Abstract

This study reports the properties of immobilized MAS1-H108A lipase from marine Streptomyces sp. strain W007 on XAD1180 resin and its application in the synthesis of n-3 polyunsaturated fatty acids (PUFA)-rich triacylglycerols (TAG) for the first time. It was found that the optimal temperature and pH for both immobilized MAS1-H108A lipase and free lipase MAS1-H108A were 70 °C and 7.0, respectively. However, immobilized MAS1-H108A lipase exhibited higher thermostability when compared with free lipase MAS1-H108A. It was also interesting that both immobilized MAS1-H108A lipase and free lipase MAS1-H108A showed no regiospecificity in the hydrolysis of triolein. Subsequently, immobilized MAS1-H108A lipase and free lipase MAS1-H108A were employed to catalyze glycerolysis of n-3 PUFA-rich ethyl esters (EE) and esterification of n-3 PUFA with glycerol under vacuum in the solvent-free system. The results showed that n-3 PUFA-rich TAG were synthesized efficiently by non-regiospecific immobilized MAS1-H108A lipase and TAG contents separately reached 92.07% and 76.13% during the esterification and glycerolysis reactions, which were significantly higher than those (71.82% and 39.62%, respectively) obtained by free lipase MAS1-H108A. Besides, TAG exhibited similar n-3 PUFA composition to the substrate. These findings indicated that non-regiospecific immobilized MAS1-H108A lipase is a promising and efficient biocatalyst for the industrial synthesis of n-3 PUFA-rich TAG.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Long-chain n-3 polyunsaturated fatty acids (PUFA), particularly docosahexaenoic acid (DHA) and eicosapentaenoic acid (EPA), have health benefits in the prevention and reduction of some diseases such as chronic inflammatory diseases, cardiovascular disease, and cancer [1,2,3]. Recent studies have shown that n-3 PUFA-rich triacylglycerols (TAG) exhibit higher bioavailability than n-3 PUFA-rich ethyl esters (EE) and are more stable than free n-3 PUFA [4, 5]. Moreover, it was demonstrated that n-3 PUFA-rich TAG could prevent cardiovascular disease and cancer, inhibit inflammation, and reduce the risk of atherosclerosis [6,7,8,9]. Therefore, there is increasing interest in synthesizing n-3 PUFA-rich TAG [10,11,12].

Nowadays, enzymatic synthesis of n-3 PUFA-rich TAG is more desirable owing to its higher catalytic efficiency, milder reaction conditions, higher substrate and positional selectivity, and less n-3 PUFA oxidation when compared with chemical methods [13,14,15]. Generally, enzymatic esterification of n-3 PUFA with glycerol and enzymatic glycerolysis of n-3 PUFA-rich EE are widely employed to synthesize n-3 PUFA-rich TAG [16, 17]. Although some lipases have been used in the synthesis of n-3 PUFA-rich TAG [18,19,20], n-3 PUFA-rich TAG are still difficult to be synthesized efficiently and rapidly. Therefore, further exploration of other lipases with greater thermostability and superior ability for the production of n-3 PUFA-rich TAG will always be required by the swiftly developing industries.

A mutant lipase MAS1-H108A from marine Streptomyces sp. strain W007 [21] with 1.6-fold enzymatic activity of wild type was discovered in our lab and has attracted widespread attention due to its thermostability and non-regiospecificity [22, 23]. Moreover, immobilized MAS1-H108A lipase exhibited high catalytic activity in the synthesis of conjugated linoleic acid (CLA)-rich TAG and CLA-rich lysophosphatidylcholine [24, 25]. However, less information is available about its catalytic performances in the production of n-3 PUFA-rich TAG. For further industrial applications, it is of great importance to fully exploit the ability of lipase MAS1-H108A to catalyze various reactions of industrial interest.

Immobilized lipases have received a great deal of attention in recent decades by virtue of their good resistant to environmental changes, high stability, activity and selectivity, good durability and recyclability when compared with free lipases [26, 27]. Therefore, the aim of this study was to evaluate the enzymatic properties of immobilized MAS1-H108A lipase and its catalytic performances in the synthesis of n-3 PUFA-rich TAG. First, a thermostable mutant lipase MAS1-H108A was immobilized onto hydrophobic XAD1180 resin by physical adsorption. Then, the properties of immobilized MAS1-H108A lipase were investigated in this study. Finally, the catalytic performances and reaction mechanism of immobilized MAS1-H108A lipase-catalyzed glycerolysis of n-3 PUFA-rich EE and esterification of n-3 PUFA with glycerol for the production of n-3 PUFA-rich TAG under vacuum in the solvent-free system were evaluated.

Materials and methods

Materials

The X33/MAS1-H108A strain was stored in 50% glycerol solution (v/v) at − 80 °C. DHA/EPA-rich ethyl esters (EE) were purchased from Sinomega Biotech Engineering Co., Ltd. (Zhejiang, China). The Amberlite XAD1180 resin was obtained from Rohm and Haas Company (USA). Formic acid, 2-propanol and n-hexane of chromatographic grade were sourced from Kermel Chemical Reagent Co., Ltd. (Tianjin, China). Standards of 37-component fatty acid methyl esters (FAME) mix (C4–C24), trioleoylglycerol, dioleoylglycerol (15% of 1,2-dioleoylglycerol and 85% of 1,3-dioleoylglycerol), monooleoylglycerol were purchased from Sigma-Aldrich. All other chemicals and solvents were of analytical grade unless otherwise stated. In this study, the composition of n-3 PUFA was the sum of the composition of EPA, docosapentaenoic acid (DPA) and DHA.

Production and immobilization of lipase MAS1-H108A

Lipase MAS1-H108A was produced by the method described earlier [22]. After fermentation, the supernatant was collected by centrifugation with a speed of 10,000 g at 4 °C for 30 min, filtered and concentrated using a 10 kDa molecular mass membrane (Sartorius, Germany). Finally, the obtained fermentation broth was stored in sealed vials at 4 °C until use. The hydrolytic activity of the mutant lipase MAS1-H108A was detected to be 930 U/mL according to the olive oil emulsion method described previously [28].

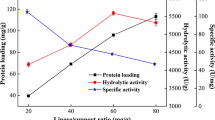

A non-commercial mutant lipase MAS1-H108A was immobilized onto XAD1180 resin (hydrophobic support) by physical adsorption according to the following procedures: First, the supernatant of crude lipase MAS1-H108A (75 mg/g resin) with an equal volume of 0.02 mol/L pH 8.0 sodium phosphate buffer were mixed and then the mixture was added to a 2 L conical flask containing XAD1180 resin. Subsequently, the flask was placed in a thermostatic water bath oscillator with a speed of 200 rpm at 30 °C for 8 h. After that, immobilized MAS1-H108A lipase was recovered by filtration and repeatedly washed with 0.02 mol/L sodium phosphate buffer (pH 8.0) until no protein was detected in the filtrate. Finally, the obtained immobilized MAS1-H108A lipase was dried under vacuum at 40 °C for 8 h and stored in sealed vials at 4 °C until use.

Determination of the esterification activity of immobilized MAS1-H108A lipase

The esterification activities of immobilized MAS1-H108A lipase and lyophilized free lipase MAS1-H108A were determined by the method described previously [29]. First, the reaction mixture containing 20 mM lauric acid, 20 mM 1-propanol and 3% water (w/w, with respect to total reactants) was added to a 100 mL conical flask. Then, the flask was incubated in a thermostatic water bath oscillator with a speed shaking of 200 r/min at 60 °C for 10 min. Subsequently, immobilized MAS1-H108A lipase and lyophilized free lipase MAS1-H108A were separately added to start the reactions. After 10 min, samples (30 μL) were withdrawn and mixed with n-heptane (970 μL). The analysis of propyl ester was performed using gas chromatography (GC) equipped with a column OV351 (60 m × 0.32 mm × 0.10 μm) as described previously [30].

Properties of immobilized MAS1-H108A lipase on XAD1180 resin

Effects of temperature on the activity of immobilized MAS1-H108A lipase

The effects of temperature on the hydrolytic activities of free lipase MAS1-H108A and immobilized MAS1-H108A lipase were investigated at pH 7.0 in temperature range varying from 50 to 90 °C. The hydrolytic activities of free lipase MAS1-H108A and immobilized MAS1-H108A lipase at different temperatures were determined according to the method described previously [28]. Relative activities of each lipase were calculated as the ratio of the hydrolytic activity of the lipase measured at various temperatures to the maximal activity of the lipase measured as described above.

Effects of pH on the activity of immobilized MAS1-H108A lipase

The effects of pH on the hydrolytic activities of free lipase MAS1-H108A and immobilized MAS1-H108A lipase were assessed at 70 °C in the pH range varying from 5 to 9. The hydrolytic activities of free lipase MAS1-H108A and immobilized MAS1-H108A lipase at different pH were measured as described previously [28]. Relative activities of each lipase were calculated as described above.

Thermostability of immobilized MAS1-H108A lipase

The thermostabilities of free lipase MAS1-H108A and immobilized MAS1-H108A lipase were evaluated by measuring their residual hydrolytic activities after incubation at 65 °C for 3 h. During incubation, samples were withdrawn at selected times and their hydrolytic activities were determined according to previous report [28]. The initial activity of the lipases was set as 100%, while the activity of the lipases after incubation was calculated accordingly.

Regiospecificity of immobilized MAS1-H108A lipase

The regiospecificities of free lipase MAS1-H108A and immobilized MAS1-H108A lipase were determined in the hydrolysis of triolein by the previous method [31]. During the reactions, samples were withdrawn periodically for high-performance liquid chromatography (HPLC) analysis. The 1,2(2,3)-DAG/1,3-DAG ratio was used as an indicator to evaluate the regiospecificity of the lipases.

Esterification of n-3 PUFA with glycerol

n-3 PUFA-rich EE were used to prepare free n-3 PUFA as described previously [32]. The catalytic performances of immobilized MAS1-H108A lipase and lyophilized free lipase MAS1-H108A were evaluated in the synthesis of n-3 PUFA-rich TAG by esterification of n-3 PUFA with glycerol under vacuum in the solvent-free system. The esterification reactions were performed under the following conditions: glycerol/n-3 PUFA molar ratio of 1:3, and enzyme loading of 150 U/g substrate at a temperature of 65 °C for 24 h. During the reactions, samples were withdrawn at periodic intervals and prepared for the glycerides compositions analysis by HPLC. Besides, the n-3 PUFA composition of n-3 PUFA-rich TAG in the final product was analyzed by GC.

Glycerolysis of n-3 PUFA-rich EE

To produce n-3 PUFA-rich TAG, immobilized MAS1-H108A lipase and lyophilized free lipase MAS1-H108A were used to catalyze the glycerolysis of n-3 PUFA-rich EE under vacuum in the solvent-free system. The glycerolysis reactions were performed in a glass vessel containing 10 g substrates (glycerol/n-3 PUFA-rich EE molar ratio of 1:4.13) and enzyme loading of 163.8 U/g substrate at a speed of 200 rpm and a temperature of 65 °C for 24 h. During the glycerolysis reactions, samples were withdrawn periodically and prepared for HPLC and GC analysis.

Analysis of FA composition of TAG by GC

Before the analysis, TAG was separated from the reaction mixtures using a thin layer chromatography plate and the developing solvent was a mixture of n-hexane, ethyl ether, and acetic acid (80:20:1, v/v/v) according to the method described previously [33]. Then, the scraped TAG bands and the substrate were separately methylated to FAME according to the literature [34]. Finally, the FA composition of TAG in the reaction mixtures and the substrate was analyzed using an Agilent 7890A GC equipped with a capillary column CP-Sil 88 (60 m × 0.25 mm × 0.2 μm) by the previous report [35].

Analysis of the composition of the reaction mixture by HPLC

A normal-phase HPLC equipped with a refractive index detector and a Phenomenex Luna column (250 mm × 4.6 mm i.d., 5 μm particle size, Phenomenex Corporation) was used to analyze the composition of the reaction mixture as described previously [36]. The mobile phase consisted of n-hexane, isopropanol and formic acid (21:1:0.003, v/v/v) with a flow rate of 1 mL/min. Peaks in HPLC were determined by comparison of their retention times with those known standards. Retention times were 3.10 min (TAG), 3.34 min (EE), 3.76 min (FA), 4.73 min [1,3-diacylglycerols (DAG)], 6.25 min [1,2(2,3)-DAG], 32.51 min [1(3)-monoacylglycerols (MAG)], 37.93 min (2-MAG). Waters 2695 integration software was utilized to analyze the data and calculate peak-area percentages. During the esterification reactions, esterification degree was expressed as the percentage of initial FA consumed in the reaction mixture as calculated from peak areas. During the glycerolysis reactions, EE conversion was defined as the weight percentage of initial EE consumed in the reaction mixture as obtained from peak areas.

Statistical analysis

All assays were performed in triplicate. The significant differences among the measured values were evaluated by an ANOVA procedure and the data were given as the means ± standard deviations (SD).

Results and discussions

Properties of immobilized MAS1-H108A lipase on XAD1180 resin

Effects of temperature on the activity of immobilized MAS1-H108A lipase

The effects of temperature on the hydrolytic activities of free lipase MAS1-H108A and immobilized MAS1-H108A lipase were investigated in the range from 50 to 90 °C. The results are given in Fig. 1. When temperature varied from 50 to 70 °C, the hydrolytic activities of free lipase MAS1-H108A and immobilized MAS1-H108A lipase increased with increasing temperature. After that, the hydrolytic activities of free lipase MAS1-H108A and immobilized MAS1-H108A lipase decreased when the temperature was further increased from 70 to 90 °C. Thus, the optimum temperature for both free lipase MAS1-H108A and immobilized MAS1-H108A lipase was 70 °C. It was also observed that immobilized MAS1-H108A lipase showed a different trend with free lipase MAS1-H108A. After immobilization, immobilized MAS1-H108A lipase retained higher hydrolytic activity than free lipase MAS1-H108A when the temperature was over 70 °C. This was probably because XAD1180 resin may be protecting lipase MAS1-H108A against thermal denaturation after immobilization. Similar results were also observed by Liu et al. [37] and Li et al. [38].

Effects of pH on the activity of immobilized MAS1-H108A lipase

The effects of pH on the hydrolytic activities of free lipase MAS1-H108A and immobilized MAS1-H108A lipase are shown in Fig. 2. The optimal pH for both free lipase MAS1-H108A and immobilized MAS1-H108A lipase was 7.0. Above or below the optimal pH, the hydrolytic activities of free lipase MAS1-H108A and immobilized MAS1-H108A lipase decreased. It was also observed that free lipase MAS1-H108A and immobilized MAS1-H108A lipase exhibited relatively higher hydrolytic activity under alkaline conditions compared with the acidic conditions. Moreover, immobilized MAS1-H108A lipase retained relatively higher hydrolytic activity than free lipase MAS1-H108A when pH varied from 5 to 9.

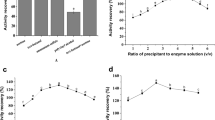

Thermostability of immobilized MAS1-H108A lipase

The thermostabilities of free lipase MAS1-H108A and immobilized MAS1-H108A lipase were evaluated and the results are presented in Fig. 3. It was observed that the hydrolytic activity of free lipase MAS1-H108A decreased more quickly than that of immobilized MAS1-H108A lipase when these two lipases were separately incubated at 65 °C for 3 h. Free lipase MAS1-H108A retained only 16% of its initial activity after incubation at 65 °C for initial 30 min. As time prolonged, the hydrolytic activity of free lipase MAS1-H108A decreased gradually and linearly. However, immobilized MAS1-H108A lipase retained 87% and 47% of its initial activity after incubation at 65 °C for 30 min and 3 h, respectively. The results indicated that the thermostability of lipase MAS1-H108A was greatly enhanced after its immobilization onto XAD1180 resin by physical adsorption.

Regiospecificity of immobilized MAS1-H108A lipase

The regiospecificities of free lipase MAS1-H108A and immobilized MAS1-H108A lipase were evaluated during the hydrolysis of triolein and the results are shown in Fig. 4. It was observed that the hydrolysates obtained by free lipase MAS1-H108A consisted of 86.88% TAG, 5.11% FFA, 4.83% 1,3-DAG, 2.75% 1,2-DAG, and 0.43% 1-MAG after 10 min of reaction. Moreover, the ratio of 1,2-DAG to 1,3-DAG obtained by free lipase MAS1-H108A decreased from 0.73 to 0.57 when reaction time increased from 1 to 10 min (Fig. 4a), which was similar to that (1,2-DAG/1,3-DAG ratio of 0.79–0.65) obtained by immobilized MAS1-H108A lipase during the hydrolysis of triolein (Fig. 4b). The results indicated that the immobilization process has no significant effect on the regiospecificity of lipase MAS1-H108A. It was also found that both immobilized MAS1-H108A lipase and free lipase MAS1-H108A exhibited no regiospecificity during the hydrolysis of triolein when compared with 1,3-regiospecific lipase rPro-ROL (1,2-DAG/1,3-DAG ratio increasing from 3.3 to 26.7, [36]) and non-regiospecific lipase AYS (1,2-DAG/1,3-DAG ratio decreasing from 4.7 to 3.0, [31]).

Synthesis of n-3 PUFA-rich TAG by immobilized MAS1-H108A lipase

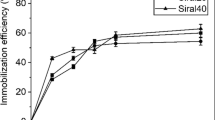

Esterification of n-3 PUFA with glycerol

The esterification activities of immobilized MAS1-H108A lipase and free lipase MAS1-H108A were determined to be 1448 U/g and 95 U/g, respectively. The time course of free lipase MAS1-H108A and immobilized MAS1-H108A lipase-catalyzed esterification of glycerol with n-3 PUFA under the same conditions are presented in Fig. 5. As shown in Fig. 5a, when the esterification reactions were catalyzed by immobilized MAS1-H108A lipase, TAG content and esterification degree increased dramatically as the reaction proceeded. However, 1,3-DAG, 1,2-DAG, and 1-MAG content separately increased slowly and reached the maximum at 3 h. After that, 1,3-DAG, 1,2-DAG, and 1-MAG content decreased gradually as reaction time was prolonged from 3 to 24 h. It was found that 2-MAG content was not observed during the esterification reactions. Moreover, it was observed that DAG content was higher than MAG content whereas DAG content was lower than TAG content during the time course of the reaction. This was probably because the formation of FA → MAG → DAG → TAG reactions catalyzed by non-regiospecific immobilized MAS1-H108A lipase was spontaneous. After 24 h of reaction, the final product consisted of 92.07% TAG, 2.46% FFA, 3.05% 1,3-DAG, 2.3% 1,2-DAG and 0.12% 1-MAG. It could be concluded that the glycerides composition obtained by immobilized MAS1-H108A lipase was similar to that of natural fish oils containing a major proportion of TAG and minor proportions of DAG and MAG. Besides, esterification degree reached 97.54% at 24 h when immobilized MAS1-H108A lipase was employed to catalyze the esterification reactions. The results indicated that the complete conversion from FA to TAG can be achieved by immobilized MAS1-H108A lipase-catalyzed esterification reactions. More importantly, TAG content (92.07%) and esterification degree (97.54%) obtained by immobilized MAS1-H108A lipase (Fig. 5a) were higher than those (71.82% and 81.2%, respectively) by free lipase MAS1-H108A (Fig. 5b) after 24 h of reaction. Furthermore, lower DAG content (5.35%) and MAG content (0.12%) were obtained by immobilized MAS1-H108A lipase (Fig. 5a) than those (9.11% and 0.27%, respectively) by free lipase MAS1-H108A (Fig. 5b). It could be concluded that immobilized MAS1-H108A lipase exhibited higher catalytic efficiency than free lipase MAS1-H108A in the esterification reactions. As shown in Table 1, n-3 PUFA-rich TAG obtained by immobilized MAS1-H108A lipase were found to have similar n-3 PUFA composition to the substrate. Therefore, non-regiospecific immobilized MAS1-H108A lipase with high catalytic activity is a promising industrial lipase for the synthesis of n-3 PUFA-rich TAG.

Glycerolysis of n-3 PUFA-rich EE

Although high n-3 PUFA-rich TAG content was obtained when immobilized MAS1-H108A lipase and free lipase MAS1-H108A were used to catalyze the esterification of n-3 PUFA with glycerol, n-3 PUFA are prepared from n-3 PUFA-rich EE [32] and are easy to isomerize, oxidize, and polymerize during the reactions [10]. Moreover, n-3 PUFA-rich EE are the main available n-3 PUFA form in the market. Thus, the catalytic abilities of free lipase MAS1-H108A and immobilized MAS1-H108A lipase-catalyzed glycerolysis of n-3 PUFA-rich EE for the synthesis of n-3 PUFA-rich TAG under vacuum were also evaluated in this study and the results are given in Fig. 6. As presented in Fig. 6a, when immobilized MAS1-H108A lipase was used to catalyze the glycerolysis reactions, EE conversion and TAG content separately increased dramatically as the reaction proceeded and finally reached 80.97% and 76.13%, respectively. After 24 h of reaction, EE content decreased to be 19.03% whereas 1,3-DAG, 1,2-DAG and 1-MAG content were 3.64%, 1.17% and 0.04%, respectively. 2-MAG content was not observed during the glycerolysis reactions. It was found that TAG content was the highest, followed by DAG content, and MAG content was the lowest throughout the whole reaction. This was probably because three consecutive reversible reactions from glycerol to TAG during the glycerolysis reactions catalyzed by non-regiospecific immobilized MAS1-H108A lipase were all fast and spontaneous. Thus, there were no MAG and DAG content accumulated during the glycerolysis reactions. More importantly, EE conversion (80.97%) and TAG content (76.13%) obtained by immobilized MAS1-H108A lipase (Fig. 6a) were higher than those (52.55% and 39.62%, respectively) by free lipase MAS1-H108A (Fig. 6b). The results showed that the catalytic efficiency of immobilized MAS1-H108A lipase was better than that of free lipase MAS1-H108A in the glycerolysis reactions. Furthermore, it was also observed that the n-3 PUFA composition of TAG in the final product obtained by immobilized MAS1-H108A lipase-catalyzed glycerolysis reactions was similar to that of the original EE (Table 1). Therefore, immobilized MAS1-H108A lipase is a potential biocatalyst for the modification of oils and fats. Overall, immobilized MAS1-H108A lipase is an efficient biocatalyst for the synthesis of n-3 PUFA-rich TAG by glycerolysis of n-3 PUFA-rich EE and esterification of glycerol with n-3 PUFA when compared with free lipase MAS1-H108A.

In the esterification reactions, water is a side product that can form a water phase in the biocatalysts and promote the hydrolytic process. The alcohol released in the glycerolysis reactions may act as a competitor for glycerol and change the conformation and performances of the lipase. Thus, the vacuum was used to eliminate the produced alcohol and water in this study. Moreover, it could be seen from the above results that lower n-3 PUFA-rich TAG content was obtained in the glycerolysis reactions than that in the esterification reactions when immobilized MAS1-H108A lipase was employed as the biocatalyst. To obtain highly pure n-3 PUFA-rich TAG product, the reaction mixture in the glycerolysis reactions needs to be further purified by molecular distillation. It could be found that the processes are complicated, high energy consumption, and high cost. However, n-3 PUFA-rich TAG content in the esterification reactions reached 92.07%, which is similar to that in natural fish oil. The results indicated that the final product in the esterification reactions don’t require further purification and the synthesis processes are simplified. Although higher TAG content was obtained in the esterification reactions, n-3 PUFA are easy to isomerize, oxidize, and polymerize during the reactions. Moreover, n-3 PUFA are prepared from n-3 PUFA-rich EE, which was the main available n-3 PUFA form in the market. Thus, these two strategies have their own advantages and problems. Nevertheless, in terms of economy and TAG content, it was better and more effective when immobilized MAS1-H108A lipase was used to catalyze the esterification of glycerol with n-3 PUFA for the synthesis of n-3 PUFA-rich TAG.

According to the above results, it could be conferred that the reaction mechanism of immobilized MAS1-H108A lipase-catalyzed the esterification and glycerolysis reactions for the efficient synthesis of n-3 PUFA-rich TAG (Fig. 7) could proceed as follows: Glycerolysis of n-3 PUFA-rich EE and esterification of glycerol with n-3 PUFA both contains three consecutive reversible reactions. Glycerol is first converted to MAG, followed by the conversion from MAG to DAG, and finally DAG is converted to TAG. Immobilized MAS1-H108A lipase is a non-regiospecific lipase and can migrate acyl groups from n-3 PUFA or n-3 PUFA-rich EE to sn-1, 2, and 3 hydroxyl group of glycerol. Thus, 1,2-DAG and 1,3-DAG are synthesized simultaneously and converted to TAG spontaneously. However, when 1,3-regiospecific immobilized lipase was employed to catalyze the esterification and glycerolysis reactions, 1,3-DAG was the main reaction product. TAG was formed mainly through the acyl migration from 1,3-DAG to 1,2-DAG and then a second acylation of 1,2-DAG because n-3 PUFA or n-3 PUFA-rich EE were difficult to react with the sn-2 hydroxyl group of 1,3-DAG (Fig. 7 dashed lines). In conclusion, the conversion from DAG to TAG is a rate-limiting step during 1,3-regiospecific immobilized lipase-catalyzed esterification and glycerolysis reactions for the synthesis of n-3 PUFA-rich TAG. Therefore, n-3 PUFA-rich TAG could be synthesized efficiently and rapidly by non-regiospecific immobilized MAS1-H108A lipase.

Conclusions

In this study, immobilized MAS1-H108A lipase on XAD1180 resin was found to have similar regiospecificity, optimal temperature and pH to free lipase MAS1-H108A, but its thermostability was higher than that of free lipase MAS1-H108A. Moreover, n-3 PUFA-rich TAG was efficiently synthesized by non-regiospecific immobilized MAS1-H108A lipase-catalyzed glycerolysis of n-3 PUFA-rich EE and esterification of n-3 PUFA with glycerol under vacuum in the solvent-free system. TAG contents separately reached 92.07% and 76.13% during the esterification and glycerolysis reactions, which were significantly higher than those (71.82% and 39.62%, respectively) obtained by free lipase MAS1-H108A. Besides, no significant difference was observed in the n-3 PUFA composition between n-3 PUFA-rich TAG obtained by immobilized MAS1-H108A lipase and the substrate. These findings suggested that non-regiospecific immobilized MAS1-H108A lipase with high catalytic activity is a promising and efficient biocatalyst for industrial production of n-3 PUFA-rich TAG.

References

Cleland LG, Caughey GE, James MJ, Proudman SM (2006) Reduction of cardiovascular risk factors with long term fish oil treatment in early rheumatoid arthritis. J Rheumatol 33:1973–1979

Corsetto PA, Montorfano G, Zava S, Jovenitti IE, Cremona A, Berra B, Rizzo AM (2011) Effects of n-3 PUFAs on breast cancer cells through their incorporation in plasma membranes. Lipids Health Dis 12:10–73

Giudetti AM, Cagnazzo R (2012) Beneficial effects of n-3 PUFA on Chronic airway inflammatory diseases. Prostag Oth Lipid M 99:57–67

Lawson LD, Hughes BG (1988) Human absorption of fish oil fatty acids as triacylglycerols, free acids, or ethyl esters. Biochem Bioph Res Co 152:328–335

Valenzuela A, Valenzuela V, Sanhueza J, Nieto S (2005) Effect of supplementation with docosahexaenoic acid ethyl ester and sn-2 docosahexaenyl monoacylglyceride on plasma and erythrocyte fatty acids in rats. Ann Nutr Metab 49:49–53

Nestel PJ (2000) Fish oil and cardiovascular disease: lipids and arterial function. Am J Clin Nutr 71:228S-231S

Ghasemi Fard S, Wang F, Sinclair AJ, Elliott G, Turchini GM (2019) How does high DHA fish oil affect health? A systematic review of evidence. Crit Rev Food Sci 59:1684–1727

Ellulu MS, Khaza’aiAbedRahmatIsmailRanneh HYAPY (2015) Role of fish oil in human health and possible mechanism to reduce the inflammation. Inflammopharmacology 23:79–89

Saraswathi V, Gao L, Morrow JD, Chait A, Niswender KD, Hasty AH (2007) Fish oil increases cholesterol storage in white adipose tissue with concomitant decreases in inflammation, hepatic steatosis, and atherosclerosis in mice. J Nutr 137:1776–1782

Kosugi Y, Azuma N (1994) Synthesis of triacylglycerol from polyunsaturated fatty acid by immobilized lipase. J Am Oil Chem Soc 71:1397–1403

Picq M, Bernoud-Hubac N, Lagarde M (2013) Synthesis and biological interest of structured docosahexaenoic acid-containing triacylglycerols and phospholipids. Curr Org Chem 17:841–847

Moreno-Pérez S, Luna P, Señorans FJ, Guisán JM, Fernandez-Lorente G (2015) Enzymatic synthesis of triacylglycerols of docosahexaenoic acid: transesterification of its ethyl esters with glycerol. Food Chem 187:225–229

Li DM, Wang WF, Li XH, Durrani R, Yang B, Wang YH (2017) Preparation of highly pure n-3 PUFA-enriched triacylglycerols by two-step enzymatic reactions combined with molecular Distillation. J Am Oil Chem Soc 94:225–233

Wang WF, Li T, Ning ZX, Wang YH, Yang B, Ma YJ, Yang XQ (2012) A process for the synthesis of PUFA-enriched triglycerides from high-acid crude fish oil. J Food Eng 109:366–371

Lin TJ, Chen SW, Chang AC (2006) Enrichment of n-3 PUFA contents on triglycerides of fish oil by lipase-catalyzed trans-esterification under supercritical conditions. Biochem Eng J 29:27–34

Liu SC, Zhang CH, Hong PZ, Ji HW (2007) Lipase-catalysed acylglycerol synthesis of glycerol and n-3 PUFA from tuna oil: optimisation of process parameters. Food Chem 103:1009–1015

Sun ZM, Xue CH, Guo ZX, Cong HH, Wang YM, Xue Y, Wang JF (2015) Preparation of triacylglycerols enriched in DHA from single cell glycerides via molecular distillation and enzymatic glycerolysis. J Aquat Food Prod T 24:796–806

Li DM, Wang WF, Liu PZ, Xu L, Faiza M, Yang B, Wang YH (2017) Immobilization of candida antarctica lipase B onto ECR1030 resin and its application in the synthesis of n-3 PUFA-rich triacylglycerols. Eur J Lipid Sci Tech 119:1700266

Li DM, Wang WF, Qin XL, Li XX, Yang B, Wang YH (2016) A novel process for the synthesis of highly pure n-3 polyunsaturated fatty acid (PUFA)-enriched triglycerides by combined transesterification and ethanolysis. J Agri Food Chem 64:6533–6538

Bispo P, Batista I, Bernardino RJ, Bandarra NM (2014) Preparation of triacylglycerols rich in omega-3 fatty acids from sardine oil using a Rhizomucor miehei lipase: focus in the EPA/DHA ratio. Appl Biochem Biotech 172:1866–1881

Yuan DJ, Lan DM, Xin RP, Yang B, Wang YH (2015) Screening and characterization of a thermostable lipase from marine Streptomyces sp. Strain W007. Biotechnol Appl Bioc 63:41–50

Zhao ZX, Hou SL, Lan DM, Wang XM, Liu JS, Khan FI, Wang YH (2017) Crystal structure of a lipase from Streptomyces sp. strain W007–implications for thermostability and regiospecificity. FEBS J 284:3506–3519

Zhao G, Wang JR, Tang QY, Lan DM, Wang YH (2018) Improving the catalytic activity and thermostability of MAS1 lipase by alanine substitution. Mol Biotechnol 60:319–328

Li DM, Wang WF, Zhang L, Liu N, Faiza M, Tan CP, Yang B, Lan DM, Wang YH (2018) Synthesis of CLA-rich lysophosphatidylcholine by immobilized MAS1-H108A-catalyzed esterification: effects of the parameters and monitoring of the reaction process. Eur J Lipid Sci Tech 120:1700529

Lian WS, Li DM, Zhang L, Wang WF, Faiza M, Tan CP, Yang B, Lan DM, Wang YH (2018) Synthesis of conjugated linoleic acid-rich triacylglycerols by immobilized mutant lipase with excellent capability and recyclability. Enzyme Microb Tech 117:56–63

Dong Z, Jiang MY, Shi J, Zheng MM, Huang FH (2019) Preparation of immobilized lipase based on hollow mesoporous silica spheres and its application in ester synthesis. Molecules 24:395

Xing X, Jia JQ, Zhang JF, Zhou ZW, Li J, Wang N, Yu XQ (2019) CALB immobilized onto magnetic nanoparticles for efficient kinetic resolution of racemic secondary alcohols: long-term stability and reusability. Molecules 24:490

Yang B, Wang YH, Yang JG (2006) Optimization of enzymatic degumming process for rapeseed oil. J Am Oil Chem Soc 83:653–658

Basso A, Froment L, Hesseler M, Serban S (2013) New highly robust divinyl benzene/acrylate polymer for immobilization of lipase CALB. Eur J Lipid Sci Technol 115:468–472

Wang WF, Xu Y, Qin XL, Lan DM, Yang B, Wang YH (2014) Immobilization of lipase SMG1 and its application in synthesis partical glycerides. Eur J Lipid Sci Technol 116:1063–1069

Wang XM, Li DM, Qu M, Durrani R, Yang B, Wang YH (2017) Immobilized MAS1 lipase showed high esterification activity in the production of triacylglycerols with n-3 polyunsaturated fatty acids. Food Chem 216:260–267

Senanayake SPJ, Shahidi F (1999) Enzymatic incorporation of docosahexaenoic acid into borage oil. J Am Oil Chem Soc 76:1009–1015

Qin XL, Huang HH, Lan DM, Wang YH, Yang B (2014) Typoselectivity of crude Geobacillus sp. T1 lipase fused with a cellulose-binding domain and its use in the synthesis of structured lipids. J Am Oil Chem Soc 91:55–62

Wang YH, Mai QY, Qin XL, Yang B, Wang ZL, Chen HT (2010) Establishment of an evaluation model for human milk fat substitutes. J Agric Food Chem 58:642–649

Qin XL, Wang YM, Wang YH, Huang HH, Yang B (2011) Preparation and characterization of 1,3-dioleoyl-2-palmitoylglycerol. J Agric Food Chem 59:5714–5719

Li DM, Qin XL, Wang JR, Yang B, Wang WF, Huang WL, Wang YH (2015) Hydrolysis of soybean oil to produce diacylglycerol by a lipase from Rhizopus oryzae. J Mol Catal B-Enzym 115:43–50

Liu N, Li DM, Wang WF, Hollmann F, Xu L, Ma YJ, Yang B, Bai WD, Sun XT, Wang YH (2018) Production and immobilization of lipase PCL and its application in synthesis of α-linolenic acid-rich diacylglycerol. J Food Biochem 42:e12574

Li XX, Li DM, Wang WF, Durrani R, Yang B, Wang YH (2016) Immobilization of SMG1-F278N lipase onto a novel epoxy resin: Characterization and its application in synthesis of partial glycerides. J Mol Catal B Enzym 133:154–160

Acknowledgements

This work was supported by the National Key R & D Program of China (2018YFC0311104), National Natural Science Foundation of China (31801462), National Science Fund for Distinguished Young Scholars (31725022), Guangdong MEPP Fund (NO.GDOE[2019]A20), Education and Research Project of Young and Middle-aged Teachers of Fujian Province (JT180467), the Cultivation Program for the Outstanding Young Scientific Research Talents of Fujian Province University (2018), Science and Technology Department of Putian (2018NP2003), Natural Science Foundation of Fujian Province (2020J05211, 2018J05063), Science and Technology Planning project of Putian University (2018055).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, X., Zhao, X., Qin, X. et al. Properties of immobilized MAS1-H108A lipase and its application in the efficient synthesis of n-3 PUFA-rich triacylglycerols. Bioprocess Biosyst Eng 44, 575–584 (2021). https://doi.org/10.1007/s00449-020-02470-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-020-02470-x