Abstract

In this work, a biologically active curcumin molecule is used as an antibacterial agent, and the insertion of this naturally occurring biomolecule into the backbone of water-dispersible polyurethane has been successfully achieved to synthesize bio-based antibacterial textile finishes. These curcumin-based water-dispersible polyurethane (CUR-WDPU) dispersions were prepared by utilizing isophorone diisocyanate (IPDI), polyethylene glycol (PEG), dimethylolpropionic acid (DMPA) and triethylamine (TEA) following the prepolymer mixing process by incorporating variable molar quantities of curcumin (CUR). Structure elucidation of synthesized CUR-WDPU dispersions was obtained through Fourier transformed infrared spectroscopy (FTIR) which confirmed the insertion of CUR into the WDPU backbone. Using the pad-dry-cure procedure, the varying varieties of plain weave polyester/cotton blended dyed and printed textile samples were treated with synthesized CUR-WDPU finishes. The antibacterial activities of these treated textiles have been assessed, and the outcomes revealed that the insertion of curcumin into the PU polymer chain has significantly boosted the antibacterial activities of PU dispersions. These newly prepared CUR-WDPUs dispersions are proved to be eco-friendly antimicrobial finishes because these are containing natural bioactive agents such as curcumin, showing potential antibacterial applications on polyester/cotton textiles. Predominantly, this research work is an attempt toward the greener approach of novel bio-based finishing materials preferably useful for textile diligences. Future investigations of these finishes will explore the other textile assets of poly-cotton textiles without adversely influencing their color fastness and mechanical properties.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Nowadays, water-dispersible polyurethanes (WDPUs) coatings have captured the attentiveness of manufacturers due to their superior properties such as good stability at low temperature conditions, excellent flexibility, very less or zero volatile organic solvents (VOS), high level of weather and water resistance, the stability of pH, excellent resistant to solvents and very striking chemical and mechanical properties [1,2,3,4].

Aqueous PU dispersions (WDPUs) are frequently consumed for coating extensive varieties of materials such as textile, leather products, plastics, furniture and flooring, in addition to being used as base coats for automotive, topcoats for vinyl upholstery, footwear adhesives and printing inks [5,6,7]. Due to unique features of polyurethanes (PUs), many researchers synthesized different types of PUs based on a number of diols and diisocyanates and studied for various applications [8,9,10,11]. To provide ease, care and comfort to consumers in this current exotic environment, the role of textile goes beyond and changes the traditional rationale of being used as clothing to the textiles with multifunctional assets [12]. WDPUs are also tremendously used as textile finishing agents to upgrade the durability, quality and fleeting appearance of the fabric and for the development of breathable and non-formaldehyde coatings [13, 14]. The antistatic, hydrophilic and anti-soiling finishing properties of water-dispersible polyurethanes are incredibly appropriate for synthetic fibers [15,16,17,18]. Several functional properties like: antimicrobial [19,20,21,22,23,24,25,26,27,28], wrinkle resistance [19, 22, 23, 29,30,31], softness [21], stain resistant [24, 25], antistatic charges [26], hydrophilicity and UV resistance/blocking properties are pioneered in textile goods [27, 28, 32]. All these potential properties can be acquired separately or combined, to obtain multifunctional textiles using chemical finishing materials [12]. In textile manufacturing, utilization, transportation and storage, the goods can be stricken by microbes like bacteria, fungi and algae. These microbes have the ability to infect textiles and causing fiber damage, imparting unpleasant odors, slick and slimy feel [12].

In the quest to protect human beings and the textile products from all expected bacterial infections, antibacterial finishing of textiles was considered the best solution. Copious chemical finishing agents have been utilized for antimicrobial finishing of textile products such as silver, TiO2, chitosan, salts containing metal atoms, triclosan, ZnO materials and quaternary ammonium salts [19, 33,34,35,36,37]. Moreover, curcumin [38,39,40,41], vanillin [42, 43] and tertiary butyl hydroquinone (TBHQ) [44,45,46,47,48] are the polyphenolic compounds which can be used to achieve antimicrobial properties. Curcumin is obtained from Curcuma longa plant that imparts numerous pharmacological effects. This naturally occurring compound manifests remarkable antibacterial [47], antifungal [48], antioxidant [49], anti-inflammatory [50], anticoagulant [51] and antitumor [52] activities. Bioavailability of curcumin is severely restricted due to its very low solubility in aqueous medium, degradation at alkaline pH, inadequate tissue absorption and rapid systemic elimination [53,54,55,56]. Curcumin has been used as a natural healing and antimicrobial agent for wounds [57]. Traditionally, it is also used as a dying or coloring agent in textiles [40, 41]. In current research work, we used curcumin as an antibacterial agent in water-dispersible polyurethane to achieve bio-based antibacterial textile finishes. The insertion of naturally occurring bioactive polymers as chain extenders into the polymeric chain of WDPUs has become the source of attraction for polymer scientists [7, 58, 59]. This addition played a considerable part in enhancing the antibacterial properties of the finished textiles. To our best knowledge, we report that curcumin is employed to extend the polymeric chain of water-dispersible polyurethane for the first time. In this research project, curcumin-based water-dispersible polyurethanes are formed by using isophorone diisocyanate (IPDI), polyethylene glycol (PEG), dimethylolpropionic acid (DMPA), dibutyltindilurate (DBTDL), triethylamine (TEA) and curcumin (CUR). Furthermore, physical, structural and antibacterial investigations were carried out in order to estimate the influence of varying molar ratios of curcumin on final WDPU properties.

Experimental section

Materials

Curcumin (99%), dimethylolpropionic acid (DMPA, 99.9%), isophorone diisocyanate (IPDI, 99.9%) and dibutyltin dilaurate (DBTDL, 99.9%) were bought from Sigma Aldrich Chemical Co, USA. Polyethylene glycol (PEG, 99%) (Mn = 600 g/mole), triethylamine (TEA, 99%), acetic acid (99%), acetone (99%) and methyl ethyl ketone (MEK, 99%) were of analytical grade and purchased from Merk Chemical Co, UK. Deionized water, emulsifiers (WN with HLB = 14 and NP-6 having HLB = 10) were purchased from a local textile chemical market. DMPA and PEG were dried to ensure the removal of water vapor and air at 60 °C for 4 h in the oven before usage. To dry MEK, anhydrous CaSO4 was used. All the other chemicals were utilized as received. Amounts of the reactants for reactions were calculated by the formula: amount = no. of moles × molecular mass.

Pretreatment of textile substrates (cotton/polyester blended)

Dyed and printed poly-cotton plain weave fabric was provided by Kamal Textile Mills Ltd., Khurarrianwala, Faisalabad, Pakistan and its specifications are given in Table 1. All the fabric samples were washed before application of CUR-WDPU-IPDI finishes, at 100 °C for 30 min with detergent in the laboratory. Afterward, the fabric samples were rinsed and dried at room temperature, and pH of the fabrics was maintained at about 6.5–7.5.

Experimental procedure

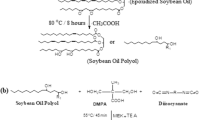

Preparation of PU prepolymer with NCO terminals and extension of this polymeric chain were carried out according to the suggested synthetic route [60]. Following this synthetic path, NCO end capped PU prepolymer was formed in a round bottom glass reactor fixed up with a reflux condenser, nitrogen inlet, mechanical stirrer, thermometer and a temperature regulator. First, PEG (1.0 mol) and DMPA (0.8 mol) were added into the reactor. Reaction was carried out at 80–90 °C for 30 min. Then, a single drop of the catalyst (DBTDL) was added into the reaction mixture followed by the addition of isophorone diisocyanate (IPDI) (2 mol) under vigorous stirring. At this moment, the reaction mixture was allowed to react for further 2 h at 70–80 °C, which resulted into a hydrophilic PU prepolymer with NCO terminals. To check the progression of PU prepolymer formation, the FTIR spectrum of this synthesized NCO end capped PU prepolymer was acquired (Fig. 2 (d)).

TEA (0.9 mol) was added to NCO terminated PU prepolymer as neutralizing agent to neutralize the carboxylic (−COOH) groups that exist in PU polymeric chain, and this neutralization was accomplished for the next 45 min at 55 °C. Neutralizing agent was added in slight excess to that of DMPA to validate the neutralization process [61]. To decrease the viscosity of polymer solution, very little amount of methyl ethyl ketone (MEK) was added into the reaction mixture. The formation of neutralized NCO terminated PU prepolymer was confirmed through FTIR analysis (Fig. 1).

Chain extension of the neutralized PU prepolymer was performed by curcumin (dissolved in the appropriate amount of MEK). Chain extension step was carried out for next 30 min followed by dropwise addition of an estimated volume of deionized water under vigorous stirring. The dispersion step was further preceded at room temperature for next 2 h. A stable CUR-WDPU dispersion having 35% solid content was formed. The schematic illustration of the synthesis of curcumin-based WDPUs is shown in Fig. 1. By the above described process, a total of 5 samples of curcumin-based water-dispersible polyurethanes using isophorone diisocyanates (IPDI) were prepared. The detailed formulation and sample code designation of all these samples is given in Table 2.

Finish application

Two different emulsifiers (WN having HLB value 14 and NP-6 having HLB value 10) were dissolved in 1 L of distilled water to which 20 g or 40 g of CUR-WDPU dispersion was added. This mixture was homogenized by a mechanical stirrer for 5–10 min to prepare a 2% or 4% solution of the polymeric dispersion. Dyed and printed textile swatches were immersed into the prepared dispersions. Pad-dry-cure method was used for dispersion applications, and the wet textile swatches were squeezed after some minutes between two stainless steel rollers of the padder machine. The padding pressure of rollers was adjusted to allow a pick-up of 75%, and padding speed was kept at 3 m/min. After that, the textile swatches were dried and cured at 150 °C for 1 min in an electric oven.

Investigations of physicochemical parameters

Physical characteristic measurements

Physical characterizations of CUR-WDPUs emulsions have been done to measure a number of variables such as emulsion stability, emulsion appearance, film appearance and tackiness. All these parameters were measured at 25 °C.

Solid content measurements

The dry weight contents or solid contents of CUR-WDPU’s have been measured by taking a weighed quantity of formulated dispersion in an aluminum cup that was put into an electric oven for drying at 80 °C till the weight of dry contents was constant. Solid contents were then estimated using the following equation.

where “B” is the mass of empty aluminum cup, “D” is mass of the cup and CUR-WDPU before drying and “A” is the mass of cup and CUR-WDPU after drying.

Molecular characterization

In order to validate the incorporation of curcumin into the PU polymeric chain, the molecular characterization of the synthesized samples was achieved in ATR mode by a Bruker-IFS 48 FTIR spectrometer (Ettlingen, Germany). All the FTIR spectral analysis of monomers and synthesized CUR-WDPU emulsion samples were recorded at 400–4000 cm−1 wavelength region.

Evaluation of antibacterial activities

Disk diffusion assay has been used to evaluate the antibacterial activity of synthesized CUR-WDPUs dispersions [62]. For inhibition studies, three different strains of bacteria were taken. 1000 mL of medium based on nutrient agar was prepared from which 150 mL of nutrient agar was poured in three flasks and autoclaved at 120 °C for 15 min and then cooled to room temperature. Afterward, the actively growing bacterial strains (Escherichia coli, Staphylococcus aureus and Bacillus subtilis) were added to the cooled mediums. Each sterilized petri plate was filled with around 20 mL of nutrient agar medium and allowed to set at ambient temperature. The untreated and treated textile swatches were cut into about 1 ± 0.5 mm disks and placed on the prepared petri plates. All the plates were put in the incubator for 24 h at 37 °C [62]. After incubation, the zones of inhibition were measured in millimeters (mm) around the untreated and treated textile disks.

Results and discussion

Physical characterization of curcumin/water-dispersible polyurethane based on IPDI (CUR-WDPU-IPDI)

The outcomes of physical characterization of CUR-WDPUs based on IPDI by varying mole ratio of curcumin are shown in Table 3. Solid contents of the prepared series of CUR-WDPU-IPDI emulsions range from 35.60 to 39.89%. The gradual enhancement in the dry weight contents may be due to the continuing rise in the molar amount of curcumin. The appearance was approximately identical in all the synthesized emulsions, i.e., mustard transparent, and the diluted solution of all the emulsions was yellow. This yellow color was due to curcumin which is a yellow-colored bioactive compound, incorporated into the WDPU backbone as a chain extender. Tackiness is another considerable aspect of the coated material. To observe the tackiness, each one of the synthesized samples was tack-free. The consequences associated to the stability of the CUR-WDPU-01 to CUR-WDPU-05 emulsions are displayed in Table 3 which shows that stability of all the emulsions was approximately the same, i.e., greater than one year.

Structural characterization

FTIR spectra of all the monomers such as IPDI, PEG (Mn = 600), TEA, DMPA, curcumin and reaction intermediate products such as NCO terminated PU prepolymer, neutralized NCO terminated PU prepolymers, and final product of CUR-WDPUs dispersions are shown in Fig. 2. All the other FTIR spectral series of five CUR-WDPUs are displayed in Fig. 3.

FTIR spectrum of polyethylene glycol (PEG) (Mn = 600) is shown in Fig. 2a. It shows a broad band at 3439.08 cm−1 representing OH stretching, and the peaks observed at 2879.72 cm−1 and 2972.31 cm−1 are ascribed to CH2 antisymmetric and symmetric stretchings. Vibrational stretching of C–O–C was observed at 1041.56 cm−1.

Dimethylolpropionic acid (DMPA) spectrum (Fig. 2b) displayed a broad band at 3560.59 cm−1 due to carboxylic group (− COOH) stretching. The other prominent bands at 3360.65 cm−1 and 2588.47 cm−1 are attributed to the hydroxyl (− OH) group stretching vibrations. The bending vibrational peak related to CH2 was observed at 1456.05 cm−1 [44].

FTIR spectrum of IPDI (Fig. 2c) showed an intense and very sharp peak at 2249.00 cm−1 which is due to the isocyanate (− NCO) stretching vibrations. The signal associated with CH2 symmetric vibration is appeared at 2951.09 cm−1, while the signal at 1463.97 cm−1 displayed CH2 bending vibrations. The peak at 1359.82 cm−1 is attributed to C(CH3)2 present on the carbocyclic ring of IPDI.

PEG, DMPA and IPDI were reacted in a flask in the presence of a catalyst DBTDL which resulted to the formation of PU prepolymer with NCO terminals. FTIR spectrum of NCO end capped PU prepolymer (Fig. 2d) exhibited a broad signal at 3323.35 cm−1 which is attributed to − NH stretchings [59]. Other significant peaks have been observed at 1699.29 cm−1 entitled to − C═O stretchings; peaks seemed at 2889.37 cm−1 and 2962.66 cm−1 are associated to − CH symmetric and − CH asymmetric stretchings of − CH2 group. The NCO end capped PU prepolymer was further allowed to react with triethylamine that leads to the formation of neutralized PU prepolymer with NCO terminals. The FTIR spectrum of neutralized PU prepolymer with NCO terminals (Fig. 2f) showed a prominent broad peak at 3323.35 cm−1 which is attributed to − NH stretching [63, 64]. The − CH2 asymmetric stretching was detected at 2960.73 cm−1 and symmetric stretching at 2881.65 cm−1. The other sharp signals that appeared at 1697.36 cm−1 and 1529.55 cm−1 were associated to − C═O and − C═C stretchings, respectively. From the FTIR spectrum of neutralized polyurethane prepolymer with NCO terminals, it was clearly observed that the peak associated with isocyanate (NCO) groups has been insignificant in appearance. Afterward, neutralized NCO terminated PU prepolymer extended with curcumin which resulted in the formation of proposed curcumin-based water-dispersible polyurethane (CUR-WDPU). FTIR spectrum of curcumin, presented in Fig. 2g, showed a prominent peak at 3515 cm−1 associated with phenolic − OH stretching vibration, sharp absorption peaks appeared at 1627 and 1602 cm−1 due to enol-carbonyl stretchings [63, 64]. Similar stretchings of benzene ring appeared at 1600–1400 cm−1. The peak at 1597 cm−1 is for − C═O, at 1508 cm−1 for − C═C vibrations and at 1426 cm−1 for olefinic − CH bending vibrations, and the absorbance peaks at 1274 cm−1, 1197 cm−1, 1153 cm−1 and 1024 cm−1 are related to − C═O stretching vibrations. FTIR spectrum of CUR-WDPU-1 (Fig. 2h) showed typical signals for − NH stretchings at 3365.78 cm−1 and − CH symmetric stretching associated to − CH2 groups was seemed at 2927.94 cm−1. The absorption peaks at 1685.79 cm−1 and 1548.84 cm−1 were correlated to − C═O stretching and − NH deformations. The peaks at 1454.33 cm−1, 1409.96 cm−1 and 1323.17 cm−1 are associated to CH2 stretching, bending and wagging vibrations, respectively. C − O − C stretching has been observed at 1041.56 cm−1–1244.09 cm−1. On extending the neutralized NCO end capped PU prepolymer with varying mole ratios of curcumin, the FTIR spectral series of CUR-WDPU 01 to CUR-WDPU-05 is presented in Fig. 3(a–e). All the five spectra have shown identical peaks of − NH stretching vibrations, − CH symmetric and asymmetric stretching vibrations of CH2 groups, hydrogen-bonded − C═O stretching, − NH bending and C − O − C vibrations of curcumin-ether-type absorption.

Antimicrobial activity of curcumin water-dispersible polyurethanes based on IPDI (CUR-WDPU-IPDI)

Curcumin is being considered the safest, effective antimicrobial agent for ages. Besides, it is also used on cotton, wool and other textile materials as a potential inhibitor for microbial growth [40, 65]. For the advancement of antimicrobial skin ointments and suspensions with enhanced wound dressing and skin protection properties, curcumin amalgamation with diverse antimicrobial agents is utilized [66]. Previous research works confirmed the biocompatibility of polyurethanes [67, 68], and the current study assessed the antibacterial potential of CUR-WDPUs based on IPDI after applying on dyed/printed poly-cotton fabrics. The outcomes reported in Table 4 presented the higher antimicrobial activity of finishes against gram-positive bacterial strains such as Bacillus subtilis and Staphylococcus aureus than gram-negative bacterial strains such as Escherichia coli. Gul and Bakht [69] investigated that curcumin excellently inhibited the growth of certain gram-positive and gram-negative bacterial strains. It was also observed that an increase in the concentration of curcumin results in increased antibacterial activity as inferred from the previous studies [70, 71]. The enhanced antibacterial properties of the fabric are very important for usage in textile diligence to prevent or delay the growth of microbes on the surface of the textile.

Curcumin has suppressed the gram-positive and gram-negative bacterial cytokinesis through induction of filamentation. The investigations on B. subtilis, S. aureus and E. coli reported that curcumin has the ability to inhibit FtsZ polymerization due to which prokaryotic cell division is disrupted [72,73,74]. The zone of inhibition generated around the fabric disks was measured which ranges from 10 to 15 mm (Fig. 4 and Table 4). The outcomes showed that the dyed and printed fabrics, after application of curcumin-based water-dispersible polyurethanes, were found to be more effective against all the tested microbes.

Conclusion

The incorporation of biologically active molecules into the water-dispersible polyurethanes (WDPUs) has been comprehended to be an advanced technique to introduce bio-based finishing materials for various textile products. Novel curcumin-based water-dispersible polyurethane series containing CUR-WDPU-01 to CUR-WDPU-05 having varying mole ratios of curcumin were synthesized. By the prepolymer mixing process, the preparation of neutralized NCO end capped PU prepolymer has been accomplished using isophorone diisocyanate (IPDI), polyethylene glycol (PEG of Mn = 600), dimethylolpropionic acid (DMPA) and triethylamine (TEA) with molar ratios of 2:1:0.9:0.8. In the chain extension step, the neutralized NCO terminated PU prepolymer was extended with varying molar ratios of pristine curcumin. The formation of aqueous dispersion was achieved by the addition of estimated amount of deionized water. Structural characterization of all the synthesized CUR-WDPUs samples was done using the FTIR technique which confirmed the suggested structure of finally synthesized CUR-WDPU emulsions. The physical parameters, for example appearance of emulsion, the stability of the emulsion, film appearance, tackiness and solid contents (%), were investigated. The dyed and printed poly-cotton textile swatches were treated with 2% or 4% dilutions of polymeric dispersion solution by the pad-dry-cure procedure. The investigations of antibacterial activities of all the untreated and treated textile swatches have been done by disk diffusion assay. The outcomes of antibacterial assessment revealed that the post-treatment of textiles with synthesized CUR-WDPUs results in a remarkable rise in antibacterial activity. Overall, the best outcomes were achieved by 2% dilution of CUR-WDPUs as compared to 4% dilution. This could be ascribed to better penetration and excellent compatibility between both fabric and CUR-WDPUs. Moreover, it was observed from the results that by increasing the molar quantity of curcumin into the PU polymeric chain, the significant enhancements in antibacterial activity were exhibited. These newly synthesized CUR-WDPUs are eco-friendly, and bio-based antibacterial textile finishes with many other potential applications for polyester/cotton textiles. Future investigations of these finishes will explore the other textile assets for polyester/cotton textiles without adversely affecting their color fastness and mechanical properties. The entire study is a pioneer step on the way to the greener approach and bio-based finishing materials that can almost certainly be utilized for perspective textile usages.

Data availability

Data regarding all the experiments have been included in the manuscript; therefore, no further data are available for sharing.

References

Russo P, Acierno D, Marletta G, Destri GL (2013) Tensile properties, thermal and morphological analysis of thermoplastic polyurethane films reinforced with multiwalled carbon nanotubes. Eur Polymer J 49(10):3155–3164

Fiori DE (1997) Two-component water reducible polyurethane coatings. Prog Org Coat 32(1–4):65–71

Aznar AC, Pardini O, Amalvy J (2006) Glossy topcoat exterior paint formulations using water-based polyurethane/acrylic hybrid binders. Prog Org Coat 55(1):43–49

Sankar RM, Roy TK, Jana T (2011) Functionalization of terminal carbon atoms of hydroxyl terminated polybutadiene by polyazido nitrogen rich molecules. Bull Mater Sci 34(4):745–754

K.K. YEE, Aqueous polyurethane dispersion with non-yellowing and good bonding strength for water borne polyurethane footwear adhesives applications, (2006).

Matsunaga K, Nakagawa K, Sawai S, Sonoda O, Tajima M, Yoshida Y (2005) Synthesis and characterization of polyurethane anionomers. J Appl Polym Sci 98(5):2144–2148

Arshad N, Zia KM, Jabeen F, Anjum MN, Akram N, Zuber M (2018) Synthesis, characterization of novel chitosan based water dispersible polyurethanes and their potential deployment as antibacterial textile finish. Int J Biol Macromol 111:485–492

Kim KT, Dao TD, Jeong HM, Anjanapura RV, Aminabhavi TM (2015) Graphene coated with alumina and its utilization as a thermal conductivity enhancer for alumina sphere/thermoplastic polyurethane composite. Mater Chem Phys 153:291–300

Nguyen DA, Raghu AV, Choi JT, Jeong HM (2010) Properties of thermoplastic polyurethane/functionalised graphene sheet nanocomposites prepared by the in situ polymerisation method. Polym Polym Compos 18(7):351–358

Choi SH, Kim DH, Raghu AV, Reddy KR, Lee H-I, Yoon KS, Jeong HM, Kim BK (2012) Properties of graphene/waterborne polyurethane nanocomposites cast from colloidal dispersion mixtures. J Macromolecular Sci Part B 51(1):197–207

Nguyen DA, Lee YR, Raghu AV, Jeong HM, Shin CM, Kim BK (2009) Morphological and physical properties of a thermoplastic polyurethane reinforced with functionalized graphene sheet. Polym Int 58(4):412–417

W.D. Schindler, P.J. Hauser, Chemical finishing of textiles, Elsevier2004.

Yun J-K, Yoo H-J, Kim H-D (2007) Preparation and properties of waterborne polyurethane-urea/poly (vinyl alcohol) blends for high water vapor permeable coating materials. Macromol Res 15(1):22–30

Zia KM, Bhatti HN, Bhatti IA (2007) Methods for polyurethane and polyurethane composites, recycling and recovery: a review. React Funct Polym 67(8):675–692

J.R. Caldwell, G. Russell, Process for treating textile fibers and other shaped products with coatings, Google Patents, 1966.

A.S. Forschirm, L.E. Trepasso, Anti-soiling polyester textile material, Google Patents, 1972.

Delebecq E, Pascault J-P, Boutevin B, Ganachaud F (2013) On the versatility of urethane/urea bonds: reversibility, blocked isocyanate, and non-isocyanate polyurethane. Chem Rev 113(1):80–118

K. Suzuki, S. Miura, Process for forming a polyurethane coated biaxially oriented polyester film, Google Patents, 1990.

Fahmy H (2009) Utilization of poly (N-vinyl-2-pyrrolidone) in easy care finishing of cotton fabrics to improve their performance properties and antibacterial activities. J Ind Text 39(2):109–122

Fahmy H (2004) 43 Enhancing some performance properties of ester crosslinked cotton fabric by pre-quaternization. Egypt J Chem 47(6):627–640

Abo-Shosha M, El-Hilw Z, Aly A, Amr A, Nagdy ASIE (2008) Paraffin wax emulsion as water repellent for cotton/polyester blended fabric. J Ind Text 37(4):315–325

M. Abo-Shosha, Z. El-Hilw, A. Aly, A. Amr, A. Rabie, New Textile Water Repellent Based on Reaction of Toluene 2, 4-diisocyanate with Stearyl Alcohol, AATCC review, 9(7) (2009).

Fahmy HM, Aly AA, Amr AA, Sayed SM, Rabie M (2017) Effect of phenolic compounds and water repellents combination on performance properties of cotton/polyester blended fabric. Egypt J Chem 60(1):69–84

Fahmy H, Eid R, Nada D, Abd El-Aziz S (2015) Functionalizaton of linen fabric using poly (N-vinyl-2-pyrrolidone). Egypt J Chem. 58(4):447–458

Gaffer H, Gouda M, Abdel-Latif E (2013) Antibacterial activity of cotton fabrics treated with sulfadimidine azo dye/chitosan colloid. J Ind Text 42(4):392–399

Eid R, Hassan T, Fahmy H, Amr A, Nada D (2015) Utilization of triclosan to enhance the antibacterial activities of linen fabric. Egypt J Chem 58(2):203–215

Abdel-Wahab BF, Gaffer H, Fouda MM, Osman E, Fahmy H (2009) Synthesis of some new 2-[(2, 3-dihydroinden-1-ylidene) hydrazinyl]-4-methylthiazole derivatives for simultaneous dyeing and finishing for UV protective cotton fabrics. J Appl Polym Sci 112(4):2221–2228

Ibrahim N, Abo-Shosha M, Fahmy H, El-Sayed Z, Hebeish A (2008) Hybrids for finishing cotton fabric with durable handle performance. J Mater Process Technol 200(1–3):385–389

Fahmy H, Aly A, Mohamed Z (2016) Synthesis of poly (N-vinyl-2-pyrrolidone)/pyrodextrins adducts and their utilization in functionalization of cotton fabric. Int J Chem Tech Res 9(9):96–109

Fahmy H, Aly A, Sayed SM (2017) Graft copolymerization of N-vinylpyrrolidone onto stearyl alcohol to impart water repellency and antibacterial properties for cotton/polyester fabric. Prog Org Coat 105:176–182

Fahmy H, Aly A, Amr A, Sayed SM, Rabie A (2016) SA/TDI/PEG adducts as water repellent finishes for cotton/polyester blended fabric. Prog Org Coat 99:166–172

N. Ibrahim, Z. El-Sayed, H. Fahmy, A. Hassabo, M. Abo-Shosha, Perfume finishing of cotton/polyester fabric cross-linked with DMDHEU in presence of softeners, Research Journal of Textile and Apparel, (2013).

Ibrahim N, Amr A, Eid B, Mohamed Z, Fahmy H (2012) Poly (acrylic acid)/poly (ethylene glycol) adduct for attaining multifunctional cellulosic fabrics. Carbohyd Polym 89(2):648–660

Ibrahim N, Fahmy H, Rehim MA, Sharaf S, Abo-Shosha M (2010) Finishing of cotton fabrics with hyperbranched poly (ester-amine) to enhance their antibacterial properties and UV protection. Polym-Plast Technol Eng 49(13):1297–1304

Fahmy H, Abo-Shosha M, Ibrahim N (2009) Finishing of cotton fabrics with poly (N-vinyl-2-pyrrolidone) to improve their performance and antibacterial properties. Carbohyd Polym 77(4):845–850

Fahmy H, Eid R, Hashem S, Amr A (2013) Enhancing some functional properties of viscose fabric. Carbohyd Polym 92(2):1539–1545

Simoncic B, Tomsic B (2010) Structures of novel antimicrobial agents for textiles-a review. Text Res J 80(16):1721–1737

Akram M, Shahab-Uddin AA, Usmanghani K, Hannan A, Mohiuddin E, Asif M (2010) Curcuma longa and curcumin: a review article. Rom J Biol Plant Biol 55(2):65–70

Asouri M, Ataee R, Ahmadi AA, Amini A, Moshaei MR (2013) Antioxidant and free radical scavenging activities of curcumin. Asian J Chem 25(13):7593–7595

Han S, Yang Y (2005) Antimicrobial activity of wool fabric treated with curcumin. Dyes Pigm 64(2):157–161

Zhou Y, Zhang J, Tang R-C, Zhang J (2015) Simultaneous dyeing and functionalization of silk with three natural yellow dyes. Ind Crops Prod 64:224–232

A. Tai, T. Sawano, F. Yazama, H. Ito. (2011) Evaluation of antioxidant activity of vanillin by using multiple antioxidant assays. Biochimica et Biophysica Acta (BBA)-General Subjects. 1810(2): 170–177.

Rakchoy S, Suppakul P, Jinkarn T (2009) Antimicrobial effects of vanillin coated solution for coating paperboard intended for packaging bakery products. Asian J Food Agro-Industry 2(4):138–147

Shahidi F (2000) Antioxidants in food and food antioxidants. Food Nahrung 44(3):158–163

Ooi N, Chopra I, Eady A, Cove J, Bojar R, A. O’neill. (2013) Antibacterial activity and mode of action of tert-butylhydroquinone (TBHQ) and its oxidation product, tert-butylbenzoquinone (TBBQ). J Antimicrobial Chemotherapy. 68(6):1297–1304

Buck D, Edwards M (1997) Antioxidants to prolong shelf-life. Food Technol Int 2:29–33

S. Zorofchian Moghadamtousi, H. Abdul Kadir, P. Hassandarvish, H. Tajik, S. Abubakar, K. Zandi, A review on antibacterial, antiviral, and antifungal activity of curcumin, BioMed research international, 2014 (2014).

Khalil OAK, de Faria Oliveira OMM, Vellosa JCR, de Quadros AU, Dalposso LM, Karam TK, Mainardes RM, Khalil NM (2012) Curcumin antifungal and antioxidant activities are increased in the presence of ascorbic acid. Food Chemistry. 133(3):1001–1005

Ak T, Gülçin İ (2008) Antioxidant and radical scavenging properties of curcumin. Chem Biol Interact 174(1):27–37

Basnet P, Skalko-Basnet N (2011) Curcumin: an anti-inflammatory molecule from a curry spice on the path to cancer treatment. Molecules 16(6):4567–4598

G. Yakub, A. Toncheva, N. Manolova, I. Rashkov, D. Danchev, V. Kussovski, Electrospun polylactide‐based materials for curcumin release: Photostability, antimicrobial activity, and anticoagulant effect, Journal of Applied Polymer Science, 133(5) (2016).

Sarika P, James NR, Raj DK (2016) Preparation, characterization and biological evaluation of curcumin loaded alginate aldehyde–gelatin nanogels. Mater Sci Eng, C 68:251–257

B.B. Aggarwal, A. Kumar, A.C. Bharti, Anticancer potential of curcumin: preclinical and clinical studies, Anticancer research, 23(1/A) (2003) 363–398.

Aggarwal BB, Sung B (2009) Pharmacological basis for the role of curcumin in chronic diseases: an age-old spice with modern targets. Trends Pharmacol Sci 30(2):85–94

Ammon HP, Wahl MA (1991) Pharmacology of Curcuma longa. Planta Med 57(01):1–7

Jagetia GC, Aggarwal BB (2007) “Spicing up” of the immune system by curcumin. J Clin Immunol 27(1):19–35

A. Kumar, A. Ahuja, J. Ali, S. Baboota, Conundrum and therapeutic potential of curcumin in drug delivery, Critical Reviews™ in Therapeutic Drug Carrier Systems, 27(4) (2010).

Zia F, Zia KM, Zuber M, Rehman S, Tabasum S, Sultana S (2016) Synthesis and characterization of chitosan/curcumin blends based polyurethanes. Int J Biol Macromol 92:1074–1081

Zia KM, Anjum S, Zuber M, Mujahid M, Jamil T (2014) Synthesis and molecular characterization of chitosan based polyurethane elastomers using aromatic diisocyanate. Int J Biol Macromol 66:26–32

Bai CY, Zhang XY, Dai JB, Zhang CY (2007) Water resistance of the membranes for UV curable waterborne polyurethane dispersions. Prog Org Coat 59(4):331–336

Jang JY, Jhon YK, Cheong IW, Kim JH (2002) Effect of process variables on molecular weight and mechanical properties of water-based polyurethane dispersion. Colloids Surf, A 196(2–3):135–143

Tabasum S, Zuber M, Jamil T, Shahid M, Hussain R (2013) Antimicrobial and pilling evaluation of the modified cellulosic fabrics using polyurethane acrylate copolymers. Int J Biol Macromol 56:99–105

Reddy KR, Raghu AV, Jeong HM (2008) Synthesis and characterization of novel polyurethanes based on 4, 4’-{1, 4-phenylenebis [methylylidenenitrilo]} diphenol. Polym Bull 60(5):609–616

Raghu A, Jeong HM, Kim JH, Lee YR, Cho YB, Sirsalmath K (2008) Synthesis and characterization of novel polyurethanes based on 4-{(4-hydroxyphenyl) iminomethyl} phenol. Macromol Res 16(3):194–199

Ammayappan L, Moses JJ (2009) Study of antimicrobial activity of aloevera, chitosan, and curcumin on cotton, wool, and rabbit hair. Fibers and polymers 10(2):161–166

Varaprasad K, Vimala K, Ravindra S, Reddy NN, Reddy GVS, Raju KM (2011) Fabrication of silver nanocomposite films impregnated with curcumin for superior antibacterial applications. J Mater Sci - Mater Med 22(8):1863–1872

Zia KM, Zuber M, Bhatti IA, Barikani M, Sheikh MA (2009) Evaluation of biocompatibility and mechanical behavior of polyurethane elastomers based on chitin/1, 4-butane diol blends. Int J Biol Macromol 44(1):18–22

Zia KM, Zuber M, Bhatti IA, Barikani M, Sheikh MA (2009) Evaluation of biocompatibility and mechanical behavior of chitin-based polyurethane elastomers Part-II: Effect of diisocyanate structure. Int J Biological macromolecules. 44(1):23–28

Gul P, Bakht J (2015) Antimicrobial activity of turmeric extract and its potential use in food industry. J Food Sci Technol 52(4):2272–2279

Chen J, Wang F-L, Chen W-D (2014) Modulation of apoptosis-related cell signalling pathways by curcumin as a strategy to inhibit tumor progression. Mol Biol Rep 41(7):4583–4594

Sun J, Tan H (2013) Alginate-based biomaterials for regenerative medicine applications. Materials 6(4):1285–1309

Kaur S, Modi NH, Panda D, Roy N (2010) Probing the binding site of curcumin in Escherichia coli and Bacillus subtilis FtsZ–a structural insight to unveil antibacterial activity of curcumin. Eur J Med Chem 45(9):4209–4214

Kannan K, Radhika D, Reddy KR, Raghu AV, Sadasivuni KK, Palani G, Gurushankar K (2021) Gd3+ and Y3+ co-doped mixed metal oxide nanohybrids for photocatalytic and antibacterial applications. Nano Express. 2(1):010014

Kannan K, Radhika D, Nesaraj A, Sadasivuni KK, Reddy KR, Kasai D, Raghu AV (2020) Photocatalytic, antibacterial and electrochemical properties of novel rare earth metal oxides-based nanohybrids. Materials Science for Energy Technol 3:853–861

Acknowledgements

This research work is taken from PhD thesis of Dr. Noureen Arshad.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Arshad, N., Zia, K.M., Hussain, M.T. et al. Synthesis of novel curcumin-based aqueous polyurethane dispersions for medical textile diligences with potential of antibacterial activities. Polym. Bull. 79, 7711–7727 (2022). https://doi.org/10.1007/s00289-021-03871-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-021-03871-y