Abstract

A type of tunable particles consisting of a soft poly(N-isopropylacrylamide) (PNIPAM) core and a solid shell were directly synthesized in toluene via a facile one-pot copolymerization of N-isopropylacrylamide (NIPAM), (3-Methacryloyloxypropyl)methyldiethoxysilane (MADS), and N,N′-methylenebis(2-propenamide) (MBA). Of particular concern is the shells’ potential to burst due to the swelling and expansion of the PNIPAM core after soaking in water, resulting in an outflow of the core. The toughness of the particle shells could be tuned by altering the feed ratio of MADS or MBA relative to NIPAM, resulting in a series of morphologies that varied from resembling a broken egg to being deformed core-shell spheres. The morphologies could be further modulated by dispersing the particles in different solvents.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Core-shell structure has attracted much attention due to their advantage in performing various functions, e.g., providing protection for the core material [1–4], exchanging substances through a permeable shell [5, 6], or controlling the release of the core substance [7, 8] resulting in their wide application in many fields, e.g., catalysis [9], biology [10], and drug delivery [11, 12]. Core-shell particles with responsive polymer cores have been reported in the literature [8, 13, 14] and exhibit attractive functionalities and potential applications for catalysis [15] or biotechnology [16], including drug delivery [17] or controlled release [18].

Most of the reported core-shell particles with responsive polymer possessed a soft polymer shell, e.g., particles with an inorganic core and a responsive polymer shell [19–21], or a core-shell polymer with polymer shell and polymer core [22], which exhibited self-assembly behavior [23]. Core-shell hybrid particles with a solid shell provide the opportunity to demonstrate many of the advantages of a core-shell structure not realized with a soft shell, such as the ability to maintain particle morphology, prepare hollow spheres [24–26], or load cargos [ 27].

The responsive particles with inorganic shell reported here were fabricated with a template method [28–30] via a sol-gel process similar to the preparation of most core-shell particles [31] that used a soft core or a hard core as a template, e.g., P(NIPAM-co-AA)/silica particles [28], poly(N-isopropyl acrylamide-co-styrene)/SiO2 [29], and poly(N-isopropylacrylamide-3-(trimethoxysilyl)propylmethacrylate)/silica particles [30] in which a functional group (e.g., carboxyl group, or silane groups) is usually needed. Particles with surface-inserted inorganic nanoparticles (SiO2) were also prepared by Pickering emulsion polymerization [32, 33], resulting in a raspberry-like particle with silica nanoparticles on surface. The Pickering method usually requires a complicated process, e.g., pre-preparation of the particles. In this study, we report a facile one-step copolymerization method to prepare a type of biomimetic particle with a tunable shell and a soft core of responsive polymer that exhibits changeable shapes; in which the shell with inorganic composition was formed directly in polymerization, resulting in core-shell particles with polymer core. The method provides a new route of producing core-shell particles and potentially preparing hollow spheres.

Experimental section

Materials

The monomers, N-isopropylacrylamide (NIPAM, 99%) and (3-Methacryloyloxypropyl) methyl-diethoxysilane (MADS, 98%), were respectively purchased from J&K Scientific Ltd. and Tokyo Chemical Industry Co. Ltd. The crosslinker, i.e., N,N′-methylene bisacrylamide (MBA, 98%), and the initiator, i.e., 2,2,-azodiisobutyronitrile (AIBN, 98%), were from Tianjin Fuchen Chemical Regents Factory. Toluene (99.7%) and 95% ethanol were respectively, purchased from Beijing Chemical Works and Beijing Tongguang Fine Chemicals Company. All of the chemical regents were used without any purification after purchase.

Synthesis of particles

The polymerization was carried out in toluene using a 100-mL three-neck flask equipped with a magnetic stirrer, in which NIPAM and MADS were used as monomers while MBA served as the crosslinker. Typically, NIPAM, MBA, MADS, and AIBN were dissolved into 50 mL toluene with a feed molar ratio of 100: 10: 5: 1. After deoxygenation with nitrogen for 30 min, the polymerization was carried out at 70 íC for 4 h. The resulting product was collected by centrifugation and washed with toluene. A transparent gel-like particle was obtained. In the absence of MADS, pure poly(N-isopropyleacrylamide) (PNIPAM) particles are obtained in polymerization.

Characterization

The morphology of the particles was investigated by scanning electron microscopy (SEM, JEOL7600). SEM samples were prepared as follows: particles were ultrasonically dispersed in various solvents (distilled water, 95% ethanol or toluene), followed by dripping the solutions onto silicon and air-drying. The SEM sample was sputtered with platinum before observation.

The structure of the particles was characterized with transmission electron microscopy (TEM). Samples were prepared by dripping the dispersion of particles onto a carbon-coated copper grid, followed by air-drying. TEM micrographs were obtained with a JEM-2200FS instrument.

The composition of the particles was investigated by thermal gravimetric analysis (TGA), which was carried out in nitrogen using a Netzsch TG209F1 instrument. In order to remove the water in the sample, the following temperature program was carried out: Particles were first heated to 100 íC at a rate of 10 íC/min; the temperature was then kept at 100 íC for 15 min and finally, the temperature increased to 600 íC at a heating rate of 10 íC/min.

Fourier transform infrared spectroscopy (FT-IR) measurement of the particles was carried out on a FTIR spectrometer (Bruke TENSOR 27).

Results and discussion

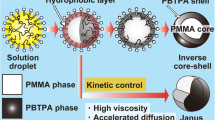

Novel soft core/solid shell particles were synthesized in a one-pot precipitation polymerization via phase separation. Most PNIPAM particles are prepared via aqueous polymerization; however, we found that the polymerization could be carried out in organic solvent, indicating the possibility to prepare a wide range of copolymers with NIPAM. The copolymerization was performed in toluene without any surfactant. Since different solubility and reactivity ratios exist between the two monomers in toluene, the PNIPAM chains would precipitate and form a core, resulting in a phase separation between the polymer chains and silicon. Scheme 1 shows how the core-shell particles were synthesized. Typically, N-isopropylacrylamide (NIPAM) and 3-Methacryloyloxypropyl)methyldiethoxysilane (MADS) were used as monomers while MBA was used as a crosslinking agent. The polymer particles were synthesized in toluene at 70 °C using MADS and MBA feed molar ratios relative to NIPAM (i.e., the S/N and M/N ratio, respectively) of 5 and 10 mol%, respectively. The particles were collected after being washed with toluene. These particles were then re-dispersed into different solvents before checking their morphology with SEM.

Schematic illustration for one-step polymerization of tuneable core-shell particles. (1) Copolymerization of NIPAM and MADS in organic solvent with the help of MBA (2) the formation of a core-shell structure through a phase separation of the different polymer chains, and (3) the change of particle shapes in different solvents

As shown in Fig. 1a, b, particles with a size of approximately 200 nm were observed after the formed particles were dispersed into water. Many of the particles were broken, with the soft polymer escaping the shell, such as a broken egg. Additional particles can be seen in Fig. S1. The “broken egg” result could be attributed to the swelling of the polymer chains that occurred after soaking in water, rupturing the shell. This phenomenon indicated that the inner core of the particles consisted mainly of the soft polymer, PNIPAM, while the solid shell contained silicon. The experiment also confirmed that MADS hydrolyzed in water and became hard due to the formation of Si–O–Si bonds, while the wet PNIPAM exhibited extendibility of the polymer chains, as shown in Fig. 1b. In short, the particles possessed a solid shell and a soft core of PNIPAM. As shown in Fig. 1c, the TEM images clearly show that the particles have a core-shell structure, confirming that novel core-shell particles were created via polymerization. Since this polymerization was performed in an organic solvent, this process could be applied using numerous other comonomers to prepare core-shell particles with different shells.

The as-prepared particle with a flowable core. a SEM image of particles. b the magnified image of a broken particle with a flowing core. c TEM image of particles. d IR spectra of the as-prepared P(NIPAM-MADS). e TGA curves of P(NIPAM-MADS) and the pure PNIPAM particles. Particles were prepared with a S/N ratio of 5 mol% and an M/N ratio of 10 mol%

The composition of these particles was characterized with infrared spectroscopy (IR) (Fig. 1d). The strong absorbance at 1647 and 1502 cm−1 was assigned to the amide group, indicating that the particles mainly consisted of NIPAM polymer. The absorbance at 1080 cm−1 indicated the existence of silicon. Their thermal stability was investigated with TGA. The onset value of particle decomposition was approximately 331 °C (Fig. 1e). The particle residue was 10.8 wt.% for the P(NIPAM-MADS) particles, which is considerably higher than that of the pure PNIPAM particles (3.7 wt.%), confirming the introduction of silicon into the particles.

A series of particles was synthesized with different S/N ratios while the M/N ratio was fixed at 10 mol%. As shown in Fig. 2a, the as-prepared particles with S/N ratio of 1 mol% exhibited a bi-compartmental structure in water due to the outflow of PNIPAM as a result of too thin shells (Fig. 2a). The particles were very small, approximately 100 nm, and the size of the biggest particles was less than 200 nm (Fig. S2a). Increasing the S/N ratio to 5 mol% resulted in the typical size of the particles increasing to close to 200 nm. The shell of the particles became hard, giving rise to a propensity to crack due to the swelling of the polymer core when placed in water, as shown in Fig. 1. When the S/N ratio was further increased to 10 or 20 mol%, the diameter of the particles became greater than 200 nm. The strength of the particle shells also improved such that most of particles remained unbroken even if they were ultrasonicated in water. Outflow of the polymer core was not typically observed for these larger particles (Fig. 2c). However, their shape often became non-spherical due to the expanding core, as shown in Fig. 2b, c. Supplementary images of the particles can be found in Fig. S2b, c. When the S/N ratio reached 50 mol%, particles became very large with a diameter of approximately 300 nm. Moreover, the morphology of particles became spherical (Fig. 2d). In addition, some small particles were observed near the large particles, which could possibly be silica particles produced after the MADS was exhausted. In sum, the strength of particles’ shells could be increased and their shape in water evolved from a broken egg shape to deformed particles to spheres by increasing the feed ratio of MADS. This result further confirmed that the shell formation primarily resulted from the MADS. In addition, the particle sizes also gradually became larger with the increase in the MADS feed.

SEM images of particles prepared with different S/N ratios. a 1 mol%. b 10 mol%. c 20 mol%. d 50 mol%. e IR spectra of particles prepared with different S/N ratios. f TGA residue fragment of particles as a function of the S/N ratio. The polymerization was carried out at 70 íC while the M/N ratio was fixed at 10 mol%

The composition of the particles was characterized with IR spectroscopy (Fig. 2e). The absorbance assigned to Si–O at 1080 cm−1 was gradually enhanced with an increase in the S/N feed ratio. The amide group peaks at 1539 and 1647 cm−1 indicated an increasing content of silica in particles.

TGA and DTG curves are shown in Fig. S3. The residue fragment at 650 °C gradually increased from 10.4 to 15.7 wt.% as the feed ratio of MADS increased from 10 to 50 mol%. The residue results from TGA are shown in Fig. 2f as a function of S/N ratio and clearly exhibit a linearly increasing residue dependent on the feed ratio of MADS. All of the DTG curves also show a shoulder peak approximately 280 °C in addition to the main decomposition peak at approximately 370 °C (Fig. S3b), confirming the presence of two different phases in the particles.

The above particles were synthesized with a fixed M/N ratio at 10%. When the feed ratio of MADS was fixed in polymerization, e.g., a 5 mol% S/N ratio, the morphologies and compositions of particles could further be tuned by changing the M/N ratio, i.e., changing the feed ratio of the crosslinking agent MBA. When the M/N ratio was reduced to 5 mol%, the outer shell burst (Fig. 3a) and the particles were destroyed. Additional images of particles with disintegrated shells can be seen in Fig. S4. The disintegration of the shell could be attributed to a low degree of crosslinking, resulting in fragile shells easily destroyed during the expansion of the swollen PNIPAM chains in water. This result again confirmed that the shell formation resulted from the MADS, which hydrolyzed in water and became stiff and brittle. Moreover, if particles were synthesized with a 5 mol% M/N ratio, the shells of most of the particles disintegrated in water, regardless of whether there was a low or high concentration of MADS in polymerization.

Fixing the S/N ratio at 5 mol% while raising the M/N ratio to 10 mol% resulted in as-prepared particles with stiff shells that merely broke in half (Fig. 1) instead of disintegrating into pieces. By further increasing the M/N ratio to 20 mol%, the strength of particles shells significantly increased and it was difficult to find broken shells; however, it was still possible for the PNIPAM soft core to flow out of the shell from a crack (Fig. 3b, S5A), and some non-spherical particles still existed. If the M/N ratio was increased to 30 mol% during polymerization, the morphology of the particles became stably spherical and no broken shells were observed, as shown in Figs. 3c and S5B. The change in morphology could mainly be attributed to the high toughness of the shells when the feed ratio of the crosslinking agent was very high. In addition, the reduced swelling of PNIPAM with increasing MBA might also be helpful for maintaining a spherical shape; however, the reduction in swelling is likely to be less important because the as-prepared particles synthesized using low concentrations of MADS were also broken even when the feed ratio of MBA was very high. Nonetheless, the crosslinking agent is very important for maintaining the integrity of particles’ morphology.

The shapes of the above particles could be controlled by dispersing them into different solvents (Fig. S6). In general, the particles were spherical in organic solvents and became non-spherical or broken in water. For example, for the particles prepared with M/N and S/N ratios each at 10 mol%, if the SEM sample was prepared directly in toluene, they usually had good spherical morphology (Fig. S6a). However, if they were dispersed into 95% ethanol, the particles were less spherical (Fig. S6b), and if they were dispersed in water, we obtained deformed particles with a vertex (Fig. S6c). These results also indicated that the shell was permeable, which can further be proven by TEM characterization after particles absorbed metal ions (Fig. S7), and this is necessary for applications in biologic medicine or catalysis.

Conclusions

We synthesized tunable particles with a core-shell structure via a facile one-pot method, which is potentially suitable to prepare particles on a large scale. The compositions of the as-prepared particles with a PNIPAM core could be tuned conveniently by adjusting the S/N and the M/N feed ratio, resulting in a series of different particle morphologies. These “egg structure” particles have wide potential application in drug delivery, catalysis, or microelectronics.

References

Wu S-H, Tseng C-T, Lin Y-S, Lin C-H, Hung Y, Mou C-Y (2011) Catalytic nano-rattle of Au@hollow silica: towards a poison-resistant nanocatalyst. J Mater Chem 21:789–794

Arnal PM, Comotti M, Schüth F (2006) High-temperature-stable catalysts by hollow sphere encapsulation. Angew Chem Int Ed 45:8224–8227

Kuwahara Y, Ando T, Kango H, Yamashita H (2017) Palladium nanoparticles encapsulated in hollow titanosilicate spheres as an ideal nanoreactor for one-pot oxidation. Chem Eur J 23:380–389

Güttel R, Paul M, Schüth F (2011) Activity improvement of gold yolk-shell catalysts for CO oxidation by doping with TiO2. Catal. Sci. Technol. Catal Sci Technol 1:65–68

Yang Y, Liu X, Li X, Zhao J, Bai S, Liu J, Yang Q (2012) A yolk-shell nanoreactor with a basic core and an acidic shell for cascade reactions. Angew Chem Int Ed 51:9164–9168

Lee I, Joo JB, Yin Y, Zaera F (2011) A yolk@shell nanoarchitecture for Au/TiO2 catalysts. Angew Chem Int Ed 50:10208–10211

Bonacucina G, Cespi M, Misici-Falzi M, Palmieri GF (2009) Colloidal soft matter as drug delivery system. J Pharm Sci 98:1–42

Timin AS, Gao H, Voronin DV, Gorin DA, Sukhorukov GB (2017) Inorganic/organic multilayer capsule composition for improved functionality and external triggering. Adv Mater Interfaces 4:1600338

Sun X, Li D, Ding Y, Zhu W, Guo S, Wang ZL, Sun S (2014) Core/shell Au/CuPt nanoparticles and their dual electrocatalysis for both reduction and oxidation reactions. J Am Chem Soc 136:5745–5749

Zhang L, Wang T, Yang L, Liu C, Wang C, Liu H, Wang YA, Su Z (2012) General route to multifunctional uniform yolk/mesoporous silica shell nanocapsules: a platform for simultaneous cancer-targeted imaging and magnetically guided drug delivery. Chem-A Eur J 18:12512–12521

Tibbitt MW, Dahlman JE, Langer R (2016) Emerging frontiers in drug delivery. J Am Chem Soc 138:704–717

Tong R, Hemmati HD, Langer R, Kghohane DS (2012) Photoswitchable nanoparticles for triggered tissue penetration and drug delivery. J Am Chem Soc 134:8848–8855

Hellweg T (2013) Responsive core-shell microgels: synthesis, characterization, and possible applications. J Polym Sci B Polym Phys 51:1073–1083

Rauh A, Rey M, Barbera L, Zanini M, Karg M, Isa L (2017) Compression of hard core-soft shell nanoparticles at liquid–liquid interfaces: influence of the shell thickness. Soft Matter 13:158–169

Zhang J, Zhang M, Tang K, Verpoort F, Sun T (2014) Polymer-based stimuli-responsive recyclable catalytic systems for organic synthesis. Small 10(1):32–46

Tardy BL, Dam HH, Kamphuis MMJ, Richardson JJ, Caruso F (2014) Self-assembled stimuli-responsive polyrotaxane core-shell particles. Biomacromolecules 15:53–59

Zhu Y-J, Chen F (2015) pH-Responsive drug-delivery systems. Chem Asian J 10:284–305

Kazemi A, Lahann J (2008) Environmentally responsive core/shell particles via electrohydrodynamic co-jetting of fully miscible polymer solutions. Small 4(10):1756–1762

Atkin R, Bradley M, Vincenta B (2005) Core-shell particles having silica cores and pH-responsive poly(vinylpyridine) shells. Soft Matter 1:160–165

Wu L, Glebeand U, Böker A (2016) Synthesis of hybrid silica nanoparticles densely grafted with thermo and pH dual-responsive brushes via surface-initiated ATRP. Macromolecules 49(24):9586–9596

Cayre OJ, Chagneux N, Biggs S (2011) Stimulus responsive core-shell nanoparticles: synthesis and applications of polymer based aqueous systems. Soft Matter 7:2211–2234

Ramli RA, Laftah WA, Hashim S (2013) Core-shell polymers: a review. RSC Adv 3:15543–15565

Duan L, You B, Zhou S, Wu L (2011) Self-assembly of polymer colloids and their solvatochromic-responsive properties. J Mater Chem 21:687–692

Li Y, Shi J (2014) Hollow-structured mesoporous materials: chemical synthesis, functionalization and applications. Adv Mater 26:3176–3205

Ding S, Zhang C, Yang M, Qu X, Lu Y, Yang Z (2006) Template synthesis of composite hollow spheres using sulfonated polystyrene hollow spheres. Polymer 47:8360–8366

Wang Y, Yu L, Lo XW (2016) Formation of triple-shelled molybdenum-polydopamine hollow spheres and their conversion into MoO2/carbon composite hollow spheres for lithium-ion batteries. Angew Chem Int Ed 55:14668–14672

Windbergs M, Zhao Y, Heyman J, Weitz DA (2013) Biodegradable core-shell carriers for simultaneous encapsulation of synergistic actives. J Am Chem Soc 135:7933–7937

Yang J, Hu D, Fang Y, Bai C, Wang H (2006) Novel method for preparation of structural microspheres poly(N-isopropylacrylamide-co-acrylic acid)/SiO2. Chem Mater 18:4902–4907

Hu J, Liu L, Xie Y, Wu L (2013) Facile synthesis of thermal-responsive P(NIPAM-S)/SiO2 hybrid hollow spheres and their controllable release properties for fragrance. Polym Chem 4:3293–3299

Li Z, Chen T, Nie J, Xu J, Fan Z, Du B (2013) P(NIPAm-co-TMSPMA)/silica hybrid microgels: structures, swelling properties and applications in fabricating macroporous silica. Mater Chem Phys 138:650–657

Priebe M, Fromm KM (2015) Nanorattles or yolk-shell nanoparticles—what are they, how are they made, and what are they good for? Chem Eur J 21:3854–3874

Nollet M, Depardieu M, Destribats M, Backov R, Schmitt V (2013) Thermo-responsive multi-cargo core shell particles. Part Part Syst Charact 30:62–66

Duan L, Chen M, Zhou S, Wu L (2009) Synthesis and characterization of poly(N-isopropylacrylamide)/silica composite microspheres via inverse Pickering suspension polymerization. Langmuir 25:3467–3472

Acknowledgements

This work was supported by the Open Foundation of the National Laboratory, the Recruitment Program of BIFT Talent, and the Beijing Innovation Project of the Teacher Team (No. IDHT20140502).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Electronic supplementary material

ESM 1

(DOCX 8575 kb)

Rights and permissions

About this article

Cite this article

Jiang, J., Deng, Y., Lou, J. et al. Facile synthesis of tunable core-shell particles via one-step copolymerization. Colloid Polym Sci 295, 613–617 (2017). https://doi.org/10.1007/s00396-017-4034-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00396-017-4034-8