Abstract

Organizations are continuously endeavoring to provide a healthy work environment without any incident, by Health, Safety, and Environment (HSE) management. As most of the activities and processes in the organizations have risk-taking nature, identification and evaluation of risks can be useful to decrease their negative effects on the system. Although Failure Mode and Effect Analysis (FMEA) technique is used widely for risk assessment, the traditional Risk Priority Number (RPN) score has shortcomings like do not considering different weights and the inherent uncertainty of risk factors as well as do not regarding all viewpoints of the experts in decision making. The aim of this study is presenting a hybrid approach based on the Linguistic FMEA, Fuzzy Inference System (FIS) and Fuzzy Data Envelopment Analysis (DEA) model to calculate a novel score for covering some RPN shortcomings and the prioritization of HSE risks. First, after identifying potential risks and assigning values to the RPN determinant factors by linguistic FMEA team members due to the differentiation of these values, FIS is used to reach a consensus opinion about these factors. Then, the outputs of FIS are used by the fuzzy DEA and its supper efficiency model to risk prioritization which can contribute to full prioritization. In addition to considering uncertainty and decreasing dependence on the team’s opinions, in this phase weights of triple factors are calculated based on mathematical programming. To show the ability of the proposed approach in terms of HSE risks prioritization, it has been implemented in an active company in the chemical industry. After identifying risks having high priority based on the proposed score, preventive/corrective actions are presented in accordance with the case study, and for more analysis of results, the self-organizing map has been applied in this study.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

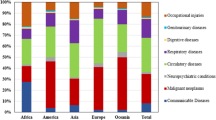

Every year, the occurrence of various incidents leads to negative outcomes such as financial and environmental damages, as well as physical or mental occupational accidents for organizations (Amir-Heidari et al. 2016). In addition to these direct and tangible damages, costs such as the reduction of organizations’ credibility are imposed as an intangible cost to organizations. Annually, 317 million occupational accidents occur around the world, and close to 6300 people per day die because of job accidents or work-related disease (ILO 2017). For this reason, the context of Safety, Health, and Environment (HSE) has been considered at the operational level in different industries in order to mitigate or even eliminate serious repercussions (Azadeh et al. 2011a).

The chemical industry is one of the most important industries where HSE principles must be considered due to the inevitable and undesirable consequences for humans and the environment (Mckenzie et al. 2012). The concern about this issue in workplaces has been dramatically raised in comparison with the past regarding the increase of chemicals production. In these industries, workers are exposed to numerous harmful chemicals and physical agents that may cause chronic occupational accidents or diseases (Si et al. 2012). HSE management as a systematic framework can create, or even maintain a healthy workplace, and lead to prolonging the production and services provided. In addition, it prevents the incurring high costs, and various compensation, that each of them may cause many problems for any industry, and undermine desirable productivity (Yousefi et al. 2018). HSE management system can be successful if it is intended to prevent occupational accidents and environmental damages. This system provides standard and desirable work conditions along with methods for identifying, assessing, controlling harmful factors, or removing them from the workplace (Guneri et al. 2015). In fact, the identification and periodic risk assessment are the basis of any HSE management system. There are many approaches for risk assessment, but a useful method in addition to simplicity should be in accordance with the nature of the activities, processes, culture, and other characteristics of the organization.

One of the prevalent risk assessment approaches is Failure Mode and Effects Analysis (FMEA) technique which presents and implements some solutions to eliminate or reduce the likelihood of potential problems’ occurrence (risk or failure mode) by predicting them and calculating their risk-taking amount (Trafialek and Kolanowski 2014). In most studies using this technique, risks have been prioritized based on the traditional Risk Priority Number (RPN) score which is the multiplication of three risk factors as Severity (S), Occurrence (O) and Detection (D). This score may lead to placing one risk in high priority which has less severity compared to other risks with lower RPN (Rezaee et al. 2017b). Despite the privileges of the FMEA technique, it has main shortcomings in risk evaluation and prioritization based on the RPN score. Due to the identification of risks by the FMEA team, the values of risk factors (RPN determinant factors) cannot be determined easily due to the necessity of considering all viewpoints of the FMEA team. Members based on their expertise, skills, and backgrounds may have different opinions about the S, O, and D (SOD) factors (Liu et al. 2012; Baghery et al. 2018). Moreover, some events may occur in the future which have not happened in the organization yet. Therefore, the values of the mentioned factors cannot be accurately defined, and there is an inherent uncertainty in these factors (Liu et al. 2012) that considering the amount of these factors as fuzzy values is of high importance, especially when integrated tools are used because of insufficient information (Liu et al. 2013a, b). Different risks have distinct outcomes and assigning a fixed set of weights of determinant factors for all of the risks may be improper, especially in the problems which have a large number of risks (Chanamool and Naenna 2016). In addition, the RPN formula is not scientific, and there is no logical reason in multiplying three determinant factors to calculate the RPN score (Liu et al. 2013a, b). Therefore, to deal with these shortcomings a new score is needed to risk prioritization.

The aim of this study is presenting a novel score to prioritize HSE risks; so that it covers some of the shortcomings of the traditional RPN score. The proposed hybrid approach is based on the Fuzzy Inference System (FIS) and the Slack-Based Data Envelopment Analysis (SBDEA) model and is implemented in two phases. In the first phase, the FMEA team is created and potential risks in terms of HSE are identified by them. After that, they asked to state their opinions about these risks in the form of the traditional 10-point scale to evaluate SOD factors. Due to the mentioned problems, the FIS is used to incorporate team members’ opinions (on each SOD factor) which are based on fuzzy logic and deal with uncertainty. So that, the FIS takes the opinions on SOD factors as input and generates the values of these factors due to all opinions as output. The outputs of this phase are fuzzy numbers. In the second phase SBDEA model without outputs and its fuzzy super-efficiency models are used to decrease the dependence on team members’ opinions, dealing with uncertainty and fuzzy numbers, and considering different weights for SOD factors, which is determined based on mathematical programming, (Rezaee and Yousefi 2018) in order to achieve a novel score for risk prioritization instead of traditional RPN score. In this phase, the potential risks are considered as Decision Making Units (DMUs), and values obtained for RPN determinant factors as the inputs which are calculated by FIS. In order to implement this model, fuzzy values of inputs converted to interval values using the α-cut method, and finally, a novel score is achieved for risk prioritization that is able to fully prioritize risks. In order to investigate the proposed approach, the HSE risks of an active company in the chemical industry are prioritized by a score derived from the FMEA technique combining with FIS and SBDEA model without outputs, and results are explained. Furthermore, the self-organizing map is applied to more analysis of results.

The rest of this study is organized as follows: in Sect. 2, some related studies are reviewed which includes studies on linguistic FMEA, the applications of the FIS and the Fuzzy Data Envelopment Analysis (DEA) model. In Sect. 3, the models used in this study are introduced in detail. In Sect. 4, the proposed approach is explained. In Sect. 5, a case study is presented, and in Sect. 6, the results of implementing the proposed approach are discussed and analyzed. Finally, in Sect. 7, the conclusion is carried out.

2 Literature review

In this section, some researches related to the studied problem and the models used in the proposed approach are examined in three sub-sections. First of all, some studies about the FMEA technique and hybrid methods in this field are reviewed. Then, in the next subsections, applications of the FIS and fuzzy DEA model are presented.

2.1 FMEA

FMEA technique has been widely used for risk assessment in different scopes. In this regard, the literature of the FMEA can be categorized into four groups such as Multi-Criteria Decision Making (MCDM), Artificial Intelligence (AI), mathematical programming, and hybrid approaches.

In the MCDM approaches, identified risks by the FMEA team are prioritized using MCDM techniques considering the information of this team. For example, Yazdi et al. (2017) applied fuzzy developed FMEA for risk assessment of an aircraft landing system. This paper has been extended classical FMEA using group decision making and fuzzy theory. Wang et al. (2019) conducted a study with the aim of ameliorating the process of risk prioritization by considering risk indicators interaction. They presented an integrated FMEA approach using TODIM (an acronym in Portuguese of interactive and MCDM) method, Choquet integral and Shapley index. Salamai et al. (2019) studied the importance of considering the impacts of both external and internal risk factors on operational parameters to improve supply chain risk management. In this paper, they discussed that it is important for firms to consider external events and risks as they directly influence the internal ones. Chang et al. (2019) presented another hybrid FMEA model for risk assessment based on Rough BWM (R-BWM) and Rough Technique for Order Preference by Similarity to Ideal Solution (R-TOPSIS). They added aspiration level to R-TOPSIS to improve the reliability of the TOPSIS method and gaining more information.

In the field of the second group (AI methods), Adar et al. (2017) applied FMEA to identify potential risks in the supercritical water gasification system and their cause and effects. For this aim, the cause-and-effect diagram, classical FMEA, and fuzzy FMEA have been implemented and potential risks prioritized. Renjith et al. (2018) applied fuzzy logic in Failure Mode and Critically Effect Analysis (FMCEA) for evaluating risks of complex systems. Rezaee et al. (2018) prioritized failures in the food industry using a hybrid approach based on the multi-stage Fuzzy Cognitive Map (FCM) and Process Failure Mode and Effects Analysis (PFMEA). They considered causal relationships between both failures (using FCM), and stages. Mangeli et al. (2019) combined the FMEA technique with Fuzzy TOPSIS and support vector machine to improve risk assessment. One of the features of their approach is making a reduction in the effect of DMs’ opinion on risk factors (factors of S and O) determination.

In the scope of mathematical programming, Rezaee et al. (2017a) combined DEA and FMEA in order to identify and prioritize risks of the stone industry. They used the DEA model instead of employing the RPN score for risk prioritization. Also, Yousefi et al. (2018) combined robust DEA with FMEA to identify and evaluate HSE risks in different industries. The proposed approach in addition to considering three risk factors as inputs of RDEA, employed two extra parameters consist of cost and duration of treatment as outputs.

Finally, in the hybrid approaches group, Zhou and Thai (2016) applied FMEA to predict the failures of tanker equipment. In this regard, they employed the fuzzy set theory to calculate Fuzzy Risk Priority Numbers (FRPNs) and used gray theory to calculate gray relational coefficients. Nazeri and Naderikia (2017) proposed a hybrid approach for developing a risk-based method in order to select a proper maintenance strategy to have available and reliable tamping equipment in the railway. For this aim, the proposed approach has been toke advantageous from FMEA, decision making trial and evaluation laboratory technique (DEMATEL), and also Analytic Network Process (ANP). In the other study, Peeters et al. (2018) used the combination of FMEA and Fault Tree Analysis (FTA) to risk assessment in the manufacturing system. Fattahi and Khalilzadeh (2018) proposed a hybrid approach for evaluating risks in the steel industry. In this method instead of using RPN, a fuzzy weighted RPN has been employed to evaluate identified risks. In this regard, they used fuzzy Analytic Hierarchy Process (AHP) and fuzzy MULTIMOORA methods to assign the weights of risks, respectively.

2.2 FIS applications

Fuzzy systems describe uncertain and unspecified phenomena, and their applications in the design of various uncertain systems represent the high performance and rapid growth of these systems (Yel and Yalpir 2011). The application of fuzzy systems has been expanded in different fields that in the following some of these studies are reviewed. Kwolek and Kepski (2016) used FIS for presenting a reliable method to detect falling. For this aim, a fuzzy system consists of the Mamdani engine and a triggering alert Takagi–Sugeno engine is constructed. Kłosowski et al. (2016) used FIS to select workers for assigning production tasks. they used Mamdani FIS as a controller which aid in the decision-making process. In this regard, a simulation model of discrete manufacturing with an implemented fuzzy controller has been designed. Wanke et al. (2017) employed FIS in order to construct a decision-making system for inventory allocation. Kang et al. (2017) used FIS for diagnosis degradation of headwater heater performance. For this aim, fuzzy numbers and fuzzy rule bases are defined due to experts’ opinions. For measuring the performance of the production system, Pourjavad and Mayorga (2019) applied Mamdani FIS and defined fuzzy rules for converting human reasoning to mathematical form.

In some cases, researchers have been combined FIS with other methods to model complex systems. Azadeh et al. (2011b) presented a new method using the Adaptive Network-based Fuzzy Inference System (ANFIS) and Genetic Algorithm Clustering Ensemble (GACE) method to calculate the efficiency score and performance evaluation of power plants. Kerk et al. (2017) proposed a FIS-based method for evaluating risks under incomplete information. In this approach incomplete information and fuzzy rules proposed with FMEA users, are considered as interval-valued fuzzy rules in order to consist of an interval fuzzy-RPN model. Deb et al. (2018) employed FIS in order to design a decision support system that is used to effective monitoring of inventory level and ensuring the availability of goods. For this aim, ANN and FIS are combined to deal with uncertainties in the parameters of the inventory system. In the other study, Halabi et al. (2018) introduced a novel method by integrating ANFIS with Particle Swarm Optimization (PSO), Genetic Algorithm (GA) and Differential Evolution (DE) algorithms respectively for prediction of solar radiation. Asemi et al. (2019) employed the ANFIS method based on MVML and MVSL active learning theories to assess the performance of dysarthric Automatic Speech Recognition (ASR) systems.

2.3 Fuzzy DEA applications

Fuzzy DEA is a methodology for measuring the relative efficiencies of a set of DMUs which uses multiple crisp/fuzzy inputs to produce multiple fuzzy/crisp outputs (Emrouznejad et al. 2014). In this scope, Chen et al. (2013) applied the expanded fuzzy slack-based measurement model for the analysis of the bank business performance and market risk. Dotoli et al. (2015) presented a novel cross-efficiency fuzzy DEA technique for evaluating the performance of healthcare systems under uncertainty. Wanke et al. (2016) used fuzzy DEA models to evaluate productive efficiency, and capture vagueness in input and output measurements obtained from airports. Egilmez et al. (2016) presented a fuzzy DEA framework to deal with uncertainty impacts of input–output life cycle assessment models on eco-efficiency assessment to perform the sustainability performance assessment of the food manufacturing sectors. Hatami-Marbini et al. (2017) developed a flexible cross-efficiency evaluation approach based on fuzzy DEA for identifying supplier performance and sustainable supplier selection in the semiconductor industry. Kumar et al. (2017) used a fuzzy DEA model to evaluate the relative efficiency of fertilizer-manufacturing organizations and ranking these organizations. Tavana et al. (2018) proposed a fuzzy two-stage game-DEA framework using a bargaining game model for the assessment of bank branches. Bakhtavar and Yousefi (2019) presented an approach based on the fuzzy DEA and FMEA to analyze risks of the mine infrastructures.

By evaluating the previous studies in the scope of risk assessment, it can be understood that most of them have tried to cover the shortcomings of the conventional FMEA technique by combining it with other methods. However, in some cases, their results may not be practical and reliable. For this aim, the presented study proposes a novel score based on the FMEA technique, FIS and fuzzy SBDEA model without outputs, which lead to full prioritization, in order to solve the mentioned shortcomings of the traditional RPN score for risk prioritization.

3 Methodology

As stated, the aim of this study is to prioritize HSE risks by presenting a hybrid approach based on the linguistic FMEA technique, FIS and fuzzy DEA model which are introduced in this section. The supplementary descriptions of these models are presented in the following subsections.

3.1 FMEA

Risk assessment as a systematic and comprehensive method for identifying, investigating and controlling potential risks in a system is used in various industries (Fattahi and Khalilzadeh 2018). FMEA is a common risk assessment technique that seeks to identify potential risks and their related causes and effects in a system and to prioritize them. The main purpose of FMEA is risk prioritization in order to assign limited resources to the most serious risks. In this regard, based on the priority of each failure mode or risk, corrective actions are implemented to eliminate or reduce the effect of the identified risks. Indeed, determination and rectification of these risks during design and production phases can contribute to improvement in the performance of the system (Liu et al. 2013a, b). In order to the implementation of this technique, after determining the scope of FMEA application, it is needed to have a comprehensive consideration of the studied problem. For this aim, a cross-functional team (FMEA team) should be created to identify potential risks and their causes and effects. As stated previously, in this technique RPN score is used to prioritize identified risks. Due to using SOD factors in the RPN formula, the value of these triple factors is determined based on the team members’ knowledge and experience in a session of systematic brain-storming (Ghasemi et al. 2016). As can be seen in Table 1, a 10-point scale has been considered for the evaluation of three risk factors. (Stamatis 2003).

After that, corrective actions are designed and implemented to eliminate or reduce their occurrences and effects. Finally, periodic evaluation is carried out to monitor the effectiveness of the solutions as well as determine the current status of the risks, and if it is necessary, new corrective actions will define based on the obtained results.

3.2 Fuzzy inference system

Fuzzy logic can be a flexible and suitable way to construct a structure for transforming an expert’s knowledge, which is linguistic descriptions, into mathematical expressions. Also, fuzzy logic has been considered as a useful way to deal with vagueness and uncertainty (Jiang et al. 2017). Fuzzy logic is based on fuzzy set theory. In classical set theory, an element may belong to a set or not. In contrast, the fuzzy set theory considers a membership function between [0,1] for each element. Indeed, in this theory, each element may belong to a set based on its membership function. In the fuzzy logic, by means of the membership function, a crisp input converted to fuzzy input can be processed using an inference engine. The inference engine consists of several rules which are defined by experts. After making inference about fuzzy input, the fuzzy output can be reverted to the crisp output using defuzzification. Executive steps of fuzzy logic consist of defining the linguistic variables based on expert’s opinions, determining membership functions, constructing the rule base, fuzzification of non-fuzzy input variables using the membership function, considering implication for evaluating the rules in the rule bases, aggregating result of the implication on the rules, and finally converting fuzzy output to crisp variables using defuzzification (Chanamool and Naenna 2016).

In the mentioned process, the first three steps are considered as initialization phase. In this phase, after collecting information about the inputs of the system, some linguistic variables are defined to express the importance of the inputs. Then corresponding membership functions of each linguistic variable are defined for all inputs due to the experts’ opinions. After that, through the definition of different rules, a rule base is made which uses expert’s viewpoint to determine the best output based on the different combination of inputs. Each rule consists of two main parts as an antecedent (if) and consequence (then). In each rule, antecedent acts as a condition on inputs to compute consequence or output. Indeed, according to the initialization phase, a robust structure is made, which can be used to apply expert’s experiences and viewpoints on identified input variables of the system, in order to make a fuzzy inference. After the initialization phase, according to fuzzification based on the defined membership functions, each input of the FIS is converted to fuzzy numbers. In this phase, the crisp inputs of the system are converted to the fuzzy numbers due to the defined membership function at the previous phase, which is used for making inference at the inference engine (Zimmermann 1996).

In the next steps based on the fuzzy operators, an inference is implemented on the input variables. In the inference phase, at first, fuzzy propositions are presented using the implication operator, and the results are combined using the aggregation operator. The result of the inference phase will be a fuzzy set, so in the last step, the outputs of FIS corresponding to each set of inputs are converted to non-fuzzy values. In the fuzzy logic, results are defuzzified considering the membership function of outputs. Therefore, due to the defuzzification phase, a crisp value is derived from the membership function of outputs using methods such as the center of gravity. Indeed, a defuzzification method aggregates certain features of the fuzzy set into a crisp value. There are different methods for defuzzification such as the center of gravity, the center of the area, largest of maximum (largest value in maximum values of the output set), middle of maximum, and smallest of maximum (Zimmermann 1996).

3.3 Fuzzy data envelopment analysis

DEA is a mathematical programming model that uses multiple inputs to produce multiple outputs for the construction of piecewise linear convex production frontiers and measure relative efficiencies within a group of DMUs. When the inputs and/or outputs of this model are fuzzy numbers, the fuzzy DEA model should be used to assess DMUs. At first, Tone (2001) presented a non-radial slack-based measure of efficiency model in 2001. The results of this model were independent of the measurement units and also were neutral to the conversion of primary data. Afterward, the SBDEA model was developed based on fuzzy logic. In this model, \( \tilde{X}_{ji} \) and \( \tilde{Y}_{jr} \) respectively represent non-deterministic inputs (\( i = 1, \ldots ,m \)) and outputs (\( r = 1, \ldots ,s \)) for DMU, and can be indicated as \( \mu_{{\tilde{X}_{ji} }} \),\( \mu_{{\tilde{Y}_{jr} }} \) by the membership function in the convex fuzzy set. In a fuzzy environment, the efficiency of the kth DMU (\( \tilde{\delta }_{k} \)) is calculated using Model (1):

In the above model, \( q \), \( \lambda_{j}^{/} \), \( S_{i}^{ - } \) and \( S_{r}^{ + } \) respectively represent the variable is greater than or equal to zero, dual variables of CCR (the first letter of the Charnes, Cooper, and Rhodes who first introduced it) model and slack variables of SBDEA model. In this Equation, all inputs/outputs are considered as fuzzy data. Then, the fuzzy set of inputs and outputs are converted to an exact set defining the threshold of membership and α-cut method. In the α-cut, both input and output can be expressed as the crisp intervals of various α standards level. According to Chen et al. (2013), Model (1) can be transformed into the one-step programming model (see “Appendix 1”). However, these models have the limitation of the maximum relative efficiency value (i.e. 1), which makes it difficult to rank due to the intervals efficiency values. For this reason, Chen et al. (2013) developed a fuzzy super efficiency SBDEA model. According to the process used in the development of the fuzzy SBDEA model, they extended the Andersen and Petersen model (1993). The fuzzy super efficiency SBDEA models have been expressed in “Appendix 2”. There are differences between traditional DEA and its fuzzy model regarding the calculation of relative efficiency values by the mentioned models. Hence, ranking DMUs evaluated based on the efficiency values, is difficult. Moreover, the membership function of the efficiency values is unknown, because efficiency values are the Upper Bound (UB) and Lower Bound (LB) of the efficiency values calculated under various α levels. To solve this problem, Chen and Klein (1997) presented the following equation used in this study:

In the Eq. (2), assuming that k (\( k = 1, \ldots ,n \)) and i (\( \alpha_{i} = ih/m,i = 0, \ldots ,m \)) are a respectively counter numbers of DMUs and counter of α levels. Also, \( (E_{k} )_{{\alpha_{i} }}^{U} \), \( (E_{k} )_{{\alpha_{i} }}^{L} \), and \( I(^{\sim} E_{k}^{\sim} ,R) \) respectively represent UB and LB of super efficiency of the kth DMU per \( \alpha_{i} \) level and fuzzy ranking index for decision-making units j under various α levels. Furthermore, the amounts of “c” and “d” are \( \min_{i,k} \left\{ {(E_{k} )_{{\alpha_{i} }} } \right\} \), and \( \max_{i,k} \left\{ {(E_{k} )_{{\alpha_{i} }} } \right\} \). According to Eq. (2), the bigger fuzzy ranking index has a higher priority for the DMU.

4 Proposed approach

In this section, a hybrid approach is proposed to identify and prioritize HSE risks. This approach is tried to overcome some of the FMEA technique’s shortcomings. In this regard, it takes advantageous of FIS and SBDEA model without outputs or fixed outputs equal to one and used the self-organizing map for clustering visualization. For this aim, first of all, potential risks in terms of HSE are identified and listed by the FMEA team. After that, all experts should be asked to state their opinions about these risks in the forms of SOD factors. In the real world, there are several problems in utilizing experts’ knowledge in a special application area; in this regard, converting experts’ knowledge of mathematical values makes their analysis simpler in decision-making processes. Experts’ opinions include their insight and experience in dealing with problems that can be gained by doing different activities in different situations, and under various limitations. The results of risk assessment are directly related to these opinions; so they must be completely considered in this process (Yazdi et al. 2017).

One of the important issues in the field of FMEA applications, identifying and prioritizing potential risks, is determining the value of SOD factors of each risk. In reality, different experts can have different opinions about these factors that some of them may be inaccurate and incomplete as a result of time constraints, lack of experience and adequate data. In order to overcome this shortcoming of conventional FMEA, the FIS is used to gather expert’s opinions on each of the RPN determinant factors. FIS is a structure to map input–output space based on fuzzy logic. There are two main FIS namely Mamdani and Takagi–Sugeno. In the present study, Mamdani-type is applied for extracting the expert’s opinions on risk factors; so that for each risk factor an FIS is independently designed, and each expert is asked to assign a value for this factor. Therefore, three independent FIS are constructed for each SOD factor.

Inputs of each FIS are experts’ opinions on the risk factor, and the output is collected opinions about that risk factor. In the context of constructing FIS, there are different methods for approximating fuzzy outputs to non-fuzzy values during the defuzzification phase. Indeed, a defuzzification method proposes an approximation for inference result whereas the inference result is a fuzzy set. In the proposed approach in order to achieve the best result in defuzzification processes, outputs of FISs are calculated using different defuzzification methods. In this regard, three defuzzification methods consisting of Smallest of Maximum (SOM), Middle of Maximum (MOM) and Largest of Maximum (LOM) are used which are LB, middle and UB of the area of maximum values in the fuzzy output (see Fig. 1).

Based on Zimmermann (1996) study, SOM, MOM, and LOM can be chosen from the fuzzy set of the output as follows:

where \( \inf_{u} \) and \( \sup_{u} \) are UB and LB, \( \mu^{coceque} \) is the membership function of the fuzzy set u, and U is the range of output values. Hence, for all three FISs, corresponding to the number of risk factors, three values are calculated. According to the proposed approach, corresponding to each potential risk, three values are calculated for each of RPN determinant factors.

Now, calculated values of RPN determinant factors are used in the fuzzy SBDEA model without outputs in order to prioritize potential risks. In the DEA model, the evaluation criteria that decision-makers seek to reduce their amount (or their lower value is better), are considered as the input, and the evaluation criteria that managers seek to increase their amount (or their higher value is better) are considered as output of this model (Charnes et al. 1978; Yousefi et al. 2019). In addition, DEA without outputs is a common model used for performance evaluation of DMUs which have multiple inputs with assuming constant outputs equal to 1 (Lovell and Pastor 1999). As the issue studied in this paper has no criteria that decision-makers seek to increase their amount, without outputs model has been used to apply SBDEA models. Therefore, the potential risks are considered as DMUs, and RPN determinant factors are considered as the inputs of the fuzzy SBDEA model. Furthermore, there is no concept defined as the output. To implement this model, fuzzy values of inputs (obtained from FIS) converted to interval values using the α-cut method. Then, fuzzy SBDEA models are used for different α levels and are calculated the lower and upper scores for each potential risk. Finally, the potential risks are prioritized using Eq. (2). It should be noted that when a risk has a higher score (fuzzy ranking index) in comparison with other risks, it has lower priority. It means that risk with the lowest score is located at the first priority. The reason for that is, in the fuzzy SBDEA without outputs model, the risks which have fewer inputs (RPN determinant factors), can obtain a higher score by assuming an output with a fixed amount equal to 1 for each risk. The proposed approach of this study is shown in Fig. 2.

5 Case study

In this section, the proposed approach has been applied to an active company in the chemical industry. K.C.K.Ch Company has been established in northwestern Iran in 2001 with the purpose of producing chemical fertilizers, Sulfuric acid, and other allowable chemicals. This Company is one of the chemical industries in Iran which has played an effective role in expanding the products of this industry in domestic, regional, and global markets by utilizing knowledgeable manpower, and making correct and suitable policy. The K.C.K.Ch company in addition to creating employment opportunities for 40 people, has the production capacity of chemical products more than 250,000 tons. The number of employees will increase to 100 and its production capacity will rise to 300,000 tons in 2020 by the implementation of the company’s development program. It is needed to explain that Small and Medium-sized Enterprises (SMEs) are more vulnerable in terms of safety; so that in 2016, 90% of job accidents had occurred in SMEs in Iran (ISIPO 2016). Therefore, regarding the nature of active SMEs in the chemical industry, and increasing the employment, the importance of HSE management and the implementation of evaluating and prioritization techniques in the company is felt. In fact, due to the lack of the safety system in the company, managers try to prevent the wasting of their human and financial resources. At present, one of the mentioned company’s short-term goals is to minimize existing risks and to create a safe working environment. For this point, the identification of HSE risks and their periodic evaluation has been considered as one of the main plans of the company.

According to the executive steps of the FMEA technique, after the creating of the FMEA team, they prepare and complete relevant forms, and then the HSE risks are identified. This team consists of the employer representative, manager of the safety sector, and workers’ representative. The members of the FMEA team have enough information on the company’s activities, HSE issues, and have close relationships with the managers of production lines. Identified risks and other supplementary information including risk causes and effects have been presented in Table 2. As shown in this table, 48 HSE risks of the company have been identified.

6 Analysis of the results

In this section, the results of implementing the proposed approach for prioritizing HSE risks in the studied company are presented. For this aim, initially, corresponding to the triple RPN determinant factors, three independent FIS is designed. It should be noted that in this study, the experience of three members of the FMEA team has been used in order to risks determination. Since the inputs of each FIS are experts’ opinions and output is collected opinion about risk factors, so in each FIS several triangular membership functions have been defined for inputs and outputs due to the expert’s guidelines. As can be seen in Figs. 3 and 4 showing the information of membership functions, these functions in three FISs are the same. Then, to construct inference engine 125 rules were defined in each FIS based on the number of inputs levels. In the determination of the FIS parameters, AND method is adjusted as “min” operator, implication function is adjusted as “min” operator, and also “max” operator is selected as aggregation function. As previously mentioned, in order to obtain better outputs of FISs, three different defuzzification methods have been used.

After the identification of HSE risks (presented in Table 2), in order to calculate the risk factors for identified potential risks, the opinions of all three experts about risk factors are used as inputs for their corresponding FISs. As a result, nine values (three values for S factor, three values for O factor, and three values for D factor) has been obtained for each potential risk; actually, each FIS has been produced three values as LB, middle, and UB for collected opinions about each risk factor. Calculated triple values for SOD factors due to their independent FIS (based on defuzzification methods consist of SOM, MOM and LOM) has been presented in Table 3.

In the following, according to the proposed approach, the fuzzy SBDEA models without outputs are used to prioritize 48 identified risks; so that this model in addition to comparing risks with each other, can calculate a score for each risk. The fuzzy values of RPN determinant factors are considered as inputs of this model (presented in Table 3), and output is considered a constant value equal to 1, for each risk. To implement the mentioned models, at first fuzzy values (SOD values) have been converted to interval values using the α-cut method (for 6 different α levels). Then, the fuzzy SBDEA model (see “Appendix 1”) for DMUs (the HSE risks) is implemented using the GAMS software. After that, if the score obtained from the UB model for some DMUs is equal to 1, the fuzzy super efficiency SBDEA model (see “Appendix 2”) is implemented for these DMUs; thus, the calculated score of them will be greater than 1. The UB and LB of calculated scores of each risk for different α levels have been shown in Table 4. Now, in order to achieve a score for risk prioritization, Eq. (2) is used to convert all the presented interval values (for each risk) in different α levels to a single score. Finally, using this score the identified risks are prioritized which have been shown in Table 4; so that risk with lower score has been placed in higher priority and needs to be assessed. As stated, the reason for this is in the fuzzy SBDEA without outputs, the risks which have fewer inputs can obtain a higher score by assuming an output with a constant value equal to 1 for each risk. It should be noted since in the conventional FMEA technique the values of risk factors are expressed in the form of numbers, as well as it is not possible to use linguistic variables and to aggregate these variables, as one of the drawbacks of this technique, the comparison between the results of the proposed approach and conventional FMEA technique cannot be drowning.

According to Table 4, it can be seen risks R11 with the score of 0.283 is in the first place, as well as, risks R3, R9, R13, and R16 with the score of 0.302, 0.308, 0.373, and 0.373 have been ranked in second to fifth priorities, respectively.

Moreover, due to the implemented prioritization based on the proposed approach, it can be understood that identified risks have been prioritized in 48 distinct ranks. In other words, the full prioritization of risks has been done in comparison with the conventional FMEA technique. Also, Bakhtavar and Yousefi (2018) believe that decision making based on a prioritization which is not done fully, may divert managers’ attention to those risks that a reduction in their occurrence likelihood cannot ameliorate the current status. Furthermore, decision-makers often are faced with limitations that enforce them to present some solutions for the specific number of risks having high priority, and if the full prioritization is not been done, decision-makers fail to recognize critical risks easily. Despite differences in the proposed frameworks of the study conducted by Bakhtavar and Yousefi (2018) and the current study, it can be seen that the TOPSIS method has been used for final risk prioritization in their study where the weight of factors is determined according to experts’ opinions. In the current study, the weight of each risk factor is determined based on mathematical programming models presented in the appendix section and this process is independent of direct experts’ opinion. In order to more interpretation of results, identified risks are clustered by using the self-organizing map due to the SOD factors; so that in each cluster the relation between these factors is evaluated. This leads to the determination of homogeneous risks regarding the triple factors, and ultimately the most important cluster is identified. As can be seen in Fig. 5, risks have been divided into six clusters using the mentioned algorithm (self-organizing map) according to the 2 × 3 configuration regarding the value of SOD factors. In fact, using this configuration, the self-organizing map has been presented a better separation of risks than other tested configurations; hence the 2 × 3 configuration has been used in this study.

According to this figure, points highlighted in celestial blue color create a cluster in which the values of O and S are more than average, but the value of D is very low. Whilst the cluster with blue points, has high values of S and D, but their respective O factor has the lowest values. Points with very low values of O, high values of S, and medium values of D are the characteristics of the cluster with red points. Cluster with yellow points has medium values of D and O which are close to each other and medium or high values of S. Points highlighted in green color create another cluster which has medium or high values of S and D, but have very low values of O. Final cluster having purple points involves risks with low values of O, and medium or high values of S, and medium values of D which are close to each other.

Prioritizing HSE risks is one of the first steps in identifying risks that have priority and providing the necessary solutions to eliminate, or reduce the effect of these risks. The reason for that is each organization due to the budget and time limitations, seeks to make the most improvement in the current situation by optimal allocation of resources. After the HSE risks prioritization, for ten risks that have priority identified based on the proposed score, preventive/corrective solutions have been presented in accordance with the case study in Table 5.

7 Discussion and conclusion

Ignoring HSE standards, and precautionary principles in the workplace can lead to an increase in occupational accidents which may have irreparable outcomes. In order to achieve an effective assessment method, it is needed to have an accurate assessment of processes for risk identification, and making necessary decisions to mitigate their effects. Furthermore, risk analysis is considered as an important tool for maintaining and improving the safety level in the industry. For this purpose, risk assessment is an essential issue for existing or developing industrial units.

Among different risk analysis methods, FMEA is one of the most popular techniques which is used in various fields, whereas, the conventional FMEA technique has some shortcomings in the RPN score. The aim of this study is presenting a hybrid approach using linguistic FMEA, FIS, Fuzzy SBDEA, and its supper efficiency model to overcome some of the traditional RPN shortcomings that led to fully risk prioritization. In the FMEA technique, risks are determined by the members of the FMEA team; so due to the knowledge and experience of each expert, achieving a consensus view about the risks may be difficult. To solve this problem, after defining risks by the FMEA team, in order to determine a value for SOD factors (related to each risk), the FIS was used to collect all of the experts’ opinions. So that, according to SOD factors, three independent FIS was designed. After that, calculated values of RPN determinant factors having uncertainty were used in fuzzy SBDEA without outputs in order to prioritize potential risks regarding different weights of risk factors. In this model, the weights of SOD factors are calculated based on the mathematical programming which shows less dependence on experts’ opinions. To implement fuzzy SBDEA, due to the obtained fuzzy values from FIS (inputs of fuzzy DEA), these values were converted to interval values using the α-cut method that was applied for six different α levels. Finally, using the obtained score, the potential risks were prioritized.

The results of the implementation of the proposed approach in the active company in the chemical industry showed that prioritizing risks based on the presented score, in addition to considering the uncertainty and assigning different weights to SOD factors, have been created a complete distinction between the identified risk priorities. This prioritization enables managers to present and implement corrective action in accordance with the organization’s resource constraints and risks which have priority. After prioritizing the HSE risks in this company, for ten risks that have priority identified based on the proposed score, preventive/corrective solutions were presented. Also, in order to more analysis of the results, the self-organizing map had been applied. However, the present study has been tried to overcome some of the shortcomings of the conventional FMEA technique, but there are some issues that should be considered in future researches. One of the limitations of this study is not considering the causal relationship between risks, which can be solved using a combination of a fuzzy cognitive map and FIS.

References

Adar E, İnce M, Karatop B, Bilgili MS (2017) The risk analysis by failure mode and effect analysis (FMEA) and fuzzy-FMEA of supercritical water gasification system used in the sewage sludge treatment. J Environ Chem Eng 5(1):1261–1268

Amir-Heidari P, Maknoon R, Taheri B, Bazyari M (2016) Identification of strategies to reduce accidents and losses in drilling industry by comprehensive HSE risk assessment: a case study in Iranian drilling industry. J Loss Prev Process Ind 44:405–413

Andersen P, Petersen NC (1993) A procedure for ranking efficient units in data envelopment analysis. Manag Sci 39(10):1261–1264

Asemi A, Salim SSB, Shahamiri SR, Asemi A, Houshangi N (2019) Adaptive neuro-fuzzy inference system for evaluating dysarthric automatic speech recognition (ASR) systems: a case study on MVML-based ASR. Soft Comput 23(10):3529–3544

Azadeh A, Rouzbahman M, Saberi M, Fam IM (2011a) An adaptive neural network algorithm for assessment and improvement of job satisfaction with respect to HSE and ergonomics program: the case of a gas refinery. J Loss Prev Process Ind 24(4):361–370

Azadeh A, Saberi M, Anvari M, Azaron A, Mohammadi M (2011b) An adaptive network based fuzzy inference system–genetic algorithm clustering ensemble algorithm for performance assessment and improvement of conventional power plants. Expert Syst Appl 38(3):2224–2234

Baghery M, Yousefi S, Rezaee MJ (2018) Risk measurement and prioritization of auto parts manufacturing processes based on process failure analysis, interval data envelopment analysis and grey relational analysis. J Intell Manuf 29(8):1803–1825

Bakhtavar E, Yousefi S (2018) Assessment of workplace accident risks in underground collieries by integrating a multi-goal cause-and-effect analysis method with MCDM sensitivity analysis. Stoch Environ Res Risk Assess 32(12):3317–3332

Bakhtavar E, Yousefi S (2019) Analysis of ground vibration risk on mine infrastructures: integrating fuzzy slack-based measure model and failure effects analysis. Int J Environ Sci Technol 16(10):6065–6076

Chanamool N, Naenna T (2016) Fuzzy FMEA application to improve decision-making process in an emergency department. Appl Soft Comput 43:441–453

Chang TW, Lo HW, Chen KY, Liou JJ (2019) A novel FMEA model based on rough BWM and rough TOPSIS-AL for risk assessment. Mathematics 7(10):874

Charnes A, Cooper WW, Rhodes E (1978) Measuring the efficiency of decision making units. Eur J Oper Res 2(6):429–444

Chen CB, Klein CM (1997) A simple approach to ranking a group of aggregated fuzzy utilities. IEEE Trans Syst Man Cybern Part B (Cybern) 27(1):26–35

Chen YC, Chiu YH, Huang CW, Tu CH (2013) The analysis of bank business performance and market risk: applying fuzzy DEA. Econ Model 32:225–232

Deb M, Kaur P, Sarma KK (2018) Inventory control using fuzzy-aided decision support system. In: Bhatia S, Mishra K, Tiwari S, Singh V (eds) Advances in computer and computational sciences. Springer, Singapore, pp 467–476

Dotoli M, Epicoco N, Falagario M, Sciancalepore F (2015) A cross-efficiency fuzzy data envelopment analysis technique for performance evaluation of decision making units under uncertainty. Comput Ind Eng 79:103–114

Egilmez G, Gumus S, Kucukvar M, Tatari O (2016) A fuzzy data envelopment analysis framework for dealing with uncertainty impacts of input–output life cycle assessment models on eco-efficiency assessment. J Clean Prod 129:622–636

Emrouznejad A, Tavana M, Hatami-Marbini A (2014) The state of the art in fuzzy data envelopment analysis. In: Emrouznejad A, Tavana M (eds) Performance measurement with fuzzy data envelopment analysis. Springer, Berlin, pp 1–45

Fattahi R, Khalilzadeh M (2018) Risk evaluation using a novel hybrid method based on FMEA, extended MULTIMOORA, and AHP methods under fuzzy environment. Saf Sci 102:290–300

Ghasemi S, Mahmoudvand R, Yavari K (2016) Application of the FMEA in insurance of high-risk industries: a case study of Iran’s gas refineries. Stoch Environ Res Risk Assess 30(2):737–745

Guneri AF, Gul M, Ozgurler S (2015) A fuzzy AHP methodology for selection of risk assessment methods in occupational safety. Int J Risk Assess Manag 18(3–4):319–335

Halabi LM, Mekhilef S, Hossain M (2018) Performance evaluation of hybrid adaptive neuro-fuzzy inference system models for predicting monthly global solar radiation. Appl Energy 213:247–261

Hatami-Marbini A, Agrell PJ, Tavana M, Khoshnevis P (2017) A flexible cross-efficiency fuzzy data envelopment analysis model for sustainable sourcing. J Clean Prod 142:2761–2779

ILO (2017) Safety and health at work. International Labor Organization. http://www.ilo.org/global/topics/safety-and-health-at-work/lang–en/index.htm. Accessed 30 Feb 2019

ISIPO (2016) Health, safety, security and environment report. Iran Small Industries and Industrial Parks organization, Tehran

Jiang W, Xie C, Luo Y, Tang Y (2017) Ranking Z-numbers with an improved ranking method for generalized fuzzy numbers. J Intell Fuzzy Syst 32(3):1931–1943

Kang YK, Kim H, Heo G, Song SY (2017) Diagnosis of feedwater heater performance degradation using fuzzy inference system. Expert Syst Appl 69:239–246

Kerk YW, Tay KM, Lim CP (2017) An analytical interval fuzzy inference system for risk evaluation and prioritization in failure mode and effect analysis. IEEE Syst J 11(3):1589–1600

Kłosowski G, Gola A, Świć A (2016) Application of fuzzy logic in assigning workers to production tasks. In: 13th International conference on distributed computing and artificial intelligence. Springer, Cham, pp 505–513

Kumar P, Singh RK, Shankar R (2017) Efficiency measurement of fertilizer-manufacturing organizations using Fuzzy data envelopment analysis. J Manag Anal 4(3):276–295

Kwolek B, Kepski M (2016) Fuzzy inference-based fall detection using kinect and body-worn accelerometer. Appl Soft Comput 40:305–318

Liu HC, Liu L, Liu N, Mao LX (2012) Risk evaluation in failure mode and effects analysis with extended VIKOR method under fuzzy environment. Expert Syst Appl 39(17):12926–12934

Liu HC, Liu L, Liu N (2013a) Risk evaluation approaches in failure mode and effects analysis: a literature review. Expert Syst Appl 40(2):828–838

Liu KFR, Ko CY, Fan C, Chen CW (2013b) Incorporating the LCIA concept into fuzzy risk assessment as a tool for environmental impact assessment. Stoch Environ Res Risk Assess 27(4):849–866

Lovell CK, Pastor JT (1999) Radial DEA models without inputs or without outputs. Eur J Oper Res 118(1):46–51

Mangeli M, Shahraki A, Saljooghi FH (2019) Improvement of risk assessment in the FMEA using nonlinear model, revised fuzzy TOPSIS, and support vector machine. Int J Ind Ergon 69:209–216

McKenzie LM, Witter RZ, Newman LS, Adgate JL (2012) Human health risk assessment of air emissions from development of unconventional natural gas resources. Sci Total Environ 424:79–87

Nazeri A, Naderikia R (2017) A new fuzzy approach to identify the critical risk factors in maintenance management. Int J Adv Manuf Technol 92(9–12):3749–3783

Peeters JFW, Basten RJ, Tinga T (2018) Improving failure analysis efficiency by combining FTA and FMEA in a recursive manner. Reliab Eng Syst Saf 172:36–44

Pourjavad E, Mayorga RV (2019) A comparative study and measuring performance of manufacturing systems with Mamdani fuzzy inference system. J Intell Manuf 30(3):1085–1097

Renjith VR, Kumar PH, Madhavan D (2018) Fuzzy FMECA (failure mode effect and criticality analysis) of LNG storage facility. J Loss Prev Process Ind 56:537–547

Rezaee MJ, Yousefi S (2018) An intelligent decision making approach for identifying and analyzing airport risks. J Air Transp Manag 68:14–27

Rezaee MJ, Salimi A, Yousefi S (2017a) Identifying and managing failures in stone processing industry using cost-based FMEA. Int J Adv Manuf Technol 88(9–12):3329–3342

Rezaee MJ, Yousefi S, Babaei M (2017b) Multi-stage cognitive map for failures assessment of production processes: an extension in structure and algorithm. Neurocomputing 232:69–82

Rezaee MJ, Yousefi S, Valipour M, Dehdar MM (2018) Risk analysis of sequential processes in food industry integrating multi-stage fuzzy cognitive map and process failure mode and effects analysis. Comput Ind Eng 123:325–337

Salamai A, Hussain OK, Saberi M, Chang E, Hussain FK (2019) Highlighting the importance of considering the impacts of both external and internal risk factors on operational parameters to improve Supply Chain Risk Management. IEEE Access 7:49297–49315

Si H, Ji H, Zeng X (2012) Quantitative risk assessment model of hazardous chemicals leakage and application. Saf Sci 50(7):1452–1461

Stamatis DH (2003) Failure mode and effect analysis: FMEA from theory to execution. ASQ Quality Press, Milwaukee

Tavana M, Khalili-Damghani K, Arteaga FJS, Mahmoudi R, Hafezalkotob A (2018) Efficiency decomposition and measurement in two-stage fuzzy DEA models using a bargaining game approach. Comput Ind Eng 118:394–408

Tone K (2001) A slacks-based measure of efficiency in data envelopment analysis. Eur J Oper Res 130(3):498–509

Trafialek J, Kolanowski W (2014) Application of failure mode and effect analysis (FMEA) for audit of HACCP system. Food Control 44:35–44

Wang W, Liu X, Qin J, Liu S (2019) An extended generalized TODIM for risk evaluation and prioritization of failure modes considering risk indicators interaction. IISE Trans. https://doi.org/10.1080/24725854.2018.1539889

Wanke P, Barros CP, Nwaogbe OR (2016) Assessing productive efficiency in Nigerian airports using Fuzzy-DEA. Transp Policy 49:9–19

Wanke P, Alvarenga H, Correa H, Hadi-Vencheh A, Azad MAK (2017) Fuzzy inference systems and inventory allocation decisions: exploring the impact of priority rules on total costs and service levels. Expert Syst Appl 85:182–193

Yazdi M, Daneshvar S, Setareh H (2017) An extension to fuzzy developed failure mode and effects analysis (FDFMEA) application for aircraft landing system. Saf Sci 98:113–123

Yel E, Yalpir S (2011) Prediction of primary treatment effluent parameters by Fuzzy Inference System (FIS) approach. Procedia Comput Sci 3:659–665

Yousefi S, Alizadeh A, Hayati J, Baghery M (2018) HSE risk prioritization using robust DEA-FMEA approach with undesirable outputs: a study of automotive parts industry in Iran. Saf Sci 102:144–158

Yousefi S, Rezaee MJ, Solimanpur M (2019) Supplier selection and order allocation using two-stage hybrid supply chain model and game-based order price. Oper Res Int J. https://doi.org/10.1007/s12351-019-00456-6

Zhou Q, Thai VV (2016) Fuzzy and grey theories in failure mode and effect analysis for tanker equipment failure prediction. Saf Sci 83:74–79

Zimmermann HJ (1996) Fuzzy control. In: Fuzzy set theory and its applications. Springer, Dordrecht, pp 203–240

Acknowledgements

The data of this research was provided by K.C.K.Ch Company. We are thankful for managing director of this company and other experts who provided data, information and contributed expert advice needed for this research.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix 1: Fuzzy SBDEA model

In Models (6) and (7), \( (\delta_{k} )_{\alpha }^{U} \) and \( (\delta_{k} )_{\alpha }^{L} \) respectively represent the Upper Bound (UB) and Lower Bound (LB) of the efficiency of the kth DMU under various α levels. Also, \( (X_{ik} )_{\alpha }^{U} \) and \( (X_{ik} )_{\alpha }^{L} \) respectively represent the UB and LB of ith deterministic input for DMUj per α level, and UB and LB of rth non-deterministic output for DMUj per α level.

Appendix 2: Fuzzy super efficiency SBDEA model

In Models (8) and (9), \( (\,\tau_{k} )_{\alpha }^{U} \) and \( (\,\tau_{k} )_{\alpha }^{L} \) respectively represent the UB and LB of the super efficiency of the kth DMU under various α levels.

Rights and permissions

About this article

Cite this article

Jahangoshai Rezaee, M., Yousefi, S., Eshkevari, M. et al. Risk analysis of health, safety and environment in chemical industry integrating linguistic FMEA, fuzzy inference system and fuzzy DEA. Stoch Environ Res Risk Assess 34, 201–218 (2020). https://doi.org/10.1007/s00477-019-01754-3

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00477-019-01754-3