Abstract

We performed hydraulic fracturing experiments on cylindrical cores of anisotropic shale obtained by drilling normal to the sedimentary plane. Experiments were conducted under ambient condition and uniaxial stresses, using three types of fracturing fluid: viscous oil, water, and liquid carbon dioxide (L-CO2). In the experiments using water and oil, cracks extended along the loading direction normal to the sedimentary plane under the uniaxial loading and extended along the sedimentary plane without loading. These results suggest that the direction of crack extension is strongly affected by in situ stress conditions. Fluorescent microscopy revealed that hydraulic fracturing with viscous oil produced linear cracks with few branches, whereas that with water produced cracks with many branches inclining from the loading axis. Statistical analysis of P wave polarity of acoustic emission waveforms showed that viscous oil tended to induce Mode I fracture, whereas both water and L-CO2 tended to induce Mode II fracture. Crack extension upon injection of L-CO2 was independent of loading condition unlike extension for the other two fluids. This result seemed attributable to the low viscosity of L-CO2 and was consistent with previous observations for granite specimens that low-viscosity fluids like CO2 tend to induce widely extending cracks with many branches, with Mode II fractures being dominant. These features are more advantageous for shale gas production than those induced by injection of conventional slick water.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Shale gas refers to the natural gas trapped within formations of shale, a fine-grained sedimentary rock that can be a rich source of petroleum and natural gas. However, since the low permeability of shale greatly inhibits the flow of gas from reservoir rocks to production wells, the economic viability of developing shale gas depends on effective stimulation of reservoirs. Recently, horizontal wells employing a multistage hydraulic fracturing technique have become the stimulation method of choice and proven successful in shale gas reservoirs (Arthur et al. 2008).

Hydraulic fracturing is the process of initiation and propagation of cracks due to injection of a fluid at a pressure higher than the failure stress of the rock. The technique of hydraulic fracturing stress measurements was developed by Hubbert and Willis (1957). Building on their work, Cleary (1958) presented an early version of hydraulic fracturing theory and the possibility of fracture control. Since then, many theoretical and experimental investigations have been conducted (e.g., Zoback et al. 1977; Schmitt and Zoback 1989; Haimson and Cornet 2003).

Underground formations are subjected to complex stress fields and affected by various geological processes, as described by Amadei and Stephansson (1977) and Zang and Stephansson (2010). The magnitude and direction of the principal stresses are important in hydraulic fracturing because they control the amount of pressure required to create and propagate a crack, the direction of the crack, and the crack shape. The direction that a crack induced by hydraulic fracturing takes in a rock is also a function of several variables, including anisotropy of rock strength. Sun et al. (2011) investigated crack extension during hydraulic fracturing in oil shale and found that the cracks are elliptical and that cracks extend along different directions due to anisotropic properties and the in situ stress condition.

Ishida et al. (2004, 2012, 2013) have previously conducted hydraulic fracturing experiments using carbon dioxide (CO2), water, and viscous oil and found that low-viscosity fluids such as CO2 tend to induce widely extending cracks with many branches. These cracks should be better suited for producing shale gas because they have a larger surface area within the shale than those induced by water.

Accordingly, by monitoring acoustic emissions (AEs), this study focuses on the crack growth in shale cores in relation to the effects of stress condition and anisotropy due to sedimentary planes. This study also examines the effects of the viscosities of various fracturing fluids (viscous oil, water, and CO2) on the fracture mode and on the microscopic features of the induced cracks. The results of this study may be beneficial in industrial energy projects such as extraction of unconventional gas from shale and the sequestration of greenhouse gases.

2 Experimental methodology

2.1 Shale cores

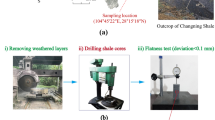

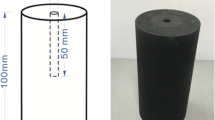

Experiments were performed on cylindrical shale cores measuring roughly 170 mm in length and 85 mm in diameter. All samples were retrieved by drilling blocks obtained from a depth of 275 m below sea level while mining a drift at the Kushiro coal mine in Hokkaido, Japan. The blocks were sandy shale from Palaeogene Harutori coal-bearing formation. Because sedimentary planes were clearly observed on the surfaces of the blocks, the drilling direction was selected to be normal to the sedimentary plane.

A hole for hydraulic fracturing with a diameter of 10 mm was drilled in the side of the core at the vertical midpoint. A Cartesian coordinate system was applied to the cores: the Z-axis was set along the cylindrical axis and normal to the sedimentary plane, the X-axis was set along the drilled hole, and the Y-axis was set orthogonal to the other two axes, as shown in Fig. 1.

P wave velocities were measured along the three selected axes for each specimen. The results of the P wave velocity measurements clearly show orthogonal anisotropy due to the sedimentary bedding with the exceptions of those in the cores K-01 and Kc-12 (Table 1).

2.2 Uniaxial stress conditions

Hydraulic fracturing tests were run at ambient condition and two uniaxial stresses of 1 and 3 MPa, applied along the Z-axis (σz, normal to the sedimentary plane). Four 10-mm-long strain gauges were attached to the cores to confirm that loading was uniformly applied to the cores before testing.

2.3 Fracturing fluid and pressurizing system for hydraulic fracturing

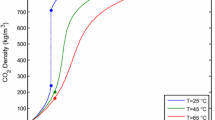

Three types of fluids, namely, viscous oil, water, and liquid carbon dioxide (L-CO2), were used for hydraulic fracturing. The viscous oil used was automobile transmission oil (Mahha Super Transmission Oil 75W-90; Fuji Kosan Co. Ltd., Tokyo, Japan). At the experimental temperature, the viscous oil was 270 times more viscous than water, whereas the L-CO2 has about 1/10 the viscosity of water.

A packer with a pressurizing section of 30 mm was set in the center along hole. Fluids were injected at a constant flow rate of 1 ml/min, and fluid injection pressures were recorded at 0.1-s intervals. A syringe pump with controllable discharge flow rate was connected to the hole via connecter pipes and used to inject the fluid. A pressure transducer was placed at a position close to the packer to detect the actual fluid pressure of the injection.

2.4 AE monitoring system

An array of 16 PICO sensors (Physical Acoustics Corporation), which were cylindrical, 3 mm in diameter, and 4 mm in length, with a resonance frequency of around 400 kHz, was used to record AE events. The detected AE signals were amplified by a total of 84 dB (36 dB in the pre-amplifier and 48 dB in the signal conditioner, except in experiments that used L-CO2 as fracturing fluid, where signal conditioner was set to 24 dB due to a high level of noise), then recorded on a hard disk via an A/D converter. For each event, the record length and sampling time of the A/D converter were selected to be 2048 words (each word size of 32 decimal digits) and 0.1 μs, respectively, with a 12-bit resolution. The dead time was set to be 1 ms after recording an event to prevent the hard disk from recording too much noise due to the vibrations following a large AE event. Recording of an AE event was triggered when one of the signals from the 16 sensors exceeded 3 V, and the triggered events usually have more than a few signals.

The AE events were monitored and recorded during the injection. Later in the process, the AE hypocenters were located by P wave arrival time at sensors based on a least squares method and then compared to the results of visual detection in order to trace the shape and orientation of cracks induced on the surface of the cores.

Furthermore, the mode of fracturing was examined by the statistical analysis determining the polarities of P wave initial motion along their respective AE waveforms following Zang et al. (1998) and Graham et al. (2010). Then, depending on their polarity, they were categorized as either compression or dilatation. The number of compressional initial motions and the number of dilatational were counted for each AE event. A ratio of the compressional initial motions to the total number of the compressional and the dilatational initial motions could then be obtained.

2.5 Microscopic observation of the cracks

Fluorescence microscopy (Nishiyama and Kusuda 1994) can be used to visualize cracks and pores in rocks using resin mixed with a fluorescent substance. In the present study, microscopy was performed on the shale samples fractured by injections of viscous oil and water.

To prepare samples for observation, the cores were soaked in the resin for about a week under vacuum and then heat treated up to 90 °C to solidify the resin. Later, cores were cut into sections normal to the crack plane extension induced by hydraulic fracturing and were prepared for observation on a microscope under ultraviolet light.

3 Results

The experiments conducted on the shale cores by testing each of the three hydraulic fracturing fluids under an ambient condition and two uniaxial stresses of 1 and 3 MPa. The tests were repeated to confirm the tendency of the results, thus yielding a total of 12 tests. Table 2 summarizes the test results where the last column shows the orientation of the induced cracks in relation with the stress conditions and the used fracturing fluid.

In this section, the results of one typical case for the respective fracturing fluid and loading conditions are shown. The selection of the typical case was made solely on the numbers and the quality of the located AE sources to compare the observed surface cracks. The located AE sources are only those that were recorded from 1 s before the breakdown to 15 s after the breakdown.

3.1 Testing observations without loading

In the experiments of the cores K-01 and K-03, water was used as the fracturing fluid, without loading (0 MPa stress along the Z-axis). Figure 2 shows an example of pressure profile in the hydraulic fracturing test of K-03: the pressure built-up and the breakdown occurred at 8.62 MPa. In both the cores, the crack extended horizontally along a sedimentary plane and was easily traced on the surfaces of the cores (as in Fig. 3a). The AE events detected by the sensors during the fracturing of the cores were located three-dimensionally. Figure 3b shows AE sources of the core K-03 projected on the horizontal plane (X–Y plane) and the two vertical planes (X–Z and Y–Z planes). AE sources seen in the vertical planes are distributed in the horizontal direction. These AE results are consistent with the cracks traced on the surfaces of the cores.

When a more viscous liquid than water (viscous oil, K-05) was injected, the fracture extended horizontally along the sedimentary bedding—the same propagation mode as that observed when the fracturing fluid was water. The aperture of the crack induced was noticeably much larger and clearer (Fig. 4a) when the fracturing fluid was oil than when it was water. The distribution projection of the AE source’s location in Y–Z plane supports the inference of the fracture path from its surface trace (Fig. 4b).

The least viscous fluid (L-CO2) was injected into core Kc-12 under 0 MPa of stress along the Z-axis, an intense audible AE occurred at the moment of breakdown, and the fracture extension was not horizontally parallel to the sedimentary planes. This result is unlike the observations recorded for the other fluids, for example, the cores K-03 and K-05. Here, the crack extended in a complex, inclined direction, and a very large aperture that completely split the core was observed on the surface (Fig. 5a). Accordingly, the distribution of AE sources’ locations (Fig. 5b) showed that the fracture extended at deviated directions in the range of 10°–30° from the vertical, which is consistent with the clearly traced fracture on the surface.

3.2 Testing observations under uniaxial loading

In the hydraulic fracturing of cores K-02 and K-04 using water as the fracturing fluid, under uniaxial loadings of 1 and 3 MPa along the Z-axis, the cracks observed on the surfaces of the cores extended along the loading direction, which was normal to the sedimentary plane. Figure 6 shows the case of the core K-04 under 3 MPa loading. Both the cores indicate that the fracture extension was in the loading direction.

When the other cores (K-07 and K-09) were tested using oil as the fracturing fluid under 1 and 3 MPa of loading stresses along the Z-axis, the crack again extended vertically, normal to the sedimentary plane, the same as the propagation mode observed when the fracturing fluid was water. Figure 7 shows the case of the core K-09 under 3 MPa loading. The distribution of the AE sources’ locations shows that the fracture extended in the vertical direction (Z-axis) in both the X–Z and Y–Z planes, which is consistent with the fractures traced clearly on the surfaces of the cores.

The last experiments were conducted by injecting L-CO2 in the cores Kc-01, Kc-06, and Kc-07 under 3 MPa of loading stress along the Z-axis. The cracks observed on the surfaces of the core Kc-01 extended in two horizontal bedding planes with an inclined crack connecting them, although it was under loading. As for the last two cores, the cracks extended in a nearly vertical, but slightly inclined direction as shown in Fig. 8, which is similar to the case of the core Kc-07, unlike in the cores injected with water and oil. The distribution of AE sources’ locations in Y–Z plane (as in Fig. 8b) shows also that the fracture extended along a deviated direction from the vertical loading direction.

3.3 Analysis of mode of fracturing

The effects of the differences in fracturing fluids’ viscosities on the mode of fracturing was examined using the cores tested under 3 MPa of uniaxial loading—K-04 (water), K-09 (oil), and Kc-07 (L-CO2)—because the crack extension under loading seemed to be stable and more clearly affected by fluid viscosity than in the cores without loading, due to the decreasing effects of the sedimentary planes.

To classify the polarities of the P wave initial motion arrivals as either compressional or dilatational, a polarity calibration test was performed by dropping a steel ball on one side of a steel plate after attaching sensors to the other side. A compressional wave resulted from the impact and radiated from the point of the impact to the sensors attached to the opposite side of the plate. Because the upward trace was recorded in all P wave initial motion arrivals in this test, the upward trace was recognized and considered as the compressional motion.

The ratios of the compressional to the total initial motions were obtained for 30 large events in each experiment with the viscous oil, water, and L-CO2 injections. The selection of these events was based on the events having at least 12 out of 16 initial motions on the sensors. The analysis revealed the higher ratios of 60–90 % for the viscous oil injection and of 40–60 % for both the water and the L-CO2 injections (Fig. 9). The ratio should be 100 % for Mode I fracture (tensile fracture) and should be 50 % for Mode II fracture (in-plane shear fracture). Thus, these results indicate that the injection of viscous oil tended to induce Mode I fracture, whereas the injections of water and of L-CO2 tended to induce Mode II fracture.

3.4 Microscopic examination of cracks

The opening of the crack in the K-05 sample (oil) is somewhat wider than that in the K-03 sample (water), as can be seen by comparing Figs. 3a and 4a. However, there is no marked difference in the fractures between the two samples under loading at 0 MPa, which is probably due to the crack extension running along the sedimentary planes. Comparing the cracks induced under loading at 3 MPa by water and oil, the core K-04, which was fractured by water, contains more inclined cracks deviating at an angle from the loading direction in its path than the core K-09 fractured by oil, (Fig. 10). On the inclined crack surfaces, shear stress develops with the angle, and it attains the maximum at the angle of 45° to the loading axis. Thus, the crack feature having the inclinations in its path causes more easily shear fracture than that induced by oil, with this result being consistent with the tendency of fracture mechanism shown in Fig. 9.

Fluorescence microscopy images of the crack shapes after a injection of water into core K-04 and b injection of oil into core K-09. In the both images, the cracks propagated across the sedimentary planes from the injection hole, which is located in the lower end of the images. The lines of 0.4-mm interval are scanning lines to count numbers of crack branches shown in Fig. 11

4 Discussion

We found the following tendency regarding crack extensions as observed from the surface cracks and distribution of AE sources’ locations. In the experiments that used water or oil as the fracturing fluid, cracks tended to extend along the loading direction normal to the sedimentary plane with uniaxial loading and tended to extend along the sedimentary plane if tests were run without loading. The elastic theory indicates that a crack extends in the direction of the maximum compressive stress. Thus, the direction of crack extension under uniaxial loading in the present study is consistent with the elastic theory. When there was no loading, the crack extended along the weakest plane due to the sedimentary bedding, even though the elastic theory indicates that the crack can extend in any direction. These experimental results suggest that the direction of crack extension is strongly affected by in situ stress condition and rock-strength anisotropy. Taking these findings to the field application, if shale strata are horizontally situated and horizontal stress is large, the cracks induced by hydraulic fracturing will tend to extend horizontally. In contrast, when vertical stress is large relative to horizontal stress, for example, in a shale stratum at great depth, the cracks will tend to extend vertically, normal to sedimentary planes, and may extend into a different stratum neighboring the shale.

In the experiments using L-CO2 as a fracturing fluid, crack extension shows an independency of loading condition and the presence of bedding plane unlike in the cases of water and oil used as fracturing fluids. In addition, even when the same conditions of loading were applied, the crack extensions are different among the cores tested with injection of L-CO2. The unstable tendency independent of the loading condition might be due to the specific properties of L-CO2.

The fracture mode can be identified by examining the polarities of P wave initial motions and obtaining the ratios of the compressional initial motions to the total number of initial motions. The ratio should be 100 % for Mode I fracture (tensile fracture) and 50 % for Mode II fracture (in-plane shear fracture). Thus, our results indicate that the viscous oil injection tends to induce Mode I fracture, whereas both water injection and L-CO2 injection tend to induce Mode II fracture.

In order to quantify the differences caused by different viscosities, a statistical analysis of the number of branches created by water and oil is carried out. The fractured samples were cut, and the section of 8 mm in length from the injection hole along the crack path is observed by setting 20 scanning lines of 0.4-mm interval (Fig. 10). Upon counting the number of fractures that cross the scanning lines (Fig. 11), it is observed that the injection of oil seems to create branches at only few parts of the crack path, while the water injection creates a random number of branches at any point of the crack path. It is noticeable also that the total number of cracks’ branches (55) resulted by water injection is larger than that (38) resulted by oil injection although this observation is restricted only in the section close to the injection hole.

Furthermore, cracks inclining to the loading direction and branching from a main crack were mainly observed in samples fractured with water. In addition, because shear stress develops on an inclined plane with an angle from the loading direction, the differences in the crack features are consistent with the AE monitoring results showing that Mode II AE events increased the with decrease of the fluid’s viscosity as shown in Fig. 9.

The crack extension in L-CO2 appeared to be unstable even under the same stress conditions. This seems be strongly affected by the difference in fracturing modes due to the viscosity of the fracturing fluid, unlike in other fluids, because the viscosity of L-CO2 is 1/10 and 1/2700 of that of water and viscous oil, respectively (see Table 2). Since the slick nature of L-CO2 enables it to fill easily into even the tiniest spaces, crack extension most likely becomes very sensitive to even small defects in the core. In addition to the low viscosity, the phase of CO2 changes from liquid to gas corresponding to the pressure decrease after crack extension. Since the compressibility of the gas is much larger than that of the liquid, expansion of CO2 gas may help to connect defects inside a core, cause the fracture to extend in an inclined direction, and also result in a much louder sound than that experienced in the case of water or oil injection at the moment of fracture. Ishida et al. (2004, 2012, 2013) previously conducted hydraulic fracturing experiments in granite specimens using carbon dioxide, water, and viscous oil. These studies revealed that low-viscosity fluids like CO2 tend to induce widely extending cracks with many branches, with the dominant fracture type being Mode II. The experimental results for the shale cores in the present study seem to be consistent with the tendency observed in granite specimens, particularly with the tendency that crack extension with Mode II-dominant fractures during CO2 injection is very sensitive to defects, such as tiny spaces in a core. CO2 fracturing, as opposed to conventional slick water fracturing, can likely induce cracks with better features for shale gas production, for example, a larger surface area. In addition, there is a possibility for CO2 to be used for enhancing shale gas production and its recovery (Kalantari-Dahaghi 2010), because shale’s affinity for CO2 is stronger (about 10 times greater) than the affinity for methane (Nuttall 2006), and thus, displacement of the absorbed methane (shale gas) with CO2 is expected.

Taken together, these and previous findings suggest that CO2 fracturing is a promising new method for shale gas recovery.

5 Conclusion

The results of this study are as follows:

-

1.

Surface crack observations and distributions of AE sources’ locations revealed that cracks extended along the loading direction normal to the sedimentary plane under uniaxial loading in the experiments that used water and oil as fracturing fluids. On the other hand, they extended along the sedimentary plane when tests were run without loading. These results suggest that the direction of crack extension is strongly affected by in situ stress condition. However, the L-CO2 fracturing did not show this tendency, which is probably related to its low viscosity.

-

2.

The ratios of polarities of P wave initial motions indicated that injection of viscous oil tends to induce Mode I fracture, whereas the injection of water and the injection of L-CO2 both tend to induce Mode II fracture.

-

3.

The observations of fluorescence microscopy revealed that hydraulic fracturing by viscous oil injection produces linear cracks with few branches, whereas hydraulic fracturing by water injection produces cracks with many branches inclining from the loading axis. This is consistent with the differences in the fracture modes based on differences in the viscosities of the fracturing fluids, as shown above.

-

4.

The crack extension after fracturing with L-CO2 is unlike those after fracturing with other fluids, which seems to be due to the low viscosity of L-CO2. This result seems to be consistent with the tendency observed by researchers of our group in granite specimens, where low-viscosity fluids like L-CO2 tend to induce widely extending cracks having many branches, with Mode II fractures being dominant. This latter pattern of cracking presents an advantage for shale gas production by fracturing with L-CO2 over fracturing with conventional slick water.

References

Amadei B, Stephansson O (1977) Rock stress and its measurement. Chapman & Hall, London

Arthur JD, Bohm B, Layne M (2008) Hydraulic fracturing considerations for natural gas wells of the Marcellus shale. In: Proceedings of the ground water protection council annual forum, Cincinnati, Ohio

Cleary J (1958) Hydraulic fracture theory part II—fracture orientation and possibility of fracture control. Division of the Illinois state geological survey, circular 252

Graham CC, Stanchits S, Main I, Dresen G (2010) Comparison of polarity and moment tensor inversion methods for source analysis of acoustic emission data. Int J Rock Mech Min Sci 47:161–169

Haimson BC, Cornet FH (2003) ISRM suggested methods for rock stress estimation—Part 3: hydraulic fracturing (HF) and/or hydraulic testing of pre-existing fractures (HTPF). Int J Rock Mech Min Sci 40:1011–1020

Hubbert M, Willis DG (1957) Mechanics of hydraulic fracturing, petroleum transactions. AIME 210:153–168

Ishida T, Chen Q, Mizuta Y, Roegiers J-C (2004) Influence of fluid viscosity on the hydraulic fracturing mechanism, Transactions of the ASME. J Energy Resour Technol 126:190–200

Ishida T, Aoyagi K, Niwa T, Chen Y, Murata S, Chen Q, Nakayama Y (2012) Acoustic emission monitoring of hydraulic fracturing laboratory experiment with supercritical and liquid CO2. Geophys Res Lett 39:L16309. doi:10.1029/2012GL052788

Ishida T, Nagaya Y, Inui S, Aoyagi K, Nara Y, Chen Y, Chen Q, Nakayama Y (2013) AE monitoring of hydraulic fracturing experiments with CO2 and water. In: Proceedings of Eurock2013, Wroclaw, Poland, 957–962

Kalantari-Dahaghi A (2010) Numerical simulation and modeling of enhanced gas recovery and CO2 sequestration in shale gas reservoirs: a feasibility study. In: Proceedings of international conference on CO2 capture, storage, and utilization, Society of Petroleum Engineeers, New Orleans, La

Nishiyama T, Kusuda H (1994) Identification of pore spaces and micro cracks using fluorescent resins. Int J Rock Mech Min Sci Geomech Abstr 31(4):369–375

Nuttall BC (2006) Sequestration in gas shale of Kentucky. In: Proceedings of 5th annual conference on carbon capture and sequestration, Alexandria, Virginia, USA, Poster No. 106

Schmitt DR, Zoback MD (1989) Poro-elastic effects in the determination of the maximum horizontal principal stress in hydraulic fracturing tests-a proposed breakdown equation employing a modified effective stress relation for tensile failure. Int J Rock Mech Min Sci Aeromech Abstr 26:499–506

Sun K, Tan J, Wu D (2011) The research on dynamic rules of crack extension during hydraulic fracturing for oil shale in situ exploitation. International conference on environmental science and engineering (ICESE 2011). Proc Environ Sci 12(2012):736–743

Zang A, Stephansson O (2010) Stress field of the earth’s crust. Springer, Berlin (ISBN 978-1-4020-8444-7)

Zang A, Wagner FC, Stanchits S, Dresen G, Andresen R, Haidekker MA (1998) Source analysis of acoustic emissions in Aue granite cores under symmetric and asymmetric compressive loads. Geophys J Int 135:1113–1130

Zoback MD, Rummel F, Jung R, Raleigh CB (1977) Laboratory hydraulic fracturing experiments in intact and pre-fractured rock. Int J Rock Mech Min Sci Geomech Abstr 14:49–58

Acknowledgments

The authors wish to acknowledge the invaluable support offered by Kushiro Coal Mine Co. Ltd. by providing the shale blocks that were used to prepare the cores for the experiments in this study.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bennour, Z., Ishida, T., Nagaya, Y. et al. Crack Extension in Hydraulic Fracturing of Shale Cores Using Viscous Oil, Water, and Liquid Carbon Dioxide. Rock Mech Rock Eng 48, 1463–1473 (2015). https://doi.org/10.1007/s00603-015-0774-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-015-0774-2