Abstract

Superabsorbent polymers (SAPs) are a class of cross-coupled hydrophilic networks that have an extraordinary capacity to absorb and retain water. It is primarily because of the additional ionic cross-linking of SAPs, their porous wavy structure, a large number of hydrophilic functionalities, the high elasticity of the chains, and the enlarged free volumes between the polymeric chains, that all contribute to the enhancement of the swelling capability of superabsorbent hydrogels. These exceptional attributes have endowed them to be an alternative to conventional hydrogels in various applications. In view of the importance of this class of absorbent material and their diverse appliances, this review deliberates the experimental methods for characterizing superabsorbent polymers, including the officially accepted industrial measurements of their unique attributes, namely, swelling among others. In addition, the review highlights recent advances in the field of superabsorbent polymers encompassing nanofiltration, heat resistance, and absorbency, drug delivery, disposable hygiene products, nanomedicines, and the removal of heavy metals from wastewater and agriculture domains.

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Superabsorbent hydrogels (SAHs) are cross-coupled hydrophilic networks that take up and hold a remarkable amount of water, primarily because of the additional-ionic cross-coupling, a curvy porous structure, the attendance of an enormous sum of hydrophilic functionalities, higher flexibility of the polymer chain, and the convenience of a large free volume among the polymer sequences, which increases the swelling capacity of hydrogels comprising superabsorbents [1]. The elevated water absorption competence of these SAHs is the consequence of the existence of a huge number of hydrophilic functionalities like hydroxyl, carboxyl, amide, amino, and sulfonic units on the backbone of the polymers. On account of such functionalities, the water uptake performance of SAHs is frequently sensitive to the pH and ionic potency of the swelling liquid. Therefore, they can react to inducements from the neighboring environment like pH, ionic strength, solvent composition, light, and electric field [2, 3].

A large volume of deionized water ranging from 1000 to 100,000% (10–1000 g/g) is taken up by such hydrogels, as related to the absorption competences of usual hydrogels with the span of < 100% (1 g/g). Nevertheless, yet in the swelled form, the SAHs preserve their arrangement due to the cross-networking that is attained by either a chemical or physical procedure. The chemically cross-coupled SAHs have the inherent unalterable covalent links created between the polymeric chains while inside the physically cross-coupled hydrogels, the polymeric links are enfolded mutually by physical connections, like van der Waals forces, H-links, and electrostatic contacts. The nature of cross-coupling in such hydrogel commands protuberance kinetics, water-holding capability, degradation speed and permeability, and rheological and mechanical attributes. Table 1 presents the various synthetic methods available for SAHs.

Assorted swelling mechanisms

The SAP mechanisms of swelling can comprise:

-

1.

Hydration-attraction of polar molecule facilitated by COO− and NH3+ groups which are present in the solvent.

-

2.

Hydrogen bonding – pulling of lone pair of electrons of oxygen by hydrogen in water; often, a hydrogen atom is attached to a small electronegative atom such as nitrogen, fluorine, oxygen, and carbon.

-

3.

Swelling of ionic polymer is beyond the simple mixing as there is another solvent/polymer interaction for ionic polymer. Overall neutral charges maintained on the chain by COO− and Na+ ion gets hydrated due to contact with water which leads to a decrease in attraction between carboxylate ions, thus contributing to the osmotic pressure of gel. This osmotic pressure difference serves as a driving force for swelling.

Nowadays, SAHs are identified as prospective contenders for/textiles/fiber, separation technology, artificial muscle, drug distribution and tissue engineering, soil conditioning, contact lenses, agricultural purposes, and fire-extinguishing gels. Additionally, it has also shown tremendous potential to overcome environmental problems such as the removal of heavy metals and dyes for water. A substantially huge number of SAHs have been prepared from natural and man-made polymers which have witnessed remarkable growth in the deployment of biopolymers as a viable substitute to man-made oligomers for the elaboration of SAHs due to their biocompatibility, biodegradability, high sponginess, non-hazardous nature, higher strength, and superb salt-endurance. Because of the increased environmental issues of the day, assorted natural oligomers ought to be utilized rather than man-made polymers as exemplified by SAHs obtained from polysaccharides that comprise the major portion of the natural oligomer-based [5,6,7] Cross-coupling of polysaccharides is a competent pathway to create novel SAHs. Likewise, SAHs obtained from alteration or cross-coupled chitin, chitosan, cellulose, dextran, pectin, xanthan gum, guar gum, alginate, and collagen, have been efficaciously prepared and investigated in assorted disciplines [3, 4, 6, 7].

This review article delineates the traits of SAHs and their appliances in diverse arenas including recent advancements in the field of superabsorbent polymers encompassing nanofiltration, heat resistance, and absorbency, drug delivery, disposable hygiene products, nanomedicines, and agriculture.

Parameters affecting synthesis and application of SAHs

Concentration of adsorbent

The effect of several parameters on swelling capacity has been studied by Soleimani et al. using acrylonitrile -sucrose-based bio superabsorbent. They synthesized various SAHs with different ratios of polyacrylonitrile/sucrose by changing the amount of polymer (0.25–1.50 g) and sucrose (0.25–1.50 g). The maximum swelling capacity was achieved at 1.50 g of polymer, however, the absorbency was lowered when the amount of polymer was exceeded (> 1.50 g). In another study, Sharma and Tiwari synthesized copolymer using acryl amide and itaconic acid and evaluated for the removal of Mn2+ ions from aqueous samples. Authors have studied the effect of the concentration of adsorbent ranging from 0.04 to 0.10 g; by increasing the concentration of adsorbent, the % removal of metal ions from the samples was also increased [8].

pH

The swelling of SAHs depends on the pH of the medium deployed. For instance, Guilherme et al. synthesized the polysaccharide-based superabsorbent hydrogel following free radical polymerization. The fabricated hydrogel was evaluated as ionic absorbent for the removal of metal ions. Authors have found that the removal of heavy metals was increased with an increase in the pH of the medium (3–5) which might be due to the deprotonation of carboxyl groups above the pKa value. Moreover, the increase in the uptake capacity of the metal ions from the solution was also increased by the hydrogels [9].

Temperature

Polyacrylamide-co-acrylic acid-based SAH was synthesized by Zendehdel et al. [10] for the removal of Pb2+ and Cd2+ from an aqueous solution; the effect of temperature ranging from 285 to 323 K was studied as well. There was an increment in the adsorption of metal ions observed when the temperature was raised from 285 to 303 K demonstrating the endothermic process. However, desorption of metal ions was observed from the hydrogel network when the temperature was increased up to 323 K.

Mazi et al. have synthesized temperature and pH-responsive SAPs based on modified maleic anhydride, wherein they noted that along with pH, the temperature has also a significant impact on the swelling capacity and swelling behavior of hydrogels. The gel exhibited low swelling capacity with two-step swelling behavior at low temperatures and high swelling capacity at higher temperatures [11].

Type and concentration of cross-linkers

The cross-linker concentration affects the physical properties such as swelling characteristics, porous structure, and mechanical strength of SAHs [12]. Singhal et al. prepared poly (acrylamide-co-acrylic acid) [poly (AAm-co-AAc)]-based hydrogels using NMBA, a cross-linker in the range of 0.0077–0.077%, and the effect of cross-linker concentration in swelling parameters was evaluated. The results demonstrated that the equilibrium water absorbency decreases from 707.23 to 389 when the concentration of the cross-linker increased from 0.0096 to 0.0385% [13].

Kabiri et al. studied the effect of cross-linker type and concentration on porosity and absorption rate by investigating N,N’ -methylenebisacrylamide (water soluble) and 1,4-butanedioldiacrylate (oil soluble) cross-linkers. The increased concentration of cross-linker resulted in a reduction in the gelation time. Further, both cross-linking agents exerted similar effects on the absorption behavior [14].

Initial heavy metal ion concentration

Agnihotri and Singhal have fabricated poly superabsorbent hydrogel using acrylic acid, sodium humate, and sodium alginate using a co-polymerization process and utilized this SAH for the adsorption of Cu2+, Pb2+, and Fe2+. It has been found that the adsorption capacity increased with the increasing initial concentration of metal ions [15].

Methods for the characterization superabsorbent polymers

Several approaches and techniques have been deployed to characterize the superabsorbent polymers during synthesis, conjugation, and various appliances of such polymers in drug delivery [6, 16] and nanomedicine [5, 17] among others; conventional practices used in superabsorbent characterization are enlisted in Fig. 1.

Thermal characterization

Differential scanning calorimetry

Thermal assets of superabsorbents can be characterized by differential scanning calorimetry (DSC) [18], wherein after swelling of the material, free water can be measured by using this technique. To perform this study, the material should be frozen initially and then need to be warmed. When the temperature of swollen material increases, then the endothermic peak is indicative of free water. The thermogravimetric analysis (described below) measures the total water and hence bound water from the superabsorbent can be calculated by subtracting free water from total water computed via thermogravimetric analysis [19].

Thermogravimetric analysis

Thermogravimetric analysis (TGA) helps to study the thermal stability of material [20]. TGA is based on the mass deficit of material with the rise of temperature. The analysis provides information related to the temperature at which the polymer degrades. The weight deficit from the material is followed by the complete degradation of the material which is often carried out under an inert atmosphere [21]. During the sample analysis, the material is heated under inert atmospheres of nitrogen at an increment of 10–20 °C/min depending on the material [22].

Fourier transform-infrared spectroscopy

Fourier transform-infrared spectroscopy (FTIR) is widely deployed as a qualitative characterization technique for polymer characterization as FT-IR functions on the absorption of IR radiation by polymeric materials [23, 24]. An absorption spectrum with the peak can be obtained by measuring the amount of IR radiation absorbed by the material as a function of emitted wavelength [25]. FT-IR spectra are generally recorded in the span of 4000–600 cm−1 [23, 26]. The peaks obtained from the measurement provide information about the chemical group of the material. Chemical modification and cross-linking of one material with another material are characterized by the appearance or disappearance of the characteristic peaks in FT-IR data [22, 23].

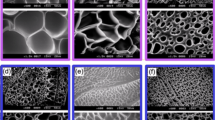

Scanning electron microscopy

Morphological assessment of any superabsorbent material is carried out by scanning electron microscopy (SEM) analysis. Understanding the absorption and swelling capacity morphology is very important. This technique can be used to assess not only the morphology of the material but also the porosity and structure of the superabsorbents [27, 28]. This analysis provides information about the pore distribution and pore sizes. The surface scanning is performed by deploying an electron beam in this qualitative technique. Once the electron from the incident beam (generated from the electron gun) interacts with the sample atoms, secondary electrons with low energy emerge from the surface [29]. Signals decoded from this are detected which results in the formation of the possible image with high resolution.

The quality of the data obtained from the samples depends on the sample preparation method. For example, to retain the surface morphology of superabsorbent hydrogels, cryogenic SEM may be required [30]. In this method, samples are to be frozen before the analysis by keeping them in liquid nitrogen, which can be imaged by deploying an SEM instrument.

X-ray diffraction

X-ray diffraction (XRD) is employed to study the crystalline arrangement of superabsorbents [31]. In this technique, small or wide-angle X-ray scattering mode is possible and uses the diffraction of an X-ray beam from a crystal lattice. Material information can be obtained from the measurement of the diffraction angles [32, 33].

Nuclear magnetic resonance

Data associated with the molecular structure can be derived using nuclear magnetic resonance (NMR) spectroscopy [34]. In this technique, studies at the molecular level are carried out by recording the possible interactions between the electromagnetic radiations and the nuclei of entities, when positioned in a robust magnetic field [35]. Based on the working principles, it is categorized into two classes; continuous and pulsed NMR. A part from qualitative information, quantitative analysis is also possible by using this technique [36].

Measurement of swelling (absorption test)

Several techniques are available to determine the swelling capacity of superabsorbents [37] which are based on the measurement of mass or change in the volume. To assess the absorption capacity of superabsorbent polymers, the standards for evaluating the absorption performance (i.e., water absorbed in relation to the mass of the sample) of superabsorbent polymers are used. These standards are laid down by several renowned international organizations (such as EDANA and INDA). The centrifuge retention capacity (CRC) and free swell capacity (FSC) are utilized as industrial quality absorption tests [38].

Free swell capacity

The “tea bag method” is another name for the “free swelling capacity (FSC)” technique. It denotes the volume of liquid that is absorbed for every gram of the given composition (g). This method is the fastest method for determining an absorbent sample's absorbency [38]. Saline solution, artificial blood, bovine blood, distilled water, and tap water can be attended as the tester fluids. The technique can be described as follows: tea bags are filled with (0.2–0.5 g ± 0.01) of SAP samples, dispersed evenly throughout the tea bag, and then soaked in tester fluid for 30 min. After being removed to reach equilibrium protuberance and given about 15 min to remove off surplus solution, the tea bags are weighed.

To be used as controls, unfilled tea bags are prepared and subjected to the same procedures. (Fig. 2). For each test sample, three controls are prepared to calculate the empty tea bag’s mean absorption factor (F, g/g), in accordance with equation (1).

where C2, C1, and F are, respectively, the weight of an unfilled filtered tea bag (the control), the weight of an empty dry tea bag (the control), and the tea bag’s absorption factor.

Consequently, the subsequent equation is used to determine the free swelling capacity (2):

where X2 represents the weight of the swollen SAP sample, X1 represents the weight of the dried tea bag when it is empty, X0 represents the weight of the SAP sample, and F represents the mean absorption factor of the tea bag (g/g). The results of three testing samples are averaged to determine the FSC of each SAP sample.

Centrifuge retention capacity

Specifically, this procedure is founded on the ability of SAPs specimens to hold fluid following saturation and centrifugation under controlled conditions. The resulting centrifuge retention capacity can be measured in terms of grams of retained fluid per gram of the sample weight (g/g). The same tea bags (including controls) collected in the previous FSC test are denoted as the test samples.

The tea bags were put in a centrifuge containing a carrier rotor that could provide approximately 250 G ( denotes the g-force) to a mass located on the inside walls of the container, which is used to test the samples. The inner basket wall of the centrifuge held the tea bags, which were centrifuged at 250 G (1400 rpm) for 3–5 min before being extracted and weighed. The centrifuge retention capacity (CRC) of the specimens is measured as the quantity of solution withheld by the SAP specimen, taking into consideration the amount of solution withheld by the tea bag itself (Fig. 3). However, Eq. (1) was also used to determine the retention factor (F, g/g) of the control tea bags. The following equation is deployed to seek out the centrifuge’s retention capacity (3).

where X2 represents the weight of the centrifuged tea bag (g), X1 represents the weight of the unfilled, dried tea bag (g), X0 represents the starting weight of the SAP sample (g), and F is the mean retention factor of the tea bag (g/g). The CRC is calculated by averaging the three tests performed on each particle specimen.

Absorption under load

The load (pressure) absorption test is intended to assess the SAP sample’s capacity for fluid absorption at particular pressures (0.3–0.9 psi) [38]. A uniform bed is made by carefully and evenly distributing 0.9 g of the SAP sample across a sieve filter.

In an aluminum cylinder with a variable height and a diameter of 60 mm, a piston is placed, and the entire apparatus comprising the cylinder, piston, and SAP sample is weighed and documented as X1. A fritted disk with a diameter of around 120 mm and a height of 10 mm is placed in a tray with a diameter of ~ 115 mm and height of 90 mm, while tap water or saline solution is added to test the fluids so that the fluid’s surface is at the same level as that of the fritted disk’s surface. On top of the sintered disk, a round filter paper is positioned carefully, thereby wetting it with the added fluid. The complete device is held on the filter paper as the wanted charge (570 g, pressure 0.3 psi) is simultaneously added to the equipment (Fig. 4). The solution is permitted to soak up for 1 h and then the entire apparatus is lifted and the charge is detached, and the cylindrical device is weighed again as X2.

The absorption under load (AUL) 0.3 psi is computed according to equation (4):

Absorption rate

The objective of this technique is to ascertain the absorption rate (AR) of SAP placed in saline solutions at various time interludes in order to investigate the absorption kinetics. After weighing, the samples are filled into tea bags and then placed in saline solution. At particular immersion time periods, it is left free of absorption. Depending on the time of immersion, the tea bags are separated and suspended to allow the drainage of superfluous liquid. Lastly, the tea bags are reweighed to establish the quantity of liquid that has been absorbed. The tea bags (comprising blanks) are made and packed with the SAP specimen as mentioned in the FSC procedure. Subsequently, the tea bags are submerged in saline solution for 30, 60, 180, 300, 900, and 1800 s, withdrawn to attain equilibrium swelling, and allowed to stand for 15 min in order to bleed the surplus solution off, and finally weighed. So, the absorption rate (AR, g/g) is computed deploying earlier described equations (1), and (2).

Point of zero charge (PZC)

The point of zero charge (PZC) is the pH at which the surface of the material becomes neutral. Measurement of PZC is very helpful to understand the behavior of adsorbent during the adsorption study. Rehman et al. have synthesized novel zwitterionic superabsorbent hydrogel via the free radical polymerization method for the removal of crystal violet and congo red. PZC of hydrogel was determined by adding 0.02 gm of dried hydrogel into the sample bottles having 0.01 M NaNO3 solution. Results of this study revealed that the synthesized hydrogel showed a point of zero charge pH 5 [39]. In other studies, PZC of adsorbent from a mixture of bagasse-bentonite for the adsorption of CD2+ and pb 2+ from the aqueous solution [40, 41], removal of Cr (VI) from waste water by activated natural zeolite-based magnetic composite and Cr (VI) -imprinted poly(4-VP-co-MMA) supported on activated Indonesia natural zeolite structure [42, 43], have been determined.

Applications of superabsorbent polymers

Drug delivery applications of SAPs

Excellent water absorption properties and biocompatibility of polymers render them suitable for deployment in drug transport systems; various SAPs have been explored for drug delivery appliances [44,45,46]. The following sections elaborate on the delivery approaches using superabsorbent polymers.

Development of drug-loaded microspheres

Microspheres have also been termed small spherical microparticles with a diameter in the range of 1 μm to 1000 μm [47] and several such SAP-based microspheres have been explored in drug delivery systems. For instance, xanthan gum-based superabsorbent polymeric microspheres were formulated and assessed for in-vitro characteristics. In this method, microspheres were developed using various ratios of poly (vinyl alcohol) (PVA) and hydrolyzed xanthan gum for sustained drug delivery of ciprofloxacin and formulation showed a satisfactory drug release profile in acidic and alkaline mediums [48].

Hydrogel-based formulations

Recently, specific interest has been devoted to hydrogel-based drug delivery systems. Hydrogels comprise a 3-dimensional network of polymer chains with two or multi-component systems and water that packs the room among macromolecules. Sadeghi et al. have developed an intelligent starch-based superabsorbent oral drug delivery system for metronidazole (sodium acrylate-co-HEMA) [49]. The authors studied the swelling behavior in a salt solution, wherein it has been observed that the aqueous sponginess of the hydrogel is lower in Ca2+ and Al3+ cations compared to NaCl. This behavior may be attributed to the ionic cross-linking of cations with carboxylate anions of the SAP [49]. Further, in-vitro drug discharge showed that the drug quantity released from synthesized hydrogel decreased as the pH of the medium was lowered.

Another starch-based superabsorbent was developed by Pourjavadi et al. for oral drug delivery systems using grafting cross-coupled poly acrylic acid-co-2-hydroxyethyl methacrylate (PAA-co-HEMA) strings with starch via a free radical polymerization protocol. Authors have used tools like SEM and FTIR for the confirmation of superabsorbent formation. The drug profile of diclofenac sodium was found to be low in mimicked gastric liquid (pH 1.6) over 3 h; the complete drug could be discharged in model gastric fluid in 8 h at pH 7.4.

The controlled delivery of bisoprolol fumarate was achieved by deploying the xanthan/lignin hydrogel carrier system. In this study, xanthan and epoxy-modified resin mixture were cross-linked by employing a cross-linking agent and the ensued superabsorbent hydrogel had a high swelling rate in an aqueous medium [50].

Implant-mediated drug delivery system

Yang et al. developed an implant-mediated drug delivery system [51] using SAP. This study aimed to assess the effect of plunger components fabricated by SAP on the plasma concentration of released drugs from the developed device comprising an in-vivo study on 18 rabbits. Results suggested that the incorporation of SAP in drug delivery devices resulted in increased initial drug level and enhanced bioavailability within two weeks of post-administration of the drug [51].

Abuse deterrent formulations

Abuse deterrent formulations are resistant to crushing and extraction to provide deterrence to abuse by injection and insufflation [52, 53]. Several SAPs have been used in the development of abuse- restraining preparations.

Mastropietro et al. have evaluated different SAPs in the elaboration of abuse- restraining preparations [54]. In this study, authors characterized polymers for protuberance in abstraction solvents and tableting attributes. By using tramadol as a model drug, the percentage of drug extraction and drug release were evaluated and the ensued results suggested that screened polymers possessed the required tableting properties besides exhibiting fast swelling properties after compaction (Fig. 5). Consequently, these polymers can be a viable option in the development of abuse-deterrent formulations [54].

Adapted from reference [54]

A. Structure of the tablet. Actual tablet (left) and schematic representation (right), B and C. Crushed tablet converted into gel mass in water.

Site-specific drug delivery

Panahi et al. have developed an extended drug delivery formulation of clarithromycin drug [55] which was based on the semi-interpenetrating hydrogel; hydrogel was prepared via the free radical graft copolymerization protocol. The polymer used for the synthesis comprised chitosan, acrylamide, acrylic acid, montmorillonite, and polyvinyl pyrrolidone. The authors have performed a swelling kinetic study in hydrochloric acid, acetate buffer, and distilled water. Thermal stability and mechanical strength of formulation were also carried out. Results suggested that the drug improved the mechanical strength of hydrogel and its thermal stability. In-vitro drug discharge demonstrated that the developed system released the drug over an extended period. The sustained release profile was attributed to the hindrance of the penetration of drug owing to the presence of an interlinked porous channel within the superabsorbent nanocomposite network [55].

Improvement in the bioavailability of the drug

A comparative study between the relative bioavailability of oral solution of risedronate sodium and drug-containing superabsorbent copolymer particles was conducted by Shahzad et al. Formulations were developed via free radical polymerization of itaconic acid, 2-hydroxyethyl methacrylate, and polyvinyl pyrrolidone (PVP), wherein N,N,N,N-tetramethyl ethylene diamine was used as an activator, potassium persulfate as the initiator, and ethylene glycol dimethacrylate as the cross-linker [56]. Authors have calculated Cmax, Tmax, AUC, and the relative bioavailability of formulation for the oral solution when a marked increment in Tmax with lower Cmax was observed. These results suggest that the developed formulation delivered the drug at a controlled rate with a remarkable increase in bioavailability [56].

Applications in nanomedicine

The use of nanomaterials for diagnosis, monitoring, control, prevention, and treatment of disease is popularly falls under the domain of nanomedicine [17, 57,58,59,60] where SAPs have been explored for such innovative development. For instance, a polyacrylic acid hydrogel with cellulose nanocrystals has been fabricated [61], wherein acrylic acid was subjected to cross-linking with cellulose nanocrystals using N,N-methylenebisacrylamide [61]; the level of crystalline cellulose varied between 0 and 25 wt% after optimization. The ensued results suggested that a significant storage modulus of the hydrogel was observed with an enhancement in cellulose concentration; maximum swelling index being attained at pH 7. Theophylline has been used as a model drug to evaluate the encapsulation efficiency when authors observed that 15% crystalline cellulose/polyacrylic acid hydrogel showed the potential for deployment in drug delivery [61].

Applications in the disposable hygiene industry

The disposable hygiene industry is contributing importantly to many lives and also has an environmental impact. Due to the unique characteristics of SAPs, it is appropriate to use them in disposable absorbent hygiene materials (DAHM) as they function by imbibing the bulk and holding large amounts of fluids per unit mass of materials. In addition, durable hydrophilic, soft, absorptive, and suitable combinations, the low cost of raw materials, does have an enormous influence on its utility. SAP research and development primarily focuses on versatile applications in the hygiene industry which currently has 80% of consumption share in these applications. The absorption rate of the diaper should not be slower than the urination rate of the baby patient otherwise leakage can occur and this can be controlled by the deployment of composites. The absorption capacity, particle size, and shape is significantly contribute to the maximum absorption capacity of the SAP [62].

In one of the studies, the impact of recycling absorbent hygiene products (AHP) on the product life cycle was evaluated under five distinct scenarios including the standard collection of MSW, two scenarios that consisted of a recycling process with null SAP recovery, and two scenarios comprising a recycling process with assumed SAP recovery. The resulting outcome revealed that SAP recycling exceeded the environmental burdens that result from the production of diapers from end-of-life. In addition, SAP was found to be the largest contributor to GWP impacts in diaper fabrication. SAP recovery and reuse appeared to have significant savings in terms of energy and water resources, which are highly associated with SAP manufacturing [63].

SAP is a synthetic material prepared from petroleum-derived precursors and prepared as granular sodium polyacrylate, which, in turn, was obtained via the polymerization of acrylic acid where ammonium persulfate served as the initiator. In one of the investigations, SAP was extracted from DBD and evaluated for a series of tests. The SAP-containing diapers show particle size in the 250–400 μm median range. The pH value was in the span of 6.9 and 7.9 while the moisture content of SAP-containing diapers was in the breadth of 12.64 and 7.64 wt% [38].

Role of SAP in agriculture

SAPs are flexible polymer chains that are cross-linked to form a 3D network that transports dissociated and ionic functional groups. They tend to absorb fluid greater than 15% of its dry weight irrespective of a load of water, electrolyte, urine, brine, biological fluid, etc. Polymers containing various functionalities like hydroxyl, carboxylic acid, imide, and amide are insoluble in water and cross-linked polyelectrolyte. Diverse industries are looking forward to exploiting the physical properties of SAPs for their utility in hygiene, cosmetics, drug delivery system, and the agriculture industry. The following are some of the applications of SAP found in the agriculture industry:

-

1.

To increase soil retention capacity

-

2.

For sustained release of pesticides

-

3.

For increasing the seed germination capacity

-

4.

In the photosynthetic process

SAP for conditioning effect on soil

Absence of rainfall in irrigation results in growth inhibition of the plant which can be circumvented by introducing cross-linked polymer in the soil; the high water-holding capacity of SAP plays a major role here in the conditioning of soil. Polyamide, polyvinyl alcohol, and starch acrylate copolymer are examples of SAP having the capacity to retain water 500 times its dried weight. Also, the addition of SAP in growing media shows 400 times more water retention capacity. This water water-filled gel act as a semi-permeable membrane. Polymer bridges serve as diffusion surfaces for the supply of water to slowly release to release the medium under deficiency of precipitation or irrigation. The addition of polyacrylamide gel in the soil produces enhancement in the bulk density of the soil so the porosity also increases which results in enhancement of the water-retaining competence of the soil [64].

In one study, the authors ensured the water-holding capacity of polymer, its effect on sandy soil, and hydraulic conductivity (HC). Mixing of SAP-like polyacrylamide (PAM) in sandy soil caused to decrease in water percolation rate and more water available to the crop. The water retention capacity of alone absorbent was ranging from 200 to 500 kg/kg of polymer, while the water retention capacity by polymer admixed with soil was 40–140 kg/kg of polymer; the concentration of polymer being directly proportional to water retention capacity. This study concluded that when soil is saturated with water it shows desorption, while dried soil with absorbent shows a sorption phenomenon. This indicates the high water retention capacity of soil when it’s in a desorption state. The successive enhancement in HC is attributed to the incomplete emptying of the inflated polymer granules caused by the hydraulic head's pressure on the polymer-soil mixtures. When no external forces are applied to the polymer granules, it is assumed that the HC of the polymer-sand mixture will stay low [65].

Johnson studied the influence of salt concentration on different polymers like acrylamide-sodium acrylate, starch -polyacrylonitrile graft, and vinyl alcohol-acrylic acid co-polymers. Such polymers can absorb huge quantities of water when cross-linked and swelled to produce gel fragments that serve as tiny moisture reservoirs in the soil. An increase in salt concentration decreases the water-holding capacity of SAP. Water having high conductivity with acrylamide shows a 249 and 231% increase in solution uptake by more absorbent products compared to starch copolymers, respectively while in deionized water starch copolymer absorbs water up to 254 to 380% more than polyacrylamide. This result indicates different concentrations of salt in water cause variations in polymer absorbing properties and their effect on soil [66].

Natural and renewable olymers like cellulose, starch, and chitosan have better degradability [5, 7], while synthetic polymers like polyacrylamide and polyvinyl alcohol are advantageous due to their low cost and higher water retention capacity than natural polymers but low degradability is the major limitation of synthetic SAP. Thus, when different types of polymers are combined or co-polymerized, it may deliver better results [67].

Poly aspartic acid (PASP) is an example of biodegradable SAP. The micro-organisms present in the soil are a primary culprit in the breakdown of polymer hence degradation of the polymer depends on enzymes and the type of microorganism present in the soil. PASP absorbs a large amount of water and forms a hydrophilic network and SAP particle shape is preserved in the swollen state due to high gel strength [68].

It is possible to improve thermal stability, gel strength, salt tolerance, and water retention by synthesizing organic–inorganic site superabsorbent polymers (OICSAPs) by adding inorganic elements to SAPs to create OICSAPs. This composite shows different water absorption capabilities at various concentrations of ions present in the soil. OICSAP has been obtained by the addition of the attapulgite in polyacrylamide which shows a 221 g/g rate of water absorption in the presence of higher valent cation, and higher anion concentration which initiates to decrease in the water absorption rate. Internal morphology offers a combined response to its water-absorption characteristics which reveal the 3D structure of a cross-linking network of swelled polymer; metal ion damages the network while anion and cation of composite show changes in pore size [69].

Slow-release fertilizer

Almost all-natural elements (92) are present in plants, but only 17 have been recognized as important nutrients for plant growth. Among these, 14 are mineral elements that plants absorb from the soil via their roots. Macronutrients are required in relatively large amounts which include nitrogen obtained from the atmosphere. Conversion of this nitrogen is carried out by soil-leaving microorganism symbiotic bacteria which are present in plants and by some chemical processes. Phosphorous in the form of inorganic phosphate and potassium in ionic form has been absorbed from the soil. Secondary macronutrients like sulfur, magnesium, and calcium are required by plants in smaller quantities. Eight essential micronutrients comprise copper (Cu), iron (Fe), manganese (Mn), zinc (Zn), chlorine (Cl), molybdenum (Mo), nickel (Ni), and boron (B). But these nutrients aren't always present in the environment in enough amounts for plants to grow well. Therefore, the need for agrochemicals like fertilizers, herbicides, and pesticides is important in farming. The usage of traditional agrochemicals has unintended consequences, such as its integration into the food chain and poisoning of the surrounding ecosystem. To avoid these problems, polymer-assisted herbicides are used which release the chemical at a regulated rate and in the quantities required over a set period of time. Nowadays, coating fertilizer with SAP is a trending topic [70, 71]. Slow-release fertilizers are classified into 4 types:

-

1.

Inorganic material with low solubility

-

2.

Chemically and biologically degradable material with low solubility

-

3.

Material that decomposes in soil by its relative solubility

-

4.

Water soluble fertilizers that have to be coated for sustained release of fertilizers

These coated fertilizers exhibit controlled release by degradation and coating erosion.

However, this delivery method shows a bursting effect which can be avoided by the double coating of super absorbent polymer on fertilizer for a slow-release effect [72,73,74].

The main advantage of superabsorbent polymer with slow-release phosphate fertilizer (SAPSRPF) is sustained and longer time supply of fertilizer to plants and decreased frequency of application. Super absorbent phosphate fertilizers are formed by the grating polyvinyl alcohol and H3PO4 via the esterification process. This study shows the release of 26% of phosphate in soil within 24 h, while after 72 h, 47%, phosphate was released. The dissolution and diffusion mechanism release of phosphate fertilizers occurs so on the 28th day 72% of release was observed. Steadily increased total phosphate release has been observed [75].

By using acrylic acid and wheat straw in an aqueous solution, graft polymerization was used to create an innovative wheat straw-g-poly(acrylic acid) (WS/PAA) superabsorbent composite. Wheat straw and poly(acrylic acid) composite show increased water absorbency from 498 to 860 g/g with increasing concentration of wheat straw from 0 to 20% but further increase in concentration show a decrease in absorbency effect. If urea is loaded (28.3%) with WS/PAA composite, it shows first-order release; escape of urea in water from composite is faster, while in soil rate of release is slow [76].

It has been possible to manufacture phosphate, potassium (NPK), and chitosan-coated nitrogen, compound fertilizer with controlled-release and water-retention (CFCW), and this fertilizer comprises a three-layered structure. It had a water-soluble NPK fertilizer granule with chitosan (CTS) as its inside coating and poly acrylic acid -co-acrylamide (P(AA-co-AM)) superabsorbent polymer as its exterior coating. The amounts of nitrogen, phosphorus, and potassium were 8.06, 8.14 (exposed by P2O5), and 7.98 (revealed by K2O) weight percent, respectively. The product had a superior slow-discharge property, and by day 30, the number of nutrients that were released had not exceeded 75% of the total. The results of the release analysis suggested that nutrition could be released from CFCW in soil by a mechanism and not the Fickian diffusion process [77, 78].

A core/shell-shaped slow-discharge potassium silicate fertilizer (SRPS) with properties like superabsorbent and water retention has been created. Its shell comprised a superabsorbent polymer made of poly (acrylic acid-co-acrylamide) and kaolin (P(AA-co-AM)/kaolin), while its core was the potassium silicate in a matrix containing alginate. Shell was swollen and formed a P (AA co-AM)/Kaolin three-dimensional network, which helped in the diffusion of fertilizer and SI in SRPS was released 17.9 and 7.5%, 26 and 9.6%, and 66 and 21.3%, respectively, on 3rd, 5th, and 30th day [79].

Seed germination

The process of initiation of growth is known as seed germination. Generally, this process starts with the water imbibition stage which is subdivided into 3 phases including rapid initial water uptake and slight alteration in water content showing the plateau phase followed by an enhancement in water content concerning radical growth. The rate of phase 2 is generally extended by dormancy, temperature variations, and water deficiency [80].

By providing an efficient amount of water, SAP indirectly promotes germination via the 3-phase system. Coating of the super absorbent polymer on the seed increases the survival rate of the seed. SAP can absorb water at a rate between 200 and 400 times its weight and increase its size by up to 100 times its original size, thus making the seed heavy and keeping it deeply buried in the soil which prevents it from blowing away due to wind.

By improving the water retention capacity of growing media, change in the physiological and morphological characteristics of the seedling is possible. Seeds that have been coated with SAP are noticeably superior because they offer protection against membrane damage. Cork oak (Quercus suber L) treated with Stockosorb hydrogel shows improvement in seedling water status and increases the rate of survival of seedlings [81]. The super absorbent hydrogel of l-carrageenan blend with agar and xylan carbohydrate. This hydrogel is biodegradable, non-toxic, and good water retentive. In the study, xylan carrageenan hydrogel with polyacrylamide shows 117.9–139.05% increased water holding capacity while the agar-carrageenan blend shows 67% water content. This hydrogel shows a good coating around the seed, which may help in germination [82].

PGPB (plant growth-promoting bacteria) carrier, a superabsorbent composite (SAPH) composed of cross-linked acrylic-cellulosic, is found to be efficacious for water retention, and drought resistance, and has utility as a matrix for mineral nutrient delivery while raising E. grandis seedlings. PGPB promotes plant growth directly through various activities and mechanisms such as nitrogen fixation, phytohormone production, iron chelation, and phosphate solubilization, via the production of siderophore, or indirectly via activities such as pathogen suppression or pathogen resistance induction. PGPB has been found to trigger a tolerance response systemically that includes hormone modulation in the presence of a water deficit. This could include indole acetic acid release, that alters the architecture of roots, or abscisic acid, which causes alleviation of abiotic stress by causing early stomatal closure or by modulating ethylene signaling, thus resulting in delayed tissue senescence. In the drive to produce climate-change adaptive agriculture while minimizing the use of agrochemicals and synthetic fertilizers, PGPB is fast gaining prominence as a cost-effective and most importantly natural alternative to boost crop production and reduce plant stress. PGPB contains Pseudomonas strains N33 and M25 which influences the water management and avoids early closing of stomata. This bacterial SAP composite may act as drought-resistant for plants and also promote the growth of the seedling [83, 84].

Applications in heat resistance and absorption capacity

When the external solution’s temperature exceeds 150 °C, most superabsorbents become water-soluble owing to amide-bond hydrolysis on network cross-linking points. This drawback limits the application of SAP at higher temperatures, namely a channel-blocking agent in a steam-stimulated oil well [85]. PVA/P(AA-AM) SAP endowed with a semi-interpenetrating network structure has been created using polyvinyl alcohol (PVA) as long-chain molecules interspersed throughout the network structure, acrylic acid (AA), and acrylamide (AM) as primary components. It has excellent heat stability and water retention attributes. The property of sandy soils and water retention could be improved after the resin has been mixed into the sandy soil. PVA/P(AA-AM) SAP was successfully prepared and had thermal stability at temperatures below 200 °C. At the same time, the water retention property of PVA/P(AA-AM) SAP was excellent, and upon its addition to sandy soil, the water-holding property of sandy soil was significantly enhanced [86].

The size of the polymeric network influences the water absorbance capacity of the composite. It is important to graft acrylic acid polymer onto mica and creates a nanocomposite comprising a polymer and extremely thin mica particles; here, mica powder act as a cross-coupling agent. The cross-link compactness of the composite increases with the quantity of mica powder deployed. The network of spaces available for water molecules to enter shrinks and consequently, the water absorbency steadily declines [87]. In situ radical polymerization has been used to create superabsorbent composites comprising montmorillonite (CTS-g-PAAm/MMT) and chitosan-g-poly(acrylamide) and by grafting cross-coupled AA onto the chitosan backbone in the company of montmorillonite (MMT) at varied filling levels. Clay is invariably added to all superabsorbent composites to enhance their water absorption; the highest amount being achieved at an MMT level of 5 wt%.

Thermal stability is ensured by thermogravimetric analysis (TGA) of the composite. The composite shows three-step thermal degradation. The first stage below 180 °C indicates loss of moisture, the second stage between 180 to 329 °C is due to the amide group and cross-linker while the third phase is above 330 °C in view of the loss of the primary broken composite chain; MMT delays the thermal decomposition rate [88]. TGA has been used to examine the influence of MMT on the thermal stability of CTS-g-PAAm and displays TGA and d(TG) thermograms of chitosan-g-poly (acrylamide) (CTS-g-PAAm) hydrogel and its CTS-g-PAAm/MMT (montmorillonite) composite. All the composites display a comparable three-stage heat deterioration in the range of 30–600 °C. The initial stage, below 180 °C, is associated with the loss of moisture present in the samples, and the second one is in the range 180 and 329 °C. Modification of vermiculite (VMT) has been attained using cetyltrimethylammonium bromide (CTAB). organo-vermiculite (CTA + -VMT), partially neutralized acrylic acid (NaA), and natural guar gum (GG)and has been solution polymerized with N,N′- methylene-bis-acrylamide (MBA) as the cross-coupling agent and ammonium persulfate (APS) as the initiator to create superabsorbent nanocomposites[89].

Clay is not only used to increase the water retention of composite but also to absorb the heavy metal component in water and polymer which decreases the hazards of metal poisoning. Nowadays, eco-friendly and widely available renewable materials like cellulose, Chitosan, starch, and peanut hull are emphasized in the studies due to their biodegradability. Attapulgite is the layered aluminum silicate containing the -OH group on the surface. A composite of polyacrylic acid/attapulgite has been prepared by graft copolymerization of attapulgite with acrylic acid in attendance of ammonium parasulfate (APS) as an initiator, and the cross-linker N,N-methylenebisacrylamide (MBA) in water. The ensued results from TGA analysis indicate that the introduction of attapulgite causes to increase in the thermal stability of the composite [90].

A study of the composite containing sodium alginate-poly (acrylic acid-co-acrylic amide)/graphite oxide (GO) shows a significant result in water absorbance and thermal stability. A DSC study performed at 430 °C reveals that the decomposition of SA-g-P (AA-co-AM) graft copolymer occurs while the decomposition peak associated with SA-g-P(AA-co-AM)/GO shows at 445 °C. This indicates that the thermal steadiness of the composite is enhanced due to the grafting of graphite oxide. Similarly, regarding water retention ability without the inclusion of GO, the absorption competencies for 0.9 percent NaCl and water are found to be 79.2 g/g and 298.6, respectively. On the other hand, the capabilities for absorption significantly enhanced and attained their highest levels, being 870.5 and 183.3 g/g, which is a significant difference given that the amount of GO was only up to 0.1 g. Although higher than that of pure SA-g-P(AA-co-AM), the values are 571.9 and 104.1 g/g, respectively (AA-co-AM) graft polymer [91].

Application of SAPs in nanofiltration

SAPs can adsorb a large amount of liquid about their weight as they form hydrogels upon water sorption. They display versatile applications in different fields including protecting and sealing products, hygienic products, agricultural applications, and food industries. However, it has shown promising applications in nanofiltration technology in variously described findings. The preparation of SAP bead comprising poly(acrylamide-co-itaconic acid) (P(AM-co-IA) has been deployed by multiple utilities. One of the studies sensed and measured the presence of the pathogen in water for the evaluation of the safety and security of drinking water; a novel method for water sample concentration is founded on SAP beads wherein the millimeter-sized beads are synthesized by simple and scalable methods. The addition of beads to the water sample is the concentration process as beads swell to acquire the form of a hydrogel while the small-sized entities intercalate with them. However, the small molecular particles and microbes bigger than several nanometres are left out which get accumulated in the remaining non-absorbed water. After this, the hydrogel beads can be separated effortlessly and reused after drying.

There have been some studies performed for the modification of substances required in the fabrication of filtering facepiece respirators (FFRs). To remove the microbial growth there is a need to remove the moisture content accumulated in these materials. Majchrzycka et al., proposed the use of SAP with a biocidal agent (halloysite) as the additive for the fabrication of polypropylene/polyester (PP/PET) multifunctional filtering material (MFM). Two types of polypropylene sieving nonwovens have been produced deploying the melt-blown method, namely, bioactive super-absorbing polypropylene-poly(tereftalan ethylene) nonwoven (Modified Filtering Nonwoven; MFM) and original polypropylene-poly (tereftalan ethylene) nonwoven (Control Sample; CS). In this study, BH (95% halloysite/5% didecyldimethylammonium chloride wt/wt) and industrially available SAP (EK-X, Nippon Shokubai, Japan) have been used as modifiers of the polymer filtering materials. Accordingly, it is concluded that micro-organism numbers are reduced for MFM in comparison with CS in three out of four species such as C. Albicans, E. coli, and S. aureus with the MFM displaying high filtration competence (99.86%) for S. aureus bacteria [92].

The gathering of biofluid samples including urine and blood has always been a challenging process because of the essential need for uninterrupted refrigeration. It is observed that without proper temperature storage, there is a higher chance of degradation of the analyte. In a study, Chen et al. examined the self–driven microfiltration facilitated by permeable SAP beads and deployed them for storing and processing biofluid samples where the mechanism entailed in this filtration process is different from conventional methods (Fig. 6). Initially, filtrates first permeate the filter because of the pressure disparity and are retained in the PSAP beads as they have a pore size of ∼2 mm that can apprehend small analytical targets (< 0.5 μm) but reject bacteria and blood cells (> 1 μm) in the biofluid specimens [93]. So, the hemolysis of the analyte and microbial spoilage can be avoided. A dry-bath batch method has been deployed to generate bullet-shaped and millimeter-size PSAP beads by polymerization-stimulated phase separation. It was highlighted that pores are created by the cross-linking and polymerization of monomeric material in a PEG aqueous solution where the chain of cross-linked polymer served as a scaffold and PEG functioned as porogen. The various attributes including reaction temperature, cross-linking degree, and monomer composition have to optimize to acquire PSAP beads with required homogeneous morphology and swelling performance.

Self-Driven “Microfiltration” Enabled by porous superabsorbent polymer (PSAP) (Adapted from [93])

Role of SAP in photosynthesis

In 1885, Kreisler observed the inhibitory effect of water deficiency on photosynthesis. While in 1991, Schneider and childer found the effect of stomatal conductance on photosynthesis and concluded that the closing of stomata affects photosynthesis under water deficit conditions. In 1996, Scarth and shaw concluded that the stomatal aperture is controlled by photosynthesis. Brix concluded that at low water potential of the leaf, stomata limit photosynthesis. The enhancement of vapor pressure deficit by affecting transpiration and decreasing soil water supply lowers the leaf water potential [94]. When plants are under stress in drought conditions, stomatal conductance continues to play an essential part in the maintenance of photosynthesis. In most cases, vital physiological processes require less than 5% of the water that is absorbed by the roots of a plant; the remaining 95 percent of water is lost by transpiration. Stomatal conductance plays a crucial function in photosynthesis during the dry state of soil stomata are closed, so the rate of photosynthesis is reduced [95].

Photosynthesis's related parameters are chlorophyll content, net photosynthesis rate, and fluorescence parameter, among others. During water deficit conditions, plants produce proline-rich output to overcome cell dehydration. Application of SAP under the moderate deficit of water promotes indirect photosynthesis by increasing chlorophyll levels and improving leaf water content.

The combined effect of photosynthesis, proline, and growth of maize plant under the water deficit conditions has been studies by addition of SAP and fulvic acid. The result of this study demonstrates that photosynthesis capacity and proline level have increased under water deficit conditions. Osmotic adjustment is a technique for sustaining photosynthesis and water interactions by keeping the water content of leaves at low water potentials. Accumulation of suitable solutes allows for osmotic correction. One of the major cyto solute is involved in this mechanism. Carotenoid and chlorophyll percentage also decreases under stress conditions. Superab A200 SAP has better efficacy to enhance water retention so that under stress conditions like drought, polymer helps retain moisture around the root. Also, an increase in carotenoid content has been observed which helps in photosynthetic activity associated with chlorophyll. During drought conditions, the accumulation of proline acts as an osmolyte to maintain the organelles and leaf in water-deficit conditions.

Water deficiency has a significant impact on photosynthetic processes by causing leaf stomata to close, increasing diffuse resistance to carbon dioxide (CO2) uptake, and decreasing CO2 absorption in the leaves. Reduced mesophyll conductivity and closed stomata slow the passage of CO2 from the atmosphere into carboxylation sites in leaves, which slows the photosynthetic processes.

Removal of heavy metals

Increased industrialization has resulted in the development of tremendous environmental pollution by various heavy metals that adversely impact human health, being mutagenic as well as carcinogenic. The source of contamination of these metals are the electroplating industry, metallurgy, and tannery, among others. Several methods have demonstrated the reduction or elimination of heavy metals from the aqueous samples. These techniques include adsorption, ion exchanger, reverse osmosis, chemical precipitation, and selective membrane.

Initially, low-cost adsorbents such as horn snail (Telescopium sp.) and mud crab (Scylla sp.) shells powder were utilized for the removal of Cu2+, and Pb2+ from wastewater [96, 97] and Archontophoenix alexandrae was used for the adsorption of Cu2+, zinc, and nickel ion [98]. A mixture of bagasse-bentonite was applied to adsorb Cd2+ and Pb2+ from an aqueous solution [40, 41], and the mixture of algae waste-bentonite was used to absorbent to remove Pb2+ from the aqueous solution [99, 100].

In one method by Neolaka et al., magnetic composite material modified ion imprinting polymer (IIP@GO-Feo4) from Schleichera oleosa was synthesized via precipitation method and NIP@GO-Fe3O4 was prepared by a similar method without CR(VI) as a template. In this study, the authors have used ten kinetic and eight isothermal adsorption models. Results suggested that IIIP@GO-Fe3O4 had higher adsorption compared to NIP@GO-Fe3O4 with better reusability due to the same level of adsorption capacity [43].

In another study, selective adsorptive removal and solid phase extraction of Cr(VI) ions were carried out from electroplating industrial wastewater using a Cr(VI) imprinted -poly(4-VP-co-EGDMA sorbent [101]; precipitation polymerization method was employed for the synthesis. Authors did investigate several parameters such as the effect of sorbent dosage, contact time, pH and temperature on Cr(VI) adsorption from aqueous solution. The adsorption of these ions has occurred highest at pH 2 with a contact time of 30 min with an initial concentration of cr(VI) 14 mg/mL at 313 K. Results of modeling kinetics demonstrated that Cr(VI) adsorption fits with the pseudo-second-order model. Further, the adsorption of ions from electroplating industrial waste reached 96% with good stability even with repetitive use up to 10 times [101]. Furthermore, the adsorption performance of Cr(VI)-imprinted poly(4-VP-co-MMA) supported on activated Indonesia (Ende-Flores) natural zeolite was also deployed for the removal of Cr(VI) from aqueous solutions [102].

Conclusion and future perspectives

In this review, prominent aspects of superabsorbent polymers (SAPs) have been deliberated that could be valuable for scientific and technological foresight offered for their further development for various purposes. As characterization is a critical part of successful chemical synthesis, the various significant characterizations of SAPs were discussed including Thermogravimetric Analysis (TGA) and Differential Scanning Calorimetry (DSC) to establish their thermal behavior as a function of time, temperature, and heat. Fourier Transform Infrared Spectroscopy (FT-IR), Nuclear Magnetic Resonance (NMR), X-ray Diffraction (XRD), and Scanning Electron Microscopy (SEM), are among the experimental techniques deployed to characterize the structural composition. FSC, CRC, AUL, and AR have already been specifically related to the officially accepted industrial swelling measurement. SAPs, in various formulation forms, have been exploited in prominent implementations to develop certain applications such as heat resistance, nanofiltration, drug delivery, the disposable hygiene industry, nanomedicine, and agriculture.

Considering that the primary characteristic of SAPs lies in their swelling performance, then all perspectives have been emphasized on swelling enhancement. Accordingly, the efforts have focused to improve the swelling properties of SAPs which are defined by the modification of cross-linking agents, testing other anionics on the polymer chains, developing new Super Slurpers, and performing surface cross-linking. On the other hand, to attain superior outcomes and to better encourage the use of the synthesized products, additional research is required, namely the absorption tests in various kinds of fluids (bovine blood, artificial blood, etc.). In addition, more effective assays to evaluate the hydrogel’s properties are also recommended, like diffusion under load, gel fractionation, and study of the SAPs particle size.

Furthermore, the study of the biodegradability of SAPs in vivo and in vitro is also of paramount importance. Scientists assume that the development of alternative biodegradable SAPs could be the ultimate ecological solution to solve environmental problems. In addition to environmental challenges, the exhaustion of oil reserves is another major conundrum facing mankind. Therefore, to overcome the shortage of oil resources, the use of renewable polymers such as cellulose, starch, etc. for the production of SAPs appears to be an appropriate solution that needs to be explored besides a life cycle assessment (LCA) of the related processes.

Data availability

Data are contained within the article.

References

Batista RA, Espitia PJP, Vergne DMC et al (2020) Development and evaluation of superabsorbent hydrogels based on natural polymers. Polymers (Basel) 12:2173. https://doi.org/10.3390/polym12102173

Chang C, Duan B, Cai J, Zhang L (2010) Superabsorbent hydrogels based on cellulose for smart swelling and controllable delivery. Eur Polym J 46:92–100. https://doi.org/10.1016/j.eurpolymj.2009.04.033

Rather RA, Bhat MA, Shalla AH (2022) An insight into synthetic and physiological aspects of superabsorbent hydrogels based on carbohydrate type polymers for various applications: a review. Carbohydr Polym Technol Appl 3:100202. https://doi.org/10.1016/j.carpta.2022.100202

Qureshi MA, Nishat N, Jadoun S, Ansari MZ (2020) Polysaccharide based superabsorbent hydrogels and their methods of synthesis: a review. Carbohydr Polym Technol Appl 1:100014. https://doi.org/10.1016/J.CARPTA.2020.100014

Salave S, Rana D, Sharma A et al (2022) Polysaccharide based implantable drug delivery: development strategies, regulatory requirements, and future perspectives. Polysaccharides 3:625–654. https://doi.org/10.3390/POLYSACCHARIDES3030037

Rana D, Salave S, Rawat G, Benival D (2022) Recent trends in drug delivery and emerging biomedical applications of gelatin for ophthalmic indications. Macromol Res 30:687–702. https://doi.org/10.1007/S13233-022-0078-9/METRICS

Desai N, Rana D, Salave S et al (2023) Chitosan: a potential biopolymer in drug delivery and biomedical applications. Pharmaceutics 15:1313. https://doi.org/10.3390/PHARMACEUTICS15041313

Sharma N, Tiwari A (2015) Nanomagnetite-loaded poly (acrylamide-co-itaconic acid) hydrogel as adsorbent for effective removal of Mn 2+ from contaminated water. Desalin Water Treat. https://doi.org/10.1080/19443994.2015.1004117

Guilherme MR, Reis AV, Paulino AT et al (2007) Superabsorbent hydrogel based on modified polysaccharide for removal of Pb2+ and Cu2+ from water with excellent performance. J Appl Polym Sci 105:2903–2909. https://doi.org/10.1002/APP.26287

Zendehdel M, Barati A, Alikhani H (2011) Removal of heavy metals from aqueous solution by poly(acrylamide-co-acrylic acid) modified with porous materials. Polym Bull 67:343–360. https://doi.org/10.1007/S00289-011-0464-5/METRICS

Mazi D, Surmeli B (2021) Temperature and Ph- sensitive super absorbent polymers based on modified maleic anhydride. J Chem Sci. https://doi.org/10.1007/s12039-020-01873-3S

Chavda H, Patel C (2011) Effect of crosslinker concentration on characteristics of superporous hydrogel. Int J Pharm Investig 1:17. https://doi.org/10.4103/2230-973X.76724

Singhal R, Tomar RS (2009) Nagpal AK (2009) Effect of cross-linker and initiator concentration on the swelling behaviour and network parameters of superabsorbent hydrogels based on acrylamide and acrylic acid. Int J Plast Technol 131(13):22–37. https://doi.org/10.1007/S12588-009-0004-4

Kabiri K, Omidian H, Hashemi SA, Zohuriaan-Mehr MJ (2003) Synthesis of fast-swelling superabsorbent hydrogels: effect of crosslinker type and concentration on porosity and absorption rate. Eur Polym J 39:1341–1348. https://doi.org/10.1016/S0014-3057(02)00391-9

Agnihotri S, Singhal R (2018) Synthesis and characterization of novel poly (acrylic acid/sodium alginate/sodium humate) superabsorbent hydrogels. Part II: the effect of SH variation on Cu2+, Pb2+, Fe2+ metal Ions, MB, CV dye adsorption study. J Polym Environ 26:383–395. https://doi.org/10.1007/S10924-017-0956-Y/METRICS

Sangole S, Salave S, Rana D et al (2022) Electrospun nanofiber composite for levofloxacin in ocular drug delivery. Pharm Nanotechnol 10:393–400. https://doi.org/10.2174/2211738510666220902151906

Rana D, Salave S, Jain S et al (2022) Systematic development and optimization of teriparatide-loaded nanoliposomes employing quality by design approach for osteoporosis. J Pharm Innov. https://doi.org/10.1007/S12247-022-09663-9/METRICS

Vickery R, Webster L, Li Y et al (2014) (406) Axelopran phase 2B study demonstrates a sustained increase in bowel movement frequency in patients regardeless of duration of opioid-induced constipation. J Pain 15:S77. https://doi.org/10.1016/j.jpain.2014.01.317

Pérez-Álvarez L, Ruiz-Rubio L, Lizundia E, Vilas-Vilela JL (2019) Polysaccharide-based superabsorbents: synthesis. Prop Appl. https://doi.org/10.1007/978-3-319-77830-3_46

Loganathan S, Valapa RB, Mishra RK et al (2017) Thermogravimetric analysis for characterization of nanomaterials. Therm Rheol Meas Tech Nanomater Charact 3:67–108. https://doi.org/10.1016/B978-0-323-46139-9.00004-9

Kalia S, Sabaa MW (2013) Polysaccharide based graft copolymers. Polysacch Based Graft Copolym 9783642365669:1–353. https://doi.org/10.1007/978-3-642-36566-9/COVER

Tomoda BT, Yassue-Cordeiro PH, Ernesto JV et al (2020) Characterization of biopolymer membranes and films: Physicochemical, mechanical, barrier, and biological properties. Biopolym Membr Film. https://doi.org/10.1016/B978-0-12-818134-8.00003-1

Dutta A (2017) Fourier transform infrared spectroscopy. Spectrosc Methods Nanomater Charact 2:73–93. https://doi.org/10.1016/B978-0-323-46140-5.00004-2

Bachra Y, Grouli A, Damiri F et al (2022) Synthesis, characterization, and swelling properties of a new highly absorbent hydrogel based on carboxymethyl guar gum reinforced with bentonite and silica particles for disposable hygiene products. ACS Omega 7:39002–39018. https://doi.org/10.1021/acsomega.2c04744

Rohman A, Ghazali MAIB, Windarsih A et al (2020) Comprehensive review on application of FTIR spectroscopy coupled with chemometrics for authentication analysis of fats and oils in the food products. Molecules 25:5485. https://doi.org/10.3390/MOLECULES25225485

Valand R, Tanna S, Lawson G, Bengtström L (2019) A review of Fourier transform infrared (FTIR) spectroscopy used in food adulteration and authenticity investigations. Food Addit Contam Part A 37:19–38. https://doi.org/10.1080/19440049.2019.1675909

Kabiri K, Zohuriaan-Mehr MJ (2004) porous superabsorbent hydrogel composites: synthesis, morphology and swelling rate. Macromol Mater Eng 289:653–661. https://doi.org/10.1002/MAME.200400010

Rahman MS, Islam MM, Islam MS et al (2019) Morphological characterization of hydrogels. Cellul Based Superabsorb Hydrogels. https://doi.org/10.1007/978-3-319-77830-3_28

Temiz C (2022) Scanning electron microscopy. Electron microsc [Working Title]. https://doi.org/10.5772/INTECHOPEN.103956

Kaberova Z, Karpushkin E, Nevoralová M et al (2020) Microscopic structure of swollen hydrogels by scanning electron and light microscopies: artifacts and reality. Polymers (Basel) 12:578. https://doi.org/10.3390/POLYM12030578

Zhang M, Zhang S, Chen Z et al (2019) Preparation and characterization of superabsorbent polymers based on sawdust. Polymers 11:1891. https://doi.org/10.3390/POLYM11111891

Bunaciu AA, Udriştioiu EG, Aboul-Enein HY (2015) X-Ray diffraction: instrumentation and applications. Crit Rev Anal Chem 45:289–299. https://doi.org/10.1080/10408347.2014.949616

Ameh ES (2019) (2019) A review of basic crystallography and x-ray diffraction applications. Int J Adv Manuf Technol 1057(105):3289–3302. https://doi.org/10.1007/S00170-019-04508-1

Wong KC (2014) Review of NMR spectroscopy: basic principles, concepts and applications in chemistry. J Chem Educ 91:1103–1104. https://doi.org/10.1021/ED500324W

Darbeau R (2006) Nuclear magnetic resonance (NMR) spectroscopy: a review and a look at its use as a probative tool in deamination chemistry. Appl Spectrosc Rev 41:401–425. https://doi.org/10.1080/05704920600726175

Simmler C, Napolitano JG, McAlpine JB et al (2014) Universal quantitative NMR analysis of complex natural samples. Curr Opin Biotechnol 25:51. https://doi.org/10.1016/J.COPBIO.2013.08.004

Zhang K, Feng W, Jin C (2020) Protocol efficiently measuring the swelling rate of hydrogels. MethodsX 7:100779. https://doi.org/10.1016/J.MEX.2019.100779

Bachra Y, Grouli A, Damiri F et al (2020) A new approach for assessing the absorption of disposable baby diapers and superabsorbent polymers: a comparative study. Results Mater 8:100156. https://doi.org/10.1016/j.rinma.2020.100156

Rehman TU, Shah LA, Khan M et al (2019) Zwitterionic superabsorbent polymer hydrogels for efficient and selective removal of organic dyes. RSC Adv 9:18565. https://doi.org/10.1039/C9RA02488C

Kuncoro EP, Mitha Isnadina DR, Darmokoesoemo H et al (2018) Characterization and isotherm data for adsorption of Cd2+ from aqueous solution by adsorbent from mixture of bagasse-bentonite. Data Br 16:354–360. https://doi.org/10.1016/J.DIB.2017.11.060

Kuncoro EP, Isnadina DRM, Darmokoesoemo H et al (2018) Characterization, kinetic, and isotherm data for adsorption of Pb2+ from aqueous solution by adsorbent from mixture of bagasse-bentonite. Data Br 16:622–629. https://doi.org/10.1016/J.DIB.2017.11.098

Neolaka YAB, Lawa Y, Naat J et al (2022) Efficiency of activated natural zeolite-based magnetic composite (ANZ-Fe3O4) as a novel adsorbent for removal of Cr(VI) from wastewater. J Mater Res Technol 18:2896–2909. https://doi.org/10.1016/J.JMRT.2022.03.153

Neolaka YAB, Lawa Y, Naat J et al (2021) Evaluation of magnetic material IIP@GO-Fe3O4 based on Kesambi wood (Schleichera oleosa) as a potential adsorbent for the removal of Cr(VI) from aqueous solutions. React Funct Polym 166:105000. https://doi.org/10.1016/J.REACTFUNCTPOLYM.2021.105000

Behera S, Mahanwar PA (2020) Superabsorbent polymers in agriculture and other applications: a review. Polym Technol Mater 59:341–356. https://doi.org/10.1080/25740881.2019.1647239

Damiri F, Kommineni N, Ebhodaghe SO et al (2022) Microneedle-based natural polysaccharide for drug delivery systems (DDS): progress and challenges. Pharmaceuticals 15:190. https://doi.org/10.3390/ph15020190

Damiri F, Rahman MH, Zehravi M et al (2022) MXene (Ti3C2Tx)-embedded nanocomposite hydrogels for biomedical applications: a review. Materials (Basel) 15:1666. https://doi.org/10.3390/ma15051666

Kim KK, Pack DW (2006) Microspheres for drug delivery. BioMEMS Biomed Nanotechnol. https://doi.org/10.1007/978-0-387-25842-3_2

Bhattacharya SS, Mazahir F, Banerjee S et al (2013) Preparation and in vitro evaluation of xanthan gum facilitated superabsorbent polymeric microspheres. Carbohydr Polym 98:64–72. https://doi.org/10.1016/J.CARBPOL.2013.05.011

Sadeghi M, Soleimani F (2011) Synthesis and characterization superabsorbent hydrogelsfor oral drug delivery systems. Int J Chem Eng Appl. https://doi.org/10.7763/IJCEA.2011.V2.125

In vitro testing of xanthan/lignin hydrogels as carriers for controlled delivery of bisoprolol fumarate. https://pubmed.ncbi.nlm.nih.gov/26793868/. Accessed 19 Jul 2022

Yang ST, Park YS (2018) Release pattern of dexamethasone after administration through an implant-mediated drug delivery device with an active plunger of super absorbent polymer. Drug Deliv Transl Res 8:702–707. https://doi.org/10.1007/S13346-018-0516-6

Rana D, Salave S, Benival D (2022) Emerging trends in abuse-deterrent formulations: technological insights and regulatory considerations. Curr Drug Deliv 19:846–859. https://doi.org/10.2174/1567201818666211208101035

Rana D, Salave S, Benival D (2021) Emerging trends in abuse-deterrent formulations: technological insights and regulatory considerations. Curr Drug Deliv 19:846–859. https://doi.org/10.2174/1567201818666211208101035

Mastropietro DJ, Muppalaneni S, Omidian H (2016) Deterred drug abuse using superabsorbent polymers. Expert Opin Drug Deliv 13:1523–1531. https://doi.org/10.1080/17425247.2016.1218459

Panahi Y, Gharekhani A, Hamishehkar H et al (2019) Stomach-specific drug delivery of clarithromycin using a semi interpenetrating polymeric network hydrogel made of montmorillonite and chitosan synthesis, characterization and in vitro drug release Study. Adv Pharm Bull 9:159–173. https://doi.org/10.15171/APB.2019.019

Relative bioavailability of risedronate sodium administered in superabsorbent copolymer particles versus oral solution to normal healthy rabbits. https://pubmed.ncbi.nlm.nih.gov/29638067/. Accessed 6 Jul 2022

Rana D, Salave S, Longare S et al (2021) Nanotherapeutics in tumour microenvironment for cancer therapy. Nanosci Nanotechnol Asia 12:32. https://doi.org/10.2174/2210681211666210908144839

Salave S, Rana D, Kumar H et al (2022) Anabolic peptide-enriched stealth nanoliposomes for effective anti-osteoporotic therapy. Pharmaceutics 14:2417. https://doi.org/10.3390/PHARMACEUTICS14112417/S1

Salave S, Rana D, Benival D (2022) Encapsulation of anabolic peptide in lipid nano vesicles for osteoporosis. Curr Protein Pept Sci 23:495–503. https://doi.org/10.2174/1389203723666220822120305

Soares S, Sousa J, Pais A, Vitorino C (2018) Nanomedicine: Principles, properties, and regulatory issues. Front Chem 6:360. https://doi.org/10.3389/FCHEM.2018.00360/BIBTEX

Lim LS, Rosli NA, Ahmad I et al (2017) Synthesis and swelling behavior of pH-sensitive semi-IPN superabsorbent hydrogels based on poly(acrylic acid) reinforced with cellulose nanocrystals. Nanomaterials 7:399. https://doi.org/10.3390/NANO7110399

Bartkowiakb G, Frydrych I (2011) Superabsorbents and their medical applications. Handbook of medical textiles. Elsevier, pp 505–546

Somers MJ, Alfaro JF, Lewis GM (2021) Feasibility of superabsorbent polymer recycling and reuse in disposable absorbent hygiene products. J Clean Prod 313:127686. https://doi.org/10.1016/j.jclepro.2021.127686

Azzam RAI (1983) Polymeric conditioner gels for desert soils. Commun Soil Sci Plant Anal 14:739–760. https://doi.org/10.1080/00103628309367404

Bhardwaj AK, Shainberg I, Goldstein D et al (2007) water retention and hydraulic conductivity of cross-linked polyacrylamides in sandy soils. Soil Sci Soc Am J 71:406–412. https://doi.org/10.2136/sssaj2006.0138

Johnson MS (1984) Effect of soluble salts on water absorption by gel-forming soil conditioners. J Sci Food Agric 35:1063–1066. https://doi.org/10.1002/jsfa.2740351004

Chang L, Xu L, Liu Y, Qiu D (2021) Superabsorbent polymers used for agricultural water retention. Polym Test 94:107021. https://doi.org/10.1016/j.polymertesting.2020.107021

Sharma S, Dua A, Malik A (2014) Polyaspartic acid based superabsorbent polymers. Eur Polym J 59:363–376. https://doi.org/10.1016/j.eurpolymj.2014.07.043

Bo Z, Renkuan L, Yunkai L et al (2012) Water-absorption characteristics of organic-inorganic composite superabsorbent polymers and its effect on summer maize root growth. J Appl Polym Sci 126:423–435. https://doi.org/10.1002/app.36652

Jin S, Wang Y, He J et al (2013) Preparation and properties of a degradable interpenetrating polymer networks based on starch with water retention, amelioration of soil, and slow release of nitrogen and phosphorus fertilizer. J Appl Polym Sci 128:407–415. https://doi.org/10.1002/app.38162

Taib M, Damiri F, Bachra Y et al (2022) Recent advances in micro- and nanoencapsulation of bioactive compounds and their food applications. Nanotechnology in intelligent food packaging. Wiley, pp 271–289

Wu L, Liu M, Liang R (2008) Preparation and properties of a double-coated slow-release NPK compound fertilizer with superabsorbent and water-retention. Bioresour Technol 99:547–554. https://doi.org/10.1016/j.biortech.2006.12.027

Damiri F, Bachra Y, Berrada M (2022) Synthesis and characterization of 4-formylphenylboronic acid cross-linked chitosan hydrogel with dual action: Glucose-sensitivity and controlled insulin release. Chin J Anal Chem 50:100092. https://doi.org/10.1016/j.cjac.2022.100092

Damiri F, Bachra Y, Bounacir C et al (2020) Synthesis and characterization of lyophilized chitosan-based hydrogels cross-linked with benzaldehyde for controlled drug release. J Chem 2020:1–10. https://doi.org/10.1155/2020/8747639

Zhan F, Liu M, Guo M, Wu L (2004) Preparation of superabsorbent polymer with slow-release phosphate fertilizer. J Appl Polym Sci 92:3417–3421. https://doi.org/10.1002/app.20361

Liang R, Yuan H, Xi G, Zhou Q (2009) Synthesis of wheat straw-g-poly(acrylic acid) superabsorbent composites and release of urea from it. Carbohydr Polym 77:181–187. https://doi.org/10.1016/j.carbpol.2008.12.018

Wu L, Liu M (2008) Preparation and properties of chitosan-coated NPK compound fertilizer with controlled-release and water-retention. Carbohydr Polym 72:240–247. https://doi.org/10.1016/j.carbpol.2007.08.020

Fouad D, Bachra Y, Ayoub G et al (2020) A novel drug delivery system based on nanoparticles of magnetite Fe3O4 embedded in an auto cross-linked chitosan. In: Chitin and Chitosan—physicochemical properties and industrial applications [Working Title]. IntechOpen

Wu L, Liu M (2007) Slow-release potassium silicate fertilizer with the function of superabsorbent and water retention. Ind Eng Chem Res 46:6494–6500. https://doi.org/10.1021/ie070573l

Bradford KJ (1990) A water relations analysis of seed germination rates. Plant Physiol 94:840–849. https://doi.org/10.1104/pp.94.2.840

Chirino E, Vilagrosa A, Vallejo VR (2011) Using hydrogel and clay to improve the water status of seedlings for dryland restoration. Plant Soil 344:99–110. https://doi.org/10.1007/s11104-011-0730-1