Abstract

This study proposes a two-stage screening system to predict the most suitable EOR method for a candidate reservoir using artificial neural networks (ANN) trained with more than 1000 worldwide experiences of EOR projects. In the first stage, an ANN is trained to classify the projects into three main categories including water-based, gas and thermal EOR. The prediction accuracy of the trained model in this stage is around 90% over non-observed projects. More specifically, for thermal category, 99 out of 108, for gas category, 96 out of 104 and for water-based category, 47 out of 55 projects in the test data (non-observed data) were assigned to the right category by the model. In the second stage, for each of three categories, a separate ANN is trained with the corresponding datasets to classify the projects into their main sub-categories. The three models developed for classifying water-based, gas and thermal EOR projects into their main sub-categories, delivered a very well performance with average accuracies of 96, 90 and 94%, respectively. The proposed screening system in this work introduces two main opportunities over the previous works in this field. First, the two-stage structure allows for a more accurate EOR selection since the model is less probable to be biased by larger EOR classes, and second, it allows for using additional input features for specific methods which are not available for all types of EOR methods. Finally, we demonstrated the applicability of the proposed system, by considering 12 Iranian candidate reservoirs, for which the primary EOR screening processes was performed in a study established by Mashayekhizadeh et al. in 2014. Screening results in both works are in a full agreement which demonstrates the efficiency and quickness of the proposed system.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

In the recent years, a great deal of effort has been made by different industries toward digitalization transformation. The clear long-term efficiency and benefits of this transformation have made it a requirement for all industries. Oil and gas industry is not an exception of this revolution, and in recent years, there has been a growing appeal for developing effective digitalization processes in this industry [1, 2]. Applying artificial intelligence (AI) and data analysis methods for creating effective solutions in various fields of this industry in recent years is a proof of this fact and has met with great success in many problems up to now [3,4,5,6,7,8,9,10].

One of challenging topics in oil and gas industry is decision making in enhanced oil recovery (EOR) processes. EOR methods are specific procedures during which external agents are injected into the oil reservoir; aiming at modifying original properties of reservoir rock and fluid in such way that more oil would be produced than the conventional recovery methods [11]. Existence of more than twenty alternatives for EOR techniques has made it a challenging task for reservoir engineers when deciding on the most suitable EOR technique for implementing in a candidate reservoir.

Considering the general roadmap of EOR selection to implementation, as shown in Fig. 1, prior to pilot and field implementation of an EOR method, some exclusive, costly and time-consuming studies such as full-filed simulation and various experimental studies need to be conducted for investigating the applicability of different EOR methods [12]. Conducting such studies for all available methods would naturally require a huge amount of costs and a long period of time to be completed. Consequently, focusing on some specific methods would be of a great profit in terms of costs and time and will make the future path more concentrated. Primary EOR screening is an extremely important step in each EOR roadmap which main function and purpose is to determine the most appropriate methods in order to make the future roadmap narrower and more concentrated on some specific EOR methods [13]. Primary screening of EOR methods is usually associated with a large amount of uncertainty, which is mainly due to lack of sufficient data and precise description of the candidate reservoir at early stages of development.

The most convenient and widely applied method for primary screening of EOR methods involves utilizing some pre-defined screening criteria to evaluate the applicability of various EOR methods. These criteria are usually in terms of acceptable ranges for some key reservoir and fluid properties. One of the earliest screening criteria have been proposed by Taber et al. in 1997 which are widely adopted in early stages of EOR screening [14]. However, with increasing the number of worldwide EOR projects and simultaneous progress in computer science in last years, an alternative approach has been gradually broadened as advanced EOR screening. This approach involves application of machine learning (ML) techniques with the past experiences of EOR projects to find the hidden patterns in the past data and then to apply these patterns to predict the suitable output for new data. In this well-known approach, ML algorithms are applied to discover the valuable screening rules from the past successful EOR projects. These rules are in terms of relationships between the reservoir rock and fluid properties and the successfully implemented EOR method.

Up to now, many studies have been the subject of this field, and various ML algorithms have been developed to create intelligent predictive models to identify the most suitable EOR method for a candidate reservoir. All of these studies have applied past experiences of EOR projects to train predictive ML algorithms. A summary on previously conducted research in this field is provided in Table 1. Since both the type (field data, simulation data, extracted from criteria, etc.) and the number of EOR projects used in the cited studies in Table 1 were not the same, any comparison between classification rates and obtained accuracy is highly biased, and hence, we merely mentioned their methods and number of used projects to avoid any faulty comparison.

Lack of sufficient amount of data in the literature of the past EOR projects and insufficient input features have caused many problems in the advanced approach of EOR screening through ML methods. For example, the number of gathered chemical EOR projects in previous works is noticeably lower than that of other EOR categories. The reason is that the worldwide implementation of chemical projects is much less than thermal and gas projects. In all previous works, due to this issue, not all of the sub-categories of EOR methods were included in the screening process. Another problem was that the most dominant and key properties in some EOR techniques were not available for all EOR methods. Hence, these key parameters could not help in the selection process. Our previous study in this area, presented a step-by-step procedure through application of ML techniques in primary EOR screening and compared the performance of different ML algorithms in classifying EOR methods [15]. Also, in this study, the most important challenges, and limitations of ML approach in primary EOR screening have been identified and explained in detail.

In our previous study, EOR selection process with several ML techniques was performed to select the most suitable EOR category out of three major categories of water-based, gas and thermal EOR. The purpose was to compare the performance of different ML algorithms and identify potential challenges in this process. Now, in the current study, we selected ANNs as a proper ML algorithm which performance was demonstrated in our previous study; then the EOR selection process is continued to a more detailed stage. In the other word, current study could be considered as a continuation of our previous work around applying ML algorithms in primary EOR screening.

In this work, we target the existing limitations and challenges by designing a two-stage screening system which improves the EOR selection accuracy in the advanced approach. This two-stage screening system allows for considering almost all EOR sub-categories and using specific input features which are not available for all EOR categories. At first, we studied available sources of data and gathered a large database of worldwide experiences of EOR projects. Particularly, in case of chemical EOR projects, we performed a further step and gathered one of the richest datasets for chemical projects in comparison with previous works. All gathered projects are first classified into three main categories including water-based, gas and thermal methods. Then, based on the recovery mechanisms similarities, the projects of each category are grouped as some unique sub-categories of the more general category.

According to this classification, a two-stage screening model is developed by applying artificial neural networks (ANN). In the first stage of screening, a deep ANN is trained to predict the suitable category out of the three main categories including water-based, gas and thermal EOR. Then, in the second stage, for each of three categories, a separate ANN is trained with the corresponding data to predict the suitable sub-category out of the main sub-categories. All of the developed models in two stages delivered a very well performance in predicting the output of non-observed projects with average accuracies up to 90% in two stages. The process of developing such system and how it will improve screening results using ML and tackle the discussed problems is explained in detail in following sections.

2 Methodology

2.1 EOR database, data gathering

The data used in this work are real-world EOR projects, which were carefully gathered from various sources. The main sources used for data gathering are as follows:

Oil and Gas Journal (OGJ) biannual EOR surveys served as the main source for collection of gas and thermal EOR projects [23,24,25,26,27,28,29,30]. A variety of worldwide EOR projects from these categories are well-aggregated in these surveys. For water-based EOR projects, however, these surveys contain a much lower amount of data in comparison with other categories. In case of water-based EOR, we performed an additional data collection step through which various sources were carefully studied to gather more projects. The main sources used in this step include a chemical EOR book established by James. J. Sheng [31, 32] and some review papers containing the information of past projects [33]. Finally, we achieved one of the richest datasets for chemical projects in comparison with previous works. The initially gathered dataset contained 1445 samples of EOR projects. Each sample in this dataset is a real-world EOR project implemented in a reservoir and is characterized by some rock and fluid properties. The common variables between the gathered data include average porosity (ф), average permeability (K), formation lithology type (sandstone index (SI), carbonate index (CI), tripolite index (TI)), reservoir depth (D), API degree (A), in situ oil viscosity (µ) and reservoir temperature (T). The implemented EOR method is considered as the output. In case of chemical projects, three more key parameters including formation water salinity (FWS), initial hydrocarbon saturation before project (Soi) and Dykstra–Parsons coefficient of formation heterogeneity (DP Coeff.) were also added to the input features.

To clean the gathered data and prepare them for screening modeling, some preprocessing operations were also performed on the dataset. The summary of all operations performed step by step from data gathering to data preparation and preprocessing is shown in Fig. 2.

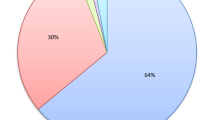

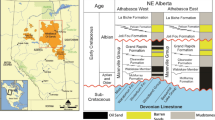

After data preprocessing, the dataset reached a total number of 1120 EOR projects, and it was ready to be used for ML modeling. Distribution of the gathered projects and the corresponding worldwide map are shown in Fig. 3 and 4, respectively.

There are definitely some degrees of uncertainty in the data sources; however, the mentioned sources were almost the only option for gathering a reasonable number of EOR projects for ML modeling. In our previous paper [15], we identified and explained in details the potential challenges and uncertainties in ML modeling of EOR screening which arise from our datasets.

2.2 Data analysis

A detailed statistical analysis is performed on the gathered data and as a summary the boxplots of reservoir rock and fluid properties in different EOR projects are shown in Fig. 5 through 12. These boxplots represent the variation ranges of some specific parameters and provide a visual tool for comparing these ranges between different methods.

Analyzing the boxplots and comparing variation ranges of reservoir properties in different EOR methods highlights some findings which are all in agreement of what is believed in the literature regarding the physical effect of various properties on each EOR process. These observations are summarized as follows:

-

The porosity of reservoir rock in thermal projects especially in steam flooding projects is sensibly higher than that in non-thermal methods. According to Figs. 5 and 6, a majority of steam flooding, CSS and SAGD projects have been implemented in reservoirs with porosities and permeabilities larger than 30% and 1000 md, respectively. High permeability and porosity are needed so that steam can transport fast enough to beat heat loss [34]. In chemical projects, permeability values range between 100 and 1000 md. Despite of chemical and thermal projects, the permeability in gas injection projects accepts a wide range of values varying from 0.1 to 1000 md.

-

Reservoir depth is another important parameter in EOR selecting processes. As widely accepted, in order to prevent extra heat loss in thermal projects, shallower reservoirs are more preferable. While in miscible gas flooding projects, in order to achieve miscibility conditions more easily, deep reservoirs with higher pressure are more preferable [32]. Figure 7 confirms these facts and reservoir depth ranges in thermal projects are obviously smaller than those in other type of projects. The median of reservoir depth in N2 miscible flooding, HC miscible flooding and CO2 miscible flooding projects is 10000 ft, 8000 ft and 5000 ft, respectively. These values well-match the fact that normally, the required depth and thus pressure, to achieve miscibility conditions in Nitrogen injection is higher than that in hydrocarbon injection, and in hydrocarbon injection is higher than that for CO2 injection [35].

-

From Fig. 8, it can be observed that high viscosity oil reservoirs are more favorable for thermal projects. On the other hand, gas miscible flooding projects have been mainly applied in low viscosity oil reservoirs with viscosities ranging from 0.01 to 10 cp. N2 miscible projects have been applied in reservoirs with the lowest oil viscosities, and after that, HC miscible flooding and CO2 miscible flooding, respectively. These results are in agreement with the fact that under the same conditions, N2 gas is more difficult to achieve miscibility than the other gases [35]. Chemical flooding projects have been applied in moderate oil reservoirs with viscosities ranging from 1 to 100 cp.

-

Reservoir temperature is an important parameter which plays a key role in the success of chemical EOR processes. Reservoir temperature should be low to guarantee the success of a chemical flooding project [31]. According to Fig. 9, most chemical projects have been conducted in low-temperature reservoirs with temperatures ranging from 100 to 150 °F.

-

As shown in Fig. 10, most of the thermal and gas projects have been implemented in reservoirs with initial oil saturations ranging from 40 up to 80% and more. However, chemical projects especially ASP projects have been implemented in reservoirs with initial saturations ranging from 30 to 40%. In contrast, polymer flooding projects have been implemented in reservoirs with high initial saturation of 60–70%.

-

Formation water salinity (FWS) is a key parameter in the success of chemical projects [31]. As shown in Fig. 11, most of the chemical projects have been implemented in reservoirs with very low FWS, less than 50,000 ppm of total dissolved solids. The median of FWS in polymer flooding, ASP flooding and microbial EOR is around 7000, 6800 and 19,000 ppm, respectively.

-

Dykstra–Parsons coefficient (DPC) of permeability variation in the gathered chemical projects was also considered as an additional feature for this category of EOR methods. Based on Fig. 12, the value of this parameter in polymer flooding projects varies from 0.65 to 0.75, and the median is 0.71. These results confirm the experimental studies conducted by Qi from which it was concluded that the optimum value for DPC in polymer flooding projects is 0.72. In case of other categories of chemical flooding methods such as in ASP projects, this parameter varies widely from 0.4 to 0.8. This difference between the acceptable range for polymer and ASP projects shows that this parameter could be applied as an input feature for classifying these categories.

-

And finally, formation lithologies of the projects as one of the most important properties for EOR applications were analyzed. According to the analyses, most thermal and chemical EOR projects were conducted in sandstone formation, while gas injection projects have been widely applied in both sandstone and carbonate reservoirs.

2.3 Two-stage EOR screening modeling

In this work, we designed a two-stage screening system to predict the suitable EOR method more efficiently. In the first stage, one of the three main categories including water-based, gas and thermal EOR will be selected for a candidate reservoir. Following the first stage, in the second stage of screening, the most suitable sub-category of the previously selected EOR group will be selected. The reason behind designing a two-stage selection process is to tackle two important challenges in EOR screening using ML methods.

The first problem is the unbalanced data which are used to train the ML models. The number of thermal, gas and water-based EOR projects not only in the gathered database in this work, but also in all EOR databases is not equal. The reason is that the worldwide implementation of chemical projects is much less than thermal and gas projects. Unbalanced data is a very common but important problem in ML modeling. In a classification problem with unbalanced data, ML models usually are biased by the category with larger number, and the classification accuracy for small categories is decreased. The large imbalance in the number of EOR projects is shown in Fig. 3. Consider the EOR selection process occurs in one stage; in this case, small classes of EOR methods such as microbial EOR or ASP with 32 and 48 projects in the gathered database cannot be distinguished from other large classes such as steam flooding with 288 projects. The two-stage system developed in this work mitigates this problem by considering some similar projects as a unique category and limiting the competition of selecting the suitable method, to several distinct model. For example, in the gathered database, some chemical EOR techniques including Alkaline, Surfactant, Micellar, AS, AP, SP and ASP flooding with a small number of projects in the dataset are considered as a unique sub-category of chemical EOR. Because these methods follow a similar recovery mechanism during EOR process. Then, this sub-category with polymer flooding projects as another sub-category will be considered in the selection process of chemical EOR screening. With the help of this two-stage screening, the different sub-categories will be involved in the selection process only when the more general category is selected. Hence, the prediction accuracy will be improved, and the effect of unbalanced data will be lowered.

Another problem which we tried to tackle by this two-stage screening model was the availability of some reservoir properties as the input features for the ML modeling. For example, as will be discussed in the following sections, the common input features including ф, K, D, A, µ, T and formation lithology failed in classifying water-based EOR methods with an acceptable accuracy into sub-categories of polymer flooding and ASP flooding. Hence, three additional and key features such as FWS, Soi and DPC were gathered to be used for training the model. These additional features were not available for all projects since they were gathered from various sources. The two-stage screening allows for considering these features only for water-based EOR classification and hence, increasing the EOR selection accuracy.

All gathered projects in the dataset were analyzed and grouped based on similarities of recovery mechanisms. Then, a suitable output classed was assigned to each of them. The schematic representation of the two-stage screening system is shown in Fig. 13. This figure also shows which projects are assigned to each sub-category.

2.4 Artificial neural networks (ANN)

Most of the previous efforts in the field of advanced EOR screening have applied supervised learning processes to train intelligent tools for predicting the suitable EOR method. Various ML algorithms have been applied so far which are summarized in Table 1. There exist a variety of ML methods which could be applied here to develop predictive models in EOR selection process. According to our previous work, in which the performance of various ML methods in EOR selection process was compared, a deep ANN with five representation layers and a random forest model delivered the best performance in classifying the three main EOR categories [15]. In this work, ANNs with different architectures are applied to develop predictive models in first and second stage of EOR selection. It should be mentioned that instead of ANNs, other ML algorithms which are expected to perform well in a classification problem, also, could be applied in this two-stage screening system.

ANNs are a sub-group of ML methods which are biologically inspired models and have been applied for solving a wide variety of problems including classification, clustering, pattern recognition, function approximation, etc. [36].

2.5 Training and testing data selection

The training and testing data required for developing the two-stage screening model were selected randomly from the gathered data using the "train-test-split" function from Scikit-learn package in Python [37]. Additionally, both training and testing data are selected in such way that represent the original dataset. In the other words, relations between the number of different categories are kept in both datasets. Details of the distribution of output classes in the first and second stage of screening are shown in Table 2. For example, as shown in this table, the number of thermal and gas EOR projects is about two times of the number of water-based EOR projects, and this imbalance is kept in both training and testing data. It should be mentioned that due to insufficient number of some specific projects, not all the projects present in the first stage of screening are considered in the second stage of screening. Hence, the total numbers of EOR categories may be different in the first and second stages of screening.

2.6 Model structure

In every ML modeling, it is necessary to optimize the model structure in order to gain the best performance of the model in the given task. The structure of every ML model is defined by its hyper-parameters, thus the suitable value for these parameters should be found in training process. In this work, we apply ANN to develop predictive models in first and second stage of EOR selection. For the first stage, a deep neural network was designed and trained using python Keras library. Keras is a deep learning framework developed for Python and provides an easy way to design and train almost any kind of deep learning model [38]. The structure of the model was optimized step by step, starting from simple structure and two hidden layers and gradually adding more layers and neurons in each layer. The optimized hyper-parameters include number of representation layers, number of neurons in each layer, activation function of each layer and type of optimizer. For example, the schematic representation of the ANN model developed for the first stage of EOR selection is shown in Fig. 14.

To tackle the overfitting problem in this model, two dropout layers were added after the first and the second representation layers. Overfitting is an issue which occurs in every ML problem. When the network tries to learn misleading and irrelevant patterns of training data, the loss of trained data decreases (optimization). However, what is important for us is the model performance on the test data which never have been seen by the model (generalization). These misleading and irrelevant patterns will cause the model not to work well on the test data. In this situation, the network is said to overfit. To prevent a model from overfitting, the most effective way is to decrease the size of the model (number of hidden layers and neurons per layer). When the size of the model is reduced, the memorizing capacity will be reduced as well, and only necessary patterns will be learnt. Adding dropout is the most commonly used techniques for preventing overfitting. When dropout is applied to a layer, a number of output features of the layer will be randomly dropped out, and their values will be set to zero [39].

Like the first stage, for the second stage of EOR selection, three separate ANNs were developed and trained with corresponding data for selecting the most suitable sub-category of the major category previously selected through the first stage. The optimized values for each hyper-parameter in the developed models for the first and second stages of screening are shown in Table 3.

3 Results and discussion

To evaluate performance of the trained models in EOR selection, one single value as the prediction accuracy over the testing data could never be a good measure on how accurate the model classifies non-observed samples. Instead, it is required to report the model performance on classifying each distinguished class in the problem. To investigate this statistically, an established technique, namely confusion matrix, was used to interpret the results.

Having n output categories in the given classification problem, the confusion matrix would be a n*n matrix. Diagonal arguments in this matrix show how many samples out of each specific category in the test data were correctly predicted as the right category. Non-diagonal arguments, however, show how many samples out of this number, were assigned to the wrong categories. Additionally, three different metrics other than the classification accuracy are measured to evaluate the performance of the models in classifying samples in the testing dataset. These metrics include Precision, Recall and F1-score and are defined by four terms True Positive (TP), True Negative (TN), False Positive (FP) and False Negative (FN). The definition of these terms is shown in Fig. 15, and the four used metrics are defined as Eq. 1 through 4 as follows:

All mentioned metrics range from 0 to 1. The closer the value to 1, the better the model performance. There is no priority between these metrics. All of them should be considered as a supplement to each other. The most important thing to note when interpreting these metrics is that the requirement to interpret a model as successful (in a given task) is to obtain a high score in all of metrics. For example, a high precision with a very low recall or vice versa indicates a weak performance of the model.

According to the screening strategy developed in this work, as shown in Fig. 13, selection of the proper EOR method proceeds in two stages. In the first stage of screening, one of the three major EOR classes including water-based EOR, gas EOR and thermal EOR is selected. Then, in the second stage of screening, the most suitable sub-category will be selected. In the following parts, performance of each model developed for the first and second stage of EOR screening will be analyzed by providing triple tables of the results (Tables 4 through 8). The first part of these tables shows the contribution of each class in the training and testing data, the next three columns show the confusion matrix of the classification performance over the test data, and the last four columns are the measures of four metrics.

3.1 First-stage EOR screening

The performance of the ANN model trained for the first stage of EOR screening is shown in Table 4. The input features of the samples used for training this model were the most common features between all projects including porosity (ф), permeability (K), formation lithology (SI, CI, TI), reservoir depth (D), API degree (A), oil viscosity (µ) and temperature (T). The schematic diagram of the optimized structure of this model is also shown in Fig. 14. According to the confusion matrix and the classification metrics, all three categories of EOR methods are well-classified by this model. In this and following tables, true positive predictions for each class are highlighted in bold. The model performs very well in recognizing Gas and Thermal EOR projects with an average score up to 0.90 in all metrics. In case of water-based projects, out of 55 projects in the test data, 47 projects were correctly assigned to the right category. Although the model performs well in this category too, but the average score is about 0.81 and is much less than the other categories. These results are in close relation with the fact that in a classification problem with unbalanced dataset, the model performance is biased by the larger categories (here Thermal and Gas EOR) and the model performance is relatively low in classifying the smaller class (here Water-based EOR). However, the overall performance of the model in predicting the suitable EOR category is quite acceptable with a total accuracy of 0.91 (the number of correctly predicted samples to the total number of samples in the test dataset). The overall scores demonstrate the robustness of the trained model in predicting the most suitable EOR category for a candidate reservoir.

3.2 Second-stage screening

The second-stage screening following the first stage (Fig. 13) focuses on selecting the most appropriate sub-category of each EOR category, previously selected through the first-stage screening. Three models at this stage are trained to classify the three major EOR categories into their main sub-categories.

3.2.1 Water-based EOR

According to Fig. 13, two major sub-categories including polymer and ASP flooding were considered for water-based EOR category. Based on recovery mechanisms of chemical EOR processes, the existing water-based projects in the dataset were divided between these two sub-categories as specified in Fig. 13. Because of a low number of microbial EOR projects, this method was not considered in the second stage of classification. Instead, as one of the most challenging parts, we only focused on classifying chemical projects into two main sub-categories of polymer and ASP flooding. The number of gathered chemical projects in this work is noticeably larger than that in other works, hence, a much better performance is delivered in case of chemical projects classification which always has been a challenging task in this area due to a low number of available projects.

The ANN developed for classifying chemical EOR projects which structure is specified in Table 3 was trained by two different sets of input features. First, the model was trained with common features used for the first-stage screening, then it was trained with three additional features including FWS, Soi and D–P Coeff other than the common features. Classification performance of the model, with two different series of input features, is shown in Tables 5 and 6. Comparing the results suggests that the common input features as mentioned above fail to classify chemical projects with an acceptable accuracy and that providing three more key properties as input features made a dramatically improvement in the classification results, raising the average classification score from 75 to 96%. This is an important finding in understanding the importance of providing relevant input features to get the maximum benefit of ML algorithms in a given task.

3.2.2 Gas EOR

Injection of different gases into hydrocarbon reservoirs has been widely applied as a successful EOR method which in general is either miscible or immiscible with the original hydrocarbon in place. In the second-stage screening of Gas EOR methods, we decided to focus on miscible gas flooding projects. Here, these methods are categorized based on the injectant gas, as shown in Fig. 13, into three sub-categories including miscible carbon dioxide injection (Miscible CO2), miscible hydrocarbon injection (Miscible HC) and miscible nitrogen injection (Miscible N2). The performance of the ANN developed for classifying gas EOR projects which structure is specified in Table 3 is shown in Table 7. As shown in below table, in case of miscible CO2 and miscible HC projects, the model successfully predicts the correct category for the non-observed data. In case of N2 injection projects, out of a total number of ten projects, six were used for training, and the other four projects were used for testing the model. Out of the four projects in the test data, three of them were correctly predicted, and only one of them was mistaken as miscible CO2, leading to a relatively lower score in this category. The total accuracy of the model in predicting the correct category in gas EOR screening is 0.90.

3.2.3 Thermal EOR

According to recovery mechanism similarities and technical operations, for thermal projects gathered in this work, two main sub-categories were considered including steam-based and combustion as shown in Fig. 13. The performance of the ANN developed for classifying thermal EOR projects which structure is specified in Table 3 is shown in Table 8. As shown in below table, out of 79 steam projects and 22 combustion projects in the test data, respectively, 78 and 17 projects were correctly predicted, leading a total accuracy of 0.94.

In summary, the results from all developed models in the first and second screening stages, demonstrate the ability of the proposed two-stage screening system in predicting the suitable EOR technique for a candidate reservoir, with a satisfactory accuracy up to 90% in all parts. All developed models are embedded into an integrated system which could be applied as a fast approach toward selecting the most appropriate EOR method in the primary screening phase.

It should be noted that the number of projects in the test datasets in the second-stage screening is relatively low which may raise doubt about the validation of the results. This issue can be mitigated by using a cross-validation technique to account for the sensitivity of model to the selection of training and testing datasets and to obtain more accurate results. We have performed this technique in our previous study for the first-stage screening [15]. Here, we show the result of the n-fold cross-validation for the second-stage screening in Table 9. In this technique, five different pairs of train and test data are selected randomly out of the whole dataset in such way that there is no overlapping in the test datasets in each run. The models are then trained and tested with the selected data. This method helps to mitigate any bias due to the selection of the test and train sets and increases the reliability of the performance of the models. The average of the accuracies of each model suggests the reliability of the results and that the trained model can perform well in distinguishing sub-categories in the second-stage screening.

Besides the efficiency and quickness of this approach in primary EOR screening, it has also some potential limitations. Here, we go through these limitations briefly and leave the more details regarding each one to be referenced to our previous study, one of the main focuses of which was to identify and discuss the limitations and challenges of application of machine learning techniques in EOR screening [15].

-

In this study, we have made an unrealistic assumption that the problem of EOR screening can be considered as a classification problem in ML content. This assumption may arise some problems. For example, for a specific reservoir, there might be more than one EOR methods which can be successfully implemented. However, with the provided data, there is only one target class for each sample reservoir, and there will remain the uncertainty regarding the other methods which might had the potential to be even more successful in that reservoir.

-

Due to the limitation in the available data in the literature, economic factors, although having a significant role in the success of an EOR project, do not have any representative feature in the data used for training the models, and it could be a hidden source of uncertainty in our work.

-

A major source of limitation in the advances EOR screening, particularly, in the second-stage screening introduced in this work, is the lack of sufficient data for a generalizable learning. This issue caused the need to ignore some methods with very low number of samples from the modeling or to combine them with larger classes.

-

Assigning a single value as the average of reservoir properties as the input features to the ML algorithm may also be a further source of limitation. In many reservoirs, due to the large size and severe heterogeneity, most of rock and fluid properties have large variations.

-

A serious problem which is common among all EOR screening approaches is that a very limited amount of information is available to be used for obtaining screening rules, both from ML and other conventional methods. Therefore, a great amount of crucial information about the candidate reservoir influencing the result of EOR screening are not considered in the screening process.

-

Unbalanced train data used for solving a classification problem is another important issue which is more highlighted in the present study and particularly in the second stage. In such datasets, when the distribution of the number of output classes varies significantly, like what we have in the second-stage screening of gas EOR methods, it will cause the model to be biased by the larger classes and underperform in smaller classes.

3.3 Case study

To evaluate and demonstrate the applicability of the proposed two-stage screening system, a number of candidate reservoirs in Iran are considered here. The properties of eleven of these reservoirs have been published in a study conducted by Mashayekhizadeh et al. in 2014 in which EOR screening process have been performed for the mentioned reservoirs [40]. General properties of these reservoirs are shown in Table 10. These properties as the input features of a new candidate entered the first-stage screening model which was successfully trained and tested with the whole dataset. The model trained for the first-stage screening, predicted gas injection EOR to be the most suitable EOR category for all reservoirs. Then, the input data entered the second stage of screening, and the model previously trained for classifying gas injection projects predicted the most suitable type of gas to be injected. It should be noticed that in case of selecting water-based EOR category in the first stage of selection, more input features including FWS, Soi and DP coefficient of the candidate reservoir would be required to proceed to the second stage. As shown in Table 11, CO2 miscible injection is predicted to be the most suitable EOR technique for most of the candidate reservoirs, and in three of them, miscible hydrocarbon injection was selected. These predictions are in full agreement with the previous study of EOR screening process for these reservoirs by Mashayekhizadeh et al. and demonstrate that the developed two-stage screening system here can increase the efficiency and decrease the time of EOR screening process, dramatically.

4 Conclusions

-

A two-stage screening model has been developed in this work which allows for a more accurate EOR selection using ML models. One of the most important conclusions of this work is that by breaking the problem of EOR selection into two stages, the overall performance of the model will be improved from two perspectives. First, the two-stage structure allows for a more accurate EOR selection since the model is less probable to be biased by larger EOR classes, and second, it allows for using additional input features for specific methods which are not available for all types of EOR methods.

-

Common reservoir properties as mentioned in previous sections are used to distinguish the three major categories in the first stage in which the trained model performs very well with an average accuracy of around 90%. According to the output of the first stage, the second stage of selection is performed via three separate ANN models. In case of gas and thermal EOR, the common reservoir features could also distinguish the main sub-categories with reasonable accuracies of 90% and 94%, respectively. However, these features alone failed to classify chemical projects with an acceptable accuracy. Our results showed that the three additional and key features including FWS, Soi and D–P Coeff made a dramatical improvement in classifying chemical projects, raising the average classification score from 75 to 96%. These results prove another advantage of the two-screening model (using additional input features for only one class of EOR method).

-

Besides the efficiency and quickness of this approach in primary EOR screening, it has also some potential limitations which are discussed in details in our previous work [15]. However, another limitation of ML approach is highlighted here which is the inability of ML in ranking EOR methods based on their suitability for a candidate reservoir. Although it may be possible with some algorithmic techniques, however, the corresponding order of EOR methods may not be relied upon as a meaningful ranking.

-

It is extremely important to note that the available data for primary screening phase in early stages of a field development plan is limited and is associated with a large amount of uncertainty. Therefore, all proposed tools for primary EOR screening using machine learning or the other approaches such as conventional screening, as well as the proposed system in this work, should only be used as an opening of the EOR roadmap.

Data availability

The datasets generated during and/or analyzed during the current study are not publicly available but are available from the corresponding author on reasonable request.

References

Kagermann H (2015) Change through digitization—value creation in the age of Industry 4.0. In: Management of permanent change. Springer, pp 23–45

Lu H et al (2019) Oil and gas 4.0 era: a systematic review and outlook. Comput Ind 111:68–90

Bravo C et al (2014) State of the art of artificial intelligence and predictive analytics in the E&P industry: a technology survey. SPE J 19(04):547–563

Shahkarami A et al. (2014) Artificial intelligence (AI) assisted history matching. In: SPE western North American and Rocky Mountain joint meeting. OnePetro

Mohaghegh SD (2005) Recent developments in application of artificial intelligence in petroleum engineering. J Pet Technol 57(04):86–91

Panja P et al (2018) Application of artificial intelligence to forecast hydrocarbon production from shales. Petroleum 4(1):75–89

Agwu OE et al (2018) Artificial intelligence techniques and their applications in drilling fluid engineering: a review. J Pet Sci Eng 167:300–315

Gumus M, Kiran MS (2017) Crude oil price forecasting using XGBoost. In: 2017 International conference on computer science and engineering (UBMK). IEEE

Aydin G (2014) Production modeling in the oil and natural gas industry: an application of trend analysis. Pet Sci Technol 32(5):555–564

An J (2019) Oil price predictors: machine learning approach, p 670216917

Lake LW et al. (2014) Fundamentals of enhanced oil recovery

Manrique EJ et al. (2008) Effective EOR decision strategies with limited data: field cases demonstration. In: SPE symposium on improved oil recovery. Society of Petroleum Engineers

Bang V (2013) A new screening model for gas and water based EOR processes. In: SPE enhanced oil recovery conference. Society of Petroleum Engineers

Taber JJ, Martin F, Seright R (1997) EOR screening criteria revisited-part 1: introduction to screening criteria and enhanced recovery field projects. SPE Reserv Eng 12(03):189–198

Cheraghi Y, Kord S, Mashayekhizadeh V (2021) Application of machine learning techniques for selecting the most suitable enhanced oil recovery method; challenges and opportunities. J Pet Sci Eng 205:108761

Alvarado V et al. (2002) Selection of EOR/IOR opportunities based on machine learning. In: European petroleum conference. Society of Petroleum Engineers

Lee J-Y, Shin H-J, Lim J-S (2011) Selection and evaluation of enhanced oil recovery method using artificial neural network. Geosyst Eng 14(4):157–164

Zerafat MM et al. (2011) Bayesian network analysis as a tool for efficient EOR screening. In: SPE enhanced oil recovery conference. Society of Petroleum Engineers

Parada CH, Ertekin T (2012) A new screening tool for improved oil recovery methods using artificial neural networks. In: SPE western regional meeting. Society of Petroleum Engineers

Kamari A et al (2014) Efficient screening of enhanced oil recovery methods and predictive economic analysis. Neural Comput Appl 25(3):815–824

Tarrahi M, Afra S, Surovets I (2015) A novel automated and probabilistic EOR screening method to integrate theoretical screening criteria and real field EOR practices using machine learning algorithms. In: SPE Russian petroleum technology conference. Society of Petroleum Engineers

Khazali N, Sharifi M, Ahmadi MA (2019) Application of fuzzy decision tree in EOR screening assessment. J Pet Sci Eng 177:167–180

Moritis G (1996) EOR worldwide survey. Oil Gas J 94:45–61

Moritis G (1998) 1998 Worldwide EOR survey. Oil Gas J

Worldwide E (2002) Survey. 2002. Oil Gas J 102(14):53–65

Worldwide E (2004) Survey. 2004. Oil Gas J 102(14):53

ETTINMUNGON N (2006) Worldwide EOR survey. Oil Gas J 104(15):45–57.

Koottungal L (2008) Special report: 2008 worldwide EOR survey. Oil Gas J 106(15):47–59

Koottungal L (2012) 2012 Worldwide EOR survey. Oil Gas J 110:57–69

Koottungal L (2014) Worldwide EOR survey, data report. Oil Gas J

Sheng JJ (2010) Modern chemical enhanced oil recovery: theory and practice. Gulf Professional Publishing

Sheng JJ (2013) Enhanced oil recovery field case studies. Gulf Professional Publishing

Standnes DC, Skjevrak I (2014) Literature review of implemented polymer field projects. J Pet Sci Eng 122:761–775

Donaldson EC, Chilingarian GV, Yen TF (1989) Enhanced oil recovery, II: processes and operations. Elsevier

Sebastian H, Lawrence D (1992) Nitrogen minimum miscibility pressures. In: SPE/DOE enhanced oil recovery symposium. Society of Petroleum Engineers

Yegnanarayana B (2009) Artificial neural networks. PHI Learning Pvt. Ltd.

Pedregosa F et al (2011) Scikit-learn: machine learning in Python. J Mach Learn Res 12:2825–2830

Chollet F (2015) Keras. GitHub repository. https://github.com/fchollet/keras

Chollet F (2018) Deep Learning mit Python und Keras: Das Praxis-Handbuch vom Entwickler der Keras-Bibliothek. MITP-Verlags GmbH & Co. KG

Mashayekhizadeh V, Kord S, Dejam M (2014) EOR potential within Iran. Spec Top Rev Porous Media Int J 5(4):325–354

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this manuscript.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Cheraghi, Y., Kord, S. & Mashayekhizadeh, V. A two-stage screening framework for enhanced oil recovery methods, using artificial neural networks. Neural Comput & Applic 35, 17077–17094 (2023). https://doi.org/10.1007/s00521-023-08557-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00521-023-08557-2