Abstract

Preparation of anisotropic particles based on phase separation of prefabricated seeds in polymerizations generally involves multiple process steps. In conventional one-pot dispersion polymerization, only spherical particles are produced. Herein, anisotropic particles with asymmetrical core-shell structure, multiple compartments, and continuously tunable surface roughness and sizes were synthesized by a modified one-pot dispersion polymerization. A mixture of polar solvents, ethylene glycol (EG), and water (6/4, vol.) was used as medium for polymerization of styrene (St). In the presence of ammonium persulfate (APS) and vinyl acetate (VA), divinylbenzene (DVB, 16.1–66.4 %) and (St, 50.3–0 %) were added at 60, 180, and 360 min, respectively. Dense cross-linking was confined to exterior of swollen growing particles, resulting in phase separation and formation of snowman-like particles with coarse, core-shell structured body, and smooth, no or partially cross-linked head. The newly formed compartments were also inhomogeneously cross-linked and their phases separated, producing three and four compartment anisotropic particles with an aspect ratio up to 2.3. Gel content of final particles was less than 75 %. Due to a sequential cross-linking from growing particle to newly formed compartments, reaction stability and particle monodispersity were maintained even when high amounts of DVB were added. Asymmetrical morphologies, structures, sizes, and surface roughness of particles were continuously tuned by varying DVB amount and its start addition time. This one-pot method provides a simple, efficient route for synthesis of anisotropic particles.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Anisotropic particles with manifold shapes, compartments, and functions have aroused tremendous interest in recent years due to their promising performances and applications as solid surfactants for stabilization, as building blocks for supramolecular structures [1–3] and so on. Many strategies have been developed for fabrication of various uniform and well-defined anisotropic particles. These include Pickering emulsion interface synthesis [4], micro-fluidics fabrication [5], selective modification [6–9], phase separation [10, 11], etc. Especially, phase separation induced by swelling spherical or non-spherical seed particles with monomers [12–16], emulsion drops [17], or water-miscible solvent [18] in seeded polymerizations [19–28] is regarded as a relatively facile and reproducible technique for large-scale production of anisotropic particles. However, this technique still has some limitations. For example, multiple steps including synthesis and surface modification of seed particles, separation, and swelling of seed particles, as well as subsequent seeded polymerization are required [20, 21, 26]. Swelling of cross-linked polymer seed particles is time-consuming [23–25]. When non-spherical duplet particles are used as seeds to synthesize triplet particles, repeated swelling and polymerizations are needed [13–15]. Moreover, surface roughness, shape, and size of each compartment of anisotropic particles cannot be altered continuously during their formation. The primary compartment usually retains its smooth or coarse surface and shows only slight change in volume [12, 18, 26]. The newly formed compartment is restricted to smooth and bulb shapes, with no additional morphologies presented [17–22]. In addition, polymers inside seed particles which are prepared by emulsion polymerization have high molecular weights (Mw) and narrow distribution, unfavorable to the achievement of high swelling capacity of seed spheres. Therefore, it is still a challenge to prepare anisotropic particles, especially those with core-shell structure, multiple compartments, and high aspect ratio, through an easy, conventional polymerization method involving fewer steps and having high yield. Anisotropic particles with core-shell structure and high aspect ratio have novel properties and great potentials for new applications [15].

Dispersion polymerization (Dis.P), particularly the two-stage dispersion polymerization, 2-Dis.P [29–32], in which functional reagents such as cross-linkers are added after the end of nucleation stage, is a simple, efficient approach for synthesis of monodisperse, functional polymer microspheres. The in situ formed growing particles can be considered as dynamically changing “seeds.” They remain swollen by monomer and oligomers throughout particle growth stage until late in reaction [29, 30]. Furthermore, molecular weight distribution of polymer inside the preformed growing particles is relatively broad. Low Mw polymers can serve as swelling agents to enhance swelling capacity [23] and can be readily expelled from the growing particles. These factors may contribute to phase separation of growing particles which are cross-linked after the completion of nucleation stage. However, as far as we know, a possible phase separation of cross-linked growing particles during Dis.P and direct preparation of anisotropic particles has not yet been explored to date. Most of the concerns are focused on how to achieve highly cross-linked, monodisperse, and stable microspheres for applications. Some involve the preparation of spherical, only shell cross-linked functional particles [33–35] with a narrow size distribution. Rapid, high cross-linking and monomer’s conversion occurred inside growing particles will extremely reduce the particle swellability and bring about difficulties in polymer migration and extrusion during Dis.P. It is not easy to control the dynamically changed cross-linking and swelling of growing particles to induce phase separation during polymerization with no or slight disturbance to particle monodispersity and reaction stability. Therefore, only spherical particles, rather than anisotropic particles, are obtained by conventional Dis.P.

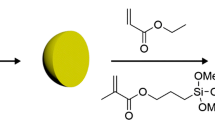

In this article, we try to explore the straightforward formation of anisotropic particles by a modified one-pot Dis.P. To avoid occurence of rapid, high cross-linking inside growing particles and maintain appropriate swelling of growing particles during Dis.P of styrene (St), (1) a mixture of polar solvents (ethylene glycol (EG) and water, 6/4, vol.) is used as reaction medium, (2) a water-soluble initiator of ammonium persulfate (APS) and a hydrophilic monomer of vinyl acetate (VA) relative to St are applied after the finish of nucleation stage, and (3) additional monomer of St is charged along with cross-linker of divinylbenzene (DVB). It is considered that the growing particles are contracted in a highly polar medium. With the initiation of APS, sulfate ions are coupled onto growing particles, and thus, surface hydrophilicity is enhanced. The contraction and surface hydrophilicity of growing particles can severely limit the diffusion of DVB and, hence, mitigate the cross-linking inside growing particles. St added along with DVB can act as a monomer and swelling agent to alleviate cross-linking and improve swellability of growing particles. Under the above conditions, the factors greatly influencing the swellability and cross-linking degree of growing particles are the start addition time and amount of DVB added, so their effects on formation of anisotropic particles are investigated in detail here. The evolutions of particle morphology, internal structure, surface roughness, and sizes are analyzed.

Compared with previous seeded polymerization method involving multiple process steps, this one-pot synthesis approach has certain features: (1) it is simple, straightforward, and time-saving. This facilitates a high yield of anisotropic particles. (2) The cross-linking occurs firstly in growing particles. Upon phase separation, it preferably turns to uncross-linked protrusions. This cross-linking behavior can ensure the stability and monodispersity of final particles, even when a high amount of DVB is added. (3) The control of cross-linking and inhomogeneity of newly formed compartment enables its phase separate continuously, so multiple compartment anisotropic particles are allowed to be produced facilely without having to use dimer as seeds and undergo repeated swelling, polymerizations, and sorting process. (4) Asymmetrical morphology, internal structure (such as core-shell structure), surface roughness, and dimensions of anisotropic particles can be tuned flexibly by varying reaction parameters such as start addition time and amount of cross-linker added.

Experimental section

Materials

Styrene (St, 98 %, Tianjin Yongda Chemical Reagent Co., Ltd.) and vinyl acetate (VA, 99.5 %, Tianjin Fuchen Chemical Reagents Factory) were distilled under reduced pressure before use. Sodium p-styrene sulfonate (NaSS, 99.9 %) and DVB (55%, mixture of isomers) were purchased from Alfa Aesar and used without further purification. Azobis(isobutyronitrile) (AIBN, 99.9 %, Sinopharm Chemical Reagent Co., Ltd.), APS (99.9 %, Alfa Aesar), ethylene glycol (EG), methanol (MeOH), and tetrahydrofuran (THF) from Beijing Chemical Reagents Co., Ltd. were used as received.

Preparation of anisotropic particles

St (2.5 ml), AIBN (0.0453 g), NaSS (0.0453 g), EG (15 ml), and deionized water (10 ml) were added to a 100-ml three-neck round-bottom flask equipped with a reflux condenser and a mechanical stirrer. Then, the flask was immersed in a water bath set at 80 °C. After a while, the mixture became a homogeneous solution (Fig. S1) under stirring at 200 rpm and reaction was started. DVB was added to reaction as follows:

-

(i)

When the reaction was carried out for 60 min, APS aqueous solution (0.02 g in 5 ml of water) was injected into reaction with a syringe, and immediately afterwards, a mixture of VA (49.4 %), DVB (16.1–66.4 %), and St (50.3–0 %) was dropped into the flask in 20 min. Then, the reaction was held for 280 min (total reaction time is 360 min). When AIBN was used as a substitute for APS, at 60 min, 5 ml of water was injected firstly, and then AIBN (0.02 g) dissolved in VA was charged and a mixture of DVB and St was dropped.

-

(ii)

When the reaction was run for 120 min, APS aqueous solution (0.02 g in 5 ml of water) and VA (49.4 %) were charged quickly and underwent reaction for 60 min. DVB (16.1–44.3 %) and St (50.3–22.1 %) were added dropwise in 20 min. Then, the polymerization lasted for 280 min (total reaction time is 480 min). Using AIBN as initiator in this step, 5 ml of water was injected firstly, and then AIBN (0.02 g) dissolved in VA was charged. DVB and St were dropped as mentioned above.

-

(iii)

When the reaction was performed for 180 min, APS aqueous solution (0.02 g in 5 ml of water) and VA (49.4 %) was injected and underwent reaction for 180 min. DVB (16.1–50.3 %) and St (50.3–16.1 %) were fed in 20 min. Then, the polymerization was maintained for 160 min (total reaction time is 540 min). In this step, if AIBN was used as initiator, it was added with VA followed by the injection of 5 ml of water.

Contents of the above added reagents were determined according to the weight of initial St, and total amount of DVB and St added (66.4 %) is kept constant. Final particles were isolated by centrifugation (10,000 rpm, 15 min), washed three cycles with MeOH, and then dried at 40 °C overnight in a vacuum oven.

The dried particles (W 0) were immersed in THF at room temperature for 24 h under stirring. To completely remove uncross-linked polymers inside particles, THF was renewed with fresh one for three times during immersing. After that, the particles were centrifuged at 10,000 rpm for 15 min, washed three times with excess THF and one time with MeOH, dried at 40 °C overnight in a vacuum oven, and weighed (W 1). Gel content, the fraction of cross-linked polymers in particles, indicating the cross-linking degree of particles, was calculated from the expression: \( \mathrm{Gel}\ \mathrm{content}\ \left(\%\right) = \frac{W_1}{W_0}\times 100 \).

Characterization

Morphology of resultant particles was observed using scanning electron microscope (SEM, Hitachi S-4700, operated at an accelerating voltage of 20 kV) and transmission electron microscope (TEM, JEOL JEM-2100, manipulated at an accelerating voltage of 200 kV). Samples were prepared by placing a droplet of particle suspension in MeOH onto a clean glass slide or by spreading diluted particle suspension in MeOH onto carbon-coated copper grids and then evaporating solvent at ambient temperature. Prior to SEM imaging, samples were sputter-coated with platinum. Average size of particle was evaluated statistically on the basis of counting at least 30 individual particles presented on SEM images using image processing software program Nano Measure 1.2.

Results and discussion

Formation of anisotropic particles

The Dis.P of St was started at 80 °C from a homogeneous solution in which monomers (St, NaSS) and initiator (AIBN) were dissolved. The end of nucleation was indicated at around 40 min from the appearance of reaction mixture (Fig. S1). Copolymer of NaSS and St produced during polymerization acted as a stabilizer (NaSS units show strong hydrophilicities and electrostatic repulsion, while St units display strong hydrophobicities) to efficiently stabilize the nuclei [33] and endowed the growing particle surface with hydrophilicity. Then, particle growth stage began, and polymerization took place primarily in the monomer-swollen growing particles [35–37]. It was observed that monomer conversion and particle size were increased rapidly soon after nucleation and then increased slowly with the consumption of monomer (Fig. S2). After the finish of nucleation stage, APS aqueous solution, VA, DVB, and St were added. VA has a very low inclination to copolymerize with St due to unfavorable reactivity ratios [38]. The polymerization of VA initiated by APS at interfacial layer between particle and continuous medium produced Poly(vinyl acetate) (PVA) chains with sulfate ions. The entry of PVA chains to growing particles enabled sulfate ions to be attached on surface [20, 21, 23]. Moreover, the (co-)polymerizations of DVB and St initiated by APS at interfacial layer or in continuous medium generated (co-)polymers with sulfate ions. These (co-)polymers were grafted or precipitated on surface of growing particle, incorporating sulfate ions on surface. Consequently, surface hydrophilicity of growing particles was improved. This could impede the diffusion of DVB into growing particles.

When conversions of initial St were 17, 61, and 82 % at reaction time of 60, 180, and 360 min, respectively, various amounts of DVB (16.1–66.4 %) and St (50.3–0 %) were added, as shown in Scheme 1. At these moments, the growing particles were considered to be (well) swollen by monomers and oligomers [30, 33], allowing DVB to diffuse onto/into and produce cross-linking. In the diffusion of DVB, cross-linking firstly occurred in the exterior of growing particles. This could also impede the diffusion of DVB into growing particles. Therefore, spatially inhomogeneous cross-linking across growing particles was produced. When the inhomogeneously cross-linked growing particles were still sufficiently swollen, monomers and oligomers inside the growing particles could be expelled, that is, phase separation was allowed to release viscoelastic stress created on polymer network [15], and anisotropic particles were produced (Scheme 1). The above described one-pot Dis.P was basically dissimilar to a seeded polymerization in which pre-synthesized, linear polymer, spherical particles were used, swollen with a monomer/cross-linker mixture, and then undergone polymerization. In the seeded polymerization, usually, the linear seed particles are uniformly and fully swollen at first [39–41] and then rapidly, homogeneously cross-linked, producing monodisperse large spherical particles with interpenetrating network (IPN) structure [13, 14, 28]. The rapid cross-linking and formation of IPN hinder phase separation of the seed particles [13]. Using the resultant cross-linked spherical particles as seeds and by swelling, heating, and polymerization, anisotropic particles are synthesized as reported previously [13–15, 20, 21].

Our results indicated that when DVB was added in a low amount of 16.1 % at 60 min, snowman-like particles with a smooth head and a coarse body were fabricated (Fig. 1(a1)). The head was removed completely by THF, while the body remained and presented core (uncross-linked)-shell (cross-linked) structure. When addition of DVB was delayed to 180 and 360 min, roughness of body surface was improved (Fig. 1(a2, a3)). After immersed in THF, the head remained and showed partially cross-linked (Fig. 1a2) or only shell cross-linked structure (Fig. 1(a3)). The body displayed a densely cross-linked shell and a core composed of linear polymer (Fig. 1(a2)) or of IPN of cross-linked and linear polymer (Fig. 1(a3)).

SEM (scale bars, 500 nm) and TEM (scale bars, 250 nm) images of particles synthesized by adding various amounts (16.1, 22.2, 33.2, and 44.3 %, relative to the weight of initial St) of DVB at 60 (a1–d1), 180 (a2–d2), and 360 min (a3–d3), respectively. The lower right inserted are TEM images of particles after immersed in THF

Increasing the amount of DVB added at 60 and 180 min, the resultant snowman-like particles had a body with coarser surface (Fig. 1(a1–d1, a2–d2)). The head changed from a spherical shape into a slightly elongated shape (Fig. 1(c1, b2)) and then into two or three compartments (Fig. 1(d1), Fig. S3, Fig. 1(c2, d2)). When a low amount of DVB was added at 360 min, the elongation of head started (Fig. 1(a3)) and then became extremely evident, forming short rod-like head with the increase of DVB amount (Fig. 1(b3, c3)). Further increasing DVD amount, the head elongation was weakened (Fig. 1(d3)). The residual part (Fig. 1(a1–d1, a2–d2)) or shell thickness of head after immersed in THF (Fig. 1(a3–c3)) was increased. Shell thickness of body was also increased (Fig. 1(a1–d1, a2, b2, a3, and b3)) until a densely cross-linked body was formed (Fig. 1(c2, d2, and c3)).

When the start addition of DVB was later, each compartment of anisotropic particles grew bigger (Fig. 2a–c). The body displayed a slight reduction in its volume when DVB amount was increased (Fig. 2a, b). This slight shrink of body could affect further improvement of aspect ratio of particle fabricated using a high DVB amount (Fig. 2a). The spherical head grew bigger at first with the increase of DVB amount (Fig. 2a, b). Thereafter, when 33.2 % of DVB was added at 60 min, 22.2 % of DVB was added at 180 min, or when 16.1 % of DVB was added at 360 min, the head elongation started (Fig. 1(c1, b2, and a3)) and the cross-section width of head reduced (Fig. 2a–c). Meanwhile, aspect ratio of resultant anisotropic particles improved gradually, and an extremely high value of 1.9 or 2.3 was reached (Fig. 2b, c). When a high DVB amount greater than 33.2 % was added at 360 min, a weakened elongation of head appeared, and therefore, unusual increase of sizes of body and head and decrease of aspect ratio were presented (Fig. 2c). Gel content of final particles was less than 75 % and increased with DVB amount (Fig. 2d). When more than 33.2 % of DVB was added at 60 min, particle gel content changed slightly. When this amount of DVB was added at 360 min, particle gel content was decreased.

Evolutions of particles during polymerization

To figure out how the above two, multi-compartment anisotropic particles were formed, evolutions of particle morphology, internal structure, surface roughness, and dimensions during polymerization were recorded carefully (Figs. 3 and 4).

SEM (scale bars, 500 nm) and TEM (scale bars, 250 nm) images of particles produced during polymerization with 44.3 % of DVB added at 60 min (a1–d1), with 33.2 % of DVB added at 180 min (a2–d2) and with 16.1 % of DVB added at 360 min (a3–d3). The lower right inserted are TEM images of particles after immersed in THF

Evolution of size of body (D), size of head or cross-section width of newly formed compartments (d), aspect ratio (L/D) (a–c), and gel content of anisotropic particles (d) prepared during polymerization, 44.3 % of DVB was added at 60 min (a), 33.2 % of DVB was added at 180 min (b), and 16.1 % of DVB added at 360 min (c)

When 44.3 % of DVB was added at 60 min, the growing particles started to deform at 80 min (Fig. 3(a1)). Then, a small, smooth bulge protruded and grew evidently, forming snowman-like particles (Fig. 3(b1)). Later, small, spherical head became short rod-like (Fig. 3(c1)) and lotus root-like shape (Figs. 1(d1) and 3(d1)), forming three compartment anisotropic particles. The head was dissolved entirely by THF at first (Fig. 3(a1)) and then small portion or most of the head was retained (Fig. 3(b1–d1)). The body (pristine growing particle) manifested a densely cross-linked shell, and the shell thickness improved gradually with reaction (Figs. 1(d1) and 3(a1–d1)).

When 33.2 % of DVB was added at 180 min, a small bulge protruded obviously at the end of the addition (Fig. 3(a2)). The body contained small portion of linear polymer which was removed by THF (Fig. 3(a2–d2)). Its cross-linking reached a dense level at the end of polymerization (Fig. 1(c2)).

When 16.1 % of DVB was added at 360 min, an evident head protruded in the process of addition (Fig. 3(a3)) and presented a core (uncross-linked)-shell (cross-linked) structure after 420 min. The body displayed a densely cross-linked shell and a core composed of IPN of cross-linked and linear polymer (Figs. 1(a3) and 3(c3, d3)).

In addition, body surface became coarser at prolonged reaction times (Fig. 3). The sizes of body and head and aspect ratio of resultant anisotropic particles increased rapidly at first. These increases were faster when DVD was added earlier (Fig. 4a–c). Then, from 60 min after the addition of DVB to the end of polymerization, the sizes of anisotropic particles changed slightly. The cross-linking degree of particles was increased sharply in 60 min no matter when DVB was added and then increased slightly (Fig. 4d). When DVB was added later, the maximum cross-linking degrees of particles reduced.

Analyses for formation of anisotropic particles

To deeply understand the formation of anisotropic particles and morphology evolution during Dis.P, the influences of DVB amount and its start addition time on dynamically changed swelling and cross-linking of growing particles were analyzed.

In thermodynamic aspect, the cross-linking and swelling of growing particles correlated closely with the free energy (\( \varDelta {\overline{G}}_{\mathrm{m},\ \mathrm{p}} \)) [13, 14, 39, 40] of hydrophobic monomers (St, DVB) and oligomers within growing particles. The cross-linking of growing particles made a positive, prominent contribution to \( \varDelta {\overline{G}}_{\mathrm{m},\ \mathrm{p}} \). The swelling of growing particles made a negative contribution to \( \varDelta {\overline{G}}_{\mathrm{m},\ \mathrm{p}} \). When \( \varDelta {\overline{G}}_{\mathrm{m},\ \mathrm{p}}>0 \), the phase separation of growing particles was allowed to occur. Upon the addition of DVB and St, the growing particles were cross-linked immediately (Fig. 4d). When their cross-linking reached a certain degree and their swellability was maintained during polymerization, phase separation occurred and snowman-like particles were generated (Fig. 3(a1–a3)). The degree of phase separation and size of head of snowman-like particles increased with the increase of cross-linking degree of growing particles (Figs. 1(a1–c1, a2–b2 and 3a1–b1, a2–b2, a3–b3)). Distinguished greatly from the previous phase separation of seed particles, the phase separation of polymerizing particles continued in the present system. After phase separation, the new phase domains contained monomers and oligomers expelled from the growing particles. In addition, they absorbed monomers (DVD, St) from continuous medium due to their un- or less cross-linking in comparison with the cross-linked growing particles, so they grew (Figs. 2a and 4a–c) and were cross-linked (Figs. 1 and 3). With the increase of cross-linking of the new domains, their phase separation occurred as that of growing particles (Fig. 1(b2–d2, c1–d1), Fig. S3).

In kinetic aspect, the diffusion of DVB greatly affected the cross-linking of growing particle and new domains. In our experiments, the contraction of growing particle in a highly polar medium, hydrophilic surface, and first immediate cross-linking occurred on surface of growing particle could severely impede the diffusion of DVB into them. Accordingly, inhomogeneous or dense cross-linking in exterior of growing particle (body of final anisotropic particle) was engendered (Fig. 3(a1–a3)). This cross-linking of growing particle was distinct from that of seed particles which were swollen for a long time by monomers before polymerization [15, 16, 20–23]. The later usually gives rise to (semi-)IPN, while the former enabled formation of core (no or sparsely cross-linked)-shell (densely cross-linked) structure (Fig. 3(a1)) even when DVB was added at 60 min (low conversion of 17 %).

When DVB was added at 180 min, the growing particles were still swollen well, especially when St was supplemented. With a low amount of DVB added, the cross-linking in exterior of growing particles was not very high. This facilitated the diffusion of DVB and allowed growing particles to be cross-linked (Fig. 3(a2)). When polymerization had run for 360 min, the growing particles were mainly composed of polymers with high Mw (SI, Table S1), and their swellability was low. At this moment, if a low amount of DVB was added, the growing particles showed a densely cross-linked shell and a core composed of IPN of cross-linked and linear polymer (Fig. 3(a3)). Increasing the amounts of DVB added at different time, the diffusion of DVB was promoted, giving rise to thicker cross-linked shell or densely cross-linked growing particles (Fig. 1(a1–d1, a2–d2, a3–c3)).

Once the growing particles were cross-linked moderately and their swellability was sufficient, viscoelastic stress was created on polymer network. Then, phase separation occurred to release this stress, and anisotropic particles were produced (Fig. 3(b1, a2, and a3)). A tunnel shown in TEM images of particles subjected to immersing in THF suggested the expelling of monomers and oligomers from growing particle (Figs. 1(d1) and 3(a1–d1)). At first, uncross-linked small bulge was protruded (Fig. 3(a1–a3)). Then, the small bulge grew and was cross-linked gradually (Fig. 3(b1–b3, c1)) by DVB expelled from growing particle or incorporated into from continuous medium. Thereafter, phase separation of the cross-linked bulge occurred, and head-elongated snowman-like particles or three compartment anisotropic particles were generated (Figs. 1(c2, d1) and 3(c1, d1, c2, and d2)). Similar phase separation took place continuously inside the last formed compartment, leading to the formation of four compartment anisotropic particles (Fig. S3, Fig. 1(d2)). A total removal or a small residue of the last compartment after immersed in THF was observed (Figs. 1 and 3 and Fig. S3). This phenomenon revealed a sequential cross-linking occurred from the growing particle to the newly formed compartments. It was this cross-linking behavior that maintained the reaction stability and particle monodispersity even when DVB amount was high up to 44.3 % (Fig. 1(d1–d3)). When DVB amount was increased to 66.4 %, there was some coalescence of final particles (Fig. S3). In contrast, in conventional 2-Dis.P, when high levels (still less than 10 %) of cross-linkers are added at a low conversion, rapid and high cross-linking is formed, and particle coagulation or colloidal instability arises or secondary nucleated particles emerge owing to interferences with particle growth [30]. In addition, the above phenomenon indicated continuous phase separations of the late formed compartments and linear growth of the following compartment adjacent to the previous one. The phenomenon also implied an inability to produce five or more compartment anisotropic particles due to the consumption of DVB. Compared with seeded polymerizations where dimer particles were used as seeds and multiple swelling processes were undergone to produce rod-like trimer particle [15], this one-pot technique is indeed a simple and efficient way for creation of multiple compartment anisotropic particles.

When DVB was added at 360 min, the protrusions on growing particles were primarily made up of high Mw linear polymers. A high viscosity of the protrusions could impede the diffusion of DVB, resulting in cross-linking in exterior and formation of a head with densely cross-linked shell (Figs. 1(a3) and 3(c3, d3)). The expelling of high Mw polymer from the cross-linked head, that is, phase separation of the head became difficult, giving rise to elongation of the head (Figs. 1(a3) and 3(d3)). Extremely evident elongation of the head (Fig. 1(b3–c3)) appeared when the head cross-linking was increased at high DVB amounts. When DVB amount was 44.3 %, an immediate and dense cross-linking could be readily brought about on surface of growing particle and of head. This could severely limit the diffusion of DVB and extrusion of polymers, leading to core-shell structured body, weakly elongated head (Fig. 1(d3)), and reduced cross-linking of final particles (Fig. 2d).

From the above analyses, it was seen that the water-soluble initiator of APS played important roles. The initiation of APS for polymerizations allowed coupling of sulfate ions to surface of growing particles and thus enhanced the surface hydrophilicity. This was unfavorable to the diffusion of DVB into growing particles and therefore led to the formation of cross-linked shell. In addition, with the initiation of APS, the copolymer produced by copolymerization of DVB at interfacial layer and in continuous medium was grafted or coagulated onto growing particles, forming coarse surface. When cross-linking in exterior of growing particles was enhanced during polymerization (Fig. 3) or when rapid and high cross-linking in exterior of growing particles occurred with high amounts of DVB added (Fig. 1(a1–d1, a2–d2, and a3–c3)) or when swellability of growing particles was reduced greatly at later DVB addition time (Fig. 1(a1–a3)), the limitation on diffusion of DVB was intensified, and more DVB was polymerized at interfacial layer and in continuous medium. As a result, coarser surface of growing particles was formed.

In previous seeded polymerizations for preparation of anisotropic particles, an oil-soluble initiator such as AIBN [14, 20] is usually used to initiate polymerizations in seeds. In this work, if AIBN was used as a substitute for APS (other conditions were same), its initiation could contribute little to the enhancement of growing particle surface hydrophilicity, though some of it in continuous medium could also initiate polymerizations. Moreover, AIBN could efficiently enter growing particles and initiate polymerization of St and DVB. This resulted in an interior cross-linking of growing particles and no cross-linked shell was formed (Fig. 5).

SEM (scale bars are 500 nm) and TEM (scale bars are 250 nm) images of particles synthesized by using AIBN (0.02 g) as initiator in the second step of Dis.P. a 44.3 % of DVB was added at 60 min, b 33.2 % of DVB was added at 180 min, and c 16.1 % of DVB was added at 360 min. The lower right inserted are TEM images of particles after immersed in THF

The cross-linking reaction of DVB that occurred within the growing particles could promote consumption of monomers and, hence, dramatically reduce the swellability of growing particles. Moreover, the content of DVB inside growing particle was relatively lower than that of St because large fraction of St was incorporated into the growing particles. This led to an inefficient cross-linking. Therefore, gel contents of particles were lower than those in the cases of using APS (Table S2). The degree of phase separation of growing particle was considerably low, just showing separation of cross-linked and uncross-linked (removed by THF) portions and no distinct protrusions (Fig. 5). In addition, copolymerization of DVB at interfacial layer and in continuous medium initiated by AIBN was diminished relatively, forming smooth surface.

Conclusions

We demonstrated a facile, straightforward one-pot Dis.P method for preparation of monodisperse anisotropic particles with asymmetrical core-shell structure, more than two compartments, and continuously tunable surface roughness and dimensions. In conventional one-pot Dis.P, only spherical particles are produced. Synthesis of anisotropic particles by seeded polymerizations using prefabricated spherical or non-spherical particles as starting materials usually involves multiple process steps. Our one-pot Dis.P method for generation of anisotropic particles was based on phase separation of in situ formed, swollen growing particles. It was simple, time-saving, and advantageous to achievement of high yields. The phase separation depended on control of cross-linking and swelling of growing particles during polymerization. Different from the rapid, high cross-linking that occurred in conventional 2-Dis.P, the cross-linking of growing particles was confined to exterior, and a gel content less than 75 % was produced due to an insufficient entry of DVB and supplementation of St. This cross-linking plus sufficient swelling capacity allowed phase separation of growing particles and formation of snowman-like particles. Afterwards, inhomogeneous cross-linking continued to occur in the newly formed, un- or less cross-linked compartments, and phase separations of the new compartments occurred continuously, producing linearly grown multiple compartment anisotropic particles. The sequential cross-linking behavior guaranteed particle monodispersity and reaction stability even when large amounts (16.1–44.3 %) of DVB were added. Varying DVB amount and its start addition time, asymmetrical morphology, structure, surface roughness, and size of each compartment were continuously tunable. Influences of other synthesis factors such as reaction media, type of cross-linker and hydrophilic monomer, etc. on formation and manipulation of anisotropic particles in one-pot Dis.P will be reported later.

References

Kaewsaneha C, Tangboriboonrat P, Polpanich D, Eissa M, Elaissari A (2013) Janus colloidal particles: preparation, properties, and biomedical applications. ACS Appl Mater Interfaces 5:1857–1869

Hu J, Zhou SX, Sun YY, Fang XS, Wu LM (2012) Fabrication, properties and applications of Janus particles. Chem Soc Rev 41:4356–4378

Du JZ, O’Reilly RK (2011) Anisotropic particles with patchy, multicompartment and Janus architectures: preparation and application. Chem Soc Rev 40:2402–2416

Liu B, Wei W, Qu XZ, Yang ZZ (2008) Janus colloids formed by biphasic grafting at a pickering emulsion interface. Angew Chem Int Ed 120:4037–4039

Kim JH, Jeon TY, Choi TM, Shim TS, Kim SH, Yang SM (2014) Droplet microfluidics for producing functional microparticles. Langmuir 30:1473–1488

Liu LY, Ren MW, Yang WT (2009) Preparation of polymeric Janus particles by directional UV-induced reactions. Langmuir 25:11048–11053

Nie L, Liu S, Shen W, Chen D, Jiang M (2007) One-pot synthesis of amphiphilic polymeric Janus particles and their self-assembly into supermicelles with a narrow size distribution. Angew Chem Int Ed 46:6321–6324

Zhang CL, Liu B, Tang C, Liu JG, Qu XZ, Li JL, Yang ZZ (2010) Large scale synthesis of Janus submicron sized colloids by wet etching anisotropic ones. Chem Commun 46:4610–4612

Tang C, Zhang CL, Sun YJ, Liang FX, Wang Q, Li JL, Qu XZ, Yang ZZ (2012) Janus anisotropic hybrid particles with tunable size from patchy composite spheres. Macromolecules 46:188–193

Tanaka T, Okayama M, Kitayama Y, Kagawa Y, Okubo M (2010) Preparation of “mushroom-like”Janus particles by site-selective surface-initiated atom transfer radical polymerization in aqueous dispersed systems. Langmuir 26:7843–7847

Tanaka T, Okayama M, Minami H, Okubo M (2010) Dual stimuli-responsive“mushroom-like”Janus polymer particles as particulate surfactants. Langmuir 26:11732–11736

Park JG, Forster JD, Dufresne ER (2010) High-yield synthesis of monodisperse dumbbell-shaped polymer nanoparticles. J Am Chem Soc 132:5960–5961

Sheu HR, El-Aasser MS, Vanderhoff JW (1990) Uniform nonspherical latex particles as model interpenetrating polymer networks. J Polym Sci Part A Polym Chem 28:653–667

Sheu HR, El-Aasser MS, Vanderhoff JW (1990) Phase separation in polystyrene latex interpenetrating polymer networks. J Polym Sci Part A Polym Chem 28:629–651

Kim JW, Larsen RJ, Weitz DA (2007) Uniform nonspherical colloidal particles with tunable shapes. Adv Mater 19:2005–2009

Kim JW, Larsen RJ, Weitz DA (2006) Synthesis of nonspherical colloidal particles with anisotropic properties. J Am Chem Soc 128:14374–14377

Liu B, Liu JG, Liang FX, Wang Q, Zhang CL, Qu XZ, Li JL, Qiu D, Yang ZZ (2012) Robust anisotropic composite particles with tunable Janus balance. Macromolecules 45:5176–5184

Yu HK, Mao Z, Wang D (2009) Genesis of anisotropic colloidal particles via protrusion of polystyrene from polyelectrolyte multilayer encapsulation. J Am Chem Soc 131:6366–6367

Tang C, Zhang CL, Liu JG, Qu XZ, Li JL, Yang ZZ (2010) Large scale synthesis of Janus submicrometer sized colloids by seeded emulsion polymerization. Macromolecules 43:5114–5120

Mock EB, De Bruyn H, Hawkett BS, Gilbert RG, Zukoski CF (2006) Synthesis of anisotropic nanoparticles by seeded emulsion polymerization. Langmuir 22:4037–4043

Mock EB, Zukoski CF (2010) Emulsion polymerization routes to chemically anisotropic particles. Langmuir 26:13747–13750

Nagao D, Hashimoto M, Hayasaka K, Konno M (2008) Synthesis of anisotropic polymer particles with soap-free emulsion polymerization in the presence of a reactive silane coupling agent. Macromol Rapid Commun 29:1484–1488

Park JG, Forster JD, Dufresne ER (2009) Synthesis of colloidal particles with the symmetry of water molecules. Langmuir 25:8903–8906

Kraft DJ, Vlug WS, Kats CM, Blaaderen A, Imhof A, Kegel WK (2008) Self-assembly of colloids with liquid protrusions. J Am Chem Soc 131:1182–1186

Kraft DJ, Hilhorst J, Heinen MA, Hoogenraad MJ, Luigjes B, Kegel WK (2010) Patchy polymer colloids with tunable anisotropy dimensions. J Phys Chem B 115:7175–7181

Meng XH, Guan YY, Zhang ZD, Qiu D (2012) Fabrication of a composite colloidal particle with unusual Janus structure as a high-performance solid emulsifier. Langmuir 28:12472–12478

Okubo M, Fujibayashi T, Yamada M, Minami H (2005) Micron-sized, monodisperse, snowman/confetti-shaped polymer particles by seeded dispersion polymerization. Colloid Polym Sci 283:1041–1045

Okubo M, Wang Z, Yamashita T, Ise E, Minami H (2001) Morphology of micron-sized, monomer-adsorbed, crosslinked polymer particles having snowmanlike shapes prepared by the dynamic swelling method. J Polym Sci Part A Polym Chem 39:3106–3111

Song JS, Tronc F, Winnik MA (2004) Two-stage dispersion polymerization toward monodisperse, controlled micrometer-sized copolymer particles. J Am Chem Soc 126:6562–6563

Song JS, Winnik MA (2005) Cross-linked, monodisperse, micron-sized polystyrene particles by two-stage dispersion polymerization. Macromolecules 38:8300–8307

Song JS, Tronc F, Winnik MA (2006) Monodisperse, controlled micron-size dye-labeled polystyrene particles by two-stage dispersion polymerization. Polymer 47:817–825

Min K, Matyjaszewski K (2007) Atom transfer radical dispersion polymerization of styrene in ethanol. Macromolecules 40:7217–7222

Wang SL, Yue K, Liu LY, Yang WT (2013) Photoreactive, core-shell cross-linked/hollow microspheres prepared by delayed addition of cross-linker in dispersion polymerization for antifouling and immobilization of protein. J Colloid Interface Sci 389:126–133

Wang SL, Yang XF, Liu LY, Yang WT (2012) High immobilization of antibacterial moieties onto monodisperse microspheres by dispersion polymerization using bicationic viologen surfmer. Chinese J Polym Sci 30:865–872

Peng B, Wee E, Imhof A, Blaaderen A (2012) Synthesis of monodisperse, highly cross-linked, fluorescent pmma particles by dispersion polymerization. Langmuir 28:6776–6785

Peng B, Vutukuri HR, Blaaderen A, Imhof A (2012) Synthesis of fluorescent monodisperse non-spherical dumbbell-like model colloids. J Mater Chem 22:21893–21900

Tan JB, Rao X, Wu XH, Deng HC, Yang JW, Zeng ZH (2012) Photoinitiated RAFT dispersion polymerization: a straightforward approach toward highly monodisperse functional microspheres. Macromolecules 45:8790–8795

Pusch J, Herk AM (2005) Emulsion polymerization of transparent core-shell latices with a polydivinylbenzene styrene and vinyl acetate. Macromolecules 38:6909–6914

Kim JW, Suh KD (2000) Monodisperse micron-sized polystyrene particles by seeded polymerization: effect of seed crosslinking on monomer swelling and particle morphology. Polymer 41:6181–6188

Kim JW, Suh KD (2008) Monodisperse polymer particles synthesized by seeded polymerization techniques. J Ind Eng Chem 14:1–9

Okubo M, Shiozaki M, Tsujihiro M, Tsukuda Y (1991) Preparation of micron-size monodisperse polymer particles by seeded polymerization utilizing the dynamic monomer swelling method. Colloid Polym Sci 269:222–226

Acknowledgments

The authors acknowledge funding from National Natural Science Foundation of China (Grant Nos. 20974008, 51273012, and 21074006) and State Key Laboratory of Chemical Resource Engineering (0-6463, CRE-2012-C-205).

Author information

Authors and Affiliations

Corresponding authors

Electronic supplementary material

Monomer conversion, size of PSt particle vs. polymerization time curves. Mw and its distribution of PSt in microspheres. SEM and TEM images of particles synthesized by adding DVB (66.4 %) at 60 min. Gel contents of particles synthesized by AIBN or APS (0.02 g) as initiator in the second step.

ESM 1

(DOC 2147 kb)

Rights and permissions

About this article

Cite this article

Liu, Y., Yang, Q., Zhu, J. et al. Facile synthesis of core-shell, multiple compartment anisotropic particles via control of cross-linking and continuous phase separations in one-pot dispersion polymerization. Colloid Polym Sci 293, 523–532 (2015). https://doi.org/10.1007/s00396-014-3444-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00396-014-3444-0