Abstract

We demonstrated a high-power dual-end-pumped passively Q-switched Ho:YAG ceramic laser with a Cr2+:ZnS saturable absorber (SA). The influence of the beam diameter on SA on the Q-switched laser performance was investigated. Up to 30.3 W average output power was obtained, to our best knowledge, which is the highest average output power obtained in a Ho-doped passively Q-switched laser. The maximum pulse energy and peak power of 0.94 mJ and 33.5 kW were achieved, when the Cr2+:ZnS SA was placed far from the laser beam waist, corresponding to a pulse width of 28 ns and a pulse repetition frequency of 28.8 kHz. In addition, we achieved the highest output power of 40.4 W from continuous-wave Ho:YAG ceramic laser.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Solid-state lasers operating in the eye-safe 2-μm spectral region have been proven vital for a variety of applications, including remote sensing, wind lidar, and medicine as well as mid-infrared generation via pumping of optical parametric oscillators [1–3]. Previously, Q-switched solid-state lasers were mostly realized in the active Q-switched scheme with acousto-optic modulators [4–6]. Additional electrical consumption and complex structure, which are caused using the acousto-optic or electro-optic modulators, make the active Q-switched scheme costly and inconvenient. In contrast, passively Q-switched (PQS) scheme possesses the advantages of inherent compactness, simplicity, and low-cost design. In recent years, PQS lasers operating around 2 μm with the saturable absorbers (SAs) of Cr2+:ZnS, Cr2+:ZnSe, and graphene have drawn more and more attentions in the laser community. Owing to the advantage that the absorption band of Tm3+ ions is around 800 nm, which matches the emission of the commercial laser diodes, Tm-doped [7–9] and Tm/Ho-codoped [10–12] PQS lasers were widely investigated. Using the Tm:LiLuF4 and Cr2+:ZnS SA, single-pulse energy of 1.26 mJ was generated with maximum average output power of 203 mW at a pulse repetition frequency (PRF) of 161 Hz and pulse duration of 7.6 ns [8]. The pulse energy of 70.5 μJ with maximum average output power of 3.2 W at a PRF of 52 kHz was obtained from a diode-pumped PQS Tm, Ho:GdVO4 laser using a Cr2+:ZnS SA; however, the pulse duration, 389 ns, was rather long [12]. Compared with the Tm-doped lasers’ Q-switching performance, Ho-doped lasers are more superior because Ho3+ ions have bigger stimulated emission cross section and longer lifetime of excited-state energy level than Tm3+ ions [13]. Using a Cr2+:ZnSe SA in a flashlamp-pumped Ho:YAG single-crystal laser, the pulse energy of 1.3 mJ with a pulse duration of 90 ns was obtained, but the efficiency was only 5 % [14]. Using the graphene SA in a Ho:YAG single-crystal laser, single-pulse energy of 13.3 μJ at a PRF of 43 kHz was obtained, corresponding to a shortest pulse width of 632 ns [15]. The maximum average output power of 16.6 W with a pulse energy of 2.37 mJ was obtained from a Tm:YLF-pumped Ho:YAG laser using a Cr2+:ZnS SA [16].

Recently, polycrystalline ceramics as laser gain host materials have attracted enormous interests owing to a number of advantages over single crystals, such as feasibility of large size, short fabrication time, ease of fabrication, mass production, and low cost [17, 18]. Compared with the single crystals, PQS Ho-doped ceramics have few reports. Ho:YAG ceramics as gain materials have been proved to give excellent results that can be compared with the Ho:YAG single crystals in the CW [19] and active Q-switched [20] regimes. As for passive Q-switching, pulse energy of 9.3 μJ at a PRF of 43 kHz was generated using a graphene SA, corresponding to the maximum average output power of 264 mW and a shortest pulse width of 2.6 μs [21]. In our previous work, the maximum average output power of 14.8 W with a pulse energy of 0.6 mJ was achieved from a PQS Ho:YAG ceramic laser using a Cr2+:ZnS SA [22].

In this paper, we report on a PQS Ho:YAG ceramic laser at 2089 nm using a Cr2+:ZnS SA, which was dual-end-pumped by two orthogonally polarized Tm:YLF lasers. High-power and efficient continuous-wave (CW) and PQS lasers were realized. The Q-switched performance was seriously studied, which was especially influenced by the beam diameter on SA.

2 Experimental setup

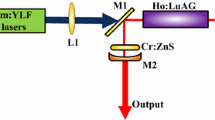

Schematic diagram of the experiment setup is shown in Fig. 1. An L-shaped hemispherical resonator was constructed for the PQS Ho:YAG ceramic laser. The pump was delivered through the plane mirror M1, which was antireflective (AR)-coated at 1.9 μm (>99.6 %) and highly reflective (HR)-coated at 2.1 μm (>99.7 %). The 45° dichroic mirror M2 was plane, HR (>99.7 %) at 2.1 μm and AR (>98 %) at 1.9 μm. Output coupler M3 with transmission of 50 % at 2.1 μm and 100 mm curvature radius was employed. The pump sources were two indiscrimination Tm:YLF lasers centered at 1908 nm with s-polarized output. Both the maximum output powers of Tm:YLF lasers were 44 W, and the maximum M 2 factors were 3. A Tm:YLF laser passed through a half-wave plate, and the polarization state was changed to p-polarized. Two thin-film polarizers (TFPs) employed in the experiment that were 45° placed were to avoid the Tm:YLF lasers being influenced by each other, which were HR for the s-polarized pump and AR for the p-polarized pump. Each of the incident pump lasers was focused to a 250-μm spot radius at the center of the Ho:YAG ceramic with a lens of 150-mm focal length.

Ho:YAG ceramic of 1 % Ho3+ doping was AR-coated for both pump and laser wavelengths. The Ho:YAG ceramic was cut with dimensions of 1.5 × 3 × 18.5 mm3. The Ho:YAG ceramic was wrapped with indium foil and mounted in a copper holder at 18 °C with water circulation for heat removal. The Cr2+:ZnS SA was cut into 9 × 9 × 2 mm3 and mounted in a copper heat sink with circulating water. The small signal transmission of the Cr2+:ZnS SA at 2 μm was 88 %. The distance between M1 and M2 was 53 mm, and the Ho:YAG ceramic located at the center of M1 and M2. The distance between M2 and M3 was 90 mm, and the total physical length of the resonator was 143 mm. Without inserting the Cr2+:ZnS SA, the thermal focal length of the Ho:YAG ceramic was measured to be 67 mm under the maximum incident pump power of 88 W, which was deduced from the backward calculation with the measured M 2 factor [23]. According to the ABCD matrix theory, the value of (A + D)/2 = −0.46 was found, which indicated the resonator was stable. Without the thermal lensing, the cavity was unstable. So it was clear that thermal lensing made the cavity stable. The calculated radius of TEM00 mode on the Ho:YAG ceramic was 240 μm at the maximum pump power, which was well matched with the pump spot. The distance L between the Cr2+:ZnS SA and M3 was variable in order to change the mode radius on the Cr2+:ZnS SA. With the increase in L, the laser beam diameter on SA became smaller, which led to the increase in the laser power intensity on SA. The spot diameters of TEM00 mode on SA with different L were calculated to be 516 μm (L = 23 mm) and 414 μm (L = 43 mm) at the maximum pump power of 88 W.

3 Results and discussion

Figure 2 shows the output powers of the CW and PQS Ho:YAG ceramic lasers versus the absorbed pump power. The single-pass absorption of the Ho:YAG ceramic at 1908 nm was measured to be 75 %. It can be noted that the output powers of CW and PQS Ho:YAG ceramic lasers linearly depended on the absorbed pump power. The maximum CW output power was 40.4 W at the maximum pump power of 88 W, corresponding to a slope efficiency of 63.5 % with respect to the absorbed pump power without inserting the Cr2+:ZnS SA into the cavity. The overall optical-to-optical conversion efficiency of 61 % was obtained with respect to the absorbed pump power. The average output power of the PQS Ho:YAG ceramic laser with Cr2+:ZnS SA was also investigated when the Cr2+:ZnS SA was placed close to (L = 43 mm) and far from (L = 23 mm) the laser beam waist. The maximum average output powers were 30.3 and 27.1 W, corresponding to the Q-switching efficiencies of 48.7 and 44.0 % with respect to the absorbed pump power at L of 43 and 23 mm, respectively. The larger the distance L (the smaller beam diameter on SA) was, the higher the average output power and slope efficiency could be. This can be attributed to the lower saturation absorption loss of Cr2+:ZnS SA at larger L caused by the distribution of intracavity laser field [10, 12]. We can conclude from Fig. 2 that there is room for further power scaling of the PQS Ho:YAG ceramic laser, because no power saturation was observed even at the maximum pump power.

The PRFs and pulse widths were measured at different L and absorbed pump power, which are shown in Fig. 3. The PRF was almost linear with the increase in the absorbed pump power (Fig. 3a). This can be attributed to the fact that the PRF is approximately linear with the pump rate in the upper laser level, which is proportional to the pump power [24]. In general, the larger the distance L (the smaller beam diameter on SA) was, the higher the PRF was, under the same absorbed pump power. The PRFs increased from 3.7 to 28.8 kHz and 3.4 to 34.3 kHz while the absorbed pump power varied from 6.1 to 66.2 W at L = 23 mm and L = 43 mm, respectively. The pulse widths decreased rapidly with the increase in the absorbed pump power at the lower absorbed pump power. When the absorbed pump power was over 25 W, the pulse width remained almost constant of 28 ns and exhibited independence with the absorbed pump power (Fig. 3b). The variation of the output pulse width depends on the change n i /n t (n i and n t are the initial and threshold inversed population, respectively). The increase in pumping power will result in the increase in the ratio of n i /n t . With the increase in n i /n t , the output pulse width decreases rapidly at first and then remained nearly constant [25, 26]. As a result, with the increase in the absorbed pump power, the pulse width decreased at first and then remained almost unchanged.

The variation of the single-pulse energy versus the absorbed pump power is shown in Fig. 4. The pulse energies almost linearly increased with the increase in the absorbed pump power at lower absorbed pump power. When the absorbed pump power was over 47 W, the pulse energies were almost independent of the absorbed pump power and kept invariable. The maximum pulse energies of 0.94 and 0.88 mJ at L = 23 mm and L = 43 mm were achieved, corresponding to peak powers of 33.5 and 31.4 kW, respectively. The relative high PRF obtained at the larger distance L of 43 mm (414 μm beam diameter on SA) made the pulse energy somewhat smaller than the pulse energy obtained at the shorter distance L of 23 mm (516 μm beam diameter on SA). The pulse temporal was detected by a Lecroy digital oscilloscope (600 MHz) with a fast PIN photodiode. The typical single-pulse envelope and pulse train at the maximum absorbed pump power of 66.2 W are depicted in Fig. 5, corresponding to a pulse duration of 28 ns and a maximum PRF of 34.3 kHz (L = 43 mm). The central wavelength operating in the PQS regime was 2089 nm, showing a shorter wavelength shift (1.5 nm) compared with the CW regime, which was discussed in [22].

The PQS laser beam at the maximum average output power of 30.3 W was measured behind a lens with focal length of 150 mm, which is shown in Fig. 6. The inset is the transverse output beam profile measured in the near field, and the M 2 factor of the PQS laser at the maximum output power of 30.3 W was estimated to be 2.3 with the 90/10 knife-edge technique.

4 Conclusion

In summary, we reported on a high-power continuous-wave and Cr2+:ZnS passively Q-switched Ho:YAG ceramic laser, which were dual-end-pumped by two orthogonally polarized Tm:YLF lasers. Passively Q-switched performance was particularly investigated and compared when the Cr2+:ZnS SA was placed close to and far from the laser beam waist. The maximum average output power of 30.3 W and maximum pulse energy of 0.94 mJ were obtained when the Cr2+:ZnS SA was placed close to (the smaller beam diameter on SA) and far from the laser beam waist (the larger beam diameter on SA), respectively. Up to 40.4 W output power was achieved in the continuous-wave regime, which is the highest output power from a Ho:YAG ceramic laser.

References

N.S. Nishioka, Y. Domankevitz, IEEE J. Quantum Electron. 26, 2271 (1990)

H. Iwai, S. Ishii, R. Oda, K. Mizutani, S. Sekizawa, Y. Murayama, J. Atmos. Ocean. Technol. 30, 429 (2013)

M.W. Haakestad, H. Fonnum, E. Lippert, Opt. Express 22, 8556 (2014)

P.A. Budni, C.R. Ibach, S.D. Setzler, E.J. Gustafson, R.T. Castro, E.P. Chicklis, Opt. Lett. 28, 1016 (2003)

W. Koen, C. Bollig, H. Strauss, M. Schellhorn, C. Jacobs, M.J.D. Esser, Appl. Phys. B 99, 101–106 (2010)

S. Lamrini, P. Koopmann, M. Schäfer, K. Scholle, P. Fuhrberg, Opt. Lett. 37, 515 (2012)

R. Faoro, M. Kadankov, D. Parisi, S. Veronesi, M. Tonelli, V. Petrov, U. Griebner, M. Segura, X. Mateos, Opt. Lett. 37, 1517 (2012)

H. Yu, V. Petrov, U. Griebner, D. Parisi, S. Veronesi, M. Tonelli, Opt. Lett. 37, 2544 (2012)

M. Segura, M. Kadankov, X. Mateos, M.C. Pujol, J.J. Carvajal, M. Aguiló, F. Díaz, U. Griebner, V. Petrov, Opt. Express 20, A3394 (2012)

X.L. Zhang, X.J. Bao, L. Li, H. Li, J.H. Cui, Opt. Commun 285, 2122 (2012)

X.L. Zhang, L. Yu, S. Zhang, L. Li, J.Q. Zhao, J.H. Cui, Opt. Express 21, 12629 (2013)

Y. Du, B. Yao, X. Duan, Z. Cui, Y. Ding, Y. Ju, Z. Shen, Opt. Express 21, 26506 (2013)

S.A. Payne, L.L. Chase, L.K. Smith, W.L. Kway, W.F. Krupke, IEEE J. Quantum Electron. 28, 2619 (1992)

T.Y. Tasi, M. Birnbaum, Appl. Opt. 40, 6633 (2001)

C.J. Jin, X.M. Chen, L.F. Li, M. Qi, Y. Bai, Z.Y. Ren, J.T. Bai, Laser Phys. 24, 035801 (2014)

Z.Y. Chen, B.Q. Yao, Y.Q. Du, Y.L. Ju, M. Chen, Y.B. Pan, X.L. Li, Laser Phys. Lett. 10, 105001 (2013)

A. Ikesue, Y.L. Aung, Nat. Photon. 2, 721 (2008)

H. Yang, J. Zhang, X. Qin, D. Luo, J. Ma, D. Tang, H. Chen, Q. Zhang, J. Am. Ceram. Soc. 95, 52 (2012)

H. Chen, D. Shen, J. Zhang, H. Yang, D. Tang, T. Zhao, X. Yang, Opt. Lett. 36, 1575 (2011)

L. Wang, C. Gao, M. Gao, Y. Li, F. Yue, J. Zhang, D. Tang, Opt. Express 12, 254 (2014)

T. Zhao, Y. Wang, H. Chen, D. Shen, Appl. Phys. B 116, 947 (2014)

B. Yao, J. Yuan, J. Li, T. Dai, X. Duan, Y. Shen, Z. Cui, Y. Pan, Opt. Lett. 40, 348 (2015)

B. Neuenschwander, R. Weber, H.P. Weber, IEEE J. Quantum Electron. 31, 1082 (1995)

X. Zhang, S. Zhao, Q. Wang, Q. Zhang, L. Sun, S. Zhang, IEEE J. Quantum Electron. 33, 2286 (1997)

J. Ma, Y. Li, Y. Sun, J. Xu, J. He, Opt. Commun. 282, 958 (2009)

X. Zhang, S. Zhao, Q. Wang, J. Opt. Soc. Am. B 17, 1166 (2000)

Acknowledgments

This work was supported by National Natural Science Foundation of China (Nos. 61308009, 61405047 and 50990301), Fundamental Research funds for the Central Universities (Grant No. HIT. NSRIF. 2014044, Grant No. HIT. NSRIF. 2015042), and Science Fund for Outstanding Youths of Heilongjiang Province (JQ201310).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Yuan, J.H., Duan, X.M., Yao, B.Q. et al. Dual-end-pumped high-power Cr2+:ZnS passively Q-switched Ho:YAG ceramic laser. Appl. Phys. B 119, 381–385 (2015). https://doi.org/10.1007/s00340-015-6086-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00340-015-6086-0