Abstract

In this study, Chitosan–green tea extract composite film was synthesized by a simple one-pot procedure and was ably characterized using XRD, FTIR, SEM, etc. The influence of noted factors such as water content, water solubility, water vapour transmission rate, contact angle and thermal stability was investigated in detail. The antimicrobial and antioxidant potentials of all the synthesized films were determined. Finally, an optimized composite film was crafted into a pouch-like bag for packing raw chicken meat. The efficiency of this smart pouch to extend shelf life of raw meat was compared with the common synthetic packaging material of low-density polyethylene.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

It was our target to exploit naturally occurring functional molecules for extending the shelf life of raw meat. In the gallery of diverse bio-active substances one of the least utilized substances for the packaging applications is green tea extract (GTE) powder. It is a good source of polyphenolic compounds and has been exploited as outstanding antioxidant substance [1, 2]. But, its excellent antimicrobial efficacy against common food spoilage microorganisms was less explored. The antimicrobial and antioxidant qualities of GTE powder are attributed to characteristic structures of various catechin molecules (tea polyphenols) present in them (Table 1). Hence, the utilization of GTE powder–Chitosan composite film for extending the shelf life of raw meat has immense importance.

As is well known, many synthetic preservatives such as butylated hydroxyl anisole (BHA), butylated hydroxyl toluene (BHT) and tertiary butyl hydroquinone (THBQ) are directly mixed with raw meat for extending the shelf life. The over concerns of consumers on artificial preservatives motivated researchers to develop an healthier and eco-friendly technologies for meat storage [3]. Recently, much attention has been paid to fabricate biodegradable packaging films incorporated with active naturally occurring functional materials for extending the shelf life of raw meat.

Herein, we present the first report on Chitosan–GTE powder based portable pouches having potential to extend the shelf life of raw meat. The incorporated GTE powder will diffuse slowly onto the meat surface. The presence of diffused molecules will prevent lipid oxidation and microbial out grow, leading to extended shelf life of raw meat. The pouches developed can be conveniently employed as a packaging material for raw meat which would create significant advances in the packaging industry.

Experimental

Materials

Chitosan with 85 per cent degree of deacetylation was purchased from Sigma Aldrich Co. Ltd (USA). GTE powder was obtained from Medizen Labs Pvt. Ltd. (Bangalore, India). Acetic acid, sodium hydroxide and zinc acetate dihydrate, methanol and ethanol were obtained from Merck (Germany). 2,2-Diphenyl-1-Picrylhydrazyl (DPPH) extra pure was purchased from SRL (India). Mineral salt broth and Nutrient agar were purchased from Himedia Chemicals (Mumbai, India). The two bacterial strains Escherichia coli (E. coli, MTCC737) and Staphylococcus aureus (S. aureus, MTCC 1687) were cultured in the UniBiosys Biotech Research Lab, Cochin. Deionized water was used to prepare all the solutions. All the chemicals used in this study were of analytical grade and were used without further purification.

Preparation of composite films

Green and facile one-pot procedure was adopted for the preparation of composite films. Chitosan flakes (2 g) were dissolved in 100 mL of 2% (v/v) aqueous acetic acid using ultra sonication for 2 h at room temperature. Previously prepared solution of 0.1 g GTE powder in 10 mL of distilled water was added to the Chitosan solution. Composite solution was magnetically stirred for 1 h to get a homogenous dispersion. To obtain even films, 25 mL of viscous mixture was cast into a circular glass dish and dried at room temperature. The dried films (C1) were peeled out and washed well with methanol (Fig. 1). Four more composite films were prepared by adopting the same procedure with different amount of GTE (0.2, 0.3, 0.4 and 0.5 g) named, respectively, as C2, C3, C4 and C5. A pure Chitosan film was prepared without GTE powder and named as C. All prepared films were stored in airtight polyethylene packets for further analysis.

Characterization of films

FT-IR spectra of the films were calibrated using an attenuated total reflection (ATR) Technique (Model, Perkin Elmer Inc. USA), the FT-IR Spectra of GTE powder was recorded in a KBr pellet form using Fourier Transform IR Spectrometer (Model: JASCO FTIR 4108). X-ray diffraction (XRD) patterns of the films were obtained in the scanning range of 20°–75° by an X-ray diffractometer (Model: Rigaku Minifex 600 diffractometer) with Cu Kα radiation (λ = 0.15406 nm). Thermo gravimetric analysis (TGA, Model: TGA/DTA851e) was performed at a scanning rate of 2 °C min−1 under dynamic nitrogen. The absorption spectra of composite films were recorded by using UV–Visible spectrophotometer (Model: JASCO V-550) in the wavelength range of 200–800 nm. Surface morphology of the samples was observed by scanning electron microscopy (SEM) (Model: Hitachi SU-6600 FESEM). Tensile strength of the films was measured by Instron Universal Testing Machine, model-3345, at a test speed of 2.0 mm min−1 at room temperature. The water vapour transmission rate (WVTR) of the films was analysed according to the ASTM E96-95 method with required modifications. The water solubility and equilibrium moisture content of the prepared films were calibrated by mass loss method.

Contact angle measurement

Contact angle was measured using sessile drop method using a video-based Goniometer (Kruss G10, Germany). A drop (5 µL) of distilled water was carefully placed by micro syringe at temperature, 25–27 °C, on the smooth side of the films. The angle between the film surface and the tangent line at the point of contact of water droplet with the surface was recorded immediately after the water drop was deposited.

Measurement of optical barrier properties

Each film specimen, having thickness 1 mm, was cut into rectangular pieces (10 × 40 mm) and placed directly in the test cell. The absorption spectrum of each film was obtained in the wavelength region 200–800 nm, using air as reference. Transparency and opacity of the films were determined using the following equation [4]:

where %T is percentage transmittance and b is the film thickness (mm).

Antioxidant properties of films

Film specimens (25 mm × 25 mm) were introduced into separate beaker containing 50 mL of distilled water. 1 mL of the sample solution was taken out at different time intervals and mixed with previously prepared 4 mL of 150 µM DPPH solution in methanol. The mixture was kept in the dark for half an hour, affording sufficient time to react the polyphenol molecules and DPPH radicals. The absorbance of the mixture was measured at 517 nm using UV–Visible spectrometer. The free radical scavenging ability of the film specimens was determined by the following equation:

where A s is the absorbance of test sample and A c is the absorbance of control solution (4 mL DPPH and 1 mL distilled water).

Antimicrobial property

Antimicrobial efficacy of composite films was evaluated against two common food pathogens, E. coli and S. aureus, using optical density (OD) procedure. A single colony of test bacteria was carefully transferred into a 100-mL nutrient broth and placed in an incubator overnight at 37 °C. One millilitre fresh culture of bacteria was inoculated separately into fresh broth medium containing film samples (10 × 10 mm) and incubated with shaking bed (100 rpm) at 37 °C for 40 h. During the incubation OD of the medium was calibrated at 600 nm using spectrophotometer at different time intervals.

The percentage of inhibition was determined by comparing the OD value of control media (without film sample) in each time interval:

where (OD)c is the optical density values of control media and (OD)s is the optical density values of film sample containing media.

Packaging applications

The potential of optimized C4 film as a packaging material for raw meat was investigated by plate count procedure. The C4 films were stitched into flexible pouches using cotton yarn by an in-house weaving machine. The shelf life efficiency of C4 pouches was compared with low-density polyethylene (LDPE) bag, which is popularly used to pack, store and transport raw meat. The composite bags and polyethylene bags were sterilized prior to the analysis. Meat samples of chicken were collected from the local poultry market and washed well with distilled water to remove blood stains. Equal amount of meat was packed in separate set of bags, each set consisting of three duplicates of composite bags (A-1, A-2 and A-3) and polythene bags (B-1, B-2 and B-3) and stored at 4 °C. Following the 1st day of storage, aerobic plate count was performed using the procedure described below. This protocol was repeated after 2 and 6 days of storage.

Standard plate count procedure

After 1 day, 1 g sample from each packet was separately transferred to different test tubes containing 9 mL phosphate buffer solution (pH 7.2). This mixture was then shaken for a few minutes to distribute the bacteria and break up any clumps. Immediately after proper dilution, 1 mL of the mixture was transferred to a second 9 mL phosphate buffer solution to get 10−2 dilution. The serial dilution was repeated until to get 10−3 and 10−4 dilutions. Then 1 mL of finally diluted solution was transferred to a Petri plate containing nutrient agar media and incubated at 37 °C for 24 h. The enumeration of microbes present in the meat sample was counted and represented as Colonies Forming Unit (CFU) per mL:

Statistical analysis

All experiments were repeated three times and the average values with standard errors were reported. Analysis of variance was conducted and differences between variables were tested for significance by one-way ANOVA with Tukey’s test using software originPro8 (Origin Lab corporation). A statistical difference at P < 0.05 was considered to be significant.

Results and discussion

Appearance and film thickness

All the composite films are visually smooth, shiny and homogenous. The colour of the prepared film is light brown and intensity of the colour is linearly proportional to the amount of GTE powder incorporated. Films have no brittle areas or bubbles and can be peeled out easily from the casting plate. Film surface is fairly soft and even and can hold water vapour on the surface (Fig. 2). All films were prepared with uniform thickness 1 ± 0.18 mm and it was observed that even the addition of 0.5 g GTE powder did not change the average thickness of films significantly (P > 0.05).

FT-IR

FT-IR spectroscopy was used to analyse the nature of interaction between Chitosan and GTE powder. The FT-IR spectra of bare Chitosan, GTE powder and composite films were calibrated and compared (Fig. 3). The spectrum of bare Chitosan film (Fig. 3a) is in accordance with previous reports. The broadband at 3355 cm−1 can be indexed to the stretching vibrations of pendant groups –OH, which overlaps with –NH stretching vibrations in the same region. The small band at 2887 cm−1 is due to asymmetric vibrations of –CH2– groups in pyranose ring. The peak at 1666 cm−1 is assigned to the stretching vibrations of C=O, and the sharp peak at 1539 cm−1 can be attributed to –NH bending vibrations. The band at 1413 cm−1 can be correlated to C–N axial deformation of amine groups. The distinct and clear band at 1091 cm−1 is due to the stretching vibration of C–O–C linkages in the polymer chain [5–7].

GTE powder is a mixture of different polyphenolic compounds containing different functional groups (Table 1). The IR spectra of extract powder (Fig. 3g) showed characteristic bands corresponding to various functional groups. The broadband in the region 3561–3454 cm−1 is assigned to –OH stretching vibrations. The distinctive bands observed at 1620 and 1520 cm−1 are due to the aromatic ring quadrant stretching and the aromatic semicircle stretching vibrations, respectively. The peak at 1152 cm−1 can be attributed to C–O stretching of aromatic alcohols. The two typical peaks at 676 and 604 cm−1 are due to the “out of plane bending vibrations” of C–H present in substituted aromatic ring [8].

The IR spectra of composite films are shown in (Fig. 3b–f). The incorporation of GTE powder into Chitosan matrix has modified the positions and intensities of characteristic peaks, reflecting the successful incorporation of GTE powder in the Chitosan matrix. In the spectrum of composite films, the width and intensities of the bands corresponding to –NH2 and –OH groups have increased linearly with the amount of GTE indicating the interactions between polyphenol molecules and Chitosan. Even though the intensity has decreased, the sharp and obvious peak observed at 1152 cm−1 in Fig. 3g is still present in all composite films. It is also observed that there is an incremental increase in the intensity of band at 1539 cm−1, indicating the interaction of GTE molecules through the pendant groups (–NH2 and –OH) of Chitosan [9]. When the GTE is added, the peak at 1091 cm−1 became more intense and shifted to lower region 1046 cm−1 indicating changes in polymer chains in the presence of GTE powder [10].

XRD results

XRD diffractograms of films were analysed to elucidate the crystallinity of samples. The pure Chitosan film has crystalline behaviour due to strong inter molecular hydrogen bond between the polymer chains and it is evidenced by characteristic peaks at 11.2°, 17.7°, 21° and 28.9° (Fig. 4a) [11–15]. In C1 (Fig. 4b) and C2 (Fig. 4c), the trend of declining of peak is clearly visible, whereas in C3 (Fig. 4d), C4 (Fig. 4e) and C5 (Fig. 4f) there are only two peaks justifying the loss of crystallinity in the presence of GTE powder. When GTE powder is added, it occupies space in between polymer chains and forms hydrogen bonds with the functional groups of Chitosan. These new interactions decline crystallinity and improve flexibility of composite films (Fig. 5).

Optical properties

It is well known that the presence of radiations will trigger undesired changes in the packed food [4]. To evaluate the light-blocking ability of composite films, the absorbance of each film was recorded in UV–Visible region (Fig. 6). As shown in the figure, pure Chitosan film exhibited lowest absorbance, lowest opacity and highest transparency (Table 2). Incorporation of GTE powder has greatly affected the optical properties of composite films. All composite films have excellent absorbance particularly in the UV region due to the presence of different catechins and epicatechin molecules of GTE powder [16]. It was already reported that poly phenol molecules present in GTE powder have characteristic λmax in UV region [17]. The incorporation of 0.1 mg of GTE powder has improved the absorbance of films fourfold higher than bare Chitosan films at the wave length 300 nm. Moreover, absorbance of composite films is linearly related to the amount of GTE powder incorporated. The excellent absorbance of composite films in the UV region extols its virtue to prevent light-induced lipid oxidation packed raw meat [18].

Thermal stability

Thermo gravimetric analysis (TGA) unravels thermal behaviour and thermal stability of prepared films [19]. The TGA analysis showed that all films had displayed similar thermal behaviour when subjected to programmed heating (Fig. 7). The characteristic mass loss that occurred at 40–145 °C is due to dehydration of the films [20]. It was reported that Chitosan can retain 5% water even at elevated temperature due to the presence of hydrophilic groups [21].The second slop onset from 200 °C ending at 450 °C corresponds to thermal degradation of Chitosan and release of volatile molecules. Pyrolysis of Chitosan starts by a random split of glycosidic bonds, followed by decomposition and leading to release of smaller volatile molecules having carbon atoms C2–C6 [22]. As shown in figure (Fig. 7), all composite films exhibit a higher mass loss in the region corresponding to evaporation of water. This behaviour vindicates lower hydrophilicity of polymer in the presence of GTE powder and it was confirmed further by contact angle measurements. When GTE powder was incorporated, new interaction between polyphenol molecules and hydrophilic groups of Chitosan developed, which decreases prospect of hydrogen bonds between Chitosan and water molecules and facilitate dehydration. Similarly, higher weight loss of composite films in the polymer decomposition region (200–450 °C) justifies the possibility of GTE powder assisted pyrolysis of Chitosan.

SEM analysis

SEM images give a clear and logical depiction of the surface changes that occurred when GTE powder was incorporated. In the case of C1 and C2, the added GTE molecules snugly fit in between the Chitosan chains without any visible surface changes. Hence their addition did not produce any discontinuity or heterogeneity on the surface. As shown in Fig. 8, surface roughness increases gradually with the amount of GTE incorporated and maximum surface roughness was observed in C5 film. The surface heterogeneity is attributed to the accumulation of agglomerated GTE powder on the surface of Chitosan. The GTE molecules are accumulated on the surface by intermolecular hydrogen bonding and extensively modify the properties of Chitosan.

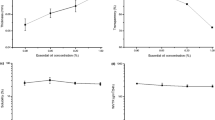

Physical properties of films

It is well known that Chitosan films are hydrophilic due to the presence of a large number of polar groups [23], but the hybridization of Chitosan with functional molecules will change its hydrophilicity as well [24, 25]. The change in hydrophilicity of Chitosan in the presence of GTE powder was evaluated by contact angle measurement (Table 3). The values given in Table 3 clearly show that hydrophilicity decreases initially and then set to increase. Similar trend is observed during water content analysis of composite films. The decrease in hydrophilicity can be ascribed to the nonavailability of hydrophilic groups of (amino and hydroxyl groups) Chitosan for water molecules when GTE powder was incorporated [26]. There exists a critical concentration of GTE, up to which the hydrophilicity decreases and above that concentration it starts to increase. At higher concentration accumulation of excess GTE powder on the film surface takes place, which can attract water molecules using its own polar groups [27].

Moisture content of composite films follow the trend of contact angle measurements justifying the tenets of hyrophilicity. The water molecules present in films were held by hydrogen bonds either with polar groups of Chitosan or polyphenol molecules. The presence of water molecules in composite films was vindicated by TGA analysis, where each film gives a characteristic slope for dehydration of water molecules.

Solubility measurement underlines the ability of films to withstand in moisture condition as well as the skill of films to transfer active molecules from its matrix to raw meat surface during the shelf life keeping [28]. In the present case, pure Chitosan film showed lowest solubility in neutral and acidic pH, whereas solubility of composite films is linearly proportional to the amount GTE powder (Table 3). In lower pH all films have higher solubility due to higher dissolution of Chitosan in acidic condition. As is well known, at neutral pH Chitosan is insoluble due to its semicrystalline nature and strong intermolecular hydrogen bonds. In lower pH, amino groups of Chitosan can be protonated leading to repulsion between positively charged polymer chains and thereby diffusion of solvent molecules and subsequent dissolution of Chitosan [29]. In contrast to pure Chitosan films, the solubility of composite films depends on various factors such as hydrophilicity, water diffusion ability, presence of polar groups, type of fillers, strength of hydrogen bonds and polymer chain relaxation ability [30]. Higher solubility of Chitosan GTE powder composite films IS not due to enhanced dissolution of Chitosan molecules, but due to the release of GTE powder from the polymer matrix in aqueous media. The mass loss that appeared to be due to the release of GTE has been identified as extended solubility. To confirm this hypothesis, we carried out solubility experiment with large sized films (6 × 6 cm) and kept it in same amount water for 7 days. The slow colouration of the supernatant liquid confirmed the release of GTE powder from the polymer matrix. The intensity of colour is linearly proportional to the amount of GTE powder (Fig. 9). Such release of GTE powder in aqueous media has a significant role in deciding antimicrobial and antioxidant properties and it was proved by further studies.

Water vapour trasmission rate (WVTR)

The values of WVTR are given in the (Table 4). As shown in the result, all composite films exhibit higher WVTR values compared to the pure Chitosan film except C1. The WVTR is related to two factors, namely hydrophilic–hydrophobic ratio of the composite films and crystallinity. WVTR is inversely related to hydrophobicity and crystallinity of films, whereas it is linearly related to hydrophilicity of the films [4, 31, 32]. The obtained result suggests that the inter play of hydrophilicity–hydrophobicity ratio and crystallinity has paved the way for enhanced WVTR of composite films. It was concluded that hydrophobicity of composite film shows rise and fall like trend whereas crystallinity decreases linearly with the amount of GTE powder. The lowest WVTR value of C1 is attributed to its comparatively higher hydrophobicity (Table 3, contact angle) and moderate crystllinity (as per XRD analysis). Even though C5 film has lowest crysallinity and reasonably higher hydrophilicity, it did not show any exceptionally higher WVTR. This anomaly is related to its higher solubility in aqueous media (Table 3). As explained earlier, higher solubility is due to the excess release of GTE powder from the matrix, and hence water molecules interact with the component present in the matrix losing more time to cross the film [33].

Measurement of tensile strength (TS) of films

The tensile strength (TS) values of films was compared and is given in (Table 5). The TS values of composite films have significantly (P < 0.05) improved when extract powder was incorporated, but the trend is not in a linear fashion. TS values of composite films have initially increased with the gradual addition of extract powder, reaching an optimum value and then set to decrease. Pure Chitosan film has a TS value 41.82 ± 0.79 MPa. The increase of TS values of composite films can be justified by the structural changes promoted by the addition of GTE powder. As it is well recognized, TS values are linearly related to the strength of inter molecular attractions present in the film [34]. When GTE powder was incorporated, cross linking effect was developed leading to the enhancement of TS of composite films [35, 36]. For a fixed amount of Chitosan precursor, there is an optimum amount of GTE for maximum cross linking effect. Hence, incorporation of more GTE powder causes agglomeration in the matrix, leading to surface discontinuity as vindicated by SEM images.

Antioxidant properties of films

DPPH is one of the stable organic radicals and widely used for the determination of antioxidant property of active packaging films [37]. As shown in the result, (Table 6) the scavenging ability of the bare Chitosan film was lowest and exhibits 31.9% of scavenging activity after 25 h immersion in water. The maximum activity was shown by C5 film sample in all time intervals and its efficiency has reached at 95.13% after 25 h long immersion.

The limited antioxidant activity of Chitosan was justified as the reaction of radical species with hydroxyl group at the C-6 position and amino group at C-2 position. These functional groups can transfer hydrogen to the unstable radical species and will form macromolecular radicals [38]. Compared to pure Chitosan, GTE powder-incorporated composite films showed increased scavenging activity. The 15-fold increase in scavenging activity of C5 film (after 1 h immersion) justifies the direct involvement of polyphenol molecules. The enhanced radical scavenging activity of composite films is related to the release of GTE powder from the polymer matrix [39]. The unusual antioxidant activity of GTE powder is due to special structural features of each catechin molecule present in the extract. Catechins and epicatechins having three hydroxyl groups in the B ring are called gallocatechins, and their esterified form to Gallic acid (3,4,5 trihydroxy benzoic acid) is named as catechin gallates. It was reported that ortho-trihydroxyl groups in the B ring of gallocatechins are responsible for its anti oxidant activities and in the case of catechine gallates, carboxylic acid and hydroxyl groups together play a major role in deciding antioxidant activity. Due to the high reactivity of these groups, they can donate hydrogen and an electron to DPPH radical.

The radical scavenging ability of different components of GTE powder follows the order epicatechin gallate = epigallocatechin gallate > epigallo catechin > Gallic acid > epicatechin = catechin.

Antimicrobial activity

Optical density (OD) values of composite films at four different time intervals are given in Tables 7 and 8. The growth of microorganism in the media is directly linked to its turbidity. The higher the turbidity, the higher the OD value and lower the antimicrobial efficacy of the film [40, 41].

All composite films exhibited enhanced antimicrobial property as compared to bare Chitosan film, but there was an exceptional increase in the case of C4 and C5 film. The enhancement of antimicrobial property of composite films rationalizes the tenets of controlled release of GTE powder from the polymer matrix in aqueous media. The exceptionally higher antimicrobial activity of C4 and C5 films are related to the extended release of GTE powder from the polymer matrix. It was generally agreed that the antimicrobial activity of GTE powder is due to the presence of catechins [42]. Among the different catechins, gallocatachins and corresponding gallates have more antimicrobial activity [43]. These molecules specifically bind to the peptide glycan present in the cell wall of microorganism leading to the precipitation. There are a few other suggestions that gallocatechins and their gallates damage lipsosame or attack and destroy lipid bilayer of bacterial cell wall or generate H2O2 for biocidel activity [44].

Packaging application

Since shelf life of meat is directly related to amount microorganisms in the sample, the comparison of total plate count of microorganisms of meat samples packed in Chitosan–GTE composite pouches and LDPE pouches obviously emphasize the ability of composite pouches to enhance the shelf life of raw meat. As shown in the result (Table 9) bacterial count of meat samples stored in composite pouches is significantly (P < 0.05) lower than polyethylene pouches. There was no growth detected in a meat sample stored in composite pouches for one day, and the rate of growth of microorganisms in meat samples stored in composite pouches are relatively low. Whereas meat samples stored in polyethylene pouch, exhibited moderately higher bacterial growth from the first day of storage and it was exponentially increased with the number of storage days. After six days of storage the total plate count of microorganisms in polythene bag was 40 times larger than microorganisms found in composite pouches (Fig. 10). This result has undoubtedly underlined the ability of composite pouches to inhibit the growth of microorganisms in raw meat and enhance its shelf life. The inhibition efficiency of composite pouch is attributed to the periodical diffusion of active molecules from the packaging material onto the meat surface. The water content in the meat sample may facilitate the diffusion of active molecules.

Conclusions

The aim of this investigation was the fabrication of an eco-friendly, smart packaging film for the extension of raw chicken meat. To optimize a suitable candidate for packaging applications five different Chitosan–GTE powder composite films were synthesized by a simple one-pot procedure. All films were well characterized by FT-IR (ATR), XRD and SEM. Physical, thermal and mechanical features of composite films were evaluated and compared with pure Chitosan films. It was observed that incorporation of GTE powder has improved all the properties, but not in linear fashion. The smartness of composite films towards antimicrobial and antioxidant properties was calibrated by in vitro analysis. DPPH scavenging activity studies have undoubtedly proven enhanced antioxidant ability of composite films. Similarly, antimicrobial studies also confirmed the ability of composite films to inhibit the growth of Gram-positive and Gram-negative bacteria. Finally, the usefulness of composite films to substitute current polyethylene bags to store meat and related items was analysed. The C4 composite film was crafted to pouch-like packaging material for investigating the potential of film to enhance the shelf life of raw meat. The result was highly encouraging, and the rate of bacterial growth in meat samples stored in composite pouches was significantly lower than that of polyethylene pouch.

References

Almajano MP, Carbó R, Jiménez JAL, Gordon MH (2008) Antioxidant and antimicrobial activities of tea infusions. Food Chem 108:55–63

Bozkurt H (2006) Utilization of natural antioxidants: green tea extract and Thymbra spicata oil in Turkish dry-fermented sausage. Meat Sci 73:442–450

Zhang H, Wu J, Guo X (2016) Effects of antimicrobial and antioxidant activities of spice extracts on raw chicken meat quality. Food Sci Hum Wellness 5:1–10

Kanatt SR, Rao MS, Chawla SP, Sharma A (2012) Active chitosan–polyvinyl alcohol films with natural extracts. Food Hydrocoll 29:290–297

Kaushik A, Khan R, Solanki PR, Pandey P, Alam J, Ahmad S (2008) Iron oxide nanoparticles chitosan composite based glucose biosensor. Biosens Bioelectron 24:676–683

Brugnerotto J, Lizardi J, Goycoolea FM, Argüelles Monal W, Desbrières J, Rinaudo M (2001) An infrared investigation in relation with chitin and chitosan characterization. Polymer (Guildf) 42:3569–3580

Pawlak Mucha M (2003) Thermogravimetric and FTIR studies of chitosan blends. Thermochim Acta 396:153–166

Fassel VA, Margoshes M (1952) The infrared spectra of aromatic compounds evidence concerning the interaction of r-electrons and a-bond orbitals in C–H out-of-plane bending vibrations. Spectrochim Acta B 78:8–11

Siripatrawan U, Harte BR (2010) Physical properties and antioxidant activity of an active film from chitosan incorporated with green tea extract. Food Hydrocoll 24:770–775

Wang L, Dong Y, Men H, Tong J, Zhou J (2013) Preparation and characterization of active films based on chitosan incorporated tea polyphenols. Food Hydrocoll 32:35–41

Wang SF, Shen L, Tong YJ, Chen L, Phang IY, Lim PQ (2005) Biopolymer chitosan/montmorillonite nanocomposites: preparation and characterization. Polym Degrad Stab 90:123–131

Xu Y, Ren X, Hanna MA (2006) Chitosan/clay nanocomposite film preparation and characterization. J Appl Polym Sci 99:1684–1691

Yamaguchi I, Tokuchi K, Fukuzaki H, Koyama Y, Takakuda K, Monma H (2001) Preparation and microstructure analysis of chitosan/hydroxyapatite nanocomposites. J Biomed Mater Res 55:20–27

Xu YX, Kim KM, Hanna M, Nag D (2005) Chitosan–starch composite film: preparation and characterization. Ind Crops Prod 21:185–192

Fernandes SCM, Freire CSR, Silvestre AJD, Pascoal Neto C, Gandini A, Berglund LA (2010) Transparent chitosan films reinforced with a high content of nanofibrillatedcellulose. Carbohydr Polym 81:394–401

Pieiro Z, Palma M, Barroso CG (2004) Determination of catechins by means of extraction with pressurized liquids. J Chromatogr A 1026:19–23

Atoui AK, Mansouri A, Boskou G, Kefalas P (2005) Tea and herbal infusions: their antioxidant activity and phenolic profile. Food Chem 89:27–36

Gómez-Guillén MC, Ihl M, Bifani V, Silva A, Montero P (2007) Edible films made from tuna-fish gelatin with antioxidant extracts of two different murta ecotypes leaves. Food Hydrocoll 21:1133–1143

Kim J, Cai Z, Lee HS, Choi GS, Lee DH, Jo C (2011) Preparation and characterization of a bacterial cellulose/chitosan composite for potential biomedical application. J Polym Res 18:739–744

Tripathi S, Mehrotra GK, Dutta PK (2009) Physicochemical and bioactivity of cross-linked chitosan–PVA film for food packaging applications. Int J Biol Macromol 45:372–376

Rubilar JF, Cruz RMS, Silva HD, Vicente AA, Khmelinskii I, Vieira MC (2013) Physico-mechanical properties of chitosan films with carvacrol and grape seed extract. J Food Eng 115:466–474

Neto CGT, Giacometti JA, Job AE, Ferreira FC, Fonseca JLC, Pereira MR (2005) Thermal analysis of chitosan based networks. Carbohydr Polym 62:97–103

Rao SB, Sharma CP (1997) Use of chitosan as a biomaterial: studies on its safety and hemostatic potential. J Biomed Mater Res 34:21–28

Tangpasuthadol V, Pongchaisirikul N, Hoven VP (2003) Surface modification of chitosan films-effects of hydrophobicity on protein adsorption. Carbohydr Res 338:937–942

Moradi M, Tajik H, Razavi Rohani SM, Oromiehie AR, Malekinejad H, Aliakbarlu J (2012) Characterization of antioxidant chitosan film incorporated with Zataria multiflora Boiss essential oil and grape seed extract. LWT Food Sci Technol 46:477–484

Ojagh SM, Rezaei M, Razavi SH, Hosseini SMH (2010) Development and evaluation of a novel biodegradable film made from chitosan and cinnamon essential oil with low affinity toward water. Food Chem 122:161–166

Ferreira AS, Nunes C, Castro A, Ferreira P, Coimbra MA (2014) Influence of grape pomace extract incorporation on chitosan films properties. Carbohydr Polym 113:490–499

Abdollahi M, Rezaei M, Farzi G (2012) Improvement of active chitosan film properties with rosemary essential oil for food packaging. Int J Food Sci Technol 47:847–853

SogiasI A, Khutoryanskiy VV, Williams AC (2010) Exploring the factors affecting the solubility of chitosan in water. Macromol Chem Phys 211:426–433

Biro A (2007) Water politics and the construction of scale. Stud Polit Econ 80:9–30

Souza MP, Vaz AFM, Silva HD, Cerqueira MA, Vicente AA, Carneiro-da-Cunha MG (2015) Development and characterization of an active chitosan-based film containing quercetin. Food Bioprocess Technol 8:2183–2191

Martins JT, Cerqueira MA, Vicente AA (2012) Influence of -tocopherol on physicochemical properties of chitosan-based films. Food Hydrocoll 27:220–227

Wang L, Wang Q, Tong J, Zhou J (2015) Physicochemical properties of chitosan films incorporated with honeysuckle flower extract for active food packaging. J Food Process Eng. doi:10.1111/jfpe.12305

Park S, Zhao Y (2004) Incorporation of a high concentration of mineral or vitamin into chitosan-based films. J Agric Food Chem 52:1933–1939

Pastor C, Sánchez-González L, Chiralt A, Cháfer M, González-Martínez C (2013) Physical and antioxidant properties of chitosan and methylcellulose based films containing resveratrol. Food Hydrocoll 30:272–280

Altiok D, Altiok E, Tihminlioglu F (2010) Physical, antibacterial and antioxidant properties of chitosan films incorporated with thyme oil for potential wound healing applications. J Mater Sci Mater Med 21:2227–2236

Sanchez-Gonzalez L, Pastorn C, Vargas M, Chiralt A, Gonzalez-Martinez C, Chafer M (2011) Effect of hydroxypropylmethylcellulose and chitosan coatings with and without bergamot essential oil on quality and safety of cold-stored grapes. Postharvest Biol Technol 60:57–63

Woranuch S, Yoksan R (2013) Preparation, characterization and antioxidant property of water-soluble ferulic acid grafted chitosan. Carbohydr Polym 96:495–502

Peng Y, Wu Y, Li Y (2013) Development of tea extracts and chitosan composite films for active packaging materials. Int J Biol Macromol 59:282–289

Liu XF, Guan YL, Yang DZ, LiZ Yao K D (2000) Antibacterial action of chitosan and carboxymethlyated chitosan. J Appl Polym Sci 79:1324–1335

Li Z, Zhuang XP, Liu XF, GuanY L, De Yao K (2002) Study on antibacterial O-carboxymethylated chitosan/cellulose blend from LiCl/N, N-dimethylacetamide solution. Polym Commun 43:1541–1547

Hamilton-Miller JM (1995) Antimicrobial properties of tea (Camellia sinensis L.). Antimicrob Agents Chemother 39:2375–2377

Yam TS, Shah S, Hamilton-Miller JMT (1997) Microbiological activity of whole and fractionated crude extracts of tea (Camellia sinensis) of tea components FEMS. Microbiol Lett 152:169–174

Shimamura T, Zhao W, Hu Z (2007) Mechanism of action and potential for use of tea catechin as an anti-infective agent. Science 6:57–62

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mujeeb Rahman, P., Abdul Mujeeb, V.M. & Muraleedharan, K. Chitosan–green tea extract powder composite pouches for extending the shelf life of raw meat. Polym. Bull. 74, 3399–3419 (2017). https://doi.org/10.1007/s00289-016-1901-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-016-1901-2