Abstract

This work demonstrates the first example of the immobilisation of MAO-N whole cells to produce a biocatalyst that remained suitable for repetitive use after 11 months of storage and stable up to 15 months after immobilisation. The production of Escherichia coli expressing recombinant MAO-N was scaled up to bioreactors under regulated, previously optimised conditions (10 % DO, pH 7), and the amount of biomass was almost doubled compared to flask cultivation. Subsequently, pilot immobilisation of the whole-cell biocatalyst using LentiKats® technology was performed. The amount of the immobilised biomass was optimised and the process was scaled up to a production level by immobilising 15 g of dry cell weight per litre of polyvinyl alcohol to produce 3 kg of whole-cell ready-to-use biocatalyst. The immobilised biocatalyst retained its initial activity over six consecutive biotransformations of the secondary amine model compound 3-azabicylo [3,3,0]octane, a building block of the hepatitis C drug telaprevir. Consecutive cultivation cycles in growth conditions not only increased the initial specific activity of biocatalyst produced on the industrial plant by more than 30 %, but also significantly increased the rate of the biotransformation compared to the non-propagated biocatalyst.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

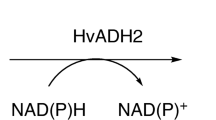

The monoamine oxidase N from Aspergillus niger (MAO-N) has been developed by directed evolution to produce biocatalysts capable of the selective oxidative deamination or deracemisation of primary (Alexeeva et al. 2002), secondary (Carr et al. 2005) and tertiary amines (Cardenas-Fernandez et al. 2012; Dunsmore et al. 2006). Recently, Ghislieri et al. (2013) designed a toolbox for the development of MAO-N variants applicable in asymmetric synthesis of the generic active pharmaceutical ingredients Solifenacin and Levocetirizine, as well as the natural products (R)-coniine, (R)-eleagnine, (R)-leptaflorine and (R)-harmicine.

The mutant MAO-N D5 (Atkin et al. 2008), which contains five amino acid mutations, has been used for the desymmetrisation of non-chiral amines such as the substituted pyrrolidine 3-azabicyclo [3,3,0]octane (Koehler et al. 2010). This amine is a building block in the hepatitis C viral serine protease inhibitor compound telaprevir (Online Resource, Fig. S1), traded under the names Incivek®. Desymmetrisation of 3-azabicyclo [3,3,0]octane by MAO-N D5 leads to an imine to which hydrogen cyanide can be selectively added. The addition is from the less-hindered face of the imine leading to a single α-amino nitrile enantiomer (Online Resource, Fig. S2), from which hydrolysis yields the chiral 3,4-substituted proline analogue (Turner 2011). Many hydroxyprolines are useful chiral building blocks for the synthesis of pharmaceuticals or are potent inhibitors of cell growth and have been tested for their antitumor activity (Bach and Takagi 2013). Znabet et al. (2010) reported the synthesis of substituted telaprevir building blocks by using the imine obtained by biocatalytic desymmetrisation in combination with a three-component Ugi-type reaction.

Over the last three decades, there has been intensive research in the immobilisation of cells and enzymes, with the idea of improving the economics of biocatalysts applications (e.g. their reusability). LentiKats® technology is a type of immobilisation which entraps the enzymes or microorganisms in a porous polyvinyl alcohol (PVA) carrier with a unique lentil-like shape. PVA hydrogel is an advantageous matrix, being cheap, biologically inert and non-toxic, with excellent physical and mechanical long-term stability (Grosová et al. 2009). LentiKats® biocatalysts have so far been used in the pharmaceutical industry, food processing industries, distilleries and wastewater treatment (Boušková et al. 2011; Durieux et al. 2000; Rebroš et al. 2009; 2005; www.lentikats.eu). The ratio of particles’ diameter (3–4 mm) vs. their thickness (250–400 μm) makes LentiKats® very amenable for separation from the reaction mixture and recycling, provides high concentration of biomass, avoids diffusion limitations and allows easy penetration of substrate into and product out of the matrix. The immobilisation process is carried out under mild conditions, allowing the entrapment of even sensitive enzymes or cells (Grosová et al. 2009; Rodriguez-Nogales et al. 2013).

Carr et al. (2005) immobilised MAO-N of >80 % purity obtained from the cell-free extract on Eupergit C resin, and although there are many works dealing with whole-cell biocatalysis with immobilised Escherichia coli (Zajkoska et al. 2013), to the best of our knowledge, this is the first one to deal with the whole-cell immobilisation of recombinant monoamine oxidase MAO-N for biocatalytic purposes.

This work explores the process of optimisation of the pilot whole-cell MAO-N immobilisation using LentiKats® technology in laboratory conditions, and immobilisation of high amounts of biomass using industrial scale equipment. The feasibility of repetitive use of the immobilised biocatalyst over time using the telaprevir building block 3-azabicyclo [3,3,0]octane as substrate was examined. The effect of cultivation cycles in growth conditions on the immobilised biocatalyst (so-called propagation) was also studied.

Materials and methods

Biomass production

E. coli BL21(DE3) cells expressing MAO-N D5 cloned in pET16b (Alexeeva et al. 2002) were produced during a 20-h cultivation carried out at 30 °C in LB medium (10 g/L tryptone, 5 g/L yeast extract, 10 g/L NaCl). Ampicillin (100 μg/mL) as a selection marker was added before the inoculation. For the flask production performed in a shaking incubator at 250 rpm, the biomass was grown in 100 mL LB medium in 500 mL culture flask inoculated with 1 % culture of an OD600 between 0.6 and 1. To start the regulated biomass fermentation in a 3-L bioreactor BioFlo®115 (New Brunswick Scientific, NL), the pre-inoculation culture was grown overnight from a single colony in 3 mL of LB medium at 37 °C and 250 rpm. The inoculum was prepared by adding 1 % of the overnight culture to 100 mL of LB in 500 mL culture flask and incubated at 37 °C and 250 rpm until OD600 0.6–1 was reached. The bioreactor was prepared by adding 2 L of LB medium and 150 μL of Dow Corning® 1510 Silicone Antifoam (Dow Corning Corporation, USA) and autoclaving at 121 °C for 20 min. Twenty millilitres of overnight culture were added to inoculate the bioreactor. The fermentation ran under controlled, previously optimised conditions of 10 % DO and pH 7 (maintained by 1.8 M H2SO4) at 30 °C for 20 h. The dissolved oxygen level was maintained by an agitation cascade from 200 to 1,000 rpm, while the air supply was kept constant at 1 L/min (0.5 vvm). The process was monitored via BioCommand software (New Brunswick Scientific, NL) which measured the dissolved oxygen, pH, temperature and agitation rate. When an increase in pH was detected the acid pump was automatically activated to return the system to pH 7.

Laboratory immobilisation

After a 20-h fermentation under optimised conditions, the biomass was drained out from the bioreactor, centrifuged (2,750 g, 30 min) and re-suspended to 1/10th of the original volume in potassium phosphate buffer (0.1 M, pH 8). According to the amount of biomass needed for immobilisation, such prepared biomass was centrifuged in falcon tubes (7,197 g, 5 min) and after re-suspension in sterile dH2O, it was ready for immobilisation. Fresh biomass was always used for immobilisation.

For the optimisation of laboratory immobilisation, 40 mL of polyvinyl alcohol (PVA) gels with different biomass concentration were prepared as shown in Table 1.

The gel was melted at max. 95 °C and then cooled to 40 °C, when the biomass suspension was added dropwise with constant stirring. The lens-shaped drops were plated on drop plates using the LentiPrinter device. The PVA drops were then dried in air flow at 35 to 37 °C, until they begin to unstick from the polyethylene drop plate. Then they were re-swelled in stabilising solution (0.1 M Na2SO4) for 30–40 min and after washing with sterile dH2O were either stored or directly used for biocatalysis. For stability testing in different environments, the LentiKats® expressing MAO were semi-aseptically transferred either to sterile LB medium or non-sterile potassium phosphate buffer (0.1 M, pH 8) and stored at 4 °C in the presence of 100 μg/mL ampicillin.

Industrial immobilisation

The biomass for the large-scale immobilisation was grown in Novaferm fermentor in 55 L of LB medium with 100 μg/mL ampicillin according to the abovementioned conditions. The industrial immobilisation procedure was performed with 15 gDCW/LPVA according to the standard large-scale protocol of the manufacturer (www.lentikats.eu). The resulting biocatalyst is referred to as LK-MAO from hereon in.

Standard biotransformation

3-Azabicyclo [3,3,0]octane (AK Scientific Inc., USA) was selected as a model substrate for the biotransformation (Online Resource, Fig. S3), catalysed by either free, or immobilised cells expressing MAO-N D5. The standard biotransformation was performed in a 50-mL falcon tube with 5 mL reaction mixture (0.1 M potassium phosphate buffer, pH 8) and 20 mM substrate in a rotatory shaker at 37 °C and 250 rpm. In case of free whole cells, biomass obtained from 50 mL broth was used. The amount of immobilised biocatalyst was a subject of testing to find the optimal filling of the reaction. Samples were taken at regular intervals for analysis by GC.

Immobilised biocatalyst stability testing

Several setups were used to test the suitability of the immobilised biocatalyst for long-term storage in different conditions. The LB medium and potassium phosphate buffer (0.1 M, pH 8) were used as storage environments for the stability testing in terms of retaining the initial specific activity and reusability. The stability testing was performed with 20 % w/v reaction loading in standard biotransformation. The immobilised biocatalyst was thoroughly washed with buffer prior to starting the biotransformation.

Propagation cycles

Consecutive propagation cycles were carried out with 1 g of LK-MAO that had been stored in LB medium with 100 μg/mL ampicillin for 2 months. Seven parallels containing 1 g of LK-MAO were set for cultivation in 10 mL of LB medium with 100 μg/mL ampicillin over 24 h at 30 °C and 225 rpm. The LB medium was changed every day in sterile conditions in each of them and also, every day one parallel was taken for standard biotransformation of 20 mM 3-azabicyclo [3,3,0]octane in 5 mL reaction mixture. Prior to starting the biotransformation, the LK-MAO were thoroughly washed with potassium phosphate buffer and immediately used for the reaction. To test for the presence of contamination, 100 μL of several dilutions of the cultivation broth after the propagation were plated on 2 % LB-agar with and without ampicillin.

Sample processing and the analytical method

Two hundred microlitres of sample were taken out from the biotransformation mixture at regular time intervals, 8 μL 10 M NaOH and 1 mL tert-butyl methyl ether (Sigma-Aldrich) were added. After vortexing, the Eppendorf tube was centrifuged for 1 min at 13,300 g. The organic phase was dried with Na2SO4 and transferred to a glass vial for analysis. The biotransformation of the secondary amine to imine catalysed by MAO-N D5 was monitored by GC-FID (Agilent 6890N), CAM column (J&W Scientific, 30 m × 320 μm × 0.25 μm) and H2 as carrier gas with flow rate of 1.6 mL/min, injection 1 μL and split 50:1. The oven temperature was held at 110 °C for 4.2 min, and then rose by 30 °C/min to 200 °C, where it was held for 0.8 min and the post-run was to 100 °C. The %bioconversion was evaluated as area imine peak / (area amine peak + area imine peak) × 100.

Data evaluation and activity calculation

The initial rate of the biotransformation is represented by the slope b of the linear part of a graph of %bioconversion against time measured in hours and was obtained by linear regression analysis. The initial specific activity of the free (or immobilised biocatalyst) is defined as milligrams of product produced per hour by 1 gDCW of biomass (or 1 g of LentiKats®).

-

a)

Calculation of the activity for free whole-cells

-

Initial rate, activity:\( a=\frac{b}{100\left[{\mathrm{h}}^{-1}\right]} \)

-

Initial specific activity:\( {a}_{sp}=\frac{a\cdot \mathrm{k}\cdot {\mathrm{m}}_{\mathrm{s}0}}{{\mathrm{m}}_{\mathrm{DCW}}}\left[{\mathrm{m}\mathrm{g}}_{\mathrm{product}}/\mathrm{h}/{\mathrm{g}}_{\mathrm{DCW}}\right] \)

-

-

b)

Calculation of the activity for the immobilised cells

-

Initial specific activity:\( {a}_{sp}=\frac{a\cdot k\cdot {c}_{\mathrm{s}0}\cdot \overline{V_R}}{m_{\mathrm{LK}}}=\frac{\frac{b}{100}\cdot k\cdot {c}_{\mathrm{s}0}\cdot \overline{V_R}}{m_{\mathrm{LK}}}\left[{\mathrm{mg}}_{\mathrm{product}}/\mathrm{h}/{\mathrm{g}}_{\mathrm{DCW}}\right] \)

- k :

-

coefficient representing the ratio of utilised substrate and formed product (the FID detector response factor is the same for substrate and product)

- m S0 (mg):

-

initial amount of the substrate

- m DCW (g):

-

biomass dry cell weight obtained from 50 mL broth

- c S0 (mg/mL):

-

initial concentration of the substrate

- m LK (g):

-

amount of LentiKats®

- \( \overline{V_R}( m L) \) :

-

middle volume of the reaction mixture \( \overline{V_R}=\frac{V_1{t}_1+{V}_2{t}_2+{V}_3{t}_3+\dots +{V}_x{t}_x}{t{}_n} \)

- V 1, V 2, V 3,…,V x :

-

volume of the reaction mixture at the sampling time

- t 1, t 2, t 3,…,t x :

-

time length of the sampling intervals

- t n :

-

total length of the sampling period

-

Results

Flask cultivation and scale-up of the biomass production

E. coli cells were grown in 100 mL LB medium in a flask and the enzyme was expressed over 20 h of cultivation. The average OD600 reached in four experiments was 4.7 ± 0.3 (1.40 ± 0.05 gDCW/L).

The biomass production was scaled up in laboratory fermentors and was optimised in series of experiments (data not shown) to reach ideal conditions in terms of biomass growth and enzyme expression. The conditions considered as optimal for this experiment are 10 % DO and pH maintained at 7 (by 1.8 M H2SO4), and the average OD600 reached after 20 h over five fermentations is 8.1 ± 0.2 (2.44 ± 0.02 gDCW/L) (Fig. 1).

Figure 2 provides comparison of standard biotransformations with biomass from 50 mL of broth cultivated either in flask (65.3 mgDCW), or the fermentor (119.9 mgDCW). Due to the much higher final biomass reached under the controlled conditions in the fermentor, this biotransformation was faster compared to the biomass produced on a flask level. However, the initial specific activity of the fermentor biomass was lower compared to the flask biomass (97.6 vs. 123.2 mgproduct/h/gDCW). Nevertheless, to meet the quantity requirements for biomass immobilisation, the biomass was produced in laboratory fermentors.

Optimisation of the laboratory immobilisation

After the biomass production in larger scale under controlled conditions, the aim was to optimise the amount of biomass suitable for immobilisation, with respect to the activity of the immobilised biocatalyst in biotransformation of the model secondary amine. Therefore, different dry cell weight (DCW) concentrations (1, 5.33, 10, 15 and 20 g/L of PVA gel) were immobilised in 40 mL PVA gel using LentiKats® technology and their activity was tested in triplicate reactions.

As shown in Fig. 3, the initial specific activity displayed a linear trend with increasing concentration of the immobilised biomass. The error bars represent the standard deviation calculated from triplicates.

The maximum biomass load used for immobilisation was 20 gDCW/LPVA, since at higher concentrations the mechanical stability of the matrix might be affected (personal communication with LentiKats a.s., Czech Republic). Although there was a 29 % increase in the initial specific activity (Fig. 3), there was no significant difference in the duration of biotransformation with 15 and 20 gDCW/LPVA (Fig. 4), probably due to the mass transfer limitation. Only minor cell release was detected by optical density measurement after the biotransformation (max. 1.6 %), proving the suitability of the method for effective entrapment of high initial biomass concentrations.

The smallest industrial production of LentiKats® is 3 L of gel. For immobilisation of 15 gDCW/LPVA that means processing biomass from ~18.7 L of media cultivated at 10 % DO and pH 7 in laboratory fermentors, while for 20 gDCW/LPVA, it is 25 L. Therefore, considering the cost of the immobilisation process, 15 gDCW/LPVA was the concentration of biomass chosen for immobilisation in the industrial plant.

Reaction loading and reusability of the industrial LentiKats®-MAO-N D5

To verify the laboratory scale immobilisation, scale-up of the immobilisation process with optimised protocol was performed on the industrial equipment with 15 gDCW/LPVA.

Repeated bioconversions with LK-MAO were performed with 1, 2, 3 and 4 g (20, 40, 60 and 80 % w/v) of the immobilised biocatalyst in 5 mL of reaction mixture in order to optimise the reaction loading and also to test the reusability of the biocatalyst. Six consecutive biotransformations with 20 mM substrate were performed in the same reaction vessel, with the following average initial specific activities: 1.48 ± 0.14 mgproduct/h/gLK (20 % w/v); 1.26 ± 0.05 mgproduct/h/gLK (40 % w/v); 1.04 ± 0.09 mgproduct/h/gLK (60 % w/v); and 1.09 ± 0.06 mgproduct/h/gLK (80 % w/v). The remainder of the reaction mixture was drained and the biocatalyst was thoroughly washed with potassium phosphate buffer between the consecutive biotransformations.

The results indicate that 20 % reaction loading showed the best performance in terms of the highest average initial specific activity. These conditions reflect the mass transfer and oxygen demands of the reaction. They are also the most suitable with regards to the process operations and scale-up of the process, since lower loading with the immobilised biocatalyst enables better mixing and aeration of the system.

Storage stability of the immobilised biocatalyst

It is advantageous to produce the LK-MAO in bulk batches and then store the immobilised enzyme for use when needed, but this requires that the biocatalyst to remain sufficiently active over time. Initially, the industrially immobilised biocatalyst was stored in LB medium with ampicillin. As the LB is a nutrition-rich medium and ampicillin undergoes degradation (do Nascimento et al. 2013), in order to avoid potential contamination the LK-MAO were transferred to potassium phosphate buffer (0.1 M, pH 8) with ampicillin after certain period of time. Figure 5 summarises the results obtained over the long-term storage in different conditions. The most important finding is that even the long-term stored biocatalyst reaches conversion >98 % within ~22 h of standard biotransformation, which is the same time range as for the fresh biocatalyst. Irrespective of the storage environment and time, the biocatalyst performs as well as it did at the start.

Similarly as with the fresh biocatalyst, six sequential standard biotransformations were performed with industrial LK-MAO that had been stored for ~11 months (4.5 months in LB medium and 6.5 months in potassium phosphate buffer, both with ampicillin). Figure 6 shows the comparison of the initial specific activities of fresh non-propagated and long-term stored LK-MAO, indicating that even the long-term stored immobilised biocatalyst is suitable for repetitive use. The average activity values are 1.48 ± 0.14 mgproduct/h/gLK for the fresh biocatalyst and 1.31 ± 0.31 mgproduct/h/gLK for the biocatalyst that has been stored for ~11 months.

In a single biotransformation performed with LK-MAO stored for 15 months after the industrial immobilisation (6 months in LB medium and 9 months in potassium phosphate buffer with ampicillin), the biocatalyst reached initial specific activity of 1.39 mgproduct/h/gLK. That is only a 9 % decrease compared to the very first biotransformation with fresh non-propagated LK-MAO. This indicates that the whole-cell immobilised biocatalyst loaded with high amount of biomass is suitable for long-term storage, with no significant loss of activity.

Propagation of the immobilised biocatalyst

Although 15 gDCW/LPVA (which is roughly estimated ~19 mgDCW/gLK) is a high biomass concentration, there was a question whether the cultivation of LentiKats® containing whole cells in growth conditions of LB medium might improve their performance in the biotransformation. Another issue was whether the presence of ampicillin combined with the biomass positive selection pressure is sufficient to prevent contamination during the eventual propagation of the biocatalyst. To investigate this, consecutive propagation cycles were carried out with LK-MAO that had been stored for 2 months. Every day over 7 days, one parallel was used for single biotransformation of the model secondary amine.

The propagation cycles demonstrated how to increase the activity of the whole-cell immobilised biocatalyst even when starting from a high concentration of immobilised biomass. After the fifth cycle, the initial specific activity had risen by 34 % (Fig. 7) and then began to drop from the 6th cycle.

The propagation steps not only increased the initial specific activity of the whole-cell immobilised biocatalyst, but from the practical point of view resulted in a significant acceleration of the biotransformation. There was 20 % increase in the percentage of conversion measured at 7 h between the non-propagated LK-MAO and the biocatalyst after five propagation cycles (Fig. 8). Moreover, only very few contaminating colonies appeared in our contamination check indicating that the presence of antibiotic together with the biomass positive selection pressure prevented an unwanted microflora growth.

Discussion

Voulgaris et al. (2011) reported that the ideal process of monoamine oxidase expression should be carried out under level of dissolved oxygen low enough to allow satisfactory growth and prevent fermentative metabolism, but not high enough to cause oxidative damage of the recombinant protein. While they ran the regulated fed batch fermentation at 30 % DO and pH 7, we proved that in batch process even 10 % DO is sufficient for an effective production of active MAO-N D5. On the other hand, our standard biotransformation of the model substrate ran with biomass from 50 mL flask-cultivated broth was in accordance with Koehler et al. (2010).

The principle of work with whole-cell immobilised LentiKats® biocatalyst is mostly based on the immobilisation of low initial biomass concentration (~0.6 gDCW/LPVA) and consequent propagation steps prior to get ready-to-use biocatalyst for biotransformations (Stloukal et al. 2007). This approach has been applied both on bacteria and yeast cells. The capability of cells to grow within the PVA matrix during the propagation cycles was proven on Oenococcus oeni in a work focused on the improvement of the malolactic fermentation of cider (Durieux et al. 2000). Rebroš et al. (2005) applied Zymomonas mobilis cells entrapped in LentiKats® (0.36 gbiomass/LPVA) for batch and continuous ethanol production. The biomass concentration had risen from the initial 0.3 to 110 mg/gPVA after 12 batch fermentations. The increase of biomass within the matrix resulted in ~3 times higher productivity of the continuous process compared to free cells. In a work dealing with the production of D-galactose by immobilised Saccharomyces cerevisiae, the concentration of the initially immobilised 0.7 gcells/LPVA reached 160 mg/gLK as a result of eight propagation steps (Grosová et al. 2009).

On the other hand, there are not many examples in the literature when initially higher biomass concentration was immobilised into LentiKats®. Kubáč et al. (2006) entrapped ~4 gDCW of Rhocococcus equi A4 per litre of PVA gel and applied the biocatalyst in repeated biotransformations of nitriles. In other study, Cardenas-Fernandez et al. (2012) immobilised 2 mL of whole (0.8 g/mL) or permeabilised cells (0.3 g/mL) with ω-transaminase activity in 8 mL commercial PVA mixture, aiming to produce aromatic chiral amines in repeated biotransformations. The biocatalyst immobilised in LentiKats® was stable for five reaction cycles. The recent work of Rebroš et al. (2014) provides an example of immobilisation of high amount of E. coli expressing cyclopentanone monooxygenase (24.4 g/LPVA), followed by three propagation cycles and IPTG induction. The LentiKats® biocatalyst retained its activity for six consecutive enantioselective Baeyer–Villiger biooxidations of the model substrate. As a result of this optimisation, we applied the approach of immobilising high amount of recombinant E. coli cells expressing monoamine oxidase for application in biocatalysis.

The propagation itself depends on the immobilised microorganism and its concentration in the matrix, the cultivation medium and particular optimal conditions. E. coli favours growth in nutrition rich media (such as LB) at pH ~7, which are conditions suitable for cultivation of many common bacterial species. The process of laboratory immobilisation is performed in non-sterile conditions. Therefore, there is an increased risk of contamination getting into the matrix and evolving during the eventual propagation steps, despite the presence of ampicillin. We demonstrated that this problem could be overcome by initially immobilising high quantities of biomass (15 gDCW/LPVA) to avoid the necessity of propagation, and thus prepare ready-to-use biocatalyst suitable for recycling. Although the propagation is not necessary when immobilising a high concentration of biomass and the LK-MAO could either be used directly or stored, the effect of consecutive cultivations in growth conditions on the activity of the biocatalyst and the presence of contamination was investigated. After five propagation cycles, a 34 % increase of the initial specific activity and acceleration of the biotransformation was achieved. That is in accordance with the 29 % difference of activity between LK-MAO with 15 and 20 gDCW/LPVA. The subsequent drop in activity indicates that the maximal biomass capacity of the matrix was reached during the fifth cycle, which is in good correlation with the manufacturer’s recommendations to not immobilise more than 20 gDCW/LPVA. As a result of the combined effect of ampicillin and the high selective pressure of the immobilised biomass, only very rare contaminating colonies were detected on the LB-agar plates between the propagation cycles.

There is also an increased risk of contamination during the long-term storage of the immobilised biocatalyst in LB medium. Therefore, potassium phosphate buffer, which does not provide the key carbon or nitrogen requirements for microorganism growth, was also tested as a storage medium. The industrially produced LK-MAO displayed stable catalytic activity over 15 months of storage and were capable of repetitive use after 11 months. This is a promising result in terms of producing large amounts of biocatalysts that do not have to be used immediately in biotransformations. To our best knowledge, no other aerobic/facultatively anaerobic whole-cell biocatalyst immobilised in LentiKats® has remained active after being stored for such a long time. We assume that the prolonged shelf-life of the biocatalyst is due to the protective effect of the PVA matrix. However, it remains to be further investigated, whether it is the cells which remain entrapped in the matrix, or they undergo lysis and it is the active enzyme.

Recently, Ramesh and Woodley (2014) verified the toxicity and inhibition effects of substrate, product and co-product (H2O2), which lead to the inactivation of the biocatalyst. It has been proven that the imine has the most negative impact on the whole-cell biocatalyst. Toxicity and inhibition effects of the reaction mixture may explain why the biotransformation with 1 and 5.33 gDCW/LPVA biocatalyst did not run to completion after more than 90 h. It is likely that the biocatalyst with 1 gDCW/LPVA was inactivated by the forming product. The long-term exposure to the imine product might explain the decrease of activity during the repetitive use of the 15 gDCW/LPVA biocatalyst. The toxicity and inhibition effect of the reaction mixture was more pronounced in the long-term stored biocatalyst, causing significant decrease of activity between the first and the second biotransformation. Irrespective of the storage time, once the immobilised biocatalyst has been used for reaction, it is not possible to increase its activity by applying propagation steps.

Easy separation of the biocatalyst, reusability and storage possibilities are in favour of the application of the whole-cell immobilised biocatalysis. In this pilot work of whole-cell immobilisation of MAO, we showed that the LK-MAO biocatalyst could be reused at least six times in the same vessel by simple draining of the reaction mixture. If needed, the product could be isolated from the reaction mixture by the procedure developed by Koehler et al. (2010) and the process potentially scaled up. Whole-cells expressing monoamine oxidase might be used in combination with expensive chemical catalysts, such as Pd(0), to produce a biometallic catalyst for the deracemisation of racemic amines (Foulkes et al. 2011). In this case, immobilisation is a greater challenge but the cost-saving aspect is even more pronounced because the biometallic catalyst can be reused.

After solving the constraints that have been identified (substrate inhibition, product inhibition causing reversible loss of activity and product toxicity causing irreversible loss of activity) and improving the protein expression (Ramesh and Woodley 2014), immobilised MAO-N biocatalysis has a potential to be scaled up. In the synthesis of Merck’s new drug boceprevir for hepatitis C treatment, the desymmetrisation of a prochiral amine to produce a key bicyclic [3.1.0]proline intermediate is catalysed by the mutant MAO-N 401 (Li et al. 2012). Since several recombinant variants of monoamine oxidase MAO-N with broad substrate specificity have been developed so far, this work might serve as a model tool how to obtain an easy producible, effective and reusable biocatalyst by applying immobilisation of whole cells, or even cell-free extract or purified enzyme, in the production of value-added substances.

References

Alexeeva M, Enright A, Dawson MJ, Mahmoudian M, Turner NJ (2002) Deracemization of α-methylbenzylamine using an enzyme obtained by in vitro evolution. Angew Chem Int Ed Engl 41:3177–3180. doi:10.1002/1521-3773(20020902)41:17<3177::aid-anie3177>3.0.co;2-p

Atkin KE, Reiss R, Turner NJ, Brzozowski AM, Grogan G (2008) Cloning, expression, purification, crystallization and preliminary X-ray diffraction analysis of variants of monoamine oxidase from Aspergillus niger. Acta Crystallogr F 64:182–185. doi:10.1107/S174430910800345X

Bach TMH, Takagi H (2013) Properties, metabolisms, and applications of l-proline analogues. Appl Microbiol Biotechnol 97:6623–6634

Boušková A, Mrákota J, Stloukal R, Trögl J, Pilařová V, Křiklavová L, Lederer T (2011) Three examples of nitrogen removal from industrial wastewater using Lentikats Biotechnology. Desalination 280:191–196

Cardenas-Fernandez M, Neto W, Lopez C, Alvaro G, Tufvesson P, Woodley JM (2012) Immobilization of Escherichia coli containing ω-transaminase activity in LentiKats®. Biotechnol Prog 28:693–698. doi:10.1002/btpr.1538

Carr R, Alexeeva M, Dawson MJ, Gotor-Fernandez V, Humphrey CE, Turner NJ (2005) Directed evolution of an amine oxidase for the preparative deracemisation of cyclic secondary amines. Chembiochem 6:637–639. doi:10.1002/cbic.200400329

do Nascimento TG, Oliveira ED, Basilio ID, de Araujo JX, Macedo RO (2013) Short-term stability studies of ampicillin and cephalexin in aqueous solution and human plasma: application of least squares method in Arrhenius equation. J Pharm Biomed Anal 73:59–64

Dunsmore CJ, Carr R, Fleming T, Turner NJ (2006) A chemo-enzymatic route to enantiomerically pure cyclic tertiary amines. J Am Chem Soc 128:2224–2225. doi:10.1021/ja058536d

Durieux A, Nicolay X, Simon JP (2000) Continuous malolactic fermentation by Oenococcus oeni entrapped in LentiKats. Biotechnol Lett 22:1679–1684. doi:10.1023/a:1005667611732

Foulkes JM, Malone KJ, Coker VS, Turner NJ, Lloyd JR (2011) Engineering a biometallic whole cell catalyst for enantioselective deracemization reactions. ACS Catal 1:1589–1594

Ghislieri D, Green AP, Pontini M, Willies SC, Rowles I, Frank A, Grogan G, Turner NJ (2013) Engineering an enantioselective amine oxidase for the synthesis of pharmaceutical building blocks and alkaloid natural products. J Am Chem Soc 135:10863–10869

Grosová Z, Rosenberg M, Gdovin M, Sláviková L, Rebroš M (2009) Production of D-galactose using β-galactosidase and Saccharomyces cerevisiae entrapped in poly(vinylalcohol) hydrogel. Food Chem 116:96–100

Koehler V, Bailey KR, Znabet A, Raftery J, Helliwell M, Turner NJ (2010) Enantioselective biocatalytic oxidative desymmetrization of substituted pyrrolidines. Angew Chem Int Ed Engl 49:2182–2184. doi:10.1002/anie.200906655

Kubáč D, Čejková A, Masák J, Jirků V, Lemaire M, Gallienne E, Bolte J, Stloukal R, Martínková L (2006) Biotransformation of nitriles by Rhodococcus equi A4 immobilized in LentiKats®. J Mol Catal B Enzym 39:59–61. doi:10.1016/j.molcatb.2006.01.004

Li T, Liang J, Ambrogelly A, Brennan T, Gloor G, Huisman G, Lalonde J, Lekhal A, Mijts B, Muley S, Newman L, Tobin M, Wong G, Zaks A, Zhang XY (2012) Efficient, chemoenzymatic process for manufacture of the boceprevir bicyclic [3.1.0] proline intermediate based on amine oxidase-catalyzed desymmetrization. J Am Chem Soc 134:6467–6472

Ramesh H, Woodley JM (2014) Process characterization of a monoamine oxidase. J Mol Catal B Enzym 106:124–131. doi:10.1016/j.molcatb.2014.04.009

Rebroš M, Rosenberg M, Stloukal R, Krištofíková L (2005) High efficiency ethanol fermentation by entrapment of Zymomonas mobilis into LentiKats®. Lett Appl Microbiol 41:412–416. doi:10.1111/j.1472-765X.2005.01770.x

Rebroš M, Rosenberg M, Grosová Z, Krištofíková Ľ, Paluch M, Šipöcz M (2009) Ethanol production from starch hydrolyzates using Zymomonas mobilis and glucoamylase entrapped in polyvinylalcohol hydrogel. Appl Biochem Biotechnol 158:561–570. doi:10.1007/s12010-008-8475-x

Rebroš M, Lipták L, Rosenberg M, Bučko M, Gemeiner P (2014) Biocatalysis with Escherichia coli-overexpressing cyclopentanone monooxygenase immobilized in polyvinyl alcohol gel. Lett Appl Microbiol 58:556–563. doi:10.1111/lam.12227

Rodriguez-Nogales JM, Vila-Crespo J, Fernandez-Fernandez E (2013) Immobilization of Oenococcus oeni in Lentikats® to develop malolactic fermentation in wines. Biotechnol Prog 29:60–65

Stloukal R, Rosenberg M, Rebros M (2007) A method for industrial production of biocatalysts in the form of enzymes or microorganisms immobilized in polyvinyl alcohol gel, their use and devices for their production WO/2007/104268

Turner NJ (2011) Enantioselective oxidation of C–O and C–N bonds using oxidases. Chem Rev 111:4073–4087. doi:10.1021/cr200111v

Voulgaris I, Arnold SA, Speight R, Harvey LM, McNeil B (2011) Effects of dissolved oxygen availability and culture biomass at induction upon the intracellular expression of monoamine oxidase by recombinant E. coli in fed batch bioprocesses. Process Biochem 46:721–729. doi:10.1016/j.procbio.2010.11.019

www.lentikats.eu; Accessed 22.5. 2014

Zajkoska P, Rebroš M, Rosenberg M (2013) Biocatalysis with immobilized Escherichia coli. Appl Microbiol Biotechnol 97:1441–1455

Znabet A, Ruijter E, de Kanter FJJ, Koehler V, Helliwell M, Turner NJ, Orru RVA (2010) Highly stereoselective synthesis of substituted prolyl peptides using a combination of biocatalytic desymmetrization and multicomponent reactions. Angew Chem Int Ed 49:5289–5292

Acknowledgments

The research leading to these results has received funding from the European Union Seventh Framework Programme BIONEXGEN under grant agreement no. 266025. This work was co-funded by the Slovak Research and Development Agency under contract no. DO7RP-0042-11.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

(PDF 189 kb)

Rights and permissions

About this article

Cite this article

Zajkoska, P., Rosenberg, M., Heath, R. et al. Immobilised whole-cell recombinant monoamine oxidase biocatalysis. Appl Microbiol Biotechnol 99, 1229–1236 (2015). https://doi.org/10.1007/s00253-014-5983-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-014-5983-1