Abstract

A solvent-free biocatalytic process for the synthesis of high quality cetyl laurate, myristate, palmitate and stearate has been optimized. This enzymatic procedure follows the fundamental principles of the Green Chemistry and lead to sustainable products, which can be labeled as natural and conform to the principal requirements for its use in high value-added goods. The four esters selected are the main components of spermaceti, a mixture of waxes very appreciated in cosmetic and pharmacy because of its physical properties and emolliency, which was formerly extracted from the head of the sperm whales. In this paper, the influence of the amount of biocatalyst, the commercially available Novozym® 435, and the temperature were studied in an open-air batch reactor before carrying out the synthesis in a high performance vacuum reactor with dry nitrogen input to shift the equilibrium towards product formation. Under optimal conditions, conversion was higher than 98.5 %. The characterization of the enzymatic cetyl esters puts in evidence that these are ultra-pure compounds, which have similar properties to the ones obtained through the conventional industrial processes with the extra benefit of being environmentally friendly.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Waxes are esters of fatty acids and long-chain alcohols (with chain lengths of 12 carbons or more) having a large number of applications, among which stand out their use in cosmetics and pharmacy due to their high added value [1]. The main natural sources of wax esters are animals (spermaceti wax, obtained around the cranial cavity of the sperm whale, Physeter macrocephalus) and vegetables (jojoba oil, a liquid wax present in high proportions in the seeds of Simmondsia chinensis, a bush from dessert areas). Both sources have a quite different composition but a common attribute: they are expensive and not easily available.

Spermaceti is a wax rich in high molecular weight esters, whose scope extends to the pharmaceutical, lubricants, plastics, paper, cosmetic and food industries. Spermaceti has been characterized by several authors, among them Hilditch in 1960 and Wellendorf in 1963, but the most complete characterization of spermaceti was provided by Horiguchi et al. in 1999 [2–4]. According to all these authors the major constituents of spermaceti are cetyl esters of linear long fatty acids, mainly myristic and palmitic but also lauric and stearic. It is a crystalline solid at room temperature, bright white, and its physical properties are related to its high content of high molecular weight esters and relatively low triglyceride content.

Obtaining of synthetic sperm whale oil can be approached using several processes. Most of them involve the esterification of cetyl alcohol and linear long chain fatty acids. These processes differ in reaction conditions, above all temperature, solvent and the catalysts used. Traditionally, conventional catalysts such as mineral acids (e.g., H2SO4 or HCl) or metal salts (e.g., tin oxalate) are used at high temperatures (160–240 °C), but many undesirable products may be formed in these conditions [5]. Other approaches for the synthesis of spermaceti oil have been performed under microwave irradiation, obtaining acceptable results only if acid activated Indian bentonite is used as catalyzer in the presence of organic solvents [6].

It is generally known the advantages of Green Chemistry technology for pollution prevention. However, Green Chemistry is also identified with the design of chemical products or processes that reduce or eliminate the use or generation of hazardous substances. Moreover, the term has been expanded recently with the new concept of chemical sustainability; furthermore it promotes the sustainable use of raw materials. Thus, the traditional chemical industry has to find solutions to achieve a cleaner, more sustainable and environmentally friendly production. These solutions involve optimizing processes for the use of less polluting reagents and solvents, and the recycling of products as more important goals [7].

An increasingly booming strategy is to completely avoid the use of solvents in catalytic synthesis. It is desirable that new processes should be not only efficient, selective and high yielding but also environmentally friendly. Among the advantages of solvent-free reactions, we can emphasize [8]:

-

(a)

Reduction of reaction times and energy consumption.

-

(b)

Decrease of the reactor volume and hence, its cost.

-

(c)

Cost savings by avoiding the use of solvents and subsequent product separation.

-

(d)

Higher reactivity, due to the maximum concentration of reagents.

-

(e)

Some processes are simpler or unnecessary.

One of the most recent examples in process development is the biocatalytic production of fatty acid esters for its use, mainly, in the cosmetics industry. Although subjected to industrial confidentiality, the biocatalytic synthesis of some esters such as myristyl myristate and cetyl ricinoleate has been described [9–12]. These reports highlight the high purity of the products obtained and the importance of the environmentally friendly process. Previous works related to the biocatalytic synthesis of cetyl ricinoleate corroborate that obtaining such esters through enzymatic-catalyzed processes leads to products which comply with the high standards required in the cosmetic field in short reaction times, avoiding secondary reactions and reprocessing steps [13, 14].

Therefore, in view of the foregoing, the aim of this paper is to optimize a green process to obtain the main components of spermaceti (cetyl laurate, CL; cetyl myristate, CM; cetyl palmitate, CP; and cetyl stearate, CS) in a solvent-free system of and using a commercial immobilized derivative of Candida antarctica lipase, Novozym® 435, as catalyst. The research started with the optimization of reaction conditions (amount of immobilized derivative and temperature) in open-air batch reactors. Then, reactions were performed in a vacuum reactor with dry nitrogen input to shift the equilibrium towards the esterification. Finally, the biosynthesized esters were analyzed and compared to those reported for commercially available products.

Experimental

Materials

The biocatalyst Novozym® 435 (Candida antarctica lipase B immobilized on an macroporous acrylic resin, Lewatit® VP OC 1600) was kindly provided by Novo Nordisk AS (Copenhagen, Denmark). Lauric acid, LA, (99 %) was purchased from Acros Organics. Myristic acid, MA, (98 %), palmitic acid, PA, (98 %), stearic acid, SA, (95 %) and cetyl alcohol, CA, were all from Fluka. All other chemicals were analytical reagent grade.

Ester synthesis

The atmospheric enzymatic synthesis was carried out in open-air jacketed reactors (250 mL), where 20 g of reactants were introduced in an equimolecular ratio and melted before adding the immobilized derivative, Novozym® 435. Biocatalyst amounts between 0.08 and 1.0 g were assayed, while different temperatures were tested in a range of 50–80 °C. All reactions were performed in a solvent-free medium with an overhead stirrer equipped with a two-bladed propeller at 350 rpm, which provided an axial flow. The importance of the stirring was considered in previous works, where it has been found out that, for the studied range, this kind of stirrer at this speed was the most suitable (results non shown), as it ensures a great mixing and no physical damage of Novozym® 435 was observed.

Enzymatic synthesis was also performed under vacuum conditions (21.3 kPa) with continuous dry nitrogen input (25 mL s−1). A glass-jacketed reactor (Parr 5101 series), 100 mL total volume, equipped with a four-bladed turbine-type impeller was used. Experimental conditions were: 20 g of reactants (1:1 molar ratio), 0.1 or 0.5 g of immobilized enzyme, 350 rpm and 60, 70 °C (CL and CM) or 80 °C (CP and CE).

Each spermaceti ester was synthesized separately and several samples of ~0.5 mL were taken at different intervals (stirring stopped a few seconds before) to follow the reaction course by measuring its acid value.

Conversion is defined as follows:

AV i is the acid value at the beginning of the reaction and AV f is acid value of the final product.

Acid value measurements

The acid value (AV) represents the number of milligrams of potassium hydroxide necessary to neutralize free acids contained in 1 g of sample. The results are the mean of three different measurements and are graphically represented including error bars (±standard deviation) [15].

Hydroxyl value measurements

The hydroxyl value is defined as the milligrams of potassium hydroxide used to neutralize the acetic acid remaining when the hydroxyl groups contained in 1 g of sample are acetylated [16].

Iodine value measurements

The iodine value is used to determine the grade of unsaturation of a substance, and it corresponds to the grams of iodine consumed per 100 g of sample [17].

Water content measurements

The determination of the amount of water contained in the samples was performed by Karl-Fischer titration (701 KF, Metrohm), using Hydranal® Composite 5 as titrant.

High performance liquid chromatography (HPLC)

HPLC analysis was carried out using a modular system from Waters, with a 717PLUS automatic injector and a 600 E quaternary-gradient pump. The system was equipped with a 2996 photodiode array detector and an XBridge C18 column (4.6 mm × 150 mm), all from waters. The analysis was performed in an isocratic elution, at 35 °C using a mobile phase of acetonitrile/acetone (50/50 v/v) at a flow rate of 2 mL min−1.

Results and discussion

Influence of the amount of biocatalyst

Lipases have the ability to catalyze the esterification of long-chained acids with fatty alcohols to produce wax esters under mild reaction conditions, and the reaction rate can be improved by using the right quantity of enzyme [5]. Nevertheless, excessive amounts of immobilized enzyme could difficult mass transfer by creating agglomerations in the reaction media , and increase production costs, as immobilized biocatalysts are often expensive [18]. Therefore, this parameter was first studied for the synthesis of the four cetyl esters (CL, CM, CP and CS). For that purpose, amounts of Novozym® 435 between 0.08 and 1 g (0.25–5 % of concentration, referred to the substrates) were tested.

Taking into account the substrates and products’ melting points, the reactions were conducted at different temperatures. The synthesis of CL and CM was run at 60 °C, because at this temperature both substrates and products were melted (Table 1) [6, 19]. For the production of CP, temperature was maintained at 65 °C, while the studies with CS were carried out at 70 °C.

In Fig. 1, it can be observed that higher reaction rates are obtained increasing the amount of immobilized enzyme. This effect is more evident for the lowest quantities of biocatalyst tested. As an example, if we compare the results obtained after 60 min of reaction for the CL, we can observe a conversion of 63.8 % (AV = 47.82 mg KOH g−1) when 0.1 g of Novozym® 435 are added to the reactor, while it reaches 95.7 % (AV = 5.70 mg KOH g−1) using 0.5 g of biocatalyst (five times more immobilized derivative) but only a slight difference is observed when reaction media contains ten times more biocatalyst than before (95.9 % of conversion, AV = 5.42 mg KOH g−1, when 1 g is used). Despite these facts, when the lowest quantity of biocatalyst is tested (0.08 g), the reaction reaches its equilibrium within a maximum time of 360 min, and it can be seen that the final acid value is virtually the same for all the amounts of Novozym® 435 assayed. Similar tendencies are patent in the synthesis of the other cetyl esters, so 0.5 g (2.5 % of concentration, referred to the substrates) is selected as the optimum amount of immobilized derivative in all cases, regardless of the operation temperature.

Influence of the biocatalyst amount in cetyl laurate (a), cetyl myristate (b), cetyl palmitate (c) and cetyl stearate (d) enzymatic synthesis (open-air reactor; 350 rpm; 60 °C for CL and CM, 65 °C for CP and 70 °C for CS). 0.08 g (diamonds), 0.1 g (squares), 0.2 g (triangles), 0.3 g (times symbol), 0.4 g (asterisk), 0.5 g (circles), 1 g (dashes)

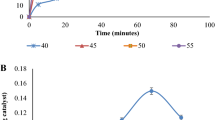

Influence of the temperature

Temperature is a key element in biotechnological processes as it is strongly conditioned by the enzyme’s stability requirements. Depending on pH, temperature of denaturalization for CalB is usually comprised between 50 and 60 °C; although under certain conditions, this phenomenon has been found to occur even at 40 °C in aqueous solutions [20]. However, when immobilized and kept dry, CalB remains functional with no significant loss of its activity for a long operation time at high temperatures [21]. In this context, it has been reported that Novozym® 435 can exhibit its highest activity at 90–110 °C, and be active even at 150 °C [22]. In addition, when biocatalysts are used, the optimum temperature should compromise the enzyme’s stability with other factors, such as economic saving, processing conditions and productivity. Whereas high temperature enhances reaction rate, diffusion and reduces substrates viscosity [23], mild reaction temperature is an appealing feature of bioprocesses, and sometimes this is decisive for making it profitable from an economic point of view [13].

In this paper, different temperatures were studied for the synthesis of each ester and the lowest values were limited by the substrate’s melting points. Thus, experiments for the CL and the CM were conducted at 50, 60, 70 and 80 °C, while for the CP and the CS were performed at 65, 70 and 80 °C. All the assays were carried out using 0.1 g of Novozym® 435 to perceive the effect of temperature on reaction rate without being covered up by the influence of the biocatalyst concentration.

Observing Fig. 2a, b, it can be noticed that the biosynthesis of CL and CM progresses faster as temperature rises until 70 °C, but an increase of 10 °C from 70 to 80 °C does not imply a significant enhancement of reaction rate. After 300 min it is noticeable that there are some differences between acid values due to the fact that the reaction performance at low temperature requires more time to reach equilibrium. Because of that, 70 °C has been chosen as optimum to produce both esters.

Influence of the reaction temperature in cetyl laurate (a), cetyl myristate (b), cetyl palmitate (c) and cetyl stearate (d) enzymatic synthesis (open-air reactor; 350 rpm; 0.1 g of Novozym® 435). 50 °C (triangles), 60 °C (squares), 70 °C (triangles), 80 °C (times symbol) for a and b, 65 °C (diamonds), 70 °C (squares), 80 °C (triangles) for c and d

On the other hand, for the CP and the CS, which have higher melting points, faster reactions are observed as the operating temperature increases and the best results are obtained at 80 °C, as shown in Fig. 2c, d. Besides the enhancement of reaction rate produced by temperature, this can also be the result of improved mass transfer as viscosity decreased, as stated above. In addition, it is interesting to highlight that reaction yields after 300 min were similar for all temperatures tested, even at the lowest one (65 °C). That would probably allow synthesizing all the esters together at the optimum temperature for the CL and the CM with good outcomes in terms of productivity. Given that higher operation temperatures would lead to a major consumption of energy and that the results obtained were considered satisfactory enough, temperatures above 80 °C were not studied.

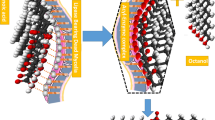

Synthesis of cetyl esters under vacuum

In processes such as esterification, the control of the amount of water in the reaction media is a key aspect to be considered to achieve high conversion values [14, 24]. Different methods have been proposed to remove water, like pervaporation [25, 26], ion-exchange resins [27] or molecular sieves [28, 29], being vacuum drying a good tool for large scale production of fatty acid esters as non-volatile compounds are removed with water [30–32]. Hence, reactions were carried out using the vacuum reactor described before, with a dry N2 input.

Our previous experience in the synthesis of CR showed that the use of the high performance reactor does not noticeably improve reaction rate [14], but the product acid value. Consequently, a preliminary assay was run comparing CM synthesis under the same experimental conditions than in the atmospheric reactor (0.1 g of biocatalyst, 60 °C). The progress of the reaction is represented in Fig. 3, being the final acid value for the product synthesized using the vacuum and the open-air reactor 1.22 and 3.94 mg KOH g−1 (99.0 and 97.2 % of conversion), respectively. These results prove that the main advantage of using this equipment lies in the possibility of improving conversion rather than increasing the reaction rate.

These results make patent the importance of water not only for maintaining the conformation of the catalytic site of CalB, which requires low quantities of water to the catalytic function [33], but also for pushing the reaction balance towards product formation. A previous work in the synthesis of ricinoleic acid estolides in the open-air reactor has shown that the water present in reaction media depends on its free evaporation, a process mainly controlled by the reaction’s temperature and the atmospheric humidity. In that sense, the polyricinoleic acid obtained when the biosynthesis was carried out at the same temperature but at different relative humidity, 20 and 70 %, had a water content that varies from 1000 to 3600 ppm, respectively, and a final product AV ~15 mg KOH g−1 higher at 70 %. Besides, results under vacuum with a continuous current of dry air showed that the product had a water content of 1500 ppm after 24 h, and after 48 h the estolide was almost anhydrous [34]. In this last case studied, the low quantity of water in reaction media might have caused problems with the enzyme activity, but results displayed in Fig. 3 prove that this negative effect is not observed during the synthesis CM, maybe because the equilibrium of the reaction was achieved within 300 min.

In light of the above results, the four cetyl esters were biosynthesized in the vacuum reactor under the best conditions assayed for the atmospheric experiments, i.e., 0.5 g of Novozym® 435 and temperatures of 70 °C for the CL and the CM and 80 °C for the CP and the CS (Fig. 4). As a result of using the optimum conditions, a similar reaction progress was observed during the synthesis of the cetyl esters, the conversion increased by more than 98.5 %, and the products obtained adjust better to the specifications given by manufacturers, as it will be discussed in the subsequent section.

These optimized values are the result of a process that balances three parameters which are intimately related among them. The amount of biocatalyst selected does not limit mass transfer and improves the rate of formation of the cetyl esters, and so does the selected temperature, which not only promotes the biocatalyst activity, and hence, the reaction rate, but also the viscosity and as a consequence, mass transfer. Vacuum drying ensures the repeatability of the process, as it makes it independent of the environmental humidity, and provides a reaction media which guaranties the enzyme activity while enhancing the product formation.

However, to verify Novozym® 435 integrity and its reusability when used in optimum conditions, three consecutive assays were carried out using the same immobilized derivative, which was recovered from reaction media, acetone washed and air dried before being reused. Figure 5 displays the results of the successive experiments, while the amount of biocatalyst recovered after each use can be found in Table 2. It can be concluded that the biocatalyst can be successfully recovered from reaction media and reused at least twice without apparent loss of its activity although literature suggest that Novozym® 435 could be used in more consecutive cycles with marginal losses on final conversion [35, 36].

Characterization of the cetyl esters and comparison with the commercial ones

Nowadays, there is a lack of legal regulations regarding the minimum requirements that fatty acid esters should meet for their cosmetic use, so manufacturers’ specifications are an interesting alternative to check if the biosynthesized esters satisfy the main requisites for these products. A comparison of the properties of the in-lab esters with those from technical data sheets corresponding to the commercially available CL, CM, CP and CS is gathered in Table 3.

As it can be observed, the cetyl esters produced by a lipase-catalyzed process are quite similar to the ones obtained through chemical synthesis and conforms the specifications in all cases. HPLC analysis confirms the high purity of the enzymatic wax esters, as the presence of by-products or unreacted substrates was not noticeable. Retention times for substrates and products are specified in Table 4. Moreover, the use of enzymatic processes for the synthesis of cosmetic products enables these goods to be labeled as “natural” [37].

Conclusions

This study shows the great potential of Novozym® 435 to biocatalyze the synthesis of long chained esters, such as the main components of natural spermaceti, in a high viscous solvent-free medium, with excellent results. Even though higher amounts of biocatalyst and reaction temperatures are suitable for enhancing the reaction rate and mass transfer, it has been proven the feasibility of synthesizing these esters under mild conditions and low concentration of Novozym® 435, in an open-air batch reactor. These facts make the process more attractive for economic reasons, especially if we consider that no special equipment is needed.

However, the specific applications expected for these products into industries with strict requirements, such as the cosmetic one, suggest the use of a vacuum reactor for water removal to increase the conversion values (conversion ≥98.5 %). Additionally, the inert atmosphere (N2) in the reactor hinders secondary reactions. The biocatalytic synthesis of cetyl laurate, myristate, palmitate and stearate under the optimum proposed conditions leads to odor and colorless products, that exhibits a high purity and fulfills the specifications for these currently commercialized fatty acid esters, with the distinctive feature of being considered natural products.

Abbreviations

- AV:

-

Acid value

- CA:

-

Cetyl alcohol

- CalB:

-

Candida antarctica lipase B

- CL:

-

Cetyl laurate

- CM:

-

Cetyl myristate

- CP:

-

Cetyl palmitate

- CS:

-

Cetyl stearate

- HPLC:

-

High performance liquid chromatography

- LA:

-

Lauric acid

- MA:

-

Myristic acid

- PA:

-

Palmitic acid

- SA:

-

Stearic acid

References

Gunawan ER, Basri M, Rahman MBA, Salleh AB, Rahman RNZA (2005) Study on response surface methodology (RSM) of lipase-catalyzed synthesis of palm-based wax ester. Enzyme Microb Technol 37:739–744

Hilditch T (1960) A century of change in dietary fats. Chem Ind 38:1172–1177

Wellendorf M (1963) Composition of spermaceti. Nature 198:1086–1087

Horiguchi T, Takase Y, Arai Y, Ageta H (1999) GC–MS studies on ester components of spermaceti. Nat Med 53:105–108

Li D, Xiaojing W, Kaili N, Fang W, Junfeng L, Pu W, Tianwei T (2011) Synthesis of wax esters by lipase-catalyzed esterification with immobilized lipase from candida sp. 99–125. Chin J Chem Eng 19:978–982

Vijayakumar B, Nagendrappa G, Prakash BSJ (2009) Synthesis of ester components of spermaceti and a jojoba oil analogue catalyzed by acid activated Indian bentonite under microwave irradiation. Indian J Chem Technol 16:377–381

García López JL (2009) Biotecnología para una química verde, respetuosa con el medio ambiente. Fundación Alternativas, Madrid. http://www.falternativas.org/laboratory/documentos/documentos-de-trabajo/biotecnologia-para-una-quimica-verde-respetuosa-con-el-medio-ambiente. Accessed 19 Sept 2015

Walsh PJ, Li H, de Parrodi CA (2007) A green chemistry approach to asymmetric catalysis: solvent-free and highly concentrated reactions. Chem Rev 107:2503–2545

Garcia T, Coteron A, Martinez M, Aracil J (1995) Optimization of the enzymatic-synthesis of isobutyl palmitate using a central composite design. Food Bioprod Process 73:140–144

Hilterhaus L, Thum O, Liese A (2008) Reactor concept for lipase-catalyzed solvent-free conversion of highly viscous reactants forming two-phase systems. Org Process Res Dev 12:618–625

Thum O (2004) Enzymatic production of care specialties based on fatty acid esters. Tenside Surf Deterg 41:287–290

Thum O, Oxenbøll KM (2008) A sustainable process for production of cosmetic ingredients. SOFW J Int J Appl Sci Engl Ed 134:44–47

Hills G (2003) Industrial use of lipases to produce fatty acid esters. Eur J Lipid Sci Technol 105:601–607

Montiel MC, Serrano M, Máximo MF, Gómez M, Ortega-Requena S, Bastida J (2015) Synthesis of cetyl ricinoleate catalyzed by immobilized Lipozyme® CalB lipase in a solvent-free system. Catal Today 255:49–53

Standard test method for acid and base number by color-indicator titration (ASTM D974–02e1)

Standard test method for hydroxyl value of fatty oils and acids (ASTM D1957–86)

Standard test method for determination of the iodine value of fats and oils (ASTM D5554–95)

Zhao X, El-Zahab B, Brosnahan R, Perry J, Wang P (2007) An organic soluble lipase for water-free synthesis of biodiesel. Appl Biochem Biotechnol 143:236–243

National Center for Biotechnology Information. PubChem Compound Database. https://pubchem.ncbi.nlm.nih.gov/. Accessed 3 Sept 2015

Homann MJ, Vail R, Morgan B, Sabesan V, Levy C, Dodds DR, Zaks A (2001) Enzymatic hydrolysis of a prochiral 3-substituted glutarate ester, an intermediate in the synthesis of an NK1/NK2 dual antagonist. Adv Synth Catal 343:744–749

Anderson EM, Larsson KM, Kirk O (1998) One biocatalyst-many applications: the use of Candida antarctica B-lipase in organic synthesis. Biocatal Biotransform 16:181–204

Ragupathy L, Ziener U, Dyllick-Brenzinger R, von Vacano B, Landfester K (2012) Enzyme-catalyzed polymerizations at higher temperatures: synthetic methods to produce polyamides and new poly(amide-co-ester)s. J Mol Catal B Enzym 76:94–105

Hasan F, Shah AA, Hameed A (2006) Industrial applications of microbial lipases. Enzyme Microb Technol 39:235–251

Petersson AEV, Adlercreutz P, Mattiasson B (2007) A water activity control system for enzymatic reactions in organic media. Biotechnol Bioeng 97:235–241

Kwon S, Song K, Hong W, Rhee J (1995) Removal of water produced from lipase-catalyzed esterification in organic-solvent by pervaporation. Biotechnol Bioeng 46:393–395

Sakaki K, Aoyama A, Nakane T, Ikegami T, Negishi H, Watanabe K, Yanagishita H (2006) Enzymatic synthesis of sugar esters in organic solvent coupled with pervaporation. Desalination 193:260–266

Lee DE, Park KM, Choi SJ, Shim J-H, Chang P-S (2013) Enhancing operational stability and exhibition of enzyme activity by removing water in the immobilized lipase-catalyzed production of erythorbyl laurate. Biotechnol Prog 29:882–889

Adnani A, Basri M, Chaibakhsh N, Salleh AB, Rahman MBA (2011) Lipase-catalyzed synthesis of a sugar alcohol-based nonionic surfactant. Asian J Chem 23:388–392

Paludo N, Alves JS, Altmann C, Ayub MAZ, Fernandez-Lafuente R, Rodrigues RC (2015) The combined use of ultrasound and molecular sieves improves the synthesis of ethyl butyrate catalyzed by immobilized Thermomyces lanuginosus lipase. Ultrason Sonochem 22:89–94

Adlercreutz P (2013) Immobilisation and application of lipases in organic media. Chem Soc Rev 42:6406–6436

Petersson AEV, Gustafsson LM, Nordblad M, Börjesson P, Mattiasson B, Adlercreutz P (2005) Wax esters produced by solvent-free energy-efficient enzymatic synthesis and their applicability as wood coatings. Green Chem 7:837–843

Ye R, Hayes DG (2011) Optimization of the solvent-free lipase-catalyzed synthesis of fructose-oleic acid ester through programming of water removal. J Am Oil Chem Soc 88:1351–1359

Klibanov AM (1989) Enzymatic catalysis in anhydrous organic solvents. Trends Biochem Sci 14:141–144

Bódalo A, Bastida J, Máximo MF, Montiel MC, Murcia MD, Ortega S (2009) Influence of the operating conditions on lipase-catalysed synthesis of ricinoleic acid estolides in solvent-free systems. Biochem Eng J 44:214–219

Sun S, Shan L, Jin Q, Liu Y, Wang X (2007) Solvent-free synthesis of glyceryl ferulate using a commercial microbial lipase. Biotechnol Lett 29:945–949

Kuperkar VV, Lade VG, Prakash A, Rathod VK (2014) Synthesis of isobutyl propionate using immobilized lipase in a solvent free system: optimization and kinetic studies. J Mol Catal B Enzym 99:143–149

Newerli-Guz J (2012) Labelling of organic and natural cosmetic products in harmonized standards. Zesz Nauk 74:36–42

Acknowledgments

This work has been funded with support from the Spanish Ministerio de Ciencia e Innovación (CTQ2011-24091) and the European Commission (FEDER/ERDF). M. Serrano-Arnaldos is beneficiary of a pre-doctoral scholarship (FPI) from the Spanish Ministerio de Economía y Competitividad (BES-2012-060261). We wish to acknowledge D. Ramiro Martínez Gutiérrez (Novozymes Spain S. A.), who kindly supplied the biocatalysts.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no competing interests.

Rights and permissions

About this article

Cite this article

Serrano-Arnaldos, M., Máximo-Martín, M.F., Montiel-Morte, M.C. et al. Solvent-free enzymatic production of high quality cetyl esters. Bioprocess Biosyst Eng 39, 641–649 (2016). https://doi.org/10.1007/s00449-016-1545-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-016-1545-5