Abstract

Elevated levels of animal waste-borne pathogen in ambient water is a serious human health issue. Mitigating influx of pathogens from animal waste such as dairy manure to soil and water requires improving our existing knowledge of pathogen reductions in dairy manure treatment methods. This study was conducted to enhance the understanding of human pathogen decay in liquid dairy manure in anaerobic (AN) and limited aerobic (LA) storage conditions. The decay of three pathogens (Escherichia coli, Salmonella spp., and Listeria monocytogenes) was assessed in bench-scale batch reactors fed with liquid slurry. A series of temperatures (30, 35, 42, and 50 °C) conditions were tested to determine the impacts of temperature on Escherichia coli, Salmonella, and L. monocytogenes decay in AN and LA conditions. Results showed prolonged survival of E. coli compared to Salmonella and L. monocytogenes in both LA and AN environments. Variations in survival among pathogens with temperature and environmental conditions (i.e., LA and AN) indicated the necessity of developing improved dairy manure waste treatment methods for controlling animal waste-borne pathogens. The results of this study will help in improving the current understanding of human pathogen decay in dairy manure for making informed decisions of animal manure treatment by stakeholders.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

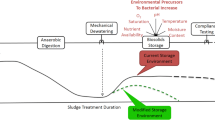

Increased disease outbreaks caused by pathogens over the last decades in the United States [1, 2] is a concern, and mitigating the public health risk requires controlling food and animal waste-borne pathogens in the environment because of potential interface between humans, animals, and the environment [3–5]. Many pathogens including Escherichia coli O157:H7, Salmonella spp. and Listeria monocytogenes, which persist in soil, manure, and water [6–9] has been linked to food related illnesses [10–12]. The shedding of these pathogens in cattle is reported extensively [13–17], and improved manure management has a potential to mitigate pathogens in the environment. In a flushed manure management system (widely used in large-scale dairy farms), water is used for flushing the manure in dairy barns, and flushed manure is passed through liquid—solid separator for separating solid materials, and liquid portion is stored in lagoons where occasional mixing (for partial aeration) is performed [18–20]. Both liquid and solid manure is applied into crop land as a fertilizer, which also poses risk of pathogen contamination in cropland [21–31].

Both the direct deposition of cattle manure to land and overland runoff events (especially after heavy rainfall) [30, 31] causes pathogens transport from crop land to streams resulting in increased surface and ground water contamination. An in vitro study by Bolton et al. [32] demonstrated that when E. coli O157:H7 inoculated manure was applied to soil, the survival of E. coli O157:H7 in soil was prolonged up to 99 days after application. The survival of E. coli O157:H7 in bovine feces ranges from 49 to 126 days at 15 °C [33]. Multiple studies have suggested that manure amended agricultural field or contaminated irrigation water can be the potential source of pathogen contamination in agricultural products [34, 35]. Often raw food and vegetables are more vulnerable to indirect contamination by irrigation water or through soil treated with farm effluents [36]. Increased frequency of outbreaks of human infections associated with raw food and vegetables are attributed to many factors including lack of efficacy of sanitizers in killing pathogens of raw food and vegetables, an increase in per capita consumption of raw or minimally processed foods, increase in the number of immunocompromised consumers, and improved monitoring [37–39].

The survival of pathogens is influenced by many factors including pH, moisture content, C:N ratio, temperature, and solar radiation [40–42]. Temperature is reported to be a dominant factor affecting pathogen survival [36, 43]. Wang et al. [10] tested E. coli survival in bovine feces at 5, 22, and 37 °C by inoculating E. coli O157:H7 (3 [low] and 5 [high] orders of magnitude) in bovine feces. Authors reported E. coli survival in low and high inocula for 42 and 49 days at 37 °C and 49 and 56 days at 22 °C, respectively. At 5 °C, E. coli survived more than 60 and 70 days for low and high inocula. Depending on the temperature conditions, a prolonged survival of pathogens in manure and manure-amended soil is reported previously [44–47]. Relationships of E. coli O157:H7 infection with seasonal temperature pattern (the highest incidence occurred during the warmer months) are also reported [24, 47] indicating the change in pathogenicity or pathogen levels with temperature.

While manure is an important source of nutrients in soil, manure-borne pathogens have the potential to contaminate water as well as soil. If the manure is not treated properly prior to land application, manure-borne pathogens are likely to be transported from crop land to ambient water. Thus, it can potentially increase the risk of transmitting infectious agents such as E. coli O157:H7, Salmonella, or L. monocytogenes from crop land to ambient water. While many of the previous studies have focused on understanding of pathogen indicator survival in manure, this study was focused on studying the extent of human pathogen survival in liquid dairy manure under anaerobic (AN) and limited aerobic (LA) storage conditions. The objectives of the current study were to: (1) understand the effects of AN and LA environment on E. coli O157:H7, Salmonella, and L. monocytogenes survivals; and (2) assess the impacts of temperature and incubation period on the extent of the three pathogens decay during storage.

Materials and methods

Feedstock preparation

To prepare feedstock, solid dairy manure was collected from the University of California, Davis dairy facility located on the campus. The milking herd has a capacity of 100 cows and is registered with Holstein Association, USA. Fresh dairy samples were collected and refrigerated at −20 °C before starting the experiment. Prior to start the experiment, about 1.07 kg of dairy manure was thawed and mixed with 2L of deionized water. It was then sieved through a 850 µm (ASTM #20) mesh to separate the residue from the liquid slurry. The properties of solid manure (collected from dairy) and slurry (feedstock) samples are provided in Table 1.

Pathogen inoculum preparation

Pure strains of E. coli O157:H7 (ATCC# 35150) and Salmonella typhimurium LT2 (ATCC # 700720) were cultured overnight in Luria–Bertani (LB) broth (Difco LB Broth Miller; Becton, Dickinson and Company, Sparks, MD, USA). The strains of L. monocytogenes (ATCC# BAA-679D-5) were cultured in Brain Heart Infusion (BHI) broth (BBL; Becton, Dickinson and Company, Sparks, MD, USA). A bench top incubator shaker (MaxQ 4000, Thermo Scientific, Ohio, USA) was used (100 rpm and 37 °C) for 24 h for growing the three pathogens. Quality control was ensured using a negative control in the respective growth media. The pathogen strains (ATCC#35150, ATCC # 700720, ATCC# BAA-679D-5) have been used previously to understand the pathogen survival in manure and food waste [48–51].

Feedstock inoculation with pathogens

The E.coli levels in manure before inoculation and after inoculation were verified by plating the pure culture samples in agar plates. MacConckey II agar with sorbitol (BBL, Becton, Dickinson and Company, Sparks, MD, USA), which is a selective and differential media for the detection of sorbitol-nonfermenting E. coli O157:H7, was used for E. coli testing and enumeration. When sample was tested on MacConckey II agar with sorbitol, the pure culture of E.coli O157:H7 produced colorless colonies. Pure strain of Salmonella Typhimurium LT2 was grown in Luria–Bertani (LB) broth, and subsequently pure culture was tested into Xylose Lysine Desoxycholate (XLD) agar (Difco, Becton, Dickinson and Company, Sparks, MD, USA) to verify the growth of Salmonella. Colonies with red-yellow with black centers in the agar plates were enumerated as Salmonella. The pure strain of L. monocytogenes grown in BHI growth media was tested in selective agar plates prior to mixing with the feedstock. Polymyxin-Acriflavin-Lithium chloride-Ceftazidime-Aessulin-Mannitol (PALCAM) (HiMedia Laboratory, Mumbai, India) agar (with supplement) was used for plating L. monocytogenes. Gray-green colonies surrounded by dark brown to black halos in the agar plates were enumerated as L. monocytogenes. Pathogen enumeration in the feedstock from the experiment was conducted following the Bacteriological Analytical Manual (BAM) procedures [52]. To enumerate pathogens in feedstock, the slurry samples were serially diluted in Phosphate Buffer Solution (PBS), and the diluted samples (10−1–10−6) were plated in the respective agar for E. coli, Salmonella, and L. monocytogenes enumeration. The detection limit of pathogen was 10 CFU/mL of sample volume. All the samples were analyzed in duplicate.

Feedstock preparation

Pathogens were inoculated in feedstock. To inoculate feedstock with pathognes, the pure culture of E. coli O157:H7, Salmonella, Listeria were grown in 37 °C under controlled conditions. The E. coli, Salmonella, and L. monocytogenes levels in pure culture were 1.7 × 109 CFU/mL, 1.4 × 109 CFU/mL, and 1.7 × 109 CFU/mL, respectively. Subsequently, 4 mL of pure culture of each pathogen was centrifuged at 8000 rpm for 10 min to form the pellets of the three pathogens (E. coli O157:H7, Salmonella spp. and L. monocytogenes). Pellets were then dissolved in the feedstock (i.e., liquid slurry) and mixed with an overhead mixer (Carfamo Limited, Model BDC 250, Georgian Bluffs, Ontario, Canada) at 150 rpm for 10 min at room temperature to form a homogeneous mixture. The initial sample of the inoculated feedstock was collected and tested on the agar plates for calculating E. coli, Salmonella, and L. monocytogenes concentrations in the feedstock.

Experiment setup

The pathogen inoculated feedstock was filled into eight batch reactors (250 mL serum bottles). A schematic diagram showing the outline of experiment describing feedstock preparation and setup is shown in Fig. 1. The four reactors were LA (with no sealing cap), and other four reactors were AN (with sealing cap). Rubber septa were used to seal the AN reactors. The AN conditions in serum bottles were created using the procedure adopted by Pandey and Soupir [43] by escaping the head space air and creating a slightly negative head space pressure. In LA conditions, the top of the serum bottles remained open throughout the experiment allowing the air inside the reactors. Since this experiment was performed for simulating field environment, where aeration and mixing in lagoons are uncertain, the source of air in LA reactors was minimal mixing (i.e., continuous injection of air was not an option). All reactors (LA and AN) were then placed at four temperatures (30, 35, 42, and 50 °C). To understand the mixing effects, a minimal mixing was provided to both LA and AN reactors. Both LA and AN reactors were taken out of incubators every day (for 1 h) and placed on the top of a magnetic stirrer to provide mixing of feedstock inside the reactors. The samples from LA and AN reactors were collected (using the method of Pandey and Soupir [43]) for testing pathogens and calculating the change in pathogen concentrations. The experiment was conducted for 2 weeks. During the first 4 days, samples was collected twice (morning and evening), and afterwards sampling was performed daily. Since the main focus of this study was to assess pathogen decay, biogas including methane content of the biogas produced in AN reactors was not measured.

Data analysis

The decay processes of each pathogen in AN and LA storage conditions were analyzed for 13 days incubation period at four different temperatures. Based on the fact (observations) that the change in pathogen levels was limited in every single day, every other day samples (Day 2, 4, 6, 8, 10, 12 and 13) were used for statistical analysis. Firstly, analysis of variance (ANOVA) was performed to evaluate the impact of treatments (LA and AN) at four temperatures at different days of incubation. The data were log transformed before using the statistical models.

where Y ijk is the pathogen enumeration at any particular day, µ is the overall mean, α i is the effect of treatment i, β j is the effect of temperature j, (αβ) ij is the effect of interaction between treatment and temperature, and ε ijk is the random error.

Secondly, ANOVA was performed to evaluate the impacts of temperatures, and incubation days on pathogen levels where days were used as repeated measures.

where Y jkl is the pathogen enumeration, µ is the overall mean, β j is the effect of temperature j, γ k is the effect of day k, (βγ) jk is the effect of interaction between temperature and day, and ε jkl is the random error. Statistical analysis was done using PROC GLIMMIX in SAS [53]. An alpha level of α = 0.05 was used to identify significant differences among treatments by “least significant difference” methods.

Results and discussion

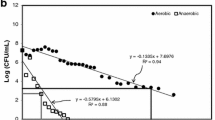

The changes in E. coli, Salmonella, and L. monocytogenes levels at four temperatures under LA and AN storage conditions are shown in Figs. 2, 3, 4 and 5, respectively. Figure 2 shows changes in E. coli, Salmonella and L. monocytogenes in 30 °C. The changes in pathogens at 35 and 42 °C are shown in Figs. 3 and 4, respectively. Figure 5 shows the changes in pathogen concentrations at 50 °C. The initial level of E.coli in the feedstock was 5.4 × 107 CFU/mL after inoculating/spiking the slurry sample with strains. The initial levels of Salmonella and L. monocytogenes in the feedstock were 4 × 107 CFU/mL and 1.26 × 107 CFU/mL, respectively.

Change in a E. coli, b Salmonella, and c L. monocytogens levels at 30 °C in limited aerobic and anaerobic conditions. Gray bars indicate limited aeration condition (LA), while black bars indicate anaerobic condition (AN). Standard deviaiton is show as error bard. Bars represent mean value of duplicate samples

Change in a E. coli, b Salmonella, and c L. monocytogens levels at 35 °C in limited aerobic and anaerobic conditions. Gray bars indicate limited aeration condition (LA), while black bars indicate anaerobic condition (AN). Standard deviaiton is shown as error bard. Bars represent mean value of duplicate samples

Change in a E. coli, b Salmonella, and c L. monocytogens levels at 42 °C in limited aerobic and anaerobic conditions. Gray bars indicate limited aeration condition (LA), while black bars indicate anaerobic condition (AN). Standard deviaiton is show as error bard. Bars represent mean value of duplicate samples

Change in a E. coli, b Salmonella, and c L. monocytogens levels at 50 °C in limited aerobic and anaerobic conditions. Gray bars indicate limited aeration condition (LA), while black bars indicate anaerobic condition (AN). Standard deviaiton is show as error bard. Bars represent mean value of duplicate samples

The change in E. coli, Salmonella and L. monocytogenes over the time at 30 °C are shown in the Fig. 2a–c, respectively. There was an increase in pathogen concentration during the first sampling day (day 1) in both LA and AN conditions at 30 and 35 °C (Figs. 2, 3). Subsequently, a reduction in pathogen levels was observed. As shown in the Figures, the reduction in E. coli levels in both LA (minimal mixing condition) and AN reactors were considerably lower than Salmonella and L. monocytogenes in all temperature conditions (Figs. 2, 3, 4, 5). In the LA process at 30 °C, there was a 2.5 log10 reduction in concentrations of E. coli (Fig. 2a) during the first 3 days of experiment. The trend was similar in the LA and AN processes at 35 °C (Fig. 3a).

At 35 °C, the highest concentration (4.8 × 108 CFU/mL) of E. coli was observed during the fourth day of the experiment under LA condition, while it was highest (2.5 × 108 CFU/mL) on the sixth day of the experiment under AN condition (Fig. 3a). After the first week of the experiment, a decrease in concentration of E. coli was observed. An average of 3 log10 reduction of concentration was observed in LA condition, while there was a 1.9 log10 reduction in AN condition by the end of the experiment. At 42 °C, the initial concentration of E. coli went up to 2.8 × 108 CFU/mL and 5.5 × 107 CFU/mL, respectively, for the LA and AN processes (Fig. 4a) and followed the generic pattern of 30 and 35 °C. At a thermophilic temperature of 50 °C (Fig. 5a), there was a decrease in concentrations of E. coli in the LA and AN processes after the first day of the experiment. After 3 days of the experiment, 1.5 and 2.6 log10 E. coli reductions in the LA and AN conditions were observed. The concentrations went up to 3.2 × 108 CFU/mL and 3.3 × 107 CFU/mL during the next 2 days and consequently pathogen level was reduced. A similar study by Pandey and Soupir [26] observed considerably larger reduction in E. coli levels at 52.5 °C in 3.5 days of incubation in AN and aerobic conditions potentially due to continuous stirring and elevated temperature. While studying the decay of different E. coli species/serotype, another study by Smith et al. [54] reported similar variation in E. coli concentrations at 35 °C, but not at relatively higher temperature (55 °C).

Contrast to E. coli, the reduction in Salmonella levels was greater in all temperatures (Figs. 2b, 3b, 4b, 5b). As shown in the figures, after 2 days of incubation, Salmonella level was undetectable (except 50 °C), although showed sporadically afterwards. There was a 4.7 log10 reduction from the initial concentration to the final day of detection (Day 11) in LA process at 30 °C (Fig. 2b) whereas a 4.3 log10 reduction at the end (Day 7) in AN process. At 35 °C, similar reductions in concentration (4.8 log10 and 4.2 log10, respectively) were observed from both LA and AN processes at the same time (Day 10 and Day 7, respectively) (Fig. 3b). At 42 °C, there was a 5.6 log10 reduction in LA condition, whereas there was a 3.6 log10 reduction in AN condition compared to the initial concentration (Fig. 4b). Similarly, at 50 °C, there was a 5.5 log10 reduction in LA process and 5.9 log10 reduction in AN process (Fig. 5b).

Erickson et al. [55] reported a 7.27 log10 Salmonella reduction within 4 days of aerobic composting of dairy manure with straw and cottonseed meal. While incubating the dairy manure at 37 °C, Toth et al. [56] found that Salmonella can survive for 2 weeks but it can persist longer at lower temperatures (22 and 4 °C). Another study by Semenov et al. [57] did not find any significant difference in survival of Salmonella (average decline 1.7 log10 cfu/gm after 5 days) between aerobic and AN storage of cattle manure during a 12 days incubation period.

Figures 2c, 3c, 4c, and 5c shows L. monocytogenes reduction pattern at 30, 35, 42 and 50 °C, respectively. Compare to E. coli and Salmonella reduction, the decay of L. monocytogenes was greater in all temperatures. Initial concentration of L. monocytogenes (1.26 × 107 CFU/mL) went to an undetectable level in 5 days of incubation at all four temperatures. In AN condition, the reductions in concentrations compared to initial concentrations were the same (5.6 log10) at 30 °C (Fig. 2c), 35 °C (Fig. 3c), and 50 °C (Fig. 5c) and 5.1 log10 at 42 °C (Fig. 4c). Erickson et al. [55] reported a 7.05 log10 L. monocytogenes reduction within 4 days after inoculation of dairy manure during the composting process. Other studies [58–61], however, reported relatively longer survival indicating considerable uncertainty in L. monocyotenes survival depending the environmental conditions.

Several previous studies focused on understanding of pathogen decay, especially in the AN process at different temperatures to achieve complete or partial pathogen decay [62–67] during anaerobic digestion process. In that context, the current study is the first of its kind where the survivals of three pathogens were observed during the LA and AN conditions at four different temperatures in dairy manure slurry. Smith et al. [62] studied the decay process of E. coli NCTC 9001, E. coli O148 and E. coli O158 after inoculating with liquid raw sludge at three temperatures (35, 55, and 70 °C). They found an initial rise in E. coli concentrations at mesophilic temperature (35 °C), but not at the thermophilic range (55 and 70 °C). Aitken et al. [63] and Popat et al. [64] have studied initial temperature perturbation influence extensively. Pandey and Soupir [43] studied the E. coli decay kinetics in dairy manure at moderate (25 °C), mesophilic (37 °C) and thermophilic (52.5 °C) temperatures, and use the decay kinetics to derive the time—temperature—survival relationship for calculating E. coli survival in AN digestions. The focus of the current study was to understand the relative decay of E. coli, Salmonella, and L. monocytogenes in liquid dairy manure at mesophilic and thermophilic temperature conditions, and the results indicated a considerable difference in decay among the pathogens.

Similar to the results presented here, previous studies also reported inconsistence in the decay pattern of E. coli in cattle manure [43, 68]. Some of the E. coli serotype (generally E.coil O157:H7) has high tolerance against acidic and dry conditions and they can survive longer [10]. As an example, Kudva et al. [68] found that E. coli O157:H7 can survive for 47 days in aerated cattle manure piles. The results of this study suggest that E. coli survival in dairy manure was considerably longer than Salmonella and L. monocytogens in both AN and LA conditions indicating that the use of E. coli as an indicator for potential pathogen presence requires careful consideration. Overall, there was higher growth or survival of E.coli compared to Salmonella or L. moncytogenes at both treatment processes at all four temperatures. A study by Kim et al. [69] observed the differences in growth potential among bacteria species, and reported a greater growth of E.coli O157:H7 compared to Salmonella or L. monocytognes in dairy compost. Factors such as temperature as well as supply of oxygen are reported to be controlling factors for bacterial survival and growth in manure [58, 70].

To understand the impact of different temperatures on specific incubation day considering the treatments separately, ANOVA analysis of E. coli in Table 2 is showing the significant effects of temperature, day and temperature—day interaction on the prevalence of E. coli. Figure 6 shows interactions among temperature and incubation days in a three day interval of E. coli levels in LA and AN treatments separately. While evaluating the impact of treatments (LA vs AN) at each temperature on individual pathogens at a particular day, results of the statistical analysis showed that there was no significant interaction (p = 0.114) between treatment and temperature on Day 2 (for E. coli decay). There was a significant difference (p = 0.01) in concentration between the LA and AN treatments at 30 °C. Table S1 (supplementary data) shows a three way interaction among treatments, temperatures and days of incubation at p < 0.0001. Similar interaction was not noticed for other three temperatures (35, 42, and 50 °C). Unlike Day 2, there was a significant interaction (p < 0.0001) between treatment and temperature at Day 4 where the concentrations were significantly different between the treatment processes at 30, 35, and 42 °C. Further, there was a significant interaction (p < 0.0001) between treatment and temperature at Day 6 where the differences between treatments were only observed at 30 and 35 °C but not at higher temperatures (42 and 50 °C). The same trend was observed at Day 8. Significant interaction effects between treatment and temperature (p < 0.0001, p = 0.014, and p < 0.0001, respectively) was observed at 30 °C (Day 10), 50 °C (Day 12) and 30 °C (Day 13).

While comparing the Salmonella concentrations between the LA and AN conditions at four temperatures (Table S1), there was a significant interaction between treatment and temperature (p = 0.004) and the difference between the treatments were significant at 30 °C (p = 0.001) and 35 °C (p = 0.007) but not at 42 °C (p = 0.108) and 50 °C (p = 0.983) during Day 2. There was significant interaction effects between treatment and temperature at Day 6 and Day 10 (p < 0.0001) but not at Day 8 (p = 0.275). A significant difference in concentration was observed between the treatments at all four temperatures in Day 6. As shown in Figs. 2, 3, 4 and 5, frequent detection and non-detection of Salmonella was observed which could be due to re-growth of pathogen. A similar regrowth of Salmonella spp. in composted and stored biosolids have been reported previously by Russ and Yanko [71], Yeager and Ward [72], and Soares [73]. While assessing L. monocytogenes survival, we did not find significant interaction between treatment and temperature (p = 0.07) at Day 4 (except 50 °C). Since the concentrations of L. moncytogenes went to non-detection level at all four incubation temperatures during early phase of experiment, there was not enough data to run the analysis for all incubation days (Table S1).

As shown in Figs. 1, 2, 3, 4 and 5, both growth and inactivation patterns of E. coli, Salmonella, and Listeria were driven by temperatures. The ranges of E. coli levels over the 14 days incubation period at LA and AN conditions at 30 °C were 3.5 × 108 − 0, and 3.8 × 108 − 1.1 × 107, respectively. The range of Salmonella levels over the 14 days incubation period at LA and AN conditions at 30 °C were 2.1 × 108 − 0, and 6.6 × 107 − 0, respectively. The ranges of Listeria levels for the same incubation period and temperature at LA and AN conditions were 2.6 × 107 − 0, and 2.6 × 106 − 0, respectively. At higher temperature (50 °C), the range of E. coli levels over the 14 days incubation period at LA and AN conditions were 3.2 × 108 − 0, and 3.3 × 108 − 0, respectively. The ranges of Salmonella levels for the similar conditions were 7.5 × 105 − 0, and 1 × 105 − 0, respectively. The ranges of Listeria levels for the same conditions were 7.5 × 103 − 0, and 1 × 104 − 0, respectively. The pathogen survival time order (shorter to longer) was: Listeria < Salmonella < E. coli. This survival ranking was identical for all four temperatures (30, 35, 42, and 50 °C).

While assessing the impacts of temperature on pathogen survival, Himathongkham et al. [13] observed a first order rate of decay of E. coli 0157:H7 and Salmonella with periodic multiplication in solid manure and slurry at different temperatures (4, 20, and 37 °C). The quickest reduction was observed at highest temperature (37 °C). The decimal reduction time was 6–21 days in manure and 2–35 days in slurry. In addition to temperature, the moisture content of feedstock is also considered as one of the important factors influencing bacterial growth and survival in biosolids [72–75]. According to Kim et al. [76] about 20–30 % moisture content is required for pathogen growth in animal manure under laboratory conditions. In our study, moisture content of feedstock was >90 % throughout the experiment indicating that the moisture content was not an inhibiting factor in this study.

Conclusions

This study was designed to evaluate the performance of LA and AN storage conditions in decay of pathogens in dairy manure. The decay of three pathogens at four temperatures under minimal mixing (1 h/day) conditions was evaluated. Results showed that the effects of both LA and AN conditions in pathogen reductions were almost similar in the minimal mixing condition potentially due to insufficient aeration of dairy manure. As continuous mixing is often cost prohibitive in dairy manure treatment at a large scale, infrequent mixing of stored flushed dairy manure is common, which may have limited impact on pathogen decay. E. coli survival was longer than Salmonella and Listeria in all temperature conditions. Salmonella and L. monocytogenes levels were reduced to non-detectable level in both LA and AN conditions within 3 days of incubation. Detection of these pathogens, however, was observed beyond 3 days potentially due to regrowth. We anticipate that this study will help in improving the existing animal waste treatment methods, and will support the stakeholders in making informed decisions while treating animal waste for pathogen reduction. Additional studies that focused on evaluating the regrowth of pathogens after treatment completion are needed to understand the recurrence of pathogens in large facilities treating manure where probability of cross-contamination is higher.

References

Food and Drug Administration (2007) FDA Finalizes Report on 2006 Spinach Outbreak. Washington, DC: Food and Drug Administration. http://www.fda.gov/NewsEvents/Newsroom/PressAnnouncements/2007/ucm108873.htm. Accessed on 29 Oct 2015

Mungai EA, Behravesh CB, Gould LH (2015) Increased outbreaks associated with nonpasteurized milk, United States, 2007–2012. Emerg Infect Dis 21(1):119–122

Costa PM, Loureiro L, Matos AJF (2013) Transfer of multidrug-resistant bacteria between intermingled ecological niches: the interface between humans, animals and the environment. Int J Envrion Res Publ Health 10:278–294

Walczak JJ, Xu S (2011) Manure as a source of antibiotic-resistant Escherichia coli and enterococci: a case study of a Wisconsin, USA Family Dairy Farm. Water Air Soil Pollut 219:579–589

Venglovsky J, Sasakova N, Placha I (2009) Pathogens and antibiotic residues in animal manure and hygienic and ecological risks related to subsequent land application. Bioresour Techonol 100:5386–5391

van Elsas JD, Semenov AV, Costa R, Trevors JT (2011) Survival of Escherichia coli in the environment: fundamental and public health aspects. ISME J 5:173–183

Cevallos-Cevallos JM, Gu G, Richardson SM, Hu J, van Bruggen AHC (2014) Survival of Salmonella enterica Typhimurium in water amended with manure. J Food Protec 77(12):2035–2042

Erickson MC, Smith C, Jiang X, Flitcroft ID, Doyle MP (2014) Survival of Salmonella enterica and Listeria monocytogenes in manure-based compost mixtures at sublethal temperatures. Agric Food Anal Bacteriol 4:224–238

Erickson MC, Smith C, Jiang X, Flitcroft ID, Doyle MP (2015) Survival of Salmonella or Escherichia coli O157:H7 during holding of manure-based compost mixtures at sublethal temperatures as influenced by the carbon amendment. J Food Protec 78(2):248–255

Wang G, Zhao T, Doyle MP (1996) Fate of enterohemorrhagic Escherichia coli O157:H7 in bovine feces. Appl Environ Microbiol 62(7):2567–2570

Mead PS, Slutsker L, Dietz V, McCaig LF, Bresee JS, Shapiro C, Griffin PM, Tauxe RV (1999) Food-related illness and death in the United States. Emerg Infect Dis 5:607–625

Council for Agricultural Science and Technology (2009) Food Safety and Fresh Produce: An Update. CAST Commentary QTA2009-1. Ames, Iowa: CAST. http://jifsan.umd.edu/docs/workshops/producesafety/outbreaks/CAST%20Commentary%20Fresh%20Produce.pdf. Accessed on 10 Oct 2015

Himathongkham S, Bahari S, Riemann H, Cliver D (1999) Survival of Escherichia coli O157:H7 and Salmonella typhimurium in cow manure and cow manure slurry. FMES Microbiol Lett 178:251–257

Alice NP (1997) Public and microbes: Public and animal health problem. J Dairy Sci 80:2673–2681

Losinger WC, Wells SJ, Garber LP, Hurd HS, Thomas LA (1995) Management factors related to Salmonella shedding by dairy heifers. J Dairy Sci 78:2464–2472

Snedeker KG, Campbell M, Sargeant JM (2012) A systematic review of vaccinations to reduce the shedding of Escherichia coli o157 in the feces of domestic ruminants. Zoonoses Public Hlth 59:126–138

Aperce CC, Heidenreich JM, Schneider CS, Drouillard JS (2013) Effect of crude glycerin on fecal shedding of Escherichia coli O157 in growing and finishing cattle. Intern J Appl Res Vet Med 11(3):202–211

Ma J, Yu L, Frear C, Zhao Q, Li X, Chen S (2013) Kinetics of psychrophilic anaerobic sequencing batch reactor treating flushed dairy manure. Bioresource Technol 131:6–12

Rico C, Rico JL, Garcı´a H, Garcı´a PA (2012) Solid–liquid separation of dairy manure: distribution of components and methane production. Biomass Bioenerg 39:370–377

Zhang Y, White MA, Colosi LM (2013) Environmental and economic assessment of integrated systems for dairy manure treatment coupled with algae bioenergy production. Bioresource Technol 130:486–494

Jones PW (1980) Animal health today- problems of large livestock units. Disease hazards associated with slurry disposal. Br Vet J 136:529–540

Woolcock JB (1991) Microbiology of animals and animal products. Elsevier Science Publishing Company Inc, New York

Mechie SC, Chapman PA, Siddons CA (1997) A fifteen month study of Escherichia coli O157:H7 in a dairy herd. Epidemiol Infect 118:17–25

Hancock DD, Rice DH, Thomas LA, Dargatz DA, Besser TE (1997) Epidemiology of Escherichia coli O157:H7 in feedlot cattle. J Food Prot 60:462–465

Zhao T, Doyle MP, Shere J, Garber L (1995) Prevalence of enterohemorrhagic Escherichia coli O157:H7 in a survey of dairy herds. Appl Environ Microbiol 61:1290–1293

Resende JA, Silva VL, de Oliveira TLR, de Olivera Fortunato S, da Costa Carneiro J, Otenio MH, Diniz CG (2014) Prevalence and persistence of potentially pathogenic and antibiotic resistant bacteria during anaerobic digestion treatment of cattle manure. Bioresour Technol 153:284–291

Strauch D (1991) Survival of pathogenic micro-organisms and parasites in excreta, manure and sewage sludge. Rev Sci Tech OIE (Off. Int. Epizoot.) 10:813–846

Joy SR, Bartelt-Hunt SL, Snow DD, Gilley JE, Woodbury BL, Parker DB, Marx DB, Li X (2013) Fate and transport of antimicrobials and antimicrobial resistance genes in soil and runoff following land application of swine manure slurry. Environ Sci Technol 47:12081–12088

Maillard É, Angers DA (2014) Animal manure application and soil organic carbon stocks: a meta-analysis. Glob Change Biol 20:666–679

Thurston-Enriquez JA, Gilley JE, Eghball B (2005) Microbial quality of runoff following land application of cattle manure and swine slurry. J Water Health 3(2):157–171

Casey JA, Curriero FC, Cosgrove SE, Nachman KE, Schwartz BS (2013) High-density livestock operations, crop field application of manure, and risk of community-associated methicillin-resistant staphylococcus aureus infection in Pennsylvania. JAMA Intern Med 173(21):1980–1990

Bolton DJ, Byrne CM, Sheridan JJ, McDowell DA, Blair IS (1999) The survival characteristics of a non-toxigenic strain of Escherichia coli O157:H7. J Appl Microbiol 86(3):407–411

Fukushima H, Hoshina K, Gomyoda M (1999) Long-term survival of Shiga toxin-producing Escherichia coli O26, O111, and O157 in bovine feces. Appl Environ Microbiol 65(11):5177–5181

Beuchat LR (1996) Pathogenic microorganisms associated with fresh produce. J Food Prot 59:204–216

Doyle MP, Erickson MC (2008) Summer meeting 2007—the problems with fresh produce: an overview. J Appl Microbiol 105:317–330

Fremaux B, Prigent-Combaret C, Vernozy-Rozand C (2008) Long-term survival of Shiga toxin producing Escherichia coli in cattle effluents and environment: an updated review. Vet Microbiol 132(1–2):1–18

Beuchat LR (2002) Ecological factors influencing survival and growth of human pathogens on raw fruits and vegetables. Microbes Infect 4:413–423

Fallah AA, Pirali-Kheirabadi K, Shirvani F, Saei-Dehkordi SS (2012) Prevalence of parasitic contamination in vegetables used for raw consumption in Shahrekord, Iran: influence of season and washing procedure. Food Control 25:617–620

Duggan S, Jordan E, Gutierrez M, Barrett G, O’Brien T, Hand D, Kenny K, Fanning J, Leonard N, Egan J (2012) Salmonella in meats, water, fruit and vegetables as disclosed from testing undertaken by Food Business Operators in Ireland from 2005 to 2009. Irish Vet J 65:17

van Elsas JD, Semenov AV, Costa R, Trevors JT (2011) Survival of Escherichia coli in the environment: fundamental and public health aspects. ISME J 5:173–183

Strawn LK, Fortes ED, Bihn EA, Nightingale KK, Gröhn YT, Worobo RW, Wiedmann M, Bergholz PW (2013) Landscape and meteorological factors affecting prevalence of three food-borne pathogens in fruit and vegetable farms. Appl Environ Microbiol 79(2):588–600

Hipsey MR, Hamilton DP, Hanson PC, Carey CC, Coletti JZ, Read JS, Ibelings BW, Valesini FJ, Brookes JD (2015) Predicting the resilience and recovery of aquatic systems: a framework for model evolution within environmental observatories. Water Resour Res 51(9):7023–7043

Pandey PK, Soupir ML (2011) Escherichia coli inactivation kinetics in anaerobic digestion of dairy manure under moderate, mesophilic and thermophilic temperatures. AMB Express 1:18

Himathongkham S, Riemann H, Bahari S, Nuanualsuwan S, Kass P, Cliver D (2000) Survival of Salmonella Typhimurium and Escherichia coli 0157:H7 in poultry manure and manure slurry at sublethal temperatures. Avian Dis 44:353–860

Scott L, McGee P, Sheridan JJ, Earley B, Leonard N (2006) A comparison of the survival in feces and water of Escherichia coli O157:H7 grown under laboratory conditions or obtained from cattle feces. J Food Prot 69:6–11

Gagliardi JV, Karns JS (2002) Persistence of Escherichia coli O157:H7 in soil and on plant roots. Environ Microbiol 4:89–96

Kudva IT, Hatfield PG, Hovde CJ (1997) Characterization of Escherichia coli O157:H7 and other Shiga toxin-producing E. coli isolated from sheep. J Clin Microbiol 35:892–899

Posada-Izquierdo GD, Pérez-Rodríguez F, López-Gálvez F, Allende A, Selma M, Gil MI, Zurera G (2013) Modelling growth of Escherichia coli O157:H7 in fresh-cut lettuce submitted to commercial process conditions: Chlorine washing and modified atmosphere packaging. Food Microbiol 33:131–138

Pao S, Patel D, Kalantari A, Tritschler JP, Wildeus S, Sayre BL (2005) Detection of Salmonella strains and Escherichia coli O157:h7 in feces of small ruminants and their isolation with various media. Appl Environ Microbiol 71(4):2158–2161

Pandey P, Lejeune M, Biswas S, Morash D, Weimer B, Young G (2015) A new method for converting foodwaste into pathogen free soil amendment for enhancing agricultural sustainability. doi:10.1016/j.jclepro.2015.09.045

Biswas S, Pandey P, Castillo AR, Vaddella VK (2014) Pathogen inactivation in liquid dairy manure during anaerobic and aerobic digestions. American Geophysical Union, Fall Meeting 2014, abstract #B21A-0028, 2014AGUFM.B21A0028B

Food and Drug Administration (2014) Center for food safety and applied nutrition: bacteriological analytical manual. Online, 8th edn. http://www.fda.gov/food/foodscienceresearch/laboratorymethods/ucm2006949.htm. Accessed 6 Apr 2014

Littell RC, Milliken GA, Stroup WW, Wolfinger RD (1996) SAS system for mixed models. SAS Institute Inc, Cary

Smith SR, Lang NL, Cheung KHM, Spanoudaki K (2005) Factors controlling pathogen destruction during anaerobic digestion of biowastes. Waste Manage 25:417–425

Erickson MC, Liao J, Ma L, Jiang X, Doyle MP (2014) Thermal and nonthermal factors affecting survival of Salmonella and Listeria monocytogenes in animal manure-based compost mixtures. J Food Prot 77(9):1512–1518

Toth JD, Aceto HW, Rankin SC, DebRoy C, Dou Z (2012) Accelerating the deactivation of Salmonella enterica Serovar Newport and Escherichia coli O157:H7 in dairy manure by modified pH or temperature. Open Waste Manag J 5:11–18

Semenov AV, van Overbeek L, Termorshuizen AJ, vanBruggen AHC (2011) Influence of aerobic and anaerobic conditions on survival of Escherichia coli O157:H7 and Salmonella enterica serovar Typhimurium in Luria-Bertani broth, farm-yard manure and slurry. J Environ Manage 92:780–787

Hutchison M, Walters LD, Avery SM, Munro F, Moore A (2005) Analyses of livestock production, waste storage, and pathogen levels and prevalences in farm manures. Appl Environ Microbiol 71:1231–1236

Miller AJ (1992) Combined water activity and solute effects on growth and survival of Listeria monocytogenes Scott A. J Food Prot 55:414–418

Nolan DA, Chamblin DC, Troller JA (1992) Minimal water activity levels for growth and survival of Listeria monocytogenes and Listeria innocua. Int J Food Microbiol 16:323–335

Nicholson FA, Groves SJ, Chambers BJ (2005) Pathogen survival during livestock manure storage and following land application. Biores Technol 96:135–143

Smith SR, Lang NL, Cheung KHM, Spanoudaki K (2005) Factors controlling pathogen destruction during anaerobic digestion of biowastes. Waste Manage 25:417–425

Aitken MD, Sobsey MD, van Abel NA, Blauth KE, Singleton DR, Crunk PL, Nichols C, Walters GW, Schneider M (2007) Inactivation of Escherichia coli O157:H7 during thermophilic anaerobic digestion of manure from dairy cattle. Water Res 4:1659–1666

Popat SC, Yates MV, Deshusses MA (2010) Kinetics of inactivation of indicator pathogens during thermophilic anaerobic digestion. Water Res 44:5965–5972

Puchajda B, Oleszkiewicz J, Sparling R, Reimers R (2006) Low-temperature inactivation of fecal coliforms in sludge digestion. Water Environ Res 78:680–685

Wagner AO, Malin C, Gstraunthaler G, Illmer P (2009) Survival of selected pathogens in diluted sludge of a thermophilic waste treatment plant and in NaCl-solution under aerobic and anaerobic conditions. Waste Manage 29:425–429

Pandey PK, Biswas S, Vaddella VK, Soupir ML (2014) Escherichia coli persistence kinetics in dairy manure at moderate, mesophilic, and thermophilic temperatures under aerobic and anaerobic environments. Bioprocess Biosyst Eng. doi:10.1007/s00449-014-1285-3

Kudav IT, Blanch K, Hovde CJ (1998) Analysis of Escherichia coli O157:H7 survival in ovine or bovine manure and manure slurry. Appl Environ Microbiol 64(9):3166–3174

Kim J, Shepherd MW Jr, Jiang X (2009) Evaluating the effect of environmental factors on pathogen regrowth in compost extract. Microb Ecol 58:498–508

Gessel PD, Hansen N, Goyal SM, Johnston LJ, Webb J (2004) Persistence of zoonotic pathogens in surface soil treated with different rates of liquid pig manure. Appl Soil Ecol 25:237–243

Russ CF, Yanko WA (1981) Factors affecting Salmonella repopulation in composted sludges. Appl Environ Microbiol 41(3):597–602

Yeager JG, Ward RL (1981) Effects of moisture content on long term survival and regrowth of bacteria in wastewater. Appl Environ Microbiol 41:1117–1122

Soares HM (1996) Pathogen indicator regrowth potential as a method to evaluate compost stability. PhD Dissertation, University of Massachusetts at Amherst, Department of Civil and Environmental Engineering

Brandon JR, Burge WD, Enkiri NK (1977) Inactivation by ionizing radiation of Salmonella enterica serotype montevideo grown in composted sewage sludge. Appl Environ Microbiol 33:1011–1012

Sidhu J, Gibbs RA, Ho GE, Unkovich I (1999) Selection of Salmonella Typhimurium as an indicator for pathogen regrowth potential in composted biosolids. Lett Appl Microbiol 29:303–307

Kim J, Jiang X (2010) The growth potential of Escherichia coli O157:O7, Salmonella spp. and Listeria monocytogenes in dairy manure-based compost in a greenhouse setting under different seasons. J Appl Microbiol 109:2095–2104

Acknowledgments

The authors thank the Division of Agriculture and Natural Resources and Veterinary Medicine Extension, University of California, Davis for supporting this work.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Biswas, S., Pandey, P.K. & Farver, T.B. Assessing the impacts of temperature and storage on Escherichia coli, Salmonella, and L. monocytogenes decay in dairy manure. Bioprocess Biosyst Eng 39, 901–913 (2016). https://doi.org/10.1007/s00449-016-1569-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-016-1569-x