Abstract

In this paper, a fuzzy logic artificial intelligence technique is delineate to predict the material removal rate (MRR) and average surface roughness (R a) during abrasive-mixed electro-discharge diamond surface grinding (AMEDDSG) of Nimonic 80A. Though, Nimonic 80A superalloy is extensively used in aerospace and automotive industries due to its high corrosion, fracture toughness, oxidation, and temperature resistance characteristics, being a difficult-to-cut material, its machining is a challenging job. The hybrid machining processes like AMEDDSG can be competently used for machining of Nimonic 80A. The face-centered central composite design is used consummate the experiments and then experimental data are used to establish fuzzy logic Mamdani model to predict the MRR and R a with respect to changes in the input process parameters viz. wheel RPM, abrasive concentration, pulse current and pulse-on-time. The results of confirmation experiments reveal an agreement between the fuzzy model and experimental results with 93.89 % accuracy implying that the established fuzzy logic model can be precisely used for predicting the performance of the AMEDDSG process. An increase in wheel RPM, pulse current, and pulse-on-time from their low level to high level contributes to increased MRR by 83.89, 71.01, 17.02 %, respectively. Also, an increase in wheel RPM contributes to reduced R a values by 5.96 %. Abrasive concentration increase from 0 to 4 g/L improves MRR by 24.03 %. The 17.10 % improvement in surface finish is achieved by increasing abrasive concentration from 0 to 8 g/L.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The traditional machining processes find many problems such as excessive heat generation in cutting zone and high friction between tool–chip interface tendency for BUE formation while machining of advanced engineering materials like superalloys, carbides, ceramics, and composites [1, 2]. These advanced materials are also known as difficult-to-cut materials. Various non-traditional machining processes have been developed since last few decades to overcome machining challenges imposed by difficult-to-cut materials. Though, these processes are capable to machine workpiece irrespective of its hardness, they suffer low cutting rate [3]. Therefore, different researchers proposed a variety of compound hybrid machining processes (HMPs) such as electro-discharge grinding (EDG), electro-discharge diamond grinding (EDDG), electrochemical discharge grinding (ECDG), and electrochemical discharge machining (ECDM), to overcome possible limitation of individual machining process and to exploit enhanced advantages due synergistic utilization two or more machining processes [1, 3]. Among these HMPs, EDDG became popular for machining of hard and electrically conductive materials. In EDDG, the synergistic action of (a) mechanical abrasion due to diamond abrasives and (b) electro-discharge erosion due to sparking between bonding materials of wheel and workpiece results in high MRR approximately 10 times more as compared to EDM process [1]. The EDDG has been classified as per configuration used into (1) electro-discharge diamond cutoff grinding (EDDCG), (2) electro-discharge diamond face grinding (EDDFG), and (3) electro-discharge diamond surface grinding (EDDSG).

To overcome low MRR and surface integrity allied issue in electro-discharge machining, Koshy et al. [4] proposed EDDG. In last few years, many research studies describing the effects of various input process parameters on machining of metals, nonmetals, ceramics, composites, metal matrix composites, etc., have been published. Chaudhary et al. [5] claimed that in EDDG of high speed steel (HSS), the MRR increases with an increase in both current and pulse-on-time while same decreases with increase in voltage and duty factor. They demonstrated that normal grinding forces decrease with an increase in current, duty factor, and voltage. Yadav et al. [6] also carried EDDG of HSS found that wheel speed and current as the most significant factors effecting the process performance. Singh et al. [7] performed the EDDFG on tungsten carbide–cobalt (WC–Co) composite and found that MRR increases with increase in current and wheel speed while it decreases with increase in pulse-on-time. They experimentally show that at optimum settings better surface finish can be achieved at higher MRR. Shrivastava and Dubey [8] optimized process parameters in EDDFG process while machining of copper–iron–graphite metal matrix composite (MMC) using genetic algorithm. The genetic algorithm-based optimized parameters yielded in improved process performance. Agrawal and Yadava [9] performed the EDDSG on Al–10 wt%SiC and Al–10 wt%Al2O3 MMCs and reported the effects of various input machining parameters on MRR and surface roughness value. They developed the artificial neural network (ANN)-based model for prediction of process performance. Increasing in wheel speed from 900 to 1400 rpm while machining Al–SiC and Al–Al2O3 composites, the MRR found be increased by 6 and 7 times, respectively, and surface roughness decreased by 0.5 and 2.2 times, respectively. In addition, the prediction capability of ANN for EDDG has also been demonstrated. Unune et al. [10, 11] developed and compared performance of ANN and RSM models in prediction of MRR and R a during EDDSG of Inconel 718. They found that mixing of abrasives/powders in dielectric fluid during EDDG enhances the MRR and improves the surface finish [12, 13]. Modi and Agrawal [13] claimed that addition of powder/abrasives improves the machining performance of EDDG on Ti–6Al–4V. The addition powder attributed to enhanced plasma channel of EDM suitable for improved MRR and surface finish. Recently, Unune et al. [14] demonstrated use of abrasives/powder for mixing in dielectric to improve the MRR in machining of Nimonic 80A by EDDG and named process as AMEDDG. They used cutoff grinding configuration in their work and experimentally show that addition of abrasives in dielectric promotes the machining rate. While they do not discuss the effects of mixing abrasives in dielectric while performing AMEDDG on the average surface roughness of machined surfaces. There are very few studies available in the literature regarding the abrasive- or powder-mixed dielectric in EDDG process; however, the main objectives of these studies were to experimentally investigate the effects of powder/abrasive in AMEDDG. Rare work on developing the model/expert system found in the literature to represent the relationship of the MRR and surface roughness values with input machining parameters related to AMEDDG.

Appropriate choice input machining parameters in AMEDDG is a challenging task owing to the contribution of various parameters and their complex relationships. Development of model for prediction of AMEDDG performance using traditional methods like mathematical or analytical may not provide accurate results. Contradictory, soft computing techniques are popular and effective technique to explain real-world complex problems where process input–output relationships are nonlinear. Soft computing techniques apply similar approach as that of the human mind for computational purposes and have capability to learn in a situation of uncertainty and inaccuracy [15–17]. Soft computing techniques offer suitable solutions while acknowledging the uncertainty and inaccuracy existing in machining. Soft computing methods such as fuzzy logic, ANN, genetic algorithm, simulated annealing, and particle swarm optimization have attracted minds of investigators owing to their capabilities to deal with nonlinear, multi-dimensional, and complex engineering problems [18, 19]. Fuzzy logic plays an important role to model input–output relationships. It is mainly efficient for solving problems when accurate mathematical models are not available. It often applied when process knowledge of experts is critical in outlining objective function and decision variable [16, 20]. Therefore, in this work, authors selected fuzzy logic technique to model AMEDDG process and used it for prediction of performances in machining of Nimonic 80A superalloy.

Fuzzy logic, being a technique for identifying, classifying, and recognizing systems, is extensively applied for monitoring and diagnostics of machines [15, 16]. The neuro-fuzzy and neural network models with highly accurate prediction capabilities in complex EDM process were reported by Pradhan and Biswas [14]. Khanlou et al. [20, 21] established neural networks, fuzzy logic, and adaptive neuro-fuzzy system (ANFIS) to predict the surface roughness during sandblasting and acid etching process. Suganthi et al. [22] reported application of ANFIS and ANN techniques in modeling of a hybrid micro-WEDM and micro-EDM process. They show that ANFIS model outperforms ANN model in predicting multiple responses in micro-EDM operations. It is reported that the tedious trial and error method in developing optimal network architecture of ANN model is not required in fuzzy logic-based modeling. Recently, Marani Barzani et al. [22, 23] proposed fuzzy logic model for prediction of surface roughness of machined Al–Si–Cu–Fe die casting alloy using different additives turning. They used fuzzy logic and Pareto-ANOVA techniques to predict and optimize the best combination of machining parameters to enhance surface roughness.

From the literature review, no work is available which attempts the modeling of AMEDDG to predict the machining performance. It was realized that fuzzy logic modeling technique provides an accurate and precise prediction of machining performance, and the developed fuzzy logic model can be directly used for industrial applications. Therefore, this study attempts to present a fuzzy logic model to predict the MRR and average surface roughness in machining of Nimonic 80A by AMEDDSG process. The four input machining parameters, namely, wheel RPM, abrasive concentration, pulse current and pulse-on-time with five levels of each, were chosen to perform the experiments. The experiments were designed according to face-centered central composite design of response surface methodology (RSM). RSM provides the interface between mathematical and statistical methods used to model and optimize the response variables. The RSM technique enables a synchronized experimental study of the individual factors and the interaction effects of the factors designed for assessing the significance of the parameters [24]. The experimental procedure, fuzzy logic model design, and validation are discussed in following sections.

2 Experimental procedure

2.1 Workpiece material

The workpiece material used was the Nimonic 80A alloy which was treated and aged to a nominal bulk hardness of 44 HRC. A fresh workpiece of size 10 mm × 10 mm × 30 mm was selected for each trial. The microstructure of the Nimonic 80A alloy is shown in Fig. 1, where inhomogeneous grain size structure is observed. The chemical composition of Nimonic 80A was determined using an optical spectrometer (LECO GDS500A) and shown in Table 1.

2.2 Experiment setup

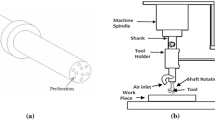

The photograph of AMEEDSG setup fabricated on Electronica ENC-35 electro-discharge machine is shown in Fig. 2a. The AMEDDSG setup (see, Fig. 2b) basically consists of permanent magnet direct current (PMDC) motor, bronze-bonded diamond grinding wheel, V-belt and pulley, acrylic container, alternating current reversible synchronous motor, etc. An automatic feeding arrangement is used to switch the direction by an alternating current reversible synchronous motor to achieve surface grinding of the workpiece. The motor is attached to lead screw of the machine table, and by changing direction of rotation of the motor, the reciprocating action of machine table is achieved. Brass-bonded diamond grinding wheel of 100 mm diameter was selected to perform electro-discharge diamond grinding action on the workpiece. The thickness of grinding wheel was 10 mm. The silicon carbide (SiC) abrasives with average grain size of 120–150 µm were chosen to mix in different concentrations in dielectric fluid EDM oil.

Mechanism of machining involves the mechanical abrasion of workpiece resulting owing to grinding action and spark erosion of workpiece due to electric discharge action. Further, the addition of abrasives/powder in the dielectric fluid results in reduced breakdown stability of dielectric fluid. Thus, the gap contamination promotes the ignition and increases the gap size. A chain of discharges takes place widening and enlarging the plasma channel resulting in rapid erosion of workpiece [25]. It is observed that the addition of abrasive helps to promote material removal rate and process stability of EDDG [14].

2.3 Experimentation

Table 2 shows the number of factors and levels used in the experiments. The input machining parameters selected include wheel RPM, abrasive concentration, pulse current, and pulse-on-time. Additionally, five levels were chosen for each input machining parameter. The MRR and the average surface roughness (R a) were selected as response variables. The experiments were planed according to face-centered central composite design of response surface methodology.

The MRR was calculated by determining the difference in the weight of un-machined and machined workpiece using electronic digital balance with the readability of 1 mg and dividing this weight difference by density of material and machining time. Taylor Hobson Surtronic-25 profilometer was used to measure R a perpendicular to feed direction of the grinding wheel. Each measurement was repeated five times, and the mean value of these measurements (Table 3) is used for response analysis. The surface roughness values measured after each experiment along with the standard deviation are listed in “Appendix”.

The experimental conditions and measured responses are shown in Table 3.

Figure 3 shows the surface morphology of AMEDDSG processes Nimonic 80A with and without abrasive-mixed dielectric at constant machining parameters viz. wheel RPM = 1000 rpm, pulse current = 6 A, and pulse-on-time = 17 µs. It is observed that, the abrasive-mixed dielectric results in smooth and narrower surface cavities as abrasives attributes enlarged and widened plasma channel [14]. Thus, it can be inferred that the AMEDDSG will lead to better machining performance.

3 Fuzzy logic

Fuzzy logic is an incessant translation from true to false conditions, as opposed to the distinct true–false conversion seen in binary logic. A degree of a subset’s probable ability to fit another subset can be represented in fuzzy logic. A wide range of applications and extensive scope offered by fuzzy logic gives it the upper hand over other statistical methods. In engineering practices, fuzzy logic exploits this continuous subset membership conversion to modify crimped numeric problems into fuzzy linguistic zones. Fuzzy logic uses traditional language to state variables and fuzzy linguistic rules to define associations as contrasting to employ with numeric variables and mathematical functions. Unlike the mathematical expression, fuzzy logic offers to use accumulated experience and knowledge based on practice rather than theory form. By sustaining the physical inference and effects of all variables, fuzzy logic simulates the complex and nonlinear systems.

It was observed that little work is available in the literature which attempts the modeling of AMEDDG to predict the machining performance. Therefore, fuzzy logic modeling technique which provides an accurate and precise prediction of machining performance used develop the fuzzy logic model which can be directly used for industrial applications. The relationship between the input parameters (wheel RPM, abrasive concentration, pulse current, and pulse-on-time) with the output parameter (MRR and average surface roughness) was mentioned for rule construction. Fuzzy linguistic variables and fuzzy expression for input and output parameters are presented in Table 4. Five membership functions (MFs) were utilized for each variable as input: very low (VL), low (L), medium (M), high (H), and very high (VH). The same (MFs) were used for MRR; however, for average surface roughness excellent (E), good (G), average (A), bad (B), and rough (R) were utilized as MFs. The membership function and associated linguistic variables were identified based on exploiting knowledge of authors in the field of EDDG. The range of linguistic variables associated with individual membership functions was adjusted manually in MATLAB software.

3.1 Membership functions for inputs and outputs

The performance of four different combinations of MF shapes for input and output was examined and based on the least root-mean-square error (RMSE), the Gaussian-shaped membership functions were chosen for input parameters while triangular-shaped membership functions were chosen for output parameters as shown in Fig. 4. The mean value of RSME values for MRR and R a for different combination of MF shapes are shown in Table 5

The equation used for calculation of RMSE is:

The Gaussian fuzzy membership function frequently describes imprecise, linguistic relations as illustrated by:

where \(C_{n}\) and \(\sigma_{n}\) are the center and width of the nth fuzzy set \(A^{n}\), respectively.

The triangular membership function for output was defined using three parameters;

where \(a\), \(b\), and \(c\) define the triangular fuzzy triplet and determine the \(x\) coordinates of the three corners of the underlying triangular membership function.

3.2 Fuzzy logic rules

In this study, the fuzzy rule base containing a set of IF–THEN statements for 25 rules with four inputs, wheel RPM (A), abrasive concentration (B), pulse current (C), and pulse-on-time (D) with two outputs as MRR (E) and average surface roughness (F) are considered. Twenty five rules were recognized founded on the experimental settings shown in Table 3 and presented in Table 6 which are as follows:

By following to the maximum–minimum compositional process, the fuzzy logic of these rules results fuzzy output. Assuming that A, B, and C are the three input parameters of the fuzzy logic unit, the membership function of the fuzzy logic output is stated as [25]:

where \(\wedge\) is the maximum and \(\vee\) is the minimum operation. Membership functions come in different forms including triangular, trapezoidal, gaussian, and sigmoid.

3.3 Defuzzification

A defuzzification process was also performed in this study. Defuzzification transform fuzzy set data into numeric data and for this purpose, a defuzzification method, called as centroid of area (COA) method [26], is used to transform fuzzy inference output into numeric value. The COA defuzzification method was used due to its wide acceptance and capability to produce more accurate results [25].

4 Results and discussion

In this study, the MRR and average surface roughness predicted by fuzzy logic in relation to changes in the process parameters are shown in Figs. 5 and 6, respectively. Figure 5a shows the MRR predicted by fuzzy logic for varying wheel RPM and abrasive concentration. It can be observed that interaction effect for higher wheel RPM (1300 RPM) at the middle value of abrasive concentration (4 g/L) gives highest MRR. Similar observation can also be seen for interaction effect of wheel RPM and pulse current (Fig. 5b) and for interaction effect of wheel RPM and pulse-on-time (Fig. 5c). The low values of wheel RPM, pulse current, abrasive concentration, and pulse-on-time are not recommended for higher cutting rate. It can be observed that combination of higher abrasive concentration and higher pulse current is best suited for high MRR (Fig. 5d). It can be observed that low value of pulse-on-time is appropriate for interactive effect with a higher value of both abrasive concentration and pulse-on-time (Fig. 5c, d).

Predicted material removal rate by fuzzy logic in relation to parameters change. a Wheel RPM and abrasive concentration, b wheel RPM and pulse current, c wheel RPM and pulse-on-time, d abrasive concentration and pulse current, e abrasive concentration and pulse-on-time, f pulse current and pulse-on-time

Predicted average surface roughness (R a) value by fuzzy logic in relation to parameters change. a Wheel RPM and pulse-on-time, b wheel RPM and pulse current, c wheel RPM and pulse-on-time, d abrasive concentration and pulse current, e abrasive concentration and pulse-on-time, f pulse current and pulse-on-time

Figure 6a shows the average surface roughness predicted by fuzzy logic for varying wheel RPM and abrasive concentration. It can be observed that abrasive concentration has a significant effect on average surface roughness value. Higher values of abrasive concentration are more suitable for better surface finish. The middle values of wheel RPM are more appropriate for lower R a values. Overall, the interaction effect wheel RPM around 1000–1100 RPM and powder concentration of 4–8 g/L result in lower R a values. Figure 6b shows the R a values predicted by fuzzy logic for varying pulse current and wheel RPM. It can be noted that too low or too high values of pulse current are not suitable for better surface finish at low wheel RPM. However, the interaction effect shows that lower values of pulse current and middle values of wheel RPM are more suitable for lower average surface roughness values. Similarly, the lower values of pulse-on-time and middle values of wheel RPM are appropriate for better surface finish (Fig. 6c). It can be perceived from Fig. 5d, the interaction effect of abrasive concentration middle value (5 g/L) and pulse current middle value (5 A) is best suited for lower average surface roughness values. A similar observation can be seen for interaction effect of abrasive concentration and pulse-on-time. At last, it can be seen that interaction effect of lower values of both pulse current and pulse-on-time is appropriate for lower R a values. The detailed discussion on individual parametric effects on response variable is included in Sect. 4.2.

4.1 Investigating fuzzy logic model accuracy and error

The accuracy of the developed fuzzy model and error rate were determined by performing nine new experiments, and then the developed fuzzy model used to predict the values of MRR and average surface roughness at same conditions (Table 7). The difference among actual experimental results and predicted values determined to denote errors using Eq. (5), where \(e_{i}\) denotes a specific error, \(V_{\text{m}}\) is the actual measured value, and \(V_{\text{p}}\) is the predicted value. The percentage for individual errors was obtained by dividing the absolute difference of the predicted by the measure value.

Accuracy is calculated by finding the proximity of the predicted value to the measured value. In Eq. (6), A is the accuracy of the model and N is the total number of datasets tested. The accuracy of the model is the average individual accuracy.

The new experiment’s input machining conditions along with measured MRR and R a values and fuzzy logic predicted MRR and R a values are listed in Table 7. Based on measured and predicted values of MRR and R a, the error percentage and the accuracy of the fuzzy logic model were determined. The average percentage error for MRR and R a was 9.73 and 2.49 %, respectively. The small error directs that MRR and R a results predicted by the fuzzy logic model were very close to the actual experimental values. It can be noted that developed fuzzy logic model gives an accuracy of 90.27 and 97.51 % in the prediction of MRR and R a, respectively. The overall average accuracy found to be 93.89 % directs that proposed model can be successfully used to predict the MRR and surface roughness of machining Nimonic 80A using AMEEDSG process.

Figure 7a, b compares the predictions from the fuzzy logic model with the actual measured MRR and average surface roughness after machining of the workpiece. It can be perceived that predicted values are in good agreement with measured values. Thus, the proposed fuzzy logic model is capable of predicting both MRR and average surface roughness values for given range of input parameters.

4.2 Parametric study using fuzzy logic model

To investigate the effects of individual process parameters, the developed fuzzy logic model is used for predicting the output responses by varying the individual input process parameter and keeping other parameters constant.

4.2.1 Effect of wheel RPM

Figure 8 illustrates the effect of varying wheel RPM on MRR and R a value at constant input parameters viz. abrasive concentration = 4 g/L, pulse current 4 A, and pulse-on-time 23 µs. It is observed that MRR increases with increase in wheel RPM while R a decreases with increase in wheel RPM. As the wheel RPM increases, the more number of diamond abrasive will come in contact with the workpiece. Also, as the wheel RPM increases, small amount of the material will be removed by each diamond abrasive particle [14, 27]. Therefore, an increase in wheel RPM will attribute to increase in MRR and decrease in R a value. Also, at higher wheel RPM, the improved flushing condition and debris extraction from inter-electrode gap (IEG) create more favorable conditions for stable spark, and hence, improved MRR and surface finish will be achieved [28]. It is observed that the increased wheel RPM from 700 to 1300 RPM results in improved MRR from 6.95 to 12.78 mm3/min, i.e., 83.89 % improved MRR. Also, average surface roughness was observed to reduce from 3.928 to 3.694 µm, i.e., 5.96 % improvement in surface finish, when wheel RPM is varied between 700 to 1300 RPM.

4.2.2 Effect of abrasive concentration

The effect of varying abrasive concentration on MRR and R a is shown in Fig. 9 at constant input parameters viz. wheel RPM = 800 RPM, pulse current 4 A, and pulse-on-time 23 µs. It is seen that the MRR increases with increase in abrasive canceration from 0 to 4 g/L but decreases after level of 4 g/L. Improved sparking condition could be attained by mixing the abrasives/powder in the dielectric fluid as it results in bridging the IEG. The bringing effect leads to increased discharge frequency due to multiple discharges taking place within single pulse [24, 29]. Thus, rapid sparking will erode workpiece fast. However, after an optimum level (4 g/L), the high abrasive concentration leads to discharge interference and therefore leading to decreased MRR. MRR is improved from 5.93 to 7.36 mm3/min, i.e., by 24.03 % when abrasive concentration in the dielectric is varied from 0 to 4 g/L. It can also be observed that increase in abrasive concentration results in decreased R a values. This is due to the fact that the bridging effect results in plasma channel to become large and wide and, therefore, a decreased spark discharge density causes smooth and narrower surfaces cavities in EDM action. The average surface roughness is observed to be reduced from 4.049 to 3.357 µm, i.e., 17.10 % improved surface finish, when varying abrasive concentration in dielectric from 0 to 8 g/L.

4.2.3 Effect of pulse current

The effect of varying pulse current on MRR and R a is shown in Fig. 10 at constant input parameters viz. wheel RPM = 900 RPM, abrasive concentration = 4 g/L, and pulse-on-time 23 µs. It is observed that both MRR and R a values increase with an increase in pulse current [28]. Increased pulse current causes more spark energy acting on the workpiece and, therefore, melting and softening of a large amount of the material. However, an increase in pulse current leads to the formation of bigger craters on workpiece surface resulting in decrease surface finish. It is observed that the increased pulse current from 2 to 10 A results in increased MRR from 5.86 to 10.02 mm3/min, i.e., 71.01 % improved MRR. Though, MRR improved by varying pulse current, but average surface roughness is observed to deteriorate from 3.442 to 4.045 µm, i.e., by 17.51 %, when pulse current is varied between 2 and 10 A.

4.2.4 Effect of pulse-on-time

The effect of varying pulse-on-time on MRR and R a is shown in Fig. 11 at constant input parameters, viz., wheel RPM = 700 RPM, abrasive concentration = 4 g/L, and pulse current 4 A. It is observed that MRR and R a increase with increase in pulse-on-time. It is observed that when pulse-on-time is increased from 17 µs to 25 µs, it results in increased MRR from 5.93 to 6.95 mm3/min, i.e., 17.02 % improved MRR. Higher pulse-on-time allows same heat energy to act on material for more amount of time. Therefore, more amount of material will be melted and softened by erosion action; therefore, increased MRR will result. However, bigger craters will be formed at larger pulse-on-time. The average surface roughness is observed to increasing from 3.108 to 4.004 µm, i.e., deteriorating by 28.84 %, when pulse-on-time is varied between 17 and 25 µs.

5 Conclusion

In the present study, an artificial intelligent approach of fuzzy logic modeling is developed to predict the effects of different input machining parameters on the MRR and R a value during AMEDDSG process for Nimonic 80A superalloy. The developed fuzzy logic model is validated by conducting confirmation experiments, and an accuracy of 93.89 % is achieved in predicting MRR and R a. Following important conclusions were drawn after fuzzy logic-based parametric analysis.

-

1.

The MRR increases while R a value decreases with increase in wheel RPM, due to improved flushing conditions at IEG. The MRR observed to be increased by 83.89 % and R a decreased by 5.96 % when wheel RPM is varied from 700 to 1300 RPM.

-

2.

The MRR increases (by 24.03 %) with an increase in abrasive concentration from 0 to 4 g/L and decreases for any further increase in abrasive concentration in the dielectric fluid. The abrasive addition plays a significant role in decreased R a values, thereby improved surface finish. The 17.10 % improvement in surface finish is achieved by increasing abrasive concentration from 0 to 8 g/L.

-

3.

The MRR increases with increase in both pulse current and pulse-on-time by 71.01 and 17.02 %, respectively. However, an increase in both pulse current and pulse-on-time deteriorates the surface finish.

Abbreviations

- MRR:

-

Material removal rate

- R a :

-

Average surface roughness

- AMEDDSG:

-

Abrasive-mixed electro-discharge diamond surface grinding

- HMPs:

-

Hybrid machining processes

- EDG:

-

Electro-discharge grinding

- EDDG:

-

Electro-discharge diamond grinding

- ECDG:

-

Electrochemical discharge grinding

- ECDM:

-

Electrochemical discharge machining

- EDDCG:

-

Electro-discharge diamond cutoff grinding

- EDDFG:

-

Electro-discharge diamond face grinding

- EDDSG:

-

Electro-discharge diamond surface grinding

- EDM:

-

Electro-discharge machining

- HSS:

-

High speed steel

- WC–Co:

-

Tungsten carbide–cobalt

- ANN:

-

Artificial neural network

- ANFIS:

-

Adaptive neuro-fuzzy system

- DC:

-

Direct current

- RSM:

-

Response surface methodology

- PMDC:

-

Permanent magnet direct current

- SiC:

-

Silicon carbide

- MF:

-

Membership function

- RMSE:

-

Root-mean-square error

- VL:

-

Very low

- L:

-

Low

- M:

-

Medium

- H:

-

High

- VH:

-

Very high

- E:

-

Excellent

- G:

-

Good

- A:

-

Average

- B:

-

Bad

- R:

-

Rough

- COA:

-

Centroid of area

- IEG:

-

Inter-electrode gap

References

Unune DR, Mali HS (2014) Current status and applications of hybrid micro-machining processes: a review. Proc Inst Mech Eng B J Eng Manuf 229(10):1681–1693. doi:10.1177/0954405414546141

Pervaiz S, Rashid A, Deiab I, Nicolescu M (2014) Influence of tool materials on machinability of titanium- and nickel-based alloys: a review. Mater Manuf Process 29(3):219–252. doi:10.1080/10426914.2014.880460

Shrivastava PK, Dubey AK (2013) Electrical discharge machining-based hybrid machining processes: a review. Proc Inst Mech Eng B J Eng Manuf 228(6):799–825. doi:10.1177/0954405413508939

Koshy P, Jain VK, Lal GK (1996) Mechanism of material removal in electrical discharge diamond grinding. Int J Mach Tool Manuf 36(10):1173–1185

Choudhury SK, Jain VK, Gupta M (1999) Electrical discharge diamond grinding of high speed steel. Mach Sci Technol 3(1):91–105. doi:10.1080/10940349908945685

Yadav SKS, Yadava V, Narayana VL (2008) Experimental study and parameter design of electro-discharge diamond grinding. Int J Adv Manuf Technol 36(1–2):34–42

Singh GK, Yadava V, Kumar R (2010) Diamond face grinding of WC-Co composite with spark assistance: experimental study and parameter optimization. Int J Precis Eng Manuf 11(4):509–518

Shrivastava PK, Dubey AK (2013) Experimental modeling and optimization of electric discharge diamond face grinding of metal matrix composite. Int J Adv Manuf Technol 69(9–12):2471–2480. doi:10.1007/s00170-013-5190-8

Agrawal SS, Yadava V (2013) Modeling and prediction of material removal rate and surface roughness in surface-electrical discharge diamond grinding process of metal matrix composites. Mater Manuf Process 28(4):381–389

Mali HS, Unune DR, Tiwari S (2014) Modelling and prediction of material removal rate in electrical discharge diamond surface grinding process of INCONEL-718. In: Proceedings of 5th AIMTDR 2014. IIT Guwahati, India, pp 822:821–822:828

Unune DR, Mali HS (2015) Artificial neural network-based and response surface methodology-based predictive models for material removal rate and surface roughness during electro-discharge diamond grinding of Inconel 718. Proc Inst Mech Eng B J Eng Manuf. doi:10.1177/0954405415619347

Modi M, Agarwal G (2012) Design, development & experimental investigation of electro-discharge diamond surface grinding of Ti–6Al–4V. Int J Adv Mater Res 418–420:1478–1481. doi:10.4028/www.scientific.net/AMR.418-420.1478

Modi M, Agarwal G (2013) Powder-mixed electro-discharge diamond surface grinding process: modelling, comparative analysis and multi-output optimisation using weighted principal components analysis. Stroj Vestn J Mech Eng 59(12):735–747. doi:10.5545/sv-jme.2013.1146

Unune DR, Singh VP, Mali HS (2015) Experimental investigations of abrasive mixed electro discharge diamond grinding of Nimonic 80A. Mater Manuf Process. doi:10.1080/10426914.2015.1090598

Pradhan MK, Biswas CK (2010) Neuro-fuzzy and neural network-based prediction of various responses in electrical discharge machining of AISI D2 steel. Int J Adv Manuf Technol 50(5–8):591–610. doi:10.1007/s00170-010-2531-8

Zalnezhad E, Sarhan AAD, Hamdi M (2013) A fuzzy logic based model to predict surface hardness of thin film TiN coating on aerospace AL7075-T6 alloy. Int J Adv Manuf Technol 68(1–4):415–423. doi:10.1007/s00170-013-4738-y

Chandrasekaran M, Muralidhar M, Krishna CM, Dixit US (2009) Application of soft computing techniques in machining performance prediction and optimization: a literature review. Int J Adv Manuf Technol 46(5–8):445–464. doi:10.1007/s00170-009-2104-x

Maher I, Ling LH, Sarhan AAD, Hamdi M (2015) Improve wire EDM performance at different machining parameters - ANFIS modeling. IFAC-PapersOnLine 48(1):105–110

Mahe, I, Eltaib MEH, El-Zahry RM (2006) Surface roughness prediction in end milling using multiple regression and adaptive neuro-fuzzy inference system. In: International conference on mechanical engineering advanced technology for industrial production (MEATIP4). Assiut University, Egypt, pp 614–620

Khanlou HM, Ang BC, Barzani MM, Silakhori M, Talebian S (2015) Prediction and characterization of surface roughness using sandblasting and acid etching process on new non-toxic titanium biomaterial: adaptive-network-based fuzzy inference System. Neural Comput Appl 26(7):1751–1761. doi:10.1007/s00521-015-1833-z

Khanlou HM, Ang BC, Barzani MM (2015) Prediction, modeling and characterization of surface texturing by sulfuric etchant on non-toxic titanium bio-material using artificial neural networks and fuzzy logic systems. Sci Eng Compos Mater. doi:10.1515/secm-2014-0230

Suganthi XH, Natarajan U, Sathiyamurthy S, Chidambaram K (2013) Prediction of quality responses in micro-EDM process using an adaptive neuro-fuzzy inference system (ANFIS) model. Int J Adv Manuf Technol 68(1–4):339–347. doi:10.1007/s00170-013-4731-5

Marani Barzani M, Zalnezhad E, Sarhan AAD, Farahany S, Ramesh S (2015) Fuzzy logic based model for predicting surface roughness of machined Al–Si–Cu–Fe die casting alloy using different additives-turning. Measurement 61:150–161. doi:10.1016/j.measurement.2014.10.003

Khanlou HM, Ang BC, Talebian S, Barzani MM, Silakhori M, Fauzi H (2015) Multi-response analysis in the processing of poly (methyl methacrylate) nano-fibres membrane by electrospinning based on response surface methodology: fibre diameter and bead formation. Measurement 65:193–206. doi:10.1016/j.measurement.2015.01.014

Kumar A, Maheshwari S, Sharma C, Beri N (2011) Analysis of machining characteristics in additive mixed electric discharge machining of nickel-based super alloy Inconel 718. Mater Manuf Process 26(8):1011–1018

Zalnezhad E, Sarhan AAD (2014) A fuzzy logic predictive model for better surface roughness of Ti–TiN coating on AL7075-T6 alloy for longer fretting fatigue life. Measurement 49:256–265. doi:10.1016/j.measurement.2013.11.042

Zimmermann HJ (1985) Fuzzy set theory and its applications. Kluwer Academic Publishers, London

Yadav RN, Yadava V (2015) Application of soft computing techniques for modeling and optimization of slotted-electrical discharge diamond face grinding process. Trans Indian Inst Met. doi:10.1007/s12666-015-0536-6

Yadav SKS, Yadava V (2013) Experimental investigations to study electrical discharge diamond cutoff grinding (EDDCG) machinability of cemented carbide. Mater Manuf Process 28(10):1077–1081

Acknowledgments

The authors would like to thank Advanced Manufacturing and Mechatronics laboratory and Materials Research Center at Malaviya National Institute of Technology, Jaipur for providing facilities for conducting this work.

Author information

Authors and Affiliations

Corresponding author

Appendix

Rights and permissions

About this article

Cite this article

Unune, D.R., Marani Barzani, M., Mohite, S.S. et al. Fuzzy logic-based model for predicting material removal rate and average surface roughness of machined Nimonic 80A using abrasive-mixed electro-discharge diamond surface grinding. Neural Comput & Applic 29, 647–662 (2018). https://doi.org/10.1007/s00521-016-2581-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00521-016-2581-4