Abstract

We investigated the statistical characteristics and probability distribution of the mechanical parameters of natural rock using triaxial compression tests. Twenty cores of Jinping marble were tested under each different levels of confining stress (i.e., 5, 10, 20, 30, and 40 MPa). From these full stress–strain data, we summarized the numerical characteristics and determined the probability distribution form of several important mechanical parameters, including deformational parameters, characteristic strength, characteristic strains, and failure angle. The statistical proofs relating to the mechanical parameters of rock presented new information about the marble’s probabilistic distribution characteristics. The normal and log-normal distributions were appropriate for describing random strengths of rock; the coefficients of variation of the peak strengths had no relationship to the confining stress; the only acceptable random distribution for both Young’s elastic modulus and Poisson’s ratio was the log-normal function; and the cohesive strength had a different probability distribution pattern than the frictional angle. The triaxial tests and statistical analysis also provided experimental evidence for deciding the minimum reliable number of experimental sample and for picking appropriate parameter distributions to use in reliability calculations for rock engineering.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The natural variety of rock is a major source of uncertainty in civil and geotechnical engineering. During the 35th Rankine Lecture, Professor R. E. Goodman observed that “Charged with responsibility for design, an engineer hopes to have available tools appropriate to the applicable materials and conditions. When the materials are natural rock, the only thing known with certainty is that this material will never be known with certainty” (Goodman 1995). Obviously, there are several common factors of uncertainty in rock engineering analysis such as the intrinsic uncertainty of rock composition, the incompleteness of statistical data, the use of simplified models, and experimental errors made during the manual operation of test equipment. However, only the natural variety of the rock material itself is irreducible (Fossum et al. 1995; Tonona et al. 2000; Cai 2011). The presence of numerous defects in rock, such as pores, flaws, and micro-cracks, has a considerable effect on its mechanical properties including the Young’s modulus, the uniaxial compressive strength, the inherent friction angle, and the strain of peak stress. There is no way to predict what the value of any one of these parameters of the rock will be at any given field.

Given these uncertainties, a stochastic rather than a deterministic description for the mechanical parameters of rock is more realistic and acceptable. In the deterministic estimation of the properties of a rock mass, only a unique value is used—usually the average of the investigated property taken from a number of samples. However, in a stochastic estimation, it is possible to consider the full range of data concerning a specific characteristic. In practice, the probabilistic approach, which views each variable not as a single value but as probability distribution, is more useful. This approach has been used as a powerful tool for representing uncertainty in the physical parameters of different materials and corresponding mechanical models during rock engineering analysis (Major et al. 1978; Einstein and Baecher 1982; Priest and Brown 1983; Hoek 1998; Nilsen 2000; Duzgun et al. 2003; Goh and Zhang 2012). Large data sets are needed to accurately carry out such probabilistic analyses (Haldar and Mahadevan 2000; Giasi et al. 2003; Park et al. 2005; Low 2007) because the appropriate probability distribution functions for the key mechanical parameters are vital for a reasonable estimation. In practice, it is desirable to use an adequate number of reliable laboratory tests or in situ observations to estimate uncertainty (Wong et al. 2006; Li and Gong 2009; Sari et al. 2010; Nomiko and Sofianos 2011; Park et al. 2013).

Unfortunately, under practical conditions, the data are frequently limited and the types of uncertain variables may not be known before the probability analysis is performed. This situation makes the application of the probabilistic approach more difficult (Dodagoudar and Venkatachalam 2000; Park et al. 2012; Sofianos et al. 2014). Although a large number of laboratory tests on rock specimens and detailed statistical analysis of experimental data are costly and time-consuming, many efforts have been devoted to investigation of the probability distribution function of mechanical parameters. Among these pioneering experimental programs carried out to estimate the distribution of parameters, such as unconfined compressive strength and elastic modulus, are studies by Hudson and Fairhurst (1969), Kostak and Bielenstein (1971), Karl et al. (1973), and Mazzoccola et al. (1997). Subsequently, efforts to define the probability distribution of rock parameters had been carried out by Bagde (2000), Deng and Bian (2005), Maheshwari (2009), Sanchidrian et al. (2012), and Bruno (2013). For a complete stress–strain curve of a rock specimen gained from a triaxial compression test, the characteristic mechanical parameters related to deformation and break are not only strength and deformational index (i.e., peak strength, cohesive strength, frictional angle, Young’s elastic modulus), but also strain characteristics (e.g., axial peak strain, axial residual strain, inflexional volumetric strain) and the break angle of the failure plane. The random features of all these mechanical parameters are meaningful. As stated by Fairhurst and Hudson (1999): “The complete force–displacement curve of an intact rock specimen is useful in understanding the total process of specimen deformation, cracking and eventual disintegration, and can provide insight into potential in situ rock mass behavior.”

Both the ISRM and the ASTM suggested that the number of specimens should be sufficient to adequately represent the body of rock being studied, recommending a minimum of five specimens per set of testing conditions (ASTM 1995; Fairhurst and Hudson 1999; ISRM 2007). Obviously, experimental data from a few rock specimens cannot determine comprehensive characteristics and such data would limit further generalization for a rock’s parameters owing to the lack of enough experimental data for a definitive statistical analysis (Martin and Chandler 1994; Palchik and Hatzor 2002; Diederichsa et al. 2004; Yang et al. 2012). According to Ruffolo and Shakoor’s (2009) suggestion, ten samples are the minimum number required for estimating rock properties at 20 % sample deviation and the 95 % confidence interval in laboratory testing. Thus, a statistical investigation for natural rock’s characteristic parameters with about 20 samples at each level of confining stress during triaxial compression can provide us intrinsic knowledge regarding its deformation and failure, which overcome the general disturbance of sample discreteness.

This paper investigates the stochastic variability of specimens of a marble by examining the results from a series of laboratory compression tests. Triaxial compression tests were carried out for the marble with different confining stresses (confining stresses of 5, 10, 20, 30, and 40 MPa), and about 20 samples were finished compression under each confining stress. Based on the stress–strain data recording the rocks’ failures, we summarized the numerical values of the mechanical parameters and also their probability distribution including the deformational parameters, characteristic strength, and characteristic strain. This statistical summary of rock mechanical parameters can provide us new understanding concerning a suite of samples’ stochastic properties and provide experimental evidence for determining parameter distributions that can be used for rock engineering reliability calculations.

2 Methods for the Mechanical Experiments and Data Analysis

2.1 Testing Scheme for Rock Specimens

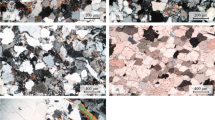

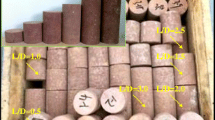

The rock sample was marble acquired from the underground powerhouse of the Chinese Jinping II hydraulic station (Feng and Hudson 2011; Jiang and Feng 2011). Mineralogically, this gray-white marble consisted largely of calcite, dolomite, and white mica and was weakly weathered. Each specimen for the test was a cylinder 100 mm in height and 50 mm in diameter, in accordance with the ISRM’s recommendations. The triaxial compression tests were carried using a MTS-815 Electro-hydraulic Servo-controlled Rock Mechanics Testing System from MTS Systems Corporation (Eden Prairie, USA). During testing, loading was done at a rate of 0.001 mm/s; axial strain was measured using a linear variable differential transformer, and the lateral strain was measured using a ring chain gauge (Fig. 1a). The confining stresses used were 5, 10, 20, 30, and 40 MPa. About 20 marble specimens were tested under each confining stress on the MTS system, and we gained all the integrated stress–strain curves under triaxial compression experiments (Fig. 1b–d).

2.2 Analysis Method for Experimental Data

The engineering mechanics-based approach to solving natural rock mechanical problems requires prior definition of the natural rock’s stress–strain behavior. Important aspects of this behavior include the constants relating to stresses and strains in the elastic range, the stress levels at each yield, the points at which fracturing or slip occurs within the rock, and the post-peak stress–strain behavior of the fractured or failed rock. From the data collected from the experiments described above, we have selected 11 significant parameters for statistical analysis (Fig. 2). These parameters, which represent the common characteristics of rock deformation and failure, are as follows:

[modified Goodman (1989)]

Illustration of mechanical parameters for a typical complete stress–strain curve under compressive loading

-

Two deformational parameters, Young’s modulus (E) and Poisson’s ratio (\(\upsilon\)). These parameters represent the fundamental compressive deformation property and volume response of rock under compression.

-

Five strength parameters, namely cracking damage stress (σ cd), peak strength (σ p), residual strength (σ r), cohesive strength (C), and internal frictional angle (ϕ). The peak strength represents the maximum loading capability. The cracking damage stress, which corresponds to the transition point of volume strain, represents the longtime strength of the rock (Goodman 1989; Martin 1993; Cai 2010; Hoek and Martin 2014). The residual strength indicates the rock’s possible loading capacity after failure, and the cohesive strength and internal frictional angle are the conventional Mohr–Coulomb strength parameters.

-

Three strain parameters: axial peak strain (ε p), axial residual strain (ε r), and volumetric inflexion strain (ε v). These represent, respectively, the rock’s maximum strain before failure, ultimate strain before structural disintegration, and the acceptable strain during longtime loading.

-

Angle of specimen’s break plane (\(\alpha\)).

For the analysis of the compressive stress–strain curves in the marble, the general statistical coefficients were calculated first, including the sample mean \(\bar{X},\) sample standard deviation S, and sample coefficient of variation, i.e., CV (Eqs. 1–3). The sample mean defines the value around which the “bell curve’’ will be centered and the sample standard deviation defines the spread of values around the sample mean. Based on these coefficients, the fundamental characters of a given rock parameter can be understood, such as the average value, the degree of dispersion of the individual result in relation to the sample group, and the dimensionless dispersion degree of the parameters (the relative standard deviation).

Current experimental and experiential knowledge indicates that there is not a unique function that can perfectly describe the probability distribution of the mechanical parameters of any rock. This is owing to the rock’s inherent inhomogeneity. However, it is generally accepted that the most reasonable probability distribution for any rock’s mechanical parameters includes the normal distribution (ND), the log-normal distribution (LND), and the Weibull distribution (WD), as stated by Yamaguchi (1970), Kostak and Bielenstein (1971), Wiles (2006), Hoek and Martin (2014), and others. Here, we propose that the above 11 mechanical parameters of this marble are in accordance with one of these distribution patterns as shown in Eqs. 4–6. A hypothesis test can be carried out to see whether the data collected fit one of the above distribution patterns. The equations that describe the three distributions are as follows:

where σ is the standard deviation, μ is the mean, β is the morphometric coefficient for the shape of density probability curve, and θ is the scaling coefficient for the curve’s magnitude.

When having a sufficient number of experimental samples is a required condition, an estimation using a statistical histogram is the conventional method to determine the probability density pattern of a statistical objective. However, a hypothesis test is a more acceptable way to assess the probability distribution of the variables, especially when there are not enough experimental results. The general methods of hypothesis testing include binomial testing, kurtosis–skewness testing, χ 2 testing, and Kolmogorov–Smirnov testing (K–S) (Bury 1999; Brani 2011). The K–S test has the advantages of being steady, independent of the mean, and insensitive to scale, as well as the integrity to absorb data. This test also satisfies the requirement for a small number of samples in the group (Deng et al. 2004; Duarte et al. 2005; Saria and Karpuz 2006; David et al. 2010). For these reasons, we have chosen to use the K–S test for hypothesis testing to determine whether our group of samples can be acceptably represented by any of the three probability distributions under consideration (Eqs. 4–6). K–S testing needs to follow four steps:

-

Step 1 Establish two hypothetical equations for the testing parameter (such as the peak strength of the rock), like H 0: F n (x) = F(x) and H 1: F n (x) ≠ F(x). Here, F n (x) is the cumulative distribution function for the observed random samples with number “n” and F(x) is the cumulative distribution function for the selected theoretical distribution function.

-

Step 2 Calculate the absolute value of the difference between the cumulative distribution probability of the observed sample and the cumulative distribution probability of the theoretical distribution probability: \(D_{n} = \hbox{max} \{ |F(x) - F_{n} (x)|\} .\)

-

Step 3 Index the critical significance level \((D_{n}^{a} )\) from the K–S testing table according to the sample size (n) and the given significance level (a).

-

Step 4 Compare the value between D n and \(D_{n}^{a} .\) The assumption (H 0) can be accepted only if the value of the D n is smaller than the value of \(D_{n}^{a} .\)

In the following K–S test on the mechanical parameter distributions for the Jinping marbles, the significance level was set at a = 0.05 (i.e., the 95 % confidence interval) with consideration for the number of samples used.

3 Statistical Characteristic of Rock Strength

Compressive strength can be considered as the most widely used and quoted rock engineering parameter, and a triaxial compression test on a cylindrical specimen is probably the most widely used rock engineering test. It is used to determine the rock’s individual compressive strengths, including longtime strength (i.e., cracking damage stress), peak strength, and residual strength. Despite its apparent simplicity, great care still needs to be exercised when interpreting the results obtained from such test.

3.1 Experimental Results of Triaxial Compression Tests

The compressive testing scheme used for this study acquired the full stress–strain data set for the marble. Consequently, all of the marble’s characteristic stresses including σ cd, σ p, and σ r can be analyzed according to the experimental stress–strain data (Table 1). The test results indicated that these characteristic stresses for this marble were not identical to each other but spanned a range even under the same experimental conditions. Consequently, the results had to be analyzed statistically.

The original data showed poor regularity. For example, some marble peak strengths under high confining pressures were smaller than the marble’s peak strengths under low confining pressure and, additionally, some cracking damage stress that occurred under high confining pressure was also larger than the peak strengths under low confining pressure (Table 1; Fig. 3). However, the means of characteristic stresses indicated that not only peak strength but also crack damage stress and residual strength clearly increased linearly with increasing confining stress within the range of confining pressures used (Fig. 3). This analysis confirmed the general idea that natural rock is a typical cohesive–frictional material. Furthermore, the transition of the marble from brittleness under low confining stress to ductility under high confining stress can be understood if we define the stress-to-drop ratio as the reduced stress between peak stress and residual stress \((\bar{\sigma }_{\text{p}} - \bar{\sigma }_{\text{r}} )\) divided by peak stress (Eq. 7).

where \(\bar{\sigma }_{\text{p}}\) and \(\bar{\sigma }_{\text{r}}\) are the average peak stress and residual stress, respectively. Our experimental result on the marble showed that the stress-to-drop ratio decreased as confining stress increased—the apparent confining pressure effect (Fig. 4).

3.2 Statistical Analysis and Hypothesis Testing of Characteristic Strength

As the characteristic strengths of the marble were, to a certain degree, unpredictable under the same triaxial confining pressure, further statistical analyses on strength were necessary. We determined the variability and the probability distributions.

The calculated sample standard deviations (Eq. 2) for the marble’s crack damage stress, peak strength, and residual stress indicated that the values of sample standard deviation increased only slightly, although the corresponding strength values had obviously risen along with the confining stress (compare Fig. 5 with Fig. 3). A more interesting experimental finding was that the sample coefficient of variation both crack damage stress and peak strength is comparatively constant and appears to have no relationship with the confining stress (Fig. 6). Yet, the CV of residual strength reduces with increasing confining stress. One possible reason for this could be that high confining pressures partly diminish the effect of preexisting micro-cracks on the rock’s compressive strength. Potentially, the entire compressive strength depends more on the rock material’s bearing capability. Another possible reason is that the variations in the roughness of the breaking plane decreases with increasing confining stress because the confining stress can suppress the unsteady expansion of cracks in the post-failure (Diederichsa et al. 2004; Hoek and Martin 2014).

The K–S tests also showed that the optimal distribution pattern for the crack damage stress, peak strength, and residual strength were not identical (Tables 2, 3, 4). We noted that:

-

All three probability distributions (the ND, LND, and WD distributions) were acceptable for the crack damage stress according the K–S test (Table 2), but judged by the D n value in Table 2, the optimal distribution pattern for this stress was the ND.

-

Similarly, all three probability distributions were acceptable for the peak stress according to the results from K–S test. The calculated K–S indices (D n ) of these probability distributions were all similar (Table 3). Therefore, under the condition of the limited sample size, the best-fit distribution for peak strength cannot be confirmed.

-

Three probability distributions were also acceptable for the residual stress (Table 4). However, the optimal distribution pattern for the residual strength, again based on the D n index, was the WD.

The K–S tests indicated the possibility that the statistical probability distribution of the natural rock’s strength parameters was different. In the physical experiments on the Jinping marble, our suggested probability distribution for the characteristic strengths was a normal or a LND if we required a uniform probability function to describe the disparate results. When we match against the ND to the marble’s peak strengths, we observed an interesting relationship. The peak point of the probabilistic density curve decreased with increasing confining stress, but the curve’s width increased at the same time (Fig. 7). The reason is that the sample means of the peak strength are not equal in different confining stresses, and the variability of the peak strength is measured with the sample coefficient of variation to unify the level of sample means. From the point of view of the variability, the confining stress has no significant effect on the variability of peak strength (see Fig. 6).

4 Statistical Characteristics of Rock Deformation Parameters

The elastic modulus (Young’s modulus) and Poisson’s ratio are two important mechanical parameters used to represent a rock’s deformational properties. They are used not only for elastic or elasto-plastic numerical engineering simulations but also for practical engineering designs during planning excavation and support schemes. Because natural rock materials contain random pores, flaws, and cracks, the Young’s modulus and Poisson’s ratio for such materials would usually be scattered within a specific range. Consequently, a detailed stochastic analysis of the rock’s deformation parameters and a reasonable estimation of its corresponding random probability density function are meaningful for understanding the deformation character of natural rock and useful for evaluating the rock’s stability risk.

4.1 Experimental Results of Marble Deformation

Based on the triaxial compression data, each specimen’s Young’s modulus and Poisson’s ratio can be calculated from the gradient of the axial stress–strain curves and ratio of the lateral strain to the axial strain (ISRM 1979; Brady and Brown 2004). The deformational parameters obtained are shown in Fig. 8, and this figure shows that the means of both the Young’s modulus and the Poisson’s ratio were relatively constant, although their individual values were scattered even at identical confining stress levels. This result means that the rock’s deformation parameters may not be sensitive to the confining stress, but that the elastic modulus and Poisson’s ratio calculated from a range of different confining pressures can be accepted as its reference value.

4.2 Probability Distribution of Deformation Parameters

A statistical analysis of all the Young’s modulus values and Poisson’s ratios obtained under different confining stresses showed that the density histograms for both parameters were similar to LNDs (Fig. 9a, b). A further quantitative K–S test showed that the only acceptable random distribution format for both the Young’s modulus and the Poisson’s ratio was the log-normal function (Table 5).

5 Statistical Analysis of Strength Parameters

The Mohr–Coulomb shearing strength parameters (cohesive strength and internal frictional angle) are the most important indices for estimating the materials resistance to shear failure. These parameters have been widely accepted in and applied by the geotechnical field because they represent two significant aspects of a rock’s shearing capability: its block strength and the magnitude of frictional resistance on the possible shearing surface.

5.1 Method of Analysis

In general, the Mohr–Coulomb shearing criterion can be expressed as the principal stresses (Eq. 8). Taking the peak strength data from each confining stress in Table 1, a regression line can be fit through the experimental data (curving with σ 3 and σ 1). The cohesive strength parameter (c) and the internal frictional angle (ϕ) can be determined from the slope and the interception of the line to the axes (Fig. 10). For this analysis, we randomly chose five experimental peak strengths in each confining stresses to regress the marble’s strength indices according to the procedures of Hudson (1969) and ISRM (1979) for determining a natural rock’s strength parameters.

5.2 Statistical Characteristics of Strength Parameters

According to the above random selection method for determining the cohesive strength and inherent frictional angle of the marble, the maximum number of the coupling parameters (c, ϕ) was the full permutation of values for peak strength under five confining stresses, i.e., \(C_{20}^{1} ,\,C_{20}^{1} ,\,C_{20}^{1} ,\,C_{20}^{1} ,\,C_{19}^{1} .\) Similar to the general method of evaluating random distribution patterns for these variables in a laboratory, we used a moderate number of points from the sample group to estimate parameters for these combined large samples. We chose the samples with magnitude 104 for further statistical analysis.

The calculation showed that the sample means of the Jinping marble’s cohesive strength and inherent frictional angle were 33.1 MPa and 31.4°, respectively, and their respective sample coefficients of variation were 0.18 and 0.14 (Fig. 11). Obviously, the variability of these strength parameters was larger than the variability of peak strengths, whose average sample coefficient of variation was about 0.083 (see Fig. 6). This indicated that the randomness of the rock strength would further increase the scatter of its strength parameters. This means that it is important to select a comparatively uniform rock material for testing and that a detailed check of the experimental data must be performed in order to obtain the representative strength parameters of rock.

Further quantitative K–S testing showed that the best acceptable random distribution format for the marble’s cohesive strength was the log-normal function, but the acceptable distribution format for the internal friction angle was the normal function (Table 6). This result is only slightly different from the generally accepted view that both the rock’s cohesive strength and internal frictional angle should follow the same probability distribution pattern. It should be noted, however, that some researchers suggested them as a normal function, but other researchers suggested them as logarithmic normal function (Yamaguchi 1970; Kostak and Bielenstein 1971; Hoek 1998; Martin et al. 2003; Saria and Karpuz 2006).

6 Break Angle of the Critical Plane

According to the Mohr–Coulomb strength envelope regarding principal stresses, there is a critical break plane along which the shear strength is reached as the peak strength. The Mohr circle can be used to determine the orientation of this critical plane by:

where β is the intersection angle between the critical plane and the minimum principle stress and ϕ is the internal frictional angle. A statistical analysis of the break plane not only can check the critical plane theory (i.e., Eq. 9), but also can recognize the end effect of loading to the rock’s failure.

6.1 Experimental Result of the Break Plane Angle

Measurements of the failed specimens’ break planes showed that the mean of the break angles under relatively low confining pressure was larger than that under relatively high confining pressure (Fig. 12). The difference between the actual break angle in the marble and the theoretical break angle was about 10° under low confining stress, but it was close to the theoretical break angle under high confining stress. There was a step-by-step decrease in the break angle with increasing confining stress (Fig. 13). We have postulated two reasons for this effect.

A combination of the experimental method and the physical properties of the material are the first and most important reason. Under low confining stress, the marble behaved as a brittle material with what was largely a tensile break and, to a lesser extent, a shearing break. Thus, its break plane was approximately parallel to the maximum principle stress owing to the end restraints (Fairhurst and Hudson 1999). Because the marble was breaking by shearing under high confining stress, its break angle fit the theoretical Mohr break angle more closely.

The second reason comes from the theory of the Mohr break angle. The theoretical break angle was deduced using the Mohr–Coulomb theory. This theory is essentially a shearing strength law that describes the shear failure of brittle material. However, natural rock commonly exhibits partly tensile shear failure under low confining stress and pure shear failure under high confining stress (Goodman 1989; Hoek and Brown 1997; Liolios and Exadaktylos 2013). Therefore, it is reasonable to expect the theoretical function to predict the rock’s shearing break angle well under high confining stress but not be able to predict the break angle under low confining stress conditions.

The above analysis indicates that the actual break angle of the marble under compression is nonlinear with the confining stress. In general, the relationship between break angle and confining stress can be approximated by Eq. 10 and is illustrated in Fig. 13.

where \(\beta^{\prime }\) is the predicted break angle, P is the confining stress, and k and q 0 are constant coefficients.

6.2 Probability Distribution of the Break Angle

Little attention has been paid to the random characteristics of a rock’s break angle, and we have found no experimental data to inspect to determine the possible probability distribution pattern. Therefore, we have applied the K–S test method to our marble data to see whether any of the general probability distribution functions discussed above was applicable. The K–S tested results indicated that the WD was the most reasonable probability function for describing the marble’s break angle (Table 7).

7 Statistical Analysis of Characteristic Strains

When the full stress–strain curve for the marble under compressive test is considered, it is possible to define special strains (the volumetric inflexion strain, the axial peak strain, and the axial residual strain), which were responding to crack damage stress, peak strength, and residual strength. Closer inspection of these three characteristic strains can provide additional useful information about the rock’s deformation and failure.

On average, the statistic curves showed that the characteristic strains increased with the rise in the confining stress (Fig. 14), which were similar to the relationship between the characteristic stresses and the confining stress (see Fig. 3). A more detailed analysis found that the gradient of the increasing volumetric inflexion strain was lower than that of the axial residual strain. This difference may be related to the marble’s brittle–ductile transition from low confining stress to high confining stress. As the confining stress increased, the dropping segment of the axial strain after reaching peak strength grew longer owing to an increase in the rock’s ductility.

Further K–S testing showed that the most appropriate probability distribution function was the ND, although the best probability distribution pattern for different characteristic strains was different from each other (Tables 8, 9, 10).

8 Discussion

Above statistical analysis for triaxial compressive tests showed that the variable property of marble’s mechanical parameters was inevitable. Determination of the minimum sample size was important for the efficacy of testing regimes to characterize aleatory variability within a parameter. Thus, we investigated the minimum acceptable sample size of the marble at the 95 % confidence interval by the deviation-approaching calculation according to Ruffolo and Shakoor’s (2009) method. The results showed that the minimum sample size for different mechanical parameter was different even at the same confidence interval, typical as Fig. 15. A summarization of the minimum sample size under different deviation is listed in Table 11. For a realistic consideration, we think the minimum sample size of marble was about 12 for gaining a reliably statistical characteristic of mechanical parameters at 20 % sample deviation and 95 % confidence interval under each confining stress.

9 Conclusions

For the purpose of investigating the statistical characteristics and probability distribution of rock mechanical parameters, we conducted triaxial compression tests on samples of marble. We tested 20 specimens at each different confining stresses (i.e., 5, 10, 20, 30, and 40 MPa). Eleven mechanical parameters that described the general deformation and strength properties of the rock were recorded, and a statistical analysis of most of them revealed some interesting probabilistic distributions.

-

Investigation of the marble’s characteristic strengths (crack damage stress, peak stress, and residual stress) showed that the statistical probability distribution of these strengths might have been somewhat different from each other. Our experiments suggested that if a uniform probability function were needed to describe the random property of these multi-characteristic strengths, the probability distributions were a ND and a LND.

-

Calculations of the marble’s crack damage stress, peak strength, and residual stress indicated that the values of their sample standard deviations increased only slightly with an increase in the confining stress, although their corresponding strengths rose markedly with the confining stress. A more interesting experimental finding was that the sample CV of the peak strength and residual strength were comparatively constant, evidently not being related to the confining stress.

-

The sample means of the deformational parameters (Young’s modulus and Poisson’s ratio) were comparatively constant under all confining pressures, but their individual values were scattered even at the same confining stress. This suggests that the rock’s deformation parameters might not be sensitive to the confining stress. Consequently, the calculated elastic modulus and the Poisson’s ratio for the specimen would be acceptable reference values even under different confining pressures. Additionally, quantitative K–S testing showed that among the three typical distribution functions considered, the only acceptable random distribution format for both Young’s modulus and Poisson’s ratio was the log-normal function.

-

The quantitative K–S testing showed that the most acceptable random distribution format for the marble’s cohesive strength was the normal function, but the acceptable distribution formats for inherent frictional angle were the log-normal function. This result was different from the normal case where both the cohesive strength and frictional angle of the rock would follow the same probability distribution pattern.

-

Measurements of the failed marble specimens’ break plane showed that there was a progressive decrease in the break angle with the confining stress and the two were related by a log function. The difference between the actual break angle of the marble and the theoretical Mohr–Coulomb break angle was about 10° under low confining stress, but the actual break angle was very close to the theoretical Mohr–Coulomb break angle under high confining stress. K–S test results indicated that the WD was the best reasonable probability function for describing the marble’s break angle.

Although there were an insufficient number of marble compression tests to fulfill the requirements for a strict stochastic model, the direct static analysis and experiential hypothesis testing presented some new knowledge regarding the marble’s probabilistic distribution characters, which will be useful for picking appropriate parameter distributions to use for calculations in rock engineering. Our further analysis indicated that the minimum number of experimental sample for marble was about 12 for gaining the reliably statistical characteristics of all the mechanical parameters at 20 % sample deviation and 95 % confidence interval under each confining stress. But more experimental samples are needed if we require higher confidence or lower variable coefficient.

References

ASTM (1995) Standard test method for unconfined compressive strength of intact rock core specimens. In: ASTM Committee D-18 on soil and rock, D2938-95, pp 1–3

Bagde MN (2000) An investigation into strength and porous properties of metamorphic rocks in the Himalayas: a case study. Geotech Geol Eng 18:209–219

Brady BHG, Brown ET (2004) Rock mechanics for underground mining, 3rd edn. Springer, Berlin

Brani V (2011) Statistics for bioengineering sciences. Springer, New York

Bruno G (2013) Statistical method for assessing the uniaxial compressive strength of carbonate rock by schmidt hammer tests performed on core samples. Rock Mech Rock Eng 46:199–206

Bury K (1999) Statistical distributions in engineering. Cambridge University Press, Cambridge

Cai M (2010) Practical estimates of tensile strength and Hoek–Brown strength parameter m i of brittle rocks. Rock Mech Rock Eng 43:167–184

Cai M (2011) Rock mass characterization and rock property variability considerations for tunnel and cavern design. Rock Mech Rock Eng 44:379–399

David LB, Justin TD, Kendra EM et al (2010) Detrital-zircon geochronology of the metasedimentary rocks of north-western Graham Land. Antarct Sci 22:65–78

Deng J, Bian L (2005) Estimating probability curves of rock variables using orthogonal polynomials and sample moments. J Cent South Univ Technol 12(3):349–353

Deng J, Li XB, Gu DS (2004) probability distribution of rock mechanics parameters by using maximum entropy method. Chin J Rock Mech Eng 23(13):2177–2218 (in Chinese)

Diederichsa MS, Kaiser PK, Eberhardt E (2004) Damage initiation and propagation in hard rock during tunnelling and the influence of near-face stress rotation. Int J Rock Mech Min Sci 41:785–812

Dodagoudar GR, Venkatachalam G (2000) Reliability analysis of slope using fuzzy sets theory. Comput Geotech 27:101–115

Duarte MT, Liu HY, Kou SQ et al (2005) Microstructural modeling approach applied to rock material. J Mater Eng Perform 14:104–111

Duzgun HSB, Yucemen MS, Karpuz C (2003) A methodology for reliability-based design of rock slopes. Rock Mech Rock Eng 36(2):95–120

Einstein HH, Baecher GB (1982) Probabilistic and statistical methods in engineering geology. Rock Mech 12(S):47–61

Fairhurst CE, Hudson JA (1999) Draft ISRM suggested method for the complete stress–strain curve for intact rock in uniaxial compression. Int J Rock Mech Min Sci 36:279–289

Feng XT, Hudson JA (2011) Rock engineering and design. CRC Pres, Leiden

Fossum AF, Sensen PE, Pfeifle TW, Mellegard KD (1995) Experimental determination of probability distributions for parameters of a salem limestone cap plasticity model. Mech Mater 21:119–137

Giasi CI, Masi P, Cherubini C (2003) Probabilistic and fuzzy reliability analysis of a sample slope near Aliano. Eng Geol 67:391–402

Goh ATC, Zhang W (2012) Reliability assessment of stability of underground rock caverns. Int J Rock Mech Min Sci 55:157–163

Goodman RE (1989) Introduction to rock mechanics, 2nd edn. Wiley, London

Goodman RE (1995) Block theory and its application. Geotecnique 45(3):383–423

Haldar A, Mahadevan S (2000) Probability. Reliability and statistical methods in engineering design. Wiley, New York, p 304

Hoek E (1998) Reliability of Hoek–Brown estimates of rock mass properties and their impact on design. Int J Rock Mech Min Sci 35(1):63–68

Hoek E, Brown ET (1997) Practical estimates of rock mass strength. Int J Rock Mech Min Sci 34(8):1165–1186

Hoek E, Martin CD (2014) Fracture initiation and propagation in intact rock—a review. J Rock Mech Geotech Eng 6(4):287–300

Hudson, JA, Fairhurst C (1969) Tensile strength, Weibull’s theory and a general statistical approach to rock failure. In: Proceedings of the Southampton civil engineering materials conference

ISRM (1979) Suggested methods for determining the uniaxial compressive strength and deformability of rock materials. Int J Rock Mech Min Sci Geomech Abstr 16(2):135–140

ISRM (2007) The complete ISRM suggested methods for rock characterization, testing and monitoring: 1974–2006. In: Ulusay R, Hudson JA (eds). ISRM Turkish National Group, Ankara

Jiang Q, Feng XT (2011) Intelligent stability design of large underground hydraulic caverns: Chinese method and practice. Energies 4(10):1542–1562

Karl I, Henke FL, Kaiser W (1973) Forecast on the strength and deformation characteristics of a stratified rock system based on the example of the Alb tunnel. Bull Eng Geol Environ 8:43–48

Kostak B, Bielenstein HU (1971) Strength distribution in hard rock. Int J Rock Mech Min Sci Geomech Abstr 8(5):501–521

Li XB, Gong FQ (2009) A method for fitting probability distributions to engineering properties of rock masses using Legendre orthogonal polynomials. Struct Saf 31:335–343

Liolios P, Exadaktylos G (2013) Comparison of a hyperbolic failure criterion with established failure criteria for cohesive-frictional materials. Int J Rock Mech Min Sci 63:12–26

Low BK (2007) Rliability analysis of rock slopes involving correlated nonnormals. Int J Rock Mech Min Sci 44:922–935

Maheshwari P (2009) Modified Stanley’s approach for statistical analysis of compression strength test data of rock specimens. Int J Rock Mech Min Sci 46:1154–1161

Major G, Ross-Brown D, Kim HS (1978). A general probabilistic analysis for 3-dimensional wedge failures. In: Proceedings of the 19th US symposium on rock mechanics, pp 45–51

Martin CD (1993) The strength of massive Lac du Bonnet granite around underground opening. Ph.D. thesis, p 278

Martin CD, Chandler NA (1994) The progressive fracture of Lac du Bonnet granite. Int J Rock Mech Min Sci 31(6):643–659

Martin CD, Kaiser PK, Christiansson R (2003) Stress, instability and design of underground excavations. Int J Rock Mech Min Sci 40:1027–1047

Mazzoccola DF, Millar DL, Hudson JA (1997) Information, uncertainty and decision making in site investigation for rock engineering. Geotech Geol Eng 15:145–180

Nilsen B (2000) New trend in rock slope stability analysis. Bull Eng Geol Environ 58:173–178

Nomiko PP, Sofianos AI (2011) An analytical probability distribution for the factor of safety in underground rock mechanics. Int J Rock Mech Min Sci 48:597–605

Palchik V, Hatzor YH (2002) Crack damage stress as a composite function of porosity and elastic matrix stiffness in dolomites and limestones. Eng Geol 63:233–245

Park HJ, West TR, Woo I (2005) Probabilistic analysis of rock slope stability and random properties of discontinuity parameters, Interstate Highway 40. Eng Geol 79:230–232

Park HJ, Um JG, Woo LK et al (2012) Application of fuzzy set theory to evaluate the probability of failure in rock slopes. Eng Geol 125:92–101

Park D, Kim HM, Ryu DW et al (2013) Probability-based structural design of lined rock caverns to resist high internal gas pressure. Eng Geol 153:144–151

Priest SD, Brown ET (1983) Probabilistic stability analysis of variable rock slopes. Trans Inst Min Metall A 92:1–12

Ruffolo RM, Shakoor A (2009) Variability of unconfined compressive strength in relation to number of test samples. Eng Geol 108(1):16–23

Sanchidrian JA, Ouchterlony F, Moser P et al (2012) Performance of some distributions to describe rock fragmentation data. Int J Rock Mech Min Sci 53:18–31

Sari M, Karpuz C, Ayday C (2010) Estimating rock mass properties using Monte Carlo simulation Ankara andesites. Comput Geotech 36:959–969

Saria M, Karpuz C (2006) Rock variability and establishing confining pressure levels for triaxial tests on rocks. Int J Rock Mech Min Sci 43:328–335

Sofianos AI, Nomikos PP, Papantonopoulos G (2014) Distribution of the factor of safety, in geotechnical engineering, for independent piecewise linear capacity and demand density functions. Comput Geotech 55:440–447

Tonona F, Bernardini A, Mammino A (2000) Determination of parameters range in rock engineering by means of random set theory. Reliab Eng Syst Saf 70:241–261

Wiles TD (2006) Reliability of numerical modelling predictions. Int J Rock Mech Min Sci 43:454–472

Wong TF, Wong RH, Chau K et al (2006) Microcrack statistics, Weibull distribution and micromechanical modeling of compressive failure in rock. Mech Mater 38:664–681

Yamaguchi U (1970) The number of test-pieces required to determine the strength of rock. Int J Rock Mech Min Sci 7:209–227

Yang SQ, Jing HW, Wang SY (2012) Experimental investigation on the strength, deformability failure behavior and acoustic emission locations of red. Rock Mech Rock Eng 45:583–606

Acknowledgments

The authors gratefully acknowledge the financial support from the State Key Research Development Program of China (Grant No. 2016YFC0600707), the National Natural Science Foundation of China (Grant Nos. 41172284 and 51379202) and the Youth Innovation Promotion Association (Grant No. 2013215). In particular, authors would also like to thank the reviewer for his valuable suggestions.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jiang, Q., Zhong, S., Cui, J. et al. Statistical Characterization of the Mechanical Parameters of Intact Rock Under Triaxial Compression: An Experimental Proof of the Jinping Marble. Rock Mech Rock Eng 49, 4631–4646 (2016). https://doi.org/10.1007/s00603-016-1054-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-016-1054-5