Abstract

This study deals with the development of an artificial neural network (ANN) and a multiple regression (MR) model that can be employed for estimating the California bearing ratio (CBR) value of some Aegean sands. To achieve this, the results of CBR tests performed on the compacted specimens of nine different Aegean sands with varying soil properties were used in the development of the ANN and MR models. The results of the ANN and MR models were compared with those obtained from the experiments. It is found that the CBR values predicted from the ANN model matched the experimental values much better than the MR model. Moreover, several performance indices, such as coefficient of determination, root-mean-square error, mean absolute error, and variance, were used to evaluate the prediction performance of the ANN and MR models. The ANN model has shown higher prediction performance than the MR model based on the performance indices, which demonstrates the usefulness and efficiency of the ANN model. Thus, the ANN model can be used to predict CBR value of the Aegean sands included in this study as an inexpensive substitute for the laboratory testing, quite easily and efficiently.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The California bearing ratio (CBR) is defined as the ratio of force per unit area required to penetrate a soil mass with standard circular piston at the rate of 1.25 mm/min to that required for the corresponding penetration of a standard material [12]. The CBR test was firstly used in 1920s in the California State Highway Department and was adapted by US Corp of Engineer in the 1940s for military airfield [60]. The CBR tests can be performed either in the laboratory or in the field. In the laboratory, the CBR test is typically performed on compacted soil samples, while in the field the CBR test is performed at a ground surface, or on a level surface excavated in a test pit, trench, or bulldozer cut [16]. The CBR test results are very important for geotechnical engineering and earth structures such as earth dams, highway embankments, bridge abutments, and the fills behind retaining walls [88]. A CBR value is affected by the type of soil and different soil properties [92]. Many researchers [1–3, 6, 39, 44, 47, 57, 62, 67, 78, 79, 85, 86, 88] have conducted studies to show the effect of soil types and characteristics on CBR values. The CBR value has also been correlated empirically with resilient modulus and a variety of other engineering soil properties [2].

Artificial neural networks (ANNs) offer an interesting approach for modeling soil behavior [70]. ANN is an oversimplified simulation of human brain [5] and is accepted as a reliable data modeling tool to capture and represent complex relationships between inputs and outputs [9]. This is in contrast to most traditional empirical and statistical methods, which need prior knowledge about the nature of relationships among the data [74]. Thus, ANNs are well suited to modeling the complex behavior of most geotechnical engineering materials which, by their very nature, exhibit extreme variability [74]. This modeling capability, as well as the ability to learn from experience, has given ANNs superiority over most traditional methods since there is no need for making assumptions about what the underlying rules that govern the problem in hand could be [74]. Since the early 1990s, ANNs have been effectively applied to almost every problem in geotechnical engineering [74], including constitutive modeling [51, 59], geo-material properties [21, 54, 56], bearing capacity of pile [15, 55], slope stability [13, 24–26, 91], shallow foundations [27, 28, 73], liquefaction potential [30, 46, 50, 58, 68, 87], and tunnels and underground openings [75, 90].

Even though there is an ample of literature related to the ANN applications in geotechnical engineering, only a few studies have been done to predict the CBR values of the soils. Taskiran [79] used CBR tests on fine-grained soils from Southeast Anatolia Region, Turkey, to develop an ANN model. Different combinations of dry unit weight, optimum water content, liquid limit, plasticity index, sand content, No: 200 sieve passing percent (clay + silt), and gravel percent were taken as inputs while developing the ANN model. The ANN model was found to be able to predict successfully the CBR values of the fine-grained soils. Yildirim and Gunaydin [88] used the CBR data collected from the public highways of Turkey’s different regions to develop an ANN and two traditional statistical (single regression (SR) and MR) models. The results obtained from the models showed that the constructed ANN model exhibited a higher performance than both traditional models in predicting the CBR values. Kaur et al. [42] developed an ANN model for the prediction of CBR of soil. While developing the ANN model, the percentage of gravel fraction, sand fraction, fine fraction, liquid limit, plasticity index, and maximum dry density were taken as input parameters. The results achieved from the model showed that the ANN model predicts CBR values quite efficiently. Ramakrishna et al. [61] developed an ANN model for the prediction of CBR of soil by using the results of CBR tests on the black cotton soil stabilized with rice husk ash and cement. The results obtained from the model showed that the ANN model predicts CBR values quite successfully. Sabat [65] developed the ANN and MR models for the prediction of CBR of lime and quarry dust stabilized soil. While developing both models, the percentage of quarry dust, the percentage of lime, curing period, optimum moisture content, and maximum dry density were taken as input parameters. The results achieved from the models showed that both ANN and MR models were very accurate in predicting the CBR of lime and quarry dust stabilized soil, and the performance of the ANN model was relatively better than the MR model.

In this paper, an ANN model, with respect to the above advantages, and a MR model were developed to predict the CBR value of some Aegean sands. To achieve this, the results of CBR tests performed on the compacted specimens of nine different Aegean sands with varying soil properties were used. Both models had ten input parameters, namely specific gravity (G), coefficient of uniformity (C u), coefficient of curvature (C c), dry density (ρ dry), water content (w), the proportions of quartz, feldspar, calcite, corund, and amorphous minerals denoted as Q, Fel, Ca, C, and A, respectively, and an output parameter, CBR. The results of the ANN and MR models were compared with those obtained from the experiments. It is found that the CBR values predicted from the ANN model are much more close to the experimental values than those obtained from the MR model. Moreover, several performance indices, such as coefficient of determination, root-mean-square error, mean absolute error, and variance, were used to evaluate the prediction performance of the ANN and MR models. The ANN model has shown higher prediction performance than the MR model based on the performance indices.

2 Artificial neural networks

ANNs are a form of artificial intelligence which are based on the biological nervous system and inspired by the structure of biological neural networks and their way of encoding and solving problems [49]. An ANN is composed basically of a large number of highly interconnected processing elements called neurons working in parallel to solve the specific problem. The neural network is first trained by processing a large number of input patterns and the corresponding output [43]. The neural network is capable of recognizing similarities when presented with a new input pattern after proper training and predicting the output pattern [43]. Neural networks are also able to detect similarities in inputs, even though a particular input may never have been known previously [43]. This property allows its excellent interpolation capabilities, especially when the input data are not definite [43]. Neural networks may be used as a direct substitute or an alternative for autocorrelation, multivariable regression, linear regression, trigonometric, and other statistical analysis techniques [43, 76].

Many authors have described the structure and operation of ANNs (e.g., [31, 40, 48, 63, 93]. ANNs architectures are formed by three or more layers, which consist of an input layer, one or more hidden layers, and an output layer [20]. Each layer consists of a number of interconnected processing elements (PEs), commonly referred to as neurons [20]. The neurons interact with each other via weighted connections [20]. Each neuron is connected to all the neurons in the next layer [20]. In the input layer, data are presented to the network [20]. The output layer holds the response of the network to the input [20]. The hidden layers enable these networks to represent and compute complicated associations between inputs and outputs [20]. This ANN architecture is commonly referred to as a fully interconnected feed-forward multilayer perceptron (MLP) [20]. In addition, there is also a bias, which is only connected to the neurons in the hidden and output layers, with modifiable weighted corrections.

The neural network “learns” by modifying the weights of the neurons in response to the errors between the actual output values and the target output values [20]. A number of learning algorithms are available for training of neural networks, but the back-propagation algorithm is the most versatile and robust technique [43]. It provides the most efficient learning procedure for multilayer neural networks [43]. Also, the fact that back-propagation algorithms are especially capable of solving predictive problems makes them so popular [43]. The back-propagation neural network has been applied with great success to model many phenomena in the field of geotechnical engineering [19, 20–22, 34, 35, 71]. In the back-propagation neural network, learning is carried out through gradient descent on the sum of the squares of the errors for all the training patterns [34, 64]. Each neuron in a layer receives and processes weighted inputs from neurons in the previous layer and transmits its output to neurons in the following layer through links [20]. Each link is assigned a weight which is a numerical estimate of the connection strength [20]. The weighted summation of inputs to a neuron is converted to an output according to a nonlinear transfer function [20]. The common transfer function widely used in the literature is the sigmoid function. The changes in the weights are proportional to the negative of the derivative of the error term [20]. One pass through the set of training patterns, together with the associated updating of the weights, is called a cycle or an epoch [20]. Training is carried out by repeatedly presenting the entire set of training patterns (updating the weights at the end of the each epoch) until the average sum-squared error over all the training patterns is minimal and within the tolerance specified for the problem [20].

At the end of the training phase, the neural network should correctly reproduce the target output values for the training data; provided errors are minimal (i.e., convergence occurs) [20]. The associated trained weights of the neurons are then stored in the neural network memory [20]. In the next phase, the trained neural network is fed a separate set of data [20]. In this testing phase, the neural network predictions using the trained weights are compared to the target output values [20]. The performance of the overall ANN model can be assessed by several criteria [5, 69, 72, 75]. These criteria include coefficient of determination R 2, mean squared error, mean absolute error, minimal absolute error, and maximum absolute error [20]. A well-trained model should result in an R 2 close to 1 and small values of error terms [20].

In this study, determination of CBR has been modeled using the ANN in which network training was accomplished with the neural network toolbox written in MATLAB environment (Math Works 7.0 Inc. 2006), and the Levenberg–Marquardt back-propagation learning algorithm [17] was used in the training stage. Details of the experimental investigations [82], which have yielded the data for the ANN and MR models, are presented in the following section.

3 Experimental investigations

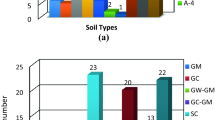

CBR tests were performed on Aegean sands obtained from nine different locations in Manisa [82], as depicted in Fig. 1. These sands were air-dried, and the fraction passing through a 4.76-mm sieve (ASTM No. 4) was separated into representative subsamples by passing through the riffle box. In order to establish gradational characteristics of these sands, sieve tests were performed in duplicate on each sample following the guidelines presented by ASTM D 422-63 [4]. Average values were used for developing the representative gradation curve for the sample. The gradational curves for the sand samples are presented in Fig. 2, and the basic soil parameters are listed in Table 1. Specific gravity tests were conducted according to Turkish Standards [80] in order to determine the G value of the samples, and the results are presented in Table 1. The ρ dry–w relationship was determined by using the 2.5 kg rammer method according to Turkish Standards [80]. The optimum water content (w opt) is given in Table 1 for each sand sample. Maximum and minimum compaction tests were also performed on each sample [7] to determine the maximum and minimum densities. The results of these tests were used to establish the maximum and minimum void ratios (e max and e min), and these ratios are given in Table 1.

Location map of the study area [82]

Particle size distribution characteristics of the sand samples [82]

Mineralogical determinations by means of X-ray diffraction analyses were performed on the sand samples by means of whole-rock powder in the Material Laboratory of Izmir Institute of Technology (Izmir-Turkey). According to the characteristic peaks for each mineral, mineral composition and their semiquantitative quantities were first identified from the X-ray diffractions on whole-rock powder. According to XRD results, 100 % proportion of quartz mineral were found in both samples A and I. Quartz was also appeared to be the dominant mineral in samples B, D, E, and F, while feldspar was the secondary dominant mineral in these samples. In sample H, higher proportions (75 %) of feldspar mineral and 25 % corundum mineral had been observed. While higher proportion of corundum (100 %) had been observed in sample G, sample C was evaluated as completely amorphous mineral (100 %). The results of XRD are also summarized in Table 2.

In the CBR tests [82], a 100-kN load cell capacity compression testing machine supplied by Humboldt, USA, was employed. The surface area of the plunger is 19.35 cm2 with the rate of penetration of 1.27 mm/min. A 60-kN load cell, attached to a digital readout unit, was used for recording the load P transmitted to the sample. Prior to loading of the sample, silicon grease was applied on the two pistons to minimize the side friction. The sample was compacted dynamically into the CBR mold in three layers to achieve a certain density. Samples B, E, and H were tested at six different densities, while samples A, C, D, G, and I were tested at seven different densities, and sample F was tested at eight different densities. For each density tested in each sample, two specimens having diameter of 152 mm, length of 127 mm were prepared at the same density and at the optimum water contents given in Table 1 for each sample. After the preparation, curing was not applied to the specimens, and CBR tests were then performed on the specimens according to Turkish Standards [81]. Then, CBR values of the specimens were determined. Finally, the average value of two tests at the same density was calculated and taken as CBR value of the sample at this density for the evaluation of test results.

After the CBR values of the individual specimens was determined for each sand sample, CBR values were plotted against dry density (ρ dry) to establish the CBR versus ρ dry relationship. The typical CBR versus ρ dry behavior was then obtained as shown in Fig. 3 for sample G. The data trends were similar for all samples, indicating an existence of a linear relationship between CBR and ρ dry. This observation is consistent with research reported by Doshi et al. [18] and Taskiran [79].

Typical CBR versus ρ dry behavior of the sample G [82]

4 Artificial neural network model

An ANN model is developed to predict the CBR value of some Aegean sands. Five soil properties (G, C u, C c, ρ dry, and w) and five mineralogical parameters (Q, Fel, Ca, C, and A) were used as the input parameters in the ANN model, whereas the measured CBR value was the output parameter. The details of the input and output parameters of the ANN model are given in Table 3.

The data were then divided into two subsets: a training set, to construct the neural network model, and an independent validation set to estimate model performance in the deployed environment. Therefore, in total (61 data sets), 80 % of the data were used for training and 20 % for testing. It has been shown that a network with one hidden layer can approximate any continuous function, provided that sufficient connection weights are used [41]. Consequently, one hidden layer was used. The neural network toolbox of MATLAB 7.0, a popular numerical computation and visualization software [84], was used for training and testing of MLPs. The optimum number of neurons in the hidden layer of the model was determined by varying their number, starting with a minimum of 1 and then increasing the network size in steps by adding 1 neuron each time. Different transfer functions (such as log-sigmoid [66], tan-sigmoid [52], and purelin) were investigated to achieve the best performance in training as well as in testing. Two momentum factors, μ (=0.01 and 0.001), were selected for the training process to search for the most efficient ANN architecture. Over-fitting makes multilayer perceptrons (MLPs) to memorize training patterns in such a way that they cannot generalize well to new data [14, 84]. Therefore, training started with a small number of epochs (=10) and kept on incrementing by 10 epochs until the onset of specialized training as reflected in the reversal of the downward trend of the error for testing data. The maximum number of epochs to train was chosen as 100. The coefficient of determination, R 2, and the mean absolute error, MAE, were used to evaluate the performance of the developed ANN models. In order to determine the optimum network geometry, the performance of the network during the training and testing processes was examined for each network size until no significant improvement occurred.

The details of the optimal performance of the networks are given in Table 4. Table 4 shows that ANN with five hidden neurons resulted in the maximum R 2 of 0.9387 and the minimum MAE of 2.53 in the testing phase. Therefore, it was chosen as the best ANN model. The architecture of the best ANN model is also given in Fig. 4. Connection weights and biases for the model are presented in Table 5.

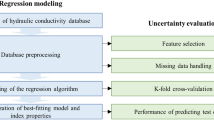

5 Multiple regression model

Multiple regression (MR), a time-honored technique going back to Pearson’s use of it in 1908, is employed to account for (predict) the variance in an interval dependent, based on linear combinations of interval, dichotomous, or dummy independent variables [89]. The general purpose of MR is to learn more about the relationship between several independent or predictor variables and a dependent or criterion variable [89]. MR analysis was carried out by using SPSS 10.0 package to correlate the measured CBR value to the five soil physical properties (G, C u, C c, ρ dry, and w) and five mineralogical parameters (Q, Fel, Ca, C, and A). The data used while developing the ANN model (i.e., 61 data sets) were used in the development of the MR model. The MR model revealed the following correlations:

6 Results and discussion

A comparison of experimental results with the results obtained from the ANN model is depicted in Figs. 5 and 6 for training and testing samples, respectively. It can be noted from the figures that CBR values obtained from the ANN model are quite close to the experimentally obtained CBR values, as their R 2 values are much close to unity. This shows that the ANN model is able to predict CBR values of the Aegean sands, if their physical properties (G, C u, C c, ρ dry, and w) and five mineralogical parameters (Q, Fel, Ca, C, and A) are known. In order to show that there might be an important relation between input and output parameters used in the ANN model which causes to achieve these performance results of the model, the correlation coefficients (r) of each input and the output one by one were calculated and given in Table 6. Smith [77] suggested the following guide for values of \(\left| r \right|\) between 0.0 and 1.0:

- \(\left| r \right| \ge 0.8\) :

-

strong correlation exists between the two sets of variables;

- \(0.2 < \left| r \right| < 0.8\) :

-

correlation exists between the two sets of variables;

- \(\left| r \right| \le 0.2\) :

-

weak correlation exists between the two sets of variables

The r values in Table 6 are smaller than 0.8, which indicate that there is not a strong correlation between the parameters causing to achieve the performance results of the ANN model. This result also indicates that ANN is a reliable data modeling tool to capture and represent complex relationships between input and output parameters.

A comparison of experimental results with the results obtained from the MR model is depicted in Fig. 7 for all samples. It can be noticed from the figure that predicted CBR values from the MR model are in good agreement with the experimentally obtained CBR values, as their R 2 of 0.812.

A paired t test, a statistical test, utilizes the mean of the difference between the observations in one group and the matched observations in the other group. A paired t test is carried out to determine whether there is a significant difference between two observations. A paired t test result can be expressed in terms of a p value, which represents the weight of evidence for rejecting the null hypothesis [53]. The null hypothesis is the equality of mean of difference between comparisons [11]. The null hypothesis can be rejected, that is, the mean of difference between comparisons are significantly different, if the p value is less than the selected significance level [11]. A significance level of 0.05 is used for all paired t tests [11]. Thus, p > 0.05 meant there was not a meaningful difference, and p < 0.05 meant there was a meaningful difference [83]. In this study, a paired t test was performed by using the SPSS 13.0 package to look for a statistically significant difference between calculated and predicted CBR values for the ANN and MR models. p value was found as 0.345 and 0.989 for the ANN and MR models, respectively, indicating no significant difference in CBR between the calculated and predicted values for both models.

The data measured and predicted from the ANN model are shown in Figs. 4 and 5. The data measured and predicted from the MR model are shown in Fig. 6. It can be noted from Figs. 4, 5, and 6 that the predicted values from the ANN model matched the measured values much better than those obtained from the MRA model. In fact, the coefficient of correlation between the measured and predicted values is a good indicator to check the prediction performance of the model [37]. In this study, variance (VAF), represented by Eq. 2, and the root-mean-square error (RMSE), represented by Eq. 3, were also computed to assess the performance of the developed models [19–26, 29, 32, 36, 38]

where var denotes the variance, y is the measured value, ŷ is the predicted value, and N is the number of the sample. If VAF is 100 % and RMSE is 0, the model is treated as excellent.

Values of VAF and RMSE for the ANN and MR models developed are listed in Table 7. It can be noted from Table 7 that the ANN model developed exhibits higher prediction performance than MR model based on the performance indices, which demonstrates the usefulness and efficiency of the ANN model. Therefore, the CBR value of the sands considered in this study could be predicted using trained ANN structures as quite easily and efficiently. Similar ANN models could also be developed for other materials using the same input parameters.

Neural network applications are treated as black-box applications in general [8, 10]. Some researchers such as Cabalar and Cevik [8], Cevik et al. [10], Köroğlu et al. [45], Erzin and Ecemis [30] opened this black box and introduced the NN application in a closed-form solution by using related NN parameters such as weights and biases. Similarly, ANN model developed in this study can be expressed in explicit function form using the related NN parameters. Using the weights and biases of the optimal ANN model (Table 5), California bearing ratio (CBR) can be expressed in terms of five soil physical properties (G, C u, C c, ρ dry, and w) and five mineralogical parameters (Q, Fel, Ca, C, and A) as follows:

where \(\tanh \left( x \right) = (e^{x} - e^{ - x} )/\left( {e^{x} + e^{ - x} } \right)\) and finally output is computed as:

It should be noted that the proposed ANN model in this study are valid for the ranges of parameters given in Table 3. Similar ANN models could also be developed for other materials using the same input parameters.

Sensitivity analyses were also carried out on the trained work to determine which of the input parameters have the most significant effect on the settlement predictions. A simple and innovative technique proposed by Garson [33], as employed by Shahin et al. [71] and Erzin and Gul [28], was utilized to interpret the relative importance of the input parameters by examining the connection weights of the trained network. For a network with one hidden layer, the technique involves a process of partitioning the hidden output connection weights into components associated with each input node [71]. The sensitivity analyses are repeated for networks trained with different initial random weights to control the robustness of the model in relation to its ability to obtain information about the relative importance of the physical factors influencing the CBR value of the sands used in this study. In this study, training of the network is repeated four times with different random starting weights. The results of the sensitivity analysis are given in Table 8. It can be seen from the table that ρ dry has the most significant effect on the predicted CBR. However, the relative importance of the remaining input variables changed depending on which initial weights were used (Table 8). The sensitivity analyses indicated that ρ dry, C u, and C c are the most important factors affecting CBR with average relative importance of 28.2, 13.6, and 11.6 %, respectively. The analyses also show that the proportion of calcite mineral (Ca) and G have less impact on the CBR value with average relative importance of 5.4 and 5.6 %, respectively.

7 Conclusions

In this study, efforts were made to develop an ANN and a MR model that can be employed for estimating the CBR value of nine different sands collected from different locations of the Manisa area (Fig. 1) located in the Aegean region. For this purpose, the results of CBR tests performed on the compacted specimens of nine different Aegean sands with varying soil properties were used in the development of the ANN and MR models. Both models had ten input parameters (G, C u, C c, ρ dry, w, Q, Fel, Ca, C, and A) and an output parameter, CBR. The results of the ANN and MR models were compared with those obtained from experiments. It is found that the ANN model exhibits more reliable predictions than the MR model.

In addition, several performance indices (R 2, RMSE, MAE, and VAF) were used to assess the prediction performance of the ANN and MR models. In the ANN model, the R 2, RMSE, MAE, and VAF values were obtained as 0.9783, 2.33, 2.05, and 97.66, respectively, for the training samples and obtained as 0.9387, 3.65, 2.53, and 92.28, respectively, for the testing samples. In the MR model, the R 2, RMSE, MAE, and VAF values were obtained as 0.8120, 6.14, 4.97, and 81.20, respectively, for all samples. Based on the performance indices, the ANN model has shown higher prediction performance than the MR model, which demonstrates the usefulness and efficiency of the ANN model. Therefore, the ANN model can be used to predict CBR value of the Aegean sands included in this study as an inexpensive substitute for the laboratory testing, quite easily and efficiently. Similar ANN models could also be developed for other materials using the same input parameters.

The sensitivity analysis indicates that the ρ dry, C u, and C c are the most important factors affecting the CBR value of the Aegean sands used in this study. The sensitivity analysis also shows that the G and the proportion of calcite mineral (Ca) have less impact on the CBR value.

References

Agarwal KB, Ghanekar KD (1970) Prediction of CBR from plasticity characteristics of soil. In: Proceeding of the 2nd south-east Asian conference on soil engineering, Singapore, June 11–15. Asian Institute of Technology, Bangkok, pp 571–576

Alawi MH, Rajab MI (2013) Prediction of California bearing ratio of subbase layer using multiple linear regression models. Road Mater Pavement Des 14(1):211–219

Al-Refeai T, Al-suhaibani A (1997) Prediction of CBR using dynamic cone penetrometer. King Saud U J Eng Sci 9(2):191–204

ASTM D 422-63 (1994) Standard test method for particle size analysis of soils. In: Annual book of ASTM standards. ASTM, West Conshohocken, pp 10–16

Banimahd M, Yasrobi SS, Woodward PK (2005) Artificial neural network for stress-strain behavior of sandy soils: knowledge based verification. Comput Geotech 32:377–386

Black WPM (1962) A method of estimating the CBR of cohesive soils from plasticity data. Geotechnique 12:271–272

BS1377 (1990) Soils for civil engineering purposes; part 4 compaction-related tests. British Standards Institution

Cabalar AF, Cevik A (2009) Modeling damping ratio and shear modulus of sand-mica mixtures using neural networks. Eng Geology 104:31–40

Caglar N, Arman H (2007) The applicability of neural networks in the determination of soil profiles. Bull Eng Geol Environ 66(3):295–301

Cevik A, Sezer EA, Cabalar AF, Gokceoglu C (2011) Modeling of the uniaxial compressive strength of some clay-bearing rocks using neural network. Appl Soft Comput 11(2):2587–2594

Ceylan H, Gopalakrishnan K, Kim S (2010) Soil stabilization with bioenergy coproduct. Transporation Research Record. No. 2186, Washington, DC, pp 30–137

Chegenizadeh A, HR Nikraz (2011) CBR test on reinforced clay. In: The 14th Pan-American conference on soil mechanics and geotechnical engineering (PCSMGE), the 64th Canadian geotechnical conference (CGC), Oct 2. Canadian Geotechnical Society, Toronto, ON, Canada

Cho SE (2009) Probabilistic stability analyses of slopes using the ANN-based response surface. Comput Geotech 36:787–797

Choobbasti AJ, Farrokhzad F, Barari A (2009) Prediction of slope stability using artificial neural network (a case study: Noabad, Mazandaran, Iran). Arab J Sci Eng 2:311–319

Das SK, Basudhar PK (2006) Undrained lateral load capacity of piles in clay using artificial neural network. Comput Geotech 33(8):454–459

Day WR (2001) Soil testing manual ‘procedures, classification data, and sampling practices, USA, p 619

Demuth H, Beale M, Hagan M (2006) Neural network toolbox user’s guide. The Math Works. Inc., Natick

Doshi SN, Mesdary MS, Guirguis HR (1983) Conference: statistical study of laboratory CBR for Kuwaiti soils. In: Fourth conference of the road engineering association of Asia and Australasia, vol 2, Jakarta, pp 43–51

Erzin Y (2007) Artificial neural networks approach for swell pressure versus soil suction behavior. Can Geotech J 44(10):1215–1223

Erzin Y, Rao BH, Singh DN (2008) Artificial neural networks for predicting soil thermal resistivity. Int J Therm Sci 47:1347–1358

Erzin Y, Gumaste SD, Gupta AK, Singh DN (2009) ANN models for determining hydraulic conductivity of compacted fine grained soils. Can Geotech J 46:955–968

Erzin Y, Rao BH, Patel A, Gumaste SD, Gupta AK, Singh DN (2010) Artificial neural network models for predicting of electrical resistivity of soils from their thermal resistivity. Int J Therm Sci 49:118–130

Erzin Y, Gunes N (2011) The prediction of swell percent and swell pressure by using neural networks. Math Comput Appl 16(2):425–436

Erzin Y, Cetin T (2012) The use of neural networks for the prediction of the critical factor of safety of an artificial slope subjected to earthquake forces. Sci Iran 19(2):188–194

Erzin Y, Cetin T (2013) The prediction of the critical factor of safety of homogeneous finite slopes using neural networks and multiple regressions. Comput Geosci 51:305–313

Erzin Y, Cetin T (2014) The prediction of the critical factor of safety of homogeneous finite slopes subjected to earthquake forces using neural networks and multiple regressions. Int J Geomech Eng 6(1):1–15

Erzin Y, Gul T (2013) The use of neural networks for the prediction of the settlement of pad footings on cohesionless soils based on standard penetration test. Int J Geomech Eng 5(6):541–564

Erzin Y, Gul T (2014) The use of neural networks for the prediction of the settlement of one-way footings on cohesionless soils based on standard penetration test. Neural Comput Appl 24:891–900

Erzin Y, Patel A, Singh DN, Tiga MG, Yılmaz I, Srinivas K (2012) Investigations on factors influencing the crushing strength of some Aegean sands. B Eng Geol Environ 71:529–536

Erzin Y, Ecemis N (2014) The use of neural networks for CPT-based liquefaction screening. B Eng Geol Environ (in press)

Fausett LV (1994) Fundamentals of neural networks: architecture, algorithms, and applications. Prentice-Hall, Englewood Cliffs

Finol J, Guo YK, Jing XD (2001) A rule based fuzzy model for the prediction of petrophysical rock parameters. J Petrol Sci Eng 29:97–113

Garson GD (1991) Interpreting neural-network connection weights. AI Expert 6(7):47–51

Goh ATC (1995) Back-propagation neural networks for modelling complex systems. Artif Intell Eng 9:143–151

Goh ATC (1995) Modelling soil correlations using neural networks. J Comput Civil Eng 9:275–278

Gokceoglu C (2002) A fuzzy triangular chart to predict the uniaxial compressive strength of Ankara agglomerates from their petrographic composition. Eng Geol 66(1–2):39–51

Gokceoglu C, Zorlu K (2004) A fuzzy model to predict the uniaxial compressive strength and the modulus of elasticity of a problematic rock. Eng Appl Artif Intell 17(1):61–72

Grima MA, Babuska R (1999) Fuzzy model for the prediction of unconfined compressive strength of rock samples. Int J Rock Mech Min 36:339–349

Gunaydin O (2009) Estimation of compaction parameters by using statistical analyses and artificial neural networks. Environ Geol 57:203–215

Hecht-Nielsen R (1990) Neurocomputing. Addison-Wesley, Boston

Hornik K, Stinchcombe M, White H (1989) Multilayer feedforward networks are universal approximators. Neural Netw 2:359–366

Kaur S, Ubboveja VS, Agarwal A (2011) Artificial neural network modeling for prediction of CBR. Indian Highw 39(1):31–37

Khandelwal M, Singh TN (2009) Prediction of blast-induced ground vibration using artificial neural network. Int J Rock Mech Min 46(7):1214–1222

Kin MW (2006) California bearing ratio correlation with soil index properties. Master degree Project, Faculty of Civil Engineering, University Technology Malaysia

Köroğlu MA, Köken A, Arslan MH, Çevik A (2013) Neural network prediction of the ultimate capacity of shear stud connectors on composite beams with profiled steel sheeting. Sci Iran 20(4):1101–1113

Kumar V, Venkatesh K, Tiwari RP, Kumar Y (2012) Application of ANN to predict liquefaction potential. Int J Comput Eng Sci 2(2):379–389

Linveh M (1989) Validation of correlations between a number of penetration test and in situ California bearing ratio test. Transp Res Rec 1219:56–67

Maren A, Harston C, Pap R (1990) Handbook of neural computing applications. Academic Press, San Diego

Mohan S, Sreeram J (2005) Application of neural network model for the containment of groundwater contamination. Land Contam Reclam 13(1):81–98

Moradi G, Khatiba BR, Sutubadi MH (2011) Determination of liquefaction potential of soil using (N1)60 by numerical modeling method. EJGE 16:407–417

Najjar YM, Ali HE (1999) Simulating the stress-strain behavior of Nevada sand byANN. In: Proceedings of the 5th U.S. National Congress on computational mechanics (USACM), Boulder, CO

Orbanić P, Fajdiga M (2003) A neural network approach to describing the fretting fatigue in aluminum-steel couplings. Int J Fatigue 25:201–207

Ott LR, Longnecker M (2001) An introduction to statistical methods and data analysis, 5th edn. Duxbury, Pacific Grave

Ozer M, Isik NS, Orhan M (2008) Statistical and neural network assessment of the compression index of clay-bearing soils. Bull Eng Geol Environ 67:537–545

Park HI, Cho CH (2010) Neural network model for predicting the resistance of driven piles. Mar Georesour Geotech 28(4):324–344

Park HI, Kim YT (2010) Prediction of strength of reinforced lightweight soil using an artificial neural network. Eng Comput 28(5):600–605

Patel SR, Desai MD (2010) CBR predicted by index properties for alluvial soils of South Gujarat, Dec. 16–18. In: Proceedings of the Indian geotechnical conference, India, pp 79–82

Pathak SR, Dalvi AN (2011) Performance of empirical models for assessment of seismic soil liquefaction. Int J Earth Sci Eng 4:83–86

Penumadu D, Zhao R (1999) Triaxial compression behavior of sand and gravel using and artificial neural networks (ANN). Comput and Geotech 24(3):207–230

Purwana YM, Nikraz HR, Jitsangiam P (2012) Experimental study of suction-monitored CBR test on sand-kaolin clay mixture. Int J Geomate 3(2):419–422

Ramakrishna AN, Pradeep Kumar AV, Gowda K (2011) Complex CBR (of BC soil-RHA-cement Mix) estimation: made easy by ANN approach [a soft computing technique]. Adv Mater Res 261–263:675–679

Ramasubbarao GV, Siva Sankar G (2013) Predicting soaked CBR value of fine grained and compaction characteristics. Jordan J Civil Eng 7(3):354–360

Ripley BD (1996) Pattern recognition and neural networks. Cambridge University Press, Cambridge

Rumelhart DH, Hinton GE, Williams RJ (1986) In: Rumelhart DE, McClelland JL (eds) Learning internal representation by error propagation: parallel distributed processing, vol 1, Chap 8. MIT Press, Cambridge

Sabat AK (2013) Prediction of California bearing ratio of a soil stabilized with lime and quarry dust using artificial neural network. Electron J Geotech Eng 18: 3261–3272

Sakellariou MG, Ferentinou MD (2005) A study of slope stability prediction using neural networks. Geotech Geol Eng 23:419–445

Satyanarayana Reddy CNV, Pavani K (2006) Mechanically stabilised soils-regression equation for CBR evaluation. In: Proceedings of the Indian geotechnical conference, Chennai, India, pp 731–734

Seed HB, De Alba P (1986) Use of SPT and CPT tests for evaluating the liquefaction resistance of sands. In: Proceedings of the In-situ, ASCE, New York, pp 281–302

Shahin MA, Jaksa MB (2005) Neural network prediction of pullout capacity of marquee ground anchors. Comput Geotech 32:153–163

Shahin MA, Jaksa MB, Maier HR (2001) Artificial neural network applications in geotechnical engineering. Aust Geomech 36(1):49–62

Shahin M, Maier H, Jaksa M (2002) Predicting settlement of shallow foundations using neural networks. J Geotech Geoenviron Eng 128(9):785–793

Shahin MA, Maier HR, Jaksa MB (2004) Data division for developing neural networks applied to geotechnical engineering. J Comput Civil Eng 18(2):105–114

Shahin MA, Jaksa MB, Maier HR (2005) Stochastic simulation of settlement prediction of shallow foundations based on a deterministic artificial neural network model. In: Proceedings of the international congress on modelling and simulation, MODSIM 2005, Melbourne, Australia, pp 73–78

Shahin MA, Jaksa MB, Maier HR (2008) State of the art of artificial neural networks in geotechnical engineering. EJGE Special Volume Bouquet 08. http://www.ejge.com/Bouquet08/Shahin/Shahin_ppr.pdf

Shi JJ (2000) Reduction prediction error by transforming input data for neural networks. J Comput Civil Eng 14(2):109–116

Singh TN, Kanchan R, Saigal K, Verma AK (2004) Prediction of p-wave velocity and anisotropic properties of rock using artificial neural networks technique. J Sci Ind Res India 63(1):32–38

Smith GN (1986) Probability and statistics in civil engineering: an introduction. Collins, London

Stephens DJ (1990) Prediction of the California bearing ratio. J Civil Eng S Afr 32(12):523–527

Taskiran T (2010) Prediction of California bearing ratio (CBR) of fine grained soils by AI methods. Adv Eng Softw 41(6):886–892

TS 1900-1 (2006) Methods of testing soils for civil engineering purposes in the laboratory—part 1: determination of physical properties

TS 1900-2 (2006) Methods of testing soils for civil engineering purposes in the laboratory—part 2: determination of mechanical properties

Turkoz D (2014) Investigations on the factors influencing the California bearing ratio value of some Aegean sands. MSc. Thesis, Celal Bayar University Manisa (in Turkish)

Tüysüz C (2010) The effect of the virtual laboratory on the students’ achievement and attitude in chemistry. IOJES 2(1):37–53

Twomey M, Smith AE (1997) In: Kartam N, Flood I, Garrett JH (eds) Validation and verification, artificial neural networks for civil engineers: fundamentals and applications. ASCE, New York, pp 44–64

Venkatasubramanian C, Dhinakaran G (2011) ANN model for predicting CBR from index properties of soils. Int J Civil Struct Eng 2(2):605–611

Vinod P, Reena C (2008) Prediction of CBR value of lateritic soils using liquid limit and gradation characteristics data. Highw Res J IRC 1(1):89–98

Venkatesh K, Kumar V, Tiwari R (2013) Appraisal of liquefaction potential using neural networks and neuro fuzzy approach. Appl Artif Intell 27(8):700–720

Yildirim B, Gunaydin O (2011) Estimation of California bearing ratio by using soft computing systems. Expert Syst Appl 38:6381–6391

Yilmaz I, Yuksek AG (2008) An example of artificial neural network application for indirect estimation of rock parameters. Int J Rock Mech Rock Eng 41(5):781–795

Yoo C, Kim J-M (2007) Tunneling performance prediction using an integrated GIS and neural network. Comput Geotech 34:19–30

Zhao HB (2008) Slope reliability analysis using a support vector machine. Comput Geotech 35:459–467

Zumrawi M (2012) Prediction of CBR from index properties of cohesive soils. In: Chang S-Y, Al Bahar SK, Zhao J (eds) Advances in civil engineering and building materials. CRC Press, Boca Raton, pp 561–565

Zurada JM (1992) Introduction to artificial neural systems. West, St. Paul

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Erzin, Y., Turkoz, D. Use of neural networks for the prediction of the CBR value of some Aegean sands. Neural Comput & Applic 27, 1415–1426 (2016). https://doi.org/10.1007/s00521-015-1943-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00521-015-1943-7