Abstract

Degradation of RC structures due to corrosion induced mechanism in the reinforcing steel is a serious durability problem worldwide. It occurs essentially when the reinforcement within the concrete is subjected to marine or aggressive environment. The aim of the present work is to predict the reliable service life of the RC structures by taking into consideration of various prominent models of corrosion and comparing the output with the predicted output of ANN model. Parametric studies have been conducted on four different models to study the effect of various parameters such as corrosion rate, cover thickness, bar diameter, and perimeter of bar which actively participates in the time dependent degradation of RC structures. The outcomes of the parametric inspection of the four chosen degradation models are shown in the present study. The acceptability of the prediction models in forecasting the service life of RC structures are shown through circumstantial illustrative analysis and the best suited model sorted out. However, with the application of soft computing such as ANN, a prediction has been made to determine the service life of RC structures, and the predicted outputs validated with the intended outputs thereby yielding good outcomes for envisaging service life of RC structure.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The deterioration of RC structures due to reinforcement corrosion is one of the serious durability problems worldwide, particularly, when the structure is subjected to marine or chemically aggressive environment (Cusson et al. 2010). The corrosion phenomenon causing degradation of reinforcing material becomes mainly due to two considerations such as: (i) Corrosion induced by chloride ingress (ii) Corrosion induced by carbonation. Carbonation generally occurs in a relatively humid environment where adequate amount of carbon dioxide is available for spreading over the concrete (Liang et al. 1999a, b). However, in case of corrosion induced by chloride ingress, the ingress of chloride is generally quicker than the process of carbonation and it causes premature deterioration by degrading the structural resistance leading to the early ending of service life/period of the structure (Liang et al. 2002; Ming-Te et al. 2009). At the later stage of deterioration, when the damage of the structure caused by reinforcement corrosion is noticeable, it becomes generally too late to carry out any preventive measures in order to safeguard the structure. Henceforth, estimation of service life become of outmost importance for damage induced in the structure due to reinforcement corrosion. When reinforcement corrosion starts, it propagates at a constant rate and cut shorts the usable life of the structure by developing stresses due to expansion of steel which result in surface cracking and concrete spalling (Beeby 1978). The corrosion rate directly effects the residual service life of a corroding RC structure (Vu and Stewart 2005). At the initial stage of damage when the reinforcement just starts corroding, it shows noteworthy degradation. In most of the cases, either regular maintenance of the structure has been neglected or the structure is not adequately strong and durable enough to maintain the structural stability. With respect to the cover cracking issues, various hypothetical models have been proposed for predicting the time of cracking of cover (Bhargava et al. 2005, 2006; Bazant 1979; IRC SP 60 2002; Morinaga 1988; Saad and Fu 2015; Weyers 1998). The results and models generated from the previous studies vary primarily due to variation in parameters, methods of experiments as well as presumptions made during modeling by various researchers.

In the present work, an ANN based approach used for predicting the service life of RC structures subjected to chloride-induced corrosion. In the recent years, ANN successfully applied to various civil engineering problems which are difficult to solve through conventional mathematical approaches. This includes prediction/forecasting of natural hazards (Zarola and Sil 2017) such as earthquake, flood, landslide, and tsunami which adversely affects the usable life or design service period of the structure by initiating a process of premature deterioration. The prediction of these natural hazards represents as well as involves a complex process depending on various physical and environmental parameters which are stochastic in nature. However, degradation of RC structures due to chloride-induced corrosion could be considered as one of these natural hazards which depend upon various environmental and physical parameters. Although reliable predictive models are available for estimating the service life of RC structures, yet, they do not have the ability to reduce the computational time to a significant extent thereby demanding a long and tedious completion process (Cardoso et al. 2008; Papadrakakis and Lagaros 2002). In order to overcome this, ANN has been implemented as a part of soft computing for avoiding complex mathematical formulations such that reliable results of the structural service life subjected to chloride-induced corrosion could be obtained. Indeed, the ANN being a highly nonlinear network exhibits the capability to generalize and learn from predefined examples without having any prior knowledge of the complex mathematical system. Therefore, in order to model a physical system for predicting service life of RC structures with reasonable accuracy and rapid computational process, a trained neural network model have been used (Imam et al. 2015). Network with respect to four selected models have been generated and the predicted outputs of the neural network model validated with the calculated outputs such that the adequacy of the network in estimating the service life of RC structures could be figured out. Parametric investigations on four different models conducted and the best possible model (Bazant’s model) for service life prediction identified and used. Consecutively, for evaluating the performance of the trained network, statistical measures such as sensitivity and specificity of the neural network model have been checked. From the statistical measures, it has been identified that the neural network model exhibits highly efficient in accurately predicting the structural service life with sensitivity and specificity equal to 94.05% and 95.44% respectively, for two different occurrences of cracking. Thus, with the application of soft computing, a reliable predictive system generated which provides conventional results of structural degradation with reasonable accuracy considering elimination of complex computational process.

2 Service life of structure and prediction models

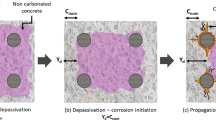

The concept of service life prediction for RC structures turned out to be an area of extensive interest for many researchers. Considering this, the durability of concrete becomes responsible for playing a crucial role in the service life prediction of the structure. The structural service life designated as a time dependent process till a time after which expensive rehabilitation becomes important (Mangat and Elgarf 1999; Morinaga 1988). However, for RC structures exposed to marine environment, the resistance of the concrete to chloride-induced damage controls, its prolonged strength execution becomes to a great extent. Weakening of concrete due to chloride ingress could be illustrated by a simple model of service life consisting of two stages such as Initiation stage or stage of depassivation and the propagation stage or stage of spreading as shown in Fig. 1.

The time from starting of corrosion initiation which causes depassivation of steel is regarded as initiation stage (Ahmad 2003). Consecutively, the time at the onset of steel corrosion to a visible spalling of concrete is referred to as propagation stage. The critical time of cracking (tcr), is the time required for spalling of concrete due to reinforcement corrosion, indeed, it considered as the sum of depassivation time (tp) and corrosion propagation period (tcorr) (Maaddawy and Soudki 2007; Tuutti 1982). Alternatively, degradation of RC structures due to chloride ingress is one of the most critical components of damage which gradually triggers the loss of structural mechanical properties.

2.1 Prediction models

2.1.1 Bazant’s model

Bazant (1979) presented a mathematical model for the prediction of service life of RC structures subjected to reinforcement corrosion in concrete. The corrosion damage takes into consideration the expansion volume due to the arrangement of hydrated rust over rebar periphery. Due to expansive nature of hydrated rust, the rust expands four times the volume of parent steel. Eventually, due to the formation of hydrated rust an outward radial stress is generated on the surrounding concrete. The radial stress exerted is similar to the increase in rebar diameter \( \Delta D \) due to increase in its volume until concrete cover splits. According to Bazant’s model, the corrosion propagation could be expressed as:

where

tcorr: Corrosion propagation period (years).

ρcor: Combined factor of density for rust as well as steel = 3600 kg/m3.

D: Reinforcement diameter (mm).

ΔD: Increase in diameter of rebar due to formation of rust (mm).

p: Perimeter of rebar (mm).

jr: Instantaneous rate of corrosion due to rust (g/m2s).

The instantaneous rate of corrosion due to rust is expressed as:

where

W: Equivalent weight of steel = 27.925.

F: Faradays constant = 96,847 C.

icorr: Corrosion current density (μA/cm2).

The critical time of cracking tcr could be developed due to corrosion throughout the whole cover and is calculated as:

where

tp: Depassivation time (years).

tcorr: Corrosion propagation period (years).

According to Bazant et al. the depassivation time, tp may be calculated as:

where

Cv: Cover thickness (mm).

Cth: Threshold value of chloride concentration (kg/m3 of concrete).

Cs: Surface concentration of chloride ions in pores of concrete (kg/m3 of concrete).

Dapp: Apparent chloride diffusion coefficient (cm2/s).

2.1.2 Morinaga’s model

An elementary model proposed by Morinaga (1988) essentially for measuring the corrosion of reinforcing steel in concrete at which the concrete cover breaks due to augmentation of steel caused due to rusting. The corrosion damage considers volume expansion caused due to generation of red rust. One of the most significant parameters used for deciding the cracking time is the rate of corrosion. The period of time from the initiation of corrosion to splitting of cover forms an element of the rate of corrosion, clear cover of concrete and distance of the reinforcing bar. Therefore, the amount of corrosion required for cracking of concrete is given by:

where

Qcr: amount of corrosion when concrete cracks (× \( 10^{ - 4} \) g/cm2).

Cv: concrete cover thickness (mm).

D: diameter of rebar (mm).

The corrosion propagation period, tcorr corresponding to Qcr is expressed as:

where

jr: Instantaneous rate of corrosion (g/m2s).

2.1.3 Wang and Zhao’s model

Wang and Zhao (1993) suggested a method for focusing on the corrosion product thickness \( \Delta \) and comparing with the time at which the concrete at the surface cracks. Moreover, with the help of large scale of information gathered from various research facilities, an exact expression for focusing the ratio of corrosion product thickness \( \Delta \) to the depth of penetration H of the rebar has been established. The ratio \( \Delta /H \) is an element of cube strength of concrete \( f_{\text{cu}} \) and is expressed as:

where

D: Diameter of reinforcing bar (mm).

Cv: Cover thickness (mm).

fcu: Cube strength of concrete (kN/cm2).

\( \Delta \): Thickness of corrosion product (cm).

H: Cracks in concrete cover.

The cracks in concrete cover, H could be evaluated taking into consideration the value of \( \Delta \). Subsequently, with the estimation of H, the corrosion propagation period tcorr is also obtained by the given expression as:

where

pr: rate of penetration of corrosion in rebar.

The rate of penetration of corrosion in rebar is obtained as:

where

W: Equivalent weight of steel = 27.925.

F: Faradays constant = 96,847 C.

icorr: Corrosion current density (μA/cm2).

\( \rho_{\text{st}} \): Density of steel (kg/m3).

2.1.4 Indian Road Congress (IRC) model

The time period of corrosion propagation in IRC model estimated based on falling pH (IRC SP 60 2002). The fact behind this is the ongoing carbonation process or chloride ingress in the steel reinforcement. In order to determine the propagation time, some governing expressions are available in IRC-SP60. If generalized corrosion occurs then the primary loss of the span of the bar is in view of cracking of cover. The corrosion propagation period, \( t_{\text{r}} \) as per IRC-SP60 could be expressed as:

where

Cv: Cover thickness (mm).

D: Diameter of rebar (mm).

r: Corrosion rate (μm/year).

tr: Corrosion propagation period (years).

The corrosion rate can be obtained from the following expression:

where

cT: Coefficient of temperature.

ro: Corrosion rate at + 20 °C.

3 Parametric investigation of corrosion models

3.1 Depassivation time

In context of depassivation time tp, the thickness of the concrete cover, Cv has a considerable influence in the corrosion propagation mechanism. The service life of the structure decreases with the decrease in thickness of the concrete cover. In this study, the thickness of the concrete cover varies from 10 to 60 mm. Factors such as humidity and temperature, effects the apparent diffusion coefficient of chloride ions which varies in the range of 0.45–6 cm2/year. However, the threshold chloride ion concentration, \( C_{\text{th}} \) and surface chloride ion concentration, \( C_{\text{s}} \) varies from 2 to 8 kg/m3 and 12 to 25 kg/m3 respectively (Sadiqual Islam 2009). In Fig. 2, it has been observed that with the gradual increase in the apparent diffusion coefficient the depassivation time decreases, the fact behind of this issue is that, when adequate amount of chlorides outreaches the reinforcing steel, it penetrates the passivating layer (protection layer provided by concrete) and increases the risk of corrosion thereby causing depassivation of steel reinforcement.

3.2 Parametric study of various deterioration models

In Bazant’s model the formation of the hydrated rust increases the original diameter of the bar from \( D \) to \( D + \Delta D \), however, \( \Delta D \) varies in the range of 0.01–0.25 mm. During the preliminary phase of rust formation, the volume of the hydrated rust occupies four times the volume of the reinforcing steel, however with the gradual progress of corrosion; there is uniform increment in the rust formation over the residual bar. Thus, with the increase in the corrosion process the critical time of cracking, \( t_{\text{cr}} \) decreases and \( \Delta D \) increases. However, Morinaga considers the concrete cover thickness, \( C_{\text{v}} \) as an important parameter. For a particular rebar, as the thickness of the cover is constant, the corrosion amount at which cracking of concrete occurs also becomes constant. In Wang and Zhao’s model, in order to calculate the cracking of the concrete cover, H, the compressive strength of concrete is taken as 2.5 kN/cm2 and the thickness of the corrosion product, \( \Delta \) varies from 0.003 to 0.007 cm respectively. It has been observed that cracks in cover, increases with the increase in thickness of the corrosion product. The penetration rate in this model measured in terms of corrosion current density, icorr. The corrosion current density, icorr for the aforementioned models varies in the range of 0.05–6 μA/cm2. Consecutively, IRC model also considers thickness of cover as one of those factors that influences the spalling and cracking of concrete due to corrosion of reinforcing steel. The rate of corrosion in this model assumed to be 5–100 μm/year. The increase in the corrosion current density or the rate of corrosion magnifies the formation of rust on the reinforcing material thereby decreasing the critical time of cracking, tcr as shown in Figs. 3, 4, 5 and 6.

4 Artificial neural network

Due to rapid growth, ANN becomes gaining interest for its application to engineering problems. ANN performs different recognition tasks such as learning and optimization at a very small amount of time as compared to today’s very high-performance computers (Haykin 2005). Being a part of machine learning, neural networks have the capability to generalize and learn from predefined samples without having any prior understanding of the complex formulations (D’Angelo et al. 2016, 2018). The application of ANN in service life prediction for corrosion induced deterioration has come out to be a new method with less computational requirements and more practical significance than traditional methods (Chojaczyk et al. 2015). From computational perspective, ANN has a large number of interconnected nodes. Each node is represented as a neuron which receives input from the other connected units and performing computational process thereby transmitting the output to other processing units. Each individual node in an ANN executes a single task autonomously. Thus, a parallel structure developed in a neural network which permits them to take the benefits of parallel processing. The connection between nodes could get transmission values known as weights, the weights could be considered as memory of the neural network. The weight of the connection or synaptic weight could be renewed when new input data provided to the system. Indeed, ANN has the capability to cut-short computational time to a great extent and control the calculation error to a reasonable range. Elimination of tedious modeling process is achieved with the application of neural networks in service life prediction problem.

4.1 Network development in ANN

McCulloch and Pitts (1943) developed the first neural network model. Since then, it has been applied to various research areas and particularly to civil engineering problems which becomes hard to solve using existing mathematical models. Figure 7 shows the schematic diagram of an artificial neuron modeled artificially by taking into consideration the functions of a similar biological neuron. Let us consider that there are n inputs (I1, I2,…, In) to a neuron j. The synaptic weights connecting n number of inputs to jth neuron are given by:

The summing junction in an artificial neuron collects the weighted inputs and finally sum it up. Thus, it resembles to the functions of combined dendrites and cell body. The transfer or activation function performs the tasks of axon and synapses. The summing junction may sometimes provide an output equal to zero, thus, in order to avoid such situation, an external input or bias of fixed value bj is added to the summing junction. Therefore, the input to transfer function f could be expressed as:

The output of the jth neuron Oj can be expressed as:

In a neural network, the output of a neuron largely depends on its activation function. Different types of activation functions such as log-sigmoid, tan-sigmoid, and hard limit exists in a neural network. The activation function adopted in this work is log-sigmoid (LOGSIG). The reason behind choosing this activation function over the other available functions is that, it takes input which may have values between \( + \,\infty \) to \( - \,\infty \) and it squashes the output in the range of 0–1. The log-sigmoid function is generally used in multilayered networks trained using back propagation algorithm; this is due to the fact that log-sigmoid function is differentiable. The function is given by:

4.1.1 Feed forward backpropagation algorithm

Among the several available algorithms, the feed forward backpropagation (FFBPN) algorithm have been used in this work. In a Feed forward network (FFN), each layer of neurons is associated with neurons in the other layer. The synaptic links consisting of weights connects each neuron in a layer to other neurons in another layer. In order to obtain the best configuration, the neurons are trained based on considering the number of trials.

The backpropagation technique is a process of iteration in order to modify the weights from output layer to input layer until no further correction is required. The backpropagation technique helps in determining the error and the error is distributed in backward direction from output node to input node such that minimum error becomes achieved. The backpropagation algorithm is predominantly based on a generalized delta rule and accelerated by a momentum term. To improve the training rate, changes in the weight factor are accelerated by introducing momentum term. The weight factors and bias are adjusted using the following equations:

where

\( \eta \): Learning rate.

\( \alpha \): Coefficient of momentum.

\( w_{ij} \): Weight factor associated between two neurons.

\( b_{j} \): Weight of bias.

\( O \): Output of the network.

\( \delta \): Gradient descent correction.

k: Number of patterns.

The performance of the trained network is checked by estimating the mean squared error (MSE). The basic equation for evaluating MSE is:

where

T: Target value of the output variables.

O: Predicted value of the output variables.

n: Number of datasets.

5 Results and discussion

In this work, the ANN model generated using MATLAB tool presented in Fig. 8. However, a total of 200 random data samples obtained and the same were used for ANN prediction. The 200 random data samples refers to the range of random values for each training parameter such as, if we consider the training parameter corrosion current density, icorr which varies in the range of 0.05–6 μA/cm2, a set of 200 random values within the given range of icorr would be generated. Similarly, for the other training parameters the same procedure has been followed. The ranges of the training parameters were obtained from the cited models i.e. Bazant’s, Morinaga’s, Wang and Zhao’s and IRC models in order to validate the numerical output of each individual model with that of ANN predicted output of the respective models. Out of 200 data samples, 70% of the samples were employed for network training, 15% of the samples were employed for network testing and the remaining 15% of the samples were employed for authentication or validation. The network is trained to an extent such that minimum error obtained for a given set of inputs and targets. The correlation, R of the training, testing and validation data is above 99% as shown in the regression plot of Fig. 9. Based on these high correlation values, it has been observed that the accuracy of the prediction is readily acceptable and the ANN model becomes successful in learning the problem. Considering the overfitting issue, although number of techniques are available in order to overcome the overfitting issue in a neural network, the current study resolves the overfitting issue using classical method. The classical method is based on dividing the data sets into three groups i.e. training set, testing set and validation set. Training set is the dataset of examples used by the network to learn. During the learning process the network tends to over fit the data. In order to avoid this, it is necessary to have a validation set which would adjust the architecture (i.e. weights) of the classifier by initiating a process of early stopping where the network training stops when the error in the validation set increases. Figure 10 shows the early stopping of network training due to increase in error in the validation set. The testing set on the other hand is an independent dataset which follows the same probability distribution as that of training set. For minimum overfitting to take place, the fit of the training set should also fit well with the testing set. However, Fig. 11 shows the validation performance of the trained network.

Tables 1, 2, 3 and 4 summarizes the actual and ANN predicted values of critical time, tcr for various service life prediction models. From the tables, it has been observed that errors with respect to ANN prediction are too small/negligible, which in fact provides a proper validation of the accuracy of the network. For structures affected by chloride ingress, the mean initiation time of corrosion varies in the range of 15–20 years indicating that the mean critical time of cracking would take place at a later stage of the structural life which approximately varies in the range of 35–40 years (Choe et al. 2008; Hassan et al. 2010; Saad and Fu 2015; Val and Melchers 1997). The approximation holds good with the results obtained from Bazant’s model. Moreover, as compared to other models, Bazant’s model avoids underestimation and overestimation of the structural service life. Therefore, Bazant’s model is considered to be the best suited model for service life prediction of RC structures subjected to chloride-induced corrosion.

Figures 12, 13, 14 and 15 shows the actual and ANN predicted critical time of various bar sizes for different service life prediction models.

Table 5 shows the comparative critical time of different service life prediction models.

Figures 16, 17 and 18 are the comparative plots of the four service life prediction models.

In order to evaluate the performance of the trained network, sensitivity and specificity of two different occurrences of cracking have been measured (D’Angelo et al. 2016, 2018; Moaveni et al. 2009). The statistical measures of sensitivity and specificity identifies efficiency of the network in accurate prediction of the service life of degrading RC structures. The sensitivity and specificity of the neural network model measures the proportion of true positive and true negative outputs that are accurately identified. The true negative and the true positive outputs refer to the occurrences of critical time of cracking that would occur before and after 40 years of service life period. The motivation behind using the 40 years of service life period as a threshold period is the results obtained from Bazant’s model. Usually, a reinforced concrete structure is designed for a service life period of at least 50 years, the protective or passivating layer of concrete cover resists diffusion of chloride into the concrete. However, after a certain period of time as the chloride-ion concentration exceeds its threshold value, there is a gradual degradation in the passivating layer of concrete due to generation of radial stresses. The radial stresses at the later stage of the life period causes cracking of concrete cover which takes place within a period of 35–40 years based on studies conducted by various researchers (Choe et al. 2008; Hassan et al. 2010; Saad and Fu 2015; Val and Melchers 1997). Therefore, it confirms that the cracking period obtained from Bazant’s model (i.e. 40 years) is realistic and can be used as a threshold period for accurate evaluation of the performance of the neural network. Also, two estimates such as negative prediction value (NPV) and positive prediction value (PPV) have been considered which represents percentages of the accurate values that has been predicted by the neural network model for cracking before and after 40 years. Two estimates such as negative prediction value (NPV) and positive prediction value (PPV) represents percentages of the accurate values that has been predicted by the neural network model for cracking before and after 40 years. The NPV and PPV of the predicted outputs were found to be 97.12% and 90.77%, which actually could be considered as a good performance of the trained network. Further, it has also been identified that the sensitivity and specificity of the trained network becomes equal to 94.05% and 95.44% respectively. Therefore, considering the statistical measures, it could be said that the proposed neural network model exhibits highly efficient in predicting service life of degrading RC structures subjected to chloride-induced corrosion with legitimate accuracy. Table 6 shows the sensitivity and specificity of two different occurrences of cracking.

6 Conclusions

Based on comparative studies of corrosion damage models, it has been observed that the mean initiation time of corrosion (i.e. the depassivation time of concrete cover) varies in the range of 15–20 years, this also indicates that the mean critical time of cracking would occur at a later stage of the life period of the structure which approximately varies between 35 and 40 years. The approximation has a good agreement with the results obtained from Bazant’s model. Also, as compared to other models Bazant’s model avoids underestimation and overestimation of the service life of degraded structure. Henceforth, Bazant’s model becomes considered to be the best one for predicting reliable service life of RC structures subjected to chloride-induced corrosion. Consecutively, the study also highlights that although reliable predictive models are available for estimating service life of RC structures, yet, it doesn’t have the ability to cut-short the computational time to a reasonable extent and thus demands a long-term and tedious computational process. In order to avoid this, a simple feed forward back propagation neural network has been used in which model problems involving with nonlinear variables. Further, ANN being a highly nonlinear network has the capability to generalize and learn from predefined examples without having any prior knowledge of the complex mathematical background. The neural network model trained for predicting the critical time of cracking yielded very good results and are proximate to the actual calculated outputs. This makes ANN a highly reliable network for predicting time dependent structural degradation. Additionally, using ANN that becomes an optimized process employed which computes robust problem at a very small amount of time with high accuracy. For evaluating the performance of the trained network, statistical measures such as sensitivity and specificity of the ANN model assessed which essentially identifies the efficiency of the trained network in accurate prediction of the structural service life. Thus, with the application of soft computing, a physical system generated which would help in solving complex problems associated with service life estimation of degraded RC structures.

References

Ahmad S (2003) Reinforced corrosion in concrete structures, its monitoring and service life prediction a review. Cem Concr Compos 25(4–5):459–471

Bazant ZP (1979) Physical model for steel corrosion in concrete sea structures-application. J Struct Div 105(6):1155–1166

Beeby AW (1978) Corrosion of reinforcing steel in concrete and its relation to cracking. Struct Eng 56A(3):77–81

Bhargava K, Ghosh AK, Mori Y, Ramanujam S (2005) Modeling of time to corrosion induced cover cracking in reinforced concrete structures. Cem Concr Res 35(11):2203–2218

Bhargava K, Ghosh AK, Mori Y, Ramanujam S (2006) Analytical model for time to cover cracking in RC structures due to rebar corrosion. Nucl Eng Des 236(11):1123–1139

Cardoso JB, de Almeida JR, Dias JM, Coelho PG (2008) Structural reliability analysis using Monte Carlo simulation and neural networks. Adv Eng Softw 39(6):505–513

Choe DE, Gardoni P, Rosowky D, Haukaas T (2008) Probabilistic capacity models and seismic fragility estimates for RC columns subject to corrosion. Reliab Eng Syst Saf 93(3):383–393

Chojaczyk AA, Teixeira AP, Neves LC, Cardosa JB, Guedes SC (2015) Review and application of artificial neural networks models in reliability analysis of steel structures. Struct Saf 52A:78–89

Cusson D, Lounis Z, Daigle L (2010) Benefits of internal curing on service life and life-cycle cost of high-performance concrete bridge decks—a case study. Cem Concr Compos 32(5):339–350

D’Angelo G, Laracca M, Rampone S (2016) Automated Eddy current non-destructive testing through low definition Lissajous figures. IEEE Metrol Aerosp. https://doi.org/10.1109/MetroAeroSpace.2016.7573227

D’Angelo G, Laracca M, Rampone S, Betta G (2018) Fast eddy current testing defect classification using Lissajous figures. IEEE Trans Instrum Meas 67(4):1–10. https://doi.org/10.1109/TIM.2018.2792848

Hassan JE, Bressollette P, Chateauneuf A, Tawil KE (2010) Reliability-based assessment of the effect of climatic conditions on the corrosion of RC structures subject to chloride ingress. Eng Struct 32(10):3279–3287

Haykin S (2005) Neural networks. Pearson Education, Hamilton

Imam A, Anifowose F, Azad AK (2015) Residual strength of corroded reinforced concrete beams using an adaptive model based on ANN. Int J Concr Struct Mater 9(2):159–172

IRC SP 60 (2002) An approach document for assessment of remaining life of concrete bridges

Liang MT, Wang KL, Liang CH (1999a) Service life prediction of reinforced concrete structures. Cem Concr Res 29:1411–1418

Liang MT, Hong CL, Liang CH (1999b) Service life prediction of existing reinforced concrete structures under carbonation-induced corrosion. J Chin Inst Civ Hydraul Eng 11(3):485–492

Liang MT, Lin LH, Liang CH (2002) Service life prediction of existing reinforced concrete bridges exposed to chloride environment. J Infrastruct Syst ASCE 8(3):76–85

Maaddawy TE, Soudki K (2007) A model for prediction of time from corrosion initiation to corrosion cracking. Cem Concr Compos 29(3):168–175

Mangat PS, Elgarf MS (1999) Bond characteristics of corroding reinforcement in concrete beams. Mater Struct 32:89–97

McCulloch WS, Pitts WH (1943) A logical calculus of the ideas immanent in nervous activity. Bull Math Biophys 5:115–133

Ming-Te L, Ran H, Shen-An F, Chi-Jang Y (2009) Service life prediction of pier for the existing reinforced concrete bridges in chloride-laden environment. J Mar Sci Technol 17(4):312–319

Moaveni B, Conte JP, Hemez FM (2009) Uncertainty and sensitivity analysis of damage identification results obtained using finite element model updating. Comput Aided Civ Infrastruct Eng 24(5):320–334

Morinaga S (1988) Prediction of service lives of reinforced concrete buildings based on rate of corrosion of reinforcing steel. Report No. 23. Shimizu Corporation, Japan, pp 82–89

Papadrakakis M, Lagaros ND (2002) Reliability-based structural optimization using neural networks and Monte Carlo simulation. Comput Methods Appl Mech Eng 191(32):3491–3507

Saad T, Fu CC (2015) Determining remaining strength capacity of deteriorating RC bridge substructures. J Perform Constr Facil 29(5):1–12

Sadiqual Islam GM (2009) Determination of the threshold chloride concentration for corrosion of steel in concrete by half-cell potential monitoring. Division of built environment

Tuutti K (1982) Corrosion of steel in concrete report 4-82. Swedish Cement and Concrete Research Institute, Sweden

Val DV, Melchers RE (1997) Reliability of deteriorating RC slab bridges. J Struct Eng 123(12):1638–1644

Vu KAT, Stewart MG (2005) Predicting the likelihood and extent of reinforced concrete corrosion-induced cracking. J Struct Eng 131(11):1681–1689

Wang XM, Zhao HY (1993) The residual service life prediction of RC structures. In: Nagataki S (ed) Durability of building materials and components, vol 6. E & FN Spon, New York, pp 1107–1114

Weyers RE (1998) Service life model for concrete structure in chloride laden environments. ACI Mater J 95(4):445–453

Zarola A, Sil A (2017) Artificial neural networks (ANN) and stochastic techniques to estimate earthquake occurrences in Northeast region of India. Ann Geophys 60(4):1–37

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

All the authors declare that they have no conflict of interest.

Animal rights statement

This article does not contain any studies with animals performed by any of the authors.

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Additional information

Communicated by V. Loia.

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Dey, A., Miyani, G. & Sil, A. Application of artificial neural network (ANN) for estimating reliable service life of reinforced concrete (RC) structure bookkeeping factors responsible for deterioration mechanism. Soft Comput 24, 2109–2123 (2020). https://doi.org/10.1007/s00500-019-04042-y

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00500-019-04042-y