Abstract

Cationic polymerization of ɛ-caprolactone (CL) mediated by anhydrous iron (III) chloride (FeCl3) or FeCl3/nH2O systems (where n = 2, 4, 6 and 8) was investigated. Reaction proceeded in tetrahydrofuran solution at room temperature. Analysis of polymers by MALDI-TOF technique revealed in both cases the formation of linear  as well as cyclic PCLs macromolecules. It was proposed, that in the presence of anhydrous FeCl3 polymerization occurs by active chain end (ACE) mechanism accompanied by inter- and intramolecular transesterification, the latter leads to the formation of cyclic macromolecules. However, in the systems containing water two mechanisms operate simultaneously, i.e. ACE ones and activated monomer (AM) mechanism mediated witch FeCl3 (catalyst)/H2O (initiator) system, which prevails and results exclusively in linear macromolecules. Unexpectedly, methanol and dipropylene glycol used as hydroxylic additives to FeCl3/6H2O system were inert in the polymerization. Moreover, synthesized polymers appeared to be polymodal. The results obtained differ strongly from reported previously. The course of the studied processes was discussed. Molar masses and dispersities of polymers were determined by means of size exclusion chromatography (SEC). 13C nuclear magnetic resonance (NMR) was also used for analysis of the polymers. Thermal properties of the polymers obtained were also examined. Wide angle X-ray scattering was used to characterize phase composition of PCL.

as well as cyclic PCLs macromolecules. It was proposed, that in the presence of anhydrous FeCl3 polymerization occurs by active chain end (ACE) mechanism accompanied by inter- and intramolecular transesterification, the latter leads to the formation of cyclic macromolecules. However, in the systems containing water two mechanisms operate simultaneously, i.e. ACE ones and activated monomer (AM) mechanism mediated witch FeCl3 (catalyst)/H2O (initiator) system, which prevails and results exclusively in linear macromolecules. Unexpectedly, methanol and dipropylene glycol used as hydroxylic additives to FeCl3/6H2O system were inert in the polymerization. Moreover, synthesized polymers appeared to be polymodal. The results obtained differ strongly from reported previously. The course of the studied processes was discussed. Molar masses and dispersities of polymers were determined by means of size exclusion chromatography (SEC). 13C nuclear magnetic resonance (NMR) was also used for analysis of the polymers. Thermal properties of the polymers obtained were also examined. Wide angle X-ray scattering was used to characterize phase composition of PCL.

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Poly (ɛ-caprolactone) (PCL) is one of the most important synthetic polymers due to wide possibilities of applying, mainly to fabrication of fibriles and for potential medical applications. PCL has uses in different fields such as scaffolds in the tissue engineering [1,2,3,4], in long-term drug delivery systems [5,6,7], in microelectronics [8], as adhesives [9] and in packaging [10]. It is semicrystalline polymer [11], which advantage is ease utilization by biodegradation [1,2,3,4,5,6,7,8,9,10]. PCL is synthesized by polycondensation of 6-hydroxycaproic acid [12] as well as ring-opening polymerization (ROP) of CL, i.e. anionic, cationic and coordinative ones [13]. The main classes of initiators used are alkali-based compounds (e.g. potassium hydroxide [14], potassium t-butoxide [14, 15], potassium hydride [14], lithium diisopropyl amide [16, 17] or phenyllithium [18]), alkaline, earth-based compounds (e.g. magnesium alkoxide complexes [19,20,21], calcium ammoniate [22,23,24] or strontium ammoniate isopropoxide [25], poor metal-based compounds (e.g. aluminium [26,27,28,29,30,31,32,33,34,35,36,37,38,39,40,41,42,43,44,45,46,47,48] or tin-based compounds [49,50,51,52,53,54,55,56,57,58,59,60,61,62], transition metal-based compounds (e.g. zinc mono- and di-alkoxides [63], zirconium (IV) acetylacetonate [94], iron (III) alkoxide complexes [64] and titanium complexes based on catechol ligands [65] or bisphenolate ligands[66], and rare earth metal-based compounds (e.g. scandium, yttrium, lanthanium, neodymium, cerium, gadolinium, and lutetium triflates [67,68,69,70,71,72,73,74,75] as catalysts with ethanol, butanol, and other hydroxylic compounds as initiators). Even organic compounds as aza-compounds [76, 77], phosphazene bases [78, 79] and various carboxylic acids, as lactic acid, tartaric acid in the presence of benzyl alcohol [80, 81] as well as enzymatic systems [82,83,84,85,86,87] can initiate the ROP of CL. However, at present metal-based compounds have been studied the most. Recently [88], simple hydrated iron group chlorides, i.e. FeCl3/6H2O, FeCl3/4H2O and RuCl3/H2O were used for cationic CL polymerization in bulk or toluene solution. Mechanism of this process was determined as activated monomer (AM) ones, in which metal chloride, as Lewis acid, is catalyst and H2O or H2O/ROH are initiators. In this paper we reported new data concerning polymerization of CL mediated by anhydrous or hydrated FeCl3 in tetrahydrofuran (THF) solutions at room temperature. We changed toluene to polar THF in order to observe its influence on polymerization. The aim of this wok was determination of water effect on the process performed at various FeCl3/H2O ratios. The effect of ROH added was also discused. Several mechanisms of processes were proposed basing of polymers analysis by MALDI-TOF and NMR techniques. Moreover, thermal properties of the prepared polymers were also examined.

Experimental

Materials

ɛ-Caprolactone (CL) was purchased from Aldrich, dried and distilled prior to use. Methanol and dipropylene glycol (DPG) (ALDRICH) were used after drying by molecular sieves. Water was distilled twice before use. Anhydrous FeCl3 and FeCl3·6H2O were purchased from Aldrich and used as received. Anhydrous tetrahydrofuran (THF) (Acros Organics) was distilled over K/Na alloy prior to use. All materials were storage in glass ampoules equipped with Teflon valves under argon atmosphere at room temperature.

Polymerization procedure

All experiments were carried out at [CL]o = 5.0 and [FeCl]o = 0.01 mol/dm3 in the presence of various amounts of H2O and also MeOH or DPG as additives in some cases. For example, anhydrous FeCl3 (0.0324 g, 0.19 mmol) was introduced into a glass reactor (50 cm3) with two Teflon valves, filled by dry argon and THF (9.0 cm3) was then added. Next, H2O (0.021 g, 1.17 mmol) was added by microsyringe and mixed vigorously by magnetic stirred for 10 min at room temperature. Finally, CL (11.0 g, 0.877 mol) was slowly added to the system and mixed for 10 h. Arise in viscosity was observed and finally the stirring ceased. After the specified time, i.e. 170 h the reaction mixture was quenched by small amount of wet THF. The polymer was precipitated by pouring the mixture in cold n-hexane, filtered and further dried in vacuum at 60 °C for 20 h.

Measurements

100 MHz 13C nuclear magnetic resonance (NMR) spectra were recorded in CDCl3 at 25 °C on a BrukerAvance 400 pulsed spectrometer equipped with 5 mm broad-band probe and applying Waltz16 decoupling sequence. Chemical shifts were referenced to an internal standard (TMS). To reveal microstructural details of the polymer main chain high quality spectrum must be recorded with 3000 scans being satisfactory amount, however to observe the signals of the polymer chain ends more than 10,000 scans was necessary.

Molar masses and dispersities of polymers were determined by means of size exclusion chromatography (SEC) on a Shimadzu Prominance UFLC instrument at 40 °C on a Shodex 300 mm × 8 mm OHpac column using tetrahydrofuran as a solvent. PSs were used as calibration standards.

Molar masses and dispersities were also determined by SEC with a Viscotek GPC Max VE 2001 and a Viscotek TDA 305 triple detection (refractometer, viscosimeter, and low angle laser light scattering). The OmniSec 5.12 was used for data processing. The apparatus was used in the triple detection mode, and absolute molecular weights and dispersities obtained with calibration with a polystyrene standard.

Matrix-assisted laser desorption/ionization-time of flight (MALDI-TOF) spectra were recorded on a Shimadzu AXIMA Performance instrument with dithranol used as a matrix.

Differential Scanning Calorimetry (DSC) was performed using the Mettler Toledo apparatus. Samples were heated, cooled and reheated with a speed of 10 °C/min, in the temperature range of −100–120 °C. The DSC curves taken for the analysis were obtained from the second run. Temperature calibration was performed with indium (melting temperature = 156.6 °C), heat of fusion (∆Hf = 28.5 J/g).

Phase composition investigations of materials were performed by powder X-ray diffraction (XRD) method using a Empyrean Panalytical diffractometer and CuKα (λ = 0.1542 nm) radiation equipped with PIXcel3D detector. The data collection was over the 2-theta range of 5°–100° in of 0.02° steps.

The phase content of each sample was calculated from the XRD scattering profiles with peak deconvolution method using the Origin OriginLab 2020b software. We used the fitting method with Gaussian profiles assumed for all scattering peaks and halos as proposed by Stoclet et al. [89]. The content of each phase (amorphous and crystalline) was calculated based on the area under the diffraction peaks by calculating the ratio from one phase to the total scattering peaks. XRD scans were taken at room temperature.

Spectrophotometer measurements were performed on the FTIR ATR device (Shimadzu IR Prestige) equipped with diamond ATR crystal purified prior to measurement with i-propanol. Data were analyzed using the LabSolutions program.

Results and discussion

Several PCLs were synthesized at the same [CL]o/[FeCl3]o (monomer/catalyst) molar ratio, i.e. 500/1 without additives and with various initiators at different initial concentrations. The chemical structure of the polymers obtained was analyzed by MALDI-TOF spectrometry and 13C NMR spectroscopy. Molar masses and dispersities of polymers were determined by SEC chromatography and, comparatively, in one case also by light scattering (LS) technique.

Structural analysis and mechanistic considerations

Polymerization of CL catalyzed by anhydrous FeCL3

In 2009 Chakraborty et al. [88] reported, that anhydrous FeCl3 alone, as Lewis acid can be used catalytically for the bulk polymerization of CL at 27 °C. The polymer prepared at [CL]o/[FeCl3]o = 200/1 ratio has appreciably high Mn = 19 400 (measured by SEC relative to polystyrene standards with Mark-Houwink corrections for Mn in the case of CL polymerizations [90]) in the relation to Mn (calcd) = 22,800. Polymer is unimodal with relatively high dispersity (Mw/Mn = 1.87). After 1 h the yield was 100%. However, the course of the process was not proposed. Therefore, we performed this polymerization at room temperature using THF as a solvent. At [M]o = 2.0 and [Cat]o = 0.1 mol/dm3 after 150 h only oligomers and unreacted monomer were found solubilized in the reaction mixture. However, at much higher initial concentration of monomer and lower concentration of catalyst trimodal polymer was obtained (Table 1). SEC chromatogram of polymer (2) was shown in Fig. 1.

The chromatogram shows two main polymer’s fractions and low molar-mass tail. This phenomenon was unexpected and needs further studies. Comparatively, the result of analysis of this polymer by light scattering was presented below in Fig. 2. This method gives real molar mass values, however, none data concerning modality of polymer.

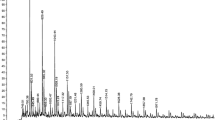

In order to determine chemical structure of the polymer several techniques, i.e. MALDI-TOF, NMR and FTIR were applied. Figure 3 presents MALDI-TOF spectrum of PCL (2).

MALDI-TOF spectrum reveals two main series of signals. First one containing signals with higher intensity at m/z 839.2 to 4284.7 represents polyester macromolecules with carboxyl and hydroxyl end groups. For example, signals at m/z 1067.4, 1752.3 and 3006.3 belongs to macromolecules containing 9,15 and 26 mers of CL as well as H and OH derived from initiator. They form adducts with Na+ ions. (Mcalcd = 1068.3, 1753.1 and 3008.0 respectively). The second series reveals the signals with much lower intensity at m/z 795.8–2989.3. They presumably represent cyclic PCL macromolecules, which form adducts with H+ ions. For example, signals at m/z 1138.2, 1708.7 and 2392.2 belong to cycles with 10, 15 and 21 mers od CL (Mcalcd = 1142.4, 1712.9 and 2397.5, respectively).

13C NMR spectrum shows high signals of carbon atoms derived. From CL mers at 24.7, 25.7, 28.5, 34.3, 64.3 and 173.7 ppm and confirm the presence of—CH2OH (62.7 ppm) and—CH2COOH (33.4 ppm) end groups in linear macromolecules of the synthesized polymer (2) (Fig. 4).

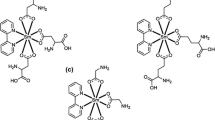

Basing on the results obtained we proposed the course of CL polymerization catalyzed by anhydrous FeCl3 (Scheme 1). In the first step exocyclic oxygen atom of the monomer attacks the catalyst. The propagation proceeds according to the principal mechanism of the cationic ROP of oxygen-containing heterocyclic monomers called active chain end (ACE) mechanism by nucleophilic attack of oxygen atom in monomer on α-carbon atom in tertiary oxonium ion located at the growing chain end. The process occurs by alkyl-oxygen bond cleavage and is accompanied by inter- and intramolecular transesterifications as side transfer reactions. The former leads to linear products and caused increasing of polymer dispersity. The second one occurs by back-biting and/or end-to-end closure resulting in the formation of cyclic macromolecules and great decreasing of molar masses.

We considered also other mechanism of this process, involving attack of the endocyclic oxygen atom of CL on FeCl3 catalyst (Scheme 2) and then on acylium cation. It also results in linear and cyclic macromolecules. However, this mechanism is less probable due to the fact, that the endocyclic oxygen is less nucleophilic, than the exocyclic one [90]. Moreover, in the first case delocalization of the positive charge strongly stabilizes the cation formed, therefore the mechanism on Scheme 1 is preferred.

Polymerization of CL mediated by hydrated FeCl3

In the second step of the work we studied the polymerization catalyzed by FeCl3 in the presence of water used as initiator. Concentration of water was in the wide range from 0.02 to 0.08 mol/dm3. The results obtained were collected in Table 2.

Synthesized polymers (3)–(6) were bimodal or trimodal and their molar masses (Mn) estimated by SEC method were lower than calculated ones. In general, disperisities of fractions (a) were relatively high (Mw /Mn = 1.11–1.52), whereas those of fractions (b) and (c) were extremely low (Mw/Mn = 1.01–1.05). Similar result obtained by use of commercial FeCl3·6H2O from ALDRICH. Comparatively, polymers obtained in [88] by FeCl3·6H2O were unimodal and had higher Mn and dispersity depending on initial concentration of monomer. Analysis of the polymers (3)–(6) by MALDI-TOF technique indicated the formation of linear and small amount of cyclic macromolecules in all cases, independently of amount of water added. The latter were not observed previously by Chakraborty et al. [88] in the polymerization of CL mediated by FeCl3·6H2O system at CL/OH ratios equal to 200/1, 167/1, 133/1, 67/1 and 33/1 in bulk or toluene solution at 27 °C. We suggested, that this polymerization proceeds predominantly by activated monomer (AM) mechanism shown on Scheme 3 adapted from [88]. In the first step of the process exocyclic oxygen atom of carbonyl and group in the monomer interacts with metal atom of catalyst and then water attacks carbonyl carbon atom. Then, CL ring opens by acyl-oxygen bond cleavage simultaneously with leasing of FeCl3. The reaction product, i.e. ε-hydroxycaproic acid reacts with complex of CL with activated monomer, which induces further chain growth. However, activated monomer can also react with next H2O molecules generating new macromolecules.

However, we proposed an alternative version of AM mechanism, in which endocyclic oxygen atom in the monomer molecule interacts with metal atom of the catalyst and water attacks carbonyl carbon atom. These way also leads to the same intermediated product, i.e. ɛ-hydroxycaproic acid (Scheme 4). Similar mechanism was suggested by Basko et al. [91] for polymerization of β-butyrolactone performed in CH2Cl2 solution at room temperature in the presence of CF3SO2H as the catalyst and isopropanol as the initiator.

Formation of cyclic PCL fraction observed in our work was rather unexpected. In order to explain this phenomenon we suggested, that small part of FeCl3 catalyzes polymerization without participation of water. Consequently, two mechanisms, i.e. AM, which prevails and ACE operate simultaneously in the polymerization mediated by FeCl3/n H2O systems in THF solution at room temperature. This phenomenon can be explained by the presence of polar solvent, which interacts with water by formation of hydrogen bonds. It decreases the reactivity of water in the initiation step of polymerization.

Polymerization of CL mediated by FeCl 3 /6 H 2 O in the presence of alcohols

It was reported by Chakraborty et al. [88], that in the CL bulk polymerization mediated by FeCl3/6 H2O addition of alcohol (EtOH, i-PrOH, BnOH or glycol at H2O/ROH = 6/5 ratio) enhance the tendency to increase of molar masses (Mn = 59,800–82,000) and produce hydroxy- and alkoxy-end terminal functionalized product, e.g.  which prevails.

which prevails.

Using toluene as a solvent, Mn of the latter diminishes from 67,200 to 18,200 at the same concentrations of reagents. Comparatively we carried out similar polymerizations in the presence of MeOH or DPG in THF solution (Table 3).

Unexpectedly, in both studied systems alkoxy-end terminal functionalized products were not detected using MALDI-TOF and NMR techniques. It means, that alcohols used did not react as initiators. Polymerization occurred according to AM and ACE mechanisms resulting mainly in  macromolecules as well as cyclic macromolecules as side products. Interestingly, in all studied systems several polymer fractions were formed with various yields, molar masses and dispersity. Presumably, polarity of the solvent used influences the formation of ionic centers with various reactivities, which are responsible for such effect. However, this phenomenon is unexpected and needs further studies.

macromolecules as well as cyclic macromolecules as side products. Interestingly, in all studied systems several polymer fractions were formed with various yields, molar masses and dispersity. Presumably, polarity of the solvent used influences the formation of ionic centers with various reactivities, which are responsible for such effect. However, this phenomenon is unexpected and needs further studies.

Properties of the obtained polymers

Differential scanning calorimetry (DSC)

One of the techniques for analyzing the thermal behavior of polymers is differential scanning calorimetry (DSC). It enables to description of the polymers structure by determining the temperature and effects associated with physical changes in these materials. The typical DSC curve of PCLs obtained are shown in Fig. 5.

The endothermic peaks at 29.28 °C (2), 33.26 °C (3), 30.07 °C (4), 30.57 °C (5), 29.58 °C (6), 30.00 °C (7), 30.85 °C (8) without mass loss is due to the melting of the crystalline phase of PCL, which gives a ΔH values of 76.20 J g−1 for polymer 2; 74.74 J g−1 for polymer 3; 77.48 J g−1 for polymer 4; 76.63 J g−1 for polymer 5; 73.86 J g−1 for polymer 6; 72.21 J g−1 for polymer 7 and 78.62 J g−1 for polymer 8. The similar results indicate that initiators and different initial concentrations used in the polymerizations do not affect the thermal properties of the obtained PCLs. The results obtained are consistent with those proposed by Ting Ting Sui et al. [92].

Wide angle X-ray scattering

XRD was used to characterize phase composition of PCL. The amorphous phase content was estimated by the area of the amorphous halo with a peak at a 2θ value of approximately 21°. For all samples the peaks of (110), (111), and (200) ortho-rhombic crystalline face were found [93]. The calculated crystalline content (%) is shown in Table 4. The samples display an isotropic scattering profile with a diffused amorphous halo and sharp crystalline peaks. Three peaks at 2θ values of 21°, 22° and 24 ° are repeatedly observed in all samples (Fig. 6). All of them are characteristic to crystalline PCL. The diffraction at 21° is attributed to the (110) faces while at 24° to the (200) faces corresponding to the orthorhombic crystal lattice of PCL [89]. A small peak seen at a 2θ value of 22° is associated with the (111) plane of the same unit cell [94]. These states of order are associated with both the LAMELLAR folding and intermolecular spacing specific to each crystal face. Variation of the peak intensities and peak widths among the samples can be seen—the broadening of a crystalline peak manifests either decreasing crystal size or increasing structural disorder within the sample.

The peak ratios of the faces is changing in the range of (I(110)/I(200)) in the studied group. The observed changes deliver information about possible formation of condis crystal mesophase orientation. Condis crystals (conformationally disorder crystals) were described as a type of mesophase in the solid state material with birefringent properties connected to positional and orientation order, and partial or full conformational disorder.

Along with increase in initiator concentration (P3-P6) 3 diffraction peaks were observed for P3, P4 and P6, while P5 XRD pattern revealed presence of 2 main diffraction peaks with side-shoulder. P5 is also the sample characterized with the lowest value of I(110)/I(200)ratio. This observation may reflect the lowest content of the mesophase-type orientation in this sample. The calculated crystalline content (%) was the highest for P4 sample (62.28%), followed by P6 (52.00%), P5 (49.75%) and P3 (34.18%). By looking at this sequence one may indicate that in this series the proneness of the PCL to form crystalic–type package is influenced by the average molecular weight of the polymer. The lowest value of Mn was reported for P4 sample (Table 2), while the highest was calculated for P3 sample (Table 2). Additionally, P4 was characterized with the highest dispersity, which is an indicator of greater extend of variation of macromolecules’ length. Additional presence of MeOH (P7) or DPG (P8) led to decrease in crystalline content to 26.32% (P7) and 46.89% (P8). P7’s XRD pattern revealed presence of 2 diffraction peaks with side-shoulder part and this sample is characterized with the lower value of I(110)/I(200) ratio. Contrary to the previous series (P3-P6) the increased average molecular weight did not hampered crystalline phase formation. It seems that there are additional forces that favor alignments, which are induced by dipropylene glycol presence.

FTIR analysis

For P2 sample FT-IR spectrum is shown in Fig. 7. The most prominent characteristic absorption peak of PCL, which is linear aliphatic polyesters, is located at 1720–1730 cm−1 and corresponds to the carbonyl stretching mode of the ester group [95]. The changes of the shape of this band correlates well with the melting and crystallization processes. Two separated carbonyl bands were prescribed to amorphous (1735 cm−1) and crystalline regions (1725 cm−1) [96]. Their intensities described as absorbances value are helpful in establishment of the relative amount of crystalline and amorphous fractions [97]. Additional strong band at 1174 cm−1 is visible corresponding to stretching vibration mode of C–O–C part [98]. Furthermore, P2 spectrum shows peaks of CH2 stretching vibrations corresponding to alkyl chain structure [99, 100]. The C-H both symmetric and anti-symmetric stretching are seen with peaks at 2864 and 2945 cm−1 respectively. A broad peak around 3425 cm−1 is due to the OH stretching of PCL end group.

Conclusions

Both anhydrous and hydrated FeCl3 mediated ɛ-caprolactone (CL) polymerization in tetrahydrofuran (THF) solution at room temperature. The main features of these processes are:

-

1.

Anhydrous FeCl3 catalyzed CL polymerization proceeding by ACE mechanism leading to linear macromolecules, however, cyclic macromolecules are also formed by intramolecular transesterification.

-

2.

Addition of water as initiator resulted in occurrence of AM mechanism of polymerization, which operates simultaneously with ACE ones at wide range of FeCl3 / H2O ratio (1/2,1/4,1/6 and 1/8), however, the AM mechanism prevails.

-

3.

Alcohols, i.e. MeOH and DPG use together with water appeared to be completely inactive in the studied process.

-

4.

The polyesters obtained were polymodal and consisted of two or three fractions with various yields, Mn and Mw/Mn.

-

5.

XRD analysis showed the coexistence of two phases, i.e. —crystal and amorphous ones with possible mesophase orientation formation. The calculated crystalline content (%) was the highest for P4 sample due to its lowest average molecular weight.

-

6.

Addition of either MeOH (P7) or DPG (P8) led to decrease in crystalline content to 26.32% (P7) and 46.89% (P8). Still it seems that there are additional forces that favor alignments, which are induced by presence of dipropylene glycol.

-

7.

Unexpectedly, the results obtained in this work differ strongly from these reported previously [88], probably due to the influence of THF used as a polar solvent.

References

Lam CXF, Teoh SH, Hutmacher DW (2007) Comparison of the degradation of polycaprolactone and polycaprolactone–(β-tricalcium phosphate) scaffolds in alkaline medium. Polym Int 56:718–728. https://doi.org/10.1002/pi.2195

Peña J, Corrales T, Izquierdo-Barba I, Doardio AL, Vallet-Regi M (2006) Long term degradation of poly(3-caprolactone) films in biologically related fluids. Polym Degrad Stab 91:1424–1432

Jenkins MJ, Harrison KL, Silva MMCG, Whitaker MJ, Shakesheff KM, Howdle SM (2006) Characterisation of microcellular foams produced from semi-crystalline PCL using supercritical carbon dioxide. Eur Polym J 42:3145–3151

Hutmacher DW, Schantz T, Zein I (2001) Hin KWNgS, Kim T, Tan C; Mechanical properties and cell cultural response of polycaprolactone scaffolds designed and fabricated via fused deposition modeling. J Biomed Mater Res 55:203–216

Sinha VR, Bansal K, Kaushik R, Kumria R, Trehan A (2004) Poly-ε-caprolactone microspheres and nanospheres: an overview. Int J Pharm 278:1–23

Chandra R (1998) Rustgi; biodegradable polymers. Prog Polym Sci 23:1273–1335

Chen DR, Bein JZ, Wang SG (2000) Polycaprolactone microparticles and their biodegradation. Polym Degrad Stab 67:455–459

Hedrick JL, Magbitang T, Connor EF, Glauser T, Volksen W, Hawker CJ, Lee VY, Miller RD (2002) Application of complex macromolecular architectures for advanced microelectronic materials. Chem-Eur J 8:3308–3319

Joshi P, Madras G (2008) Degradation of polycaprolactone in supercritical fluids. Polym Degrad Stab 93:1901–1908

Ikada Y, Tsuji H (2000) Biodegradable polyesters for medical and ecological applications. Macromol Rapid Commun 21:117–132

Iroh JO (1999). In: Mark JE (ed) Polymer data, handbook. Oxford University Press, New York, pp 361–362

Braud CC, Devarieux R, Atlan A, Ducos C, Michel V (1998) Capillary zone electrophoresis in normal or reverse polarity separation modes for the analysis of hydroxy acid oligomers in neutral phosphate buffer. J Chromatogr B: Biomed Sci Appl 706:73–82

Labet M, Thielemans W (2009) Synthesis of polycaprolactone: a review. Chem Soc Rev 38:3484–3504

Grobelny Z, Matlengiewicz M, Skrzeczyna K, Swinarew A, Golba S, Jurek-Suliga J, Michalak M, Swinarew B (2015) Ring-Opening Polymerization of Lactones Initiated with Metal Hydroxide-Activated Macrocyclic Ligands: Determination of Mechanism and Structure of Polymers. Int J Polym Anal Chem 5:457–468

Grobelny Z, Golba S, Jurek-Suliga J (2019) Mechanism of ε-caprolactone polymerization in the presence of alkali metal salts: investigation of initiation course and determination of polymers structure by MALDI-TOF mass spectrometry. Polym Bull 76:3501–3515

Bhaw-Luximon A, Jhurry D, Matala-Timol S, Lochee Y (2005) Polymerization of ε-Caprolactone and its Copolymerization with γ-Butyrolactone using Metal Complexes. Macromol Symp 231:60–68

Kitayama T, Yamaguchi H, Kanzawa T, Hirano T (2000) Living ring-opening polymerization of ɛ-caprolactone with combinations of tert-butyllithium and bilky aluminium phenoxides. Polym Bull 45:97–104

Deng X, Yuan M, Xiong C, Li X (1999) Polymerization of lactides and lactones. IV. ring-opening polymerization of ε-caprolactone by rare earth phenyl compounds. Appl Polym Sci 73:1401–1408

Sanchez-Barba LF, Garcez A, Fajardo M, Lara-Sanchez A, Lopez-Solera ML (2007) Well-defined alkyl heteroscorpionate magnesium complexes as excellent initiators for the ROP of cyclic esters. Organometallics 26:6403–6411

Yu T-L, Wu CC, Chen C-C, Huang B-H, Wu J, Lin C-C (2005) Catalysts for the ring-opening polymerization of ε-caprolactone and l-lactide and the mechanistic study. Polymer 46:5909–5917

Ko BT, Lin C-C (2001) Synthesis, characterization, and catalysis of mixed-ligand lithium aggregates, excellent initiators for the ring-opening polymerization of l-lactide. J Am Chem Soc 123:7973–7977

Zhong Z, Dijkstra PJ, Bing C, Westerhausen M, Feijen J (2001) A novel and versatile calcium-based initiator system for the ring-opening polymerization of cyclic esters. Macromolecules 34:3863–3868

Piao L, Deng M, Chen X, Jiang L, Jing X (2003) Ring-opening polymerization of ε-caprolactone and l-lactide using organic amino calcium catalyst. Polymer 44:2331–2336

Rong G, Deng M, Deng C, Tang Z, Piao L, Chen X, Jing X (2003) Synthesis of poly(ε-caprolactone)-b-poly(γ-benzyl-l-glutamic acid) block copolymer using amino organic calcium catalyst. Biomacromol 4:1800–1804

Tang Z, Chen X, Liang Q, Bian X, Yang L, Piao L, Jing X (2003) Strontium-based initiator system for ring-opening polymerization of cyclic esters. J Polym Sci Part A: Polym Chem 41:1934–1941

Platel RH, Hodgson LM, Williams CK (2008) Biocompatible initiators for lactide polymerization. Polym Rev 48:11–63

Wang Y, Kunioka M (2005) Ring-opening polymerization of cyclic monomers with aluminum triflate. Macromol Symp 224:193–206

Dubois P, Degee P, Jerome R, Teyssie P (1992) Macromolecular engineering of polylactones and polylactides. 8. Ring-opening polymerization of iε-caprolactone initiated by primary amines and trialkylaluminum. Macromolecules 25:2614–2618

Florjańczyk Z, Plichta A, Sobczak M (2006) Ring opening polymerization initiated by methylaluminoxane/AlMe3 complexes. Polymer 47:1081–1090

Duda A, Florjańczyk Z, Hofman A, Słomkowski S, Penczek S (1990) Living pseudoanionic polymerization of iε-caprolactone. Poly (iε-caprolactone) free of cyclics and with controlled end groups. Macromolecules 23:1640–1646

Bergeot V, Tassaing T, Besnard M, Cansell F, Mingotaud A-F (2004) Anionic ring-opening polymerization of ε-caprolactone in supercritical carbon dioxide: parameters influencing the reactivity. J Supercrit Fluid 28:249–261

Duda A (1996) Polymerization of ε-caprolactone initiated by aluminum isopropoxide carried out in the presence of alcohols and diols kinetics and mechanism. Macromolecules 29:1399–1406

Duda A, Penczek S (1995) Polymerization of ε-caprolactone initiated by aluminum isopropoxide carried out in the presence of alcohols and diols kinetics and mechanism. Macromolecules 28:5981–5992

Duda A, Penczek S (1995) On the difference of reactivities of various aggregated forms of aluminium triisopropoxide in initiating ring-opening polymerizations. Macromol Rapid Commun 16:67–76

Kricheldorf HR, Berl M, Scharnagl N (1988) Poly (lactones) 9 Polymerization mechanism of metal alkoxide initiated polymerizations of lactide and various lactones. Macromolecules 21:286–293

Martin E, Duboais P, Jérôme R (2003) Polymerization of ε-caprolactone initiated by Y alkoxide grafted onto porous silica. Macromolecules 36:7094–7099

Miola-Delaite C, Spitz THR (1999) Anionic coordinated polymerization of ε-caprolactone with aluminium, zirconium and some rare earths alkoxides as initiators in the presence of alcohols. Macromolecules ChemPhys 200:1771–1778

Ropson N, Duboais P, Jérôme R, Teyssie P (1995) Macromolecular engineering of polylactones and polylactides. 20. effect of monomer, solvent, and initiator on the ring-opening polymerization as initiated with aluminum alkoxides. Macromolecules 28:7589–7598

Mecerreues D, Jerome J (1999) From living to controlled aluminium alkoxide mediated ring-opening polymerization of (di) lactones, a powerful tool for the macromolecular engineering of aliphatic polyesters. Macromol Chem Phys 200:2581–2590

Duda A, Penczek S, Duboais P, Mecerreyes D, Jérôme R (1996) Oligomerization and copolymerization of γ-butyrolactone—a monomer known as unable to homopolymerize, 1 Copolymerization with ε-caprolactone. Macromol Chem Phys 197:1273–1283

Taden I, Kang H-C, Massa W, Okuda J (1997) Aluminum complexes of sterically hindered tetradentate schiff bases: synthesis, structure, and reactivity toward ɛ-caprolactone. J Organomet Chem 540:189–192

Arbaoui A, Redshaw C, Hughes DL (2008) Multinuclear alkylaluminium macrocyclic Schiff base complexes: influence of procatalyst structure on the ring opening polymerisation of ε-caprolactone. Chem Commun 39:4717–4719

Iwasa N, Liu J, Nomura K (2008) Notable effect of imino substituent for the efficient ring-opening polymerization of ε-caprolactone initiated by Al complexes containing phenoxy-imine ligand of type, Me2Al(L) [L: O-2-tBu-6-(RNCH)C6H3; R: 2,6-iPr2C6H3, tBu, adamantyl, C6F5]. Catal Commun 9:1148–1152

Nomura N, Aoyama T, Ishii R, Kondo T (2005) Salicylaldimine-Aluminum complexes for the facile and efficient ring-opening polymerization of e-caprolactone. Macromolecules 38:5363–5366

Yao W, Mu Y, Gao A, Su Q, Zhang Y (2008) Efficient ring-opening polymerization of ɛ-caprolactone using anilido-imine–aluminum complexes in the presence of benzyl alcohol. Polymer 49:2486–2491

Emdo M, Aida T, Inoue S (1987) Immortal polymerization of. epsilon.-caprolactone initiated by aluminum porphyrin in the presence of alcohol. Macromolecules 20:2982–2988

Huang C-H, Wang FC, Ko B-T, Yu T-L, Lin C-C (2001) Ring-opening polymerization of ε-caprolactone and l-lactide using aluminum thiolates as initiator. Macromolecules 34:356–361

Lai S-M, Don T-M, Liu Y-H, Chiu W-Y (2006) Graft polymerization of vinyl acetate onto granular starch: Comparison on the potassium persulfate and ceric ammonium nitrate initiated system. J Appl Polym Sci 102:3017–3027

Möller M, Kange R, Hedrick JL (2000) Sn(OTf)2 and Sc(OTf)3: Efficient and versatile catalysts for the controlled polymerization of lactones. J Polym Sci Part A: Polym Chem 38:2067–2074

Degirmenci M, Hizal G, Yagci Y (2002) Synthesis and characterization of macrophotoinitiators of poly(ε-caprolactone) and their use in block copolymerization. Macromolecules 35:8265–8270

Degirmenci M, Izgin O, Yagci Y (2004) Synthesis and characterization of cyclohexene oxide functional poly(ε-caprolactone) macromonomers and their use in photoinitiated cationic homo- and copolymerization. J Polym Sci Part A: Polym Chem 42:3365–3372

Kiskan B, Yagci Y (2005) Synthesis and characterization of naphthoxazine functional poly (ε-caprolactone). Polymer 46:11690–11697

Kowalski A, Duda A, Penczek S (1998) Kinetics and mechanism of cyclic esters polymerization initiated with tin (II) octoate, 1 Polymerization of ε-caprolactone. Macromol Rapid Commun 19:567–572

Duda A, Penczek S, Kowalski A, Libiszowski J (2000) Kinetics and Mechanism of Cyclic Esters Polymerization Initiated with Tin(II) Octoate. Polymerization of ε-Caprolactone and l, l-Lactide Co-initiated with Primary Amines. Macromolecules Symp 153:41–53

Kowalski A, Duda A, Penczek S (2000) Mechanism of cyclic ester polymerization initiated with Tin (II) Octoate. 2. macromolecules fitted with Tin (II) alkoxide species observed directly in MALDI− TOF Spectra. Macromolecules 33:689–695

Libiszowski J, Kowalski A, Duda A, Penczek S (2002) Kinetics and mechanism of cyclic esters polymerization initiated with covalent metal carboxylates, 5†. End-group studies in the model ε -caprolactone and L, L-dilactide/Tin(II) and zinc octoate/butyl alcohol systems. Macromol Chem Phys 203:1694–1701

Celiz AD, Scherman OA (2008) Controlled ring-opening polymerization initiated via self-complementary hydrogen-bonding units. Macromolecules 41:4115–4119

Bratton D, Brown M, Howdle SM (2005) Tin (II) ethyl hexanoate catalyzed precipitation polymerization of ε-caprolactone in supercritical carbon dioxide. Macromolecules 38:1190–1195

Kowalski A, Libiszowski J, Biela T, Cypryk M, Duda A, Penczek S (2005) Kinetics and mechanism of cyclic esters polymerization initiated with Tin(II) octoate. polymerization of ε-caprolactone and l, l-lactide Co-initiated with primary amines. Macromolecules 38:8170–8176

Stassin F, HalleuO JR (2001) Ring-opening polymerization of ε-caprolactone in supercritical carbon dioxide. Macromolecules 34:775–781

Stassin F, Jerome R (2003) Effect of pressure and temperature upon tin alkoxide-promoted ring-opening polymerisation of ε-caprolactone in supercritical carbon dioxide. Chem Commun 2:232–233

Möller M, Nederberg F, Lim LS, Kange R, Hawker CJ, Hedrick JL, Gu Y, Shah R, Abbott NL (2001) Stannous(II) trifluoromethane sulfonate: a versatile catalyst for the controlled ring-opening polymerization of lactides: Formation of stereoregular surfaces from polylactide “brushes.” J Polym Sci Part A: Polym Chem 39:3529–3538

Barakat I, Duboais P, Jérôme R, Teyssie P (1991) Living polymerization and selective end functionalization of iε-caprolactone using zinc alkoxides as initiators. Macromolecules 24:6542–6545

Keefe Ò, Brendan J, Breyfogle LE, Hillmyer AM, Tolman WB (2002) Mechanistic comparison of cyclic ester polymerizations by novel iron (III)− alkoxide complexes: single vs multiple site catalysis. J Am Chem Soc 124:4384–4393

Davidson MG, Jones MD, Lunn MD, Mahon MF (2006) Poly (ε-caprolactone)-based electrospun nano-featured substrate for tissue engineering applications: a review. Org Chem 45:2282–2287

Takeuchi D, Nakamura T, Aida T (2000) Bulky titanium bis (phenolate) complexes as novel initiators for living anionic polymerization of ε-caprolactone. Macromolecules 33:725–729

Nomura N, Taira A, Tamioka T, Okada M (2000) A catalytic approach for cationic living polymerization: Sc(OTf)3-catalyzed ring-opening polymerization of lactones. Macromolecules 33:1497–1499

Nomura N, Taira A, Nakase A, Tamioka T, Okada M (2007) Ring-opening polymerization of lactones by rare-earth metal triflates and by their reusable system in ionic liquids. Tetrahedron 63:8478–8484

Deng XM, Zhu Z, Xiong C, Zhang L (1997) Ring-opening polymerization of ϵ-caprolactone initiated by rare earth complex catalysts. J Appl Polym Sci 64:1295–1299

Stevels WM, Ankone MJK, Dijkstr PK, Feijen J (1996) Kinetics and mechanism of ε-caprolactone polymerization using yttrium alkoxides as initiators. Macromolecules 29:8296–8303

Poncelect O, Sartain WJ, Hubert-Pfalzgraf LG, Folting K, Caulton KG (1989) Chemistry of yttrium triisopropoxide revisited. Characterization and crystal structure of Y5 (mu 5-O)(mu 3-OPr-iso) 4 (mu 2-OPr-iso) 4 (OPr-iso) 5. Inorg Chem 28:263–267

Agarwal S, Karl M, Dehnicke K, Seybert G, Massa W, Greiner A (1999) Ring-opening polymerization of ε-caprolactone and δ-valerolactone using new Sm (III) μ-halo-bis (trimethylsilyl) amido complexes. J Appl Polym Sci 73:1669–1674

Lin W, Sun WL, Shen ZQ (2007) Lanthanum heterocyclic schiff-base complex initiated ring-opening polymerization of ɛ-caprolactone. Chin Chem Lett 18:1133–1136

Nishiura M, Hou Z, Koizumi T-A, Imamoto T, Wakatsuki Y (1999) Ring-opening polymerization and copolymerization of lactones by samarium (II) aryloxide complexes. Macromolecules 32:8245–8251

Yamashita M, Takemoto Y, Ihara E, Yasuda H (1996) Organolanthanide-initiated living polymerizations of ε-caprolactone, δ-valerolactone, and β-propiolactone. Macromolecules 29:1798–1806

Lohmeijer BGG, Pratt RC, Leibfarth F, Logan JW, Long DA, Dove AP, Nederberg F, Choi J, Wade C, Waymounth RM, Hedrick JL (2006) Guanidine and amidine organocatalysts for ring-opening polymerization of cyclic esters. Macromolecules 39:8574–8583

Pratt RC, Lohmeijer BGG, Long DA, Waymounth RM, Hedrick JL (2006) Triazabicyclodecene: a simple bifunctional organocatalyst for acyl transfer and ring-opening polymerization of cyclic esters. J Am Chem Soc 128:4556–4557

Chuma A, Horn HW, Swope WC, Pratt RC, Zhang L, Lohnmeijer BGG, Wade CG, Waymounth RM, HedricK JL, Rice JE (2008) the reaction mechanism for the organocatalytic ring-opening polymerization of l-lactide using a guanidine-based catalyst: hydrogen-bonded or covalently bound? J Am Chem Soc 130:6749–6754

Zhang L, Nederberg F, Pratt RC, Waymounth RM, Hedrick JL, Wade CG (2007) Phosphazene bases: a new category of organocatalysts for the living ring-opening polymerization of cyclic esters. Macromolecules 40:4154–4158

Casas J, Persson PV, Iversen T, Cordova A (2004) direct organocatalytic ring-opening polymerizations of lactones. Adv Synth Catal 346:1087–1089

Persson PV, Schroder J, Wickholm K, Hedenstrom E, Iversen T (2004) Selective organocatalytic ring-opening polymerization: a versatile route to carbohydrate-functionalized poly (ε-caprolactones). Macromolecules 37:5889–5893

Kobayashi S (1999) Enzymatic polymerization: a new method of polymer synthesis. J Polym Sci Part A: Polym Chem 37:3041–3056

Kobayashi S, Uyama H, Ohmac M (2001) Enzymatic polymerization for precision polymer synthesis. Bull Chem Soc Jpn 74:613–635

MacDonald RT, Pulapura SK, Svirkin YY, Gross RA, Kaplan DJ, Akkara J, Swift G, Wolk S (1995) Enzyme-catalyzed. epsilon.-caprolactone ring-opening polymerization. Macromolecules 28:73–78

Nobes GAR, Kazlauskas RJ, Marchessault RH (1996) Lipase-catalyzed ring-opening polymerization of lactones: a novel route to poly (hydroxyalkanoate) s. Macromolecules 29:4829–4833

Loeker FC, Duxbury DJ, Kumar R, Gao W, Gross RA, Howdle SM (2005) Thiol end-functionalization of poly (epsilon-caprolactone), catalyzed by Candida antarctica lipase B. Macromolecules 38:647–649

Bisht KS, Deng F, Gross RA, Kaplan DJ, Swift G (1998) Ethyl glucoside as a multifunctional initiator for enzyme-catalyzed regioselective lactone ring-opening polymerization. J Am Chem Soc 120:1363–1367

Gowda RR, Chakraborty D (2009) Environmentally benign process for bulk ring opening polymerization of lactones using iron and ruthenium chloride catalysts. J Mol Catal A: Chemical 301:84–92

Stoclet G, Seguela R, Lefebvre JM, Rochas C (2010) New insights on the strain-induced mesophase of poly(d, l-lactide). in situ WAXS and DSC study of the thermo-mechanical stability. Macromolecules 43:7228–7237

Kricheldorf HR, Jonté JM, Dunsing R (1986) Polylactones, 7 the mechanism of cationic polymerization of β-propiolactone and ϵ-caprolactone. Macromol Chem 187:771–785

Basko M, Duda A, Kazmierski S, Kubisa P (2013) Cationic copolymerization of racemic-β-butyrolactone with L, L-lactide: one-pot synthesis of block copolymers. J Polym Sci Part A: Polym Chem 51:4873–4884

Su TT, Jiang H, Gong H (2008) Thermal stabilities and the thermal degradation kinetics of poly (ε-caprolactone). Polym-Plast Technol Eng 47:398–403. https://doi.org/10.1080/03602550801897695

Baptista C, Azagury A, Shin H, Baker CM, Ly E, Lee R, Mathiowitz E (2020) The effect of temperature and pressure on polycaprolactone morphology. Polymer 191:122227–122240. https://doi.org/10.1016/j.polymer.2020.122227

Hu H, Dorse DL (1990) Crystal structure of poly (iε-caprolactone). Macromolecules 23:4604–4607

Phillipson K, Jenkins MJ, Hay JN (2016) The kinetics of crystallization of poly (ε-caprolactone) measured by FTIR spectroscopy. J Therm Anal Calorim 123:1491–1500

Castilla-Cortázar I, Vidaurre A, Marí B, Campillo-Fernández AJ (2019) Morphology, crystallinity, and molecular weight of poly (ε-caprolactone)/graphene oxide hybrids. Polymers 11:1099–1119

He Y, Inoue Y (2000) Novel FTIR method for determining the crystallinity of poly (ε-caprolactone). Polym Int 49:623–626

Vogt L, Boccaccini AR (2021) Random and aligned electrospun poly (ε-caprolactone)(PCL)/poly (1, 8-octanediol-co-citrate)(POC) fiber mats for cardiac tissue engineering using benign solvents. Eur Polymer J 160:110772–110781

Persenaire O, Alexandre M, Degée P, Dubois P (2001) Mechanisms and kinetics of thermal degradation of poly (ε-caprolactone). Biomacro 2:288–294

Elzein T, Nasser-Eddine M, Delaite Ch, Bistac S, Dumas P (2004) FTIR study of polycaprolactone chain organization at interfaces. J Coll. Interf. Sci. 273:381–387

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Grobelny, Z., Jurek-Suliga, J. & Golba, S. The influence of hydroxylic compounds on cationic polymerization of ɛ-caprolactone mediated by iron (III) chloride in tetrahydrofuran solution. Polym. Bull. 80, 6307–6326 (2023). https://doi.org/10.1007/s00289-022-04355-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-022-04355-3