Abstract

Due to the high competition in today’s global market, design of an efficient supply chain is necessary to achieve competitive advantages. Having concerned this issue, scheduling is one of critical concepts in supply chain management that leads to increase efficiency and customer satisfaction as well as decrease costs. Recently, build-to-order supply chain (BTO-SC) system has attracted considerable attention because of its successful implementation in high-tech companies such as Dell, BMW, Compaq, and Gateway. Despite several studies in the context of BTO-SC, there has been revealed several gaps that this study attempts to eliminate them. In this paper, a fuzzy mixed-integer linear programming optimization model is proposed for an integrated supply, production, and distribution supply chain of multi-product, multi-level, multi-plant. Because of uncertainty, imprecision and variability associated with real data, fuzzy approach is utilized for processing such information in modeling the problem. Usually, supply chain problems have conflicting objectives that should be optimized simultaneously. Thus, the proposed model aims to optimize customer satisfaction as well as chain supply costs, simultaneously. Due to high complexity and lack of proper benchmark for this problem, the model is solved by some popular multi-objective meta-heuristic algorithms. Also, Taguchi method is deployed to calibrate as well as control the parameters in four mentioned algorithms. Finally, a new framework is proposed for ranking of these algorithms use of fuzzy VIKOR method. The presented framework is an excellent comparison dashboard, and it is applicable not only for comparing multi-objective genetic algorithms but also for comparing all of multi-objective meta-heuristic algorithms.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The contemporary age can be called the era of brutal competition that makes the organizations promote their system with more efficient and effective design (Ebrahimzadeh Shermeh et al. 2018; Gholamipoor et al. 2014; Nemati et al. 2018). In such an era, the companies cannot continue competition in modern business as an independent entity having a unified trade name (Lambert and Cooper 2000). In other words, the organizations prefer to have closer trade cooperation with their upstream and downstream organizations for survival and increasing profitability. In this regard, supply chain management (SCM) makes the trade companies and manufacturers capable of achieving such objectives.

The important role of an effective SCM is increasing significantly along with raised competition and the complexity of the business environment. The key factor for controlling the effectiveness and growth of a supply chain is a coordinated relationship between various members of the chain (Manoj et al. 2008). Moreover, a proper assignment of activities to supply chain in a production network characterized by distributed structure could lead to improving the efficiency of supply chain management, reducing the costs, and increasing customer satisfaction (Li et al. 2011). Thus, one of the main issues in the supply chain is the simultaneous consideration of planning and scheduling along the chain.

The diversity of customers’ preferences, rapid technological developments, and the globalization process are the main concerns of producers to compete in global markets (Hsu and Wang 2004). Nowadays, there is severe competition among organizations to influence customers. In other words, unlike before, the customers’ need for high quality and rapid servicing leads to increased pressure on producers. In such a condition, two strategies including agility and leanness have been the subject of intense attention by producers to achieve more market share. Recently, build-to-order (BTO) strategy has been regarded by producers as it considers both agility and leanness strategies in mass production (Yimer and Demirli 2010). Moreover, successful implementation of BTO in many companies such as Dell, Compaq, and BMW has attracted the considerable attention of both researchers and manufacturers (Gunasekaran and Ngai 2005). Build-to-order’ supply chain (BTO-SC) is defined as a system that delivers products and services according to the individual customer requirements meeting several competitive objectives such as price and time (Gunasekaran and Ngai 2005). Having considered BTO-SC as a forward system, this definition can be restated as a system in which materials are directed by customers’ orders toward downstream of the supply chain (Yimer and Demirli 2010). Indeed, this system is specified as a combination of both forecast-driven (MTS) and demand-driven (MTO) strategies (Demirli and Yimer 2008).

2 Literature review

Most of the proposed models concerning scheduling and planning of the supply chain consider deterministic conditions in problem formulation (McDonald and Karimi 1997; Feng et al. 2008; Mohammadi Bidhandi et al. 2009; Viergutz and Knust 2010; Ahumada and Villalobos 2011; Pal et al. 2011; Pan and Choi 2012), whereas real-world problems are affected by different types of uncertainty. In this connection, there have been proposed different methods in the literature to cope with uncertainty: (1) distribution-based (stochastic or probabilistic) approach, (2) fuzzy theory-based approach, and (3) scenario-based approach. Since this paper utilizes a fuzzy approach to deal with uncertainty, in the following, a literature review is made with a focus on the fuzzy approach applied to tackle uncertainty. Meanwhile, the studies with less concentration on the uncertainty are described briefly.

2.1 Supply chain planning and scheduling under uncertainty condition

Many efforts have been made to address supply chain planning and scheduling. In this regard, the stochastic approach deals with the uncertainty encountered in the modeling process. In one of the early studies, an integrated distribution–production system consisting of a single station model of a plant, a warehouse of final products, and a retailer is introduced in (Pyke and Cohen 1994). Then, a two-stage stochastic programming modeling approach is proposed by Gupta and Maranas (Gupta and Maranas 2000) for medium-term in multistage supply chain planning problem when uncertain demand conditions are established. Galasso et al. (2008) proposed a mixed-integer linear programming (MILP) model to treat production processes problems in a supply chain.

The performance of a multistage programming approach on the network structure of the supply chain with uncertain conditions is investigated in (Nagar and Jain 2008), which resulted in introducing a production planning model for this problem. The global risk of SCM is studied in (You et al. 2009) considering several commodities-related uncertainties in demand and delivery price. Also, a two-stage supply chain model concerning uncertainty in customer demand, operational costs, and facility capacity is developed by Mohammadi Bidhandi and Mohd Yusuff (2011). Later, a two-stage stochastic programming model is presented for the supply chain when uncertain conditions are held (You and Grossmann 2011). Liao et al. (2011) developed a comprehensive model by combining inventory control decisions with facility location models. The effect of minimum demand on a two-echelon supply chain with a quick response regarding the uncertainty involved is investigated by Chow et al. (2012).

The first attempt to establish a fuzzy supply chain model is done in (Petrovic et al. 1998), where the modeling process and supply chain simulation are treated under uncertain conditions. Afterward, their work is extended through another study (Petrovic et al. 1999) such that uncertainty in material handling across the chain is incorporated into the model accompanied by uncertainty in both demand and raw material supply. In this accord, a production–distribution system planning model was offered for a supply chain having many companies by Chen et al. (Chen et al. 2003). Considering the fuzzy approach to account uncertainty associated with parameters, a multi-product, multi-echelon, multi-period model is proposed by Chen and Chang (2006) to decrease costs and achieve more appropriate approaches for delivering commodities to customers. A fuzzy production–distribution supply chain model is proposed by Aliev et al. (2007), where the genetic algorithm (GA) is applied to solve it. Also, in this line, a multi-objective mixed-integer linear programming (MOMILP) model is presented for the distribution–production supply chain system considering multi-supplier, multi-distribution center, and only one producer conditions by Torabi and Hassini (2008). Finally, to deal with uncertainty associated with raw material supply, demand, and processes, a fuzzy mathematical programming model is proposed in Peidro et al. (2009) to deal with such a problem.

Having combined scenario-driven and goal programming approaches, a robust optimization method is proposed by Mulvey et al. (1995) to cope with the problem associated with noisy, inaccurate, and unspecific data. In light of this study, a robust optimization approach is also proposed to deal with the supply chain scheduling and planning problem by Van Landeghem and Vanmaele (2002). Accordingly, a robust optimization model based on demand uncertainty is developed for an integrated multi-station production–distribution system in Kanyalkar and Adil (2010). Furthermore, an integrated production planning model is provided concerning both price and customer demand uncertainties by Mirzapour Al-E-Hashem et al. (2011).

The literature in this context has provided several combined approaches contributing to deal with uncertainty. For example, in Chen and Lee (2004), a multi-commodity, multistage, and multi-period scheduling model is proposed for a multi-level supply chain network that respects uncertainty in both demand and price. Also in this line, regarding uncertainty conditions, a mathematical model for production–distribution supply chain planning is proposed in (2014), where a validation study was performed through applying in a case study. In Mula et al. (2006, Fahimnia et al. 2013, Lalmazloumian and Wong 2012), the studies related to the planning and scheduling of the supply chain are reviewed in detail.

To cope with the high level of complexity associated with supply chain problems, the use of meta-heuristic methods is inevitable. For instance, a supply chain scheduling model considering both production and transportation units is developed by Pei et al. (2015), where two meta-heuristic methods are applied to solve them. Also, a production and rail transportation scheduling model is provided by Hajiaghaei-Keshteli et al. (2014), in which GA and simulated annealing (SA) methods are deployed as a solving approach.

Among the mentioned works, some researchers have applied meta-heuristic methods to schedule the supply chain. These works are reviewed in the following.

2.2 Bto-sc

An increasingly growing number of papers in the context of BTO-SC reveal the importance of this strategy and its role in the competitive advantage of a firm (Gunasekaran and Ngai 2005). Among these works, a mathematical model is developed by Sen et al. (2004) to investigate the effect of combining different strategies on the performance of a supply chain. They combined traditional supply chain strategy with BTO in the electronics industry and showed that using this method, firms can achieve their expected optimum business even in a large dynamic supply chain. In another work, the effect of BTO strategy in the production and marketing cycle is studied by Sharma and LaPlaca (2005). In this line, the processes involved in a BTO supply chain and the relationships between customers and suppliers are considered in Krajewski et al. (2005). In an empirical study, Prasad et al. (2005) investigated the critical differences between MTN and BTO strategies. In Demirli and Yimer (2006, 2008), an integrated production–distribution model is developed for scheduling a multi-product, multi-firm, multi-echelon supply chain in a BTO environment. Following the mathematical approach, a multi-objective programming model is proposed by Che and Chiang (2010) for BTO-SC to optimize total time, quality, and costs, simultaneously. Also, a two-phase MILP model is suggested in the BTO framework by Yimer and Demirli (2010) to deal with supply, production, and distribution scheduling problems.

Furthermore, an order-driven programming model is provided by Volling and Spengler (2011) for the BTO system in the automotive industry, in which using a simulation approach, potential opportunities are investigated as well. Moreover, having considered the demand and back-order uncertainties, an analytical model is provided for the mass customization system by Liu et al. (2012). They also proposed closed-form solutions for the best decisions under such conditions. A robust MILP model for a multi-product, multi-period, multi-echelon BTO-SC planning problem is presented regarding different sources of uncertainties in Lalmazloumian et al. (2013). In another work, the MILP model is provided for a multi-product, multi-period, multi-echelon BTO-SC by Lalmazloumian et al. (2014).

As can be seen, despite much attention paid on supply chain programming and scheduling, most of the conducted studies have dealt with the MTS problem. Regarding today’s competitive market place, these models are considered as inefficient. Also, several studies dealing with the BTO-SC modeling problem no longer consider all its dimensions. Meanwhile, in some of them, the problem has been considered under deterministic conditions (Yimer and Demirli 2010; Che and Chiang 2010; Lalmazloumian et al. 2014). Also, those scholars who have concerned uncertainty have provided only one source of uncertainty (Demirli and Yimer 2006, 2008). Meanwhile, several studies have incorporated an integrated approach including supply, production, and distribution processes (Demirli and Yimer 2008; Sharma and LaPlaca 2005; Krajewski et al. 2005; Demirli and Yimer 2006; Volling and Spengler 2011; Liu et al. 2012). Finally, meta-heuristic algorithms are not considerably applied in the solving process despite the high efficiency of such methods in highly complex problems (Demirli and Yimer 2006, 2008; Liu et al. 2012; Lalmazloumian et al. 2014).

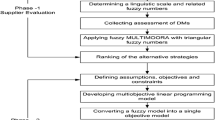

To the best of our knowledge, there is no similar study proposing a fuzzy multi-objective model for integrated BTO-SC scheduling problem such that (1) supply, production, and distribution levels are considered having employed multi-objective evolutionary algorithm as a solution procedure and (2) the uncertainty sources are not limited to only one source of uncertainty. To respond to this gap, this study aims at providing a two-objective fuzzy optimization model for scheduling a multi-product, multi-period, multi-plant BTO supply chain problem. Also, regarding the high complexity associated with such problems, it is necessary to use meta-heuristic methods as an essential step in solving the process to achieve a solution, as done in (Yimer and Demirli 2010). Therefore, in this paper, meta-heuristic algorithms are utilized to solve the proposed model. Because of the popularity of the NSGA-II algorithm in the context of multi-objective evolutionary algorithms, the NSGA-II algorithm is applied to achieve a solution. Besides, since there is no reliable benchmark provided in the literature to solve BTO-SC problems, three multi-objective meta-heuristic algorithms, namely PESA-II, NRGA, and SPEA-II, are used to validate and compare generated solutions and results. Also, the Taguchi method is deployed to calibrate and control the parameters in the four mentioned algorithms. Finally, a novel methodology is proposed to score the algorithms utilizing f-VIKOR, by which all the considered methods are ranked.

The remainder of this paper proceeds as follows. Section 3 is dedicated to providing the problem formulation and presenting the assumptions. In Sect. 4, solving procedure and meta-heuristic algorithms are presented. Section 5 introduces the comparison criteria. In Sect. 6, the obtained solutions delivered by each algorithm are presented and several approaches are compared. Finally, concluding remarks and suggestions for the future direction of the study are provided in Sect. 7.

3 Problem statement

In this study, the BTO system is decomposed into its components, including the following three main subsystems:

-

I.

Procurement subsystem

-

II.

Production subsystem

-

III.

Distribution subsystem

As shown in Fig. 1, the supply subsystem consists of suppliers, the production subsystem includes fabricators and product assemblers, and the distribution subsystem contains retailers and final product distribution centers (DCs).

3.1 Assumptions

The main feature and assumptions considered in this study are provided in the following:

-

In this system, the customers select their orders from the list of retailer’s commodities and then inform them. The retailers classify the orders into product classes and transfer and then to assemblers before the time required for production and delivery. In this system, an effective communication channel is considered between retailers and assemblers of the final product to assure product availability and to increase the customer service level.

-

DCs are considered as middle agents that collect final products form assemblers and distribute them among the corresponding retailers. Each DC may stock a determined amount of the final products as an inventory due to possible inconsistencies between the rate of entry and output of the final products.

-

There are also two more kinds of warehouses in addition to DCs including product warehouse (at the assembly place) and raw material warehouse (at the components’ production place).

-

Assembly companies classify special orders requested by the retailers into product components so that they can satisfy the demands before determined the due date. Based on assembly activities in the queue and capacity constraints, two options are specified for assembly scheduling in each period, i.e., activity in regular work time and overtime.

-

Each assembly activity requires different components and/or subassembly units that are supplied by producers of upstream parts within the chain. Considering the activity order in the queue and the limited capacity volume of producers, two options of production scheduling are drawn in each period: activity in regular work time and overtime.

-

The orders for raw material and components are supplied from raw material inventory and part inventory, respectively. If the inventory is not sufficient for the specific order, the raw materials order will be satisfied by the upstream supplier, while the order of the components is satisfied by the upstream fabricator.

-

The variable price of each product includes the prices of its components and is presented with the association with the material price and labor price per item.

-

The uncertainty associated with the model is originated from the demand volume and the product price, which is represented by triangular fuzzy numbers (TFNs).

-

The purpose of this problem is to provide an economic and feasible design of resources and the chain components capacities (including the capacity of suppliers, fabricators, assemblers, and DCs) in a planning horizon so that all operational costs have to be minimized whereas customer service satisfaction level should be maximized.

-

Supply, production, and distribution subsystems are interdependent such that materials provided from the supply subsystem are transferred into the production subsystem in which they are converted to final products, and then, the products are delivered to the customers by distribution subsystem. For this reason, an integrated supply, production, and distribution model is developed in this study.

3.2 Problem formulation

In this section, the mathematical model of the mentioned SC is described. The used indices, parameters, and variables to formulate the problem mathematically are described as follows:

3.2.1 Notation

Sets

\( S_{s} \) | Set of raw material supplier plants |

\( S_{f} \) | Set of fabricating plants |

\( S_{a} \) | Set of assembling plants |

\( S_{d} \) | Set of distribution centers (DCs) |

\( S_{r} \) | Set of product retailers |

Indices

\( i \) | Products, \( i = 1, 2, \ldots , I \) |

\( j \) | Components, \( j = 1, 2, \ldots , J \) |

\( k \) | Raw materials, \( k = 1,2, \ldots ,K \) |

\( t \) | Planning periods, \( t = 1,2, \ldots ,T \) |

\( s \) | Raw material supplier plants, \( s \in S_{s} \) |

\( f \) | Fabricators plants, \( f \in S_{f} \) |

\( a \) | Assembler plants, \( a \in S_{a} \) |

\( d \) | Distribution centers (DCs), \( d \in S_{d} \) |

\( r \) | Retailers, \( r \in S_{r} \) |

Fuzzy Parameters:

\( \widetilde{Ch}_{fk}^{1} \) | Unit holding cost of raw material k by fabricator f |

\( \widetilde{Ch}_{aj}^{2} \) | Unit holding cost of component part j by assembly plant a |

\( \widetilde{Ch}_{di}^{3} \) | Unit inventory holding cost of product I by DC d |

\( \widetilde{Co}_{fk}^{1} \) | Order set up cost of raw material k by fabricator f |

\( \widetilde{Co}_{ri}^{2} \) | Order set up cost of product I by retailer r |

\( \widetilde{Cr}_{sfk} \) | Unit purchase cost of providing raw material k to fabricator f from supplier s |

\( \widetilde{Cp}_{fjk} \) | Unit production cost of component part j from raw material k by fabricator f |

\( \widetilde{Cc}_{aij} \) | Unit customization cost of component part j to manufacture product I by assembler a |

\( \widetilde{Cf}_{ai} \) | Fixed cost of assembler a to generate product i |

\( \widetilde{Crt}_{fj}^{1} \) | Unit regular time cost for production of component part j by fabricator f |

\( \widetilde{Co}t_{fj}^{1} \) | Unit overtime time cost for production of component part j by fabricator f |

\( \widetilde{Crt}_{ai}^{2} \) | Unit regular time cost for production of product I by assembler a |

\( \widetilde{Cot}_{ai}^{2} \) | Unit overtime time cost for production of product I by assembler a |

\( \widetilde{Ct}_{sfk}^{1} \) | Unit transport cost of raw material k from supplier s to fabricator f |

\( \widetilde{Ct}_{adi}^{2} \) | Unit transport cost of product I from assembly plant a to DC d |

\( \widetilde{Ct}_{dri}^{3} \) | Unit transport cost of product I from assembly plant d to DC r |

\( \widetilde{Cbo}_{ri} \) | Penalty cost of retailer r per unit back-ordered of product i |

\( \tilde{D}_{rit} \) | Demand volume of product I from retailer r in period t |

Deterministic parameters

Deterministic coefficients:

\( l_{sf}^{1} \) | Delivery lead time of raw material s to fabricator f |

|---|---|

\( l_{ad}^{2} \) | Delivery lead time of product from assembly plant a to DC d |

\( l_{dr}^{3} \) | Delivery lead time for transportation of product I from DC d to retailer r |

\( L \) | Total supply production–distribution lead time \( \left( {l_{sf}^{1} + l_{ad}^{2} + l_{dr}^{3} } \right) \) |

\( u_{jk}^{1} \) | Quantity of raw material k required per unit of component part j |

\( u_{ij}^{2} \) | Quantity of components part j required per unit of product i |

Deterministic resources

\( rtCap_{fjt}^{1} \) | Regular time capacity of fabricator f to produce component part j in period t |

|---|---|

\( otCap_{fjt}^{1} \) | Over time capacity of fabricator f to produce component part j in period t |

\( rtCap_{ait}^{2} \) | Regular time capacity of assembly plant a to assemble product I in period t |

\( otCap_{ait}^{2} \) | Over time capacity of assembly plant a to assemble product I in period t |

\( hCap_{fk}^{1} \) | Stock capacity for raw material k to carry in warehouse of fabricator f |

\( hCap_{aj}^{2} \) | Stock capacity for component part j to carry in warehouse of assembly plant a |

\( hCap_{di}^{3} \) | Stock capacity for product I to carry in warehouse of distribution center d |

\( tCap_{sfk}^{1} \) | Transportation capacity for raw material k from supplier s to fabricator f |

\( tCap_{adi}^{2} \) | Transportation capacity for product I from assembler a to DC d |

\( tCap_{dri}^{3} \) | Transportation capacity for product I from DC d to retailer r |

\( T \) | Planning Horizon |

Fuzzy variables

\( \widetilde{TC}p \) | Total product cost |

|---|---|

\( \widetilde{TC}o \) | Total order set up cost |

\( \widetilde{TC}s \) | Raw material price |

\( \widetilde{TC}h \) | Total holding cost |

\( \widetilde{TC}t \) | Total transportation cost |

\( \widetilde{TC}b \) | Total penalty of product back-ordered |

\( \widetilde{Qb}o_{rit} \) | Back-ordered volume of product I from retailer r in period t |

\( \widetilde{\text{MDS}} \) | The Maximum level of customer dissatisfaction |

Deterministic variables

\( I_{fkt}^{1} \) | Inventory level of raw material k in fabricator f in period t |

|---|---|

\( I_{ajt}^{2} \) | Inventory level of component part j in assembly plant a in period t |

\( I_{dit}^{3} \) | Inventory level of product I in DC d in period t |

\( Q_{fkt}^{1} \) | Received quantity of raw material k by fabricator f in period t |

\( Q_{fajt}^{2} \) | Provided quantity of component j by assembler a from fabricator f in period t |

\( Q_{rit}^{3} \) | Delivered quantity of product I to retailer r in period t |

\( Qrt_{fjt}^{1} \) | Produced quantity of component part j by fabricator f in regular time in period t |

\( Qot_{fjt}^{1} \) | Produced quantity of component part j by fabricator f in overtime in period t |

\( Qrt_{ait}^{2} \) | Produced quantity of product I by assembler a in regular time in period t |

\( Qot_{ait}^{2} \) | Produced quantity of product I by assembler a in overtime in period t |

\( Qt_{sfkt}^{1} \) | Transported quantity of raw material k from supplier s to fabricator f in period t |

\( Qt_{adit}^{2} \) | Transported quantity of product I from assembler a to DC d in period t |

\( Qt_{drit}^{3} \) | Transported quantity of product I from DC d to retailer r in period t |

Binary variables

\( Xo_{fkt}^{1} \) | If fabricator f orders raw material k in period t, then takes 1, otherwise 0; |

|---|---|

\( Xo_{rit}^{2} \) | If retailer r orders to purchase product I in period t, then takes 1, otherwise 0; |

\( Xsu_{ait} \) | If assembler a manufactures product I in period t, then takes 1, otherwise 0; |

\( X_{fjt} \) | If overtime working is required to produce component part j in period t, then takes 1, otherwise 0; |

\( Y_{ait} \) | If overtime working is required to product I in period t, then takes 1, otherwise 0; |

3.2.2 Fuzzy objective functions

The fuzzy objective functions considered in our SCM problem are as follows:

-

1.

Minimize the total operational cost of the supply chain during a given planning time horizon (Eq. 1).

-

2.

Maximize customer satisfaction level (Eq. 2).

$$ \tilde{F}_{1} \cong {\text{Min}}\left( {\widetilde{TC}p + \widetilde{TC}o + \widetilde{TC}s + \widetilde{TC}h + \widetilde{TC}t + \widetilde{TC}b} \right) $$(1)$$ \tilde{F}_{2} \cong {\text{Min}}\left\{ {\mathop {\hbox{max} }\limits_{r,i,t} \left( {\frac{{\widetilde{Qb}o_{rit} }}{{\tilde{D}_{rit} }}} \right)} \right\} $$(2)

The first objective function (Eq. 1) aims at minimizing the total costs associated with the supply chain including the costs corresponding to purchasing, production, raw material supply, inventory holding, warehousing, transportation, and back-ordered. In comparison, the second function (Eq. 2) is devoted to minimizing the maximum dissatisfaction level of customers, i.e., the proportion ratio of backorders to total demands. Here, the symbol \( \cong \) indicates a fuzzy equality operator.

3.2.3 Constraints

Equations (3)–(36) present the list of constraints subjected to the model resulting from capacity limitations, material balance equations, and service level requirements, as follows:

Equation (3) considers the total production cost of the chain, with the differentiation between regular and overtime production. This equation consists of several components corresponding to production cost including the total costs of regular and overtime for production of component and product, and set up cost. Equation (4) deals with the ordering costs of the chain so that product ordering costs and raw material costs are included. Equation 5() concerns the cost of raw material supply. The total holding cost of the chain can be obtained through Eq. (6), which is derived through summing holding costs corresponding to the raw material, component, and final product. Meanwhile, Eq. (7) handles transportation costs regarding several routing ways in which transportations are done, i.e., transportation from suppliers to fabricators, from assemblers to DCs, and DCs to retailers. The penalty incurred for back-ordered products is expressed by Eq. (8). Equations (9)–(12) represent the inventory control policy. Equation (9) shows that the raw materials inventory level warehoused in fabricator at the end of each period is equal to the inventory level at the previous period plus the amounts provided by the supplier during the period and minus the amounts consumed to produce components in the current period. Similarly, Eq. (10) accounts for the balance of the inventory level of component j in assembly factory a, which is equal to the inventory level of the previous period plus the amount of component produced in the current period minus the amount of consumed component for the production of products in the current period. Equation (11) shows the inventory level of the product I in DC d, which is equal to previous inventory level added to the amount of product received from assemblers in the previous period minus the amount of delivered product to retailers during the period. Equation (12) represents the balanced relationship between the number of components delivered to assembler a and those generated by fabricator f. Equations (13)–(15) guarantee that the overtime capacity for the production should not be deployed until the regular time capacity is not completely used. Equation (16) ensures that, in a specific period, all components produced in the fabricators have been shipped to the assemblers. Also, Eqs. (17)–(19) assure that the overtime capacity for the production of components will not be employed until regular time capacity is not completely consumed. Eliminating the warehouse of products in assemblers is established by applying Eq. (20), which guarantees that all products produced in assemblers in the specific period are delivered to DCs. Meanwhile, Eq. (21) is used to enhance the level of responding to customers’ demand. This equation indicates the balance between products transferred by DCs and those received by retailers. Equation (22) determines the amount of delayed orders corresponding to product I. According to this equation, in any period, this amount equals the sum of delayed orders of the previous period plus the unresponded demand of the current period. Equations (23) and (24) show the amount of produced components in regular working time and overworking time, respectively. These equations guarantee that the production of the component will not exceed the allowed capacities. Equations (25) and (26) limit the number of assembled products in regular working time and overworking time, respectively, ensuring that the production of the product will not exceed the allowed capacities. Similarly, Eqs. (27), (28), and (29) determine the capacity limits corresponding to raw material in any fabricator, components in any assembler, and products in any DC, respectively. Equations (30), (31), and (32) express the limited capacity of raw material transported from suppliers to fabricators, products from assemblers to DCs, and products from DCs to retailers, respectively. Equation (33) addresses the purchasing rule in which \( Xo_{fkt}^{1} \) takes the value of 1 if the producer f purchases raw material k; otherwise, it takes 0. Equation (34) considers whether the product I is produced in period t by assembler a; if so, \( Xsu_{ait} \) gives value 1, otherwise, value 0 will be assigned to it. Equation (35) shows that if demand is exhibited \( Xo_{rit}^{2} \) takes 1 in case of demand and otherwise, deserves 0. Here, symbol \( { \preccurlyeq } \) indicates less or equal fuzzy operator. Finally, Eq. (36) determines the decision variables space.

As implied, considering fuzzy characteristics of parameters, variables, objective functions, and constraints appeared in the proposed model, the following section presents a confrontation approach dealing with such conditions.

4 Solution approach

As concerned earlier, in this paper, meta-heuristic approaches are deployed to solve the model. In the next section, having tackled the proposed fuzzy BTO-SC model, an attempt is first made to deal with fuzzy numbers and describe the meta-heuristic algorithms.

4.1 Fuzzy numbers

In this research, TFNs are employed to incorporate the uncertainty involved in the variables. A TFN is recognized by defining triplet points \( \tilde{A} = \left( {A_{1} ,A_{2} ,A_{3} } \right) \) (Shermeh et al. 2016; Nemati and Alavidoost 2018; Alavidoost 2017; Nemati et al. 2017). A membership function (MF) for TFN and its corresponding equation is presented in Fig. 2 and Eq. (1), respectively (Reddy et al. 2019; Reddy and Khare 2018; Alavidoost et al. 2016; Mousavi et al. 2019). Here, the TFN is chosen because of its flexibility of the fuzzy arithmetic operations, computational efficiency, and simplicity in data acquisition.

Membership function of TFN (Tarimoradi et al. 2015)

As can be seen from Fig. 2, a fuzzy triangular MF consists of three main elements including:

-

The most optimistic value \( \left( {c^{o} } \right) \)

-

The most possible value \( \left( {c^{m} } \right) \)

-

The most pessimistic value \( \left( {c^{p} } \right) \)

As can be seen from Fig. 2, a fuzzy triangular MF consists of three main elements including:

Also, according to Fig. 2, the first two elements are located in the upper bound and lower bound of feasible areas, respectively. Although the most optimistic and most pessimistic values are located at the beginning and end of the interval, respectively, they have the lowest membership degree \( \left( {\mu_{{\tilde{t}}} \left( {t^{p} } \right) = \mu_{{\tilde{t}}} \left( {t^{o} } \right) = 0} \right) \). The most possible value is placed within the interval and has a maximum degree of membership (\( \mu_{{\tilde{t}}} \left( {t^{m} } \right) = \beta \)). It is assumed that all other points are placed between these three points and they have a linear membership degree varying between 0 and β. It is of note that if the MF is normal, the value for \( \beta \) will be 1 (Alavidoost et al. 2016).

4.1.1 Fuzzy arithmetic

Fuzzy arithmetic is performed according to interval arithmetic. For this purpose, first, using the α-cut approach, fuzzy numbers are transformed into the closed interval, and then, interval arithmetic is performed (Klir and Yuan 1995). Let symbol * indicate four main mathematical operations (+, −, × , and ÷); then, interval arithmetic will be defined according to Eq. (38) as follows:

where \( d,e, g, h, f, \) and \( u \) are real numbers and \( \left[ {d,e} \right] \) refers to an interval between \( d \) and \( e \). According to fuzzy arithmetic, four main operations will be performed on the close intervals employing Eqs. (39)–(42).

Generally, applying a-cut approach is associated with a high degree of computational complexity. It may lead to generate nonlinear results and thus increase computational complexity. To deal with such deficiency, an approximation method has been suggested (63–65) in which results produced by interval arithmetic operations are transformed into a linear form. Applying this approximation method not only allows treating with computational complexity but also survives the form of a fuzzy number simultaneously. In other words, using this procedure, every fuzzy operation on two TFNs results in providing a new TFN (Eqs. 43–51).

where \( \tilde{A} \) and \( \tilde{B} \) are TFNs (\( \tilde{A} = \left( {A_{1} , A_{2} , A_{3} } \right) \) and \( \tilde{B} = \left( {B_{1} , B_{2} , B_{3} } \right) \)), respectively, and E is a scalar value. As can be seen in Eq. (43), the sum of two TFNs is also a TFN. In general, it can be concluded that summing up the several TFNs results in a TFN as well (Eq. 52).

where \( \tilde{C}_{q} = \left( {C_{q}^{o} , C_{q}^{m} , C_{q}^{p} } \right) \) is a TFN. According to Eq. (52), the first objective functions, which are composed of several TFNs, are transferred to a TFN number expressed by \( \tilde{F}_{1} = \left( {F_{1}^{o} ,F_{1}^{m} ,F_{1}^{p} } \right) \). Also, the second objective function can be transferred to \( \tilde{F}_{2} = \left( {F_{2}^{o} ,F_{2}^{m} ,F_{2}^{p} } \right) \) by Eq. (49).

4.1.2 Fuzzy comparison and ranking

Two TFNs are equal when all their points are equal to each other, correspondingly.

In other words, Eq. (53) is applied to deal with the \( \cong \) operator.

Notably, a fuzzy ranking approach is applied to deal with fuzzy maximum and minimum operators, \( { \preccurlyeq } \), and \( { \succcurlyeq } \) operators. For this purpose, several criteria are considered as provided in Eqs. (54)–(56) in the order of their priorities.

-

Criterion 1 The number is greater which the weighted average of its three points (i.e., Beginning, Peak, and End) be greater (Eq. (54)).

-

Criterion 2 The number is greater which its midpoint be greater. The greater midpoint, the greater number (Eq. 55).

-

Criterion 3 The number is greater which in terms of distance between the beginning and end point be greater (Eq. (56)).

A comparison between TFNs is initially established using the first criterion (Eq. 54). So, if this criterion results in the same value for both TFNs, then the second criterion (Eq. 55) will be taken to account for comparing two numbers and so on. To compare a fuzzy number with a crisp one, first, the fuzzy number is defuzzified using Eq. (51), and then, it is compared with a crisp one.

4.2 Meta-heuristic algorithms

Meta-heuristic algorithms are considered as powerful random search methods inspired by nature that seek for optimum solutions. In general, in multi-objective problems, a set of optimum points solutions are reached, instead of one optimum point that is generated by the single-objective ones. In contrast to single-objective problems that generate one optimum point, multi-objective ones produce a set of optimum points as a solution. In this regard, the main contribution considered in classic multi-objective models is to provide methods in which by converting multi-objective problems into single-objective ones, one optimum point is derived from the set of optimum solutions. Here, several iterations should be implemented to obtain a different solution. In this line, the main advantage of multi-objective meta-heuristic methods compared to classic ones is their capability of producing the set of the optimum solution in one iteration instead of several iterations (Deb et al. 2002).

As mentioned earlier, since there is no standard benchmark in the literature to solve this problem, in this paper, some well-known multi-objective evolutionary algorithms namely SPEA-II, NSGA-II, NRGA, and PESA-II are employed for this purpose. Because each of these methods is considered as a multi-objective approach of the GA algorithm, a brief overview of the GA procedure and a description of the selected algorithm is presented in the following.

4.2.1 Genetic algorithm

GA is one of the most well-known meta-heuristic algorithms. These algorithms, which were introduced by Holland (Holland 1975), consist of three main operations including (1) selection operator, (2) crossover operator, and (3) mutation operator. It should be remarked that this algorithm would be considered as an effective one if its operators have been adjusted appropriately (Alavidoost et al. 2014, 2015; Mousavi et al. 2015). Owing to the significance of these operators, in the following, further explanation and definitions of these operators are provided.

4.2.1.1 Selection operator

This operator functions for a new population generation in which several chromosomes are selected among all chromosomes existing in a population to generate chromosomes. Several procedures such as random selection, roulette wheel selection, and tournament selection are applied for this purpose (Haupt and Haupt 2004). It is noteworthy that chromosomes that acquired the best fitness value are those that are more probable to be selected.

4.2.1.2 Crossover operator

The crossover operator, which is performed on a couple of chromosomes, results in generating a new chromosome. For this operator, three methods including single-point crossover, two-point crossover, and uniform crossover are considered as the possible operations in the optimization process of algorithms in the context of integer and binary numbers. In comparison, in real number context, arithmetic crossover is usually applied (Haupt and Haupt 2004).

4.2.1.3 Mutation operator

This operator randomly selects a specified portion of genes from a chromosome and changes its content. In this process, if genes are considered as Boolean, this operator converts them into their reverse form (null to active or active to null). In comparison, if those belong to the specific set, it substitutes the selected genes with other values or members of that set. It should be also remarked that if the selected genes belong to real numbers, Gaussian Mutation could be applied (Haupt and Haupt 2004).

4.2.2 Non-dominated sorting genetic algorithm-II (NSGA-II)

In the context of multi-objective meta-heuristic algorithms, NSGA-II is considered as the most reputed and effective one algorithm in the literature (Deb et al. 2002). Two main operators utilized in NSGA-II are non-dominated sorting and crowding distance. The first one classifies the obtained solutions in different Pareto fronts, and the second one computes their diversity value attempting to retain the variety of algorithm solutions. The pseudocode for the algorithm of non-dominated sorting (NS) and NSGA-II is presented as follows (Alavidoost and Nayeri 2014; Babazadeh et al. 2018):

The pseudo-algorithm for the algorithm of NS is provided as follows;

The pseudo-algorithm for NSGA-II is provided as follows:

4.2.3 Non-dominated ranking genetic algorithms (NRGA)

The NRGA, introduced by Al Jadaan et al. (2008), is among the popular multi-objective meta-heuristic algorithms in which elitism approach is employed to provide Pareto fronts for solving the problem. The NRGA algorithm stems from the NSGA-II with applying non-dominating and crowding distance concepts. The main difference between these algorithms lies in their member selection process so that the selection strategy transforms from the tournament selection to the roulette wheel selection. In this line, the NRGA algorithm utilizes the roulette wheel selection based on the ranking (RWBR) approach for choosing parents. This ranking is a modified version of roulette wheel selection. According to RWBR, the possibility of selecting a member like I from the population is equal to Pi, which can be obtained employing Eq. (57). It is noteworthy that N represents the population size and \( {\text{Rank}}_{i} \) denotes the ith member rank in the population.

4.2.4 Pareto envelope-based selection algorithm-II (PESA-II)

The PESA-II algorithm was introduced by Corne et al. (2001) to make NSGA-II faster and to reduce its complexity. In this algorithm, in addition to the main population, an archive population exists that stores the best-obtained solutions resulted from each iteration. To reach such capability, it transforms objective space to hyper-grids and assigns a number to every hyper-grid that is equal to the number of archive members in that place. Therefore, there is no need to compute rank and crowding distance for every member of the sort. In this regard, only the places containing the archive population are assigned by a number. In this way, it is possible to reduce the calculation load and make the algorithm operation faster (Alavidoost et al. 2015).

The pseudocode for PESA-II is as follows: (\( {\text{Pop}}_{t} \) donates the main generation in iteration t and \( {\text{Arch}} \) represents the archive population):

4.2.5 Strength Pareto evolutionary algorithm-II (SPEA-II)

The SPEA-II, introduced by Zitzler et al. (2001), is also considered as one of the multi-objective evolutionary algorithms. In this algorithm, similar to PESA-II, an archive population is established to accompany the main population to collect best-obtained solutions in terms of fitness criteria. According to this algorithm, the fitness of a chromosome is derived using integrating its raw fitness and density. In this line, the raw fitness corresponding to each chromosome is obtained by summing the strengths associated with the chromosomes that are dominated by it. Here, the strength of each chromosome is defined by the number of chromosomes that are dominated by it. It is noteworthy that the density estimation technique used in SPEA-II is an adaptation of the kth nearest neighbor method, where the density at any point is reverse of the distance to the kth nearest neighbor. The following steps are performed to run this algorithm.

The initial population is generated with the use of random numbers. The generated population is combined with the archive one resulting in a new population. Then, the fitness of members is calculated and assigned to all members of the new population. Next, the best individuals from the union of population and archive members that acquired higher value regarding the fitness criteria are selected to create a new archive population (the same size to archive population) replacing the old one. Afterward, the next offspring population is formed using a selection operator. To this end, having applied tournament operations to identify the number of parents from archive population producing infants, mutation, and crossover operations are employed on those parents aiming to derive (generate) infants as a new offspring population. This algorithm is performed repeatedly and is terminated until the termination rule holds.

The pseudocode for SPEA-II is given as follows (here, the number of population and the maximum number of archive population members are equal to \( nPop \)):

5 Performance measures

The obtained non-dominated solutions resulted from different meta-heuristic algorithms should be compared through different performance measures. Among several performance measures in the literature, the following performance measures are selected and considered in this paper (Alavidoost et al. 2015; Fazel Zarandi et al. 2015a, b; Mohamadi et al. 2017; Mohammadi and Khaloozadeh 2016):

-

CPU Time

-

Ratio of non-dominated individuals (RNI)

-

Uniformly distribution (UD)

-

Diversity

-

Quality metric (QM)

In the following, a description of each of these measures is presented.

5.1 CPU time

This parameter refers to the processing time of each algorithm. A shorter CPU time is a more desired value in this regard.

5.2 Ratio of non-dominated individuals (RNI)

The RNI measure is defined as the ratio of non-dominated member numbers to the number of the total population (Eq. 58). Here, \( n \) is the number of points in identified Pareto front and \( nPop \) is the population size.

It is of note that the greater the \( {\text{RNI}} \) (approaching 1), the more desirable this metric will be.

5.3 Uniformly distribution (UD) of Pareto front

The UD of the Pareto front could be determined using the Schott’s spacing (SS) metric (Eqs. 59–61):

where \( f_{k}^{i} \) is the kth objective function value for the ith point in the known Pareto front and \( nObj \) is the number of objectives.

Also, there is an inverse relationship between the SS metric and UD measures as Eq. (62).

It can be inferred from this measure that the higher the UD is, the more its utility will be.

5.4 Diversity measure

The diversity of the obtained Pareto front solutions can be determined using Eq. (63).

Here, the greater this measure is, the more its utility will be.

5.5 Quality metric (QM)

The quality of the obtained solutions is evaluated through QM (Rabiee et al. 2012). To this end, global non-dominated points (\( {\text{PT}}^{*} \)) are reached having combined all non-dominated solutions produced by each algorithm (\( {\text{PT}}_{\text{l}} \)) and performing a complete comparison between them. In this line, the QM value is obtained by dividing the number of each algorithm’s non-dominated results (entitled to be members of \( {\text{PT}}^{*} \)) on the total number of non-dominated results of this specific algorithm (Eq. 64):

5.6 Coverage of two set I

After introducing the concept of coverage of two set by Zitzler (1999), an attempt is made to identify the domination of two sets points against each other aiming to determine how many Y set is dominated by X set (C (X, Y)) and vice versa.

6 Experimental results

In this section, the performance of meta-heuristic algorithms is evaluated and is compared. It should be noted that in the presented study, a new model is developed for BTO-SC and there is no benchmark test to evaluate the quality of the obtained results. Therefore, a numerical example is randomly generated and then the performance of meta-heuristic algorithms is evaluated on it. In this example, the number of suppliers is considered to be 7, the number of assemblers is 2, the number of DCs is 15, the number of retailers is 20, and the number of fabricators is 6. Furthermore, in this instance, a 10-period time horizon is considered for BTO-SC with 5 products, 8 components, and 12 raw materials.

First, parameters of algorithms are tuned using the tuning method presented in the following.

6.1 Parameters control using Taguchi method

Various methods have been proposed in the literature to calibrate the meta-heuristic algorithm parameters. Some of these parameters are full factorial designs in which all possible combinations are examined; thus, much time and cost are spent (Ruiz et al. 2006; Montgomery 2008). To remove this drawback, the Taguchi method was proposed by Taguchi (1986). In this method, employing a special design of orthogonal arrays, the entire parameter space could be studied with a small number of experiments. In contrast to other full factorial approaches, it requires less time and cost of the experiment (Alavidoost et al. 2014; Alavidoost and Nayeri 2014).

The Taguchi method classifies the factors into two main categories, namely controllable and noise factors (uncontrollable ones). Since noise factors are uncontrollable and eliminating them is unpractical and almost impossible, the Taguchi method aims to reach the best level for controllable factors regarding robustness criterion. Also, the Taguchi method along with determining the best level establishes a relative relationship between the impact of each factor and the objective function (Alavidoost et al. 2014, 2015; Babazadeh and Esfahanipour 2019).

Having deployed the Taguchi method, a single signal-to-noise (S/N) ratio is utilized to analyze the experimental data and to identify the optimal combination of factors and thus maximize this criterion. In this regard, along with the S/N ratio, the related deviation index (RDI) is also employed to determine the optimal combination of factors as well. RDI represents the deviation from the best existing optimal solution that should be minimized (Eq. 65)

where \( {\text{Alg}}_{\text{sol}} \) denotes the solution obtained from the algorithm and \( {\text{Best}}_{\text{sol}} \), \( {\text{Max}}_{\text{sol}} \), and \( {\text{Min}}_{\text{sol}} \) represent the best, maximum, and minimum results among the solutions, respectively.

In light of the earlier discussion, the preferred level will be established as the one in which the means of S/N ratio have the maximum value compared to other levels, while the means of RDI have a minimum value. If this requirement condition is not satisfied simultaneously for a parameter, another experiment should be implemented for that specific parameter.

In single-objective problems, the objective function is considered as a response variable to determine the S/N and RDI ratios. In comparison, in multi-objective ones, it is tried to identify the relationship between “objective function” and “response variable.” In this work, this relationship is obtained by employing Eq. (66).

where \( w_{q} : \forall q = 1,2, \ldots ,7 \) denotes the weights of each performance measure. In Table 1, for each algorithm, the controllable parameters and their associated levels are provided concerning their characteristics and attributes. It should be noted that in this paper, the numbers of archives are considered equal to the number of population for both PESA-II and SPEA-II algorithms. Also in the PESA-II algorithm, mutation and crossover rates are correlated such that their summation should be equal to 1.

The Taguchi method is implemented using Minitab 17 software. The S/N and RDI ratios for parameters of each algorithm with their corresponded level are provided in Figs. 3, 4, 5, and 6 and Table 2, respectively.

7 Results

In this section, we explore the performance of the mentioned algorithms. For this purpose, first, the obtained Pareto fronts produced by these algorithms are compared and then an evaluation study is conducted according to formerly mentioned comparison metrics for the assessment of their performance capability. Each algorithm is run 30 times. The results produced by the four considered algorithms in one run are provided in Fig. 7.

As illustrated in Fig. 7, the results suggested by the SPEA-II algorithm are better compared to other algorithms in terms of closeness to the optimal solution. Since NRGA and NSGA-II produce better solutions compared with PESA-II, they deserved the second rank after SPEA-II. Each algorithm is run 30 times. In the following, the results of the considered algorithms are compared together using measures mentioned in Sect. 5 (Figs. 8, 9, 10, 11, 12, and Fig. 13).

As can be observed from Fig. 8, in the PEAS-II algorithm, crowding distance calculation and ranking process are not performed for all members of the population. Therefore, it requires less CPU time compared to other algorithms. In other words, PEAS-II has a higher speed in comparison with other ones. Accordingly, in terms of CPU time, the PESA-II algorithm is ranked second.

Considering the RNI index, Fig. 9 demonstrates that three algorithms including NSGA-II, NRGA, and SPEA-II have the same value, but PESA-II outperforms the others.

Using the UD measure (Fig. 10) demonstrates that NSGA-II and SPEA-II obtained the best performance, with the NRGA and PESA-II algorithms being in the next orders.

In terms of the diversity criterion, the highest value is acquired by the PESA-II algorithm (Fig. 11). Accordingly, NRGA poses the second rank and the last position is dedicated to NSGA-II and SPEA-II having the close value of results.

As shown in Fig. 12, SPEA-II outperforms other algorithms in terms of the QM criterion.

Based on the coverage of the two set index (Fig. 13), SPEA-II possesses the best position in comparison with other ones, followed by NSGA-II and NRGA algorithms (that are almost close together) and PESA-II.

In the next section, the results obtained using the meta-heuristic algorithms are reviewed and compared.

7.1 Comparison and discussions

In this section, an evaluation framework is proposed for multi-objective genetic algorithms in which a fuzzy multi-criteria decision-making (FMCDM) approach is used to rank the considered algorithms.

One of the main issues in the context of MCDM is to rank and select a set of alternatives regarding the set of criteria. In this accord, while meta-heuristic algorithms are considered as alternatives, comparison metrics are regarded as criteria. In this study, the fuzzy VIKOR (f-VIKOR) method is employed as a fuzzy MCDM method to solve a discrete fuzzy multi-criteria problem with non-commensurable and conflicting criteria. For this purpose, first, the f-VIKOR method is briefly described, and then using this method, a new fuzzy framework is presented for ranking the meta-heuristic algorithms.

7.1.1 f-VIKOR method

The VlseKriterijumska Optimizacija I Kompromisno Resenje (VIKOR) method has been proposed in (Opricovic 2011). This MCDM method concentrates on ranking and selecting from a set of alternatives. It also determines compromise solutions for a problem with non-commensurable and conflicting criteria enabling the decision-makers to reach a final decision (Tzeng and Huang 2011). This method is particularly powerful when the decision-maker is unable or does not know how to express his/her preference. VIKOR is particularly applied under a deterministic decision-making environment. In comparison, in real-world problems, due to imprecision associated with the weight of decision-making indexes, criteria scores, and qualitative and incomplete information of the process, the fuzzy MCDM method whose fuzzy approach is based on fuzzy set theory is more practical. This work utilizes the f-VIKOR for ranking and comparing of meta-heuristic algorithms. The f-VIKOR’s steps are described as follows (Shahrasbi et al. 2017):

Assume a matrix in which the scores of all rows and columns corresponding to each alternative are placed against the related criterion (Eq. 67), where \( \tilde{f}_{ij} \) is a TFN with ith row and jth column).

Step 1 Define the positive ideal value \( \left( {\tilde{f}_{i}^{*} = \left( { l_{i}^{*} , m_{i}^{*} , r_{i}^{*} } \right)} \right) \) and the negative one \( \left( {\tilde{f}_{i}^{0} = \left( { l_{i}^{0} , m_{i}^{0} , r_{i}^{0} } \right)} \right) \) associated with each criterion functions applying Eqs. (68) and (69), respectively (\( S^{b} \) denotes the set of positive criteria and \( S^{c} \) refers to set of negative criteria).

Step 2 Determine normalized fuzzy difference (\( \tilde{d}_{ij} \)) according to Eqs. (70) and (71).

Step 3 Compute \( \tilde{S}_{j} = \left( {S_{j}^{l} , S_{j}^{m} ,S_{j}^{r} } \right) \;{\text{and}}\; \tilde{R}_{j} = \left( {R_{j}^{l} , R_{j}^{m} ,R_{j}^{r} } \right) \) employing Eqs. (72) and (73), respectively. Here, \( \tilde{S}_{j} \) shows the sum of fuzzy weighted distance and \( \tilde{R}_{j} \) indicates the maximum fuzzy distance. Moreover, \( \tilde{W}_{i} \) represents the fuzzy weight of each criterion expressing its relative importance that is considered based on the preference of decision-makers.

Step 4 Calculate the values \( \tilde{Q}_{j} = \left( {Q_{j}^{l} , Q_{j}^{m} ,Q_{j}^{r} } \right) \) for each index through Eq. (74). Here, \( \tilde{S}^{*} = \mathop {\hbox{min} }\limits_{j} \tilde{S}_{j} \), \( S^{0r} = \mathop {\hbox{max} }\limits_{j} S_{j}^{r} \), \( \tilde{R}^{*} = \mathop {\hbox{min} }\limits_{j} \tilde{R}_{j} \) and \( R^{0r} = \mathop {\hbox{max} }\limits_{j} R_{j}^{r} \) such that \( \tilde{S}^{*} \) and \( \tilde{R}^{* } \) are the best values for S and R, respectively. Here, v is introduced as a weight for the strategy of “the majority of criteria” (or “the maximum group utility”), whereas \( \left( {1 - {\nu}} \right) \) is the weight of the individual regret. While considering 0.5 for v, these two approaches could be compromised, in the general case, v can be obtained using \( \nu = \left( {n + 1} \right)/2n \).

Step 5 “Core ranking”: in this step, the core values of \( Q_{j}^{m} \) are sorted by decreasing order, which is denoted by \( \left\{ A \right\}_{{Q^{m} }} \).

Step 6 Defuzzification of \( \tilde{S}_{j} \), \( \tilde{R}_{j} \), \( \tilde{Q}_{j} \) applying Eq. 51.

Step 7 Rank the alternatives: This step ranks the crisp values of S, R, and Q in decreasing order. The obtained results are three lists denoted by \( \left\{ A \right\}_{S} \), \( \left\{ A \right\}_{R} \), and \( \left\{ A \right\}_{Q} \).

Step 8 First, a compromise solution that is the best ranked by the measure Q (in \( \left\{ A \right\}_{Q} \)) is identified if the following two other required conditions are established:

-

The first condition is considered as “Acceptable Advantage” such that \( Adv \ge DQ \). Here, \( {\text{Adv}} = {{\left[ {Q\left( {A^{\left( 2 \right)} } \right) - Q\left( {A^{\left( 1 \right)} } \right) } \right]} \mathord{\left/ {\vphantom {{\left[ {Q\left( {A^{\left( 2 \right)} } \right) - Q\left( {A^{\left( 1 \right)} } \right) } \right]} {\left[ {Q\left( {A^{\left( J \right)} } \right) - Q\left( {A^{\left( 1 \right)} } \right)} \right]}}} \right. \kern-0pt} {\left[ {Q\left( {A^{\left( J \right)} } \right) - Q\left( {A^{\left( 1 \right)} } \right)} \right]}} \) in which \( A^{\left( 1 \right)} \) and \( A^{\left( 2 \right)} \) refer to alternatives of the first and the second rank in list Q, respectively. Also, the threshold is \( DQ = 1/\left( {m - 1} \right) \).

-

The second condition is defined as “acceptable stability in decision makes.” According to this condition, the best alternative introduced must also be considered as the best ranked by S or/and R.

If one of the above conditions is not satisfied, a set of compromising solutions will be proposed according to the following principles:

-

If only the second condition is not met, the first and second alternatives will be introduced as the best alternatives.

-

If the first condition is not satisfied, \( A^{\left( 1 \right)} , A^{\left( 2 \right)} , \ldots ,A^{\left( m \right)} \) will be identified as alternatives with close values. Also, the maximum value represented by M is determined using the following equation: \( Q\left( {A^{\left( M \right)} } \right) - Q\left( {A^{\left( 1 \right)} } \right) < DQ \).

7.1.2 Ranking of meta-heuristic algorithms

The uncertainty involved in the behavior of meta-heuristic algorithms can be presented by a fuzzy logic approach. Accordingly, in this study, TFNs are considered to represent fuzzy data. Also, the solutions obtained by deploying each algorithm are produced for each measure (Fig. 14). As introduced earlier, meta-heuristic algorithms and comparison measures are considered as alternatives and criteria, respectively. In this regard, for each measure, a TFN is associated with each algorithm that is provided by Box Plots as illustrated in the following. The minimum, median, and maximum values for each measure are considered as three points of TFN \( \left( {A_{1} , A_{2} , A_{3} } \right) \).

To rank the performance of considered algorithms, it is required to assign a weight for each criterion. In this work, these weights are set to be 1 for all criteria. Implementing the f-VIKOR method for the ranking process, the results are presented as follows.

-

Rank1: SPEA-II

-

Rank2: NRGA

-

Rank3: NSGA-II

-

Rank4: PESA-II

Applying f-VIKOR taking into account the same weight for all criteria, SPEA-II was ranked the first among all four algorithms, suggesting that it is the most appropriate one for solving such problems. Certainly, this result will change by rearranging the weights of criteria. For example, increasing the weight of CPU time (with fixing other criteria) makes the PESA-II as the best algorithm.

In addition to multi-objective genetic algorithms, this presented framework is applicable for comparing all of the multi-objective meta-heuristic algorithms. Also, it presents an excellent comparison dashboard to decision-makers and helps them choose the best algorithm for their preferences. For example, according to Fig. 14, in terms of diversity measure, the NRGA and PESA-II outperform the SPEA-II and NSGA-II, while in terms of CPU time, the NRGA and NSGA-II have the worst situation.

8 Conclusion

In this paper, a new FMILP model for optimizing an integrated multi-product, multi-level, multi-plant supply chain system is introduced. This system consists of supply, production, and distribution processes in the BTO environment. Due to uncertainty associated with real production systems, fuzzy numbers are employed to represent the uncertainty of the parameters, objective functions, and constraints. Because of considering conflicting objectives, the complexity of such problems, and the lack of appropriate benchmark for these problems, four multi-objective meta-heuristic algorithms including PESA-II, NRGA, NSGA-II, and SPEA-II are deployed as solving procedure. Next, the obtained results are compared. The Taguchi method is utilized for tuning algorithm parameters. Finally, considering the fuzzy approach and using f-VIKOR and some criteria, a new framework is proposed to compare and rank the performance of multi-objective genetic algorithms. This network is applicable not only for comparing multi-objective genetic algorithms but also for comparing all multi-objective meta-heuristic algorithms. The presented framework provides an excellent comparison dashboard for decision-makers and helps them choose the best algorithm for their preferences.

References

Ahumada O, Villalobos JR (2011) A tactical model for planning the production and distribution of fresh produce. Ann Oper Res 190:339–358

Alavidoost MH (2017) Assembly line balancing problems in uncertain environment: a novel interactive fuzzy approach for solving multi-objective fuzzy assembly line balancing problems. Lap lambert Academic Publishing

Alavidoost MH, Nayeri MA (2014) Proposition of a hybrid NSGA-II algorithm with fuzzy objectives for bi-objective assembly line balancing problem. In: Tenth international industrial engineering conference

Alavidoost MH, Zarandi MHF, Tarimoradi M, Nemati Y (2014) Modified genetic algorithm for simple straight and U-shaped assembly line balancing with fuzzy processing times. J Intell Manuf 28(2):313–336

Alavidoost MH, Tarimoradi M, Zarandi MHF (2015a) Fuzzy adaptive genetic algorithm for multi-objective assembly line balancing problems. Appl Soft Comput 34:655–677

Alavidoost MH, Tarimoradi M, Zarandi MHF (2015b) Bi-objective mixed-integer nonlinear programming for multi-commodity tri-echelon supply chain networks. J Intell Manuf 29(4):809–826

Alavidoost MH, Babazadeh H, Sayyari ST (2016) An interactive fuzzy programming approach for bi-objective straight and U-shaped assembly line balancing problem. Appl Soft Comput 40:221–235

Aliev RA, Fazlollahi B, Guirimov B, Aliev RR (2007) Fuzzy-genetic approach to aggregate production–distribution planning in supply chain management. Inf Sci 177:4241–4255

Al Jadaan O, Rajamani L, Rao CR (2008) Non-dominated ranked genetic algorithm for solving multiobjective optimization problems. J Theor Appl Inform Technol 2008:60–67

Ariafar S, Ahmed S, Choudhury IA, Bakar MA (2014) Application of fuzzy optimization to production-distribution planning in supply chain management. Math Probl Eng 2014(4):1–8

Babazadeh H, Esfahanipour A (2019) A novel multi period mean-VaR portfolio optimization model considering practical constraints and transaction cost. J Comput Appl Math 361:313–342. https://doi.org/10.1016/j.cam.2018.10.039

Babazadeh H, Alavidoost MH, Fazel Zarandi MH, Sayyari ST (2018) An enhanced NSGA-II algorithm for fuzzy bi-objective assembly line balancing problems. Comput Ind Eng 123:189–208

Che Z, Chiang C (2010) A modified Pareto genetic algorithm for multi-objective build-to-order supply chain planning with product assembly. Adv Eng Softw 41:1011–1022

Chen S-P, Chang P-C (2006) A mathematical programming approach to supply chain models with fuzzy parameters. Eng Optimiz 38:647–669

Chen C-L, Lee W-C (2004) Multi-objective optimization of multi-echelon supply chain networks with uncertain product demands and prices. Comput Chem Eng 28:1131–1144

Chen C-L, Wang B-W, Lee W-C (2003) Multiobjective optimization for a multienterprise supply chain network. Ind Eng Chem Res 42:1879–1889

Chow P-S, Choi T-M, Cheng T (2012) Impacts of minimum order quantity on a quick response supply chain. IEEE Trans Systems Man Cybern Part A Syst Humans 42:868–879

Corne DW, Jerram NR, Knowles JD, Oates MJ (2001) PESA-II: region-based selection in evolutionary multiobjective optimization. In: Proceedings of the Genetic and Evolutionary Computation Conference (GECCO’2001:2001)

Deb K, Pratap A, Agarwal S, Meyarivan T (2002) A fast and elitist multiobjective genetic algorithm: nSGA-II. IEEE Trans Evolut Comput 6:182–197

Demirli K, Yimer AD (2006) Production-distribution planning with fuzzy costs. In Fuzzy information processing society, 2006. NAFIPS 2006. Annual meeting of the North American, pp 702–707

Demirli K, Yimer AD (2008) Fuzzy scheduling of a build-to-order supply chain. Int J Prod Res 46:3931–3958

Ebrahimzadeh Shermeh H, Alavidoost MH, Darvishinia R (2018) Evaluating the efficiency of power companies using data envelopment analysis based on SBM models: a case study in power industry of Iran. J Appl Res Ind Eng 5:286–295

Fahimnia B, Farahani RZ, Marian R, Luong L (2013) A review and critique on integrated production–distribution planning models and techniques. J Manuf Syst 32:1–19

Fazel Zarandi MH, Tarimoradi M, Alavidoost MH, Shakeri B (2015) Fuzzy approximate reasoning toward Multi-Objective optimization policy: deployment for supply chain programming. In Fuzzy information processing society (NAFIPS) held jointly with 2015 5th world conference on soft computing (WConSC), 2015 Annual Conference of the North American, pp 1–6

Fazel Zarandi MH, Tarimoradi M, Alavidoost MH, Shirazi MA (2015) Fuzzy comparison dashboard for multi-objective evolutionary applications: an implementation in supply chain planning. In: Fuzzy information processing society (NAFIPS) held jointly with 2015 5th world conference on soft computing (WConSC), 2015 annual conference of the North American, 2015, pp 1–6

Feng Y, D’Amours S, Beauregard R (2008) The value of sales and operations planning in oriented strand board industry with make-to-order manufacturing system: cross functional integration under deterministic demand and spot market recourse. Int J Prod Econ 115:189–209

Galasso F, Merce C, Grabot B (2008) Decision support for supply chain planning under uncertainty. Int J Syst Sci 39:667–675

Gholamipoor M, Ghadimi P, Alavidoost MH, Feizi Chekab MA, Pham D (2014) Application of evolution strategy algorithm for optimization of a single-layer sound absorber. Cogent Eng 1:945820

Gunasekaran A, Ngai EW (2005) Build-to-order supply chain management: a literature review and framework for development. J Oper Manage 23:423–451

Gupta A, Maranas CD (2000) A two-stage modeling and solution framework for multisite midterm planning under demand uncertainty. Ind Eng Chem Res 39:3799–3813

Hajiaghaei-Keshteli M, Aminnayeri M, Ghomi SF (2014) Integrated scheduling of production and rail transportation. Comput Ind Eng 74:240–256

Haupt RL, Haupt SE (2004) Practical genetic algorithms. Wiley, Hoboken

Holland JH (1975) Adaptation in natural and artificial systems, vol 5. University of Michigan press, Ann Arbor, p 5

Hsu H-M, Wang W-P (2004) Dynamic programming for delayed product differentiation. Eur J Oper Res 156:183–193

Kanyalkar AP, Adil GK (2010) A robust optimisation model for aggregate and detailed planning of a multi-site procurement-production-distribution system. Int J Prod Res 48:635–656

Klir G, Yuan B (1995) Fuzzy sets and fuzzy logic: theory and applications

Krajewski L, Wei JC, Tang L-L (2005) Responding to schedule changes in build-to-order supply chains. J Oper Manage 23:452–469

Lalmazloumian M, Wong KY (2012) A review of modelling approaches for supply chain planning under uncertainty. In: 2012 9th international conference on service systems and service management (ICSSSM), pp 197–203

Lalmazloumian M, Wong KY, Govindan K, Kannan D (2013) A robust optimization model for agile and build-to-order supply chain planning under uncertainties. Ann Oper Res 240(2):1–36

Lalmazloumian M, Wong KY, Ahmadi M (2014) A mathematical model for supply chain planning in a build-to-order environment. In: Enabling manufacturing competitiveness and economic sustainability, Springer, pp 315–320

Lambert DM, Cooper MC (2000) Issues in supply chain management. Ind Mark Manage 29:65–83

Li C, Wang S-L, Zhang X-M, Gu H (2011) Scheduling optimisation for supply chain in networked manufacturing. Int J Comput Appl Technol 40:85–90

Liao S-H, Hsieh C-L, Lin Y-S (2011) A multi-objective evolutionary optimization approach for an integrated location-inventory distribution network problem under vendor-managed inventory systems. Ann Oper Res 186:213–229

Liu N, Choi T-M, Yuen C, Ng F (2012) Optimal pricing, modularity, and return policy under mass customization. IEEE Trans Syst Man Cybern Part A Syst Humans 42:604–614

Manoj U, Gupta JN, Gupta SK, Sriskandarajah C (2008) Supply chain scheduling: just-in-time environment. Ann Oper Res 161:53–86

McDonald CM, Karimi IA (1997) Planning and scheduling of parallel semicontinuous processes. 1. Production planning. Ind Eng Chem Res 36:2691–2700

Mirzapour Al-E-Hashem S, Malekly H, Aryanezhad M (2011) A multi-objective robust optimization model for multi-product multi-site aggregate production planning in a supply chain under uncertainty. Int J Prod Econ 134:28–42

Mohamadi S, Amindavar H, Ali Tayaranian Hosseini SM (2017) ARIMAGARCH modeling for epileptic seizure prediction. In: 2017 IEEE international conference on acoustics, speech and signal processing (ICASSP), New Orleans, LA, 2017, pp 994–998

Mohammadi SS, Khaloozadeh H (2016) Optimal motion planning of unmanned ground vehicle using SDRE controller in the presence of obstacles. In: 4th international conference on control, instrumentation, and automation (ICCIA), Qazvin, Iran, 2016, pp 167–171. https://doi.org/10.1109/ICCIAutom.2016.7483155

Mohammadi Bidhandi H, Mohd Yusuff R (2011) Integrated supply chain planning under uncertainty using an improved stochastic approach. Appl Math Modell 35:2618–2630

Mohammadi Bidhandi H, Mohd Yusuff R, Megat Ahmad MMH, Abu Bakar MR (2009) Development of a new approach for deterministic supply chain network design. Eur J Oper Res 198:121–128

Montgomery DC (2008) Design and analysis of experiments. Wiley, Hoboken

Mousavi S, Esfahanipour A, Zarandi M (2015) MGP-INTACTSKY: multitree genetic programming-based learning of INTerpretable and ACcurate TSK sYstems for dynamic portfolio trading. Appl Soft Comput 34:449–462. https://doi.org/10.1016/j.asoc.2015.05.021

Mousavi S, Esfahanipour A, Fazel Zarandi M (2019) A modular Takagi-Sugeno-Kang (TSK) system based on a modified hybrid soft clustering for stock selection. Scientia Iranica. https://doi.org/10.24200/SCI.2019.52323.2661

Mula J, Poler R, Garcia-Sabater J, Lario F (2006) Models for production planning under uncertainty: a review. Int J Prod Econ 103:271–285

Mulvey JM, Vanderbei RJ, Zenios SA (1995) Robust optimization of large-scale systems. Oper Res 43:264–281

Nagar L, Jain K (2008) Supply chain planning using multi-stage stochastic programming. Supply Chain Manage Int J 13:251–256

Nemati Y, Alavidoost MH (2018) A fuzzy bi-objective MILP approach to integrate sales, production, distribution and procurement planning in a FMCG supply chain. Soft Comput 23(13):4871–4890

Nemati Y, Madhoushi M, Alavidoost MH (2017) Modeling of S&OP in a large scale Dairy supply chain. Scholar’s Press, Cambridge

Nemati Y, Mohaghar A, Alavidoost MH, Babazadeh H (2018) A CLV-based framework to prioritize promotion marketing strategies: a case study of telecom industry. Iranian J Manage Stud 11:437–462

Opricovic S (2011) Fuzzy VIKOR with an application to water resources planning. Expert Syst Appl 38:12983–12990

Pal A, Chan F, Mahanty B, Tiwari M (2011) Aggregate procurement, production, and shipment planning decision problem for a three-echelon supply chain using swarm-based heuristics. Int J Prod Res 49:2873–2905

Pan A, Choi T-M (2012) An agent-based negotiation model on price and delivery date in a fashion supply chain. Ann Oper Res 242(2):1–29

Pei J, Pardalos PM, Liu X, Fan W, Yang S, Wang L (2015) Coordination of production and transportation in supply chain scheduling. J Ind Manage Optim 11:399–419

Peidro D, Mula J, Poler R, Verdegay J-L (2009) Fuzzy optimization for supply chain planning under supply, demand and process uncertainties. Fuzzy Sets Syst 160:2640–2657

Petrovic D, Roy R, Petrovic R (1998) Modelling and simulation of a supply chain in an uncertain environment. Eur J Oper Res 109:299–309

Petrovic D, Roy R, Petrovic R (1999) Supply chain modelling using fuzzy sets. Int J Prod Econ 59:443–453

Prasad S, Tata J, Madan M (2005) Build to order supply chains in developed and developing countries. J Oper Manage 23:551–568

Pyke DF, Cohen MA (1994) Multiproduct integrated production—distribution systems. Eur J Oper Res 74:18–49

Rabiee M, Zandieh M, Ramezani P (2012) Bi-objective partial flexible job shop scheduling problem: NSGA-II, NRGA, MOGA and PAES approaches. Int J Prod Res 50:7327–7342

Reddy GT, Khare N (2018) Heart disease classification system using optimised fuzzy rule based algorithm. Int J Biomed Eng Technol 27:183–202

Reddy GT, Reddy MPK, Lakshmanna K, Rajput DS, Kaluri R, Srivastava G (2019) Hybrid genetic algorithm and a fuzzy logic classifier for heart disease diagnosis. Evolut Intell 13(2):185–196

Ruiz R, Maroto C, Alcaraz J (2006) Two new robust genetic algorithms for the flowshop scheduling problem. Omega 34:461–476

Sen W, Pokharel S, YuLei W (2004) Supply chain positioning strategy integration, evaluation, simulation, and optimization. Comput Ind Eng 46:781–792