Abstract

Bacterial cellulose (BC)/Chitosan (Ch) composite has been successfully prepared by immersing wet BC pellicle in Ch solution followed by freeze-drying process. The morphology of BC/Ch composite was examined by scanning electron microscope (SEM) and compared with pristine BC. SEM images show that Ch molecules can penetrate into BC forming three-dimensional multilayered scaffold. The scaffold has very well interconnected porous network structure and large aspect surface. The composite was also characterized by Fourier transform infrared spectrum, X-ray diffraction, thermogravimetric analysis and tensile test. By incorporation of Ch into BC, crystallinity tends to decrease from 82% to 61%, and the thermal stability increases from 263 °C to 296 °C. At the same time, the mechanical properties of BC/Ch composite are maintained at certain levels between BC and Ch. The biocompatibility of composite was preliminarily evaluated by cell adhesion studies. The cells incubated with BC/Ch scaffolds for 48 h were capable of forming cell adhesion and proliferation. It showed much better biocompatibility than pure BC. Since the prepared BC/Ch scaffolds are bioactive and suitable for cell adhesion, these scaffolds can be used for wound dressing or tissue-engineering scaffolds.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Bacterial cellulose (BC), which is synthesized by Acetobacter xylinum, consists in the biogenous nanofiber network structure formed by self-assembling in an efficient way. BC possesses higher water holding capacity, higher crystallinity, higher tensile strength, and a fine web-like network. Compared with other natural biodegradable polymers such as collagen, chitin and gelatin, BC presents much higher mechanical properties, which are required in most cases when used as scaffold in tissue engineering.

Several applications for BC in medical fields have already been reported such as artificial skin for humans with extensive burns [1], artificial blood vessels for microsurgery [2], scaffolds for tissue engineering of cartilage [3], and wound-dressing [4]. BC shows high hydrophlicity, good sorption of liquids, non-allergenic, and can be safely sterilized without any change to its characteristics. However, BC has problems in some cases when it is used in its natural state. For instance, a study by Schonfelder et al. indicates that BC has no influence on the concentration of elastase in vitro and little antioxidant capacity against reactive oxygen species [5]. BC itself has no antimicrobial activity to prevent wound infection. To improve its properties, one method is that BC is coated with another polymer. Another strategy is hybridizing BC with another polymer by mechanically mixing BC solution with the solution of another polymer [6].

Scaffold made by BC can interact with the surroundings at the OH-functionalized outer surface, the surface area of nanofiber architecture, and with large pore system. Water, synthetic macromolecules and biopolymers as well as living cells can be accumulated by in situ or post modification forming a multitude of composites [7].

Ch, like BC, has been recognized for its applications in various fields including the biomedical area. It has been known for its absorption of exudes, anti-fungal, anti-microbial, anti-viral and wound-healing properties. Ch is useful as a wound management aid to reduce scar tissue. Ch has been also found to have beneficial biological properties including hemostasis [8], antimicrobial activity stimulation of healing [9], tissue-engineering scaffolds [10], cell culture [11] and drug delivery [12].

This study aims to prepare a composite of BC and Ch for potential biomedical application by post modification in an attempt to use the synergic beneficial aspects of both polymers.

Experimental

Materials

Ch, medium molecular weight, Brookfield viscosity 200,000 cps, was purchased from Aldrich (St. Louis, USA). Other chemicals of the highest purity available were used and were purchased from Sigma-Aldrich (St. Louis, USA).

Preparation of bacterial cellulose pellicles

Gluconacetobacter xylinum BRC-5 was obtained from Yonsei University and used to produce the BC pellicles. The bacterium was cultured on Hestrin and Schramm (HS) medium, which was composed of 2% (w/v) glucose, 0.5% (w/v) yeast extract, 0.5% (w/v) bacto-peptone, 0.27% (w/v) disodium phosphate, and 0.115% (w/v) citric acid. All the cells pre-cultured in a test tube containing a small cellulose pellicle on the surface of the medium were inoculated into a 500 mL Erlenmeyer flask containing 100 mL of the HS medium. The flasks were incubated statically at 30 °C for 14 days. The cellulose pellicles were dipped into 0.25 M NaOH for 48 h at room temperature in order to eliminate the cells and components of the culture liquid. The pH was then lowered to 7.0 by repeated washing with distilled water. The purified cellulose pellicles were stored in distilled water at 4 °C to prevent drying [13].

Preparation of BC/Ch composite scaffold

The wet BC pellicle was placed between two sheets of filter paper to remove excessive water on it. Then it was immersed in 1% Ch-dissolved acetic acid solution for 6 h in room temperature. After that, it was withdrawn from the vessel and the excess Ch solution was removed using filter paper. Finally, it was dried by freeze-dryer (IP3 Jouan, France) at −40 °C for 3 days.

BC/Ch composite characterization

Scanning electron microscopy (SEM) images of BC and BC/Ch composite were taken with a microscope (Hitachi S-4200, Japan) to study the morphology. The surface and cross-section of the samples were sputtered with gold, and photographed. Fourier transform infrared (FT-IR) spectra were obtained using a Perkin-Elmer System 2000 FT-IR spectrophotometer. The samples were cut into very little particles for the evaluation of chemical structures using a KBr pellet. The obtained data were transferred to the PC for the line fitting. X-ray diffraction (XRD) pattern were recorded on an X-ray diffractometer (D/MAX-2500, Rigaku), by using Cu Kα radiation at 40 kV and 30 mA. The diffraction angle ranged from 5 to 40°. Thermogravimetric analysis (TGA) was carried out with a NETZSCH STA 409 PC/PG system. All analyses were performed with a 10 mg sample in alumina pans under a dynamic nitrogen atmosphere between 30 and 1,000 °C. The experiments were run at a scanning rate of 20 °C/min. Tensile test specimens were prepared by cutting the membranes to 10 mm wide and 65 mm long strips using a precise cutter. Young’s modulus of samples were found from the tensile test results conducted according to ASTM D-882-97 as a standard test method for tensile elastic properties of thin plastic sheeting. Tensile test was done on a universal testing machine. Two ends of the specimens were placed between the upper and lower jaws of the instrument, leaving a length of 50 mm of the film in between the two jaws. Extension speed of the instrument was 2 mm/min. The test was performed in ambient condition.

Cell adhesion studies

The BC and BC/Ch cylinder scaffolds (20 mm diameter × 4 mm height) were used for the cell attachment studies. Prior to cell culture work, the samples were sterilized using ethylene oxide for 18 h. The samples were then pre-treated by immersing in DMEM (Dilbecco’s Modified Eagle Medium) for 24 h. After the pre-treatment, the samples were carefully placed in 24 well plates and the cells were seeded at a density of 2.5 × 104 cells/well. And the samples were incubated at 37 °C /5% CO2 for 48 h. The morphology of the cells seeded on the samples was investigated after 48 h of incubation with SEM. For preparing SEM analysis, the samples washed twice with PBS to remove nonadherent cells and the attached cells were fixed with 2.5% glutaraldehyde buffer solution (pH 7.4) at 4 °C for 12 h. The samples were subsequently rinsed in distilled water and dehydrated by freeze-dryer at −40 °C. The samples were sputter coated with platinum and the cell morphology was examined using SEM.

Results and discussion

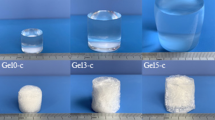

Prepared BC/Ch composite

The extended polyglucosan chains of BC produced by Acetobacter xylinum are surrounded by layers of water molecules forming a soft gel. If this gel undergoes dehydration through evaporation of water, it is converted from a “gel” into a “film” by irreversible formation of new hydrogen bonds between cellulose hydroxyl groups [14]. In the present study, the soft gel obtained by Acetobacter xylinum was treated with Ch acetic acid solution, instead of being dehydrated. Ch is widely employed in pharmaceutical and tissue engineering as an excipient in drug delivery and scaffolds for tissue culture [15]. It is also used in the manufacture of wound dressing due to its anitmicrobial activity. Thus, we expect that, by immersing the BC gel in Ch solution, the multiple layers of water surrounding polyglucosan chains would be displaced, inducing the formation of bonds between cellulose and Ch, with consequent marked structural modifications. The averaged weight ratio of BC and Ch was 75:25. In other words, the weight percent of Ch with respect to BC/Ch composite was 25%.

SEM image observation

Figure 1 presents typical SEM images of freeze-dried BC and BC/Ch composite. As seen from Fig. 1, BC nanofibrils can be observed on the surface. The mean diameter of the nanofibrils is about 40 nm. From cross sectional images we can see this multiple layers structure with high aspect ratio. Evidently, a well-organized three-dimensional network structure was observed. The BC sample has porous morphology, which has been subject of discussion in the last decade and already established. Cellulose biosynthesis is characterized by unidirectional growth and crystallization, where glucose molecules are linear bonded by β(1 → 4)-glycosidic bond. The union of glycosidic chains forms oriented microfibrils with intramolecular hydrogen bonds [16]. The cellulose is crystallized outward the organisms, particularly in Acetobacter xylinum that synthesizes cellulose chains by introducing glucose units to the reducing ends of the polymer. The growth mechanism during bacterial activity determines the morphology of the final cellulose.

After treated by Ch, the surface morphology of BC was changed. BC nanofibrils cannot be observed due to coverage by a thick layer of Ch. Porous structure remains but the pore size becomes much bigger. From cross sectional image, we can see that Ch molecules can penetrate into BC and forms layers of BC/Ch composite. BC nanofibrils can be observed between layers. Note that the present nanofibrous BC and BC/Ch composite has well interconnected pore network structure and large surface area necessary for cellular attachment and vascularization. In other words, this BC/Ch composite, when used as tissue engineering scaffolds, can promote cellular ingrowth.

FT-IR spectra

Since the molecular structure of BC and Ch is very similar, it is expected that these two polymers have good compatibility and miscibility. Figure 2 depicts the FT-IR spectra of BC and BC/Ch composite samples. In the case of pure BC, a broad band at 3,450 cm−1 is attributed to O-H stretching vibration. Band at 2,820 cm−1 represents the aliphatic C-H stretching vibration. A sharp and steep band observed at 1,080 cm−1 is due to the presence of C-O-C stretching vibrations. In the case of BC/Ch composite, N-H stretching vibration band is located at 3,420 cm−1, which is combined with O-H stretching vibration band. Three new bands observed at 1,647 cm−1, 1,575 cm−1 and 1,375 cm−1 are attributed to amide-I, amide- II and amide- III, respectively, which exist in Ch molecules.

XRD and crystallinity index

Regarding the crystalline structure of cellulose fibers, it is known to be classified into four crystallization types, viz. cellulose I, II, III and IV, and their crystalline structure are able to be transformed form one type to another [17]. Figure 3 shows the X-ray diffraction pattern of the BC and BC/Ch composite samples. Three main peaks can be identified in both spectra, which are assigned to the \( {\left( {1\bar{1} 0} \right)} \), (1 1 0) and (2 0 0) reflexions planes of cellulose I [18]. For BC, the location of these three peaks is 14.2°, 16.6° and 22.4°. For BC/Ch composite, characteristic peaks are remained in the same location, but the height of the \( {\left( {1\bar{1} 0} \right)} \) peak decreased and the ratio of the \( {\left( {1\bar{1} 0} \right)} \) peak to the (2 0 0) peak was also decreased from 0.50 for BC to 0.46 for BC/Ch composite. This result means that the presence of Ch affected the preferential orientation of the \( {\left( {1\bar{1} 0} \right)} \) plane during the water removal from BC pellicle.

Crystallinity index obtained form X-ray diffraction data was calculated according to the literature method [19]. This method is fast and easy. It uses the height of (2 0 0) peak and the minimum between (2 0 0) and (1 1 0) peaks, assuming that Intensity of (2 0 0) represents both crystalline and amorphous parts while the minimum intensity at the mentioned location is for amorphous part only.

Where CrI is the crystallinity index, I (200) is the intensity at (2 0 0) peak (2θ = 22.3°) and I (am) is the intensity at the minimum between (1 1 0) and (2 0 0) peak.

The estimated degree of crystallinity index of the BC was 87% and for BC/Ch composite it was 75%. With the introduction of Ch, the crystallinity index decreases. This maybe due to the intermolecular reaction between BC and Ch, which causes BC molecular chains difficult to move. Although it was an estimative of crystallinity based on the X-ray diffractograms, it is relevant to point out that the BC exhibits high crystallinity, which is associated with its high mechanical properties.

TGA

Thermo-gravimetric analysis (TGA) is a continuous process, involving the measurement of sample weight in accordance with increasing temperature in the form of programmed heating. Since TGA provides better understanding of thermal decomposition behavior, the thermal stability and thermal decomposition of BC and BC/Ch composite were investigated using TGA and are given in Fig. 4. The TGA curves obtained by plotting percentage weight loss against temperature indicated that BC was stable up to a temperature of 220 °C. The percentage weight loss for BC at 250 °C was 29.66%, while for BC/Ch composite it was 23.99%. In the case of BC, 50% weight loss was noticed at 263 °C, while the BC/Ch composite was 296 °C. Major weight loss of chitosan is seen between 210 and 360 °C [20]. 50% weight loss can be seen at 325 °C. The weight loss temperature of BC/Ch is higher than that of BC but lower than the Ch.

Mechanical properties

To investigate the mechanical characteristics of BC/Ch composites, the tensile test was performed according to ASTM D-882-97 standard test method. Four samples were tested to calculate the average value and derivations. The sample exhibits almost linear elastic behavior from beginning until it breaks. No yield point can be observed. These results indicate that the BC/Ch composite has typical brittle properties. The tensile strength is about 450 MPa and the elongation at break is about 8.5%. The Young’s modulus found from the tensile test was 7.0 GPa for BC/Ch composite. Compared with pure Ch, the mechanical properties were improved by introduction of BC. After tensile test, we check the morphological changes for both surface and cross-section of fracture region. Figure 5 shows the morphological changes of the BC/Ch composite after tensile test. On the surface, we can see some BC nanofibrils assemble together and align to the pull direction. From cross-section, we can clearly see the alignment of nanofibrils. This alignment of nanofibrils can improve the strength of the sample. These mechanical properties of BC/Ch composite make it possible to be used as potential scaffold material in tissue engineering or other medical applications such as wound dressing, etc.

Cell attachment test

Figure 6 shows the cell attachment on pure BC and BC/Ch composite. Fibroblast cells (3 T3) were seeded on cylinder scaffolds. After 48 h of incubation, there were many cells attached on pure BC scaffolds (Fig. 6a). And most of the cells remained in round-shape. But for BC/Ch composite scaffolds, cells adhered and almost completely spread on the surface (Fig. 6b). They had many pseudopodia and formed a layer on the surface. These results indicated that the cells stretched their morphology and were proliferating. This preliminary experiment suggests that BC/Ch composite has better biocompatibility compared with pure BC in terms of fibroblast cell culture. It would have potentials to be used as wound dressing materials or tissue regeneration scaffold in vitro. Further investigation such as cellular proliferation and differentiation assays are underway.

Conclusions

BC/Ch composite has been prepared by immersing wet BC pellicle in Ch solution followed by freeze-drying. SEM images show that Ch molecules can penetrate into BC forming multilayered structure of BC/Ch composite. The scaffold has very well interconnected porous network structure and large aspect surface. By incorporation of Ch in BC, crystallinity tends to decrease while the thermal stability has certain improvement. At the same time, the mechanical properties of BC/Ch composite maintain some levels. Cell culture test results indicate that BC/Ch composite has much better biocompatibility than pure BC. Thus, the prepared BC/Ch scaffolds are bioactive and maybe suitable for cell adhesion/attachment suggesting that these scaffolds can be used for wound dressing or tissue-engineering scaffolds.

References

Fontana JD, de Sousa AM, Fontana CK, Torriani IL, Moreschi JC, Gallotti BJ, de Sousa SJ, Narcisco GP, Bichara JA, Farah LF (1990) Appl Biochem Biotech 24/25:253

Klemm D, Schumann D, Udhardt U, Marsch S (2001) Prog Polym Sci 26:1561

Svensson A, Nicklasson E, Harrah T, Panilaitis B, Kaplan DL, Brittberg M, Gatenholm P (2005) Biomaterials 26:419

Alvarez OM, Patel M, Booker J, Markowitz L (2004) Wounds 16:224

Schonfelder U, Abel M, Wiegand C, Klemm D, Elsner P, Hipler UC (2005) Biomaterials 26:6664

Millon LE, Wan WK (2006) J Biomed Mater Res 79B:245

Klemm D, Schuman D (2007) 2 nd International cellulose conference, Tokyo, Japan K04, P5

Pusateri AE, McCarthy SJ, Gregory KW, Harris RA, Cardenas L, McManus AT (2003) J Trauma 54:177

Azas AK, Sermsintham N, Chandrkrachang S, Stevens WF (2004) J Biomed Mater Res B Appl Biomater 69:216

Martino AD, Sittinger M, Risbud MW (2005) Biomaterials 26:5983

Ayşe GK, Cristina S, Menemşe G, Giovanni M (2008) Acta Biomater 4:989

Aksungur P, Sungur A, Unal S, Iskit AB, Squier CA, Senel S (2004) J Contr Release 98:269

Seok HY, Jin H-J, Kim M-C, Yu RP (2006) Biomacromol 4:1280

Alberto S, Giovanni T, Anna MB, Erinestina DP, Elena S, Bruni M (2001) Macromol Mater Eng 286:524

Wu Y, Liu C, Zhao X, Xiang J (2008) J Polym Res 15:181

Saxena IM, Kudlicka K, Okuda K, Brown RM Jr (1994) J Bacter 176:5735

Jung HZ, Benerito RR, Berni RJ, Mitcham D (1977) J Appl Polym Sci 21:1981

Tokoh C, Takabe K, Fujita M, Saiki H (1998) Cellulose 5:249

Segal L, Creely JJ, Martin AE, Conrad CM (1959) Tex Res J 29:786

Huacai G, Wan P, Dengke L (2006) Carbohydrate Polymers 66:372

Acknowledgement

This work was supported by Creative Research Initiatives (EAPap Actuator) of NRF/MEST.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kim, J., Cai, Z., Lee, H.S. et al. Preparation and characterization of a Bacterial cellulose/Chitosan composite for potential biomedical application. J Polym Res 18, 739–744 (2011). https://doi.org/10.1007/s10965-010-9470-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10965-010-9470-9