Abstract

A novel Ho:LuAG ceramic laser Q-switched by a polycrystalline Cr2+:ZnS saturable absorber was reported for the first time in this paper. We took a diode-pumped Tm:YLF laser emitting at 1.9075 μm as the pump source. The laser operated in both continuous wave mode and passively Q-switching (PQS) mode. The maximum PQS output power of 2.67 W was obtained with a slope efficiency of 26.4%. When the absorbed pump power increased from 4.78 to 10.8 W, with three output couplers of T = 2%, T = 10% and T = 25%, the pulse widths decreased as the pump power increased, from 102.9 to 89.2 ns, from 147.1 to 127.6 ns, and from 173 to 150 ns, respectively, and the repetition frequency varied from 10.2 to 20.1 kHz, from 9.3 to 18.3 kHz, and from 8.45 to 16.66 kHz as well. The central wavelength remained constant 2100.64 nm with the change of output couplers and operation modes. Furthermore, the output laser had a beam quality factor M 2 of 1.1.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Two-micrometer solid-state lasers in the eye-safe range can be widely applied in many fields such as ladar, medical treatment, material processing, and atmospheric remote sensing [1,2,3]. Additionally, it is an efficient source at this particular wavelength for pumping optical parametric oscillators (OPOs) to generate mid-infrared laser output [4, 5]. Currently, in order to achieve 2-μm laser output, one major method is to utilize Tm3+-doped [6], Ho3+-doped [7], or Tm3+, Ho3+ co-doped [8] lasers. The Ho3+-doped laser may be a better choice, since it has some obvious advantages over the two other lasers. Its larger emission cross section and lower cooperative up-conversion loss are beneficial for laser operation at room temperature. Various Ho3+-doped crystals including oxide crystals (YAG [9], LuAG [10]) fluoride crystals (YLF [11]), and vanadate crystals (LuVO4 [12]) have been studied. In recent years, optical transparent ceramics undergo a development with a high speed. For the solid-state lasers, YAG and LuAG ceramics were fabricated and doped with Ho3+ ions [13,14,15]. YAG transparent ceramics have the similar optical spectroscopic properties with the single crystals [15]. And ceramic YAG is easy to be fabricated into large sizes and complicated structures [15]. When considering about mass production and short fabrication period, YAG transparent ceramics can be competitive laser material [15]. However, LuAG shows a superior thermal conductivity in the case of high rare earth ions doping concentrations or operating at high temperatures [15]. Ho:LuAG ceramics belong to cubic oxide crystal system, and the characteristics of Ho:YAG [16] and Ho:LuAG [17] are similar, for they are both oxide crystals. In Ref [15], by the method of the reactive sintering in the condition of vacuum, high-quality Ho3+-doped YAG and LuAG transparent polycrystalline ceramics were fabricated. The crystal field strength of Ho:LuAG is larger than that of Ho:YAG. Therefore, LuAG is more like a four-level system, considering about a stronger splitting of ground manifold of 5I8 in Ho3+ ion and a lower thermal occupation of lower laser levels [17]. LuAG ceramic is an ideal material for 2-μm lasers for its excellent mechanical properties and thermal performance. The nanosecond laser pulse can be achieved under the Q-switching technology, and its characteristics of high peak power and high repetition rate are beneficial to the application for nonlinear optics and ranging [18, 19]. The characteristics of the saturable absorber (SA) are very important and crucial for PQS lasers. The widely used SAs in 2-μm region include PbS-doped glass [20], MoS2 [21], single walled carbon nanotube: SWCNT [22], graphene [23], and Cr2+-doped chalcogenide (including ZnS, ZnSe, and so on) crystals [24]. In general, the generation of passively Q-switched (PQS) laser pulses mainly depends on the availability of suitable saturable absorbers (SAs). In 2011, Dergachev reported a single-frequency operation ring cavity PQS laser with the Cr2+:ZnSe as a SA, the pulse energy of 0.26–0.42 mJ and the pulse width of 175–140 ns were obtained [25].

In this work, we demonstrated a PQS Ho:LuAG ceramic laser pumped by a Tm:YLF laser with a Cr2+:ZnS saturable absorber, and the influence of output couplers with different transmissions has been investigated. The experimental observation of two regimes in operation of a Ho:LuAG laser: a stable continuous wave and Q-switching was reported. The maximums PQS output power of 2.67 W was obtained with a slope efficiency of 26.4%. When the absorbed pump power increased from 4.78 to 10.8 W, with three output couplers of T = 2%, T = 10% and T = 25%, the pulse widths decreased as the pump power increased, from 102.9 to 89.2 ns, from 147.1 to 127.6 ns, and from 173 to 150 ns, respectively, and the repetition frequency varied from 10.2 to 20.1 kHz, from 9.3 to 18.3 kHz, and from 8.45 to 16.66 kHz. The central wavelength remained constant 2100.64 nm with the change of output couplers and operation modes. Additionally, the beam quality factor M 2 of the output laser was 1.1.

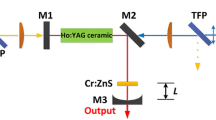

2 Experimental setup

The experimental setup of CW and PQS Ho:LuAG ceramic laser is shown in Fig. 1. A simple L-shaped concave–concave cavity is employed. The size of Ho:LuAG ceramic is 1.5 × 3 × 16 mm3, and it has an Ho3+ ions doping concentration of 0.8 at.%. Both end surfaces of the ceramic are coated with anti-reflection (AR) film at 1.91 (R < 0.5%) and 2 μm (R < 0.3%). The Ho:LuAG ceramic wrapped with indium foil was mounted on a copper heat sink which was cooled by water to maintain the temperature. The Ho:LuAG ceramic laser was pumped by a Tm:YLF laser with the central wavelength of 1907.5 nm and the maximum output power of 20 W. The Tm:YLF laser was pumped by two fiber-coupled LDs emitting at 792 nm. The Tm:YLF laser was focused into the Ho:LuAG ceramic by a focus lens whose focal length is 100 mm, the beam spot in the ceramic center has a radius of 0.16 mm. M1 is a 45° dichroic mirror AR-coated at 1.91 μm and HR-coated at 2.1 μm. M2 is the output coupler with a curvature of 75 mm and have a transmittance of 2, 10, and 25% at 2.1 μm, respectively. M3 is a concave mirror with a curvature radius of 500 mm and is highly reflective (HR)-coated at 2.1 μm. For PQS operation, a Cr2+:ZnS SA was employed as the passively Q-switch. The SA has a transmittance of 90% at 2.1 μm. The SA is placed in the resonator 5 mm away from the output coupler M2. The total physical length of the resonator is 100 mm. The beam radius of the Ho:LuAG ceramic laser inside the resonator was calculated by using the well-known ABCD matrix. The calculated radii of TEM00 mode in the center of the Ho:LuAG ceramic and SA were, respectively, ~125 and ~295 μm with an analysis of cold resonator. The laser pulse width, repetition frequency, and temporal profile were observed with a digital oscilloscope (Tektronix MSO 2034, 300 MHz, 2.5 GS/s) and an InGaAs detector.

3 Results and discussion

SAs with different transmissions were inserted into the cavity to investigate the output performance of PQS operation. Figure 2 shows the average output power as a function of the pumped power with the output couplers of T = 2%, T = 10% and T = 25%, respectively. As shown in Fig. 2, the average output power linearly depends on the pump power, and the best result was obtained with the T = 25% output coupler. At the absorbed pump power of 10.8 W, we obtained a highest average output power of 2.67 W with a slope efficiency of 26.4%. While with the two other output couplers of T = 2% and T = 10%, the maximum output power of PQS operation was 1.9 and 1.79 W, corresponding to slope efficiencies of 17.2 and 16.8%, respectively.

The duration of the laser pulse versus the pump power is shown in Fig. 3a. The laser pulse was recorded by a digital oscilloscope (Tektronix MSO 3034, 300 MHz, 2.5 GS/s) with an InGaAs detector. As shown in Fig. 3a, with three output couplers of T = 2%, T = 10% and T = 25%, the pulse widths decreased as the pump power increased, from 102.9 to 89.2 ns, from 147.1 to 127.6 ns, and from 173 to 150 ns, respectively. As we can see, the pulse widths were different with three different output couplers. When the transmission of the output coupler was 2%, the gain of the resonator was larger which produced narrower pulse duration. Comparatively, for T = 25%, the gain was low and the pulse duration was broaden. When the output coupler was determined, the pulse width became short when the pump power increased that was because when the pump power was higher, the upper-level population under the low Q value was larger than that in low pump power condition, which gives to a rapidly increasing of photon in the resonator, resulting in a shorter pulse width. The pulse repetition frequencies versus the pump power with three output couplers are shown in Fig. 3b, as we can see from it, with the three different output couplers, the pulse repetition frequency grew with the pump power from 10.2 to 20.1 kHz, from 9.3 to 18.3 kHz, and from 8.45 to 16.66 kHz, respectively. The repetition rate was increasing with the pump power. Because of the lens effect of LuAG crystal, the spot on the Cr2+:ZnS crystal became smaller and the repetition rate increased obviously near 7 W. In the pump power regions both lower and higher than 7 W, the repetition rates actually depended on the in-cavity energy and energy–density on the SA. The lens effect can explained the rigid increase in the repetition, but it does not influence the overall development trend. Lens effect can be the main reason to explain the fluctuations in Figs. 2 and 3a. We can draw a rough conclusion that by changing the pump power and output coupler, the pulse repetition could be controlled.

The pulse train and single-pulse profile obtained with the T = 2% output coupler is shown in Fig. 4, with a repetition frequency of 20.1 kHz and a pulse width of 89.3 ns. What we can see from the inserted picture in Fig. 4 is that the pulse train is quite stable. A pyroelectric camera was used to record the laser beam profile. The ratio of the ground state absorption cross section of the Cr2+:ZnS SA σ gsa and the stimulated-emission cross section of the Ho:LuAG ceramic σ em decides the bleaching difficulty α of the Cr2+:ZnS SA in the Ho:LuAG ceramic laser setup, which can also be put as α in proportion to σ gsa/σ em. As α grows, Cr2+:ZnS SA gets easier to be bleached, so with the same transmissivity of the output coupler, the pulse duration of the laser is narrower. Additionally, limited by the growth method, single crystal with large size and high doping concentration is difficult to obtain. Compared with single crystal, Ho:LuAG transparent ceramic has several advantages such as improved mechanical properties, increased range of composition, fabrication of large size and high doping concentration, mass production, and lower cost. All these can contribute to a shorter pulse width.

As shown in Fig. 5, the spectral was measured with a Spectrum Analyzer (Bristol Instruments 721). The central wavelength remained constant 2100.64 nm with the change of output couplers and operation modes. For a output coupler with a transmissivity of 2%, at the absorbed pump power of 10.8 W, a convex lens with the focus length of 100 mm was used to transform the output laser of the Ho:LuAG ceramic laser. The transverse beam profile of the transformed laser was measured by using a 90/10 knife-edge technique. And the beam quality factor M 2 was calculated with Gaussian fitting, which was figured out to be 1.1, indicating nearly diffraction-limited beam propagation and the laser was fundamental TEM00 mode. The measuring result is shown in Fig. 6. A low spatial-resolution laser beam profile (inset in Fig. 6) at the highest absorbed pump power was observed by a pyroelectric camera.

At the same pump power of 16 W, when we choose the output coupler with a transmissivity of 25%, comparing with the Cr2+:ZnS SA with a initial transmissivity of 82% in the Ref. [17], the initial transmissivity of the Cr2+:ZnS SA we used is 90%, which is higher than that in Ref. [17], galvanizing a lower cavity loss and longer photon lifetime, and eventually resulting in a wider pulse duration than that of the Ref. [17], which is 36 ns. To obtain a shorter pulse duration, we can reduce the length of the cavity, the small signal transmission of the SA and the transmittance of the output coupler. Besides, it can be found that the output power in this paper is lower than that of 2.19 W demonstrated in the Ref. [17], which is ascribed to the premature quality of the Ho:LuAG ceramic since the Ho:LuAG ceramic is a novel laser media with immaturity. It is believed that the quality of the Ho:LuAG ceramic can be improved with the maturity of the technology.

4 Conclusion

In conclusion, we demonstrated a novel passively Q-switched Ho:LuAG ceramic laser pumped by a Tm:YLF laser for the first time, to our knowledge. The Q-switching operation was obtained by inserting different initial transmission polycrystalline Cr2+:ZnS SAs into the laser cavity. The laser operated in both continuous wave (CW) mode and passively Q-switching (PQS) mode. The maximums PQS output power of 2.67 W was obtained with a slope efficiency of 26.4%. When the absorbed pump power increased from 4.78 to 10.8 W, with three output couplers of T = 2%, T = 10%, and T = 25%, the pulse widths decreased as the pump power increased, from 102.9 to 89.2 ns, from 147.1 to 127.6 ns, and from 173 to 150 ns, respectively, and the repetition frequency varied from 10.2 to 20.1 kHz, from 9.3 to 18.3 kHz, and from 8.45 to 16.66 kHz as well. The central wavelength was 2100.64 nm, and the output laser had a beam quality factor M 2 of 1.1. The laser beam profile was close to TEM00 mode.

References

S.W. Henderson, C.P. Hale, J.R. Magee, M.J. Kavaya, A.V. Huffaker, Opt. Lett. 16, 773–775 (1991)

G.J. Koch, B.W. Barnes, M. Petros, J.Y. Beyon, F. Amzajerdian, J. Yu, R.E. Davis, S. Ismail, S. Vay, M.J. Kavaya, U.N. Singh, Appl. Opt. 43, 5092 (2004)

M.C. Gower, Opt. Express 7, 56 (2000)

E. Lippert, H. Fonnum, G. Arisholm, K. Stenersen, Opt. Express 18, 26475 (2010)

E. Lippert, G. Rustad, G. Arisholm, K. Stenersen, Opt. Express 16, 13878 (2008)

L. Wu, D.C. Li, S.Z. Zhao, K.J. Yang, X.Y. Li, R. Wang, J. Liu, Opt. Express 23, 15469 (2015)

J.H. Yuan, X.M. Duan, B.Q. Yao, J. Li, Z. Cui, Y.J. Shen, T.Y. Dai, Y.L. Ju, C.Y. Li, H.M. Kou, Y.B. Pan, Appl. Phys. B 119, 381 (2015)

Y.Q. Du, B.Q. Yao, J. Li, Y.B. Pan, X.M. Duan, Z. Cui, Z.C. Shen, Y.L. Ju, Laser Phys. Lett. 11, 115817 (2014)

S. Lamrini, P. Koopmann, M. Schäfer, K. Scholle, P. Fuhrberg, Opt. Lett. 37, 515 (2012)

Y.J. Shen, B.Q. Yao, X.M. Duan, Y.L. Ju, Y.Z. Wang, Laser Phys. 22, 858 (2012)

H. Fonnum, E. Lippert, M.W. Haakestad, Opt. Lett. 38, 1884 (2013)

Z. Cui, B.Q. Yao, X.M. Duan, S. Xu, Y.Q. Du, J.H. Yuan, T.Y. Dai, Y.L. Ju, Opt. Express 23, 13482 (2015)

L. Wang, C.Q. Gao, M.W. Gao, Y. Li, F.Y. Yue, J. Zhang, D.Y. Tang, Opt. Express 22, 254 (2014)

T. Zhao, Y. Wang, D.Y. Shen, J. Zhang, D.Y. Tang, H. Chen, Opt. Express 22, 19014 (2014)

H. Yang, L. Zhang, D.W. Luo, X.B. Qiao, J. Zhang, T. Zhao, D.Y. Shen, D.Y. Tang, Opt. Mater. Express 5, 142 (2015)

X.M. Duan, Z. Cui, L.J. Li, T.Y. Dai, K.K. Yu, B.Q. Yao, Quantum Electron. 45, 701 (2015)

B.Q. Yao, Z. Cui, X.M. Duan, Y.Z. Yang, Y.Q. Du, J.H. Yuan, Y.J. Shen, Appl. Phys. B 118, 235 (2015)

J. Ren, S.X. Wang, Z.C. Cheng, H.H. Yu, H.J. Zhang, Y.X. Chen, L.M. Mei, P. Wang, Opt. Express 23, 5607 (2015)

B. Xu, Y.J. Cheng, Y. Wang, Y.Z. Huang, J. Peng, Z.Q. Luo, H.Y. Xu, Z.P. Cai, J. Weng, R. Moncorgé, Opt. Express 22, 28935 (2014)

M.S. Gaponenko, A.M. Malyarevich, K.V. Yumashev, H. Raaben, A.A. Zhilin, A.A. Lipovskii, Appl. Opt. 44, 536–539 (2006)

F. Lou, R.W. Zhao, J.L. He, Z.T. Jia, X.C. Su, Z.W. Wang, J. Hou, B.T. Zhang, Photon. Res. 3, 25 (2015)

Z.S. Qu, Y.G. Wang, J. Liu, L.H. Zheng, L.B. Su, J. Xu, Appl. Phys. B 109, 143–147 (2012)

Z. Cui, B.Q. Yao, X.M. Duan, Y.Q. Du, S. Xu, Y.Z. Wang, Opt. Eng. 53, 126112 (2014)

S. Mirov, V. Fedorov, I. Moskalev, D. Martyshkin, C. Kim, Laser Photon. Rev. 4, 21 (2010)

A. Dergachev, Opt. Express 19, 6797–6806 (2011)

Acknowledgements

This work is supported by National Natural Science Foundation of China (Nos. 61308009, 61405047, 50990301), China Postdoctoral Science Foundation funded project (No. 2013M540288), Fundamental Research funds for the Central Universities (Grant No. HIT. NSRIF. 2014044, Grant No. HIT. NSRIF. 2015042), and Science Fund for Outstanding Youths of Heilongjiang Province (JQ201310).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, Y., Yao, B.Q., Cui, Z. et al. The performance of a novel Ho:LuAG ceramic laser Q-switched by a polycrystalline Cr2+:ZnS saturable absorber. Appl. Phys. B 123, 28 (2017). https://doi.org/10.1007/s00340-016-6590-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00340-016-6590-x