Abstract

A novel type of biodegradable non-phosphor detergent builder was prepared by anionic ring-opening copolymerization of disodium cis-epoxysuccinate and 2,3-oxiranernethane sulfonic acid sodium. The structure of the copolymer was confirmed by FTIR, 1HNMR and X-ray diffraction. The molecular weights of the copolymers were 1,000–2,000 obtained from laser light scattering data indicating that they were oligomers. The builder performances and biodegradability of the copolymers were systematically investigated. The results demonstrate that the copolymer is amorphous, and it exhibits high calcium-ion chelating ability and dispersion capacity and buffer capacity which are even better than that of sodium tripolyphosphate and sodium polyacrylate. Moreover, this copolymeric detergent builder displays excellent biodegradability, which can meet the requirement of environment-friendly and non-polluting. These copolymers of disodium cis-epoxysuccinate and 2,3-oxiranernethane sulfonic acid sodium have great potential in theory and application as effective and environmentally friendly detergent builders.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Detergent builders are often used in conjunction with surfactants to remove Ca2+ and Mg2+ ions existing in hard water and in soils, which is helpful to lower the content of surfactants in the detergent formulations. A promising detergent builder should primarily satisfy the following requirements including sequestering ability, dispersion power, buffer capacity, and environmental and economic practicability [1].

Sodium tripolyphosphate (STPP) meets the essential requirements and had been widely used as builder for a long time in the past, because of its good detergent properties and the cost-effectiveness. However, STPP is almost prohibited now in detergents for the eutrophication problem caused by phosphates to still or slow moving water system [2]. Possible alternatives to STPP are water-soluble polyelectrolyte polymers. Some polyacrylates such as sodium polyacrylate (PAAS) and sodium salt of maleic anhydride–acrylic acid copolymer have been reported to have good builder performances in detergent formulations as compared with STPP [3, 4]. However, there is still an environmental latent danger with respect to these polycarboxylate-based detergent builders due to their non-biodegradability. To avoid further accumulation of recalcitrant substances in waterways, the commercial development of biodegradable polymer builders is particularly needed [5].

As a non-nitrogen, non-phosphor and biodegradable polymer, polyepoxysuccinic acid (PESP) exhibits good calcium sequestration capacity, which can be used in detergent industry. However, the dispersion power of PESP is not good enough to replace STPP. Research has shown that the introduction of –SO3H groups with strong electrolytic capacity into PESP molecule can effectively enhance the dispersion power [6]. Consequently, in the hope of improving the builder performances especially the dispersion power of the PESP so as to obtain an environmentally friendly detergent builder with high performances, 2,3-oxiranernethane sulfonic acid sodium containing –SO3H group was incorporated into the PESP molecular structure by anionic ring-opening copolymerization in this study. The builder performances and biodegradability of the novel detergent builder would be mainly studied.

Experimental

Materials

Disodium cis-epoxysuccinate was synthesized according to the previous report [7], 2,3-oxiranernethane sulfonic acid sodium was synthesized according to the report [8]. Sodium hydroxide and calcium hydroxide were purchased from Tianjin Damao Chemical Reagent Factory. The strong-acid cation exchange resin was purchased from Jiangsu Yonghua Fine Chemicals Co., Ltd.

Copolymerization of disodium cis-epoxysuccinate and 2,3-oxiranernethane sulfonic acid sodium

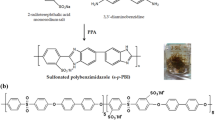

The polymerization mechanism of the target copolymer is illustrated in Fig. 1. A typical synthetic process can be shown as follows:

To a solution of disodium cis-epoxysuccinate (8.8 g, 0.05 mol) in H2O (15 mL) at 80–85 °C was added a certain amount of calcium hydroxide, followed by addeing dropwise the solution of 2,3-oxiranernethane sulfonic acid sodium salt (4 g, 0.025 mol) in H2O (10 mL). When the addition was completed, the pH of the solution was adjusted to 13.0 by sodium hydroxide and then the reaction mixture was stirred for 6 h at 90 °C, with the reaction mixture being more and more viscous. When the reaction was completed, the resultant mixture was diluted and replaced Ca2+ and Na+ with H+ through a strong-acid cationic exchange resin. The pH of obtained solution was then adjusted to 7 by sodium hydroxide and then removed most of the H2O by rotary evaporation. After that, the residue was poured into a lot of ethanol, and then the precipitate was filtered and dried in vacuum to yield the copolymer (10.9 g, 85.4 %). The copolymer obtained with different content of initiator calcium hydroxide was named with different codes such as Copo.1–Copo.6 as shown in Table 1.

Characterization of the copolymer

FTIR spectrum was measured in KBr on a Nicolet 6700 FTIR spectrometer. 1H-NMR Spectrum was recorded on a Varian Mercury-Plus 300 spectrometer. Average molecular weight and distribution were measured using a Brookhaven BI-200SM multi-angle laser light scattering instrument. XRD was measured by Riga D/max-2400 from 10° to 70°.

Measurements of builder performances

Calcium-ion sequestration capacity

The calcium-ion sequestration capacity as one of the most important detergent builder performances was determined according to China National Standard method (GB/T 21884-2008). In brief, a sample (5.0 g) was dissolved in water within a volumetric flask (capacity 500 mL) to form an aqueous solution. Then 100 mL of the solution and 10 mL ammonia–ammonium chloride buffer solution were added to a conical beaker. After adjusting the pH to 10, the mixed indicator (0.03 g, mass ratio (acid chrome blue K:naphthol green B:potassium chloride) = 1:2:40) was added in the flask. The concentration of calcium ion in the solution was measured using titration of calcium acetate. The calcium-ion sequestration capacity was calculated using the following Eq. (1):

where C (mol/L) is the concentration of calcium acetate standard solution, V (mL) is titrated volume of calcium acetate solution, and m (g) is the mass of the sample.

Dispersion capacity

Dispersion capacity of calcium was evaluated by the Hampshire test [9]. The procedure consisted of dissolving 1 g of the sample in 100 mL of distilled water, followed by adding 10 mL of a 10 % sodium carbonate solution in the sample solution. Then the acid solution was neutralized with sodium hydroxide solution (0.5 mol/L), after adjusting the pH to 11, the mixture was titrated with a 0.25 mol/L calcium acetate solution until turbidity persists. The dispersion capacity was calculated by the equation ξ(CaCO3) = 25V, where V (mL) is the titrated volume of calcium acetate.

Buffer capacity

The test procedure of buffer capacity was as follows: 0.1 mol/L sodium hydroxide solution was added into the 100 mL of the 0.1 % copolymer solution to adjust pH to 10.0. After that, 0.1 mol/L hydrochloric acid was added dropwise to bring pH to 8.0. The value of buffer capacity was the volume of the hydrochloric acid which had been consumed in the titration.

Measurements of biodegradability

The biodegradability of the copolymers was measured by shaking table test method [10]. The degree of biodegradability of the copolymers could be measured by potassium permanganate index [ρ(CODMn)]. The value of ρ(CODMn) would decrease with the degradation of the copolymers.

The microorganism was obtained from activated sludge from Guangzhou Lijiao Wastewater Treatment Plant. The nutrient composition (g/L) contained in the microorganism is as follows: phosphate buffer: KH2PO4 (8.50), K2HPO4 (21.75), Na2HPO4.2H2O (33.40), NH4Cl (1.7); calcium chloride solution: CaCl2.2H2O (36.40); magnesium sulfate solution: MgSO4.7H2O (22.50); ferric chloride solution: FeCl3.6H2O (0.25); and ammonium sulfate solution: (NH4)2SO4 (40).

The testing procedure was as follows:

-

1.

The sample was prepared with a concentration of 50 mg/L [ρ(CODMn) = 10–20 mg/L]. 1 L of the above solution was added into the following nutrient solution: calcium chloride solution (2 mL), magnesium sulfate solution (2 mL), ammonium sulfate solution (2 mL), ferric chloride solution (4 mL), phosphate buffer (2 mL) and inoculums (20 mg). Besides, the same nutrient solution but without adding the sample was also prepared as a blank sample for the control test.

-

2.

The above sample and blank sample solution with the same amount (50 mL) were, respectively, added to conical beakers, which were sealed by cotton plug and plastic paper. Then they were put in shaking table to culture (30 °C, 120 r/min), and the test time began.

-

3.

A series of ρ(CODMn) values were measured according to the sample concentration after 1, 4, 8, 12, 16, 20, 28 days, respectively. Each test time included three measurements to yield an average value.

The biodegradation rate of the sample was calculated by the following Eq. (2):

- η n :

-

Biodegradation ratio

- ρ(COD nMn ):

-

Potassium permanganate index of the first n days

- ρ(COD 0Mn ):

-

Potassium permanganate index of initial solution

Results and discussion

Synthesis and characterization

The results for copolymerization of disodium cis-epoxysuccinate and 2,3-oxiranernethane sulfonic acid sodium under different content of Ca(OH)2 as initiator are summarized in Table 1. It can be seen that the yields of the copolymers are quite good. The average molecular weight (M w) of the copolymers synthesized for set time span is around 1,000–2,000. The M w of the copolymers is slightly increased with the decrease of the content of initiator Ca(OH)2, and its distribution (M w/M n) is relatively narrow following in the range of 1.05–1.15, which indicates the characteristics of anionic polymerization [11].

The structure of the resultant copolymeric detergent builder was characterized by IR and 1H NMR spectra.

IR spectrum of the synthesized product is shown in Fig. 2. It can be seen that the stretching vibration peak of O–H group appears at 3,440 cm−1, the characteristic absorption peak of C=O group appears at 1,725 cm−1, and the absorption peaks assigned to C–O bond of COO− are around 1,620 and 1,400 cm−1. These indicate that the disodium cis-epoxysuccinate part is in the copolymer structure. In addition, the absorption peaks of S=O group appear at 1,200 and 1,050 cm−1 and the peak of S–O group appears at 617 cm−1, which certifies that sulfonic functional group is introduced to the copolymer structure. Moreover, the peak around 1,120 cm−1 should be attributed to the C–O–C group in the backbone. It can be deduced from the above spectral data that we have successfully synthesized the target copolymer having oxygen atoms in the backbone chain and carboxylic and sulfonic acid groups in pendant chains.

1H NMR spectrum of the copolymer is shown in Fig. 3. From the spectrum, we can obtain the main NMR signals around 2.96–3.05, 3.49–3.65, 3.91–4.02, and 4.14–4.23 ppm, respectively. The peaks at 2.96–3.05 ppm are assigned to [–CH2SO3Na], 3.49–3.65 ppm [–O–CH2–], 3.91–4.02 ppm [–O–CH2–CH(CH2SO3Na)–], and 4.14–4.23 ppm [–O–CH(COONa)–CH(COONa)–]. In other words, these 1H NMR peaks are all as expected, which confirm the results from IR and demonstrate the synthesized copolymer as target product.

The crystallinity of the copolymer was tested by X-ray diffraction (XRD) and the wide-angle X-ray diffraction (WAXD) pattern of the copolymer is shown in Fig. 4. The result shows that the prepared copolymer of disodium cis-epoxysuccinate and 2,3-oxiranernethane sulfonic acid sodium is amorphous, which may be attributed to the branched structure of the copolymer. Since the biodegradation of the polymer always starts from the amorphous area, we can infer that the copolymer may have good biodegradability.

Builder performances of the copolymers

The builder performances of the copolymer were evaluated in terms of calcium-ion sequestration capacity, dispersion capacity and buffer capacity. The results for a series of the synthesized detergent builders and that of two control samples are summarized in Table 2.

As shown in Table 2, we can find that the calcium-ion sequestration capacities of all the samples listed are higher than that of STPP and PAAS, but the variation of different copolymers with different molecular weight seems inconspicuous. This result can be explained by the fact that the calcium-ion sequestration capacity is mainly determined by the acid radical density of the copolymer, which changes little with polymerization degree for random copolymers. The buffer capacity of detergent builder is associated with the conjugate acid–base pair of COOH/COONa, so all the buffer capacities of copolymers are shown better than that of STPP and comparative to that of PAAS. As to the dispersion capacity, it is indicated from Table 2 that the dispersion capacity increases first and then decreases with the decrease of M w of the copolymers. The dispersion capacities of Copo.3 and Copo.4 (128.4 and 130.1, respectively) with the M w in the range of 1,300–1,600 are even better than that of STPP and more or less than that of PAAS. Based on the above overall analysis, we can obtain that the synthesized copolymers have excellent combination builder performances, especially for Copo.3 and Copo.4 as the optimal samples which can be competitive replacers of the STPP or PAAS.

Biodegradability of the copolymer

The degree of biodegradation of the copolymers under different test times is shown in Fig. 5. The degree of biodegradation for all the copolymers increases with time, and after 28 days, at least 60 % of the biodegradation has been finished. Moreover, the biodegradation degree increases with the decrease of the molecular weight of the copolymer, which follows the general rules. It can be shown that the degradation degree for Copo.5 with the minimum molecular weight of 1,120 even surpasses 80 % after 28 days, and it is above 70 % for sample Copo.3 which has the optimal builder performances. So it can be concluded that the copolymer of poly (2,3-oxiranernethane sulfonic acid sodium-co-disodium cis-epoxysuccinate) has excellent biodegradability.

Conclusions

Disodium cis-epoxysuccinate and 2,3-oxiranernethane sulfonic acid sodium were copolymerized with calcium hydroxide as initiator to obtain the copolymeric detergent builder. The copolymers not only exhibit excellent builder performances including calcium-binding capacity, dispersion capacity and buffer capacity, but also have wonderful biodegradability. In a word, the synthesized poly (2,3-oxiranernethane sulfonic acid sodium-co-disodium cis-epoxysuccinate) can be an advantageous substitute for STPP or PAAS as an efficient and green environmental-protective detergent builder.

References

Yu YX, Zhao J, Bayly AE (2008) Development of surfactants and builders in detergent formulations. Chin J Chem Eng 16:517–527

Tynkkynen N, Schönach P, Pihlajamäki M, Nechiporuk D (2014) The governance of the mitigation of the Baltic Sea eutrophication: exploring the challenges of the formal governing system. Ambio 43:105–114

Xia YM, Cho HY, Fang Y, Liou XY, Suh JM (2002) Relationship between structure and performance of polyacrylates used as chelator in detergents. J Ind Eng Chem 8:108–113

Agarwal P, Yu QY, Harant A, Berglund KA (2003) Synthesis and characterization of polymaleimide. Ind Eng Chem Res 42:2881–2884

Gross RA, Kalra B (2002) Biodegradable polymers for the environment. Science 297:803–807

Xu Y, Wang L, Zhao L, Cui Y (2011) Synthesis of polyaspartic acid–aminobenzenesulfonic acid grafted copolymer and its scale inhibition performance and dispersion capacity. Water Sci Technol 64:423–430

Payne GB, Williams PH (1959) Reactions of hydrogen peroxide. IV. Sodium tungstate catalyzed epoxidation of α, β-unsaturated acids. J Org Chem 24:54–55

Wang HP, Chen ZG (2005) The synthesis and application of oxiranemethanesulfonic acid sodium salt. Fine Chem Intermed 35:20–23

Sheng Y, Xu XC, Jiang WY, Song YH, Gan SC, Zou HF (2012) Application of oxidized cornstarch as a nonphosphoric detergent builder. J Surfactants Deterg 15:393–398

Dailey R, Daniel M, Leber AP (2013) Biodegradability of the antioxidant diaryl-p-phenylene diamine using a modified inherent biodegradation method at an environmentally relevant concentration. Chemosphere 93:1023–1028

Lee W, Lee H, Cha J, Chang T, Hanley KJ, Lodge TP (2000) Molecular weight distribution of polystyrene made by anionic polymerization. Macromolecules 33:5111–5115

Acknowledgments

The authors greatly appreciate the financial support by the Key Program for Scientific and Technological Innovations of Higher Education Institutes in Guangdong Province (No. CXZD1022), and the support from the National Natural Science Foundation of China (21476051).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhu, D., Guo, J., Chen, S. et al. Synthesis and performances of biodegradable copolymers of disodium cis-epoxysuccinate and 2,3-oxiranernethane sulfonic acid sodium used as nonphosphoric detergent builders. Polym. Bull. 72, 93–102 (2015). https://doi.org/10.1007/s00289-014-1261-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-014-1261-8