Abstract

Fiber-reinforced polymers (FRP) have been widely used in shear strengthening applications of reinforced concrete (RC) beams. The accurate prediction of the FRP contribution to the shear strength of beams is essential for reliable design. Gene expression programming (GEP) has been widely utilized because it reliably expresses complex relationships between experimental variables. In this study, three new GEP models are proposed for three different strengthening configurations of FRP such as fully-wrapping, U wrapping, and side-bonding to predict the FRP contribution to shear strength. These models are developed using the most comprehensive database containing a total of 811 strengthened beams (350 fully-wrapped, 328 U-wrapped, and 133 side-bonded. Many variables have been considered in the proposed GEP models, including those that have been experimentally effective but are often neglected in existing literature equations, such as the shear span-to-effective depth ratio \((a/d)\) and the stirrup ratio (\({\rho }_{w}\)). Additionally, the reliability of existing equations in the literature and the proposed GEP models for predicting the FRP contribution to shear strength was statistically evaluated. As a result of this evaluation, the proposed GEP models for each strengthening configuration of FRP yielded the most accurate statistical results, with the lowest coefficient of variation (COV), and the highest coefficient of correlation (R).

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The strengthening of reinforced concrete (RC) structures to achieve the required performance is a widely preferred method. Recently, the strengthening method using fiber-reinforced polymer (FRP) has become popular in both academic studies and projects. FRP, an alternative composite material, is favored for strengthening structural elements such as columns, beams, and slabs due to its superior properties, including corrosion resistance, resistance to various chemicals, high strength-to-weight ratio, ease of application, and high tensile modulus. RC beams with insufficient shear strength could be strengthened using FRP by mainly four different strengthening configurations including fully-wrapped, U-wrapped with anchoraged, U-wrapped, and side-bonded.

Many previous experimental [1,2,3,4,5,6,7,8,9,10,11,12,13,14,15,16,17,18,19,20,21,22,23,24,25,26,27,28,29,30,31,32,33,34,35,36,37,38,39,40,41,42,43,44,45,46,47,48,49,50,51,52,53,54,55,56,57,58,59,60,61,62,63,64,65,66,67,68,69,70,71,72,73,74,75,76,77,78,79,80,81,82,83,84,85,86,87,88,89,90,91,92,93,94,95,96,97,98,99,100,101,102,103,104,105,106,107,108,109,110,111,112,113,114,115,116,117,118,119,120,121,122,123,124,125,126,127,128,129,130,131,132,133,134,135,136,137], analytical [3, 36, 82, 119, 123, 131, 138, 139], and statistical [140,141,142,143,144] studies were conducted on FRP-strengthened beams in shear. Li and Leung [6, 91] and Sengun and Arslan [35, 36] elaborately investigated the effect of \(a/d\) on the RC beams strengthened with various FRP configurations. Accordingly, it was stated that \(a/d\) affects the FRP contribution to shear strength by altering the angle of the shear crack and the load-carrying mechanism of beam. Therefore, \(a/d\) should be taken into account in the analytical equations. Bousselham and Chaallal [145] stated that the increase in shear capacity of the beams was limited by the increase in FRP reinforcement ratio (\({\rho }_{f}\)) in slender beams. However, no significant increase in shear capacity was observed in deep beams. The size effect on the shear strength of beams strengthened with FRP was experimentally examined by Godat et al. [4] and Benzeguir et al. [146]. Godat et al. [4] concluded that the effect of FRP decreased as the effective depth of beam (\(d\)) and the beam width (\({b}_{w}\)) increased. Benzeguir et al. [146] demonstrated that the size effect was more prominent in the FRP-strengthened beams without stirrups. The shear strip width-to-spacing ratio (\({w}_{f}/{s}_{f})\) was one of the important variables effective on the behavior of the FRP-strengthened beams studied by various researchers [1, 2, 35, 36, 82]. Akkaya et al. [1, 2], Sengun and Arslan [35, 36], and Mofidi and Chaallal [82] pointed out that the FRP contribution to the shear strength of the beam increased as the spacing between the FRP strips decreased. Mofidi and Chaallal [82] emphasized that variable \(({w}_{f}/{s}_{f})\) was not considered in the proposed equations. However, they suggested that it should be included. Additionally, several experimental studies indicated [16, 35,36,37, 121, 145] that the increase in the stirrups ratio (\({\rho }_{w}\)) was inversely proportional to the increase in the FRP contribution to shear strength. It was stated by various researchers [74, 119, 147,148,149,150,151,152] that the contribution of FRP to the shear strength depended on \(({\rho }_{f})\), FRP thickness (\({t}_{f}\)) and the concrete compressive strength (\({f}_{c}\)).

The effect of FRP type on the shear behavior of beam was studied by Cao et al. [8] and Baggio et al. [57]. Chen and Teng [138, 139] expressed that there were mainly two different failure modes named as FRP debonding and rupture depending on the FRP strengthening configuration and proposed equations to calculate the FRP shear contribution for each of these failure modes considering effective FRP strain. The effects of different variables on the prediction accuracies of the equations were statistically analyzed by Kar and Biswal [140]; Kotynia et al. [141]; Lima and Barros [142]; Oller et al. [143]; Pellegrino and Vasic [144]. It was stated by Oller et al. [143] that the accuracies of the predicted equations were lower in the beams with stirrups. Kar and Biswal [140] concluded that (1) the experimental FRP shear contribution increased for the specimens without stirrups by the increase in beam depth; (2) the strengthening efficiency of the external strengthening system increased with an increase in a/d ratio, whereas the prediction accuracies of different design guidelines for the prediction of FRP shear contribution become lower with an increase in \(a/d\) ratio.

Researchers widely employ various computational methods [153, 154] and intelligent design techniques, such as utilizing origami structures [155,156,157], for solving engineering problems. In addition, the use of artificial intelligence for solving engineering problems is increasing day by day. With the rapid development of technology, it has become preferable to utilize artificial intelligence in the construction industry due to its advantage of easily learning complex datasets and making predictions with high accuracy. Machine learning is a subset of artificial intelligence that can be used in many different engineering fields. Machine learning has become a main topic in recent publications [158,159,160]. Various machine learning approaches such as gene expression programming, random forest, support vector regression, multiple expression programming, Gaussian process regression, artificial neural networks, and adaptive neuro-fuzzy interface system have been frequently applied in modeling complex problems in structural engineering [161,162,163,164].

Gene expression programming (GEP) is one of the widely used machine learning programs. GEP is a genetic algorithm using populations to derive analytical expressions, taking into account the complex relationships between the relevant variables. Model outputs are easier to interpret and analyze in GEP method compared to other machine learning and nonlinear regression methods due to the tractability and adaptability. In addition, unlike other machine learning methods, the GEP method derives an equation by considering the complex relationships among different variables in the dataset. There are studies providing different GEP models for the calculation of shear strength, deflection, and strains of different structural components/materials using the GEP method and examining the validity of these equations. Alshboul et al. [165], Gandomi et al. [166], and Kara [167] first determined the relevant input variables considering the previous experimental investigations conducted by various researchers on beams without stirrups and then gave an equation for the shear strength of beams without stirrups using the GEP method. Al-Ghrery et al. [168] dealt with the concrete cover separation on RC beams strengthened with FRP in flexure and proposed a model by using a total of 127 beams. Ism and Rabie [169] performed an experimental study to examine the flexural behavior of CFRP-strengthened beams and proposed an equation with the GEP method to calculate the rupture strain of FRP. Anvari et al. [170] gave a GEP model to calculate the total shear strength in RC beams strengthened with externally bonded FRP in shear and verified the validity of the model. The statistical results of the equations predicting the FRP contribution to shear strength carried out in the literature were discussed.

When previous experimental studies are evaluated, it could be expressed that the behavior of FRP-strengthened specimens varies significantly depending on many variables such as stirrups ratio (\({\rho }_{w}\)), \(a/d\), and the FRP reinforcement ratio (\({\rho }_{f}\)). Furthermore, as the limited number of the statistical studies conducted using the limited number of the equations proposed to calculate the FRP contribution is analyzed, the predictions of the equations are not in good agreement with the experimental results. This is due to the fact that many important variables such as stirrups ratio (\({\rho }_{w}\)) and \(a/d\) are not effectively taken into account in the proposed equations. Besides, the number of studies examining the FRP contribution using the extensive database by the GEP method is quite limited. The aim of this study is to propose equations that provide better predictions than those obtained using existing equations in the literature. Therefore, three different GEP models were proposed in this study using an extensive dataset containing a total of 811 specimens to determine the FRP contribution for each strengthening configuration. In the proposed models, a total of 12 variables whose effects have been shown experimentally have been tried to be effectively considered. The prediction accuracies of the different equations proposed in the literature to calculate the contribution of FRP to the shear strength were statistically evaluated and compared with the prediction results of the proposed GEP models.

2 Description of experimental database

Most of the experimental studies performed to date were attempted to be considered in collecting dataset. However, data quality is crucial for data mining projects. Some data may contain missing or incorrect values, which can negatively affect the accuracy and reliability of the model. Therefore, such corrupt or misleading data were removed from the datasets to increase the reliability of the models, their generalization ability, and the accuracies of the results. A database of 811 FRP reinforced beams with or without stirrups was considered in this study.

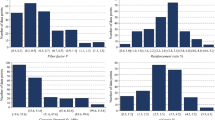

The database includes three different strengthening configurations such as fully-wrapped (350 beams), U-wrapped (328 beams), and side-bonded (133 beams). Since it is difficult to strengthen T-section RC beams with FRP due to the RC slabs, U-wrapped strengthening configuration with a proper anchoring system can be used in the strengthening applications. It is indicated in ACI 440.2R [171] that anchorage systems used in U-wrapped and side-bonded beams can result in higher FRP strains compared to U-wrapped and side-bonded configurations without anchorage. According to ACI 440.2R [171], the effective strain limits to account for the FRP contribution to shear strength in U-wrapped beams with anchored systems can be taken as the same as for fully-wrapped beams. In addition, fib TG 9.3 [172] has similar provisions regarding the calculation of the contribution of FRP to the shear strength for both fully-wrapped and anchored U-wrapped. Therefore, RC beams strengthened with anchored U-wrapped were considered as fully-wrapped beams to determine the contribution of FRP to the shear strength of the beam in this study. The number of beams in terms of FRP type in each strengthening configuration is given in Fig. 1. Test specimens where FRP strips were applied perpendicular to the beam axis were considered. Furthermore, 20 equations for fully-wrapped beams, 13 equations for U-wrapped beams, and 10 equations for side-bonded beams provided by various codes and researchers were statistically compared with the GEP equations.

The variables considered as input variables in GEP models are as follows: effective depth of beam (\(d\)), the effective depth of FRP (\({d}_{{\text{fe}}}\)), the shear span-to-effective depth ratio \((a/d)\), the beam width (\({b}_{w}\)), the FRP width-to-spacing ratio \({(w}_{f}/{s}_{f})\), the FRP thickness \(\left({t}_{f}\right),\) the FRP reinforcement ratio (\({\rho }_{f}\)), the ultimate strain (\({\varepsilon }_{{\text{fu}}}\)), the modulus of elasticity (\({E}_{f}\)), the concrete compressive strength (\({f}_{c}\)), the stirrups ratio (\({\rho }_{w}\)), and the yield strength of stirrups (\({f}_{{\text{yw}}}\)).

Within the scope of this study, the maximum and minimum values of each variable for references in the databases gathered to derive GEP models of three different strengthening configurations are given in Table A1-3. The histograms for all input variables were separately given for each strengthening configuration in Figs. 2, 3 and 4.

The rose diagrams of the input variables consisting of degrees of a circle to display the frequency of each class are presented in Fig. 5 for each strengthening configuration. Each spoke has a proportional length to indicate its quantity. θ, \(R\) bar, and \(v\) represent the mean direction, mean resultant length, and circular standard deviation in the rose diagrams. If the R bar is close to one, it indicates a high concentration. v also refers to the circular analog of the linear standard deviation. The summary of the statistical results of the rose diagrams is shown in Table 1 for each strengthening configuration separately.

Additionally, the Pearson correlation coefficients matrices were given as heat map in Fig. 6 to measure the linear correlation between the two variables for each strengthening configuration. The correlation coefficient could be different values between -1 and 1 and indicate the relationship between two variables in terms of force and direction. Positive values of correlation coefficients mean indicate a positive correlation between variables, and negative values indicate a negative correlation. In addition, the correlation coefficients close to zero demonstrate the poor relationship between the variables.

3 Derivation of equations with GEP

Gene expression programming (GEP) invented by Ferreira [173] is one of the machine learning tools frequently used to derive related prediction models for various engineering problems in recent years. The most important feature of gene expression programming is the generation of chromosomes representing any parse tree [173]. The GEP model consists of fixed length genes and chromosomes forming an expression tree (ET). The expression tree (ET) representation of a typical chromosome expressing the mathematical expression \(\sqrt[3]{\left(a*b\right)/(c+d)}\) is presented in Fig. 7. ET consists of nonlinear entities of different sizes and shapes. A new language was created to read and express the information encoded in chromosomes. This reading of the expression tree is called the Karva language and is written in the format Q/* + abcd, where “Q” represents the cube root function of Fig. 7.

The schematic representation of the expression tree of a chromosome [173]

In this study, a computer program called GeneXproTools 5.0 [174] was used to derive the models for the prediction of the FRP contribution to the shear strength in fully-wrapped, U-wrapped, and side-bonded beams. The input variables such as \(d, {d}_{fe},{b}_{w}, {t}_{f},{E}_{f},\) \({f}_{c },{{f}_{{\text{yw}}},a/d,{w}_{f}{/s}_{f},{\rho }_{f}, \rho }_{w },\) and \({\varepsilon }_{fu}\) were used to obtain the output variable (\({V}_{f})\). Root-mean-square error (RMSE) was taken as a fitness function in the derivation of GEP models. The GEP variable settings are summarized in Table 2 by considering the previous studies [175,176,177].

The database was randomly divided into training (75%) and validation (25%) sets to overcome the problem of overfitting. For fully-wrapped, U-wrapped, and side-bonded beams, 262, 246, and 100 data points (75%) were used for the training sets, respectively, while the remaining 88, 82, and 33 data points (25%) were employed in the validation datasets. The proposed GEP model consisted of four different sub-expression trees linked by the linkage function for each strengthening configuration as shown in Figs. 8, 9 and 10. The GEP-based formulations for the contribution of FRP to the shear strength (\({V}_{f}\)) were given in Eqs. (1)–(3) for fully-wrapped, U-wrapped, and side-bonded beams, respectively. The proposed models are valid for three different FRP types such as CFRP, GFRP, and AFRP whose properties are between the limit values in the databases.

For fully-wrapped beams:

For U-wrapped beams:

For side-bonded beams:

4 Results and discussion

The experimental FRP contribution (\({V}_{f}\)) to the shear strength was calculated by subtracting the shear strength of the reference beams from the shear strength of the strengthened beams. The predicted FRP contribution (\({V}_{f}\)) to shear strength was calculated by substituting the necessary variables (Tables A1-3) in both investigated equations and proposed GEP models. The accuracies of the considered equations were statistically interpreted by comparing the experimental (\({V}_{f}\)) and predicted FRP contribution (\({V}_{f}\)). Statistical variables such as the mean value (M), standard deviation (SD), mean absolute percentage error (MAPE), root-mean-square error (RMSE), coefficient of correlation (R), and coefficient of variation (COV) were considered in evaluation of the equations. The number of evaluated beams might differ due to the limitations of some equations to determine FRP contribution to shear strength as shown in Tables 3, 4 and 5. In order for the proposed models to be statistically in agreement with the experimental results, the MAPE, RMSE, and COV values should be low and the correlation coefficient (R) should be close to one value.

The Pearson correlation matrix (Fig. 6) shows that \({d}_{{\text{fe}}}\) and \({b}_{{\text{w}}}\) were the most effective variables for the experimental FRP contribution (\({V}_{f}\)) of fully-wrapped beams, while \({f}_{c}\) and \({w}_{f}{/s}_{f}\) are less effective. In the proposed model for fully-wrapped beams, the same results related to the variables were obtained as shown in Fig. 11. For U-wrapped beams, \(d, {d}_{fe},\) and \({b}_{{\text{w}}}\) were highly effective on the experimental performance in contrast to \({f}_{c}\), \({\rho }_{f}\) and \({\rho }_{w}\) as shown in Fig. 6. However, \({d}_{{\text{fe}}}\),\({t}_{f}\), \({f}_{{\text{yw}}}\), and \({\varepsilon }_{{\text{fu}}}\) had a significant impact on the prediction accuracy of the proposed GEP model in U-wrapped beams (Fig. 11). In addition, for side-bonded beams, \(d, {d}_{{\text{fe}}},\) and \({b}_{{\text{w}}}\) were highly effective on the experimental performance in opposition to \({\rho }_{f}\),\({E}_{f}\),\({\varepsilon }_{{\text{fu}}}\), and \({w}_{f}{/s}_{f}\). However, \(d\) and \({b}_{{\text{w}}}\) had a strong effect on the prediction accuracy of the proposed GEP model in side-bonded beams (Fig. 11). To summarize, it was evaluated that the geometric dimensions such as \(d, {d}_{{\text{fe}}},\) and \({b}_{{\text{w}}}\) are more effective on the FRP contribution to the shear strength and these variables were effectively considered in the proposed GEP models.

The comparisons between FRP contribution to shear strength calculated by the proposed GEP models and experimental results were given for each FRP strengthening configuration in Figs. 12 and 13. As a result of this comparison, it was seen that the density of the distribution between the predicted and the experimental results of \({V}_{f}\) was in the prediction limit of the 5%. As shown in Table 3 for fully-wrapped beams, compared to the other equations, the GEP model was the most reliable with COV and R values of 0.492 and 0.880, respectively. It was seen that the equations given the statistically closest predictions to the GEP model in terms of COV and R values were Sengun and Arslan [36], Akkaya et al. [3], Khalifa et al. [178], Zhang and Hsu [123] and NCHRP Rep. No. 678 [183]. On the contrary, it was also seen that the COV and R values of the Chen and Teng [139], ACI 440.2R [171], DAfStf [182], CSA-S806-12 [184], CIDAR [185], EN 1998-3 [190], CECS 146 [187], and TEC-18 [188] equations were between 1.060–1.160 and 0.418–0.527, respectively. Thus, it was understood that the prediction accuracies of these equations were low. The predictions by NCHRP Project No. 678 and CNR-DT 200 R1 for fully-wrapped beams were not economical due to the lowest mean values.

For U-wrapped beams shown in Table 4, the GEP model was the most reliable as fully-wrapped beams with COV and R values of 0.594 and 0.882, respectively, whereas the CAN/CSA [192] was the worst result with COV and R values of 2.124 and 0.115, respectively. In accordance with COV and R values, the equations given the closest predictions to the GEP model were Khalifa et al. [178], Khalifa and Nanni [74], Mofidi and Chaallal [82] and Sengun and Arslan [36]. However, it was also seen that the COV and R values of the ACI 440.2R [171], fib TG 9.3 [172], Bukhari et al. [32], CNR-DT 200 [191], and CNR-DT 200 R1 [180] equations were between 0.849–1.025 and 0.279–0.486, respectively. Thus, it was understood that the prediction accuracies of these equations were low.

As for side-bonded beams as shown in Table 5, the GEP model had the best prediction accuracy with COV and R values of 0.381 and 0.922, respectively. The equation by Sengun and Arslan [36], with a COV value of 0.468 and an R value of 0.667, had the closest predictions to the GEP model statistically. Contrary, the COV and R values of the CAN/CSA [192] equation were 1.047 and 0.315, respectively. Therefore, it was understood that the prediction accuracy of CAN/CSA [192] equation was incompatible for side-bonded beams. Considering the COV and R values among the three models derived by the GEP method, it was seen that the model with the highest predictive accuracy was for side-bonded beams. The predictions by Bukhari et al. [32], Chen and Teng [138, 139], and CNR-DT 200 R1/2013 for side-bonded beams were not economical due to the lowest mean values.

5 Conclusions

In this study, three different GEP models were proposed to assess the FRP contribution to the shear strength of the RC beams for each strengthening configuration. The prediction accuracies of the GEP models proposed and the existing equations commonly used in the literature were compared utilizing a comprehensive dataset with a total of 811 RC beams strengthened with FRP. Furthermore, the relative contribution of each input variable in GEP models proposed for different strengthening configurations was investigated. The main results obtained were as follows:

The effects of 12 experimental variables on the shear behavior of RC beams strengthened with FRP were considered to propose GEP models. Experimental variables with the most influence in the proposed GEP models were \({d}_{{\text{fe}}}\) and \({b}_{{\text{w}}}\) for fully-wrapped beams, \({d}_{{\text{fe}}}\) and \({f}_{{\text{yw}}}\) for U-wrapped beams, \(d\) and \({b}_{{\text{w}}}\) for side-bonded beams.

The proposed GEP models outperformed equations commonly used in the literature, exhibiting higher R values and lower COV values. These models incorporated variables such as \(a/d\) and \({\rho }_{w}\), which significantly influence shear behavior. Among the derived GEP models, it was observed that the model yielding the best statistical results was for side-bonded beams.

The GEP models proposed in this study are valid for beams where the shear failure occurs, effective depth of beam greater than 100 mm, and \(a/d\) ratio greater than 0.71. Strengthened with carbon, glass and aramid strips was applied perpendicular to the beam axis. In future research, it is recommended to derive equations with higher accuracy by gathering a wider data set, including beams strengthened with different inclined type of FRP strips such as carbon, glass, aramid, and basalt.

Finally, this study proved that GEP models can be used effectively and reliably in various scientific fields, thanks to their robustness and ability to adapt to different conditions and problems. With these features, it can be said that GEP models have the potential to make significant contributions to research studies.

Source codes of the GEP

Data availability

The data used in this are available upon request to the corresponding author.

Abbreviations

- COV:

-

Coefficient of variation

- ET:

-

Expression tree

- GEP:

-

Gene expression programming

- FEM:

-

Finite element model

- FRP:

-

Fiber-reinforced polymers

- M :

-

Mean value

- MAPE:

-

Mean absolute percentage error

- R :

-

Coefficient of correlation

- RC:

-

Reinforced concrete

- RMSE:

-

Root-mean-square error

- SD:

-

Standard deviation

- b w :

-

Beam width (mm)

- f c :

-

Concrete compressive strength (MPa)

- V f :

-

Contribution of FRP to the shear strength (kN)

- d :

-

Effective depth of beam (mm)

- d fe :

-

Effective depth of FRP (mm)

- ρ f :

-

FRP reinforcement ratio

- t f :

-

FRP thickness (mm)

- E f :

-

Modulus of elasticity (GPa)

- a/d :

-

Shear span-to-effective depth ratio

- w f/s f :

-

Shear strip width-to-spacing ratio

- ρ w :

-

Stirrup ratio

- ε fu :

-

Ultimate strain

- f yw :

-

Yield strength of stirrups (MPa)

References

Akkaya HC, Aydemir C, Arslan G (2022) Investigation on shear behavior of reinforced concrete deep beams without shear reinforcement strengthened with fiber reinforced polymers. Case Stud Constr Mater 17:e01392. https://doi.org/10.1016/j.cscm.2022.e01392

Akkaya HC, Aydemir C, Arslan G (2022) An experimental research on reinforced concrete deep beams fully wrapped with fiber reinforced polymers against shear. Case Stud Constr Mater 17:e01198. https://doi.org/10.1016/j.cscm.2022.e01198

Akkaya HC, Aydemir C, Arslan G (2024) Evaluation of shear behavior of short-span reinforced concrete deep beams strengthened with fiber reinforced polymer strips. Eng Struct 299:117145. https://doi.org/10.1016/j.engstruct.2023.117145

Godat A, Qu Z, Lu XZ, Labossière P, Ye LP, Neale KW (2010) Size effects for reinforced concrete beams strengthened in shear with CFRP strips. J Compos Constr 14(3):260–271. https://doi.org/10.1061/(asce)cc.1943-5614.0000072

Diagana C, Li A, Gedalia B, Delmas Y (2003) Shear strengthening effectiveness with CFF strips. Eng Struct 25(4):507–516. https://doi.org/10.1016/S0141-0296(02)00208-0

Li W, Leung CKY (2016) Shear span-depth ratio effect on behavior of RC beam shear strengthened with full-wrapping FRP strip. J Compos Constr 20(3):4015067. https://doi.org/10.1061/(asce)cc.1943-5614.0000627

Araki N, Matsuzaki Y, Nakano K, Kataoka T, Fukuyama H (1997) Shear capacity of retrofitted RC members with continuous fiber sheets. In: Non-metallic (FRP) reinforcement for concrete structures, proceedings of the third symposium, vol 1, pp 515–522

Cao SY, Chen JF, Teng JG, Hao Z, Chen J (2005) Debonding in RC beams shear strengthened with complete FRP wraps. J Compos Constr 9(5):417–428. https://doi.org/10.1061/(asce)1090-0268(2005)9:5(417)

Moradi E, Naderpour H, Kheyroddin A (2020) An experimental approach for shear strengthening of RC beams using a proposed technique by embedded through-section FRP sheets. Compos Struct 238:111988. https://doi.org/10.1016/j.compstruct.2020.111988

Leung CKY, Chen Z, Lee S, Ng M, Xu M, Tang J (2007) Effect of size on the failure of geometrically similar concrete beams strengthened in shear with FRP strips. J Compos Constr 11(5):487–496. https://doi.org/10.1061/(asce)1090-0268(2007)11:5(487)

Funakawa I (1997) Experimental study on shear strenghthening with continuous fiber reinforcement sheet and methacrylate resin. In: Proceeding of third international symposium of non-metallic (FRP) reinforcement for concrete strutures, vol 1, pp 475–482

Umezu K (1997) Shear behavior of RC beams with aramid fiber sheet, Japan Concrete Institute, non-metallic (FRP) reinforcement for concrete structures. In: Proceeding of the third international symposium, vol 1, pp 491–498

Beber AJ, Campos Filho A (2005) CFRP composites on the shear strengthening of reinforced concrete beams. Rev IBRACON Estruturas 1:3

Ianniruberto U, Imbimbo M (2004) Role of fiber reinforced plastic sheets in shear response of reinforced concrete beams: experimental and analytical results. J Compos Constr 8(5):415–424. https://doi.org/10.1061/(asce)1090-0268(2004)8:5(415)

Miyajima H, Kosa K, Tasaki K, Matsumoto S (2005) Shear strengthening of RC beams using carbon fiber sheets & its resistance mechanism. In: Proceedings, pp 114–125

Grande E, Imbimbo M, Rasulo A (2009) Effect of transverse steel on the response of RC beams strengthened in shear by FRP: experimental study. J Compos Constr 13(5):405–414. https://doi.org/10.1061/(asce)1090-0268(2009)13:5(405)

Zhang G, Kishi N, Mikami H (2007) Effects of bonding configurations on shear behaviour of RC beams reinforced with aramid FRP sheets. In: Proceedings 8th international symposium FRP reinforcement for concrete structures, Patras, Greece

Alzate A, Arteaga A, De Diego A, Cisneros D, Perera R (2013) Refuerzo externo a cortante con láminas de CFRP en elementos de hormigón armado. Mater Constr 63:251–265. https://doi.org/10.3989/mc.2012.06611

Uji K (1992) Improving shear capacity of existing reinforced concrete members by applying carbon fiber sheets. Trans Japan Concr Inst 14:253–266

Al-Tersawy SH (2013) Effect of fiber parameters and concrete strength on shear behavior of strengthened RC beams. Constr Build Mater 44:15–24. https://doi.org/10.1016/j.conbuildmat.2013.03.007

Miyauchı K, Inoue S, Nishibayashi S, Tanaka Y (1998) Shear behavior of reinforced concrete beam strengthened with CFRP sheet. Trans Japan Concr Inst 19:97–104

Adey B, Brühwiler E. Carbon fıbre shear strengthening of reinforced concrete beams. Retrieved from https://files/27694/AdeyveBrühwiler-Carbonfibreshearstrengtheningofreinforcedcon.pdf

Taerwe L, Khalil H, Matthys S (1997) Behaviour of RC beams strengthened in shear by external CFRP sheets. In: Proceedings of the third international symposium on non-metallic (FRP) reinforcement for concrete structures (FRPRCS-3), Sapporo (Japan), 14–16 October Volume 1

Mitsui Y, Murakami K, Takeda K, Sakai H (1997) A study on shear reinforcement of reinforced concrete beams externally bonded with carbon fiber sheets. Compos Interfaces 5:285–295. https://doi.org/10.1163/156855498X00081

Khalifa A (1999) Shear performance of reinforced concrete beams strengthened with advanced composites. Ph.D. dissertation, Structural Engineering Department, Alexandria University, Alexandria, Egypt

Dan Zhao JX, Ziqiang D (2000) Experimental study on increasing shear capacity of reinforced concrete beams with carbon fiber cloth. Arch Struct 7:21–25

Matthys S, Taerwe L (2000) Use of advanced composites in concrete construction. In: Proceedings of the international conference technology watch and innovation in the construction industry, Brussels, 5–6 April 2000, pp 177–184

Adhikary BB, Mutsuyoshi H, Ashraf M (2004) Shear strengthening of reinforced concrete beams using fiber-reinforced polymer sheets with bonded anchorage. Struct J 101(5):660–668

Carolin A, Täljsten B (2005) Experimental study of strengthening for increased shear bearing capacity. J Compos Constr 9(6):488–496. https://doi.org/10.1061/(asce)1090-0268(2005)9:6(488)

Zhou Y (2009) Theoretical and experimental research on the strength and ductility of FRP- high strength concrete beams. Dalian University of Technology, p 226

Teng JG, Chen GM, Chen JF, Rosenboom OA, Lam L (2009) Behavior of RC beams shear strengthened with bonded or unbonded FRP wraps. J Compos Constr 13(5):394–404. https://doi.org/10.1061/(asce)cc.1943-5614.0000040

Bukhari IA, Vollum RL, Ahmad S, Sagaseta J (2010) Shear strengthening of reinforced concrete beams with CFRP. Mag Concr Res 62(1):65–77. https://doi.org/10.1680/macr.2008.62.1.65

Colalillo MA, Sheikh SA (2012) Seismic retrofit of shear-critical reinforced concrete beams using CFRP. Constr Build Mater 32:99–109. https://doi.org/10.1016/j.conbuildmat.2010.12.065

Li J (2014) Research on the size effect of CFRP shear strengthened reinforced concrete beams under different shear failure modes. Shenzhen University

Sengun K, Arslan G (2022) Parameters affecting the behaviour of RC beams strengthened in shear and flexure with various FRP systems. Structures 40:202–212. https://doi.org/10.1016/j.istruc.2022.04.024

Sengun K, Arslan G (2022) Investigation of the parameters affecting the behavior of RC beams strengthened with FRP. Front Struct Civ Eng 16(6):729–743. https://doi.org/10.1007/s11709-022-0854-9

Khalifa A, Nanni A (2000) Improving shear capacity of existing RC T-section beams using CFRP composites. Cement Concr Compos 22(3):165–174. https://doi.org/10.1016/S0958-9465(99)00051-7

Gang WLA, Zhitao L (2000) Experimental study on shear reinforcement of reinforced concrete beams with carbon fiber cloth. Build Struct 7:16–20

Annaiah RH (2021) Shear performance of RC beams strengthened in situ with composites. Masters Theses. https://scholarsmine.mst.edu/masters_theses/2021

Deniaud C, Cheng JR (2001) Shear behavior of reinforced concrete T-beams with externally bonded fiber-reinforced polymer sheets. Structural journal 98(3):386–394

Cui X (2001) Experimental study on shear performance of reinforced concrete beams reinforced with carbon fiber cloth. Beijing University of Technology, p 55

Zhiping KCL, Haobo W (2004) Experimental study on carbon fiber shear reinforcement of concrete beam without web reinforcement. J Tongji Univ (Nat Sci Edn) 5:575–579

Xuesong FZC (2004) Experimental study on shear properties of reinforced beams with carbon fiber sheets. The third national FRP academic exchange conference (China)

Danying GWQ, Jun Z (2007) Research on calculation method of shear bearing capacity of concrete beam reinforced with carbon fiber cloth. J Hydroelectric 26(6):41–45

Altin S, Anil Ö, Kopraman Y, Mertoǧlu Ç, Kara ME (2010) Improving shear capacity and ductility of shear-deficient RC beams using CFRP strips. J Reinf Plast Compos 29(19):2975–2991. https://doi.org/10.1177/0731684410363182

Gamino AL, Sousa JLAO, Manzoli OL, Bittencourt TN (2010) Estruturas de concreto reforçadas com PRFC Parte II: análise dos modelos de cisalhamento. Revista IBRACON de Estruturas e Materiais 3(1):24–49. https://doi.org/10.1590/s1983-41952010000100003

Luo Y (2010) Shear reinforcement of reinforced concrete t-beam wound with u-shaped carbon fiber cloth-study on strengthening factors. Central South University, p 80

Belarbi A, Bae SW, Brancaccio A (2012) Behavior of full-scale RC T-beams strengthened in shear with externally bonded FRP sheets. Constr Build Mater 32:27–40. https://doi.org/10.1016/j.conbuildmat.2010.11.102

Tang Q (2012) Influence of concrete strength on shear performance of T beam reinforced with u-shaped carbon fiber girders. Central South University, p 60

Koutas L, Triantafillou TC (2013) Use of anchors in shear strengthening of reinforced concrete T-beams with FRP. J Compos Constr 17(1):101–107. https://doi.org/10.1061/(ASCE)CC.1943-5614.0000316

Manos GC, Theofanous M, Katakalos K (2014) Numerical simulation of the shear behaviour of reinforced concrete rectangular beam specimens with or without FRP-strip shear reinforcement. Adv Eng Softw 67:47–56. https://doi.org/10.1016/j.advengsoft.2013.08.001

Ozden S, Atalay HM, Akpinar E, Erdogan H, Vulas YZ (2014) Shear strengthening of reinforced concrete T-beams with fully or partially bonded fibre-reinforced polymer composites. Struct Concr 15(2):229–239. https://doi.org/10.1002/suco.201300031

Deniaud C, Roger Cheng JJ (2003) Reinforced concrete T-beams strengthened in shear with fiber reinforced polymer sheets. J Compos Constr 7(4):302–310. https://doi.org/10.1061/(asce)1090-0268(2003)7:4(302)

Zhuang TLY (2003) Experimental study on shear behavior of concrete beam reinforced by fiber composite fabric. J Civ Eng 36(11):12–18

Haidong RCH, Jian Y (2003) Study on shear properties of reinforced concrete beams reinforced with glass fiber cloth. Concrete 5:35–37

Panda KC, Bhattacharyya SK, Barai SV (2013) Effect of transverse steel on the performance of RC T-beams strengthened in shear zone with GFRP sheet. Constr Build Mater 41:79–90. https://doi.org/10.1016/j.conbuildmat.2012.11.098

Baggio D, Soudki K, Noël M (2014) Strengthening of shear critical RC beams with various FRP systems. Constr Build Mater 66:634–644. https://doi.org/10.1016/j.conbuildmat.2014.05.097

Panigrahi AK, Biswal KC, Barik MR (2014) Strengthening of shear deficient RC T-beams with externally bonded GFRP sheets. Constr Build Mater 57:81–91. https://doi.org/10.1016/j.conbuildmat.2014.01.076

Zheng HSC, Ruixing Z (2004) Analysis and calculation of the behavior of inclined section of beams strengthened with CFRP. Ind Constr 2:82–84

Mofidi A, Chaallal O (2014) Tests and design provisions for reinforced-concrete beams strengthened in shear using FRP sheets and strips. Int J Concr Struct Mater 8(2):117–128. https://doi.org/10.1007/s40069-013-0060-1

Zhouhong ZYC, Xueyang H (2013) Experimental study on shear behavior of RC&PPC beams strengthened with CFRP plates. Eng Mech 6:236–246

Guangfu SJZ, Yanhong Z (2005) Comparison of shear strength between GFRP and CFRP reinforced t-section RC overhanging beams. Sichuan Build Sci 6:63–68

Chaoyang ZJL, Fan X (2017) Shear test of concrete beam reinforced with mixed anchor. Acta Materiae Compositae Sinica 8:714–721

Bae S-W, Belarbi A (2013) Behavior of various anchorage systems used for shear strengthening of concrete structures with externally bonded FRP sheets. J Bridg Eng 18(9):837–847. https://doi.org/10.1061/(asce)be.1943-5592.0000420

Chen GM, Zhang Z, Li YL, Li XQ, Zhou CY (2016) T-section RC beams shear-strengthened with anchored CFRP U-strips. Compos Struct 144:57–79. https://doi.org/10.1016/j.compstruct.2016.02.033

Kim Y, Quinn K, Ghannoum WM, Jirsa JO (2014) Strengthening of reinforced concrete T-beams using anchored CFRP materials. ACI Struct J. https://doi.org/10.14359/51687025

Bourget S, El-Saikaly G, Chaallal O (2017) Behavior of reinforced concrete t-beams strengthened in shear using closed carbon fiber-reinforced polymer stirrups made of laminates and ropes. ACI Struct J 114(5):1087–1098. https://doi.org/10.14359/51700786

El-Saikaly G, Chaallal O, Benmokrane B (2017) Comparison of anchorage systems for RC T-beams strengthened in shear with EB-CFRP. In: Proceeding 6th asia-pacific conference on FRP in structures, pp 1–5

Frederick FFR, Sharma UK, Gupta VK (2017) Influence of end anchorage on shear strengthening of reinforced concrete beams using CFRP composites. Curr Sci 112(5):973–981. https://doi.org/10.18520/cs/v112/i05/973-981

Chajes MJ, Januszka TF, Mertz DR, Thomson TA, Finch WW (1995) Shear strengthening of reinforced concrete beams using externally applied composite fabrics. Struct J 92(3):295–303

Norris T, Saadatmanesh H, Ehsani MR (1997) Shear and flexural strengthening of R/C beams with carbon fiber sheets. J Struct Eng 123:903–911. https://doi.org/10.1061/(ASCE)0733-9445(1997)123:7(903)

Matthys S (2000) Structural behaviour and design of concrete members strengthened with externally bonded FRP reinforcement. Doctoral dissertation, Ghent University

Chaallal O, Shahawy M, Hassan M (2002) Performance of reinforced concrete T-girders strengthened in shear with carbon fiber-reinforced polymer fabric. Struct J 99(3):335–343

Khalifa A, Nanni A (2002) Rehabilitation of rectangular simply supported RC beams with shear deficiencies using CFRP composites. Constr Build Mater 16(3):135–146. https://doi.org/10.1016/S0950-0618(02)00002-8

Abdel-Jaber MS, Walker PR, Hutchinson AR (2003) Shear strengthening of reinforced concrete beams using different configurations of externally bonded carbon fibre reinforced plates. Mater Struct 36:291–301

Allam SM, Ebeido TI (2003) Retrofitting of RC beams predamaged in shear using CFRP sheets. Alex Eng J 42(1):87–101

Zhang Z, Hsu C-TT, Moren J (2004) Shear strengthening of reinforced concrete deep beams using carbon fiber reinforced polymer laminates. J Compos Constr 8(5):403–414. https://doi.org/10.1061/(asce)1090-0268(2004)8:5(403)

Islam MR, Mansur MA, Maalej M (2005) Shear strengthening of RC deep beams using externally bonded FRP systems. Cement Concr Compos 27(3):413–420. https://doi.org/10.1016/j.cemconcomp.2004.04.002

Dias SJ, Barros JA (2005) Experimental research of a new CFRP-based shear strengthening technique for reinforced concrete beams. Revista IBRACON de estruturas 1(2):103–114

Teng JG, De Lorenzis L, Wang B, Li R, Wong TN, Lam L (2006) Debonding failures of RC beams strengthened with near surface mounted CFRP strips. J Compos Constr 10(2):92–105. https://doi.org/10.1061/(asce)1090-0268(2006)10:2(92)

Qu Z (2008) Analysis and design model of concrete beams strengthened with FRP shear. Tsinghua University, Beijing

Mofidi A, Chaallal O (2011) Shear strengthening of RC beams with externally bonded FRP composites: effect of strip-width-to-strip-spacing ratio. J Compos Constr 15(5):732–742. https://doi.org/10.1061/(asce)cc.1943-5614.0000219

El-Ghandour AA (2011) Experimental and analytical investigation of CFRP flexural and shear strengthening efficiencies of RC beams. Constr Build Mater 25(3):1419–1429. https://doi.org/10.1016/j.conbuildmat.2010.09.001

Bae SW, Tann BD, Belarbi A (2012) Size effect of reinforced concrete beams strengthened in shear with externally bonded CFRP sheets. In: 6th International conference on FRP composites in civil engineering. CICE

Godat A, Chaallal O (2013) Strut-and-tie method for externally bonded FRP shear-strengthened large-scale RC beams. Compos Struct 99:327–338. https://doi.org/10.1016/j.compstruct.2012.11.034

Ebead U, Saeed H (2017) FRP/stirrups interaction of shear-strengthened beams. Mater Struct 50(2):103. https://doi.org/10.1617/s11527-016-0973-7

Al-Sulaimani GJ, Sharif A, Basunbul IA, Baluch MH, Ghaleb BN (1994) Shear repair for reinforced concrete by fiberglass plate bonding. Struct J 91(4):458–464

Mosallam AS, Banerjee S (2007) Shear enhancement of reinforced concrete beams strengthened with FRP composite laminates. Compos B Eng 38(5–6):781–793. https://doi.org/10.1016/j.compositesb.2006.10.002

Nguyen-Minh L, Rovňák M (2015) Size effect in uncracked and pre-cracked reinforced concrete beams shear-strengthened with composite jackets. Compos B Eng 78:361–376. https://doi.org/10.1016/j.compositesb.2015.02.035

Al-Rousan RZ, Haddad RH, Swesi AO (2015) Repair of shear-deficient normal weight concrete beams damaged by thermal shock using advanced composite materials. Compos B Eng 70:20–34. https://doi.org/10.1016/j.compositesb.2014.10.032

Li W, Leung CKY (2017) Effect of shear span-depth ratio on mechanical performance of RC beams strengthened in shear with U-wrapping FRP strips. Compos Struct 177:141–157. https://doi.org/10.1016/j.compstruct.2017.06.059

Panigrahi SK, Deb A, Bhattacharyya SK (2016) Modes of failure in shear deficient RC T-beams strengthened with FRP. J Compos Constr 20(1):4015029. https://doi.org/10.1061/(asce)cc.1943-5614.0000586

Peng, W. (2016). Coupling Effect of Shear Failure Mode And Steel Stirrup Ratio on Shear Behavior of RC Beams Externally Bonded with CFRP Strips. Shenzhen University, 78–80. (in Chinese)

Al-Lebban YF, Mackie KR (2019) Polyurethane-FRP external strengthening of RC beams with no steel stirrups. J Compos Constr 23(1):4018074. https://doi.org/10.1061/(asce)cc.1943-5614.0000916

Gonzalez-Libreros JH, Pellegrino C, Giacomin G (2018) RC beams strengthened on shear with FRP and FRCM composites. In: Proceedings of Italian concrete days 2016. Springer, pp 400–410

Pham TM, Hao H (2016) Impact behavior of FRP-strengthened RC beams without stirrups. J Compos Constr 20(4):4016011. https://doi.org/10.1061/(asce)cc.1943-5614.0000671

Al-Rousan R, Alhassan M, Ababneh A (2016) Simulating the response of CFRP strengthened shear-keys in composite concrete bridges. Mater Des 90:733–744. https://doi.org/10.1016/j.matdes.2015.11.032

Huo J, Li Z, Zhao L, Liu J, Xiao Y (2018) Dynamic behavior of carbon fiber-reinforced polymer-strengthened reinforced concrete beams without stirrups under impact loading. ACI Struct J 115(3):775–787. https://doi.org/10.14359/51701283

El-Saikaly G, Godat A, Chaallal O (2015) New anchorage technique for FRP shear-strengthened RC T-beams using CFRP rope. J Compos Constr 19(4):4014064. https://doi.org/10.1061/(asce)cc.1943-5614.0000530

Galal K, Mofidi A (2010) Shear strengthening of RC T-beams using mechanically anchored unbonded dry carbon fiber sheets. J Perform Constr Facil 24(1):31–39. https://doi.org/10.1061/(asce)cf.1943-5509.0000067

Randl N, Harsányi P (2018) Developing optimized strengthening systems for shear-deficient concrete members. Struct Concr 19(1):116–128. https://doi.org/10.1002/suco.201600187

Qin S, Dirar S, Yang J, Chan AHC, Elshafie M (2015) CFRP shear strengthening of reinforced-concrete T-beams with corroded shear links. J Compos Constr 19(5):4014081. https://doi.org/10.1061/(asce)cc.1943-5614.0000548

Oller E, Pujol M, Marí A (2019) Contribution of externally bonded FRP shear reinforcement to the shear strength of RC beams. Compos B Eng 164:235–248. https://doi.org/10.1016/j.compositesb.2018.11.065

Nguyen-Minh L, Vo-Le D, Tran-Thanh D, Pham TM, Ho-Huu C, Rovňák M (2018) Shear capacity of unbonded post-tensioned concrete T-beams strengthened with CFRP and GFRP U-wraps. Compos Struct 184:1011–1029. https://doi.org/10.1016/j.compstruct.2017.10.072

Altin S, Anil Ö, Ocakli RÖ, Kopraman Y (2011) Retrofitting of shear damaged RC beams using diagonal CFRP strips. J Reinf Plast Compos 30(17):1495–1507. https://doi.org/10.1177/0731684411421843

Panda KC, Bhattacharyya SK, Barai SV (2013) Shear strengthening effect by bonded GFRP strips and transverse steel on RC T-beams. Struct Eng Mech 47(1):75–98. https://doi.org/10.12989/sem.2013.47.1.075

El-Maaddawy T, Chekfeh Y (2013) Shear strengthening of t-beams with corroded stirrups using composites. ACI Struct J 110(5):779–789. https://doi.org/10.14359/51685831

Mofidi A, Thivierge S, Chaallal O, Shao Y (2014) Behavior of reinforced concrete beams strengthened in shear using L-shaped CFRP plates: experimental investigation. J Compos Constr 18(2):4013033. https://doi.org/10.1061/(asce)cc.1943-5614.0000398

Samir D, Lees J, Morley C (2012) Precracked reinforced concrete T-beams repaired in shear with bonded carbon fiber-reinforced polymer sheets. ACI Struct J. https://doi.org/10.14359/51683632

El-Maaddawy T, Chekfeh Y (2012) Retrofitting of severely shear-damaged concrete T-beams using externally bonded composites and mechanical end anchorage. J Compos Constr 16(6):693–704. https://doi.org/10.1061/(asce)cc.1943-5614.0000299

Chaallal O, Mofidi A, Benmokrane B, Neale K (2011) Embedded through-section FRP rod method for shear strengthening of RC beams: performance and comparison with existing techniques. J Compos Constr 15(3):374–383. https://doi.org/10.1061/(asce)cc.1943-5614.0000174

Farghal O (2012) Shear strengthening of RCT-beams by means of CFRP sheets. J Eng Sci 40(5):1293–1307. https://doi.org/10.21608/jesaun.2012.114499

Sato Y (1997) Ultimate shear capacity of reinforced concrete beams with carbon fiber sheet. In Proceedings of third international symposium of non-metallic (FRP) reinforcement for concrete syructures, vol 1, pp 499–506

Park SY, Naaman AE, Lopez MM, Till RD (2001) Shear strengthening effect of RC beams using glued CFRP sheets. In: FRP composites in civil engineering. Proceedings of the international conference on FRP composites in civil engineering, Hong Kong Institution of Engineers, Hong Kong Institution of Steel Construction (No. Volume 1)

Täljsten B (2003) Strengthening concrete beams for shear with CFRP sheets. Constr Build Mater 17(1):15–26. https://doi.org/10.1016/S0950-0618(02)00088-0

Pellegrino C, Modena C (2008) An experimentally based analytical model for the shear capacity of FRP-strengthened reinforced concrete beams. Mech Compos Mater 44(3):231–244. https://doi.org/10.1007/s11029-008-9016-y

Deniaud C, Cheng JJR (2001) Shear behavior of RC T-beams with externally bonded FRP sheets. ACI Struct J 98(3):386–394

Chaallal O, Nollet M-J, Perraton D (1998) Shear strengthening of RC beams by externally bonded side CFRP strips. J Compos Constr 2(2):111–113. https://doi.org/10.1061/(asce)1090-0268(1998)2:2(111)

Triantafillou TC (1998) Shear strengthening of reinforced concrete beams using epoxy-bonded FRP composites. ACI Struct J 95(2):107–115. https://doi.org/10.14359/531

Kachlakev DI, Barnes WA (1999) Flexural and shear performance of concrete beams strengthened with fiber reinforced polymer laminates. Spec Publ 188:959–972

Pellegrino C, Modena C (2002) Fiber reinforced polymer shear strengthening of reinforced concrete beams with transverse steel reinforcement. J Compos Constr 6(2):104–111. https://doi.org/10.1061/(asce)1090-0268(2002)6:2(104)

Wong RS, Vecchio FJ (2003) Towards modeling of reinforced concrete members with externally bonded fiber-reinforced polymer composites. ACI Struct J 100(1):47–55

Zhang Z, Hsu C-TT (2005) Shear strengthening of reinforced concrete beams using carbon-fiber-reinforced polymer laminates. J Compos Constr 9(2):158–169. https://doi.org/10.1061/(asce)1090-0268(2005)9:2(158)

Monti G, Liotta M (2007) Tests and design equations for FRP-strengthening in shear. Constr Build Mater 21(4):799–809. https://doi.org/10.1016/j.conbuildmat.2006.06.023

Grande E, Imbimbo M, Rasulo A (2008) Experimental study on the capacity of RC beams strengthened in shear by CFRP-sheets. In: Fourth international conference on FRP composites in civil engineering (CICE2008), pp 1–6

Kim G, Sim J, Oh H (2008) Shear strength of strengthened RC beams with FRPs in shear. Constr Build Mater 22(6):1261–1270. https://doi.org/10.1016/j.conbuildmat.2007.01.021

Siddiqui NA (2009) Experimental investigation of RC beams strengthened with externally bonded FRP composites. Latin Am J Solids Struct 8:343–362

Lim DH (2010) Shear behaviour of RC beams strengthened with NSM and EB CFRP strips. Mag Concr Res 62(3):211–220. https://doi.org/10.1680/macr.2010.62.3.211

Ebead U, Saeed H (2013) Hybrid shear strengthening system for reinforced concrete beams: an experimental study. Eng Struct 49:421–433. https://doi.org/10.1016/j.engstruct.2012.11.039

Sundarraja MC, Rajamohan S, Bhaskar D (2008) Shear strengthening of RC beams using GFRP vertical strips—an experimental study. J Reinf Plast Compos 27(14):1477–1495. https://doi.org/10.1177/0731684407081772

Bukhari IA, Vollum R, Ahmad S, Sagaseta J (2013) Shear strengthening of short span reinforced concrete beams with CFRP sheets. Arab J Sci Eng 38(3):523–536. https://doi.org/10.1007/s13369-012-0333-z

Moren JE (2002) Shear behaviour of reinforced concrete deep beams strengthened with CFRP laminates. Master of Science in Civil Engineering, p 677. https://digitalcommons.njit.edu/theses/677

Sengun K, Arslan G (2017) Influence of CFRP on the strength of retrofitted RC beams without stirrups. Sigma J Eng Nat Sci 35(1):77–85

Keskin RSO, Sengun K, Arslan G (2017) Retrofitting SFRC beams by using CFRP. Eur Proc Sci Technol Eng Math 1:310–315

Keskin RSO, Arslan G, Sengun K (2017) Influence of CFRP on the shear strength of RC and SFRC beams. Constr Build Mater 153:16–24. https://doi.org/10.1016/j.conbuildmat.2017.06.170

Sengun K, Arslan G (2023) Performance of RC beams strengthened in flexure and shear with CFRP and GFRP. Iran J Sci Technol Trans Civ Eng. https://doi.org/10.1007/s40996-023-01305-5

Cakir F, Aydin MR, Acar V, Aksar B, Akkaya HC (2023) An experimental study on RC beams shear-strengthened with intraply hybrid U-jackets composites monitored by digital image correlation (DIC). Compos Struct 323:117503. https://doi.org/10.1016/j.compstruct.2023.117503

Chen JF, Teng JG (2003) Shear capacity of FRP-strengthened RC beams: FRP debonding. Constr Build Mater 17(1):27–41. https://doi.org/10.1016/S0950-0618(02)00091-0

Chen JF, Teng JG (2003) Shear capacity of fiber-reinforced polymer-strengthened reinforced concrete beams: fiber reinforced polymer rupture. J Struct Eng 129(5):615–625. https://doi.org/10.1061/(ASCE)0733-9445(2003)129:5(615)

Kar S, Biswal KC (2020) Shear strengthening of reinforced concrete T-beams by using fiber-reinforced polymer composites: a data analysis. Arab J Sci Eng 45(5):4203–4234. https://doi.org/10.1007/s13369-020-04412-x

Kotynia R, Oller E, Marí A, Kaszubska M (2021) Efficiency of shear strengthening of RC beams with externally bonded FRP materials—state-of-the-art in the experimental tests. Compos Struct 267:113891. https://doi.org/10.1016/j.compstruct.2021.113891

Lima JL, Barros JA (2011) Reliability analysis of shear strengthening externally bonded FRP models. Proc Inst Civ Eng Struct Build 164(1):43–56. https://doi.org/10.1680/stbu.9.00042

Oller E, Kotynia R, Marí A (2021) Assessment of the existing models to evaluate the shear strength contribution of externally bonded FRP shear reinforcements. Compos Struct 266:113641. https://doi.org/10.1016/j.compstruct.2021.113641

Pellegrino C, Vasic M (2013) Assessment of design procedures for the use of externally bonded FRP composites in shear strengthening of reinforced concrete beams. Compos B Eng 45(1):727–741. https://doi.org/10.1016/j.compositesb.2012.07.039

Bousselham A, Chaallal O (2006) Effect of transverse steel and shear span on the performance of RC beams strengthened in shear with CFRP. Compos B Eng 37(1):37–46. https://doi.org/10.1016/j.compositesb.2005.05.012

Benzeguir ZEA, El-Saikaly G, Chaallal O (2019) Size effect in RC T-beams strengthened in shear with externally bonded CFRP sheets: experimental study. J Compos Constr 23(6):4019048. https://doi.org/10.1061/(ASCE)CC.1943-5614.0000975

Kumari A, Nayak AN (2021) Strengthening of shear deficient RC deep beams using GFRP sheets and mechanical anchors. Can J Civ Eng 48(1):1–15. https://doi.org/10.1139/cjce-2019-0333

Nayak AN, Kumari A, Swain RB (2018) Strengthening of RC beams using externally bonded fibre reinforced polymer composites. Structures 14:137–152. https://doi.org/10.1016/j.istruc.2018.03.004

Panda KC, Bhattacharyya SK, Barai SV (2011) Shear strengthening of RC T-beams with externally side bonded GFRP sheet. J Reinf Plast Compos 30(13):1139–1154. https://doi.org/10.1177/0731684411417202

Li W, Li J, Ren X, Leung CKY, Xing F (2015) Coupling effect of concrete strength and bonding length on bond behaviors of fiber reinforced polymer-concrete interface. J Reinf Plast Compos 34(5):421–432. https://doi.org/10.1177/0731684415573816

Chen JF, Teng JG (2001) Anchorage strength models for FRP and steel plates bonded to concrete. J Struct Eng 127(7):784–791. https://doi.org/10.1061/(asce)0733-9445(2001)127:7(784)

Yuan H, Teng JG, Seracino R, Wu ZS, Yao J (2004) Full-range behavior of FRP-to-concrete bonded joints. Eng Struct 26(5):553–565. https://doi.org/10.1016/j.engstruct.2003.11.006

Chen Y, Sareh P, Feng J, Sun Q (2017) A computational method for automated detection of engineering structures with cyclic symmetries. Comput Struct 191:153–164. https://doi.org/10.1016/j.compstruc.2017.06.013

Chen Y, Fan L, Feng J (2018) Automatic and exact symmetry recognition of structures exhibiting high-order symmetries. J Comput Civ Eng 32(2):1–14. https://doi.org/10.1061/(asce)cp.1943-5487.0000743

Chen Y, Yan J, Feng J, Sareh P (2021) Particle swarm optimization-based metaheuristic design generation of non-trivial flat-foldable origami tessellations with degree-4 vertices. J Mech Des 143(1):1–12. https://doi.org/10.1115/1.4047437

Chen Y, Lu C, Yan J, Feng J, Sareh P (2022) Intelligent computational design of scalene-faceted flat-foldable tessellations. J Comput Des Eng 9(5):1765–1774. https://doi.org/10.1093/jcde/qwac082

Chen Y, Fan L, Bai Y, Feng J, Sareh P (2020) Assigning mountain-valley fold lines of flat-foldable origami patterns based on graph theory and mixed-integer linear programming. Comput Struct 239:106328. https://doi.org/10.1016/j.compstruc.2020.106328

Fan W, Chen Y, Li J, Sun Y, Feng J, Hassanin H, Sareh P (2021) Machine learning applied to the design and inspection of reinforced concrete bridges: resilient methods and emerging applications. Structures 33:3954–3963. https://doi.org/10.1016/j.istruc.2021.06.110

Rao Z, Tung PY, Xie R, Wei Y, Zhang H, Ferrari A, Raabe D (2022) Machine learning-enabled high-entropy alloy discovery. Science 378(6615):78–85

Alacali S (2022) A prediction model for strength and strain of CFRP-confined concrete cylinders using gene expression programming. Comput Concr 30(6):377–391. https://doi.org/10.12989/CAC.2022.30.6.377

Alavi AH, Gandomi AH, Sahab MG, Gandomi M (2010) Multi expression programming: a new approach to formulation of soil classification. Eng Comput 26:111–118. https://doi.org/10.1007/s00366-009-0140-7

Sharifzadeh M, Sikinioti-Lock A, Shah N (2019) Machine-learning methods for integrated renewable power generation: a comparative study of artificial neural networks, support vector regression, and Gaussian process regression. Renew Sustain Energy Rev 108:513–538. https://doi.org/10.1016/j.rser.2019.03.040

Khan MA, Memon SA, Farooq F, Javed MF, Aslam F, Alyousef R (2021) Compressive strength of fly-ash-based geopolymer concrete by gene expression programming and random forest. Adv Civ Eng 2021:1–17. https://doi.org/10.1155/2021/6618407

Khan MA, Zafar A, Farooq F, Javed MF, Alyousef R, Alabduljabbar H, Khan MI (2021) Geopolymer concrete compressive strength via artificial neural network, adaptive neuro fuzzy interface system, and gene expression programming with K-fold cross validation. Front Mater 8:621163. https://doi.org/10.3389/fmats

Alshboul O, Almasabha G, Shehadeh A, Mamlook RE, Al Almuflih AS, Almakayeel N (2022) Machine learning-based model for predicting the shear strength of slender reinforced concrete beams without stirrups. Buildings 12(8):1166. https://doi.org/10.3390/buildings12081166

Gandomi AH, Alavi AH, Kazemi S, Gandomi M (2014) Formulation of shear strength of slender RC beams using gene expression programming, part I: without shear reinforcement. Autom Constr 42:112–121. https://doi.org/10.1016/j.autcon.2014.02.007

Kara IF (2011) Prediction of shear strength of FRP-reinforced concrete beams without stirrups based on genetic programming. Adv Eng Softw 42(6):295–304. https://doi.org/10.1016/j.advengsoft.2011.02.002

Al-Ghrery K, Al-Mahaidi R, Kalfat R, Oukaili N (2022) Genetic programming in the prediction of concrete cover separation in RC beams strengthened with FRP. In: Bridge safety, maintenance, management, life-cycle, resilience and sustainability, 1st edn. CRC Press, pp 2487–2494. https://doi.org/10.1201/9781003322641-310

Ism MM, Rabie M (2019) Flexural behavior of continuous RC beams strengthened with externally bonded CFRP sheets. Alex Eng J 58(2):789–800. https://doi.org/10.1016/j.aej.2019.07.001

Anvari AT, Babanajad S, Gandomi AH (2023) Data-driven prediction models for total shear strength of reinforced concrete beams with fiber reinforced polymers using an evolutionary machine learning approach. Eng Struct 276:115292. https://doi.org/10.1016/j.engstruct.2022.115292

ACI Committee 440 (2017) Guide for the design and construction of externally bonded FRP systems for strengthening concrete structures (ACI 440.2R-17). American Concrete Institute, Farmington Hills

Federation Internationale du Beton (FIB) (2001) Externally bonded FRP reinforcement for RC structures. Task Group 9.3, Bullettin No. 14, Lausanne, Switzerland

Ferreira C (2001) Gene expression programming: a new adaptive algorithm for solving problems. Cmplx Syst 13:87–129. https://doi.org/10.48550/arXiv.cs/0102027

Gepsoft GeneXproTools 5.0. (2022) Data modeling and analysis software

Iqbal MF, Liu QF, Azim I, Zhu X, Yang J, Javed MF, Rauf M (2020) Prediction of mechanical properties of green concrete incorporating waste foundry sand based on gene expression programming. J Hazard Mater 384:121322. https://doi.org/10.1016/j.jhazmat.2019.121322

Khan MA, Zafar A, Akbar A, Javed MF, Mosavi A (2021) Application of gene expression programming (GEP) for the prediction of compressive strength of geopolymer concrete. Materials 14(5):1–23. https://doi.org/10.3390/ma14051106

Sabetifar H, Nematzadeh M (2021) An evolutionary approach for formulation of ultimate shear strength of steel fiber-reinforced concrete beams using gene expression programming. Structures 34:4965–4976. https://doi.org/10.1016/j.istruc.2021.10.075

Khalifa A, Gold WJ, Nanni A, Mi AA (1998) Contribution of externally bonded FRP to shear capacity of RC flexural members. J Compos Construct 2(4):195–202. https://doi.org/10.1061/(asce)1090-0268(1998)2:4(195)

Triantafillou TC, Antonopoulos CP (2000) Design of concrete flexural members strengthened in shear with FRP. J Compos Constr 4(4):198–205. https://doi.org/10.1061/(ASCE)1090-0268(2000)4:4(198)

CNR-Italian Research Council, Advisory Committee on Technical Recommendations for Construction (2013) Guide for the design and construction of externally bonded FRP systems for strengthening existing structures. Materials, RC and PC Structures, Masonry Structures (CNR-DT 200/2013). Rome, Italy

Concrete Society (2012) Design guidance for strengthening concrete structures using fibre composite materials, TR 55, Crowthorne, UK

German Committee for Structural Concrete (2012) Strengthening of concrete members with adhesively bonded reinforcement. DAfStb, German

Belarbi A, Bae SW, Ayoub A, Kuchma D, Mirmiran A, Okeil AM (2011) Design of FRP systems for strengthening concrete girders in shear. NCHRP Rep. No. 678, Transportation Research Board, Washington, DC

CSA-S806–12 (2012) Design and construction of building components with fibre-reinforced polymers. Canadian Standards Association, Mississauga

CIDAR, Design guideline for RC structures retrofitted with FRP and metal plates: beams and slabs. Draft 3- Submitted to Standards Australia, The University of Adelaide, p 206

JSCE (Japan Society of Civil Engineers) (2001) Recommendations for upgrading of concrete structures with use of continuous fiber sheets. Concrete engineering series no. 41. JSCE, Tokyo

CECS 146 (2003) Technical specification for strengthening concrete structure with carbon fiber reinforced polymer laminate. Association for Engineering Construction Standardization, Chin Planning Press, Beijing

TEC-18 (2018) Specifications for buildings to be built in seismic areas, Turkish building earthquake code. Ministry of Public Works and Settlement, Ankara

ISIS Design Manual 4 (2001) Strengthening reinforced concrete structures with externally-bonded fiber reinforced polymers, intelligent sensing for innovative structures, Winnipeg, Canada

BS EN 1998-3 (2005) Eurocode 8-design of structures for earthquake resistance—part 3: assessment and retrofitting of buildings. European Committee for Standardization, Brussels

CNR-Italian Research Council, Advisory Committee on Technical Recommendations for Construction (2004) Guide for the design and construction of externally bonded FRP systems for strengthening existing structures. Materials, RC and PC Structures, Masonry Structures (CNR-DT 200/2004), Rome, Italy

CAN/CSA (2002) Design and construction of building components with fiber-reinforced polymer. S806-02. Canadian Standards Association, Rexdale, Canada

Funding

Open access funding provided by the Scientific and Technological Research Council of Türkiye (TÜBİTAK). The authors did not receive support from any organization for the submitted work.

Author information

Authors and Affiliations

Contributions

Conceptualization and writing—original draft, were performed by SA; conceptualization, methodology, and writing—review, were provided by HCA and KS; and supervision and writing—review, were approved by GA. Review and data analysis were analyzed by SA, HCA, KS, and GA.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Alacali, S., Akkaya, H.C., Sengun, K. et al. Proposal and evaluation of new models for predicting the FRP contribution to shear strength in reinforced concrete beams using gene expression programming. Neural Comput & Applic 36, 15515–15544 (2024). https://doi.org/10.1007/s00521-024-09892-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00521-024-09892-8