, respectively, were 170, 150 and 125 MPa. Figure 7 shows an example of physical fracturing and the corresponding extension strain distribution which formed the basis for the correlation presented in Table 1.

Based on borehole observations, Louchnikov (2011) assigned different extension strain values to different levels of extension fracture damage (Table 1).

From these data, it can be seen that an increasing degree of “failure” or damage corresponds with increased magnitudes of extension strain. The definition of such magnitudes of extension strain will depend on the rock type and will also be site dependent. The information in Table 1 is illustrated in the σ 1 − σ 2 chart in Fig. 8 again using the format used by Ryder and Jager (2002) in Fig. 2. The single solid negatively inclined lines of constant ε 3 represent the divisions between rock mass condition zones identified in Table 1. An extensional failure mechanism is not applicable to all stress states. Although the exact extent of the zone of applicability is not currently clear, the equivalent extension strain lines shown in Fig. 8 are shown with arbitrary length.

5 The Extension Strain Criterion as a Failure Criterion

The extension strain criterion was originally proposed as a fracture initiation criterion and not as a criterion for rock failure. Citing some early polyaxial testing, Ryder and Jager (2002) claim that the reduction in strength in extensional loading is at odds with reality. However, several recent publications dealing with polyaxial testing of rock, lead to new insights regarding the effect of the intermediate principal stress on the failure of rock, especially for stress states in which σ 1 is reasonably close in magnitude to σ 2, facilitating growth of fracturing in the plane of the two larger principal stresses, as described by Sahouryeh et al. (2002). The publications of Colmenares and Zoback (2002), Benz et al. (2008) and Lee and Haimson (2011) are particularly relevant in this regard, and Fig. 9 shows the interpretation by Benz et al. (2008) for several rock types.

Results from the Hoek–Brown Matsuoka–Nakai criterion. Continuous lines give calculated results for the specified σ 3 (Benz et al. 2008)

These studies all show a reduction in the strength with an increase in the intermediate stress under loading conditions in which the major and intermediate stresses are similar. This suggests that the extension strain criterion may be applied as a measure of failure in situations when the intermediate and major stress values are of similar magnitude.

Figures 10, 11, 12, 13 and 14 presents polyaxial data of failure for different rock types, interpreted from published information. The extension strain criteria applied to the failure, shown as solid blue lines, are superimposed on each of these graphs. Also shown, as dashed grey lines, are the corresponding Hoek–Brown failure criteria: the solid negatively inclined lines show the strength in the triaxial loading condition, and the horizontal lines show the Hoek–Brown failure criteria for polyaxial loading at each of the tested confining stress levels.

Polyaxial failure data for Shirahama sandstone with the polyaxial adaption of the Hoek–Brown failure criterion (Benz et al. 2008) and the extension strain criterion

Polyaxial failure data for KTB amphibolite with the polyaxial adaption of the Hoek–Brown failure criterion (Benz et al. 2008) and the extension strain criterion

Our interpretation of published data has been restricted to those rocks for which we could obtain the Young’s modulus and Poisson’s ratio from the literature and for which steep failure planes and extensional fracturing were reported. Shirahama sandstone showed consistent compaction and the formation of multiple conjugated shear fractures for confining effective pressures >60 MPa whilst brittle failure with dilatational behaviour on a unique shear fracture formed under effective confining pressures lower than 60 MPa (Takahashi et al. 2006). The data for Shirahama sandstone used in this analysis are limited to effective confining stresses less 60 MPa therefore excluding possible crushing failure under high confinement from the analysis. The parameter values used in the calculation of the envelopes in Figs. 9, 10, 11, 12 and 13 are listed in Table 2.

In contrast with the original extension strain criterion for fracture initiation, the extension strain values for failure are dependent on the stress level. Each of the individual extension strain criterion lines plotted on the graphs in Figs. 10, 11, 12, 13 and 14 has a different ε3ultimate value. This is in contradiction of the conclusions of Fujii et al. (1997). Figure 15 shows the relationship between σ 3 and ε 3ultimate for the different rocks. For all of the rock types investigated, a linear relationship between σ 3 and ε 3ultimate is a satisfactory approximation. However, the slopes and intercepts on the ε 3ultimate axis of these lines are quite different for the different rocks. Since the minor principal stress is a stabilising component working against the development of extensional damage and failure, the positive slope of these trends seems reasonable.

Although the linear relationships are different for the different rock types, there appears to be a systematic change in the slope and intercept values. To investigate this systematic change further, two parameters are defined: the slope of the σ 3 − ε 3ultimate relationship we denote as α, and the intercept value as γ.

The intercept value, γ, appears to be proportional and linearly related to the rock stiffness (Fig. 16a). As one would reasonably expect a correlation between the strength in triaxial compression and triaxial extension, one would expect the value of α to be proportional to m i . It is also reasonable to expect a higher sensitivity to the stabilising stress for rocks with larger Poisson’s ratio and a proportionality between α and Poisson’s ratio can reasonably be expected. This is also shown in Fig. 16b.

It should be noted that the use of m i in this relationship is a matter of convenience and a similar relationship should be possible using other parameters that capture the strength increase with confinement, such as the Mohr–Coulomb internal friction angle.

The trends shown in Fig. 16 are based on a limited number of data sets and need to be confirmed by further research. The relationships utilise only three parameters which are all obtained from standard triaxial testing. This suggests a way of estimating the strength of rock under extensional conditions which may greatly influence the rock mass behaviour in the field but for which we seldom, if ever, have any laboratory test data.

6 Conclusions

Published experience of the use of the extension strain criterion has proved its usefulness for the prediction of fracture initiation, and also of failure in some cases. The criterion has also been criticised, but this criticism appears to be rooted in a misunderstanding and a lack of distinction between a fracture initiation criterion and a failure criterion.

The criterion is successful in predicting extension fracture under triaxial compression, often indicating fracture development at very low stress levels. In contrast, under these conditions, conventional and commonly used criteria do not predict failure and certainly would not predict fracture orientations that correspond with observed fracture orientations. Predictions using the extension strain criterion define the extent of potential zones of fracture, and the fracture orientations within these zones. Within these zones, the rock is “conditioned”, to convert the rock into a “suitable” condition for subsequent failure to occur by mechanisms usually other than extension. Such conditioning may, for example, be that multiple orientated extension fractures lead to the creation of pseudo-stratification in the rock, similar to a transverse anisotropy, which could lead to subsequent failure of the rock by bending or buckling of the incipient slabs in the “conditioned” rock or rock mass.

Under confinement, failure by an extension mechanism (i.e. propagation and extension of the extension fractures) is generally not physically possible. However, the fractures formed can promote failure by other mechanisms. For example, the buckling of slabs in the form of strainbursting or rockbursting, and the coalescence of fractures to form a shear surface (Lee and Haimson 2011).

Failure of rock and rock masses is usually complex, involving multiple mechanisms of failure. Therefore, prediction of failure requires methods of analysis that take into account the actual mechanisms of fracture initiation and propagation and therefore, incorporate multiple failure criteria. Extension strain should be one of these criteria, but others, such as tension, shear, rotation, bending, and buckling, also need to be taken into account.

The work of Louchnikov (2011) suggests that, under confined conditions with low confining stress, the extension strain criterion is useful in providing an indication of rock mass damage level.

The extension strain criterion can be extended to predict failure under extensional conditions, when σ 1 and σ 2 magnitudes are similar. Analysis of published polyaxial test data shows that, for the rock material data used, the ultimate extension strain is linearly related to σ 3. The results analysed indicate that the slope of this linear relationship is proportional to Poisson’s ratio and proportional to the rate of strength increase with confinement. The intercept of this linear relationship, i.e. the ultimate extension strain, appears to be proportional to the Young’s modulus of the material.

It should be noted that the relationships for the extension strain failure criterion presented here are based on a limited amount of polyaxial test data. These trends require confirmation with additional test data.

References

Alber M, Heiland J (2001a) Investigation of a limestone pillar failure part 1: geology, laboratory testing and numerical modeling. Rock Mech Rock Eng 34(3):167–186

Alber M, Heiland J (2001b) Investigation of a limestone pillar failure part 2: stress history and application of fracture mechanics approach. Rock Mech Rock Eng 34(3):187–199

Andersson JC, Martin CD, Stille H (2009) The Äspö pillar stability experiment: part II—Rock mass response to coupled excavation-induced and thermal-induced stresses. Int J Rock Mech Min Sci 46(5):879–895

Benz T, Schwab R, Kauther RA, Vermeer PA (2008) A Hoek–Brown criterion with intrinsic material strength factorization. Int J Rock Mech Min Sci 45:210–222

Bridgman PW (1912) Breaking tests under hydrostatic pressure and conditions of rupture. Philos Mag 24:63–80

Bridgman PW (1938) Reflections on rupture. J Appl Phys 9:517–528

Bridgman PW (1947) The effect of hydrostatic pressure on the fracture of brittle substances. J Appl Phys 18:246–258

Colmenares LB, Zoback MD (2002) A statistical evaluation of intact rock failure criteria constrained by polyaxial test data for five different rocks. Int J Rock Mech Min Sci 39:695–729

Cox SJD, Scholz CH (1988) On the formation and growth of faults: an experimental study. J Struct Geol 1988(10):413–430

Dyskin AV, Germanovich LN, Ustinov KB (1999) A 3-D model of wing crack growth and interaction. Eng Fract Mech 63:81–110. doi:10.1016/S0013-7944(96)00115-4

ELFEN (2006) Rockfield Software Ltd, 2006. Version 3.7.1

Fujii Y, Uehara Y (2006) A study on deformation and failure behaviour of rock subjected to axial extension under confining pressure. Shigen-to-Sozai 01 122:330–337

Fujii Y, Kiyama T, Ishijima Y (1997) Condition insensitive damage indicator for brittle rock. Int J Rock Mech Min Sci 34(3–4):086

Griffith AA (1920) The phenomena of rupture and flow in solids. Philos Trans R Soc Lond Ser A 221:163–198

Hadjiabdolmajid V, Kaiser PK, Martin CD (2002) Modelling brittle failure of rock. Int J Rock Mech Min Sci 39:731–741

Haimson B (2011) Consistent trends in the true triaxial strength and deformability of cores extracted from ICDP deep scientific holes on three continents. Tectonophysics 503(1):45–51. doi:10.1016/j.tecto.2010.10.011

Haimson B, Chang C (2000) A new true triaxial cell for testing mechanical properties of rock, and its use to determine rock strength and deformability of Westerly granite. Int J Rock Mech Min Sci 37:285–296

Haimson B, Chang C (2002) True triaxial strength of the KTB amphibolite under borehole wall conditions and its use to estimate the maximum horizontal in situ stress. J Geophys Res 107(B10): ETG 15, 1–14

Haimson B, Rudnicki JW (2010) The effect of the intermediate principal stress on fault formation and fault angle in sandstone. J Struct Geol 32:1701–1711

Jaeger JC, Cook NGW (1979) Fundamentals of rock mechanics, 3rd edn. Chapman & Hall, London

Joughin WC, Stacey TR (2005) Risks associated with rockpasses in deep-level tabular mines based on historical pass performance. J S Afr Inst Min Metall 105(11):795–802

Kwasniewski M, Takahashi M (2010) Strain-based failure criteria for rocks: state of the art and recent advances. In: Zhao J, Labiouse V, Dudt JP, Mathier JF (eds) Rock mechanics in civil and environmental engineering. Taylor & Francis Group, London, pp 45–56

Lee H, Haimson BC (2011) True triaxial strength, deformability, and brittle failure of granodiorite from the San Andreas Fault Observatory at Depth. Int J Rock Mech Min Sci 48:1199–1207

Li D, Wong LNY (2013) The Brazilian disc test for rock mechanics applications. Rock Mech Rock Eng 46:269–287

Li D, Li C, Li X (2011) Influence of sample height-to-width ratios on failure mode for rectangular prism samples of hard rock loaded in uniaxial compression. Rock Mech Rock Eng 44:253–267

Louchnikov V (2011) Simple calibration of the extension strain criterion for its use in numerical modelling. In: Potvin Y (ed) Strategic vs tactical approaches in mining. Australian Centre for Geomechanics, Perth, pp 85–96

Martin CD (1993) The strength of massive Lac du Bonnet granite around underground openings. Ph.D. Thesis, University of Manitoba

Minney DS (1990) Damage and remedial action taken to secure the Free State Saaiplaas No 3 Shaft on 1780 Level. In: Proc. Symp. Rock Instability Problems in Mine Shafts, S. Afr. Nat. Group of Int. Soc. Rock Mech., Potchefstroom, May 1990, pp 65–72

Mogi K (1967) The effect of the intermediate principal stress on rock failure. J Geophys Res 72:5117–5131

Mogi K (2007) Experimental rock mechanics. Taylor & Francis/Balkema, Leiden

Ndlovu X (2006) Three dimensional analyses of stress and strain distributions around bord and pillar geometries. M.Sc. Eng Dissertation, University of the Witwatersrand, 171p

Ndlovu X, Stacey TR (2007) Observations and analyses of roof guttering in a coal mine. J S Afr Inst Min Metall 107(8):477–492

Nicksiar M, Martin CD (2012) Evaluation of methods for determining crack initiation in compression tests on low-porosity rocks. Rock Mech Rock Eng 45(4):607–617

Oku H, Haimson B, Song S-R (2007) True triaxial strength and deformability of the siltstone overlying the Chelungpu Fault (Chi-Chi earthquake), Taiwan. Geophys Res Lett 34(L09):306

Ortlepp WD (1997) Rock fracture and rockbursts. S. Afr. Inst. Min. Metall., 255p

Pang SS, Goldsmith W (1990) Investigation of crack formation during loading of brittle rock. Rock Mech Rock Eng 23(1):53–63

Reches Z (1999) Mechanisms of slip nucleation during earthquakes. Earth Planet Sci Lett 170:475–486

Reches Z, Lockner DA (1994) Nucleation and growth of faults in brittle rocks. J Geophys Res 99(B9):18159–18173

Ryder JA, Jager AJ (2002) A textbook on rock mechanics for hard rock mines. SIMRAC, Safety in Mines Research Advisory Committee, South Africa

Sahouryeh E, Dyskin AV, Germanovich LN (2002) Crack growth under biaxial compression. Eng Fract Mech 69:2187–2198. doi:10.1016/S0013-7944(02)00015-2

Simmons JV (2011) Extensional deformation triggers for potential composite failure of bedded rock slopes. In: Slope Stability 2011, Proc. int. symp. on rock slope stability in open pit mining and civil engineering, Vancouver, Canada, 13p

Simmons JV, Simpson PJ (2007) Extension, stress and composite failure in bedded rock masses. In: Potvin Y (ed) Proc. int. symp. on rock slope stability in open pit mining and civil engineering. Australian Centre for Geomechanics, pp 213–223

Stacey TR (1981) A simple extension strain criterion for fracture of brittle rock. Int J Rock Mech Min Sci 18:469–474

Stacey TR (1982) Contribution to the mechanism of core discing. J S Afr Inst Min Metall 82(9):269–274

Stacey TR (1989) Boring in massive rocks—rock fracture problems. In: Proc. seminar on mechanised underground excavation, S. Afr. Nat. Council on Tunnelling, November 1989, pp 87–90

Stacey TR, de Jongh CL (1977) Stress fracturing around a deep level bored tunnel. J S Afr Inst Min Metall 78(5):124–133

Stacey TR, Harte ND (1989) Deep level raise boring—prediction of rock problems. In: Maury V, Fourmaintraux D, Balkema AA (eds) Proc. int. symp. rock at great depth, vol 2, pp 583–588

Stacey TR, Yathavan K (2003) Examples of fracturing at very low stress levels. In: Proc. 10th Int. Cong. Int. Soc. Rock Mech., Sandton, S. Afr. Nat. Inst. For Rock Engng and S. Afr. Inst. Min. Metall., vol 2, pp 1155–1159

Stacey TR, Yu X, Armstrong R, Keyter GJ (2003) New slope stability considerations for deep open pit mines. J S Afr Inst Min Metall 103(6):373–389

Stacey TR, Ortlepp WD, Ndlovu X (2007) Dynamic rock failures due to “high” stress at shallow depth. In: Proc 4th int. seminar on deep and high stress mining. Australian Centre for Geomechanics, Perth, pp 193–204

Steffanizzi S, Barla G, Kaiser PK (2007) Numerical modelling of strain driven fractures around tunnels in layered rock masses. In: Ribeiro, Olalla and Grossmann (eds) Proc. 11th Int. Cong. Int. Soc. Rock Mech. Taylor and Francis Group, London, pp 971–974

Takahashi M et al (2006) Hydro-mechanical behavior in sandstone during from brittle to ductile deformation and its relation to inner structural change. In: Eurock 2006: multiphysics coupling and long term behaviour in rock mechanics: Proceedings of the international symposium of the international society for rock mechanics, Eurock 2006, Liège, Belgium, 9–12 May 2006. CRC Press, Boca Raton, pp 155–161

Tarasov BG, Randolph MF (2011) Superbrittleness of rocks and earthquake activity. Int J Rock Mech Min Sci 48:888–898

Waldeck HG (1979) The design and support of large underground chambers at depth in the mines of the Gold Fields Group of South Africa. In: Proc. 4th Int. Cong. Int. Soc. Rock Mech., Montreux, vol 1, pp 565–571

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wesseloo, J., Stacey, T.R. A Reconsideration of the Extension Strain Criterion for Fracture and Failure of Rock. Rock Mech Rock Eng 49, 4667–4679 (2016). https://doi.org/10.1007/s00603-016-1059-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-016-1059-0