Abstract

This study investigated the saccharification of orange peel wastes with crude enzymes from Aspergillus japonicus PJ01. Pretreated orange peel powder was hydrolyzed by submerged fermentation (SmF) and solid-state fermentation (SSF) crude enzymes, the results showed that 4 % (w/v) of solid loading, undiluted crude enzymes, and 45 °C were suitable saccharification conditions. The hydrolysis kinetics showed that the apparent Michaelis–Menten constant \(K_{{\text{m}_{app} }}\) and maximal reaction rate \(V_{{\max_{app} }}\) were 73.32 g/L and 0.118 g/(L min) for SmF enzyme, and 41.45 g/L and 0.116 g/(L min) for SSF enzyme, respectively. After 48 h of hydrolysis, the saccharification yields were 58.5 and 78.7 %, the reducing sugar concentrations were 14.9 and 20.1 mg/mL by SmF and SSF enzymes. Material balance showed that the SmF enzymatic hydrolysate was enriched galacturonic acid > arabinose > galactose > xylose, and the SSF enzymatic hydrolysate was enriched galacturonic acid > xylose > galactose > arabinose.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Global orange production was 51.3 million metric tons in 2012/13, among which 22.4 million metric tons were processed into orange juice, essential oils and other by-products [1]. Orange peel is the principal solid by-product of the orange processing industry and constitutes about 50 % of the fresh fruit weight. On the other hand, waste orange peel contains a lot of fibers (pectin, lignin, cellulose and hemicellulose), flavonoids, d-limonenes, sugars, and proteins [2, 3]. Hydrolysis of the fibers for production of monosaccharides is the most important and critical step because monosaccharides serve as a base material for production of value-added products such as ethanol, vitamins and organic acids [4, 5].

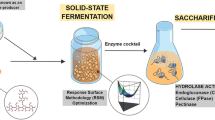

Production of monomeric sugars from agricultural wastes using commercial pectinase, cellulase and beta-glucosidase has been reported [6–8]. However, separation and purification of industrial enzymes are expensive, and optimization of enzyme loadings is complicated. Recent years, fungal crude enzymes have been used for enzymatic hydrolysis of lignocellulosic biomass, such as sugar cane bagasse, rice straw, corn cob and potato pulp [9–12]. In our previous work, a new isolated strain Aspergillus japonicus PJ01 could produce crude enzymes under submerged fermentation (SmF) and solid-state fermentation (SSF) [13]. In this work, the crude enzymes were used for saccharification of orange peel wastes.

Furthermore, sound kinetic schemes have been studied for cellulose hydrolysis by cellulase [14, 15], however, only few literatures focused on the kinetics of pectin enzymatic hydrolysis [16–18], and there is no study about the hydrolysis kinetics of orange peel by fungal crude enzymes.

Therefore, the aims of this work are: (a) to study the enzymatic hydrolysis conditions of orange peel powder by fungal crude enzymes from SSF and SmF; (b) to investigate the kinetic schemes of the crude enzymes; and (c) to perform a material balance on this bioconversion process.

Materials and methods

Microorganisms

Strain A. japonicus PJ01 (GenBank Accession number KF550286) was isolated from soil in Yuelu Mountain, Changsha City, China. Colonies showing degradation capacity for pectin, carboxymethyl cellulose (CMC), and xylan were assayed by plate screening using the Congo red overlay method, clearing zones appeared around the colony due to the hydrolysis of polysaccharides [19]. The strain was identified based on internal transcribed spacer (ITS) rDNA sequence analysis [20], the strain showed high identity (100 %) with A. japonicus. The approximate phylogenetic position of the strain is shown in Fig. 1.

Raw materials

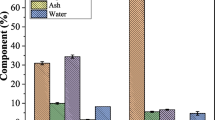

Orange peel was obtained locally (Changsha, China) and dried in an oven at 60 °C for 24 h, milled and sieved. Particles in size of less than 20 mesh were washed with distilled water (4 %, w/v) for 6 h at 30 °C with a rotating speed of 170 rpm, and the soluble material was separated by centrifugation. The thoroughly washed pretreated orange peel powder (POPP) was dried in an oven at 60 °C for 24 h.

Submerged fermentation (SmF) and solid-state fermentation (SSF)

SmF and SSF by A. japonicus PJ01 were carried out as the previous methods, orange peel and wheat bran were used as the sole substrates for crude enzymes production in SmF and SSF, respectively [13]. The cultured medium (pH were 5.0 ± 0.5) was filtered through coarse filter paper, the filtrate was centrifuged at 10,000×g for 10 min at 4 °C, and the supernatant was used as crude enzyme solution. After 72 h of cultivation under SmF and SSF, the maximal pectinase, carboxymethyl cellulase (CMCase), filter paper cellulase (FPase), and xylanase activities were obtained (Table 1). Commercial pectinase NCB-PE40 (Hunan Youtell Biochemical Co., Ltd. Yueyang, China) was used for comparison. Enzyme loading was 1.2 % (w/v) using 0.1 M acetate buffer (pH 5.0), and enzyme activities were also determined and shown in Table 1.

Analytical methods

Pectinase activity was determined by the method of Díaz et al. [21]. Saccharifying cellulase (FPase and CMCase) assays followed the method recommended by IUPAC committee [22]. Xylanase activity assay was determined by the method of Bailey et al. [23]. One unit of pectinase, FPase, CMCase, and xylanase was defined as the amount of enzyme required to release 1 μmol of d-galacturonic acid, glucose, glucose, and xylose per minute under standard assay conditions, respectively. Reducing sugar content of the fermentation broth was determined by DNS method [24]. The carbohydrates were determined by phenol–sulfuric acid method using glucose as a standard [25].

Enzymatic hydrolysis

Enzymatic hydrolysis experiments were carried out in 100-mL Erlenmeyer flasks containing 20 mL solution. In the enzymatic hydrolysis temperature experiment, 4 % (w/v) of POPP was added to the undiluted crude enzyme solution at 35, 45, and 55 °C. In the enzyme dose experiment, 4 % (w/v) of POPP was added to diluted crude enzyme solution, which was diluted to 20–100 % (v/v) by distilled water. In the substrate loading experiment, 2–10 % (w/v) of POPP was directly added to the undiluted crude enzyme solution. All samples were incubated in an air incubator shaker at 170 rpm for different time intervals. Reaction was terminated by keeping the digests at 100 °C for 5 min. The solution was then centrifuged at 10,000×g for 15 min, and the supernatant was subsequently filtered through a 0.22 μm syringe filter for reducing sugar and carbohydrate analysis. Saccharification was calculated and expressed as shown in the method of Pal et al. [26].

Carbohydrates in substrate were the sum of polysaccharides of orange peel (cellulose, hemicellulose, and pectin were 14.0, 21.3, and 22.1 % (w/w), respectively), which accounted for 57.4 % of the substrate [13].

Data presented in this article show the mean of three replicates with their standard deviation (mean ± SD).

Preparation of standard solution and 1-phenyl-3-methyl-5-pyrazolone (PMP) derivatization

PMP derivatization of monosaccharides was carried out as previous description with proper modification [27]. Briefly, 8 standard monosaccharides or hydrolyzed samples (100 μL) were dissolved in 0.3 M aqueous NaOH (100 μL) and a 0.5 M methanol solution (100 μL) of PMP was added to each. Fucose as an internal standard was added to each sample before the derivatization. Each mixture was allowed to react for 120 min at 70 °C, then cooled to room temperature and neutralized with 100 μL of 0.3 M HCl. The resulting solution was mixed with chloroform (1 mL), fully shook and allowed to stand for a while, then organic phase was removed and the extraction process was carried out three times. The aqueous layer was centrifuged at 10,000×g for 2 min and filtered through a 0.45 μm membrane for HPLC analysis.

HPLC equipment and conditions

The analysis of PMP-labeled monosaccharide was carried out on a Shimadzu LC-2010A HPLC system, a diode array detector (DAD), and LabSolutions chromatography workstation. The analytical column was a Thermo Hypersil C18 column (4.6 mm × 150 mm, 5 μm). The wavelength for DAD detection was 250 nm. Elution was carried out at a flow rate of 1.0 mL/min. The mobile phase A consisted of 40 mM KH2PO4 buffer (pH 7.0) and the mobile phase B was acetonitrile, A:B was 83:17, and the injection volume was 20 μL.

Results and discussion

Enzymatic hydrolysis of pretreated orange peel powder (POPP)

Effect of temperature and enzyme dose on the enzymatic hydrolysis of POPP

Figure 2 shows the effect of temperature on enzymatic hydrolysis of POPP [4 % (w/v)] using SmF and SSF crude enzymes, which indicates that 45 °C was the most suitable temperature for both crude enzymes. So, 45 °C was fixed in the following studies. Figure 3 shows the enzymatic hydrolysis of POPP under different dose of crude enzymes in the range of 20–100 % (v/v). At the same dose of the crude enzymes, the reducing sugar concentrations in SSF hydrolysates were higher than SmF hydrolysates after 24 h of incubation. For SmF enzyme, the reducing sugar concentration increased rapidly before 6 h, afterwards the growth was insignificant. As for SSF enzyme, the reducing sugar concentration increased rapidly until 12 h. Figure 3 also shows that reducing sugar concentration increased with enzyme dose. To obtain the maximum saccharification, undiluted crude enzymes were used in the following experiments. It is noteworthy that both SmF and SSF enzymes exhibited xylanase activity, which might contribute to the hydrolysis of hemicellulose. Previous studies demonstrated the hydrolysis of orange peel using the mixtures of pectinase and cellulase, but hydrolysis of orange peel by xylanase has not been reported [6, 28].

Effect of substrate loading on the enzymatic hydrolysis of POPP

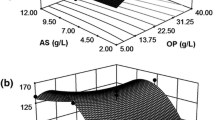

Figure 4 shows the effect of substrate loading on reducing sugar concentration and yield under SmF and SSF enzymes, respectively. Reducing sugar concentration increased with solid loading, but the relationship between the reaction rate and the solid loading was not proportional when the solid loading was more than 8 % (w/v). The results imply that product inhibition might occur during the reaction. High reducing sugar concentration was usually found to be one of the main factors reducing hydrolysis rates and impeding high fermentable sugar yield [15]. Figure 4 shows a significant reduction in hydrolysis yield with the increase of solid loading. After 24 h, hydrolysis yields by SmF and SSF enzymes decreased from 58.3 to 80.0 % (2 % solid loading) to 31.5 and 42.3 % (10 % solid loading), respectively. In this work, end-product inhibition was significant, which was not the same with enzymatic hydrolysis of sugar beet pulp [29]. Therefore, 4 % (w/v) of POPP loading was used for reducing sugars production in further experiments, because relatively high reducing sugar concentration and yield were obtained at this substrate loading.

Figure 5 shows a Lineweaver–Burk plot of experimental data for the crude enzymes. The apparent Michaelis–Menten constants of SmF and SSF crude enzymes were \(K_{{\text{m}_{app} }}\) = 73.32 and 41.45 g/L, and maximal reaction rates were \(V_{{\max_{app} }}\) = 0.118 and 0.116 g/(L.min), respectively. SSF enzyme had a smaller Km app than SmF enzyme, indicating the enzyme required only a small amount of substrate to become saturated, the maximum velocity was obtained at lower substrate concentrations than SmF crude enzyme.

Effect of time on the enzymatic hydrolysis of POPP

Table 1 shows the enzyme activities and enzymatic hydrolysis performances from SmF, SSF, and commercial enzyme. Pectinase activities were not significant among these enzyme, however, SSF crude enzyme showed higher cellulase and xylanase activities. The higher enzyme activities led to higher hydrolysis efficiency. After 48 h of incubation, the reducing sugar concentrations were 14.9, 20.1, and 18.1 mg/mL for SmF, SSF, and commercial enzymes, respectively. Figure 6 depicted the reducing sugar and carbohydrates production, and saccharification yields of POPP with SmF and SSF crude enzymes. Grohmann et al. [28] observed high level of conversion (>70 %) to monomeric sugars from orange peel after treatment with pectinase enzyme. Wilkins et al. [6] found grapefruit peel waste could be hydrolyzed by pectinase, and the yield of total sugars reached 63.8 %. In this work, saccharification yields of POPP using SmF and SSF enzymes were 58.5 and 78.7 %, respectively, which indicated that SSF crude enzyme showed higher hydrolysis efficiency than commercial enzymes.

Carbohydrates concentration was higher than reducing sugar concentration, which indicated that some oligosaccharides were produced during enzymatic hydrolysis [30, 31]. The difference in concentrations between carbohydrates and reducing sugars by SSF enzyme was more obvious than SmF enzyme (Fig. 6). The results indicate that more oligosaccharides were produced by SSF enzyme.

Monosaccharide analysis

Table 2 shows the monosaccharides production from SmF and SSF enzymatic hydrolysates. Since SSF crude enzyme provided higher CMCase, FPase, and xylanase activities (Table 1), the concentrations of glucose and xylose in SSF enzyme hydrolysate were higher than that in SmF. However, the concentrations of galacturonic acid and arabinose were higher in SmF enzyme hydrolysate, which indicated that SmF might provide higher endopolygalacturonase and arabinase activities. In the case of SmF crude enzyme hydrolysis, the monosaccharides increased significantly in the initial 12 h and then maintained constant (Table 2). As for SSF crude enzyme hydrolysis, monosaccharides kept an increased tendency during 48 h (Table 2). Presence of significant amounts of glucose and galacturonic acid in the medium might lead to catabolite repression to cellulase and pectinase [7].

Figure 7 shows the HPLC chromatograms of PMP derivatives of 8 standard monosaccharides released from orange peel enzymatic hydrolysis after 24 h. It can be concluded that the proposed method is suitable for determining the monosaccharides in orange peel hydrolysates. Compared with the gradient elution of the mobile phase [32, 33], isocratic elution in this work had a good elution profile. Refractive index detection was usually used in monitoring monosaccharide of enzymatic hydrolysates [34]. However, this method is not sensitive and/or selective enough for differentiating the trace amounts of aldoses and uronic acids [35]. PMP-labeled method could obviously improve the sensitivity and detection limit of monosaccharides, in which the aldoses and uronic acids could be simultaneously determined by HPLC method [27].

The HPLC chromatograms of mixed standard sample of monosaccharides (a); and hydrolysates of POPP by SmF (b) and SSF (c) crude enzymes. Enzymatic hydrolysis experiments were carried out at 45 °C and 170 rpm with substrate loading 4 % (w/v) for 24 h. Peaks: 1 mannose, 2 rhamnose, 3 glucuronic acid, 4 galacturonic acid, 5 xylose, 6 glucose, 7 galactose, 8 arabinose, 9 fucose (internal standard)

Material balance

Before enzymatic hydrolysis, the orange peel powders were washed with distilled water (see “Raw materials”). In this stage, the nonvolatile solutes accounted for 44.7 % (w/w) of oven-dry OPP, and the water-extracted solid (POPP) accounted for 55.3 % (w/w) of oven-dry OPP. Table 3 shows the material balance after enzymatic hydrolysis. After 48 h of enzymatic hydrolysis, total monosaccharides from enzymatic hydrolysis of POPP by SmF and SSF enzymes were 53.4 and 58.5 % (w/w) of oven-dry POPP, respectively. These results indicate that SSF crude enzyme provided higher enzymatic hydrolysis efficiency than SmF. SmF enzymatic hydrolysate was enriched with galacturonic acid > arabinose > galactose > xylose, and the SSF enzymatic hydrolysate was enriched with galacturonic acid > xylose > galactose > arabinose. Galacturonic acid concentrations were similar between SmF and SSF enzymatic hydrolysate, which could be attributed to the equivalent pectinase activities. Xylose concentration from SSF enzymatic hydrolysate was much more than SmF hydrolysate, which could be attributed to the higher xylanase activity.

Conclusions

Orange peel can be hydrolyzed to monomeric sugars using the crude enzymes produced by A. japonicus PJ01 in submerged and solid-state fermentations. Pectinase activity from SSF crude enzyme was similar to SmF crude enzyme, but FPase, CMCase and xylanase activities of the former were much higher than the latter. 4 % (w/v) of solid loading, undiluted crude enzymes, and 45 °C were suitable conditions for reducing sugars production by these two crude enzymes. After 48 h of incubation, the reducing sugars concentration using SmF and SSF enzyme was 14.9 mg/mL (saccharification 58.5 %) and 20.1 mg/mL (saccharification 78.7 %), respectively. This study demonstrated that enzymatic hydrolysis of orange peel using SSF crude enzyme showed promise for further scale-up. Compared with commercial enzymes, fungal crude enzymes would help improve the productivity and economic viability of the pectin-rich biomass hydrolysis.

References

USDA (2013) Citrus: world markets and trade. Available from http://www.fas.usda.gov/psdonline/psdHome.aspx

Pfaltzgraff LA, Cooper EC, Budarin V, Clark JH (2013) Food waste biomass: a resource for high-value chemicals. Green Chem 15:307–314

Marín FR, Soler-Rivas C, Benavente-García O, Castillo J, Pérez-Alvarez JA (2007) By-products from different citrus processes as a source of customized functional fibres. Food Chem 100:736–741

Rezzadori K, Benedetti S, Amante E (2012) Proposals for the residues recovery: orange waste as raw material for new products. Food Bioprod Process 90:606–614

Awan AT, Tsukamoto J, Tasic L (2013) Orange waste as a biomass for 2G-ethanol production using low cost enzymes and co-culture fermentation. RSC Adv 3:25071–25078

Wilkins MR, Widmer WW, Grohmann K, Cameron RG (2007) Hydrolysis of grapefruit peel waste with cellulase and pectinase enzymes. Bioresour Technol 98:1596–1601

Oberoi HS, Sandhu SK, Vadlani PV (2012) Statistical optimization of hydrolysis process for banana peels using cellulolytic and pectinolytic enzymes. Food Bioprod Process 90:257–265

Ghorbanpour Khamseh AA, Miccio M (2012) Comparison of batch, fed-batch and continuous well-mixed reactors for enzymatic hydrolysis of orange peel wastes. Process Biochem 47:1588–1594

Garai D, Kumar V (2013) A Box-Behnken design approach for the production of xylanase by Aspergillus candidus under solid state fermentation and its application in saccharification of agro residues and Parthenium hysterophorus L. Ind Crops Prod 44:352–363

Gao M-T, Yano S, Minowa T (2014) Characteristics of enzymes from Acremonium cellulolyticus strains and their utilization in the saccharification of potato pulp. Biochem Eng J 83:1–7

Yamada R, Yoshie T, Sakai S, Wakai S, Asai-Nakashima N, Okazaki F, Ogino C, Hisada H, Tsutsumi H, Hata Y, Kondo A (2015) Effective saccharification of kraft pulp by using a cellulase cocktail prepared from genetically engineered Aspergillus oryzae. Biosci Biotechnol Biochem 79:1034–1037

Wang D, Sun J, Yu H-L, Li C-X, Bao J, Xu J-H (2012) Maximum saccharification of cellulose complex by an enzyme cocktail supplemented with cellulase from newly isolated Aspergillus fumigatus ECU0811. Appl Biochem Biotechnol 166:176–186

P-j Li, J-l Xia, Shan Y, Z-y Nie (2015) Comparative study of multi-enzyme production from typical agro-industrial residues and ultrasound-assisted extraction of crude enzyme in fermentation with Aspergillus japonicus PJ01. Bioprocess Biosyst Eng 38:2013–2022

Bansal P, Hall M, Realff MJ, Lee JH, Bommarius AS (2009) Modeling cellulase kinetics on lignocellulosic substrates. Biotechnol Adv 27:833–848

Philippidis GP, Smith TK, Wyman CE (1993) Study of the enzymatic hydrolysis of cellulose for production of fuel ethanol by the simultaneous saccharification and fermentation process. Biotechnol Bioeng 41:846–853

Bélafi-Bakó K, Eszterle M, Kiss K, Nemestóthy N, Gubicza L (2007) Hydrolysis of pectin by Aspergillus niger polygalacturonase in a membrane bioreactor. J Food Eng 78:438–442

Baciu I-E, Jördening H-J (2004) Kinetics of galacturonic acid release from sugar-beet pulp. Enzyme Microb Technol 34:505–512

Demirel D, Hakkı Boyacı İ, Mutlu M (2003) Determination of kinetic parameters of pectolytic enzymes at low pectin concentrations by a simple method. Eur Food Res Technol 217:39–42

P-j Li, J-l Xia, Shan Y, Z-y Nie, F-r Wang (2015) Effects of surfactants and microwave-assisted pretreatment of orange peel on extracellular enzymes production by Aspergillus japonicus PJ01. Appl Biochem Biotechnol 176:758–771

Li P-J, Xia J-L, Shan Y, Nie Z-Y, Su D-L, Gao Q-R, Zhang C, Ma Y-L (2015) Optimizing production of pectinase from orange peel by Penicillium oxalicum PJ02 using response surface methodology. Waste Biomass Valor 6:13–22

Díaz AB, Bolívar J, de Ory I, Caro I, Blandino A (2011) Applicability of enzymatic extracts obtained by solid state fermentation on grape pomace and orange peels mixtures in must clarification. LWT Food Sci Technol 44:840–846

Ghose T (1987) Measurement of cellulase activities. Pure Appl Chem 59:257–268

Bailey MJ, Biely P, Poutanen K (1992) Interlaboratory testing of methods for assay of xylanase activity. J Biotechnol 23:257–270

Miller GL (1959) Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal Chem 31:426–428

Masuko T, Minami A, Iwasaki N, Majima T, Nishimura S-I, Lee YC (2005) Carbohydrate analysis by a phenol–sulfuric acid method in microplate format. Anal Biochem 339:69–72

Pal S, Banik SP, Khowala S (2013) Mustard stalk and straw: a new source for production of lignocellulolytic enzymes by the fungus Termitomyces clypeatus and as a substrate for saccharification. Ind Crops Prod 41:283–288

Lv Y, Yang X, Zhao Y, Ruan Y, Yang Y, Wang Z (2009) Separation and quantification of component monosaccharides of the tea polysaccharides from Gynostemma pentaphyllum by HPLC with indirect UV detection. Food Chem 112:742–746

Grohmann K, Baldwin E (1992) Hydrolysis of orange peel with pectinase and cellulase enzymes. Biotechnol Lett 14:1169–1174

Zheng Y, Cheng Y-S, Yu C, Zhang R, Jenkins BM, VanderGheynst JS (2012) Improving the efficiency of enzyme utilization for sugar beet pulp hydrolysis. Bioprocess Biosyst Eng 35:1531–1539

Martínez Sabajanes M, Yáñez R, Alonso JL, Parajó JC (2012) Pectic oligosaccharides production from orange peel waste by enzymatic hydrolysis. Int J Food Sci Technol 47:747–754

Mandalari G, Bennett RN, Kirby AR, Lo Curto RB, Bisignano G, Waldron KW, Faulds CB (2006) Enzymatic hydrolysis of flavonoids and pectic oligosaccharides from bergamot (Citrus bergamia Risso) peel. J Agric Food Chem 54:8307–8313

Fu D, Oneill RA (1995) Monosaccharide composition analysis of oligosaccharides and glycoproteins by high-performance liquid chromatography. Anal Biochem 227:377–384

Yang X, Zhao Y, Wang Q, Wang H, Mei Q (2005) Analysis of the monosaccharide components in Angelica polysaccharides by high performance liquid chromatography. Anal Sci 21:1177–1180

Visser EM, Falkoski DL, de Almeida MN, Maitan-Alfenas GP, Guimarães VM (2013) Production and application of an enzyme blend from Chrysoporthe cubensis and Penicillium pinophilum with potential for hydrolysis of sugarcane bagasse. Bioresour Technol 144:587–594

Wang Q, Fang Y (2004) Analysis of sugars in traditional Chinese drugs. J Chromatogr B Analyt Technol Biomed Life Sci 812:309–324

Acknowledgments

We thank Dr. Yi Yang (Central South University) for valuable help with the language polishing. This work was supported by a Grant from the National High Technology Research and Development Program of China (863 Program) (No. 2011AA100804), Hunan Provincial Innovation Foundation for Postgraduate (CX2013B084), and Open-End Fund for the Valuable and Precision Instruments of Central South University (CSUZC2014003).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Li, Pj., Xia, Jl., Nie, Zy. et al. Saccharification of orange peel wastes with crude enzymes from new isolated Aspergillus japonicus PJ01. Bioprocess Biosyst Eng 39, 485–492 (2016). https://doi.org/10.1007/s00449-015-1531-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-015-1531-3