Abstract

Non-conventional machining processes always suffer due to their low productivity and high cost. However, a suitable machining process should improve its productivity without compromising product quality. This implies the necessity to use efficient multi-objective optimization algorithm in non-conventional machining processes. In this present paper, an effective standard deviation based multi-objective fire-fly algorithm is proposed to predict various process parameters for maximum productivity (without affecting product quality) during WEDM of Indian RAFM steel. The process parameters of WEDM considered for this study are: pulse current (I), pulse-on time (T on), pulse-off time (T off) and wire tension (WT).While, cutting speed (CS) and surface roughness (SR) were considered as machining performance parameters. Mathematical models relating the process and response parameters had been developed by linear regression analysis and standard deviation method was used to convert this multi objective into single objective by unifying the responses. The model was then implemented in firefly algorithm in order to optimize the process parameters. The computational results depict that the proposed method is well capable of giving optimal results in WEDM process and is fairly superior to the two most popular evolutionary algorithms (particle swarm optimization algorithm and differential evolution algorithm) available in the literature.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

After being introduced in 1960 [1] the wire-cut electro discharge machining (EDM) has come a long way to become one of the most sophisticated machining processes of modern era. It is basically used to cut very hard conductive material and very difficult shape with great accuracy with the help of electric spark. It does not require a special shaped electrode; instead it uses a continuous-travelling vertical wire under tension as the electrode. Electro discharge machining is basically a spark erosion process where with each spark a small amount of workpiece material melts or vaporizes and washed away by the dielectric [2]. This machining process is a stochastic in nature as sparking itself is a stochastic phenomenon [3]. In electrical discharge machining, selection of machining parameters is very important to achieve high machining performance. Generally based on experience or handbook values the desired machining parameters are chosen. But this method of selecting machining parameters does not ensure optimal or near optimal machining performance for particular electrical discharge machine and environment [4].

In any machining process machining time and surface finish are the most important performance characteristics. In the case of WEDM also it is same. But the problem is that cutting speed and surface roughness are two very contradictory parameters for choosing the optimal process parameters. To solve this problem many researchers had carried out extensive research using various optimization techniques. Tarng et al. [3] used feed forward neural network and simulated annealing to get optimized WEDM process parameters for better machining speed and surface roughness taking SUS-304 stainless steel as workpiece material. Equal weightage were given to both the responses. Spedding and Wang [2] incorporated response surface method to model the cutting speed and surface roughness of WEDM and tried to optimize the process parameters by artificial neural network (ANN) technique. A regression model and feasible direction method was used by Liao et al. [5] to reduce the machining time while not compromising the surface quality of WEDM process. Lin et al. [6] proposed a control strategy based fuzzy logic for better machining accuracy in WEDM. Tosun et al. [7] developed a mathematical model for kerf and material removal rate (MRR) by regression analysis and used analysis of variance (ANOVA) and signal to noise ratio (S/N ratio) to optimize the process parameters. Singh et al. [8] carried out a multi-objective optimization of EDM process parameters by using orthogonal array (OA) with Grey relational analysis. Sarkar et al. [9] investigated the wire cut electro discharge machining on γ-titanium aluminide alloy and modeled the process with additive model. They also tried to optimize the process parameters by constrain optimization and Pareto optimization algorithm. Kuriakose and Shunmugam [10] used multiple regression models to represent the relationship between input and output of WEDM. Optimization of the process parameters for cutting velocity and surface roughness was done by a multi-objective optimization method based on a non-dominated sorting genetic algorithm (NSGA). Chiang and Chang [11] deployed Taguchi based grey relational analysis to optimize the wire electric discharge machining (WEDM) process of Al2O3 particle reinforced material (6061 alloy) with multiple performance characteristics. Mahapatra and Patnaik [12] established the relationship between WEDM process parameters and responses like MRR, surface finish and kerf width by nonlinear regression analysis. Genetic algorithm (GA) was used by them to optimize process parameters with multiple objectives. Artificial neural network (ANN) with back propagation algorithm with non-dominating sorting genetic algorithm-II was used by Mandal et al. [13] for multi-objective optimization of WEDM process. Kanagarajanet et al. [14] studied the influence of various parameters of EDM of WC/CO composites on material removal rate and surface roughness. Process characteristics were modeled by second order polynomial equation and for optimization purpose non-dominated sorting genetic algorithm (NSGA-II) was used by them. Ramkrishnan and Karunamoorthy [15] used back propagation ANN algorithm to predict the response parameters like material removal rate and surface roughness for WEDM of Inconel 718 material. Sarkar et al. [16] correlated surface roughness, dimensional shift and cutting speed with various process parameters of WEDM of γ-TiAl alloy by response surface response surface methodology. In their study optimization of process parameters was done by desirability function approach and Pareto optimization algorithm. To predict the cutting speed and kerf width Saha et al. [17] deployed normalized radial basis function network (NRBFN) with enhanced k-means clustering technique for WEDM of 5 vol% TiC/Fe in situ metal matrix composite (MMC). Chen et al. [18] used back propagation neural network based simulated annealing algorithm to optimize the process parameters to get better cutting velocity and surface roughness for WEDM of pure tungsten. Neuro-Genetic technique; a combination of a radial basis function network (RBFN) and non-dominated sorting genetic algorithm (NSGAII) was deployed by Saha et al. [19] to optimize the process parameters for multi responses of WEDM of WC/CO composites. Arindam Majumder [20] developed the relation between various process parameters with response parameter by response surface methodology (RSM) and then used genetic algorithm to minimize the electrode wear rate in EDM. Saha et al. [21] used neuro-genetic algorithm for multi-objective optimization of WEDM of 5 vol% titanium carbide (TiC) reinforced austenitic manganese steel metal matrix composite (MMC). The relation between multiple input and outputs of WEDM of AISI 316LN Stainless Steel was modeled by Majumder et al. [22] with the help of response surface methodology (RSM). They employed desirability based multi-objective particle swarm optimization (DMPSO) algorithm to optimize the process parameters for maximizing the MRR and Minimizing the EWR. From the literature it can be seen that various techniques is used to optimize the WEDM process parameters for multiple performance characteristics. However as per as machining is concerned WEDM does not depend upon the variety of material if they are conductive but optimum machining conditions varies with different workpiece material. In the other hand optimization techniques also can make a noticeable difference while finding the optimum machining conditions. Metaheuristic algorithms are very powerful in searching global optima for very difficult engineering and industrial problems. Especially they are proved to very efficient tool to solve multi-objective optimization problems [23, 24]. It has also been seen from the previous literature that the population base meta-heuristics algorithms performed better than the single point search meta-heuristics [25].

Currently firefly algorithm (FA) draws the attention of various researchers, working in different fields due to its flexibility to solve continuous problems, clustering and classifications, and combinatorial optimization problems very efficiently [26]. Apostolopoulos and Vlachos [27], proposed the firefly algorithm for multi-objective minimization problem of economic emissions load dispatch to minimize fuel cost and emission of generating units. The results show that firefly algorithm is much more accurate than other metaheuristic algorithms to find out the global optima with high success rates. Gandomi et al. [28] in their study to solve mixed variable structural optimization implemented firefly algorithm. The optimization results confirm the superiority firefly algorithm than other metaheuristic algorithms such as particle swarm optimization, genetic algorithm, simulated annealing and hunting search. Senthilnath et al. [29] used firefly algorithm for clustering and compared the results with artificial bee colony (ABC), particle swarm optimization (PSO) and other widely used algorithms. Their findings conclude that firefly algorithm is more worthy, efficient and successful to generate optimum result. Taleizadeh and Leopoldo [30] showed the applicability firefly algorithm in supply chain management problems. Rao et al. [31] implemented firefly algorithm and bat algorithm for optimizing placement as well as sizing of static VAR compensator to enhance voltage stability. But yet a less effort has been given by the previous researchers in order to use this technique in the manufacturing field.

This paper investigated the optimum process parameters values for wire-electro discharge machining of Indian RAFM steel. RAFM steel is one of the newly developed materials profoundly used in nuclear power plant industry. To carry out the study, pulse current (I), pulse-on time (T on), pulse-off time (T off) and wire tension (WT) were taken as input process parameters, based upon the various literature available, as they are the very significant parameters for WEDM. These process parameters were than optimized with respect to the response parameters i.e. cutting speed and surface roughness. Mathematical models to relate the machining parameters with the response parameters had been developed by linear regression analysis. The adequacy of the mathematical models was checked by deploying analysis of variance (ANOVA). While, Standard deviation based technique was used to select individual weights for each responses during this study. Later, a firefly algorithm (FA) was employed to find out the optimum set of data for the described process parameters. The results thus obtained were then compared with the results obtained by particle swarm optimization algorithm (PSO) and differential evolution algorithm (DE) as well as the response parameters at the initial condition. Finally the optimized results were validated experimentally.

2 Regression analysis

Linear regression analysis is a statistical process. It estimates the relationships among variables. This method is extensively used in mathematical model building depending upon the relationship between the dependent and independent variables [32]. Linear regression technique consists of simple linear regression and multiple linear regression analysis. In simple linear regression only one independent variable can be used. But multiple linear regression analysis does not have such limits. That means, more than one independent variable can be used to explain the variation of dependent variable.

To describe a particular response or dependent variable using the independent ones general linear model for multiple regression analysis is used. General linear model and its assumption are shown below.

where y = response or independent variable; β 0, β 1, β 2 …, β n are unknown constants. x 1, x 2, …, x n are independent variables; ∊ = random error.

Each value of y is deviate from the average y value by random error amount. Certain assumptions have to be taken into account.

-

1.

∊ values are independent.

-

2.

∊ values have a mean of 0 and a common variance σ 2 for any set x 1, x 2, …, x n .

-

3.

∊ values are normally distributed.

When the above listed assumption met about random error (∊) the basic equation (deterministic general linear model) can be written as [33]

3 Firefly algorithm (FA)

3.1 Basic foundation of firefly algorithm

The firefly algorithm was developed by Xin-She Yang. This is a meta-heuristic type algorithm, inspired by the social behavior of fireflies. Fireflies produce flash by virtue of bioluminescence [28]. The varied flashing light patterns are used to send courtship signal to other fireflies for mating. Firefly algorithm is based on the idealized behavior of the flashing characteristics of fireflies. To simplify, the flashing characteristics can be described by the following three rules:

-

1.

As fireflies are unisex, so the attract each other regardless of their sex.

-

2.

Attractiveness is defined by the brightness. With higher the brightness the firefly becomes more attractive. That means the lesser one attracts towards the brighter one.

-

3.

With increase in distance the brightness and attractiveness decrease. If no one is brighter than a particular firefly, it will move randomly [34].

The pseudo code used to summarize the basic steps of firefly algorithm is shown below (Fig. 1).

3.2 Characteristic description of FA

Firefly algorithm basically depends upon the light intensity variation and formulation of attractiveness. In basic firefly algorithm the solution of the fitness function is defined by the light intensity. The light intensity varies with the distance (r) between two fireflies. The following equation shows the relation between light intensity and distance between two fireflies.

where I(r) is the light intensity at distance (r), I 0 is the original light intensity at r = 0 and γ is the light absorption coefficient. Inverse square law and approximation of absorption in Gaussian form jointly omit the singularity at r = 0 in the expression I/r 2 effectively.

On the other hand attractiveness and light intensity of fireflies are proportional to each other. So the attractiveness of fireflies also can be described by a similar equation to light intensity as follows.

where β is the attractiveness measure at distance (r) and β 0 is the original attractiveness at zero distance.

From the above description it may be concluded that attractiveness and light intensity are synonyms. But there is a major difference between the two terms. Light intensity gives the absolute measure of light emitted by a firefly whereas attractiveness gives the relative measure of light that is seen by the other one [35].

Distance between two fireflies i and j at x i and x j can be expressed by a Euclidean equation as follows.

where x ik represents the component of the spatial coordinate x i of the ith firefly and ‘d’ defines the number of dimensions [27].

Brighter firefly ‘j’ attracts the other firefly ‘i’. The movement of ‘i’ towards ‘j’ can be formulated by the following equation.

where the second term is for attraction factor and the third term is for randomization. The randomness factor is denoted by ‘α’. ɛ i is random vector quantity drawn from Gaussian distribution.

In most cases the values for β 0 can be taken as 1 and α ϵ [0, 1]. Theoretically the value the value of the absorption coefficient γ ϵ [0, ∞], but in most time the value of it typically varies from 0.1 to 10 [35].

4 Experimental procedure

For this study Indian RAFMS was used as workpiece material. The composition and physical properties of the material [36] are shown in Tables 1 and 2. Figure 2 shows the optical micro graph of Indian RAFMS. Electronica Sprintcut WEDM was used to perform the experiments. For conducting the experiments distilled water was used as dielectric medium. While cutting brass wire (CuZn37) electrode was used due to its favorable thermal property, easy availability and low cost.

During the experiment pulse current (I), pulse-on time (T on), pulse-off time (T off) and wire tension (WT) were taken as variable process parameters [3, 5] whereas the discharge voltage (V), flushing pressure (FP) and wire feed (WF) were taken as constant parameters due to machine constrains. The values taken for the constant parameters were 20 V for discharge voltage, 5 atm for flushing pressure and 4 mm/min for wire feed. For experimentation the ranges of process parameters were selected through trial and error method. Then three levels for each parameter were taken and the leveling of parameters was done accordingly. Table 3 shows the leveling of parameters.

The experiments started by selecting a suitable design of experiment. In this case Taguchi’s L9 (34) orthogonal array was selected. After that the workpiece material (RAFMS) had been prepared by scaling it for nine number of cutting pass. The Scaling was done in such a way that the distance between two cuts remains 10 mm. The cutting length for the experiments was taken as 15 mm. Then the work material machined in the WEDM. Time taken by the machine to cut the 15 mm length for each pass was recorded very minutely with the help of a stopwatch.

There after the pieces of the workpiece material were cut down to find out the surface roughness of the Wire-EDMed faces. Figure 3 shows the work piece after WEDM. The surface roughness of the pieces was measured by Taylor Hobson surface profiler. The cutting speed and surface roughness values are shown in the Table 4.

5 Proposed methodology

The section deals with description of the proposed methodology for optimizing the process parameters during WEDM of RAFM. A brief description of this methodology is presented in the following subsections.

5.1 Mathematical model building

In this study with the help of multiple linear regression analysis mathematical models for cutting speed (CS) and surface roughness (SR) were developed. To find out the coefficients for the given four factors the deterministic general linear model of multiple linear regression analysis shown in Eq. 7 was used.

where y = Cutting speed or Surface roughness, x 1 = pulse-peak current (I), x 2 = pulse on time (T on), x 3 = pulse of time (T off) and x 4 = wire tension (WT).

After determining the coefficients square root transformation (y* = y (1/2)) was determined to develop mathematical models. The mathematical models thus obtained for cutting speed (CS) and surface roughness (SR) are as follow:

5.2 Model adequacy checking

In this present study, to find out the adequacy of the developed mathematical models analysis of variance (ANOVA) was conducted. The analysis result values for cutting speed and surface roughness are shown in the Tables 5 and 6.

The cutting speed and surface roughness models have F value of 65.82 and 12.86 respectively which implies that the models are significant. The P values of the models also assure the significancy of them. The determination coefficient (R 2) values of the models are 0.9850 and 0.9278 which indicates their capability to explain more than 98 % and 92 % of the total variations respectively. Further it has been observed that the adjusted R 2 value and predicted R 2 values of each regression model have reasonable agreement with each other. Moreover, for both the models the adequate precision, which measures the signal to noise ratio, were also calculated (Tables 5, 6). A ratio >4 is desirable. While in this present investigation the calculated adequate precision of CS and SR model are 19.511 and 10.569 respectively, which indicate adequate signal.

Additionally, for further illustration of accuracy the scatter plots between the predicted and actual values for cutting speed and surface roughness were drawn during this study. From the Figs. 4 and 5 it have been observed that the datas are spreaded closer to the 45° line, which shows adequacy of the developed models.

5.3 Calculation of individual weight using standard deviation method

In this study standard deviation method was used to give adequate individual weightage to the responses. The purpose for selecting this method over desirability method is to consider the degree of variability of responses with sequences during determining individual weight [37]. The individual weightages determined during this method is based upon the non-dimensional variation characteristic of the responses with experimental sequences. Figure 6 represents the box plot for linearly normalized values of response variables which justifies the use of this standard deviation method. The box plot graphically summarizes the statistical distribution of each response during experimentation. From the figure it has clearly been seen that the 50 % normalized cutting speed values collected during experimentation were clustered between 0.097 and 0.905. While for surface roughness the 50 % data collected during experimentation were lying within the range 0.413–0.816. Therefore from the plot it can be conclude that the variation of cutting speed is more than surface roughness and it is unjust to give equal weightages to them. The various steps involved in this approach are as follow:

-

Step 1 Initially the experimental values of responses (cutting speed and surface roughness) were normalized linearly using Eqs. 10 and 11 respectively. For cutting speed the normalization was carried out by “larger the better” scheme, while surface roughness were normalized using “lower the better” method (Table 7).

Table 7 Normalized result Larger the better:

$$x_{i}^{*} (k) = \frac{{x_{i}^{(o)} (k) - {\hbox{min}} {x}_{i}^{(o)} (k)}}{{{\hbox{max}} x_{i}^{(o)} (k) - {\hbox{min}} x_{i}^{(o)} (k)}}$$(10)Lower the better:

$$x_{i}^{*} (k) = \frac{{{\hbox{max}} {x}_{i}^{(o)} (k) - {x}_{i}^{(o)} (k)}}{{{\hbox{max}} x_{i}^{(o)} (k) - {\hbox{min}} x_{i}^{(o)} (k)}}$$(11)where: x (o) i (k) = experimental value of output parameter ‘i’ at kth experiment, minx (o) i (k) = the minimum value of output parameter ‘i’ and maxx (o) i (k) = the maximum value of output parameter ‘i’.

Step 2 During this step the variances of normalized cutting speed and surface roughness values were found by using Eq. 12. The standard deviation values were acquired by Eq. 13 (Table 8).

$$v_{i} = (x_{i}^{*} (k) - \mu_{i} )^{2}$$(12)$$S = \sqrt {\frac{1}{n}\sum\limits_{i = 1}^{n} {\nu_{i} } }$$(13)where, ν i = variances of normalized output parameter ‘i’, μ i = mean of all normalized experimental values (n) for output parameter ‘i’, n = number of experiments.

Table 8 Standard deviation and individual weight values of each response Step 3 In final step the ratio of the standard deviation value for each response to sum of the standard deviation values of both responses gives the individual weight for each response. Equations 14 and 15 represents the weightage equations for cutting speed and surface roughness respectively.

$$w_{1} = \frac{{S_{1} }}{{S_{1} + S_{2} }}$$(14)$$w_{2} = \frac{{S_{2} }}{{S_{1} + S_{2} }}.$$(15)

Thus by using the proposed approach, the calculated individual weight of cutting speed and surface roughness are 0.565 and 0.435 respectively. After calculating the individual weight, the two mathematical models as mentioned above (Eqs. 8, 9) were combined and a single mathematical model was generated shown in Eq. 16.

5.4 Optimization through firefly algorithm

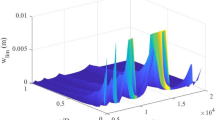

For the present study firefly algorithm was used to optimize the process parameters. In this regard the combined mathematical model was used as a fitness function for firefly algorithm. The population size for the algorithm was taken as 20. While the maximum number of iteration was taken as 200 in order to decide when to stop algorithm. The values for the tuning factors of FA like randomness factor (α), actual attractiveness (β 0) and absorption factor (γ) 0.2, 1 and 1 respectively [38]. The FA was coded in Matlab 2009a and executed in a PC with Intel i5-2450 M CPU with 4 GB RAM running at 2.50 GHz. To eliminate the effect of the stochastic behavior of this algorithm while finding the best optimal solution the algorithm was run thirty times. Figure 7 shows the best convergence rate of fitness value obtained when firefly algorithm.

6 Results and discussion

In this section the optimal results (shown in table) obtained by the algorithm were compared with the results achieved by experiments and the existing algorithms (DE and PSO) to find the effectiveness of the proposed approach. The detailed discussions are given below.

6.1 Confirmative test

The present investigation consist a confirmation test to validate the optimized parameters. The confirmation test results are shown in Table 9.

The percentage of errors between the predicted and experimental values of cutting speed and surface roughness can be seen in Table 9. It can be observed from the table that the percentages of errors are very small. Thus excellent reproducibility of the experimental conclusions is confirmed by the confirmation test results.

6.2 Comparison of FA with PSO, DE and experimental results

In this section the performance of the proposed approach was investigated. For such investigation initially the computational performance of the applied Firefly algorithm (FA) was compared with the existing particle swarm optimization algorithm (PSO) [39] and differential evolution optimization algorithm (DE) [40]. During this comparison the achieved maximum fitness value, number of iterations and computational time were considered as performance parameters. The process parameters used for existing PSO and DE in this study were taken from previous literature, Majumder [39] and Roque et al. [40] respectively and are shown in Table 10. However, the maximum number of iteration and population size for PSO and DE were taken as 100 and 20 respectively to make the performance comparison more appropriate. Both of these existing meta-heuristics (PSO and DE) were coded in MATLAB 2009a programming environment. Figure 7 represents the comparison between the convergence characteristic of applied firefly algorithm (FA) and existing particle swarm optimization algorithm (PSO) and differential evolution optimization algorithm (DE) during one of the test run.

In addition to that the performance of the developed approach was checked by comparing the achieved optimal condition with the initial condition. The initial experiment results and predicted results are shown in the Table 11.

6.3 Discussion of results

The comparison of applied FA with existing PSO and DE was carried out by running each of these algorithms thirty times during this study. Table 12 presents the best, worst, mean and standard deviation of the optimal solutions achieved from thirty trial runs. From the results it has been observed that each of these three algorithms achieved a similar best optimum solution. However, standard deviation of these test runs indicates a consistency in performance of FA as compared to the other two. For further illustration pair-wise t test between the three algorithms (Table 13) were performed with 95 % confidence interval. The hypotheses, used for this paired t test are as follows: Null hypothesis: [mean (term 1) − mean (term 2) ≤ 0], Alternative hypothesis: [mean (term 1) − mean (term 2) > 0]. If the calculated t value and P value of pair difference is positive and <0.05 respectively, then term 1 performed significantly better term 2. In this case, the results of this analysis indicate that FA significantly outperformed PSO and DE. This is expected due to two major advantageous characteristics of FA, namely automatic subdivision and the ability of controlling the randomness with the progression of convergence [26].

The calculated values of mean, best, worst and standard deviation of number of iterations required for convergence of FA, PSO and DE during thirty number of trail runs were reported in Table 14. The results shown in this table indicates that the applied firefly algorithm (FA) requires significantly less iteration as compare to particle swarm optimization algorithm (PSO) and differential evolution optimization algorithm (DE). This has also been verified by paired t tests of iterations (Table 15) used by FA, PSO and DE during convergence. The following hypotheses are used for this t test study: Null hypothesis: [mean (term 1) − mean (term 2) ≥ 0], Alternative hypothesis: [mean (term 1) − mean (term 2) < 0].

Based on the results of Table 16 it has been seen that the PSO requires less computational time for convergence as compare to the applied FA and existing DE. While for more elaboration of analysis a paired t test between the CPU time taken by FA, PSO and DE for convergence were conducted and the results were shown in Table 17. The results reflect that PSO converges quickly followed by FA and DE. It is because of the fact that the complexity of PSO (O(NT)) is lower than FA (O (N2T)) and is same as required by DE (O(NT)). However in case of PSO the number of iteration taken for convergence is much lesser than DE and moderately higher than FA.

Moreover from Table 11 it can be clearly seen that with optimized parameters the cutting speed increases along with the surface roughness. The increase in cutting speed is 141.44 % and increase in surface roughness is 32.53 %. As the cutting speed increased by a very high rate, the slight increment in surface roughness can be neglected.

Thus it can be conclude that the proposed approach is the best performed technique for optimizing WEDM process parameters.

7 Conclusion

The present study investigated the application of Standard Deviation Method based multi-objective firefly algorithm to predict the optimal process parameters during wire electro discharge machining (WEDM) of Indian reduced activation ferritic martensitic (RAFM) steel. The study includes pulse current (I), pulse-on time (T on), pulse-off time (T off) and wire tension (WT) as the process parameters. However, the response parameters considered in this study are: cutting speed and surface roughness. Based on the results the following conclusions can be drawn:

-

1.

The solution quality achieved by applied firefly algorithm (FA) is significantly better than the two efficient algorithms (PSO and DE) found in literature.

-

2.

The applied firefly algorithm (FA) has faster convergence rate as compare to DE in terms of CPU time. While comparing with PSO the proposed FA requires more CPU time for convergence.

-

3.

By using standard deviation method multiple criterions can be logically aggregated to convert a single performance index (MPI). Single performance index (MPI) can easily be optimized to determine the optimal machining environment which facilitates it for mass production and consequently product quality improvement.

-

4.

The proposed integrated approach was found to be capable to optimize the process parameters during WEDM of Indian RAFMS.

Even though, the proposed technique is efficient enough to solve the multi-attribute optimization problem. But the major disadvantage of this approach is its dependency on the collected experimental data set during individual weight selection. Therefore, it is required to overcome such uncertainty in individual weight selection by combining some other approach such as fuzzy logic and principal component analysis with standard deviation method. This can be taken as a future scope of this research. Aside from this in future, the proposed approach can also be used in other real life multi-objective optimization problems.

Abbreviations

- I :

-

Pulse current

- T on :

-

Pulse-on time

- T off :

-

Pulse-off time

- WT:

-

Wire tension

- CS:

-

Cutting speed

- min CS:

-

The minimum value of cutting speed

- max CS:

-

The maximum value of cutting speed

- SR:

-

Surface roughness

- min SR:

-

The minimum value of surface roughness

- max SR:

-

The maximum value of surface roughness

- FA:

-

Firefly algorithm

- PSO:

-

Particle swarm optimization algorithm

- DE:

-

Differential evolution algorithm

- RAFM:

-

Reduced activation ferritic martensitic steel

- WEDM:

-

Wire electrical discharge machining

- r :

-

Distance between two fire-fly

- I(r):

-

Light intensity at distance (r)

- I 0 :

-

Original light intensity at zero distance

- γ :

-

Light absorption coefficient

- β :

-

Attractiveness measure at distance (r)

- β 0 :

-

Original attractiveness at zero distance

- x i *(k):

-

Normalized value of output parameter ‘i’ at kth experiment

- x (o) i (k):

-

Experimental value of output parameter ‘i’ at kth experiment

- minx (o) i (k):

-

The minimum value of output parameter ‘i’

- maxx (o) i (k):

-

The maximum value of output parameter ‘i’

- ν i :

-

Variances of normalized output parameter ‘i’

- μ i :

-

Mean of all normalized experimental values (n) for output parameter ‘i’

- n :

-

Number of experiments

- w 1, w 2 :

-

Individual response weight of cutting speed and surface roughness respectively

- N :

-

Population size/size of the swarm

- T :

-

Number of iteration

References

Ho KH et al (2004) State of the art in wire electrical discharge machining (WEDM). Int J Mach Tools Manuf 44(12):1247–1259

Spedding TA, Wang ZQ (1997) Study on modeling of wire EDM process. J Mater Process Technol 69:8–28

Tarng YS, Ma SC, Chung LK (1995) Determination of optimal cutting parameters in wire electrical discharge machining. Int J Mach Tools Manuf 35:1693–1701

Abbas N, Solomon DG (2007) Md. FuadBahari, A review on current research trends in electrical discharge machining (EDM). Int J Mach Tools Manuf 47:1214–1228

Liao YS, Huang JT, Su HC (1997) A study on the machining-parameters optimization of wire electrical discharge machining. J Mater Process Technol 71(3):487–493

Lin C-T, Chung I, Huang S-Y (2001) Improvement of machining accuracy by fuzzy logic at corner parts for wire-EDM. Fuzzy Sets Syst 122(3):499–511

Tosun N, Cogun C, Tosun G (2004) A study on kerf and material removal rate in wire electrical discharge machining based on Taguchi method. J Mater Process Technol 152:316–322

Singh PN, Raghukandan K, Pai BC (2004) Optimization by grey relational analysis of EDM parameters on machining Al–10% SiCP composites. J Mater Process Technol 155:1658–1661

Sarkar S, Mitra S, Bhattacharyya B (2005) Parametric analysis and optimization of wire electrical discharge machining of γ-titanium aluminide alloy. J Mater Process Technol 159:286–294

Kuriakose S, Shunmugam MS (2005) Multi-objective optimization of wire-electro discharge machining process by non-dominated sorting genetic algorithm. J Mater Process Technol 170:133–141

Chiang K-T, Chang F-P (2006) Optimization of the WEDM process of particle-reinforced material with multiple performance characteristics using grey relational analysis. J Mater Process Technol 180(1):96–101

Mahapatra SS, Patnaik A (2007) Optimization of wire electrical discharge machining (WEDM) process parameters using Taguchi method. Int J Adv Manuf Technol 34(9–10):911–925

Mandal D, Pal SK, Saha P (2007) Modeling of electrical discharge machining process using back propagation neural network and multi-objective optimization using non-dominating sorting genetic algorithm-II. J Mater Process Technol 186(1):154–162

Kanagarajan D et al (2008) Optimization of electrical discharge machining characteristics of WC/Co composites using non-dominated sorting genetic algorithm (NSGA-II). Int J Adv Manuf Technol 36(11-12):1124–1132

Ramakrishnan R, Karunamoorthy L (2008) Modeling and multi-response optimization of Inconel 718 on machining of CNC WEDM process. J Mater Process Technol 207(1):343–349

Sarkar S et al (2008) Modeling and optimization of wire electrical discharge machining of γ-TiAl in trim cutting operation. J Mater Process Technol 205(1):376–387

Saha P et al (2009) Modeling of wire electro-discharge machining of TiC/Fe in situ metal matrix composite using normalized RBFN with enhanced k-means clustering technique. Int J Adv Manuf Technol 43(1–2):107–116

Chen H-C et al (2010) Optimization of wire electrical discharge machining for pure tungsten using a neural network integrated simulated annealing approach. Expert Syst Appl 37(10):7147–7153

Saha, P, Saha P, Pal SK (2011) Parametric optimization in WEDM of WC-Co composite by Neuro-Genetic technique. In: Proceedings of the World Congress on Engineering, vol 3

Majumder A (2012) Parametric optimization of electric discharge machining by GA-based response surface methodology. J Manuf Sci Prod 12(1):25–30

Saha P et al (2013) Multi-objective optimization in wire-electro-discharge machining of TiC reinforced composite through Neuro-Genetic technique. Appl Soft Comput 13(4):2065–2074

Majumder A et al (2014) An approach to optimize the EDM process parameters using desirability-based multi-objective PSO. Prod Manuf Res 2(1):228–240

Yang X-S (2013) Multiobjective firefly algorithm for continuous optimization. Eng Comput 29(2):175–184

Coello CAC (1999) A comprehensive survey of evolutionary-based multiobjective optimization techniques. Knowl Inf Syst 1(3):269–308

Roeva O, Slavov T, Fidanova S (2014) Population-based vs. single point search meta-heuristics for a PID controller tuning. In: Vasant P (ed) Handbook of research on novel soft computing intelligent algorithms: theory and practical applications. Information Science Reference, Hershey, pp 200–233. doi:10.4018/978-1-4666-4450-2.ch007

Yang X-S, He X (2013) Firefly algorithm: recent advances and applications. Int J Swarm Intell 1:36–50

Apostolopoulos T, Vlachos A (2010) Application of the firefly algorithm for solving the economic emissions load dispatch problem. Int J Comb 2011:523806. doi:10.1155/2011/523806

Gandomi AH, Yang X-S, Alavi AH (2011) Mixed variable structural optimization using firefly algorithm. Comput Struct 89(23):2325–2336

Senthilnath J, Omkar SN, Mani V (2011) Clustering using firefly algorithm: performance study. Swarm Evolut Comput 1(3):164–171

Taleizadeh AA, Cárdenas-Barrón LE (2013) Metaheuristic algorithms for supply chain management problems. In Vasant P (ed) Meta-heuristics optimization algorithms in engineering, business, economics, and finance. Information Science Reference, Hershey, pp 110–135. doi:10.4018/978-1-4666-2086-5.ch004

Rao BV, Kumar GN (2015) A comparative study of BAT and firefly algorithms for optimal placement and sizing of static VAR compensator for enhancement of voltage stability. Int J Energy Optim Eng (IJEOE) 4(1):68–84. doi:10.4018/ijeoe.2015010105

Montgomery DC, Runger GC (2003) Applied statistics and probability for engineer. Wiley, Hoboken

Mendenhall W, Beaver RJ, Beaver BM (2012) Introduction to probability and statistics. Cengage Learning

Fister I, Yang XS, Brest J (2013) A comprehensive review of firefly algorithms. Swarm Evolut Comput 13:34–46.doi:10.1016/j.swevo.2013.06.001

Yang X-S (2010) Nature-inspired metaheuristic algorithms. Luniver Press, Beckington

Raj B, Rao K, Bhaduri AK (2010) Progress in the development of reduced activation ferritic-martensitic steels and fabrication technologies in India. Fusion Eng Des 85(7):1460–1468

Majumder A, Majumder A (2015) Application of standard deviation method integrated PSO approach in optimization of manufacturing process parameters. In: Vasant P (ed) Handbook of research on artificial intelligence techniques and algorithms. Information Science Reference, Hershey, pp 536–563. doi:10.4018/978-1-4666-7258-1.ch017

Yang X-S (2009) Firefly algorithms for multimodal optimization. In: Stochastic algorithms: foundations and applications. Springer, Berlin, pp 169–178

Majumder A (2014) Comparative study of three evolutionary algorithms coupled with neural network model for optimization of electric discharge machining process parameters. In: Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, 0954405414538960

Roque CMC, Martins PALS (2015) Differential evolution optimization for the analysis of composite plates with radial basis collocation meshless method. Compos Struct 124:317–326

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Majumder, A., Das, A. & Das, P.K. A standard deviation based firefly algorithm for multi-objective optimization of WEDM process during machining of Indian RAFM steel. Neural Comput & Applic 29, 665–677 (2018). https://doi.org/10.1007/s00521-016-2471-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00521-016-2471-9