Abstract

In this paper, fuzzy inference system (FIS) is employed to develop a more accurate approach to evaluate the strength and strain capacity of axially loaded concrete columns with the square section confined by fiber-reinforced polymer (FRP) wraps. To do so, an experimental database containing 261 test data on compressive strength and 112 test data on ultimate strain is collated from the literature. By using subtractive clustering algorithm to extract cluster centers from the experimental database, the structure of FIS model is identified. To select the best FIS model, several constant and linear (i.e., zeroth- and first-order) Takagi–Sugeno FIS models with different numbers of rules are developed and their performances in terms of the model output errors with respect to training data set as well as validation data set are compared. The finally proposed FIS models for calculation of strength and strain contain as few as three rules. Besides, the proposed FIS models are expressed as closed-form formulations, which can be conveniently used in practice. The outputs of the proposed FIS models agree favorably with the test data and outperform the existing models by providing more accurate prediction of both strength and strain capacity. In view of the FIS models, a parametric study is carried out to examine the influence of various variables including the section corner radius as well as the elastic modulus and tensile strength of FRP on the capacity of FRP-confined square columns.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

There is an increasing need for seismic strengthening of buildings and bridges worldwide. As for reinforced concrete (RC) structures, a major approach for strengthening is to increase confinement for column sections. This follows from the well-known fact that concrete confinement enhances strength and, more importantly, ductility of plain concrete. Among different techniques available for confinement of concrete, fiber-reinforced polymer (FRP) materials have received much attention thanks to their outstanding characteristics including high strength per weight, non-corrosive behavior, and construction ease. To facilitate the rapid application of FRP for confinement, many researchers have made efforts to evaluate the capacity of FRP-wrapped concrete columns since two decades ago. However, most of these studies have been devoted to circular columns, while very few investigations have dealt with square/rectangular sections. Besides, the majority of existing models have been aimed at predicting only strength capacity of FRP-wrapped concrete without getting into estimation of the strain capacity of that. The fact is that the efficiency of FRP confinement is more pronounced regarding the ultimate strain enhancement rather than strength increment. Therefore, evaluation of the ultimate strain as well as strength of axially loaded square columns wrapped with FRP is in high demand.

In order to arrive at a closed-form equation to estimate the capacity of FRP-confined concrete, the researchers have mostly used a regression analysis to fit a mathematical expression to the available experimental data. The basic form of the regression equations used for FRP-confined concrete has been pretty much similar to what was initially developed for steel-confined concrete that was itself based on a proposal by Richart et al. [1] originally for the concrete cylinders subjected to uniform lateral stress. It is, however, obvious that FRP-confined concrete behaves very differently from steel-confined concrete since non-yielding FRP material induces a passive confinement, whereas steel exerts an active confinement beyond yielding. The researchers who developed such regression equations for the circular sections confined with FRP expressed the compressive strength (i.e., the maximum axial stress) of confined concrete as a function of the lateral stress provided by FRP wraps [2–13]. It is worth mentioning that at the ultimate lateral confining pressure, the hoop strain in the FRP wraps cannot reach the maximum tensile strain of FRP materials [14]. However, the current models differ in the way they evaluate the actual rupture strain for FRP hoops. As for square sections, the form of the regression equation presented by researchers is similar to that for circular sections except that an additional parameter called the shape factor is included in the model [15–22]. The shape factor is to take into account the non-uniform distribution of the confining pressure on the perimeter of non-circular sections. In the literature, the expressions presented for the shape factor vary greatly in the manner they incorporate different parameters. Although most of the previously mentioned investigations have employed the same list of the parameters affecting the strength/strain of FRP-confined square sections, their proposed predictive equations are much different as they contain these parameters with totally different magnitudes.

To overcome the problems inherent in the existing regression-based models, this paper employs fuzzy inference system (FIS) approach toward modeling the ultimate capacity of the square sections wrapped with FRP. Unlike the regression approach, which requires an initial assumption on the form of a mathematical expression containing an arbitrary combination of the parameters involved in the problem in hand, the FIS approach starts from scratch without any need to assume a particular form of equation in advance. In the FIS method similar to other soft computing techniques, knowing the list of influential parameters is the only information needed to train a model using an experimental database. The FIS technique has recently been applied by the author to another application of FRP composites [23]. Also, fuzzy logic has been employed by researchers to predict the concrete strength and/or strain [24, 25]. Other neural computing techniques including neural network, genetic algorithm, and ANFIS have already been applied for modeling the strength of FRP-confined columns with circular sections [26, 27]. Also, neural network has been used to predict the ultimate strain of circular specimens wrapped with FRP [28]. For non-circular columns confined by FRP, the application of soft computing methods has been very limited as compared to circular sections. Pham and Hadi [29] employed artificial neural network (ANN) to estimate strength/strain of non-circular sections wrapped by FRP. Their proposed ANN strength model was trained, tested, and validated by the use of an experimental database containing 104 square/rectangular sections, whereas their ANN model for strain was based on 69 test data on only square columns. The ANN strength model had eight input parameters including length of two sides of the section, the corner radius, the FRP thickness, the tensile strength and elastic modulus of FRP, the unconfined compressive strength, and the corresponding axial strain. The input variables for their strain model were identical to the above-mentioned parameters, but length of only one side of section was considered since the strain model was for only square sections. They indicated that the proposed ANN models outperformed several existing confinement models suggested by other researchers. They also explicitly derived user-friendly equations from the ANN models in order to propose a simpler relationship to estimate the confined concrete strength/strain. Doran et al. [30] have recently used fuzzy logic approach to model the capacity of CFRP-wrapped square/rectangular concrete columns. However, their proposed model focused on only strength enhancement without dealing with the strain. They developed a Mamdani-type fuzzy inference system to predict the so-called lateral confinement coefficient, which was the ratio of the compressive strength of confined concrete to that of unconfined concrete. Five input variables were considered as follows: width and length of column section, total thickness and the elastic modulus of CFRP wrap and unconfined concrete compressive strength. Using 100 test data on FRP-wrapped column specimens collected from the literature, a FIS model containing 196 fuzzy rules with trapezoidal-shaped membership functions was established. The proposed model was then validated against 40 additional experimental data and was also compared with several nonlinear regression equations.

The current study utilizes a Takagi–Sugeno FIS approach to estimate the strength/strain capacity of the axially loaded FRP-wrapped concrete columns with square sections. To this aim, a large database containing the axial test results of square specimens wrapped with FRP is assembled from the literature. The database consists of 261 test data to be used for developing the strength model and 112 test data for the strain model. A novelty of the FIS model proposed in the current paper rests in presenting closed-form formulations for the problem in hand. This facilitates the application of FIS modeling in practice. In addition, the accuracy of the suggested FIS models is assessed against predictions by several existing models developed by other researchers. Furthermore, the effects of different parameters on strength/strain are addressed through a parametric study.

2 Experimental database and existing confinement models

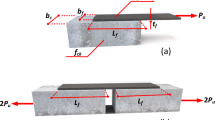

In this paper, a large experimental database of concrete columns with square sections wrapped with FRP under uniaxial compression was compiled by an extensive survey of the literature. The current database includes 261 test results on the compressive strength while 112 test results for the ultimate strain. The test data for the strength were adopted from 18 various investigations [17, 18, 21, 31–45], and those for the strain were collated from 10 experimental programs [17, 18, 21, 31, 32, 34–36, 39, 45]. It should be mentioned that in the literature the number of experiments reporting results of the ultimate axial strain is much smaller than that of the compressive strength. All the specimens reported in the mentioned experimental campaigns were included in the current study. Nevertheless, in the case that an experimental campaign contained both rectangular and square sections, only the latter were considered since our study has been limited to the square columns. Besides, the column specimens reinforced with steel either longitudinally or transversely were omitted as the focus has been on the plain concrete sections without rebars. With these in mind, a careful investigation was conducted to extract the geometrical/mechanical properties along with the reported experimental values for the strength/strain capacity from the original papers published in open literature. To our knowledge, the test database collated herein is the largest one which has been ever used to study the FRP-confined square columns. The test specimens were rounded at the corners of the section and were wrapped with the unidirectional FRP composites whose fiber types were carbon, glass, or aramid. The height-to-width ratios of the specimens ranged between 1.6 and 4, and the section side length of the samples was in the range of 100–458 mm. The maximum value of the unconfined concrete cylindrical strength for the column samples in the present database was about 57 MPa. Table 1 presents further details on the statistical descriptions for the mechanical and geometrical properties of the columns considered in the current test database. The geometric parameters of the column section are demonstrated in Fig. 1, which shows especially the radius at the section corner (i.e., r), which is a crucial parameter for the performance of the FRP-confined square column. All specimens in the database were made of plain concrete without any steel reinforcement.

In the current study, eight existing models [15–22] for estimation of the compressive strength for square/rectangular sections confined with FRP are considered. Four of these models [16, 18, 19, 21] have been developed to calculate the ultimate strain as well. All of these models have been derived based on the regression of the experimental data. The basic form of the equation used in the existing models in the case of strength is as follows:

where f l is the confining stress exerted by FRP, k s is the shape factor to account for non-uniform distribution of the confining stress in a non-circular section, and k 1 is a coefficient to be tuned with respect to the experimental results. A similar equation has been employed in the available models for the strain capacity. Tables 2 and 3 present the equations for the existing models for the strength and strain, respectively. Some of these models could be used for both square and rectangular sections, while some others were developed only for square sections such as Campione and Miraglia [16], Al-Salloum [17], and Shehata et al. [21]. As given in Tables 2 and 3, different researchers have suggested various definitions for different parameters in Eq. (1). For instance, the shape factor k s in Mirmiran’s model [15] was taken as 2r/D, whereas in Lam and Teng’s model [18], it was related to the effectively confined area of the section based on the arching action defined as the parabolas initiated from the rounded corners with the initial slope equal to the section diagonal. Besides, Mirmiran assumed that if a parameter called as modified confinement ratios (i.e., MCR) was <15%, the confinement effects could be negligible.

In an analogy with circular sections, the confining stress f l as used in most of the existing models for rectangular/square sections is determined by the following expression:

where ε j is the ultimate tensile strain mobilized in the FRP wraps, and D for a rectangular/square section is assumed as the diameter of an equivalent circular section. There is a variety of definitions for D in different models. For instance, D was taken as length of the longer side [15] or even the shorter side [20] in rectangular sections and the side length in square sections [16, 21]. In some other models, D was assumed as length of the diagonal of the square section [17], or the diameter of the circle circumscribed about the rectangular section [18]. Various formulations for f l are listed in Table 4. In most of the existing models, ε j was taken equal to the maximum tensile strain of FRP material despite the fact that the FRP hoop strain at the actual rupture condition could be substantially less than the maximum strength of material. The model by Lam and Teng [18] was the only model which considered the actual hoop strain at rupture by assuming ε j to be equal to almost half of the maximum tensile strain of CFRP material. Also, Campione and Miraglia [16] expressed ε j as a function of the maximum strength of FRP material as well as the corner radius of the section.

With reference to the mathematical expressions of the existing confinement models presented in Tables 2 and 3, it is concluded that a wide variety of forms for equations predicting strength/strain have been used in the literature so far. This is the main incentive for the authors to employ the FIS approach as it does not require a particular form of equation.

3 Overview of fuzzy inference system

Fuzzy inference system (FIS) is the method that employs fuzzy logic in order to derive conclusion (i.e., output) from known premises (i.e., given inputs). A FIS model is expressed by a list of logical statements called rules, which contain variables that are the members of given fuzzy sets. The fuzzy sets, which are the basis of fuzzy logic approach, were introduced by Zadeh [46]. A fuzzy set can admit variables with partial memberships in it. The membership function is a curve, which assigns a number in the range of 0–1 to a variable, showing the degree to which the variable is a member of a fuzzy set. The rules in a FIS model are IF–THEN statements as follows: IF x 1 is A 1 AND x 2 is A 2 AND … THEN y is B, where the antecedent, namely IF part, is composed of multiple parts interconnected with fuzzy logical operators such as AND. Once an input variable x 1 such as the unconfined concrete strength \(f_{\text{co}}^{\prime }\) is presented to an IF–THEN rule, it is first fuzzified according to the corresponding membership function A 1. That means the value of \(f_{\text{co}}^{\prime }\) is mapped to a value in 0–1 range, which is called the membership value. Then, the fuzzy operator AND, which may be defined as multiplication of membership values, is applied to all parts of the antecedent. As a result, the antecedent yields a value in range 0–1, indicating the rule’s degree of truth. As for the consequent, namely THEN part of a rule, we here use a particular type of FIS called Takagi–Sugeno model [47] where the output membership function is a value calculated as a linear combination of all input variables, i.e., y = a 0 + a 1 x 1 + a 2 x 2 + ···. There are two kinds of Takagi–Sugeno FIS model: constant and linear. In the former, all coefficients except for a 0 are zero, whereas in the latter all coefficients have nonzero values. Finally, the effects of all rules are combined to give a single output by calculating weighted average of all rule outputs, in which each rule is weighted by its degree of truth.

3.1 Identification of FIS model by clustering of data

The idea employed in this paper is that clustering of data can serve as a basis to identify a FIS model. By clustering of numerical data, a number of cluster centers can be extracted from the database. Once a cluster center is determined, it implies a fuzzy IF–THEN rule in the form: “IF a given input is near a cluster center, THEN the desired output is near the output corresponding to that cluster center.” The truth degree for this fuzzy rule depends on how close the given input is to the considered cluster center. Among different algorithms available for data clustering, we here utilize subtractive clustering method proposed by Chiu [48]. A brief description of this method is presented herein.

Firstly, each test datum is considered as a vector whose coordinates include all input variables plus the corresponding output value. For instance, the ith test data for the compressive strength in the current study are presented as \({\mathbf{x}}_{i} = \left[ {b,r,f_{\text{co}}^{\prime } ,t_{f} ,f_{f} ,E_{f} ,f_{\text{cc}}^{\prime } } \right]_{i}\), where various notations are defined in Table 1. Then, the coordinates are normalized with respect to their own range of values. For example, to normalize \(f_{\text{co}}^{\prime }\), it is divided by (\(f_{\text{co,max}}^{\prime } - f_{\text{co,min}}^{\prime }\)), in which \(f_{\text{co,max}}^{\prime }\) and \(f_{\text{co,min}}^{\prime }\) denote the maximum and minimum of \(f_{\text{co}}^{\prime }\) in all test data, respectively. Secondly, the potential of being a cluster center is calculated for each test datum, as follows:

where || || denotes the Euclidean distance between the normalized vectors of two test data \({\hat{\mathbf{x}}}_{i}\) and \({\hat{\mathbf{x}}}_{j}\), n is the number of all test data, r c is a user-specified parameter that indicates the radius of influence for cluster centers, and P i is the potential for the ith test data. Thirdly, the test data point that has the largest potential is chosen as the center of the first cluster. This is because the highest potential occurs for the point with the largest number of surrounding test data. Once a cluster is determined, the potential values of all test data are subtracted by the following amount:

where \({\hat{\mathbf{x}}}_{k}^{*}\) and \(P_{k}^{*}\) are the center coordinates and the potential value of the kth cluster, respectively, and \(\bar{r}_{\text{c}}\) is assumed to be equal to 1.25r c. Again, the next cluster center is the one with the highest subtracted potential. The procedure is repeated until the subtracted potentials fall below some user-specified thresholds. The method of subtraction from potentials ensures that the test data located very near a cluster center are not eligible to become another cluster center since their potentials are much reduced. Thereby, the cluster centers are distributed within the whole database. It is important to notice that the number of clusters obtained by subtractive clustering depends on the user-specified value of r c. Later, the criteria for optimum selection of r c will be described.

3.2 Optimization of the FIS model

Once the cluster centers of a test database are determined by use of subtractive clustering algorithm, a FIS model is identified following the previously mentioned explanations. It is obvious that the number of IF–THEN rules in the FIS model is equal to the number of clusters. The final output of the FIS model is derived as weighted average of outputs for all rules. For example, for the strength model in this paper and for a given input vector denoted by [\(b,r,f_{\text{co}}^{\prime } ,t_{f} ,f_{f} ,E_{f}\)], the model output, i.e., \(f_{\text{cc}}^{\prime }\), is calculated as follows:

where c is the number of rules, and \(a_{0i} ,a_{1i} , \ldots\) are unknown constants, which are determined during training the model by minimizing the error between the model output and the corresponding experimental value using the least-squares optimization procedure. Other notations in Eq. (6) are explained in Table 1. It should be noted that Eq. (6), which expresses the consequent as a linear combination of all input variables, develops a particular type of FIS called Takagi–Sugeno model [47]. The degree of truth for the ith rule (i.e., w i ) is determined by an exponential function of the Euclidean distance from the ith cluster center to a given input data, as follows:

where the variables with a star indicate the cluster center’s coordinates. The denominator of each term in Eq. (7) is the range of values in the test database for a given input variable. In the context of FIS formulations, Eq. (7) refers to the fuzzy rule antecedent with Gaussian membership functions. With reference to the above-mentioned equations, Appendices 1 and 2 present the closed-form relations for the FIS models proposed in this paper.

4 Development of FIS model for compressive strength and ultimate axial strain of FRP-confined square column

4.1 Selection of input variables

A crucial step in developing a FIS model is to identify all input variables affecting the problem in hand. As for FRP-wrapped concrete, the main parameters that are believed to be influential in evaluating the strength/strain capacity are as follows: \(b,r,f_{\text{co}}^{\prime } ,t_{f} ,f_{f}\), and E f . It should be noted that all above-mentioned input variables are independent from each other. In other words, any other variable that is dependent on the considered variables should not be taken in the list of inputs for the prospective FIS model because its effect has already been captured through the existing variables. For instance, there is no need to include the maximum tensile strain of FRP as it can be derived from two other existing input variables, namely f f divided by E f .

It should be emphasized that in the FIS approach, there is no need to assume a pre-defined mathematical expression so as to incorporate the input variables into the model. Instead, the FIS approach itself captures each variable’s effect on the output without requiring a priori knowledge. This is the difference between FIS modeling and regression-based equations as the latter need to assume an arbitrary format for the equation with a finite number of unknown constants, which are tuned with respect to the test results. Since the form of this equation is generally not known, the performance of regression models depends to some extent on making assumption about the form of the function being used. By looking at the available confinement models that are mostly based on regression, it is observed that a wide variety of forms for functions have been used so far by different researchers. Contrary to regression-based models, the FIS model starts from scratch by adopting only the list of input variables without assuming any function format for them.

4.2 The optimum value for radius of influence of cluster centers

Another major step toward establishing a FIS model is to identify the cluster centers that are to be extracted from the experimental database. To do so, it is required to specify a value for r c (i.e., the cluster’s radius), and then, the cluster centers are readily determined by use of subtractive clustering algorithm. As stated earlier, the user-specified parameter r c affects the number and coordinates of the cluster centers that will be identified during subtractive clustering process. Basically, a larger value of r c leads to fewer number of clusters. It is recalled that in the FIS approach presented herein the number of clusters and number of rules are the same. Thereby, a larger r c corresponds to a fewer number of fuzzy rules, resulting in a simpler FIS model. A model is, however, accepted if it can demonstrate low values of error in predicting the model output. To examine the effect of varying r c, several FIS models corresponding to different values for r c are constructed and compared in terms of various error measures listed in Tables 5 and 6 for strength and strain, respectively. The error measures considered here include mean absolute percentage error (MAPE) between model outputs and test results, average and coefficient of variation (COV) for the ratio of the test value to the model output. These error measures for each r c are reported in three separate groups: training, validation, and total data sets as listed in Tables 5 and 6. It should be noted that the test data are partitioned into two groups: training and validation data sets. The training data contain those experimental data that are utilized for tuning the FIS model parameters during training stage, whereas the validation data include new data that have not yet been introduced to the FIS model. In this study, almost 70% of all experimental data is used for training data set, and the rest is assigned to the validation data set. Tables 7 and 8 summarize the statistical information on both training and validation data for strength and strain, respectively.

The best value of r c is the one whose corresponding FIS model yields the least error measures for the model output. In this regard, several error measures including mean, MAPE, and COV, which are calculated based on the total experimental data, are evaluated in order to become optimum. Furthermore, the errors calculated for the validation data should not be much different from those obtained for the training data in order to maintain the capability of the proposed model to generalize the results. In other words, if the performance of a model is good on the training data while being poor on the validation data, it is concluded that the model is so much fit to the training data (what is called as overfitting), and thus, it is no longer able to generalize the results. In the case that more than one FIS model perform similarly in terms of the error measures, the simplest model with less number of rules/clusters is preferred. Tables 5 and 6 compare the performance of several FIS models corresponding to different values of r c. In each of Tables 5 and 6, two categories of FIS models are presented: linear and constant, which refer to the first-order and zeroth-order Takagi–Sugeno FIS models, respectively. According to the above-mentioned criteria and with reference to Tables 5 and 6, the final values of r c are selected to be equal to 0.85 and 0.8 for the strength and strain FIS models, respectively. These selected values for r c result in the FIS models whose performances are optimum in terms of minimizing all error measures simultaneously. Both of the proposed FIS models are linear and contain three rules/clusters.

5 Results and discussion

5.1 Proposal of closed-form equations for compressive strength/ultimate strain

A major drawback for most of soft computing models is that they do not provide closed-form equations for the problem in question. That is why soft computing paradigms are sometimes referred to as black-box models having invisible formulations. This may also limit their application in practice although their prediction accuracy is usually superior to the existing conventional models. To overcome such disadvantages associated with soft computing, an objective of this paper is to facilitate proposal of closed-form equations by employing subtractive clustering algorithm as a basis to develop FIS models. The form of the proposed equations in this work may not be as simple as what usually appears in the design codes, but instead they shed light on the underlying formulations of the proposed FIS model. Besides, the proposed equations can be easily programmed by design engineers to evaluate the strength and strain capacity of square concrete columns wrapped with FRP with an accuracy higher than that of the available confinement models.

As explained in the last section, the final values of r c (i.e., cluster’s radius) for the optimum FIS models were determined as 0.85 and 0.80 for the strength and strain FIS models, respectively. Given the value of r c, subtractive clustering algorithm instantly identifies the cluster centers, which can be extracted from the available experimental data. Tables 9 and 10 list the input coordinates of the three cluster centers identified for the strength and strain FIS models, respectively. Also, the consequent parameters (i.e., a 0, a 1, a 2, … in Eq. 6) for the proposed FIS models are reported in Tables 9 and 10. The consequent parameters were determined following a linear optimization procedure as explained earlier. Information provided in Tables 9 and 10 is sufficient to express the explicit formulation of the proposed FIS models, as presented in Appendices 1 and 2 for the strength and strain capacity of square columns wrapped with FRP, respectively. In addition, numerical examples are included in the Appendices 1 and 2. Moreover, Figs. 2 and 3 illustrate the membership functions for the strength and strain FIS models, respectively.

5.2 Comparison between the proposed FIS models and experimental data

Predictions by the proposed FIS models are compared against the test results in Figs. 4 and 5 for the strength and strain, respectively. It is evident that the accuracy of the proposed FIS models with as few as three rules is quite satisfactory as the model predictions agree with the test data. Besides, in Figs. 4 and 5, the scatter of data points around the diagonal line, where the experimental value equals the predicted value by the FIS model, for validation data is as good as that for training data, indicating the generalization ability of the proposed FIS models.

5.3 Comparison between the proposed FIS models and existing confinement models

Eight existing models for the compressive strength [15–22] and four models for the ultimate axial strain [16, 18, 19, 21] of FRP-confined square columns were considered herein for comparison with the FIS models proposed in this paper. Tables 2 and 3 present the equations for the existing models for the strength and strain, respectively, which relate strength/strain to the confining stress f l exerted by FRP wraps. Different researchers have suggested various formulations for lateral confining pressure for square sections as listed in Table 4.

Tables 11 and 12 report several error measures for the proposed FIS models and the existing confinement models suggested by other researchers for the strength and strain, respectively. All models are evaluated by the database of FRP-confined square specimens containing 261 test results on the compressive strength and 112 test results for the ultimate strain. It is evident from Tables 11 and 12 that both of the proposed FIS models for strength/strain outperform all other existing models when taking into account all error measures simultaneously. In particular, the proposed FIS model for the ultimate axial strain demonstrates a higher accuracy against the other available models. The calculated mean for the proposed strain model is equal to 1.03 with COV of about 40%, whereas mean of the best existing models ranges 1.17–1.47 with COV of approximately 60–67%. The predictions by the proposed strength/strain FIS models versus other existing models are depicted in Figs. 6 and 7. It is observed from Figs. 6 and 7 that the proposed FIS models develop a superior performance by demonstrating the least scatter of data points around the diagonal line as compared with the other models.

5.4 Parametric study on influence of stiffness and strength of FRP wraps

A parametric investigation is carried out using the proposed FIS models to evaluate the effect of the elastic modulus, E f , as well as the tensile strength, f f , of the FRP material on the confined strength/strain capacity. To do so, the parameter under question is varied within its range of values, while other input parameters are kept constant. Figures 8 and 9 show the FIS model outputs along with the predictions by other models for varied values of the elastic modulus and tensile strength of FRP materials, respectively. With reference to Fig. 8, the proposed FIS model demonstrates that a larger elastic modulus of FRP enhances the strength but reduces the strain capacity of the FRP-wrapped concrete. This result agrees with the mechanics of confinement and can be explained as follows. By increasing the elastic modulus of FRP wraps, the lateral stiffness of confining device increases, leading to exert a larger value of confining pressure on the concrete. As a result, the compressive strength is improved by changing the uniaxial stress state to a triaxial one. On the other hand, the higher lateral stiffness limits dilation of the concrete subjected to compression, and hence, the axial strain decreases owing to Poisson’s effect. It is noted that the elastic modulus is an indicator of type of FRP materials used for confinement. Therefore, the FRP materials having lower elastic modulus such as glass FRP (GFRP) are more effective in enhancing the ultimate axial strain while being less effective in improving the compressive strength of FRP-wrapped concrete. In the available models for strength, the FRP elastic modulus E f is not independently incorporated, but it is used for calculating the FRP tensile strength f f (or the effective ultimate strength) through multiplication by the FRP rupture strain (or the actual hoop strain). Since the FRP tensile strength f f is kept constant in Fig. 8, the existing models do not vary with E f despite the FIS model that is able to capture the impact of E f on the compressive strength. As for the current strain models, only two of them take into account the effect of varying E f , namely Lam and Teng [18] and Campione and Miraglia [16]. The FIS model predictions for the ultimate axial strain fall in between the two aforementioned existing models, as illustrated in Fig. 8. In regard to the effect of varying f f in the proposed FIS models, Fig. 9 illustrates that the higher values of f f result in improvement of strength as well as strain capacity. This conclusion is consistent with the general trends of the available models as depicted in Fig. 9.

5.5 Parametric study on influence of the corner radius of square section

It is well known that a larger corner radius improves the confinement effects in non-circular sections by increasing the effectively confined parts of section. In the existing strength/strain models, the influence of r is considered through introducing a coefficient called shape factor, which is the ratio of the area of effectively confined concrete to the total area of section. There are various formulations proposed for shape factor by researchers so far. In our proposed FIS models, although no input variable is introduced as a shape factor, the effect of the corner radius can be captured through the FIS approach. Figure 10 presents the effect of different values of the corner radius on the strength/strain capacity as predicted by the proposed FIS models and other existing models. It is observed from Fig. 10 that the proposed FIS model is capable of taking into account the beneficial effect due to increasing the corner radius.

6 Conclusions

In this paper, fuzzy inference system (FIS) has been applied to propose two models for estimating the compressive strength and ultimate axial strain of square concrete columns wrapped with FRP. In order to identify FIS model, subtractive clustering algorithm has been used and performances of several Takagi–Sugeno FIS models with different numbers of rules have been examined. Predictions by the proposed FIS models have been compared with those by the available experimental data and the existing confinement models. The conclusions are as follows:

-

1.

Both of the proposed FIS models for strength and strain are expressed as closed-form formulations, which are simple to use in practice (see Appendices 1 and 2). The proposed FIS models with as few as three fuzzy rules offer a reliable alternative method to calculate the compressive strength and ultimate axial strain of FRP-wrapped square sections.

-

2.

Comparison between the two proposed FIS models and a large database of axially tested FRP-wrapped square specimens containing 261 test results on the compressive strength and 112 test results for the ultimate strain indicates that predictions using the proposed FIS models quite agree with the test data. Besides, the performance of the FIS models on an unfamiliar data set is shown to be as good as that on the familiar data set used for model training, confirming the generalization ability of the proposed FIS models.

-

3.

The proposed FIS models outperform the existing models for the strength and strain capacity of square columns confined by FRP. The experimental-to-predicted ratio of the strength or strain for the proposed FIS models has an average value of about unity. Furthermore, the coefficient of variation for the proposed FIS models is less than that of the other existing models.

-

4.

In light of the proposed FIS models, the influences of elastic modulus along with tensile strength of FRP materials used for confinement are examined through parametric studies. The results reveal that the proposed FIS models are capable of capturing the underlying mechanics of FRP confinement. According to the proposed FIS approach, a higher FRP elastic modulus enhances the compressive strength but reduces the ultimate axial strain. Also, the predictions of the FIS models for the effect of FRP tensile strength on the strength/strain are consistent with the general trends of the existing models. Besides, the proposed FIS models for strength and strain are capable of predicting the beneficial effects of increasing the corner radius of square sections confined with FRP wraps although the commonly used shape factor is not introduced as an input variable in the proposed model, meaning that the FIS approach itself can account for such an effect.

Based on the attained results, the FIS approach is successfully applied to model the confinement effects in square concrete columns wrapped by FRP. It is noteworthy that applicability of the FIS models is limited to the numerical domain of input parameters used in this study. It is, however, unlikely that the FIS models are capable of extrapolating beyond this domain. Further research may be focused on extending application of FIS modeling to other fields of structural use of FRP composites.

References

Richart FE, Brandtzaeg A, Brown RL (1929) The failure of plain and spirally reinforced concrete in compression. In: Engineering experiment station bulletin no. 190. University of Illinois, Urbana, IL

Fardis MN, Khalili H (1982) FRP-encased concrete as a structural material. Mag Concr Res 34(121):191–202

Karbhari VM, Gao Y (1997) Composite jacketed concrete under uniaxial compression–verification of simple design equations. J Mater Civ Eng 9(4):185–193

Samaan M, Mirmiran A, Shahawy M (1998) Model of concrete confined by fiber composites. J Struct Eng 124(9):1025–1031

Toutanji H (1999) Stress–strain characteristics of concrete columns externally confined with advanced fiber composite sheets. ACI Mater J 96(3):397–404

Miyauchi K, Inoue S, Kuroda T, Kobayashi A (1999) Strengthening effects with carbon fiber sheet for concrete column. Proc Jpn Concr Inst 21(3):1453–1458

Theriault M, Neale KW (2000) Design equations for axially-loaded reinforced concrete columns strengthened with FRP wraps. Can J Civ Eng 27:1011–1020

Xiao Y, Wu H (2000) Compressive behavior of concrete confined by carbon fiber composites jackets. J Mater Civ Eng 12(2):139–146

Matthys S, Toutanji H, Audenaert K, Taerwe L (2005) Axial load behavior of large-scale columns confined with fiber-reinforced polymer composites. ACI Struct J 102(2):258–267

Teng J, Jiang T, Lam L, Luo Y (2009) Refinement of a design-oriented stress–strain model for FRP-confined concrete. J Compos Constr 13(4):269–278

Realfonzo R, Napoli A (2011) Concrete confined by FRP systems: confinement efficiency and design strength models. Compos Part B Eng 42(4):736–755

Rousakis T, Rakitzis T, Karabinis A (2012) Design-oriented strength model for FRPconfined concrete members. J Compos Constr 16(6):615–625

Guler S, Ashour A (2015) Review of current design guidelines for circular FRP-wrapped plain concrete cylinders. J Compos Constr 20(2):04015057. doi:10.1061/(ASCE)CC.1943-5614.0000619

Lam L, Teng JG (2003) Design-oriented stress–strain model for FRP-confined concrete. Constr Build Mater 17(6–7):471–489

Mirmiran A, Shahawy M, Samman M, Echary H, Mastrapa JC, Pico O (1998) Effect of column parameters on FRP-confined concrete. ASCE J Compos Constr 2(4):175–185

Campione G, Miraglia N (2003) Strength and strain capacities of concrete compression members reinforced with FRP. J Cem Concr Compos 25(1):31–41

Al-Salloum YA (2007) Influence of edge sharpness on the strength of square concrete columns confined with FRP composite laminates. Compos Part B Eng 38(5–6):640–650

Lam L, Teng JG (2003) Design-oriented stress-strain model for FRP-confined concrete in rectangular columns. J Reinf Plast Compos 22(13):1149–1186

Ilki A, Peker O, Karamuk E, Demir C, Kumbasar N (2008) FRP retrofit of low and medium strength circular and rectangular concrete columns. J Mater Civ Eng 20(2):169–188

Wu YF, Wang LM (2008) A unified model for the compressive strength of FRP-confined square and circular concrete columns. In: Fourth international conference on FRP composites in civil Engineering (CICE2008)

Shehata IAEM, Carneinro LAV, Shehata LCD (2002) Strength of short columns confined with CFRP sheets. J Mater Struct 35(1):50–58

Kumutha R, Vaidoyanathan R, Palanichamy MS (2007) Behavior of reinforced concrete rectangular columns strengthened using GFRP. J Cem Concr Compos 29(8):609–615

Nasrollahzadeh K, Basiri MM (2014) Prediction of shear strength of FRP reinforced concrete beams using fuzzy inference system. Exp Syst Appl 41(4):1006–1020

Dilmaç H, Demir F (2013) Stress–strain modeling of high-strength concrete by the adaptive network-based fuzzy inference system (ANFIS) approach. Neural Comput Appl 23(1):385–390

Subaşı S, Beycioğlu A, Sancak E, Şahin İ (2013) Rule-based Mamdani type fuzzy logic model for the prediction of compressive strength of silica fume included concrete using non-destructive test results. Neural Comput Appl 22(6):1133–1139

Cevik A, Guzelbey IH (2008) Neural network modeling of strength enhancement for CFRP confined concrete cylinders. J Build Environ 43(5):751–763

Cevik A (2011) Modeling strength enhancement of FRP confined concrete cylinders using soft computing. Expert Syst Appl 38(5):5662–5673

Elsanadedy HM, Al-Salloum YA, Abbas H, Alsayed SH (2012) Prediction of strength parameters of FRP-confined concrete. Compos Part B Eng 43(2):228–239

Pham TM, Hadi MNS (2014) Predicting stress and strain of FRP-confined square/rectangular columns using artificial neural networks. ASCE J Compos Constr 18(6):83–90

Doran B, Yetilmezsoy K, Murtazaoglu S (2015) Application of fuzzy logic approach in predicting the lateral confinement coefficient for RC columns wrapped with CFRP. J Eng Struct 88(1):74–91

Demers M, Neale KW (1994) Strengthening of concrete columns with unidirectional composite sheets. In: Mufti AA, Bakht B, Jaeger LG (eds) Development in short and medium span bridge Engineering’94. Proceedings of the fourth international conference on short and medium span bridges. Canadian Society for Civil Engineering, Montreal, Canada, pp 895–905

Rochette P, Labossiere P (2000) Axial testing of rectangular column models confined with composites. ASCE J Compos Constr 4(3):129–136

Suter R, Pinzelli R (2001) Confinement of concrete columns with FRP sheets. In: Proceedings, fifth international conference on fibre reinforced plastics for reinforced concrete structures, Cambridge, UK, pp 793–802

Pessiki S, Harries KA, Kestner JT, Sause R, Ricles JM (2001) Axial behavior of reinforced concrete columns confined with FRP jackets. ASCE J Compos Constr 5(4):237–245

Parvin A, Wang W (2001) Behavior of FRP jacketed concrete columns under eccentric loading. ASCE J Compos Constr 5(3):146–152

Chaallal O, Hassan M, Shahawy M (2003) Confinement model for axially loaded short rectangular columns strengthened with fiber-reinforced polymer wrapping. ACI Struct J 100(2):215–221

Ilki A, Kumbasar N, Koc V (2004) Low strength concrete members externally confined with FRP sheets. J Struct Eng Mech 18(2):167–194

Wu YF, Liu T, Oehlers DJ (2006) Fundamental principles that govern retrofitting of reinforced concrete columns by steel and FRP jacketing. J Adv Struct Eng 9(4):507–533

Rousakis TC, Karabinis AI, Kiousis PD (2007) FRP-confined concrete members: axial compression experiments and plasticity modeling. J Eng Struct 29(7):1343–1353

Wang LM, Wu YF (2008) Effect of corner radius on the performance of CFRP-confined square concrete columns: test. J Eng Struct 30(2):493–505

Harajli MH, Hantouche E, Soudki K (2006) Stress-strain model for fiber-reinforced polymer jacketed concrete columns. ACI Struct J 103(5):672–682

Masia MJ, Gale TN, Shrive NG (2004) Size effects in axially loaded square-section concrete prisms strengthened using carbon fibre reinforced polymer wrapping. Can Civ Eng J 31(1):1–13

Wu YF, Wei YY (2010) Effect of cross-sectional aspect ratio on the strength of CFRP-confined rectangular concrete columns. J Eng Struct 32(1):32–45

Wang ZY, Wang DY, Smith ST, Lu DG (2012) CFRP-confined square RC columns. I: experimental investigation. ASCE J Compos Constr 16(2):150–160

Tao Z, Yu Q, Zhong YZ (2008) Compressive behaviour of CFRP-confined rectangular concrete columns. Mag Concr Res 60(10):735–745

Zadeh LA (1965) Fuzzy sets. Inform Control 8(3):338–353

Takagi T, Sugeno M (1985) Fuzzy identification of systems and its applications to modeling and control. IEEE Trans Syst Man Cybern 1:116–132

Chiu SL (1994) Fuzzy model identification based on cluster estimation. J Intell Fuzzy Syst 2(3):267–278

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Appendices

Appendix 1: Closed-form formulation of the proposed FIS model for compressive strength of FRP-confined square columns

Example

Let us consider a column with b = 152 mm, r = 5 mm, \(f_{\text{co}}^{\prime }\) = 43 MPa, t f = 5.04 mm, f f = 230 MPa, E f = 13.6 GPa. This gives: w 1 = 7.1e−6, w 2 = 6e−7, w 3 = 0.01151, \(f_{\text{cc1}}^{\prime }\) = 242 MPa, \(f_{\text{cc2}}^{\prime }\) = 445 MPa, \(f_{\text{cc3}}^{\prime }\) = 52.9 MPa. Then, the confined compressive strength by the FIS model is calculated as \(f_{\text{cc}}^{\prime }\) = 53 MPa (the experimental value: \(f_{\text{cc,exp}}^{\prime }\) = 54.2 MPa).

Appendix 2: Closed-form formulation of the proposed FIS model for ultimate axial strain of FRP-confined square columns

Example

Let us consider a column with b = 152 mm, r = 5 mm, \(f_{\text{co}}^{\prime }\) = 43 MPa, t f = 5.04 mm, f f = 230 MPa, E f = 13.6 GPa. This gives: w 1 = 1.5e−8, w 2 = 0.00223, w 3 = 6.4e−9, ε cu1 = 0.00379, ε cu2 = 0.01187, ε cu3 = 0.05567. Then, the confined ultimate axial strain by the FIS model is calculated as ε cu = 0.0119 (the experimental value: ε cu,exp = 0.0124).

Rights and permissions

About this article

Cite this article

Nasrollahzadeh, K., Nouhi, E. Fuzzy inference system to formulate compressive strength and ultimate strain of square concrete columns wrapped with fiber-reinforced polymer. Neural Comput & Applic 30, 69–86 (2018). https://doi.org/10.1007/s00521-016-2658-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00521-016-2658-0