Abstract

A series of κ-carrageenan (κ-CG) hydrogels were prepared by using glutaraldehyde (GA) as crosslinker for controlled releasing of copper and manganese micronutrients. The hydrogels were characterized by gel content, swelling and degradation tests, Attenuated Total Reflectance Fourier Transform Infrared Spectroscopy (ATR-FTIR) and Scanning Electron Microscope (SEM) observations. The variations of swelling percentages (S%) with time, temperature and pH were determined for all hydrogels. As the amounts of crosslinker increased, S% decreased regularly in contrast to gel content results. The higher swelling values were obtained in basic medium than acidic and neutral mediums for all κ-CG hydrogels. Releasing of copper and manganese micronutrients from κ-CG hydrogels was investigated in water and soil. A simulated releasing model was also applied to estimate the releasing behaviors in agricultural irrigations. In all release studies, the cumulative release values increased with decreasing GA amounts. The release kinetic parameters were also calculated. It was detected that the releasing of micronutrients in soil was slower than that in water.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

All plants must need several nutrient elements from their environment to ensure successful growth and development of both vegetative and reproductive tissues. Micronutrients are one of the essential nutrient elements required by plant organisms in small quantities and play an important role to increase crop yields as well as improving the nutritional quality of food. A lack of any one of them in the soil can limit plant growth, even when all other nutrients are present in adequate amounts [1].

Copper is essential in several enzyme systems and plant respiration. It activates some enzymes in plants which are involved in lignin synthesis. It is also required in plant metabolism of carbohydrates and proteins and assists photosynthesis. Copper also serves to intensify flavor and color in vegetables and color in flowers. Its deficiency symptoms are the formation of cupping and interveinal chlorosis (between the veins of the new leaves or the whole leaf), wilting of leaves and the decrement newest leaves [2, 3]. The range of copper concentration in dry matter is 2–20 mg kg−1 for plants. 1.0–3.0 mg kg−1 of copper exists in soils with over 8% organic matter. The toxicity level of copper is 30 mg kg−1 [4,5,6].

Manganese plays a fundamental role in the absorption of iron, calcium and magnesium and the activation of vital enzymes such as decarboxylase, dehydrogenase and oxidase. It is involved in the structure of the superoxide dismutase enzyme. It assists in the process of photosynthesis, respiration, and nitrogen assimilation. It is also required in pollen germination, pollen tube growth, root cell elongation and resistance to root pathogens. Manganese deficiency symptoms appear as interveinal chlorosis between the veins or in young leaves. Plant growth may also be slowed, so plant may be stunted [3, 7]. Adequate concentrations of manganese for plant growth vary between 20 and 200 mg kg−1 (dry weight). The toxicity level is 1000 mg kg−1.

Controlled-release fertilizers (CRFs) are widely used in agriculture applications. CRFs deliver nutrients to plants at a rate that closely approximates plant nutrient demand over an extended period [5, 6]. One possible way to provide the controlled releasing of plant nutrients is forming the matrix structures. In matrix type formulation, nutrients are dispersed in the matrix and diffused through the matrix pores or channels. Many kinds of natural (starch, cellulose, gelatin, cellulose derivatives, etc.) or synthetic polymers (polyolefins, polydiolefins and their copolymers, etc.) are used to synthesize the matrix phase [7, 8].

Hydrogels are three-dimensional crosslinked networks which depend on hydrophilic polymers that can absorb or retain water without dissolution. The hydrophilic property is due to the presence of chemical residues such as –OH, –COOH, –NH2, –CONH2, –SO3H and others within molecular structure. In response to stimuli pH, temperature, light or pressure, hydrogels have the properties or ability to change their shape or volume [9, 10]. Because of their excellent characteristics, hydrogels can also be used for controlled release of agrochemicals and nutrients in agricultural and horticultural applications [11, 12]. The combination of hydrogels and various agricultural chemicals may improve nutrition of plants and mitigate at the same time the environmental impact from water-soluble fertilizers, reduce evaporation losses and lower frequency of irrigation [13, 14].

Carrageenans (CG) are family of linear sulfated polysaccharides that are extracted from red seaweeds. There are three main types of carrageenans (κ-CG, ι-CG and λ-CG) which differ in degree of sulfation in molecule structure [15, 16]. κ-CG is a non-toxic, hydrophilic, biodegradable and ionic polysaccharide found as a matrix material in numerous species of seaweed. It comprises of repeating units of (1,3)-D-galactopyranose and (1,4)-3,6-anhidro-α-D-galactopyranose with sulfate groups in a certain amount and position. Several crosslinker reagents have been used to crosslink κ-CG such as glutaraldehyde (GA), genipin, vinyltriethoxysilane, CaCl2 and epichlorohydrin [17]. GA is selected for this research because of inexpensiveness and easily availability. κ-CG is widely used for gelling, thickening and stabilizing properties in the food, cosmetic, chemical industries, etc [18].

The aim of this study was to prepare a controlled-release micronutrient fertilizer (copper and manganese) using κ-CG polymer. We focused to obtain the most convenient hydrogel structure for micronutrient release. For this purpose, six types of κ-CG hydrogels were synthesized by chemical crosslinking method using GA as a crosslinker. The effects of the crosslinker amount on gel content, morphological structure, swelling and degradation behaviors of the hydrogels were investigated. Depending on the swelling behaviors, we planned to choose the suitable hydrogel for micronutrient release studies to be carried out in water and soil. The release kinetics parameters and release mechanism of micronutrient from hydrogels were also determined.

Experimental

Materials

κ-CG (300.000 g/mol Fluka Chemie), copper (II) sulfate pentahydrate, manganese (II) sulfate monohydrate and phosphate-buffered saline (PBS) tablets were purchased from Sigma-Aldrich. GA (25 wt% in H2O) solution was obtained from Merck.

κ-CG hydrogel preparation

κ-CG hydrogel was prepared by chemical crosslinking method using GA as a crosslinker. 2.0% of κ-CG aqueous solution was prepared at 80 °C by continuous stirring. 5.0 mL of polymer solutions was transferred into glass tubes, and the different volumes of GA solution changing from 0.25 to 1.50 mL were added. The crosslinking reaction was proceeded for 24 h at room temperature. Then, the glass tube was broken, and cylinder-shaped hydrogel rods were cut into pieces of 0.5 cm long. Hydrogel disks were washed several times with distilled water to remove unreacted chemicals. Then, they were dried first in air and then in a vacuum oven at 40 °C.

ATR-FTIR analysis

The chemical structures of κ-CG polymer and hydrogel were characterized by ATR-FTIR. The measurements were performed using a Bruker Vertex 70 Infrared Spectrometer equipped with diamond. The measurements were recorded in transmission mode with an incident beam angle of 65°, using ZnSe wire grid polarizer. The ATR-FTIR spectrums were set between 400 and 4000 cm−1, using a resolution of 4 cm−1 and 25 scans.

Gel content

The gel content expressed as the fraction of insoluble weight was obtained by extracting the soluble part in boiling water for 24 h using Soxhlet apparatus and drying the insoluble part completely in a vacuum oven at 50 °C [16]. Gel content (%) is determined gravimetrically from Eq. 1:

where Wo is the initial weight of dried samples before extraction (total of soluble weight and insoluble weight); W1 is final weight (weight of insoluble part of hydrogels after extraction). This experiment was carried out in triplicate.

Swelling behaviors

The gravimetric method was used to study the stimuli-responsive swelling behavior of hydrogels. A preweighed dry hydrogel sample was immersed into PBS at pH = 7.0, 30 °C. At certain time intervals, the hydrogel was taken out of the swelling medium. Excessive surface water of the swollen hydrogel was removed with a filter paper, and swollen hydrogels were weighed. Taking an average value of three measurements for each sample, swelling percentage (%S) of the hydrogel is calculated using Eq. 2. The mass measurements were preceded until reach constant weight [19,20,21].

where Wd and Ws refer to the weight of dry and swollen hydrogels, respectively.

The weights of swollen gels were considered as equilibrium values when they remained constant for a period of 12 h. To study the influence of pH on the equilibrium swelling percentage, hydrogels were swollen in PBS solutions in the pH range of 2.0–12.0 [22, 23]. Temperature-dependent equilibrium swelling degrees were determined in the temperature range of 4–60 °C at pH 7.0. The reproducible results for all swelling studies were obtained with triplicate measurements [24].

Degradation test

Degradation test of hydrogels was performed at pH 7.0, 30 °C. Dried samples were left to swell in PBS. At the end of 24 h, swollen gels were removed from solution and weighed. This mass (Wm) was recorded as the maximum swollen state of hydrogels. Then, they were placed into the same medium, and the weighing measurement was proceeded at regular intervals until hydrogels completely degraded [25,26,27]. The degradation is determined in terms of weight loss (%) from Eq. 3:

where Wm is the weight of hydrogel at most swollen stage and Wt is the weight of hydrogel at time t. All measurements were performed in triplicate.

SEM studies

κ-CG hydrogels swelled to equilibrium state in water at room temperature. They were removed from swelling medium and were rapidly frozen at − 80 °C and then dried in a Labconco FreeZone 4.5 Freeze Dryer. Dried and swollen samples were mounted by double-sided tape on stubs and coated with gold in a Polaron SC 502 Sputter Coater. The surface micrographs of the samples were obtained with a JEOL, JSM 6060 LV Scanning Electron Microscope [28,29,30,31].

Preparation of micronutrient-loaded κ-CG hydrogels

CG-4, CG-5 and CG-6 hydrogels were chosen for release studies depending on their swelling values. Micronutrient-loaded κ-CG (ML-CG) hydrogels were obtained by classic entrapment method. ML-CG hydrogel samples were prepared by adding the micronutrient into the κ-CG and GA mixture during crosslinking reactions. The micronutrient contents (0.5 mg per hydrogel) were arranged according to the literature [32]. Similar to our standard hydrogel formation method explained previously, the cylinder-shaped fresh hydrogel rods were taken from glass tubes and cut into 0.5-cm-long pieces. ML-CG hydrogel disks were dried first in air and then in a vacuum oven at 40 °C [33].

Release studies

Release studies were carried out using three different experimental sets: continuous releasing in water, intermittent releasing model in water and releasing in soil. ML-CG hydrogel was placed in 100 mL of distilled water in a glass beaker. At different time intervals, aliquots of 100 µL were drawn from the medium to follow the release, so the volume can be considered constant. The release always maintained at “sink” conditions. The amount of micronutrient released from hydrogel was determined using atomic absorption spectrometer (AAS, PerkinElmer A4000). The measurements were proceeded until reaching the equilibrium release value. The reproducible results were obtained with triplicate measurements [34, 35].

The cumulative release (%) of micronutrient from hydrogels is calculated according to Eq. 4:

where Mt and M∞ are the amount of micronutrient released at time t and initial loaded micronutrient contents, respectively.

As the agricultural irrigation is usually carried out once a day, a new intermittent release study was designed to estimate the releasing of micronutrient from the hydrogel in the soil. For this purpose, ML-CG hydrogel was placed in a 100 mL of distilled water in a glass beaker and it was kept at room temperature. After 15 min, hydrogel was taken from water and left to dry. The released amount of micronutrient in water was determined using AAS. After 24 h, dried hydrogel was placed into the same release medium and the procedure was repeated. The cumulative release (%) was calculated using Eq. 4. The measurements were proceeded until reaching the equilibrium release value.

The other release studies were also performed in soil. A dry ML-CG hydrogel was put into permeable chiffon package to preserve the sample from soil sticking. A package was buried into a plastic beaker containing 200 g of dry soil at 2.0 cm depth. About 60 numbers of beakers were prepared in this way. Then, 150 mL of distilled water was added to each of them and the beakers were kept at room temperature. At certain time intervals (every 24 h) during the period, one package was removed from the beaker and ML-CG hydrogel was placed into 100 mL of distilled water. The sum of micronutrient was extracted from the hydrogel into the water, and the amount of micronutrient diffused was measured by using AAS. Thus, the amount of released micronutrient into the soil has been calculated using Eq. 4. This process was continued until the equilibrium release value was reached [35,36,37].

Results and discussion

Gel formation

General mechanisms about the crosslinking mechanism are well documented in the literature [38]. The hydroxyl group of κ-CG polymer reacts with aldehyde groups of GA by forming a hemiacetal structure. A suggested mechanism for crosslinking reaction is given in Fig. 1. Gel contents (%) of hydrogels calculated via Eq. 1 are given in Table 1.

The results were found in the range of 72–94%. The highest and lowest gel content was obtained for CG-6 and CG-1 hydrogels, respectively. It can be said that network density in hydrogel structure was increased with GA. It is well known that polymer and crosslinker amounts promote the gel content, so the results are compatible with the literature [39, 40].

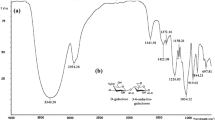

ATR-FTIR spectra

Figure 2 shows ATR-FTIR spectra of κ-CG polymer and hydrogel. In the spectra, the absorption observed at 3500–3000 cm−1 was characteristic of the O–H stretching and absorption at ~ 2920 cm−1 was due to C–O groups and the interlayer C–H stretching. Besides, the absorption at ~ 1500 cm−1 for –CH2 stretching, absorption at ~ 1446 cm−1 for sulfate stretch, absorption at ~ 1260 cm−1 for ester sulfate group S=O, absorption at ~ 1080 cm−1 for glycosidic linkage, absorption at ~ 933 cm−1 for C–O of 3,6-anhydro-D-galactose and absorption at ~ 850 cm−1 for C–O–SO3 of D-galactose-4-sulfate were observed. In hydrogel spectra, the sharp increment of absorption bands at ~ 2920 cm−1 and 1200–1000 cm−1 can be attributed to hemiacetal structure formed by crosslinking between polymer and GA [41].

Swelling behaviors

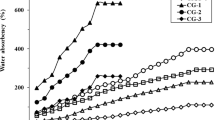

Figure 3a presents the variations of S% values with time at pH 7.0 and 30 °C. All hydrogels swelled with time initially, and then remained constant at nearly 12 h. The amount of GA significantly influenced the swelling value of hydrogels, so S% increased with GA content. The possible reason for this phenomenon might be correlated with the increment network interactions between GA, water molecules and polymer [42,43,44]. S% values were determined to be 970% for the most swollen hydrogel CG-1 and 258% for the least swollen hydrogel CG-6.

As can be seen from Fig. 3b, S% of hydrogels increased with temperature at the beginning. This increment may be due to an increase in the thermal mobility of the polymer molecules. While the temperature was increased above 40 °C, the slight decreasing in swelling values was observed. CG-6 hydrogel having the most gel content exhibited more stable structure than the others. It could be said that the formation of close-packed structure increased the resistance of hydrogel to temperature [43].

Figure 3c shows the effects of pH on the swelling behaviors of the κ-CG hydrogels. All hydrogels exhibited lower S% values in acidic medium in comparison with neutral and basic medium. For example, S% values were determined to be 275% at pH 2.0 and 1883% at pH 12.0 for CG-1 hydrogel. pH-sensitive behavior of κ-CG hydrogels arose from their ionic properties. It can be postulated that the protonation of ionic groups accelerated the formation of hydrogen bonds, so the swelling was precluded in acidic solution. On the contrary, ionization and charge density in the hydrogel networks expanded at pH (7–12) due to the strong electrostatic repulsion between ionic groups. Consequently, the electrostatic repulsion provided the relaxation of structure and hydrogels could easily swell [45, 46].

Degradation behaviors of the hydrogels

The stability of hydrogels structure is very important for long-term application. In some conditions, the crosslinking network may break down and the network chains dissolve into the medium. Therefore, it is essential to know the degradation behaviors of the hydrogels. Degradation behaviors of κ-CG hydrogels at pH 7.0 and 30 °C are presented in Fig. 3d. 100% of weight loss of the hydrogels varied 4–8 days. The least swollen CG-6 hydrogel had the longer degradation time. The result indicated that the crosslinker density caused more durable hydrogel structures [42, 45, 47].

SEM analysis

SEM photographs of κ-CG hydrogels are given in Fig. 4. The morphological differences between dry and swollen forms of the hydrogels can be clearly observed. While swollen hydrogels possessed large number of pores, dry hydrogel had a non-porous surface with rough structure. The porosity provided easy diffusion and absorption of water into the hydrogel. The largest and smallest pores were obtained for CG-1 and CG-6 hydrogels, respectively. It is observed that pore sizes reduced and the pore numbers increased with increasing crosslinker content [33, 39, 48]. The structure of κ-CG hydrogel could be called as “sponge-type structure.”

The porosity values of the hydrogels determined from SEM images are presented in Table 2. It was observed that the pore sizes of hydrogels were in micro-size. This value varied from 0.47 ± 0.10 to 1.11 ± 0.03 µm. SEM evaluations were in good agreement with the observed swelling results. The most swollen CG-1 hydrogel displayed more porosity relative to others. While the average pore density of CG-6 hydrogel was very high, its small pores resulted in the lowest swelling value [19, 39].

Release behavior

Figure 5 represents release behavior of the ML-CG hydrogels in water. When the hydrogel adsorbed water within its structure, the water dissolved copper or manganese chloride leads to concentration difference between the inside structure of the hydrogel and the outer solution. Consequently, copper or manganese ions were released from the hydrogel [49, 50]. The release rates of all hydrogels were increased regularly and then became constant between 11 and 16 h. It can be concluded from the results that the crosslinking density of the hydrogel is one of the factors affecting the release behavior of ML-CG hydrogels. The cumulative release of all hydrogels increased with a decreasing GA amount. The results are in good agreement with the swelling results. As emphasized before, CG-1 hydrogel swelled much more than others depending on network density. While hydrogel swelled, the loaded micronutrient molecules easily escaped through the large pores of hydrogel [51,52,53].

The values of total percent cumulative release of copper were found to be 99%, 98% and 95%, for CG-4, CG-5 and CG-6 hydrogels, respectively. Besides, the values of total percent cumulative release of manganese from CG-4, CG-5 and CG-6 hydrogels were 98%, 96% and 93%, respectively. The results showed that the values were close to each other.

A semiempirical equation is introduced to represent the micronutrient release process of swelling polymer.

where F is fractional uptake, Mt is the amount of micronutrient released at time t and M∞ is the total content of micronutrient loaded into hydrogels; k is releasing factor and the releasing exponent n describes the type of diffusion. The release mechanism is a function of the diffusion exponent n. The value of n < 0.5 suggests quasi-Fickian diffusion; n = 0.5 suggests a Fickian diffusion; 0.5 < n < 1.0 supports an anomalous non-Fickian transport (both diffusional and relaxational transport); for n = 1.0, the release mechanism is represented by a case II, relaxational transport, time-independent, zero-order model [54]. Results of release exponent and release factor for hydrogels were determined from the graphs driven via Eq. 5 and are listed in Table 3. As n value of all hydrogels was calculated near 1.0, it corresponds to case II transport, where the release rate is constant and controlled by polymer chain relaxation. Relaxation release is the transport mechanism associated with stresses and state transition in hydrophilic glassy polymers which swell in water or biological fluids. This process also involves polymer disentanglement and erosion [55].

A new intermittent release experiment was improved to be a model for soil release study. The intermittent release behavior of copper and manganese, from all the CRF hydrogels, is presented in Fig. 6. The results showed that the cumulative release values were gradually increased at the beginning and then the release rates became slower. The release became constant after 8–10 days. The release values were satisfactory, even if they were slightly decreased in comparison with continuous release values. The values of total percent cumulative release were ranged from 78 to 88%. Besides, the release time was nearly 10 times longer than the continuous release in water. It can be obviously said that the micronutrient release rates and the total cumulative release values are dependent upon the release method and the values increased with decreasing GA content like continuous release study.

The release behavior of copper and manganese, from ML-CG hydrogels, into soil is presented in Fig. 7. It was found that the cumulative release of micronutrients into soil increased with time and became constant about 10 days. The values of total percent cumulative release were ranged from 80 to 88%. It was observed that the release results in soil coincided with intermittent release results. It was concluded that the new model release system designed in this study was in good agreement with releasing behaviors in soil.

In conclusion, for all the synthesized hydrogels, the total cumulative release values in soil solution were less than those in water. According to the literature [56, 57], the nutrient release from hydrogels into soil occurs when hydrogels are swollen by soil solution. The solution, then, dissolves the soluble part of nutrient, and the nutrient molecules slowly diffuse through the hydrogel pores and release into the soil. Thus, it can be said that the diffusion of soluble nutrients from the hydrogel into soil is more difficult than that in water [58, 59].

Conclusion

Six types of κ-CG hydrogels were prepared by using GA crosslinker, and their swelling/degradation behaviors and morphological properties were investigated. The swelling percentages (S%) regularly decreased with increasing GA amount, in contrast to gel content results. Hydrogels were found to be sensitive to pH variations. They had porous structure sensitive to changes in the amount of crosslinker. The average pore sizes and density of the least swollen CG-6 hydrogel were found to be 0.47 ± 0.10 µm and 4.8 × 108 ± 0.09 number of pores in cm2. Copper and manganese micronutrients were loaded in κ-CG hydrogel by classic entrapment method. The release behaviors of micronutrients from κ-CG hydrogels, both in water and in soil, were investigated. A new intermittent release model was also developed to estimate the release behavior in agricultural area. The release results closely related to S% values of the hydrogels. It was found that the values of release exponent for all hydrogels were close to 1.0, which corresponds to case II transport. The results of the present work indicate that the κ-CG hydrogels are good support materials for controlled release of micronutrients with their excellent swelling/degradation behaviors and morphological properties.

References

Shaviv A (2001) Advances in controlled-release fertilizers. Adv Agron 71:1–49

Manivasagaperumal R, Vijayarengan P, Balamurugan S, Thiyagarajan G (2011) Effect of copper on growth, dry matter yield and nutrient content of Vigna Radiata (L.) Wilczek. J Phytol 3(3):53–62

Ducic T, Polle A (2005) Transport and detoxification of manganese and copper in plants. Braz J Plant Physiol 17(1):103–112

Barker AV, Pilbeam DJ (2007) Handbook of plant nutrition. CRC Press Taylor & Francis Group, Boca Raton, pp 411–430

Bolatı I, Kara O (2017) Plant Nutrients: sources, functions, deficiencies and redundancy. J Bartin Fac For 19(1):218–228

Mahler RL (2004) Nutrients plants require for growth. University of Idaho Extension Idaho Agricultural Experiment Station, Moscow, pp 1–4

Millaleo R, Reyes-Diaz M, Ivanov AG, Mora ML, Alberdi M (2010) Manganese as essential and toxic element for plants: transport, accumulation and resistance mechanisms. J Soil Sci Plant Nutr 10(4):470–481

Azeem B, KuShaari K, Man ZB, Basit A, Thanh TH (2014) Review on materials & methods to produce controlled release coated urea fertilizer. J Control Release 181:11–21

Xie L, Liu M, Ni B, Wang Y (2012) Utilization of wheat straw for the preparation of coated controlled-release fertilizer with the function of water retention. J Agric Food Chem 60(28):6921–6928

Ji Y, Liu G, Ma J, Xu H, Yagi K (2012) Effect of controlled-release fertilizer on nitrous oxide emission from a winter wheat field. Nutr Cycl Agroecosyst 94(1):111–122

Cong Z, Yazhen S, Changwen D, Jianmin Z, Huoyan W, Xiaoqin C (2010) Evaluation of waterborne coating for controlled-release fertilizer using wurster fluidized bed. Ind Eng Chem Res 49(20):9644–9647

Pulat M, Akalin GO (2013) Preparation and characterization of gelatin hydrogel support for immobilization of Candida Rugosa lipase. Artif Cells Nanomed Biotechnol 41(3):145–151

Pulat M, Akalin GO, Karahan ND (2014) Lipase release through semi-interpenetrating polymer network hydrogels based on chitosan, acrylamide, and citraconic acid. Artif Cells Nanomed Biotechnol 42(2):121–127

Wu L, Liu M, Liang R (2008) Preparation and properties of a double-coated slow-release NPK compound fertilizer with superabsorbent and water-retention. Bioresour Technol 99(3):547–554

Shavit U, Reiss M, Shaviv A (2003) Wetting mechanisms of gel-based controlled-release fertilizers. J Control Release 88(1):71–83

Pulat M, Yoltay N (2016) Smart fertilizers: preparation and characterization of gelatin-based hydrogels for controlled release of MAP and AN fertilizers. Agrochim -Pisa Univ Press 60(4):249–261

Pulat M, Uğurlu N (2016) Preparation and characterization of biodegradable gelatin-PAAm-based IPN hydrogels for controlled release of maleic acid to improve the solubility of phosphate. Soft Mater 14(4):217–227

Popa EG, Gomes ME, Reis RL (2011) Cell delivery systems using alginate–carrageenan hydrogel beads and fibers for regenerative medicine applications. Biomacromol 12(11):3952–3961

Abad LV, Relleve LS, Aranilla CT, Rosa AMD (2003) Properties of radiation synthesized PVP-kappa carrageenan hydrogel blends. Radiat Phys Chem 68(5):901–908

Salgueiro AM, Daniel-da-Silva AL, Fateixa S, Trindade T (2012) κ-Carrageenan hydrogel nanocomposites with release behavior mediated by morphological distinct Au nanofillers. Carbohydr Polym 91(1):100–109

Daniel-da-Silva AL, Ferreira L, Gil AM, Trindade T (2011) Synthesis and swelling behavior of temperature responsive κ-carrageenan nanogels. J Colloid Interface Sci 355(2):512–517

Popa EG, Caridade SG, Mano JF, Reis RL, Gomes ME (2015) Chondrogenic potential of injectable κ-carrageenan hydrogel with encapsulated adipose stem cells for cartilage tissue-engineering applications. J Tissue Eng Regen Med 9(5):550–563

Chang C, Duan B, Cai J, Zhang L (2010) Superabsorbent hydrogels based on cellulose for smart swelling and controllable delivery. Eur Polym J 46(1):92–100

Gao X, He C, Xiao C, Zhuang X, Chen X (2013) Biodegradable pH-responsive polyacrylic acid derivative hydrogels with tunable swelling behavior for oral delivery of insulin. Polymer 54(7):1786–1793

Bao Y, Ma J, Li N (2011) Synthesis and swelling behaviors of sodium carboxymethyl cellulose-g-poly (AA-co-AM-co-AMPS)/MMT superabsorbent hydrogel. Carbohyd Polym 84(1):76–82

Wang W, Wang A (2010) Synthesis and swelling properties of pH-sensitive semi-IPN superabsorbent hydrogels based on sodium alginate-g-poly(sodium acrylate) and polyvinylpyrrolidone. Carbohyd Polym 80(4):1028–1036

Loh XJ, Peh P, Liao S, Sng C, Li J (2010) Controlled drug release from biodegradable thermoresponsive physical hydrogel nanofibers. J Control Release 143(2):175–182

Dang QF, Yan JQ, Li JJ, Cheng XJ, Liu CS, Chen XG (2011) Controlled gelation temperature, pore diameter and degradation of a highly porous chitosan-based hydrogel. Carbohyd Polym 83(1):171–178

Deshmukh M, Singh Y, Gunaseelan S, Gao D, Stein S, Sinko PJ (2010) Biodegradable poly(ethylene glycol) hydrogels based on a self-elimination degradation mechanism. Biomaterials 31(26):6675–6684

Tan R, She Z, Wang M, Fang Z, Liu Y, Feng Q (2012) Thermo-sensitive alginate-based injectable hydrogel for tissue engineering. Carbohyd Polym 87(2):1515–1521

Varghese JS, Chellappa N, Fathima NN (2014) Gelatin-carrageenan hydrogels: role of pore size distribution on drug delivery process. Colloids Surf B Biointerfaces 113:346–351

Sarkar DJ, Singh A, Mandal P, Kumar A, Parmar BS (2015) Synthesis and characterization of poly (CMC-gcl-PAam/Zeolite) superabsorbent composites for controlled delivery of zinc micronutrient: swelling and release behavior. Polym-Plast Technol 54(4):357–367

Han J, Guenier A, Salmieri S, Lacroix M (2008) Alginate and chitosan functionalization for micronutrient encapsulation. J Agric Food Chem 56:2528–2535

Ma Z, Jia X, Hu J, Liu Z, Wang H, Zhou F (2013) Mussel-inspired thermosensitive polydopamine-graft-poly(N-isopropylacrylamide) coating for controlled-release fertilizer. J Agric Food Chem 61(50):12232–12237

Jamnongkan T, Kaewpirom S (2010) Potassium release kinetics and water retention of controlled-release fertilizers based on chitosan hydrogels. J Polym Environ 18(3):413–421

Wu L, Liu M (2008) Preparation and properties of chitosan-coated NPK compound fertilizer with controlled-release and water-retention. Carbohyd Polym 72(2):240–247

Jin S, Yue G, Feng L, Han Y, Yu X, Zhang Z (2011) Preparation and properties of a coated slow-release and water-retention biuret phosphoramide fertilizer with superabsorbent. J Agric Food Chem 59(1):322–327

Distantina S, Rochmadi R, Fahrurrozi M, Wiratni W (2013) Preparation and characterization of glutaraldehyde-crosslinked kappa carrageenan hydrogel. Eng J 17(3):58–66

Akalin GO, Pulat M (2018) Preparation and characterization of nanoporous sodium carboxymethyl cellulose hydrogel beads. J Nanomater. https://doi.org/10.1155/2018/9676949

Islam A, Yasin T, Bano I, Riaz M (2012) Controlled release of aspirin from pH- sensitive chitosan/poly (vinyl alcohol) hydrogel. J Appl Polym 124(5):4184–4192

Pereira L, Amado AM, Critley AT, Van de Velde F, Ribeiro-Claro PJA (2009) Identification of selected seaweed polysaccharides (phycocolloids) by vibrational spectroscopy (FTIR-ATR and FT-Raman). Food Hydrocoll 23(7):1903–1909

Tan H, DeFail AJ, Rubin JP, Chu CR, Marra KG (2010) Novel multiarm PEG-based hydrogels for tissue engineering. J Biomed Mater Res A 92(3):979–987

Yi G, Huang Y, Xiong F, Liao B, Yang J, Chen X (2011) Preparation and swelling behaviors of rapid responsive semi-IPN NaCMC/PNIPAm hydrogels. J Wuhan Univ Technol-Mater Sci Ed 26(6):1073–1078

Hezaveh H, Muhamad II (2013) Modification and swelling kinetic study of kappa-carrageenan-based hydrogel for controlled release study. J Taiwan Inst Chem Eng 44(2):182–191

Gao X, He C, Xiao C, Zhuang X, Chen X (2012) Synthesis and characterization of biodegradable pH-sensitive poly(acrylic acid) hydrogels crosslinked by 2-hydroxyethyl methacrylate modified poly(l-glutamic acid). Mater Lett 77:74–77

Liu Z, Yang Z, Luo Y (2012) Swelling, pH sensitivity, and mechanical properties of poly(acrylamide-co-sodium methacrylate) nanocomposite hydrogels impregnated with carboxyl-functionalized. Polym Compos 33(5):665–674

Hu X, Li D, Zhou F, Gao C (2011) Biological hydrogel synthesized from hyaluronic acid, gelatin and chondroitin sulfate by click chemistry. Acta Biomater 7(4):1618–1626

Zamora-Mora V, Velasco D, Hernández R, Mijangos C, Kumacheva E (2014) Chitosan/agarose hydrogels: cooperative properties and microfluidic preparation. Carbohydr Polym 111:348–355

Jamnongkan T, Kaewpirom S (2010) Controlled-release fertilizer based on chitosan hydrogel: phosphorus release kinetics. Sci J UBU 1(1):43–50

Rudzinski WE, Chipuk T, Dave AM, Kumbar SG, Aminabhavi TM (2003) pH-sensitive acrylic-based copolymeric hydrogels for the controlled release of a pesticide and a micronutrient. J Appl Polym Sci 87:394–403

Abedi-Koupai J, Varshosaz J, Mesforoosh M, Khoshgoftarmanesh AH (2012) Controlled release of fertilizer microcapsules using ethylene vinyl acetate polymer to enhance micronutrient and water use efficiency. J Plant Nutr 35:1130–1138

Saruchi Kaith BS, Jindal R, Kapur GS (2013) Enzyme-based green approach for the synthesis of gum tragacanth and acrylic acid cross-linked hydrogel: its utilization in controlled fertilizer release and enhancement of water-holding capacity of soil. Iran Polym J 22:561–570

Li Q, Wu S, Ru T, Wang L, Xing G, Wang J (2012) Synthesis and performance of polyurethane coated urea as slow/controlled release fertilizer. J Wuhan Univ Technol-Mater Sci Ed 27(1):126–129

Singh B (2007) Psyllium as therapeutic and drug delivery agent. Int J Pharm 334(1–2):1–14

Adams C, Frantz J, Bugbee B (2013) Macro- and micronutrient-release characteristics of three polymer-coated fertilizers: Theory and measurements. J Plant Nutr Soil Sci 176(1):76–88

Tomaszewska M, Jarosiewicz A (2004) Polysulfone coating with starch addition in CRF formulation. Desalination 163(1–3):247–252

Jayakumar R, Prabaharan M, Reis RL, Mano JF (2005) Graft copolymerized chitosan—present status and applications. Carbohyd Polym 62(2):142–158

Bajpai AK, Giri A (2002) Swelling dynamics of a macromolecular hydrophilic network and evaluation of its potential for controlled release of agrochemicals. React Funct Polym 53(2–3):125–141

Sankar C, Mishra B (2003) Development and in vitro evaluation of gelatin A microspheres of Ketorolac tromethamine for intranasal administration. Acta Pharm 53:101–110

Acknowledgements

This work was financially supported by the Scientific Research Projects Coordination Unit of Gazi University (Grant No. 05/2015-08).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare that they have no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Akalin, G.O., Pulat, M. Preparation and characterization of κ-carrageenan hydrogel for controlled release of copper and manganese micronutrients. Polym. Bull. 77, 1359–1375 (2020). https://doi.org/10.1007/s00289-019-02800-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-019-02800-4