Abstract

The biodegradability of magnesium (Mg) metal implants necessitates surface modification to mitigate the high corrosion rate in the body’s physiological environment. This study focuses on synthesizing and applying a nanocomposite coating of polydimethylsiloxane-nanosized bioactive glass (PDMS-nBG) on the surface of a plasma electrolytic oxidation (PEO)-modified AZ91 Mg alloy. The PDMS-1 wt% nBG nanocomposite coating was deposited on the PEO-treated substrate using the dip-coating method. Surface and cross-sectional morphologies of the nanocomposite coatings were examined using field emission scanning electron microscopy (FESEM). Corrosion behavior of the AZ91 substrate, PEO coating, and double-layer PEO/PDMS-nBG coating was investigated using electrochemical impedance spectroscopy (EIS) and potentiodynamic polarization (PDP) tests. Results showed that the corrosion resistance and corrosion current density of Mg substrates increased and decreased from 4815 Ω.cm2 and 8.96 µA.cm− 2 to 18 MΩ.cm2 and 0.00016 µA.cm− 2 for AZ91 and PEO/PDMS-nBG coating, respectively. Additionally, the morphology and adhesion of cultured human mesenchymal cells on the PEO-modified AZ91 substrates with a single PDMS polymer coating and a PDMS-nBG nanocomposite coating were investigated using fluorescent light microscopy and FESEM. The PEO/PDMS-nBG bilayer coating effectively addressed the limitations of magnesium alloys and holds potential for biomedical applications, particularly in orthopedic implants, due to the enhanced biocompatibility and bioactivity of Mg alloys.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Over the past few years, there has been considerable interest in using magnesium (Mg) and its alloys as biomaterials for creating biodegradable bone implants due to their favorable biocompatibility and biodegradability [1, 2]. These metals have exceptional mechanical properties, including the Young’s modulus that is similar to that of the natural bone and can reduce stress shielding effects on the bone/implant interface compared to conventional metallic biomaterials, as well as higher strength than polymers, and greater ductility than bio-ceramics [1,2,3,4]. Mg2+ is the fourth most abundant cation in the human body and is also involved in various metabolic processes. Its presence in the skeletal system promotes the creation and development of new bone tissues [2, 5,6,7].

Nonetheless, the primary issue in utilizing Mg-based materials for biomedical purposes is their rapid degradation in physiological environments, leading to a rapid decline in their mechanical integrity during early implantation stages [1, 3, 5]. Additionally, their high corrosion rate may result in a substantial volume of hydrogen evolution and a significant increase in the local pH values of body fluids surrounding implant surfaces, which can be detrimental to adjacent tissues [1, 5,6,7].

Various surface modification methods have been proposed to decrease the corrosion rate of Mg alloys, including electrochemical deposition, plasma electrolytic oxidation (PEO), alkaline treatment, polymeric coatings, thermal spraying, and laser surface processing [4, 8,9,10,11]. PEO, also known as micro-arc oxidation, is a high-voltage plasma-assisted anodic oxidation process that can create porous ceramic coatings on Mg and its alloys, resulting in enhanced corrosion resistance and high adhesion strength to the substrate [9, 12,13,14]. However, the presence of micropores and microcracks in the porous outer layer of the PEO coating allows access to aggressive and corrosive ions on the substrate surface, thereby reducing the protection ability of the PEO coating [12, 15,16,17,18]. Therefore, sealing the pores of PEO coatings is necessary to enhance their corrosion resistance and provide longer protection [14, 15, 17,18,19].

Numerous studies have reported that applying a polymer coating to seal a porous PEO coating can increase corrosion resistance and enhance the adhesion of the polymer coating to the substrate by physically interlocking it with the PEO layer [12, 13, 19,20,21,22,23]. This approach can provide long-term corrosion resistance to Mg substrates. Polydimethylsiloxane (PDMS) is a commonly used synthetic material with excellent abrasion and corrosion resistance, chemical and biological inertness, biocompatibility, permeability to oxygen, low surface energy, and hydrophobicity, making it a promising candidate for a long-term interfacial coating for orthopedic implants [24,25,26]. However, PDMS exhibits no bioactivity [25].

Bioactive glasses (BGs) have gained a good reputation in the orthopedic field for promoting bone repair and regeneration due to their biocompatibility, osteoconductivity, and osteoinductivity [6, 27, 28]. They form a hydroxyapatite layer on their surfaces, to which osteogenic stem cells can attach and differentiate, which improves bone-implant contact and promotes bone ingrowth [29, 30]. Recently, Francis et al. [31]. evaluated the cytocompatibility of silicone (polysiloxane)/BG composite films on stainless-steel substrates using osteoblast-like (MG-63) cells. In their study, the polysiloxane/BG composite films exhibited acceptable cytocompatibility and no toxicity toward MG-63 cells. However, the corrosion behavior of these composite films has not yet been investigated.

Several polymer coatings have been used to seal PEO coatings on Mg alloys. However, it is not clear yet whether a dense, adhesive, and thick coating can seal the porous structure of the PEO layer and simultaneously enhance biocompatibility and bioactivity while reducing the corrosion rate of Mg alloys. In our previous study, the PEO process was carried out to enhance in vitro the corrosion resistance of AZ91 Mg alloy coated with PDMS [32]. Following that, in the present study, we employed the biocompatible PDMS as a protective layer on the PEO-modified AZ91 alloy surface and added nanosized bioactive glass (nBG) powder to the PDMS to induce and increase the bioactivity of the composite coating. Our findings suggest that a bilayer coating, consisting of an inner PEO layer and an outer PDMS-nBG nanocomposite coating, on AZ91 alloy can significantly enhance corrosion resistance and bioactivity. Therefore, it can be a promising option for biomedical implant applications.

2 Materials and methods

2.1 Sample preparation

An AZ91 Mg alloy was used as the substrate with a chemical composition (wt%) of 8.90 Al, 0.62 Zn, 0.25 Mn, 0.024 Si, 0.013 Sn, 0.008 Zr, ≤ 0.005 Fe, ≤ 0.001 Cu, and balance Mg. The surfaces of the AZ91 alloy samples with a dimension of 20 mm×20 mm×3 mm were ground and polished with the SiC abrasive paper to remove superficial contaminants, and a native oxidation layer to obtain a surface roughness of Ra = 0.12 μm. The samples were then cleaned in deionized water and ethanol by ultrasonic agitation for 10 min and dried quickly in a warm stream of air. Each specimen was connected to a copper wire that was used as the working electrode in the PEO treatment.

2.2 Fabrication of PEO coating on AZ91 alloy

The PEO treatment was carried out in an alkaline electrolyte containing 6 g/L of sodium silicates as liquid glass ([Na2O]x.SiO2, 37 wt%, Merck), 2 g/L of potassium fluoride (KF, Merck) and 8 g/L of potassium hydroxide (KOH, Merck) at a pH of over 12. The PEO process was conducted at a constant voltage of 440 V and a frequency of 1000 Hz for 600 s.

In the PEO process, the Mg samples were used as the anode, and the electrolyte cell was a 316-L stainless-steel container that served as a cathode with a 7 L volume that was equipped with an electrical pump for stirring, cooling, and maintaining the electrolyte temperature at 30 ± 5 °C. After the coating fabrication, the samples were washed with distilled water and dried with warm air.

2.3 Preparation of PDMS-nBG nanocomposite coating on PEO coating

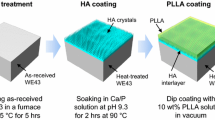

Firstly, 1 wt% 45 S BG nanopowder (particle size < 150 nm, U.S. Biomaterials Inc., USA) was dispersed in ethanol (Merck) based on the amount of polymer (solution A). At the same time, PDMS Part-A (SYLGARD® 184 elastomer base, DOW CORNING Co. USA) was added to the toluene (Merck) and stirred for about 20 min (solution B). Solution B was then added to solution A and stirred by a magnetic stirrer for about 20 min. After that, the prepared solution was sonicated for about 20 min to eliminate the possibility of agglomeration of the nanoparticles and obtain a further homogenized dispersion of them in the solution. In the next stage, PDMS Part-B (SYLGARD® 184 curing agent, DOW CORNING Co. USA) was added to the above solution (PDMS elastomer base: PDMS curing agent weight ratio = 10:1), and the entire mixture was continuously stirred for another 10 min to obtain a homogenous solution of PDMS-nBG nanocomposite coating. The PDMS-nBG nanocomposite coating was obtained by the dip coating method. The PEO-treated AZ91 substrate was immersed into the coating solution at a 45° angle at a speed of 10 cm/min and kept for 5 min. Afterward, the sample was withdrawn at the same speed to provide a uniform thickness of the coating on the PEO-treated substrate and then allowed to dry at room temperature. Finally, the coated sample was placed into an oven at 60 °C for 4 h to cure the PDMS. The schematic of PDMS-nBG nanocomposite coating fabrication on the PEO-treated AZ91 substrate is shown in Fig. 1.

2.4 Characterization of coated AZ91 samples

2.4.1 Surface morphology and coating thickness

Field emission scanning electron microscopy (FESEM, MIRA3, TESCAN) was used in both the secondary electron and back-scattered electron modes to observe the coating surface morphology, thickness, and integrity.

2.4.2 Chemical composition and elemental distribution

The chemical composition of the nanocomposite coating was determined by energy dispersive spectroscopy (EDS). Moreover, elemental maps from the surface and cross-section of this coating were obtained using FESEM-EDS element mapping to investigate the dispersion of BG nanoparticles within the PDMS-nBG nanocomposite coating. According to the insulative nature of the coatings, a thin layer of gold was sputtered on the samples to create surface conductivity before the FESEM analysis. An acceleration voltage of 15 kV was applied for FESEM and EDS investigations. The average thickness of the coatings was determined on cross-sectional FESEM images using Image J software.

2.5 Evaluation of corrosion behavior

The corrosion resistance of PEO-treated and PEO/PDMS-nBG coated samples was evaluated by potentiodynamic polarization (PDP) and electrochemical impedance spectroscopy (EIS) using an AMETEK potentiostat/galvanostat (PARSTAT 2273, Princeton Applied Research, USA) in Ringer’s solution (pH = 7.4) at 37 °C. All electrochemical measurements were conducted in a typical three-electrode cell in which coated and uncoated samples, a saturated calomel electrode, and a platinum plate were used as the working electrode, the reference electrode, and the counter electrode, respectively. Before electrochemical measurements, the samples were immersed in Ringer’s solution (pH = 7.4) at 37 °C for 2 h to reach a steady open circuit potential (OCP) value. The EIS test was obtained at OCP by applying a sinusoidal input potential with an amplitude of 10 mV peak-to-peak at a frequency range of 100 kHz to 10 mHz. The impedance data were analyzed by fitting an appropriate electrical equivalent circuit using Zview software. The PDP tests were performed in a potential range of ± 250 mV (± 0.5 V) versus the OCP at a scan rate of 1 mV/s. Measurements were performed three times to ensure the repeatability of the results.

2.6 Biocompatibility assessment

2.6.1 Cell culture

Human Bone Marrow-Derived Mesenchymal Stem Cells (hBM-MSCs) were purchased from Imam Khomeini Hospital, Iran. The protocol for bone marrow aspiration was approved by the Ethical Committee of Iran University of Medical Sciences. Briefly, the cells were cultured in a complete medium composed of Dulbecco’s Modified Eagle Medium-F12 (DMEM-F12, Invitrogen) supplemented with 1% antibiotic penicillin/streptomycin (Sigma-Aldrich) and 10% (v/v) Fetal Bovine Serum (FBS, Gibco). The culture medium was changed every two days, and the cells were split after reaching 80-90% confluence.

2.6.2 Hoechst 33,342 nuclear staining

AZ91 Mg alloy substrates modified by the PEO method with PDMS (1 A) and PDMS-nBG nanocomposite (2B) were studied to investigate the proliferation rates of the cells. Before culturing the cells, samples were placed on plates (3.5 cm) and sterilized with ultraviolet light for 20 min. The cells at passage three in the control and treatment groups were cultured on the samples in DMEM-F12 culture medium containing 10% FBS, and the culture medium was replaced every 48 h. To evaluate the ability of cell attachment to the surface of the coated substrates and the absence of abnormalities in the cultured cells, the treatment and control groups were analyzed on day seven from the beginning of the differentiation using fluorescence microscopy (Olympus Fluoview FV600, Olympus, Middlesex, UK). Firstly, the cells cultured on the samples were rinsed in PBS and then fixed in 2.5% paraformaldehyde for 1 h. The samples were then stained with 1 µg/mL of Hoechst 33,342 or nuclei identification per 5 µg/mL of samples for 5 to 10 min. The fluorescent staining of the cell nuclei was observed under a fluorescence microscope.

2.7 Statistical analysis

The data were analyzed using IBM SPSS (version 21). A statistical comparison was carried out by one-way analysis of variance (ANOVA) for all different groups at a significance level of P < 0.05.

3 Results and discussion

3.1 Surface morphology of coatings

3.1.1 Surface morphology of PEO coating

In previous findings [32], the surface morphology of PEO coating contained a network of microcavities, microcracks (with a size of 0.5 to 5 μm), and oxide granules, which were formed due to the release of gas during the oxidation process, the difference in thermal expansion coefficient during the rapid freezing, and the exit of molten products from discharge channels, respectively [13, 32,33,34].

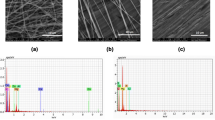

3.1.2 Investigation of morphology and distribution map of surface elements of nanocomposite coating

Figure 2 (a-c) shows FESEM images of the surface morphology of the PDMS-nBG nanocomposite coating on the AZ91 Mg alloy substrate modified by the PEO method at different magnifications. The surface of the nanocomposite coating was smooth and uniform and completely covered and sealed the microholes and microcracks on the surface of the PEO coating. Similar observations have been reported in similar studies [13, 14, 20, 22]. In the FESEM images of the surface of the nanocomposite coating, even at high magnifications (100000x), BG nanoparticles are not observed in the PDMS field, which means that the agglomerates of these nanoparticles with distinguishable dimensions are not seen in FESEM images at such a scale.

As mentioned, to confirm the presence of BG nanoparticles in the PDMS field and investigate the distribution and dispersion of these nanoparticles in the PDMS field of the nanocomposite coating, a planar elemental analysis of the coating surface was performed. Figure 2 (d-f) shows the image of the surface of the nanocomposite coating and the distribution map of calcium and phosphorus elements. Calcium and phosphorus are two elements that represent and characterize the presence of 45 S BG nanoparticles in the PDMS field. In 10000x magnification (scale 2 μm), the uniform distribution of calcium and phosphorus in the polymer field is quite clear, which confirms the non-agglomeration of BG nanoparticles in the PDMS field.

3.1.3 Investigation and determination of the thickness and chemical composition of the nanocomposite coating cross-section

In Fig. 3 (a-b), a two-layer structure can be seen in the FESEM image of the cross-section of the AZ91 Mg alloy substrate modified by the PEO method with a PDMS-nBG nanocomposite coating, which includes a PDMS-nBG layer with a thickness of 15.7±1.7 μm, as the top layer, and a PEO coating layer with a thickness of 16.5±2.7 μm, as the bottom layer. It is quite clear that this nanocomposite coating has penetrated the microholes and microcracks of the PEO coating, creating a completely dense and uniform coating. There is no gap between the nanocomposite coating and the PEO coating, and the good adhesion and physical interlocking between the nanocomposite coating and the PEO coating is completely clear. The physical interlocking of the polymer coating on the PEO-coated substrate has also been observed in previous studies [21, 23, 35].

The element distribution map of the cross-section of the nanocomposite coating is shown in Fig. 3 (c-g). The images show the presence of the three main elements, including silicon, carbon, and oxygen, in this nanocomposite coating. Moreover, the elemental distribution map for carbon indicates the penetration of the PDMS-nBG coating into the microholes and microcracks of the PEO coating, which confirms the physical interlocking and the good adhesion of this nanocomposite coating with the PEO coating. The penetration into the micropores of the PEO coating can also be seen in the distribution map of silicon.

The EDS spectrum analysis performed on the cross-section of the PDMS-nBG nanocomposite coating is shown in Fig. 3 (h). The EDS spectrum clearly shows that this coating is mainly composed of silicon, oxygen, and carbon and also contains peaks of phosphorus and calcium. Since the PDMS polymer is a silicone polymer whose main chain is made of the repetition of silicon-to-oxygen bonds and its side chain is methyl groups (\(\:-\)CH3), the presence of silicon, oxygen, and carbon is characteristic of this polymer in the coating. In addition, BG nanoparticles are of the 45 S type and contain silicon, oxygen, calcium, and phosphorus. As explained in the element distribution map of the surface of the nanocomposite coating, calcium and phosphorus confirm the presence of BG nanoparticles. Moreover, the peaks related to silicon and oxygen for both PDMS and nBG nanocomposite coating components are jointly justified.

(a-b) FESEM images of the cross-section of the PDMS-nBG coating at 1000x magnification, (a) in the secondary electron emission mode, and (b) backscattered electron emission. (c-g) The element distribution maps of carbon, silicon, oxygen, and magnesium in the PDMS-nBG nanocomposite coating. (h) EDS spectrum of constituent elements of the PDMS-nBG nanocomposite coating

3.2 Corrosion behavior of coatings

An evaluation was conducted on the corrosion behavior of AZ91 Mg Alloy substrate and PEO and PDMS-nBG bilayer coatings in Ringer’s solution at a pH of 7.4 at 37 °C after stabilization conditions during the OCP test by PDP and EIS tests.

3.2.1 Electrochemical impedance spectroscopy analysis

Nyquist, Bode Z, and Bode-phase plots for different coatings are shown in Fig. 4 (a, b, and c, respectively). Zview software was used to fit the EIS data and find the optimum equivalent circuit model. In the AZ91 sample, Rs, Rct, and Qdl (CPEdl) are the solution resistance, the double-layer charge transfer resistance, and the double-layer constant-phase element, respectively (Fig. 5a). Also, at low frequencies, an inductive loop was seen, in which L and RL were the inductor and the inductor resistance, respectively. For the PEO-treated sample, Rs is the solution resistance, Rc1 and Qc1 represent the resistance and CPE of the outer porous layer, while Rct and Qdl are the resistance and CPE of the inner dense layer and double layer, respectively (Fig. 5b) [36,37,38]. In Fig. 5 (c), for the PEO/PDMS-nBG coating, Rc2 and Qc2 are the resistance and CPE of the PDMS-nBG nanocomposite coating, while Rc1 and Qc1 show the resistance and CPE of the outer porous layer, and Rct and Qdl represent the resistance and CPE of the inner dense layer and double layer, respectively [39]. CPE is used as a non-ideal capacitance that can be attributed to the roughness of the surface and the non-uniformity of the coating [40, 41].

According to Bode-phase plots (Fig. 4c), AZ91 substrate, PEO coating, and PEO/PDMS-nBG coating contain one-, two-, and three-time constants, respectively. In the Nyquist plots, the first loop of AZ91 substrate is related to the corrosion resistance of the substrate, and the induction element is related to the adsorption intermediate species and the reaction between them [42]. The two capacitive loops of the PEO coating at low and high frequencies correspond to the inner dense layer and the outer porous layer, respectively [43, 44]. The results of the EIS data fitting are displayed in Table 1. As shown in the Nyquist plots, improving the surface of the AZ91 substrate using PEO coating has considerably increased the corrosion resistance. According to Table 1, in the PEO coating, the resistance of the inner layer is much higher than that of the outer layer due to the penetration of corrosive ions from the pores of the outer layer to the inner layer of the coating, which increases the contact surface between the corrosive solution and the PEO coating [16]. Therefore, the inner dense layer plays a key role in the corrosion resistance of the PEO coating [36, 43, 44]. Generally, the impedance at the lowest frequency in the bode plots indicates the overall corrosion resistance of the coating [19, 23]. According to the results presented in Table 1 and bode-phase plots, the resistance of AZ91 substrate, PEO coating, and PEO/PDMS-nBG nanocomposite coating is 4815 Ω.cm2, 0.52 MΩ.cm2, and 18 MΩ.cm2, respectively. The resistance of the PEO/PDMS-nBG coating is 34.6 times higher than that of the PEO coating. As shown in Fig. 3 (a-g), the PDMS-nBG nanocomposite coating seals the micropores of the outer layer of the PEO coating and prevents the penetration of corrosive agents into the inner layer of the coating and the surface of the substrate [12, 20]. Therefore, the corrosion resistance of the PEO/PDMS-nBG coating increases significantly compared to that of the PEO single-layer coating.

3.2.2 Potentiodynamic polarization test

Figure 6 shows the PDP curves of the samples. Table 2 reports the corrosion potential (Ecorr), the corrosion current density (icorr), the slope of the anodic region (βa), and the slope of the cathodic region (βc) extracted from the plots of Fig. 6 by the Tofel extrapolation method. The polarization resistance of the samples (Rp) is calculated by the Stern-Gray equation (Eq. 1) [36, 43, 45, 46]. It has been known that the corrosion potential (Ecorr) indicates the thermodynamics of corrosion reactions, with the positive value of the corrosion potential (Ecorr) indicating the better corrosion resistance of the coatings. Also, corrosion current density (icorr) is used to evaluate the kinetics of corrosion reactions, and the smaller the corrosion current density (icorr), the slower the kinetics of corrosion reactions and the lower the corrosion rate [20, 21, 35, 43].

The main limitation of using Mg and its alloys for biomedical applications is their high corrosion rate in the physiological environment. Therefore, to reduce the corrosion rate, surface modification of Mg is suggested, and the PEO method is a common method to improve corrosion performance [39, 47]. According to Table 2, the corrosion potential (Ecorr) of the PEO coating has decreased from − 1508.3 mV to -1025.4 mV compared to the AZ91 substrate. On the other hand, the current density (icorr) has also significantly reduced from 8.96 to 0.0172 µA.cm− 2. This decrease in the corrosion rate of the Mg alloy is due to surface modifications by the PEO method [13, 21]. In the PEO/PDMS-nBG nanocomposite coating compared to the PEO coating, the corrosion potential (Ecorr) has increased to a more positive value (-672.5 mV), and the corrosion current density (icorr) has decreased to 0.000161 µA.cm− 2. The sealing of the holes in the outer layer of the PEO coating by the PDMS-nBG nanocomposite coating reduces the corrosion rate of the PEO/PDMS-nBG nanocomposite coating [23, 48, 49]. For this reason, in the PDP plot of the PEO/PDMS-nBG nanocomposite compared to other samples, the passive region is visible (Fig. 6). This passive layer causes extreme protection of the surface of the substrate. Another parameter that can be evaluated by the PDP test is polarization resistance (RP), which is known as a measure of corrosion resistance. The polarization resistance of the PEO/PDMS-nBG nanocomposite coating is the highest value compared to other samples, and is equal to 232 MΩ.cm2.

3.3 Biocompatibility of substrate on mesenchymal stem cells

In this study, Hoechst 33,342 staining was used for the cell Morphology and adhesion assessment of MSCs on the AZ91 Mg alloy substrate modified by the PEO method with PDMS (1 A) and PDMS-nBG nanocomposites (2B). Microscopy pictures of MSCs cultured on samples under normal and fluorescent light are illustrated in Fig. 7. Under the fluorescence microscope, the nuclei of the living cells would exhibit uniform blue dots, and the chromatin of apoptotic cells was seen as bright and had no uniform blue dots.

3.3.1 Cell adhesion and morphology

The presence of cells on the samples indicates their biocompatibility for cell culture. Cell adhesion on the surface of the sample with PDMS (1 A) and PDMS-nBG coatings (group 2B) using Hoechst staining is illustrated in Fig. 8. As it is clear in Fig. 8, low cell density can be seen on the surface of group 1 A, which is in accordance with the research conducted by Lee et al. They showed that despite the many attractive properties of PDMS scaffolds, due to their inherent hydrophobic properties, they do not support cell adhesion and proliferation. Therefore, to use them as a cell-supporting scaffold, it is necessary to induce hydrophilicity on their surfaces [25]. In contrast, the surface of group 2B shows a high density of cells. FESEM images of cell morphology in groups 1 A and 2B at different magnifications are illustrated in Fig. 9.

The biocompatibility of the samples was confirmed by evaluating the morphology and adhesion of MSCs cultured on the samples. The cell density in group 2B was greater than that of group 1 A, as evident from the fluorescent microscope photographs. In previous studies, Francis et al. reported that PDMS-BG composite coatings had good cellular compatibility and did not show any toxicity to MG-63 cells [31]. The research findings of Verrier et al. also supported the biocompatibility of PDLLA-BG composite foams and the beneficial effects of BG on the behavior of MG-63 cells. Additionally, they demonstrated for the first time the potential for adhesion and proliferation of type II human lung mucosal cells (A549) on this composite foam. They also revealed the potential of PDLLA-BG composites with an optimum concentration of 45S5 BG not only in bone tissue engineering but also in lung tissue engineering and described the positive effects of 45S5 BG on A549 cell behavior in a dose-dependent manner [50].

Another study showed that the viability and proliferation of bone cancer cells (MG-63) and human dental ligament fibroblast cells on an alginate/BG composite scaffold were superior to those on an alginate scaffold (used as a control sample) [46]. On the other hand, Ying et al. found that the addition of BG nanoparticles to the poly-caprolactone coating caused the formation of calcium phosphate after seven days of immersion in simulated body fluid (SBF). However, such behavior has not been observed for poly-caprolactone coating alone [6]. The presence of a hydroxyapatite (HA) layer on the surface of chitosan/BG composites after seven days of immersion in SBF was confirmed by Khoshakhlaq et al. They demonstrated a connection between the rise in human osteoblast proliferation and the greater concentration of BG in the chitosan/BG composite. They demonstrated that increasing the quantity of BG improved bone conduction using an in vivo investigation with a rat spinal fusion model [51]. These outcomes were also demonstrated by Cordero et al., who examined the bioactivity of the chitosan/BG coating by submersion for two, five, and seven days in SBF. Due to the presence of BG in this coating, they observed that a bioactive HA layer only developed on its surface after two days of immersion in SBF [52]. Another study used samples that had been submerged in the SBF for various lengths of time to examine the bioactivity of chitosan/BG composite and nanocomposite coatings. HA, which had formed on the samples’ surfaces, was used to measure bioactivity. A much thicker HA coating has been created on the surface of the sample containing nBGs. The observed differences in the formation of HA between these two samples can be due to the fact that the surface area of BG nanoparticles is higher than that of micron-sized particles and will have more ion exchange with the surrounding environment, thereby increasing the formation of the HA in the surface. This may explain the observed differences in HA formation between these two samples, which were also confirmed in previous studies [53, 54]. The presence of BG nanoparticles induces bioactivity, as shown by all papers that were reviewed; therefore, there was no bioactivity analysis in the current study. The data collected confirmed that group 2B produced a biocompatible structure for biomedical applications, including orthopedic implants.

4 Conclusion

In this study, we applied a PDMS-1 wt% nBG nanocomposite coating using the immersion method on a PEO-modified AZ91 alloy substrate. The resulting PEO/PDMS-nBG coating exhibited excellent density, uniformity, and crack-free characteristics. It also effectively sealed microholes and microcracks within the PEO coating. Electrochemical impedance spectroscopy (EIS) demonstrated impressive corrosion resistance, with a value of 18 MΩ.cm², representing a 3738-fold and 34.6-fold increase compared to the AZ91 alloy and PEO coating, respectively. Polarization resistance tests confirmed a substantial reduction in the corrosion rate compared to the AZ91 alloy and PEO coating. Furthermore, the PDMS-1 wt% nBG nanocomposite coating significantly enhanced the adhesion, proliferation, and growth of human MSCs, making it a promising choice for biomedical applications, such as orthopedic implants.

Data availability

Data and materials are available upon written request to the corresponding author.

Change history

20 September 2024

A Correction to this paper has been published: https://doi.org/10.1007/s00339-024-07903-y

References

K.S. Akshay, V.P.M. Rabeeh, S.A. Rahim et al., Electrophoretic deposition of alginate/bioglass composite coating on mg ca alloy for degradable metallic implant applications. Surf. Coat. Technol. 448, 128914 (2022). https://doi.org/10.1016/j.surfcoat.2022.128914

C. Liu, Z. Ren, Y. Xu et al., Biodegradable magnesium alloys developed as bone repair materials: a review. Scanning. 2018, 1–15 (2018). https://doi.org/10.1155/2018/9216314

S. Heise, T. Wirth, M. Höhlinger et al., Electrophoretic deposition of chitosan/bioactive glass/silica coatings on stainless steel and WE43 mg alloy substrates. Surf. Coat. Technol. 344, 553–563 (2018). https://doi.org/10.1016/j.surfcoat.2018.03.050

F. Xing, S. Li, D. Yin et al., Recent progress in Mg-based alloys as a novel bioabsorbable biomaterials for orthopedic applications. J. Magnesium Alloys. 10, 1428–1456 (2022). https://doi.org/10.1016/j.jma.2022.02.013

X. Liu, Q. Yang, Z. Li et al., A combined coating strategy based on atomic layer deposition for enhancement of corrosion resistance of AZ31 magnesium alloy. Appl. Surf. Sci. 434, 1101–1111 (2018). https://doi.org/10.1016/j.apsusc.2017.11.032

A. Kocijan, J. Kovač, I. Junkar et al., The influence of plasma treatment on the corrosion and biocompatibility of Magnesium. Materials. 15, 7405 (2022). https://doi.org/10.3390/ma15207405

X. Lu, C. Blawert, B.J.C. Luthringer, M.L. Zheludkevich, Controllable degradable plasma electrolytic oxidation coated mg alloy for Biomedical Application. Front. Chem. Eng. 4 (2022). https://doi.org/10.3389/fceng.2022.748549

K. Kumar, R.S. Gill, U. Batra, Challenges and opportunities for biodegradable magnesium alloy implants. Mater. Technol. 33, 153–172 (2018). https://doi.org/10.1080/10667857.2017.1377973

Y. Husak, J. Michalska, O. Oleshko et al., (2021) Bioactivity Performance of Pure Mg after Plasma Electrolytic Oxidation in Silicate-Based Solutions. Molecules 26:2094. https://doi.org/10.3390/molecules26072094

M. Nasr Azadani, A. Zahedi, O.K. Bowoto, B.I. Oladapo, A review of current challenges and prospects of magnesium and its alloy for bone implant applications. Prog. Biomater. 11, 1–26 (2022). https://doi.org/10.1007/s40204-022-00182-x

L. Qiu, C. Zhang, X. Yang et al., A SiO2 layer on PEO-treated mg for enhanced corrosion resistance and bone regeneration. Front. Bioeng. Biotechnol. 10 (2022). https://doi.org/10.3389/fbioe.2022.1053944

A. Fattah-alhosseini, R. Chaharmahali, A. Rajabi et al., Performance of PEO/Polymer Coatings on the Biodegradability, Antibacterial Effect and Biocompatibility of Mg-Based materials. J. Funct. Biomaterials. 13, 267 (2022). https://doi.org/10.3390/jfb13040267

H.R. Bakhsheshi-Rad, E. Hamzah, R. Ebrahimi-Kahrizsangi et al., Fabrication and characterization of hydrophobic microarc oxidation/poly-lactic acid duplex coating on biodegradable Mg–Ca alloy for corrosion protection. Vacuum. 125, 185–188 (2016). https://doi.org/10.1016/j.vacuum.2015.12.022

A. Santos-Coquillat, E. Martínez‐Campos, N. Vargas‐Alfredo et al., Hierarchical Functionalized Polymeric‐Ceramic Coatings on Mg‐Ca alloys for biodegradable Implant applications. Macromol. Biosci. 19 (2019). https://doi.org/10.1002/mabi.201900179

M. Bobby Kannan, R. Walter, H. Khakbaz et al., A triple-layered hybrid coating with self‐organized microporous polymer film on magnesium for biodegradable implant applications. Med. DEVICES Sens. (2020). https://doi.org/10.1002/mds3.10070. 3:

P. Tian, D. Xu, X. Liu, Mussel-inspired functionalization of PEO/PCL composite coating on a biodegradable AZ31 magnesium alloy. Colloids Surf., B 141, 327–337 (2016). https://doi.org/10.1016/j.colsurfb.2016.02.004

Z. Wei, P. Tian, X. Liu, B. Zhou, Hemocompatibility and selective cell fate of polydopamine-assisted heparinized PEO/PLLA composite coating on biodegradable AZ31 alloy. Colloids Surf., B 121, 451–460 (2014). https://doi.org/10.1016/j.colsurfb.2014.06.036

R.-C. Zeng, W.-C. Qi, Y.-W. Song et al., In vitro degradation of MAO/PLA coating on Mg-1.21Li-1.12Ca-1.0Y alloy. Front. Mater. Sci. 8, 343–353 (2014). https://doi.org/10.1007/s11706-014-0264-6

C. Yu, L.-Y. Cui, Y.-F. Zhou et al., Self-degradation of micro-arc oxidation/chitosan composite coating on Mg-4Li-1Ca alloy. Surf. Coat. Technol. 344, 1–11 (2018). https://doi.org/10.1016/j.surfcoat.2018.03.007

N.A. Dewi, A.E. Tontowi, (2019) Optimization of Design Parameters of Biodegradable Magnesium-Based Alloy AZ31 Stent Using Response Surface Method. In: 2019 2nd International Conference on Bioinformatics, Biotechnology and Biomedical Engineering (BioMIC) - Bioinformatics and Biomedical Engineering. IEEE, pp 1–6

R.-C. Zeng, L. Cui, K. Jiang et al., In Vitro Corrosion and Cytocompatibility of a Microarc Oxidation Coating and Poly(< scp > l -lactic acid) composite coating on Mg–1Li–1Ca Alloy for Orthopedic implants. ACS Appl. Mater. Interfaces. 8, 10014–10028 (2016). https://doi.org/10.1021/acsami.6b00527

G. Chandra, A. Pandey, Preparation strategies for Mg-Alloys for biodegradable Orthopaedic implants and other Biomedical Applications: a review. IRBM. 43, 229–249 (2022). https://doi.org/10.1016/j.irbm.2020.06.003

L.-Y. Cui, S.-D. Gao, P.-P. Li et al., Corrosion resistance of a self-healing micro-arc oxidation/polymethyltrimethoxysilane composite coating on magnesium alloy AZ31. Corros. Sci. 118, 84–95 (2017). https://doi.org/10.1016/j.corsci.2017.01.025

O.J. Bareiro Ferreira, K. Bendo Demétrio, L.A. Loureiro dos Santos, Nanostructured hydroxyapatite/polydimethylsiloxane composites obtained by reactive synthesis. Compos. Part. B: Eng. 121, 152–161 (2017). https://doi.org/10.1016/j.compositesb.2017.05.009

J. Li, X. Liu, J.M. Crook, G.G. Wallace, Development of a porous 3D graphene-PDMS scaffold for improved osseointegration. Colloids Surf., B 159, 386–393 (2017). https://doi.org/10.1016/j.colsurfb.2017.07.087

S. Tavakoli, S. Nemati, M. Kharaziha, S. Akbari-Alavijeh, Embedding CuO nanoparticles in PDMS-SiO2 coating to improve Antibacterial characteristic and Corrosion Resistance. Colloid Interface Sci. Commun. 28, 20–28 (2019). https://doi.org/10.1016/j.colcom.2018.11.002

S. Heise, M. Höhlinger, Y.T. Hernández et al., Electrophoretic deposition and characterization of chitosan/bioactive glass composite coatings on mg alloy substrates. Electrochim. Acta. 232, 456–464 (2017). https://doi.org/10.1016/j.electacta.2017.02.081

S. Kargozar, M. Mozafari, R.G. Hill et al., (2018) Synergistic combination of bioactive glasses and polymers for enhanced bone tissue regeneration. Materials Today: Proceedings 5:15532–15539. https://doi.org/10.1016/j.matpr.2018.04.160

M. Miola, L. Cordero-Arias, G. Ferlenda et al., Electrophoretic deposition of composite coatings based on alginate matrix/45S5 bioactive glass particles doped with B, Zn or Sr. Surf. Coat. Technol. 418, 127183 (2021). https://doi.org/10.1016/j.surfcoat.2021.127183

D. Jugowiec, A. Łukaszczyk, Ł. Cieniek et al., Electrophoretic deposition and characterization of composite chitosan-based coatings incorporating bioglass and sol-gel glass particles on the Ti-13Nb-13Zr alloy. Surf. Coat. Technol. 319, 33–46 (2017). https://doi.org/10.1016/j.surfcoat.2017.03.067

A. Francis, R. Detsch, A.R. Boccaccini, Fabrication and cytotoxicity assessment of novel polysiloxane/bioactive glass films for biomedical applications. Ceram. Int. 42, 15442–15448 (2016). https://doi.org/10.1016/j.ceramint.2016.06.195

N. Mehri Ghahfarokhi, B. Shayegh Broujeny, A. Hakimizad, A. Doostmohammadi, Plasma electrolytic oxidation (PEO) coating to enhance in vitro corrosion resistance of AZ91 magnesium alloy coated with polydimethylsiloxane (PDMS). Appl. Phys. A 128, 112 (2022). https://doi.org/10.1007/s00339-021-05239-5

S.L. Aktuğ, S. Durdu, I. Kutbay, M. Usta, Effect of na 2 SiO 3 ·5H 2 O concentration on microstructure and mechanical properties of plasma electrolytic oxide coatings on AZ31 mg alloy produced by twin roll casting. Ceram. Int. 42, 1246–1253 (2016). https://doi.org/10.1016/j.ceramint.2015.09.056

A. Toulabifard, M. Rahmati, K. Raeissi et al., The Effect of Electrolytic Solution Composition on the structure, corrosion, and wear resistance of PEO Coatings on AZ31 Magnesium Alloy. Coatings. 10, 937 (2020). https://doi.org/10.3390/coatings10100937

T. Zehra, A. Fattah-alhosseini, M. Kaseem, Surface properties of plasma electrolytic oxidation coating modified by polymeric materials: a review. Prog. Org. Coat. 171, 107053 (2022). https://doi.org/10.1016/j.porgcoat.2022.107053

L. An, Y. Ma, L. Sun et al., Investigation of mutual effects among additives in electrolyte for plasma electrolytic oxidation on magnesium alloys. J. Magnesium Alloys. 8, 523–536 (2020). https://doi.org/10.1016/j.jma.2019.09.003

A. Golshirazi, M. Kharaziha, M.A. Golozar, Polyethylenimine/kappa carrageenan: micro-arc oxidation coating for passivation of magnesium alloy. Carbohydr. Polym. 167, 185–195 (2017). https://doi.org/10.1016/j.carbpol.2017.03.025

C. Liu, J. Liang, J. Zhou et al., Characterization and corrosion behavior of plasma electrolytic oxidation coated AZ91-T6 magnesium alloy. Surf. Coat. Technol. 304, 179–187 (2016). https://doi.org/10.1016/j.surfcoat.2016.07.021

C. Liu, X. Lu, Y. Li et al., Influence of post-treatment process on corrosion and wear properties of PEO coatings on AM50 mg alloy. J. Alloys Compd. 870, 159462 (2021). https://doi.org/10.1016/j.jallcom.2021.159462

Y. Ge, X. Xie, J. Roscher et al., How to measure and report the capacity of electrochemical double layers, supercapacitors, and their electrode materials. J. Solid State Electrochem. 24, 3215–3230 (2020). https://doi.org/10.1007/s10008-020-04804-x

M. Ghafaripoor, K. Raeissi, M. Santamaria, A. Hakimizad, The corrosion and tribocorrosion resistance of PEO composite coatings containing α-Al2O3 particles on 7075 Al alloy. Surf. Coat. Technol. 349, 470–479 (2018). https://doi.org/10.1016/j.surfcoat.2018.06.027

J. Moreno, J.L. Merlo, A.C. Renno et al., In vitro characterization of anodized magnesium alloy as a potential biodegradable material for biomedical applications. Electrochim. Acta. 437, 141463 (2023). https://doi.org/10.1016/j.electacta.2022.141463

A. Bordbar-Khiabani, B. Yarmand, M. Mozafari, Enhanced corrosion resistance and in-vitro biodegradation of plasma electrolytic oxidation coatings prepared on AZ91 mg alloy using ZnO nanoparticles-incorporated electrolyte. Surf. Coat. Technol. 360, 153–171 (2019). https://doi.org/10.1016/j.surfcoat.2019.01.002

M. Rahmati, K. Raeissi, M.R. Toroghinejad et al., Effect of Pulse Current Mode on microstructure, composition and corrosion performance of the Coatings produced by plasma electrolytic oxidation on AZ31 mg alloy. Coatings. 9, 688 (2019). https://doi.org/10.3390/coatings9100688

L. Mu, Z. Ma, J. Wang et al., Corrosion behavior and Biological Activity of Micro Arc Oxidation Coatings with Berberine on a pure Magnesium Surface. Coatings. 10, 837 (2020). https://doi.org/10.3390/coatings10090837

D. Zamani, F. Moztarzadeh, D. Bizari, Alginate-bioactive glass containing zn and mg composite scaffolds for bone tissue engineering. Int. J. Biol. Macromol. 137, 1256–1267 (2019). https://doi.org/10.1016/j.ijbiomac.2019.06.182

A. Fattah-alhosseini, R. Chaharmahali, K. Babaei, Impressive strides in amelioration of corrosion and wear behaviors of mg alloys using applied polymer coatings on PEO porous coatings: a review. J. Magnesium Alloys. 10, 1171–1190 (2022). https://doi.org/10.1016/j.jma.2022.01.015

J. Xie, J. Hu, X. Lin et al., Robust and anti-corrosive PDMS/SiO2 superhydrophobic coatings fabricated on magnesium alloys with different-sized SiO2 nanoparticles. Appl. Surf. Sci. 457, 870–880 (2018). https://doi.org/10.1016/j.apsusc.2018.06.250

X. Cui, G. Zhu, Y. Pan et al., Polydimethylsiloxane-titania nanocomposite coating: fabrication and corrosion resistance. Polymer. 138, 203–210 (2018). https://doi.org/10.1016/j.polymer.2018.01.063

G. Vergnol, N. Ginsac, P. Rivory et al., In vitro and in vivo evaluation of a polylactic acid-bioactive glass composite for bone fixation devices. J. Biomedical Mater. Res. Part. B: Appl. Biomaterials. 104, 180–191 (2016). https://doi.org/10.1002/jbm.b.33364

P. Khoshakhlagh, S.M. Rabiee, G. Kiaee et al., Development and characterization of a bioglass/chitosan composite as an injectable bone substitute. Carbohydr. Polym. 157, 1261–1271 (2017). https://doi.org/10.1016/j.carbpol.2016.11.003

L. Cordero-Arias, A.R. Boccaccini, Electrophoretic deposition of chondroitin sulfate-chitosan/bioactive glass composite coatings with multilayer design. Surf. Coat. Technol. 315, 417–425 (2017). https://doi.org/10.1016/j.surfcoat.2017.02.037

S. Seuss, M. Lehmann, A. Boccaccini, Alternating current Electrophoretic deposition of Antibacterial Bioactive Glass-Chitosan Composite Coatings. Int. J. Mol. Sci. 15, 12231–12242 (2014). https://doi.org/10.3390/ijms150712231

S. Vaez, R. Emadi, S. Sadeghzade et al., Electrophoretic deposition of chitosan reinforced baghdadite ceramic nano-particles on the stainless steel 316L substrate to improve biological and physical characteristics. Mater. Chem. Phys. 282, 125991 (2022). https://doi.org/10.1016/j.matchemphys.2022.125991

Acknowledgements

The authors gratefully acknowledge the financial supports from the Iran National Science Foundation (INSF) and Shahrekord University.

Funding

This research was financially supported by the Iran National Science Foundation (INSF) under grant number 4003142.

Author information

Authors and Affiliations

Contributions

Negar Mehri Ghahfarokhi: Conceptualization, Data curation, Formal analysis, Investigation, Methodology, Validation, Visualization; Behrooz Shayegh Broujeny: Conceptualization, Formal analysis, Methodology, Supervision; Amin Hakimizad: Formal analysis, Methodology, Investigation, Validation, Supervision; Fatemeh Forouzandeh: Data curation, Formal analysis, Validation, Writing - original draft; Latifeh Karimzadeh Bardeei: Data curation, Formal analysis, Validation, Writing - original draft; Hassan Nazari: Formal analysis, Methodology, Investigation, Supervision; Narges Ghafouri Varnosfaderani: Data curation, Formal analysis, Investiogation, Validation, Writing - original draft; Delara Aarabisamani: Data curation, Formal analysis, Validation, Writing - review & editing; Ali Doostmohammadi: Conceptualization, Formal analysis, Funding acquisition, Investigation, Methodology, Project administration, Resources, Supervision, Writing - review & editing.

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare that they have no conflict of interests.

Ethics approval

Human Bone Marrow-Derived Mesenchymal Stem Cells (hBM-MSCs) donation procedure was approved by the Human Research Ethics committee at Imam Khomeini Hospital, Iran.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Mehri Ghahfarokhi, N., Shayegh Boroujeny, B., Hakimizad, A. et al. Enhancing biocompatibility of magnesium implants: nanocomposite coating for corrosion resistance and bioactivity. Appl. Phys. A 130, 693 (2024). https://doi.org/10.1007/s00339-024-07820-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-024-07820-0