Abstract

A new green approach was developed in the present study to pre-activate and modify the cellulose/polyester blended fabrics surfaces using atmospheric plasma, as a green alternative to non-eco-friendly conventional chemical modification processes, followed by post-dyeing/functional finishing to obtain high value-added, multifunctional, protective and colored blended fabrics. The obtained results demonstrated that the imparted antibacterial and anti-UV functional properties and the increase in color strength are greatly improved owing to plasma pre-modification step. Type of plasma gas, O2− or N2−, blended substrate, cotton/polyester (C/PET) or viscose/polyester (V/PET), kind of coloring agent: pigment, basic dye or curcumin natural dye, as well as the chemical nature of functional additive: thyme oil, clove oil, lavender, tulsi, ginger, vanillin, ascorbic acid or salicylic acid, ZnO − or Al2O3− NPs have a significant impact on extent of coloration and bi-functionalization of the final products. The extent of surface modification as well degree of fixation and immobilization of the used coloring and functional agents as well as the durability to wash were confirmed by SEM & EDX analysis and washing test, respectively.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Cellulose-based textiles have many inherent desirable properties such as hydrophilicity, wettability, comfortability, biodegradability and softness [26, 34]. However, they lack antibacterial functionality, UV-blocking ability, and easy-care property [26]. Blending of cellulosic fibers like cotton and viscose with polyester (PET) fibers results in minimizing the total production costs and upgrading the performance and functional properties of the fabricated textiles quality [16].

On the other hand, there are many negative impacts and environmental concerns in the conventional textile wet processing industry, i.e., pretreatment, coloration, and chemical finishing stages, of cellulose-containing fabrics that negatively affect both the product and ecology quality and hinder its own sustainable development such as high clean water, energy and chemicals consumption along with the associated environmental hazards [10, 15, 21].

Recently, a great efforts and attention have been paid for the adoption and implementation of emerging, environmentally friendly and sustainable technologies such as plasma [1, 18], nano- [14, 17, 24], and/or bio-technologies [7, 10, 21] in textile wet processing industry taken into account product and environment quality, water-shortage and energy crisis, cleaner production principles, consumer demands and awareness for hygienic, durable, sustainable, high performance multifunctional, and fashionable textile products with high value-added to suit the ever-growing end use requirements, environmental, economic and social concerns [10, 26].

Therefore, it is expected that pre-surface modification and activation of blended substrates with appropriate plasma gas, as an eco-friendly, dry, energy efficient and economic green alternative to the conventional chemical finishing process [8, 25], followed by simultaneous dyeing and functional finishing in a single step using various dyestuffs along with selected functional additives and different functional finishing formulation constituents can be considered as a new strategy for surface modification, dyeing, and multifunctionalization of the blended fabrics to get textile products with advances or novel properties cope with both the textile user demands and the environmental requirements. To date, there are few articles focused on coloration and multifunctionalization of blended fabrics using emerging technologies [2, 3, 13, 19, 20, 25, 27, 32].

Herein, a new environmentally sound strategy has been adopted and implemented to develop multifunctionalized dyeings. A combination of atmospheric plasma preactivation, using O2- or N2-working gas, followed by post-treatment with different dyeing/functional finishing formulations in a 37- KHz sonicator bath at 50 W, squeezing and microwave fixation at 450 W for 6 min resulted in a remarkable improvement in the imparted antibacterial and UV-protection properties along with a significant increase in the color strength of the obtained dyeings. The change in the extent of functionalization and coloration was governed by type of coloring agent (pigment, basic dye or curcumin), kind of bio-active ingredient (thyme oil, clove oil, lavender, tulsi, ginger, vanillin, ascorbic acid, or salicylic acid) as well as metal oxide nanoparticles (ZnO NPs or Al2O3 NPs). The imparted functionalities, extent of dyeability and nitrogen content of the developed products were assessed, and the possible interactions among the preactivated substrates, additives and coloring agents were also proposed and discussed.

Experimental procedure

Mill-scoured and bleached cotton/polyester (C/PET, 50/50, 230 g/m2) and viscose/polyester (V/PET, 50/50, 220 g/m2) were used in this study.

Nano-Zinc Oxide (ZnO NPs, particle size 40–100 nm, APS powder Alfa Aesar, Germany), and nano-Aluminum Oxide (Al2O3 NPs, NanoArc ™ AL-0450, 50% in H2O colloidal dispersant, 45 nm APS, for dry powder, Alfa Aesar, Germany) were of commercial grade.

Environmentally sound pigment colorant namely Bezaprint® Blue Got (CHT, Bezema, Germany), Printofix® binder MTB01 EG Liq. (anionic binder based on self-crosslinking acrylate copolymer, Egcodar), Basic dye 18 (Aizen Cathilon Red GTLH, Astrazon Red GTL, Ciba) and curcumin (powder, 99.8% pure and anhydrous, Sigma-Aldrich, Germany) was used.

Ascorbic acid, salicylic acid, citric acid, Na- hypophosphite monohydrate (NaH2PO2), Ammonium persulfate ((NH4)2S2O8) and vanillin were of laboratory reagent grade.

All the used green functional additives based on natural products like thyme oil, lavender, clove oil, ginger oil, and tulsi oil were purchased from the local market.

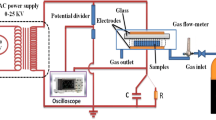

Plasma pretreatment

C/PET and V/PET blended fabrics were preactivated with atmospheric pressure plasma for 45 s through placing between the two electrodes of dielectric barrier discharge (DBD) plasma: power supply (20,000 Hz), frequency (50 W), output (5 kV) using N2– or O2– as working gas at fixed flow rate: 3L/min. [31].

Post-pigment dyeing and functional finishing

Immediately after O2-plasma pre-modification, the preactivated cotton/polyester (C/PET) and viscose/polyester (V/PET) blended fabric samples were post-dyed/functional finished in a single stage using the exhaustion technique with the following bath constituents:

Pigment (10 g/L), binder (20 g/L), (NH4)2S2O8 (2 g/L) alone and in combination with: Ascorbic acid (10 g/L), Thyme oil (20 g/L), Clove oil (20 g/L), Lavender (20 g/L), Tulsi (20 g/L), Ginger (20 g/L), Vanillin (20 g/L), ZnO NPs (10 g/L) or Al2O3 NPs (10 g/L) as active ingredient with an LR of 1/20 at 80 °C for 30 min in a 37-kHz sonicator bath at 50 W. The preactivated/dyed/finished fabric samples were then squeezed to wet pickup of 70% followed by microwave fixation at 450 W for 6 min, thoroughly washed to remove unfixed/unreacted constituents and finally, dried and conditioned before evaluation.

Post-basic dyeing and functional finishing

Immediately after O2-plasma pre-activation, the plasma-pretreated substrates were post-dyed with basic dye/functional finished simultaneously using the exhaustion method with the following bath ingredients:

Basic dye (2.5 g/L, citric acid (CA, 20 g/L), and NaH2PO2 (SHP, 10 g/L) in the absence and the presence of the following additive namely Tulsi (20 g/L), Vanillin (20 g/L), Ascorbic acid (10 g/L), Salicylic acid (10 g/L), ZnO NPs (10 g/L) or Al2O3 NPs (10 g/L) as active ingredient with an LR of 1/20 at 80 °C for 30 min in a 37-kHz sonicator bath at 50 W. The treated fabric samples were then squeezed to wet pickup of 70% followed by microwave fixation at 450 W for 6 min, thoroughly washed to remove unfixed/unreacted molecules and ingredients and finally, dried and conditioned before characterization and evaluation.

Post-curcumin dyeing and functional finishing

Immediately after N2-plasma pre-activation, the treated fabric samples were post-dyed/functional finished in one step using the exhaustion method with the following bath constituents:

Curcumin (2.5 g/L), CA (10 g/L), and SHP (5 g/L) alone and in combination with: Tulsi (20 g/L), Vanillin (20 g/L), Ginger (20 g/L), Ascorbic acid (10 g/L), Salicylic acid (10 g/L), ZnO NPs (10 g/L) or Al2O3 NPs (10 g/L), as functional additive, with an LR of 1/20 at 80 °C for 30 min in a 37-kHz sonicator bath at 50 W. The treated samples were then microwave fixed at 450 W for 6 min, thoroughly washed to remove unfixed finishing bath constituents, and finally dried and conditioned before evaluation.

Characterization

The surface morphology of selected fabric samples was observed using SEM Model Quanta SEM 250 FEG (Field Emission Gun) attached with EDX unit (Energy-Dispersive X-ray analysis with accelerating voltage – 30 kV FEI Co. Netherlands) for the surface composition analysis of MONPs-loaded fabric samples.

Testing

Nitrogen content (N%) of Treated fabric samples was evaluated by Kjeldahl method.

The antibacterial activity of untreated and post-treated fabric samples was tested by using plate count agar method according to the AATCC Test Method 100–1999. The reduction percentage of bacterial colonies was calculated using the following equation: R (%) = (B−A)/B × 100, where R% is the reduction percentage of bacterial colonies, A is the number of bacterial colonies on the agar plate for treated fabric, and B is the number of bacterial colonies on the agar plate of untreated one.

UV-protection factor (UPF) of both untreated and treated fabrics was assessed according to the Australian/New Zealand standard Method AS/NZS 4366–1996 and rated as follows: good (UPF: 15–24), very good (UPF:25–39), and excellent UV-protection (UPF˃ 40). The higher the UPF value, the better the UV-protecting efficacy.

Color strength (K/S) values of the obtained dyeings were calculated using kubelka–Munk equation: K/S = (1−R)2/2R, where K, S, R are absorption, scattering coefficient, and reflectance of colored fabrics, respectively, at maximum absorbance wavelength, respectively.

Durability to washing was determined according to AATCC Test method 2A-1996, after 10 launder cycles.

All the tests have performed in triplicate and presented as mean values.

Results and discussion

In the present study, cotton/polyester (C/PET) and viscose/polyester (V/PET) blended fabrics were preactivated and modified using O2- or N2- atmospheric plasma to enhance the extent of fixation of the used dyestuffs and immobilization of included bioactive ingredients and nano-metal oxides in the subsequent union dyeing and functional finishing treatments. The extent of coloration and multifunctionalization of the developed substrates was investigated as a function of type of plasma gas and substrate, kind of dye and bio-active ingredient as well as nanometal oxide additive.

Simultaneous pigment dyeing and functional finishing

As far as the change in % N, the extent of post-pigment dyeing, expressed as K/S value, the imparted antibacterial activity, expressed as R %, against both the G + ve (S. aureus) and G−ve (E.coli) pathogenic bacteria, as well as the UV-protection ability, expressed as UPF, as a function of type of blended substrate and kind of active ingredient, the data in Table 1 signify that incorporation of any of the used active ingredients along with pigment in the dyeing/finishing bath results in an increase in the % N, a remarkable improve in the K/S value, a noticeable increase in the imparted antibacterial activity against the tested harmful bacteria as well as a significant improve in the imparted UV-protection ability against the harmful UV-B radiation, keeping O2-plasma pretreatment step constant.

The extent of increase in post-pigment dyeing and functional finishing of O2-plasma premodified and activated substrates is governed by type of substrate, C/PET ˃ V/PET, as well as kind of active ingredient and a functional agent [16, 30].

The variation in the extent of post-coloration and functionalization of the treated substrates reflects their differences in fabric construction, fiber chemistry and hydrophilicity [34], extent of surface modification and preactivation by O2-plasma [20, 42], number, location and accessibility of created O2- containing reactive sites such as -OH, -C = O and -COOH groups [5, 42], which in turn affects fabric hydrophilicity, wettability as well as degree of fixation and immobilization of post-dyeing/finishing bath constituents, i.e., pigment molecules, binder, and functional additives, onto/within the fabric structure during the microwave fixation step [20, 33].

On the other hand, the variation in the performance and imparted antibacterial and anti-UV functional properties upon using various active ingredients namely Ascorbic acid, Thyme oil, Clove oil, Lavender, Tulsi, Ginger and Vanillin along with the pigment and binder in the union pigment dyeing/functional finishing bath could be discussed in terms of differences among them in number of active compounds and their concentration, chemical structure mode of interaction and fixation or entrapment along with pigment dye during microwave fixation step, extent of modification and functionalization of the preactivated substrate, antibacterial mechanism as well as UV-shielding, blocking and/or absorbing capability [29, 30].

Additionally, the obtained data in Table 1 signify that inclusion the aforementioned active ingredients along with binder, and pigment in the union dyeing and finishing bath not only imparts multifunctional properties namely antibacterial, anti-UV [4, 30, 46] to treated substrates but also acts as a dye provider or supporter and good fragrance in most cases. (except in case of using ascorbic acid as additive).

The extent of improvement in the imparted antibacterial activity of the obtained functional dyeings follows the decreasing order: G + ve (S. aureus)> G−ve (E.coli), keeping other parameters constant, which reflects their differences in their membrane structure as well as amenability to cell wall structure damage [11, 37, 44].

Union pigment dyeing and nano-finishing

As far as the change in the extent of post-pigment dyeing and nanofinishing of O2-plasma preactivated substrates as a function of type of blended substrate and kind of nano-metal oxide, i.e., ZnO NPs or Al2O3 NPs, the experimental data in Table 2 demonstrate that inclusion of ZnO NPs or Al2O3 NPs into post-pigment dyeing followed by sonication and microwave fixation results in a reasonable increase in % N, a significant improvement in the color strength, K/S, of the obtained dyeings along with outstanding enhance in the imparted antibacterial activity against both the G + ve (S. aureus) and G−ve (E.coli) bacteria and excellent UV-protection property, irrespective of the used substrate.

The variation in the aforementioned properties is governed by type of substrate as discussed earlier and follows the decreasing order: C/PET > V/PET, as well as kind of metal oxide nanoparticles, MONPs, and follows the descending order: ZnO NPs > Al2O3 NPs, keeping other parameters constant.

The improvement in both % N and K/S values upon using MONPs along with pigment and binder could be discussed in terms of the positive role of nanometal oxide particles, binding agent along with the created -COOH groups onto O2-plasma pre-treated fabric surface in enhancing the extent of pigment fixation and/or developing darker depth of color [19, 20] during the microwave fixation step, under acidic condition.

Additionally, the variation in the imparted antibacterial efficacy against the tested G + ve and G−ve bacteria upon using ZnO- or Al2O3- NPs as functional additive could be discussed in terms of their differences in: i) extent of fixation and immobilization onto the treated substrates during microwave fixation step, ii) ability to: damage the cell wall, disrupt bacterial membrane and inhibit the growth of the bacterial cell as in case of using Al2O3 NPs, iii) extent of deactivation of essential enzymes in bacterial cells, iv) generation of reactive oxygen species ROS, e.g., •OH, •O2–, H2O2, etc., through photocatalysis, as in case of using ZnONPs, and v) disruption of vital components, e.g., DNA, lipid, protein, etc., in bacterial cells via oxidative stress, which is turn results in the death of microbial cells [22, 48].

Moreover, the excellent improvement in UV- protection functionality of post-dyed/ nano-finished substrates could be attributed to the positive role of immobilized and fixed MONPs onto the developed substrates in refracting, scattering and blocking of the harmful UV-B radiation and hindering its transmittance from fabric to the textile user skin [34].

Post-basic dyeing and functional finishing

As far as the change in % N, K/S, R% and UPF values of O2-plasma pretreated substrates followed by cationic dyeing, the data in Table 3 reveal that: i) post-basic dyeing of O2-plasma-treated substrates results in an increase in % N, K/S, R% and UPF values, regardless of the used substrate, ii) the variation in these properties follows the decreasing order: C/PET > V/PET, keeping other parameters fixed, iii) The imparted antibacterial activity against both the G + ve and G−ve bacteria is attributed to the interaction between cationic active sites ( N+) of the used basic dye and the negatively charged cell membrane of pathogenic bacteria which is turn results in damaging of cell membrane, denaturing protein, inhibiting DNA and avoiding multiplication [28], and iv) the excellent protection against the harmful UV-B radiation reflects the positive role of fixed dye in absorbing and shielding the harmful UV-radiation thereby avoiding its negative impacts on human body [6, 28].

The experimental results in Table 3 demonstrate also that inclusion of Tulsi, Vanillin, Ascorbic acid or Salicylic acid, as functional additive, along with the basic dye is accompanied by an increase in %N, K/S, R% and UPF values regardless of the used substrate and follows the decreasing order: Basic dye + Salicylic acid ˃ Basic dye + Ascorbic acid > Basic dye + Tulsi > Basic dye + Vanillin > Basic dye alone. The variation in the imparted performance and functional properties of the developed basic dyed/functional finished substrates reflects the differences among the used additives in: chemical structure, active ingredients, extent of interaction and fixation during the microwave fixation step, its positive role in improving the extent of cationic dyeing, inherent functional properties, i.e., antibacterial action and UV-blocking absorbing and/or scattering effect [29, 30], which in turn affects the extent of modification and functionalization of the treated substrates.

The improvement in the imparted coloration and functionalization properties of O2-plasma treated substrates followed by combined basic dyeing and functional finishing using the abovementioned additives could be discussed as follows [20]:

where HO.Cell = cotton or viscose component.

Combined basic dyeing and nanofinishing

For a given set of O2-plasma pretreatment followed by subsequent union basic dyeing and nanofinishing using ZnO NPs or Al2O3 NPs, the experimental results, Table 4, successfully classify that inclusion of ZnO NPs or Al2O3 NPs into the cationic dyeing bath results in an increase in the %N, K/S, the imparted anti-bacterial activity, R%, as well as in UV-protection ability, regardless of the treated substrate. The enhancement in the aforementioned properties follows the decreasing orders:

Substrate: C/PET > V/PET,

N% and K/S values: Al2O3 NPs > ZnO NPs > None, and.

R% and UPF values: ZnO NPs >Al2O3 NPs >None, keeping other parameters constant.

The %N and K/S differences are attributed to the differences between the used MONPs in extent of catalyzation and fixation of the used cationic dye in the microwave fixation step [28]. On the other hand, the extent of loading ZnO NPs or Al2O3 NPs onto the O2-plasma pretreated substrate due to the generation of new active sites, especially polar -COOH groups, as well as the created -COOH groups as a direct consequence of ester crosslinking using CA/SHP system which could attach and anchor the MONPs as follows [22, 25, 38, 40]:

On the other hand, fixation and entrapment of the used MONPs via the cationic active sites in the dye structure during cationic dyeing and nano-finishing step cannot be ruled out.

On the other hand, the remarkable improvement in the imparted antibacterial activity of simultaneously basic dyed and nanofinished substrates is ascribed to: i) introduction of cationic active site N+, onto the dyed substrate, ii) photo-catalysis activity of the loaded ZnO-NPs onto fabric surface which in turn Leads to generation of highly reactive oxygen species, ROS, e.g., •OH, •O2, H2O2, etc., as follows [22]:

which in turn causes the disruption of vital bacterial cell components, e.g., protein, DNA, lipids, etc., via oxidative stress, iii) disruption of the bacterial membrane by MONPs, and/or iv) interaction between thiol groups and ZnO-NPs thereby deactivating of essential enzymes in the pathogenic bacterial cell [36].

Additionally, the variation in the imparted antibacterial functionality is governed by type of MONPs and mode of action, by generation of ROS as in case of using ZnO-NPs as mentioned before or by inhibiting the production of ROS as in case of using Al2O3-NPs [39]. The imparted antibacterial activity in case of using Al2O3-NPs is ascribed to its binding ability onto the bacterial cell wall, thereby causing its damage followed by subsequent penetration into the cell which in turn negatively affects and inhibits the growth of the bacterial cell.

The data in Table 4 also signify that inclusion of ZnO-NPs or Al2O3-NPs along with the dyeing/nanofinishing formulation results in a remarkable increase in UPF value, regardless of the used substrate as a direct consequence of increasing the UV-blocking and shielding efficacy along the positive role of the used basic dye in upgrading the UV-absorption capacity [22, 28].

Post-curcumin dyeing and functional finishing

For a given set of N2-plasma pretreatment and subsequent natural dyeing using curcumin dye and functional finishing, the results in Table 5 demonstrate that i) N2-plasma pretreatment results in an increase in the %N, an improve in antibacterial activity due to the created cationic sites, -NH2 groups, at fabric surface as well as an improve in UPF values, irrespective of the used substrate, and ii) the extent of variation in these properties is governed by type of substrate and follows the decreasing order: C/PET ˃ V/PET.

Inclusion of Tulsi, Vanillin or Ginger along with other constituents in curcumin dyeing bath, i.e., CA + SHP, is accompanied by an increase in the %N, K/S of the obtained dyeings, a noticeable improvement in the imparted antibacterial activity against both the G + ve (S. aureus) and G−ve (E.coli) bacteria along with an excellent increase in the UPF values of the obtained natural dyed/functional finished substrates, regardless of the used fabric blend. The variation in the aforementioned properties reflects the differences among the included active ingredients in: chemical structure, active ingredients such as: eugenol, carvacrol, methyl eugenol, B-caryophyllene and oleanolic acid ingredients in Tulsi [41], active phenolic groups in Vanillin [29], and α-pinene, borneol, camphere and linalool in Ginger [47] and their antibacterial activity and UV-blocking and/or absorbing ability [12, 35], mode of interaction with other constituents in dyeing/functional finishing formulation during the microwave fixation step [30].

It is also observed that incorporation of ascorbic or salicylic acid in post-dyeing/functional finishing bath results in an increase in the % N, K/S values along with a remarkable improvement in the imparted antibacterial activity and anti-UV functionality of the developed substrates. The extent of coloration and functionalization is governed by type of acid as discussed earlier, and mode of interaction and extent of damaging the tested bacteria. The antibacterial effect of ascorbic acid is ascribed to its ability to act as a barrier for oxygen availability to the tested pathogenic bacterial [9]. However, the damaging effect of phenolic compound on the DNA is believed to be responsible for the antibacterial activity of salicylic acid [23, 45].

It can be included that creation of cationic active sites -NH2 groups, by N2-plasma pre-modification [20, 25], fixation of curcumin dyestuff onto the preactivated substrate via ionic attraction and Van der Waals forces [49], antibacterial activity of methoxy and hydroxyl active groups of fixed curcumin dye [43], along with the loaded bioactive ingredients during the microwave fixation step under acidic condition exhibited a remarkable improvement in extent of coloration, antibacterial and anti-UV functionalization of the developed products.

Combined curcumin dyeing and nano-finishing

As far as the change in %N, K/S, R% and UPF values of simultaneously dyed and nano-finished substrates after N2-plasma pre-modification, the data in Table 6 signify that: i) curcumin dyeing of N2-plasma pre-treated substrates results in an increase in K/S, antibacterial activity and anti-UV properties of the simultaneously dyed and nano-finished substrates, ii) the enhancement in the aforementioned properties is attributed to fixation of curcumin dye with its methoxyl and hydroxyl groups onto the obtained products via ionic attraction and Van der Waals forces which in turn positively affects dye fixation and functionalization iii) inclusion of ZnO or Al2O3-NPs along with other constituents in the dyeing/finishing formulation brings about a slight increase in %N, a noticeable increase in the K/S value, along with a remarkable improve in the imparted antibacterial and UV- shielding property of the developed products. The extent of improvement in the imparted properties is governed by kind of MONPs, i.e., ZnO NPs > Al2O3 NPs, as well as type of blended fabric, i.e., C/PET/V/PET, keeping other parameters fixed, as discussed before.

Cationic modification of blended substrates by N2-plasma, as well as ester-crosslinking via CA/SHP during microwave fixation step, enhance bonding of curcumin dye/MONPs and fixation of the curcumin/MO nanocomposites onto and/or within the fabric structure, which in turn positively affects the extent of simultaneous coloration and functionalization of the dyed/finished substrates [20, 28].

SEM and EDX analysis

Figures 1, 2, 3 and 4 (a and c) show the surface morphology of untreated C/PET and V/PET fabric samples as well as plasma preactivated, post-dyed/functional finished fabric samples (Figs. 2, 3, and 4). While the untreated ones (Fig. 1 a and c) showed a smooth and even surfaces, preactivated post-dyed/functional finished fabric samples show a noticeable change to the surface morphology regardless of the used substrate, dye type and kind of MONPs. The extent of variation in the surface morphology of treated fabric samples is governed by type of substrate, extent of pre-activation and modification by plasma gas, surface morphology, location and extent of dye fixation as well as MONPs immobilization onto the preactivated substrates during the microwave fixation step.

On the other hand, EDX analysis of premodified post-dyed/functional finished fabric samples showed clearly the presence of carbon, oxygen, nitrogen elements along with Zn or Al element as shown in Figs. 2, 3 and 4 (b & d), which in turn confirms the fixation of the used dye along with ZnO NPs or Al2O3 NPs on the developed dyed/functional finished substrates especially during the microwave fixation step.

Durability to wash

As shown in Table 7, increasing washing cycle up to 10 is accompanied by a slight or a reasonable decrease in nitrogen content (%N), color strength (K/S), as well as in the imparted antibacterial (R%) and UV-blocking (UPF) properties of the selected substrates, regardless of the used finishing regime. The higher is the extent of pre-modification and subsequent fixation/immobilization of the used coloring agent and the MONPs, the better is the durability to wash.

The experimental results demonstrate again that the suggested strategy for preactivation of the blended substrates with O2- or N2-plasma followed by subsequent coloration and functionalization in a single stage develops various colored/multifunctionalized cellulosic blends with a remarkable functionality and durability even after 10 laundering cycles. The extent of improvement in coloration, functionalization and durability to wash is governed by type of blended fabric, kind of plasma gas as well as constituents of union dyeing/functionalizing formulation as discussed earlier.

Conclusion

The main task of the present work is to explore the feasibility of using O2- or N2-plasma as an eco-friendly tool for preactivation and surface-modification of C/PET and V/PET blended fabrics followed by subsequent pigment, basic or curcumin dyeing and functional finishing in one step, to develop various colored/multifunctional textile products taking in consideration both the product and ecology quality as well as the ever-growing consumer demands. The functional additives considered were Thyme oil, Clove oil, Lavender oil, Tulsi, Ginger, Vanillin, Ascorbic acid, Salicylic acid, ZnO NPs and Al2O3 NPs.

The data so obtained demonstrate that plasma pretreatment followed by simultaneous coloration and functionalization results in a remarkable enhancement in the imparted antibacterial and anti-UV protection functions to the obtained dyeings. The variation in the extent of coloration and functionalization of the developed textile products is governed by type of blended fabric, kind of plasma gas, as well as the used dye and functional agent chemistry.

Also, SEM and EDX analysis for selected untreated and treated fabric samples confirm both the change in surface morphology as well as deposition and immobilization of the used color and active ingredients onto the premodified, dyed/functional finished surface.

References

Abd Jelil R (2015) A review of low-temperature plasma treatment of textile materials. J Mater Sci 50:5913–5943

Abdel-Aziz MS, Eid BM, Ibahim NA (2014) Biosynthesized silver nanoparticles for antibacterial treatment of cellulosic fabrics using O2-Plasma AATCC. J Res 1:6–12

Ahmed H, Ahmed K, Mashaly H, El-Halwagy A (2017) Treatment of cotton fabric with dielectric barrier discharge (DBD) plasma and printing with cochineal natural dye. Indian J Sci Technol 10:1–10

Balasubramanian K, Kodam KM (2014) Encapsulation of therapeutic lavender oil in an electrolyte assisted polyacrylonitrile nanofibres for antibacterial applications RSC. Advances 4:54892–54901. https://doi.org/10.1039/c4ra09425e

Caschera D et al (2014) Effects of plasma treatments for improving extreme wettability behavior of cotton fabrics. Cellulose 21:741–756

Chaudhary H, Gupta D, Gupta C (2017) Multifunctional dyeing and finishing of polyester with Sericin and Basic dyes. J Text Inst 108:314–324

Chen J, Wang Q, Hua Z, Du G (2007) Research and application of biotechnology in textile industries in China. Enzyme Microb Technol 40:1651–1655. https://doi.org/10.1016/j.enzmictec.2006.07.040

Dave H, Ledwani L, Nema SK (2019) Nonthermal plasma: a promising green technology to improve environmental performance of textile industries. In: Butola BS (ed) The impact and prospects of green chemistry for textile technology. Woodhead Publishing, Elsevier

Edwards JV et al (2022) Ascorbic acid as an adjuvant to unbleached cotton promotes antimicrobial activity in spunlace nonwovens. Int J Mol Sci 23:3598

Eid BM, Ibrahim NA (2021) Recent developments in sustainable finishing of cellulosic textiles employing biotechnology. J Clean Product. https://doi.org/10.1016/j.jclepro.2020.124701

Fayaz AM, Balaji K, Girilal M, Yadav R, Kalaichelvan PT, Venketesan R (2010) Biogenic synthesis of silver nanoparticles and their synergistic effect with antibiotics: a study against gram-positive and gram-negative bacteria Nanomedicine: nanotechnology. Biol Med 6:103–109

Ghosh J (2021) Development of UV protective finished fabric using herbal synthesized colloidal solution of silver nanoparticles. J Inst Eng. https://doi.org/10.1007/s40034-021-00228-y

Gorjanc M, Jazbec K, Šala M, Zaplotnik R, Vesel A, Mozetič M (2014) Creating cellulose fibres with excellent UV protective properties using moist CF4 plasma and ZnO nanoparticles. Cellulose 21:3007–3021. https://doi.org/10.1007/s10570-014-0284-5

Harifi T, Montazer M (2012) Past, present and future prospects of cotton cross-linking: new insight into nano particles. Carbohydr Polym 88:1125–1140. https://doi.org/10.1016/j.carbpol.2012.02.017

Hasanbeigi A, Price L (2015) A technical review of emerging technologies for energy and water efficiency and pollution reduction in the textile industry. J Clean Prod 95:30–44. https://doi.org/10.1016/j.jclepro.2015.02.079

Ibrahim NA (2011) Dyeing of textile fibre blends. In: Clark M (ed) Handbook of textile and industrial dyeing. Woodhead Publishing, UK

Ibrahim NA (2015) Nanomaterials for antibacterial textiles. In: Rai M, Kon K (eds) Nanotechnology in diagnosis, treatment and prophylaxis of infectious diseases. Elsevier Publisher, UK, pp 191–216

Ibrahim NA, Eid BM (2020) Plasma treatment technology for surface modification and functionalization of cellulosic fabrics. In: Shahid M, Adivarekar R (eds) Advances in functional finishing of textiles. Springer Singapore, Singapore

Ibrahim NA, Eid BM, Abdel-Aziz MS (2016) Green synthesis of AuNPs for eco-friendly functionalization of cellulosic substrates. Appl Surf Sci 389:118–125. https://doi.org/10.1016/j.apsusc.2016.07.077

Ibrahim NA, Eid BM, Abdel-Aziz MS (2017) Effect of plasma superficial treatments on antibacterial functionalization and coloration of cellulosic fabrics. Appl Surf Sci 392:1126–1133. https://doi.org/10.1016/j.apsusc.2016.09.141

Ibrahim NA, Eid BM, Amin HA (2021) Chapter 27 - Sustainable textile finishing processes and pollution control based on enzyme technology. In: Ibrahim N, Hussain CM (eds) Green chemistry for sustainable textiles. Woodhead Publishing, Cambridge

Ibrahim NA, Eid BM, El-Aziz EA, Elmaaty TMA, Ramadan SM (2017) Loading of chitosan – Nano metal oxide hybrids onto cotton/polyester fabrics to impart permanent and effective multifunctions. Inter J Biol Macromol 105:769–776. https://doi.org/10.1016/j.ijbiomac.2017.07.099

Ibrahim NA, Eid BM, El-Zairy EM, Emam E, Barakat S (2019) Environmentally sound approach for imparting antibacterial and UV-protection functionalities to linen cellulose using ascorbic acid. Int J Biol Macromol 135:88–96

Ibrahim NA, Eid BM, Fouda MMG (2021) Chapter 29 - The potential use of nanotechnology for antimicrobial functionalization of cellulose-containing fabrics. In: Ibrahim N, Hussain CM (eds) Green chemistry for sustainable textiles. Woodhead Publishing, Cambridge

Ibrahim NA, Eid BM, Hashem MM, Refai R, El-Hossamy M (2010) Smart options for functional finishing of linen-containing fabrics. J Ind Text 39:233–265. https://doi.org/10.1177/1528083709103144

Ibrahim NA, Eid BM, Sharaf SM (2019) Functional finishes for cotton‐based textiles: current situation and future trends. In: Shabbir M (ed) Textiles and clothing. Wiley, pp 131–190. https://doi.org/10.1002/9781119526599.ch7

Ibrahim NA, Eid BM, Youssef MA, El-Sayed SA, Salah AM (2012) Functionalization of cellulose-containing fabrics by plasma and subsequent metal salt treatments. Carbohyd Polym 90:908–914. https://doi.org/10.1016/j.carbpol.2012.06.019

Ibrahim NA, Eid BM, Youssef MA, Ibrahim HM, Ameen HA, Salah AM (2013) Multifunctional finishing of cellulosic/polyester blended fabrics. Carbohyd Polym 97:783–793. https://doi.org/10.1016/j.carbpol.2013.05.063

Ibrahim NA, El-Ghany NAA, Eid BM, Mabrouk EM (2018) Green options for imparting antibacterial functionality to cotton fabrics. Int J Biol Macromol 111:526–533

Ibrahim NA, El-Zairy EM, Eid BM, Abd Allah SS, Emam E-AM (2021) Durable surface functionalisation and pigment coloration of cellulosic fabrics using bioactive additives. Colorat Technol. https://doi.org/10.1111/cote.12555

Ibrahim NA, Hashem MM, Eid MA, Refai R, El-Hossamy M, Eid BM (2010) Eco-friendly plasma treatment of linen-containing fabrics. J Text Inst 101:1035–1049. https://doi.org/10.1080/00405000903205467

Irfan M et al (2019) Antibacterial, highly hydrophobic and semi transparent Ag/plasma polymer nanocomposite coating on cotton fabric obtained by plasma based co-deposition. Cellulose 26:8877–8894. https://doi.org/10.1007/s10570-019-02685-6

Kim TNT, Vu Thi Hong K, Vu Thi N, Vu Manh H (2021) The effect of DBD plasma activation time on the dyeability of woven polyester fabric with disperse dye. Polymers 13:1434

Koh J (2011) Dyeing of cellulosic fibres. Handbook of textile and industrial dyeing. Elsevier, pp 129–146. https://doi.org/10.1533/9780857094919.1.129

Lo Nostro P, Fratoni L, Baglioni P (2002) Modification of a cellulosic fabric with β-cyclodextrin for textile finishing applications. J Incl Phenom Macrocycl Chem 44:423–427

Mahawar H, Prasanna R (2018) Prospecting the interactions of nanoparticles with beneficial microorganisms for developing green technologies for agriculture environmental nanotechnology. Monitor Manag 10:477–485. https://doi.org/10.1016/j.enmm.2018.09.004

Mai-Prochnow A, Clauson M, Hong J, Murphy AB (2016) Gram positive and gram negative bacteria differ in their sensitivity to cold plasma. Sci Rep 6:38610. https://doi.org/10.1038/srep38610

Palaskar S, Desai A, Shukla S (2016) Development of multifunctional cotton fabric using atmospheric pressure plasma and nano-finishing. J Text Inst 107:405–412

Popescu MC et al (2019) Antibacterial efficiency of cellulose-based fibers covered with ZnO and Al2O3 by atomic layer deposition. Appl Surf Sci 481:1287–1298. https://doi.org/10.1016/j.apsusc.2019.03.268

Radetić M, Marković D (2022) A review on the role of plasma technology in the nano-finishing of textile materials with metal and metal oxide nanoparticles. Plasma process Polymer 19:2100197

Ravindra KB, Murugesh Babu K (2016) Study of antimicrobial properties of fabrics treated with ocimum sanctum l (tulsi) extract as a natural active agent. J Nat Fib 13:619–627. https://doi.org/10.1080/15440478.2015.1093577

Ražić SE, Čunko R, Bautista L, Bukošek V (2017) Plasma effect on the chemical structure of cellulose fabric for modification of some functional properties. Proced Eng 200:333–340. https://doi.org/10.1016/j.proeng.2017.07.047

Reddy N, Han S, Zhao Y, Yang Y (2013) Antimicrobial activity of cotton fabrics treated with curcumin. J Appl Polym Sci 127:2698–2702

Semeniuc CA, Pop CR, Rotar AM (2017) Antibacterial activity and interactions of plant essential oil combinations against Gram-positive and Gram-negative bacteria. J Food Drug Anal 25:403–408. https://doi.org/10.1016/j.jfda.2016.06.002

Tajkarimi M, Ibrahim SA (2011) Antimicrobial activity of ascorbic acid alone or in combination with lactic acid on Escherichia coli O157:H7 in laboratory medium and carrot juice. Food Control 22:801–804

Vijayalakshmi D, Ramachandran T (2015) A Study on The Anti-Bacterial Property Of Essential Oils And Metal Oxides In Denim Garments International. J Text Fashion Technol 5:49–54

Yadav S, Sharma PK, Alam MA (2016) Ginger medicinal uses and benefits. Europ J Pharm Med Res 3:127–135

Zarrindokht E-K, Pegah C (2011) Antibacterial activity of ZnO nanoparticle on gram-positive and gram-negative bacteria. African J Microbiol Res 5:1368–1373

Zemljič LF, Volmajer J, Ristić T, Bracic M, Sauperl O, Kreže T (2014) Antimicrobial and antioxidant functionalization of viscose fabric using chitosan–curcumin formulations. Text Res J 84:819–830

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB). This research did not receive any specific grant from funding agencies.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have declared that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Ibrahim, N.A., Eid, B.M., El-Zairy, E.M. et al. Development of eco-friendly colored/multifunctionalized cellulose/polyester blended fabrics using plasma preactivation and subsequent coloration/multifunctionalization in single stage. Polym. Bull. 80, 12353–12372 (2023). https://doi.org/10.1007/s00289-022-04653-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-022-04653-w