Abstract

A combination of microbial strain improvement and statistical optimization is investigated to maximize echinocandin B (ECB) production from Aspergillus nidulans ZJB-0817. A classical sequential mutagenesis was studied first by using physical (ultraviolet irradiation at 254 nm) and chemical mutagens (lithium chloride and sodium nitrite). Mutant strain ULN-59 exhibited 2.1-fold increase in ECB production to 1583.1 ± 40.9 mg/L when compared with the parent strain (750.8 ± 32.0 mg/L). This is the first report where mutagenesis is applied in Aspergillus to improve ECB production. Further, fractional factorial design and central composite design were adopted to optimize the culture medium for increasing ECB production by the mutant ULN-59. Results indicated that four culture media including peptone, K2HPO4, mannitol and l-ornithine had significant effects on ECB production. The optimized medium provided another 1.4-fold increase in final ECB concentration to 2285.6 ± 35.6 mg/L compared to the original medium. The results of this study indicated the combined application of a classical mutation and medium optimization can improve effectively ECB production from A. nidulans and could be a promising tool to improve other secondary metabolites production by fungal strains.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

In the past several decades, both the incidence and the types of fungal infection severely detrimental to human health continuously increased, especially for the immunosuppressed patients [12]. At the same time, the clinical application of certain commonly used clinical antifungal agents, such as amphotericin, imidazoles and triazoles, was restricted due to significant neurotoxicity and drug resistance [3]. Echinocandins are a novel class of antifungal agents with antifungal activity against Candida and Aspergillus species and Pneumocystis carinii [9]. These compounds interrupt biosynthesis of β-1,3-glucan linkages, an essential component of the fungal cell wall [3]. There is little human toxicity attributed to the mechanism of action, because glucan polymers are not components of mammalian cells. In recent years, more concerns have been raised on echinocandin antifungal drug due to its low toxicity and rapid and broader-spectrum antifungal activity [1].

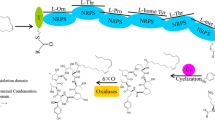

Echinocandin B (ECB) (see the chemical structure of ECB, Fig. 1), a novel linoleoyl-containing cyclic hexapeptide echinocandin-type compound, was isolated from a culture broth of the fungus Aspergillus nidulans [3]. Anidulafungin is derived from the modification of ECB with deacylase to replace linoleoyl groups and introduce newly synthesized side chains [7]. Increasing production of ECB and improvement of fermentation condition for ECB was necessary for the industrial manufacturing of anidulafungin. Furthermore, a steady supply of producing strains for each manufacturing lot was needed to maintain the high production of ECB. However, no scientific report has been published on mutant screening for improved ECB production to the best of our knowledge.

Owing to their inherent metabolic control systems, microorganisms usually produce secondary metabolites in very low concentrations. Strain improvement plays a central role in the commercial development of microbial fermentation processes [4, 10, 29, 31]. Although the modern techniques of gene engineering and metabolic engineering are considered to be effective methods in the microorganism breeding [11, 16, 27], the application of these modern techniques frequently encounters serious impediments due to limited insight into the genetics, physiology, and biochemistry of organisms [21]. Thus, the classic strain improvement technology is still an effective and practical approach to obtain improved strains for production of both primary and secondary metabolites [13, 18, 26]. Sequential mutation is methodologically simple, it is an extremely effective way to enhance productivity of strains [2], and many scientists have used this methodology to generate industrial strains [2, 15, 23]. The improvement of microbial strains using different mutagenic agents, such as ultraviolet (UV), X-rays and plasma, as well as various chemical mutagens, for increased production of industrial products has been considered in the commercial fermentation process [25].

Medium optimization is essential to enhance performance of the production system and yield of the process. Conventionally, the fermentation medium was optimized using a one-factor-at-a-time strategy, which was relatively simple and did not require statistical analysis. Major disadvantage of this approach is that it does not include interactive effects among the variable parameters, and it is highly time consuming as well [4, 22, 24]. To overcome these limitations, optimization of the variable parameters has been carried out using a statistical factorial design called as response surface methodology (RSM). RSM is a combination of mathematical and statistical techniques used for optimizing the process. It can also be used to determine and evaluate several factors affecting the process and their relative significance, even in presence of complex interactions, in a limited number of experiments [22, 28].

The present work was carried out to find out a mutant with high level of ECB production by mutating A. nidulans ZJB-0817 with sequential mutagenesis. Further attempt was made to optimize the basic culture medium for achieving high level of ECB production by the mutant using RSM.

Materials and methods

Chemicals

Echinocandin B was purchased from BioAustralis (Smithfield, AUS). Acetonitrile and methanol were HPLC grade and purchased from Honeywell Burdick & Jackson Chemical Ltd., USA. All other chemicals and reagents were of analytical grade and purchased from Mike Chemical Reagents Co., Ltd. (Hangzhou, China).

Microorganism mutagenesis and mutant screening

A. nidulans ZJB-0817, used in the present study, was preserved at the China Center for Type Culture Collection (CCTCC M 2010275, Wuhan, China). The strain was maintained on 200 g potato, 20 g dextrose, 20 g agar, and 1000 mL water (PDA) slants, stored at 4 °C, and renewed periodically. Spore suspensions were obtained by culturing the strain at 25 °C on a PDA slant for 7 days, followed by washing with 10 mL sterile saline. Spore suspension of the wild strain was adjusted to 107 cells/mL in sterile water. A 20 mL sample of spore suspension was irradiated with ultraviolet light (wavelength, 254 nm; power, 30 W; distance, 30 cm) for 80 s, and then treated with lithium chloride (0.6 %, v/v) for 30 min, and finally treated with sodium nitrite (0.1 M, 1 M pH 4.5 acetate buffer) for 50 s. Subsequently, the treated spore suspension was plated in PDA plates and incubated at 25 °C for 7 days. After clones were formed, 460 clones were randomly selected and inoculated on PDA slants.

Cultivation of wild strain and mutants for ECB production

Spore suspension of a 7-day-old culture grown on PDA slants was prepared by dispensing 20 mL of sterilized water and adjusted to 107 cells/mL. A 1.2 mL spore suspension was inoculated to a 500 mL Erlenmeyer flask containing 100 mL of basic medium (10 g glycerol, 10 g peptone, 40 g soybean meal, 20 g peanut oil, 5 g l-proline, 5 g CaCl2, 8 g K2HPO4·3H2O, 0.05 g FeSO4·7H2O, 5 g MgSO4·7H2O, 0.1 g MnSO4·H2O, 0.6 g CuSO4·5H2O, and 1000 mL water, initial pH 6.6) and cultured in a rotary shaker at 200 rpm and 25 °C for 12 days.

Analysis of ECB production

The concentrations of ECB were determined by HPLC. The chromatographic conditions were as follows: ODS column (Shim-pack, VP-ODS, 4.6 mm × 250 mm, Shimadzu Corporation, Kyoto, Japan); UV detector; detection wavelength 222 nm; flow rate 1.0 mL/min; mobile phase, methanol: acetonitrile: water in the ratio of 70:10:20 (v/v); injection volume 10 μL. The retention times for ECB were around 13.5 min. Moreover, all samples were filtered through a 0.22 μm one-off filtration membrane prior to injection into HPLC system to get accurate results. The ECB was confirmed by liquid chromatography/mass spectrometry (Suppl. Fig. S1) and NMR spectroscopy (Suppl. Fig. S2), the concentration of ECB was determined using standard plots obtained with pure ECB.

Fractional factorial design and data analysis

Fractional factorial design (FFD) was used to screen significant factors affecting ECB production. The first-order model was suggested, as follows Eq. (1):

where Y is the response of ECB production; α 0 is the model intercept and α i is the coefficient of the linear equation, and x i is the dimensionless coded level of the independent variable. Each coded variable represents two levels, low (−1) and high (+1), according to the following Eq. (2):

where x i is the dimensionless coded value of the real test variable X i ; X i1 is the real value of the variable X i ; X i0 is the value of X i using the central point of the investigated ranged, and ∆X i is the change in size of the step. Eight variables (peptone, MnSO4, soybean, CaCl2, K2HPO4, tomato powder, mannitol, l-ornithine) were selected and evaluated using FFD. 28–3 fractional factorial design (32 experimental runs) using four central point replications are carried out. All experiments were carried out in triplicates. The statistical software package “Minitab Release 16”, Minitab Inc., State College, PA, USA, was used for analyzing the experimental data. The fit of the first-order equation model was checked using the coefficient of determination R 2 and the adjusted R 2. The significant variables were screened on the basis of the F test and the p value at a confidence interval of 99 %.

Central composite design and data analysis

Optimization of the four most significant variables (peptone, mannitol, l-ornithine and K2HPO4), identified by FFD was carried out by central composite design (CCD) for enhancing ECB production. The four independent variables were studied at five different levels (−2, −1, 0, +1, +2), in a set of 31 experiments that including eight axial points, sixteen factorial points and seven center points. The same software package as used for FFD was used for analyzing the experimental data. All experiments were conducted in triplicates and the mean production of ECB (mg/L) was taken as the response (Y). Quadratic regression analysis of the data was carried out for obtaining an empirical model that relates the response measured to the independent variables. The behavior of the system was explained by the following second-order polynomial Eq. (3):

where Y is the predicted response, β 0 is offset term, β i are coefficients for the linear terms, β ii are for the square terms, β ij are the coefficients of interactive terms. Optimum levels of all four independent variables were determined by solving the regression equation and analyzing the response surface contour plots.

Results

Sequential mutagenesis and screening high-yield mutants

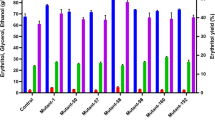

The production of ECB after sequential mutagenesis by various mutants is indicated in Table 1. A. nidulans ZJB-0817 was initially exposed to UV irradiation. The best UV-mutant strain, UV-30, produced 1060.3 ± 43.8 mg ECB/L, showing a 1.4-fold production improvement compared to the parent strain (750.8 ± 32.0 mg/L). The UV-treated mutant strain was further treated with lithium chloride and sodium nitrite, and one of the resulting mutants, ULN-59, had the highest production of ECB (1583.1 ± 40.9 mg/L), showing a 2.1-fold production improvement compared to the parent strain (Suppl. Fig. S3). The stability of mutant A. nidulans ULN-59 for ECB production was determined by successive subculturing on ECB production agar for over 1 year. The mutant was subcultured every month and evaluated for its ability to stably produce ECB. The mutant ULN-59 maintained the same production yield after being subcultured ten times (Suppl. Fig. S4), indicating that the mutant has heritable character.

Screening significant culture medium for enhancing ECB production

According to the results of single-factor research, peptone, MnSO4, soybean, CaCl2, K2HPO4, tomato powder, mannitol, l-ornithine were taken as the main medium component. The fractional factorial design-based experiments with eight variables were performed to select the significant culture medium affecting ECB production by mutant ULN-59 (Suppl. Table S1). The FFD was utilized because it is accurate for estimating the main effects and interaction effects with a reduced number of experimental runs compared to a complete factorial design [8]. Table 2 presents the statistical analysis of the FFD with the estimated coefficients and significant levels for the variables in the ECB production. The R 2 value was 0.963, indicating that 96.3 % of the variability in the response could be explained by the model. The F value and p value were selected for analysis of variance (ANOVA) of the model. According to an ANOVA of FFD results with replicated center points, the curvature in the tested region was significant with a p value of less than 0.01, which suggests that a response surface study with a quadratic model is required to optimize ECB production with the selected significant variables.

Based upon the statistical analysis data, four variables (peptone, mannitol, K2HPO4 and l-ornithine) were significant model terms at the 99 % level with p values of less than 0.01 (Table 2). A response surface study with a quadratic model can be applied with the significant variables determined from the FFD study. The common significant variables (peptone, mannitol, K2HPO4 and l-ornithine) in the production of ECB were chosen for response surface studies.

Optimization of culture medium for ECB production

Before optimizing the culture medium, the steepest ascent experiment was carried out, and the results (Suppl. Table S2) showed that the center point of the four significant components was chosen as 10 g/L peptone, 10 g/L K2HPO4, 100 g/L mannitol, and 6 g/L l-ornithine. To have an accurate optimization of the four significant components, a four-factor, five-level rotatable central composite design was carried out. The design matrix and corresponding experimental data are given in Table 3. The regression coefficient, F value, p value and standard error are summarized in Table 4. F value and p value indicate the significance of the regression coefficient. From Table 4, the linear coefficients x 1, x 5 and x 8, the quadratic coefficient x 21 , x 25 and x 27 as well as the interaction coefficient x 1 x 5, x 1 x 7, x 1 x 8 and x 7 x 8 are all significant at a 1 % significance level. Therefore, the linear coefficients x 1, x 5 and x 8, the quadratic coefficient x 21 , x 25 and x 27 as well as the interaction coefficient x 1 x 5, x 1 x 7, x 1 x 8 and x 7 x 8 are the most influential factors. On the other hand, the linear effect x 7 and the interactive effects of x 5 x 7 and x 5 x 8 on ECB yield were all slight, as indicated by the large p value. By applying multiple regression analysis on the experimental data, the following second-order polynomial Eq. (4) was established to explain the production of ECB:

where Y is the predicted response, and x 1, x 5, x 7, and x 8 are the coded values for peptone, K2HPO4, mannitol, and l-ornithine, respectively.

The optimal conditions for maximum ECB production, calculated by setting the partial derivatives of Eq. (4) to zero with respect to the corresponding variables, were as follows: peptone 8.6 g/L, K2HPO4 8.4 g/L, mannitol 97.3 g/L, l-ornithine 5.3 g/L. The maximum response value for ECB production was estimated as 2277.2 mg/L.

With ECB production value as the response, the three-dimensional response surfaces and two-dimensional contour plots are displayed in Fig. 2a–d. These figures demonstrated the relative effects of two variables on the production of ECB while the third value is kept constant. Figure 2a–d depicts the three-dimensional response surfaces and two-dimensional contour plots for the optimization of the medium compositions for the production of ECB. Each response surface plot presented a clear peak and the corresponding contour plot depicted the effect of two variables (among them peptone, K2HPO4, mannitol and l-ornithine) on the production of ECB within their experimental range, while the other variable was constant at its central point level. As shown in Fig. 2a–d, the maximum ECB production was predicted within the range of this study, indicating that further increase of peptone, K2HPO4, mannitol and l-ornithine concentrations would not cause a further increase in ECB production. Figure 2a represents the interaction between peptone and K2HPO4 and its effect on the level of ECB produced. The ECB production generally increased to a peak value with an increase in peptone concentration and a decrease in K2HPO4 concentration, and then decreased with a further increase in peptone concentration or a decrease in K2HPO4 concentration. The variable of peptone concentration is relatively more significant than the K2HPO4 concentration on the production of ECB. The two-dimensional contour plot shows a symmetrical mound shape with a coordinate axis and the p value (0.0032, ANOVA) is far lower than 0.05, indicating a significant effect on the interaction between K2HPO4 and peptone concentrations. Similar result was also found in the significant interaction effect on ECB production against peptone and mannitol (Fig. 2b), peptone and l-ornithine (Fig. 2c), mannitol and l-ornithine (Fig. 2d).

Experimental verification of theoretical optimum

To validate the model of the optimization approach, confirmation experiments were carried out in triplicate under conditions as predicted by the model: peptone 8.6 g/L, K2HPO4 8.4 g/L, mannitol 97.3 g/L, l-ornithine 5.3 g/L and a mean experimental value of ECB production 2285.6 ± 35.6 mg/L was obtained. There was a good agreement between the predicted value (2277.2 mg/L) and the empirical experimental results (2285.6 ± 35.6 mg/L) verifies the validity of the model. ECB production using the predicted optimal medium was significantly enhanced, being 1.4-fold higher than that with original medium (1583.1 ± 40.9 mg/L). It demonstrates that the CCD design is a successful approach for estimating optimal medium parameters for ECB production.

Discussion

There have been no reports made concerning the development of an Aspergillus strain via mutagenesis for the production of ECB. In our study, the strain improvement using sequential mutagenesis proved to be an effective method in enhancing ECB production from A. nidulans. Four hundred and sixty colonies were screened after sequential mutation that involved the use of physical UV radiations and chemical mutagens (lithium chloride and sodium nitrite) treatment, and a total of 15 mutants was detected with notably improved level of ECB production. The mutant A. nidulans ULN-59 exhibited the highest ECB production (1583.1 ± 40.9 mg/L) and improved the yield 2.1 times as compared to production by parent strain (Suppl. Fig. S3). These results suggested that physical and chemical mutations are considered to have the potential to change the echinocandin-type compound content of fungal strain. Kanda also reported increased echinocandin-type compound FR901379 production by a non-foaming mutant of Coleophoma empetri F-11899 which was generated through UV mutagenesis. Under the optimum culture conditions, the mutant produced 5.0 U/mL FR901379, while 1.0 U/mL of production was achieved in wild type strain [9, 14]. Masurekar et al. isolated Zalerion arboricola MF5415 by two chemical mutagens (N-nitroso-N-methylurethane and N-methyl-N-nitro-N-nitrosoguanidine) treatment which was found to be increased 2.5-fold yield of pneumocandins A 0 compared to their parent strain [20]. The stability of strains is considered an important and useful criterion for industrial fermentation. As shown in Suppl. Fig. S4, the mutant A. nidulans ULN-59 maintained the same production yield after being subcultured ten times and hence should have great potential use in the industrial production of ECB.

Productivity of any fungal fermentation is affected by media composition and process parameters and therefore the further investigation was performed to statistically optimize the culture medium for the production of ECB from A. nidulans ULN-59 using FFD and CCD methodologies. All significant variables involved in ECB production were evaluated by FFD because it can test a large number of variables while avoiding the loss of any essential information in subsequent optimization studies. Based on analysis of FFD, four key variables, viz., peptone, mannitol, K2HPO4 and l-ornithine were all positively significant factors for ECB production (Table 2). Among the four factors, peptone, as a nitrogen source, had the most influence on ECB yield (p < 0.002). It was also a supplementary nitrogen source and benefited other lipopeptide antibiotics (such as pneumocandin A0, FR901379, and iturin A) production by fungi [14, 20]. Mannitol, the most significant medium component effecting ECB production by A. nidulans ULN-59, was also used as an important carbon source for producing echinocandins-type pneumocandin A 0 by Zalerion arboricola [20]. It is rich cost-effective, making it a valuable nutrient source in the fermentation industry. The biosynthesis of many different types of antibiotics and other secondary metabolites is regulated by phosphate. K2HPO4, as an available phosphate and inorganic salts, is often an important factor for the production of secondary metabolites by certain fungi. K2HPO4 had significant effects on the production of streptolydigin in Streptomyceslydicus AS 4.2501 [19]. In the present study, K2HPO4 appeared to have an important role in ECB production. In addition, according to the chemical structure of ECB (Fig. 1), l-ornithine can be a biosynthetic precursor of ECB production; thus, it is reasonable why l-ornithine has obvious effect on ECB production. This was followed by use of a multifactorial response surface approach employing CCD, an effective design strategy, for studying the effects of key variables and their mutual interactions. The optimum medium contained: 8.6 g peptone, 97.3 g mannitol, 8.4 g K2HPO4 and 5.3 g l-ornithine per liter. The optimized medium provided another 1.4-fold increase in final ECB concentration to 2285.6 ± 35.6 mg/L compared to the original medium. The results of the validation experiment and the predicted value matched perfectly, proving that the statistically based experimental designs had been effective in enhancing the production of ECB.

To explore the difference between the original and optimized medium, carbon and nitrogen contents in the two mediums were analyzed and carbon–nitrogen ratio was calculated in Table 5. Comparing the original medium, carbon–nitrogen ratio of the optimized medium was increased from 9.23:1 to 18.09:1 (Table 5), which might be the most important reason for ECB production enhancement. ECB is a cyclic hexapeptide with a fatty acid (linoleoyl) side chain (Fig. 1). Fatty acids are synthesized with acetyl-CoA and malonyl-CoA starters [5, 6, 30]. Leman reported that a relatively high carbon–nitrogen ratio would improve fatty acids synthesis from acetyl-CoA and malonyl-CoA [17]. Coincidentally, in our case, ECB has a fatty acid side chain and it was postulated to be synthesized from acetyl-CoA and malonyl-CoA. Therefore, a relatively high carbon–nitrogen ratio would also improve the ECB production.

Low yield and high production costs in the currently available commercial ECB have limited its widespread use [9]. Thus there is a need for high ECB producing strain and improvement of ECB productivity. In this work, a combined approach of microbial strain improvement and statistical optimization was successfully developed for enhanced production of echinocandin B by A. nidulans ZJB-0817. The overall results obtained show a remarkable 3.0-fold (from 750.8 to 2285.6 mg/L) improvement in ECB production when compared to that using the original medium. The applied methods of sequential mutagenesis and statistical optimization were efficient, relatively simple, and time and material saving. These results of this work promise to improve the present production of ECB and may be adopted to enhance other objective products’ production by fungal strains.

References

Balkovec JM, Hughes DL, Masurekar PS, Sable CA, Schwartz RE, Singh SB (2014) Discovery and development of first in class antifungal caspofungin (CANCIDAS (R))-A case study. Nat Prod Rep 31(1):15–34

Baltz RH (2011) Strain improvement in actinomycetes in the postgenomic era. J Ind Microbiol Biotechnol 38(6):657–666

Bauer A, Brönstrup M (2014) Industrial natural product chemistry for drug discovery and development. Nat Prod Rep 31(1):35–60

Bhavsar K, Gujar P, Shah P, Kumar VR, Khire J (2013) Combinatorial approach of statistical optimization and mutagenesis for improved production of acidic phytase by Aspergillus niger NCIM 563 under submerged fermentation condition. Appl Microbiol Biotechnol 97(2):673–679

Cai MH, Zhou XS, Sun XQ, Tao KJ, Zhang YX (2009) Statistical optimization of medium composition for aspergiolide A production by marine-derived fungus Aspergillus glaucus. J Ind Microbiol Biotechnol 36(3):381–389

Choi JW, Da Silva NA (2014) Improving polyketide and fatty acid synthesis by engineering of the yeast acetyl-CoA carboxylase. J Biotechnol 187:56–59

Denning DW (2003) Echinocandin antifungal drugs. Lancet 362(9390):1142–1151

Du TF, He AY, Wu H, Chen JN, Kong XP, Liu JL, Jiang M, Ouyang PK (2013) Butanol production from acid hydrolyzed corn fiber with Clostridium beijerinckii mutant. Bioresour Technol 135:254–261

Emri T, Majoros L, Tóth V, Pócsi I (2013) Echinocandins: production and applications. Appl Microbiol Biotechnol 97(8):3267–3284

Hughes SR, Gibbons WR, Bang SS, Pinkelman R, Bischoff KM, Slininger PJ, Qureshi N, Kurtzman CP, Liu S, Saha BC (2012) Random UV-C mutagenesis of Scheffersomyces (formerly Pichia) stipitis NRRL Y-7124 to improve anaerobic growth on lignocellulosic sugars. J Ind Microbiol Biotechnol 39(1):163–173

Ikeda M (2006) Towards bacterial strains overproducing l-tryptophan and other aromatics by metabolic engineering. Appl Microbiol Biotechnol 69(6):615–626

Jun P, Russell M, El-Sayed I, Dillon W, Glastonbury C (2013) Primary and secondary invasive facial fungal infections in immunocompromised patients. Radiol Case Rep 8(2):33–38

Jung WS, Yoo YJ, Park JW, Park SR, Han AR, Ban YH, Kim EJ, Kim E, Yoon YJ (2011) A combined approach of classical mutagenesis and rational metabolic engineering improves rapamycin biosynthesis and provides insights into methylmalonyl-CoA precursor supply pathway in Streptomyces hygroscopicus ATCC 29253. Appl Microbiol Biotechnol 91(5):1389–1397

Kanda M, Tsuboi M, Sakamoto K, Shimizu S, Yamashita M, Honda H (2009) Improvement of FR901379 production by mutant selection and medium optimization. J Biosci Bioeng 107(5):530–534

Kumari R, Pramanik K (2012) Improvement of multiple stress tolerance in yeast strain by sequential mutagenesis for enhanced bioethanol production. J Biosci Bioeng 114(6):622–629

Lee P, Schmidt-Dannert C (2002) Metabolic engineering towards biotechnological production of carotenoids in microorganisms. Appl Microbiol Biotechnol 60(1–2):1–11

Leman J (1997) Oleaginous microorganisms: an assessment of the potential. Adv Appl Microbiol 43:195–243

Li H, Song Y, Li Q, He J, Song Y (2014) Effective microbial calcite precipitation by a new mutant and precipitating regulation of extracellular urease. Bioresour Technol 167:269–275

Li L-z, Zheng H, Xian M (2010) Optimization of the medium for streptolydigin production by Streptomyces lydicus AS 4.2501 with precursor feeding using response surface methodology. J Taiwan Inst Chem E 41(3):252–258

Masurekar PS, Fountoulakis JM, Hallada TC, Sosa MS, Kaplan L (1992) Pneumocandins from Zalerion arboricola. 2. Modification of product spectrum by mutation and medium manipulation. J Antibiot 45(12):1867–1874

Olano C, Lombó F, Méndez C, Salas JA (2008) Improving production of bioactive secondary metabolites in actinomycetes by metabolic engineering. Metab Eng 10(5):281–292

Patil SA, Surwase SN, Jadhav SB, Jadhav JP (2013) Optimization of medium using response surface methodology for l-DOPA production by Pseudomonas sp. SSA. Biochem Eng J 74:36–45

Sangkharak K, Prasertsan P (2013) The production of polyhydroxyalkanoate by Bacillus licheniformis using sequential mutagenesis and optimization. Biotechnol Bioprocess Eng 18(2):272–279

Singh P, Shera SS, Banik J, Banik RM (2013) Optimization of cultural conditions using response surface methodology versus artificial neural network and modeling of l-glutaminase production by Bacillus cereus MTCC 1305. Bioresour Technol 137:261–269

Vu VH, Pham TA, Kim K (2011) Improvement of fungal cellulase production by mutation and optimization of solid state fermentation. Mycobiology 39(1):20–25

Wang H-Y, Zhang J, Zhang Y-J, Zhang B, Liu C-X, He H-R, Wang X-J, Xiang W-S (2014) Combined application of plasma mutagenesis and gene engineering leads to 5-oxomilbemycins A3/A4 as main components from Streptomyces bingchenggensis. Appl Microbiol Biotechnol. doi:10.1007/s00253-014-5970-6

Wendisch VF, Bott M, Eikmanns BJ (2006) Metabolic engineering of Escherichia coli and Corynebacterium glutamicum for biotechnological production of organic acids and amino acids. Curr Opin Microbiol 9(3):268–274

Xiao Y, Zhang X, Zhu ML, Tan WS (2013) Effect of the culture media optimization, pH and temperature on the biohydrogen production and the hydrogenase activities by Klebsiella pneumoniae ECU-15. Bioresour Technol 137:9–17

Xu XY, Zhong J, Zhang XY, Bao J, Qi SH, Nong XH (2013) Enhanced production of a novel cytotoxic chromone oxalicumone A by marine-derived mutant Penicillium oxalicum SCSIO 24–2. Appl Microbiol Biotechnol 97(22):1–10

Xue C, Zhang X, Yu Z, Zhao F, Wang M, Lu W (2013) Up-regulated spinosad pathway coupling with the increased concentration of acetyl-CoA and malonyl-CoA contributed to the increase of spinosad in the presence of exogenous fatty acid. Biochem Eng J 81:47–53

Zhu X, Zhang W, Chen X, Wu H, Duan Y, Xu Z (2010) Generation of high rapamycin producing strain via rational metabolic pathway-based mutagenesis and further titer improvement with fed-batch bioprocess optimization. Biotechnol Bioeng 107(3):506–515

Acknowledgments

This work was financially supported by Zhejiang Zhenyuan Pharmaceutical Co., Ltd. (Shaoxing, China).

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Zou, SP., Zhong, W., Xia, CJ. et al. Mutagenesis breeding of high echinocandin B producing strain and further titer improvement with culture medium optimization. Bioprocess Biosyst Eng 38, 1845–1854 (2015). https://doi.org/10.1007/s00449-015-1425-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-015-1425-4